Page 1

FormNo.3362-759RevB

TRX-15,TRX-19,andTRX-26

Trencher

ModelNo.22970—SerialNo.310000001andUp

ModelNo.22970G—SerialNo.310000001andUp

ModelNo.22971—SerialNo.310000001andUp

ModelNo.22971G—SerialNo.310000001andUp

ModelNo.22974—SerialNo.310000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

Thismachineisdesignedtodigtrenchesinsoiltobury

G007797

1

cablingandpipingforvariousapplications.Itisnot

intendedtocutrock,wood,oranyothermaterialother

thansoil.

Warning

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Theremaybeburiedpower,gas,and/or

telephonelinesintheworkarea.Shockor

explosionmayoccurifyoudigintothem.

Havethepropertyorworkareamarkedfor

buriedlinesanddonotdiginmarkedareas.

Contactyourlocalmarkingserviceorutility

companytohavethepropertymarked(for

example,intheUnitedStates,call811forthe

nationwidemarkingservice).

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

YoumaycontactTorodirectlyatwww .T oro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

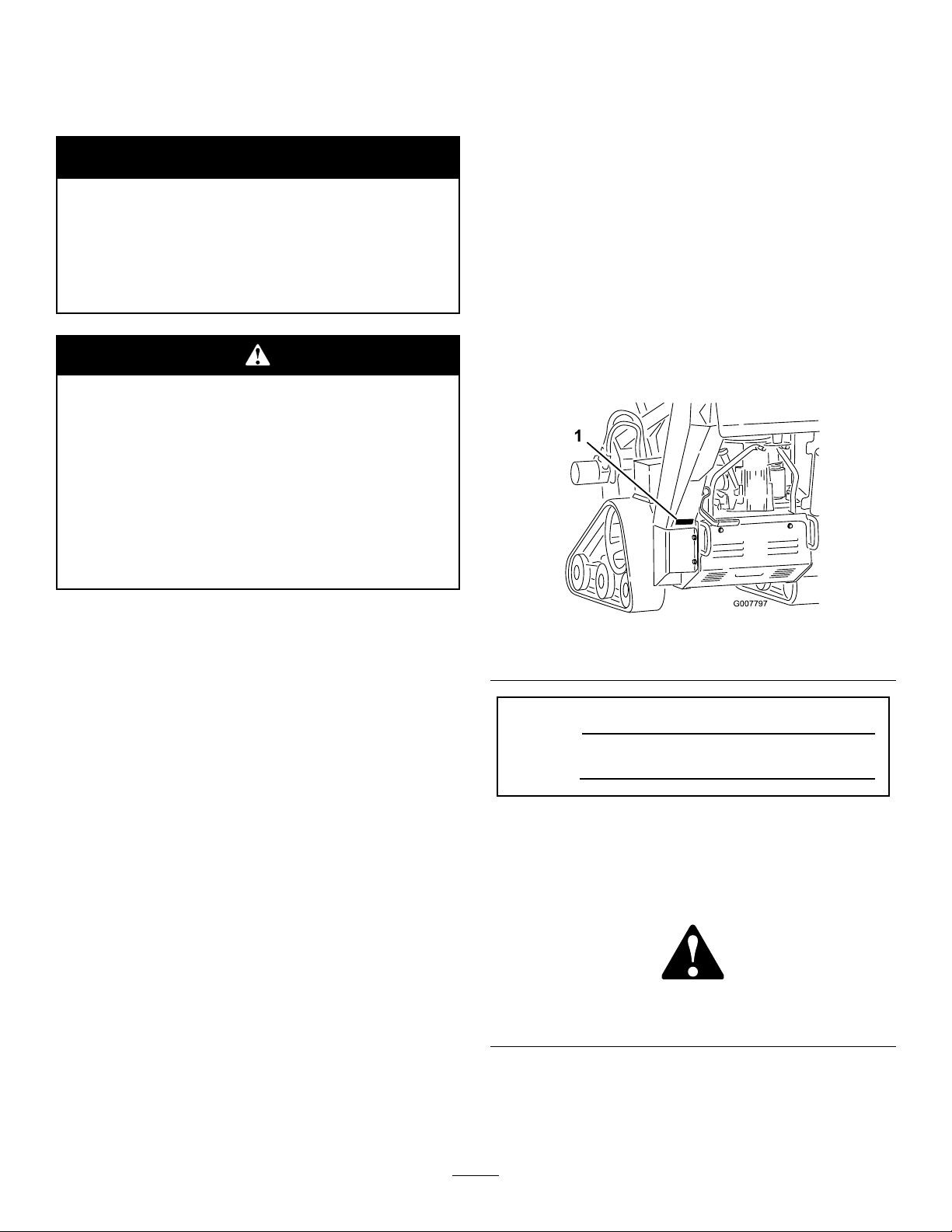

andserialnumbersofyourproductready.Figure1

illustratesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Figure1

1.Modelandserialnumberplate

ModelNo.

SerialNo.

Theenclosed

Engine Owner’ s Man ual

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCalifornia

EmissionControlRegulationofemissionsystems,

maintenance,andwarranty.Replacementsmaybe

orderedthroughtheenginemanufacturer.

issupplied

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

ThisproductcomplieswithallrelevantEuropean

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

1.Safetyalertsymbol

Figure2

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2009—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

2

Contactusatwww.Toro.com.

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

SoundPressure.....................................................6

SoundPower........................................................6

Vibration..............................................................6

SlopeIndicator.....................................................8

SafetyandInstructionalDecals.............................9

Setup..........................................................................12

1InstallingtheBoomandChain.........................12

2CheckingFluidLevels......................................13

3ChargingtheBattery(ElectricStartModels

Only)..............................................................13

ProductOverview......................................................13

Controls.............................................................13

Specications.....................................................16

Attachments/Accessories...................................16

Operation...................................................................16

AddingFuel.......................................................16

CheckingtheEngineOilLevel............................17

CheckingtheHydraulicFluidLevel.....................18

StartingandStoppingtheEngine........................19

StoppingtheMachine.........................................20

MovingaNon-functioningMachine...................20

DiggingaTrench................................................20

SecuringtheMachineforTransport....................20

LiftingtheMachine............................................21

OperatingTips...................................................21

Maintenance...............................................................22

RecommendedMaintenanceSchedule(s)................22

PremaintenanceProcedures....................................23

RemovingtheCoverPlate...................................23

InstallingtheCoverPlate....................................23

RemovingtheBottomShield..............................23

InstallingtheBottomShield................................23

Lubrication.............................................................24

GreasingtheMachine.........................................24

GreasingtheTrencherHousing..........................24

EngineMaintenance...............................................25

ServicingtheAirCleaner(Models22970and

22971)............................................................25

ServicingtheAirCleaner(Model22974)..............26

ServicingtheEngineOil.....................................27

ServicingtheSparkPlug.....................................28

FuelSystemMaintenance.......................................30

DrainingtheFuelTank.......................................30

ReplacingtheFuelFilter.....................................30

ElectricalSystemMaintenance................................31

ServicingtheBattery(Models22971and

22974)............................................................31

ReplacingtheFuses(Models22971and

22974)............................................................33

DriveSystemMaintenance.....................................34

ServicingtheTracks............................................34

BeltMaintenance....................................................36

ReplacingthePumpDriveBelt...........................36

ControlsSystemMaintenance.................................37

AdjustingtheTractionControl

Alignment......................................................37

AdjustingtheTractionControlNeutral

Position..........................................................38

AdjustingtheTrackingoftheTraction

Control,FullForwardPosition........................38

HydraulicSystemMaintenance...............................39

ReplacingtheHydraulicFilter.............................39

ChangingtheHydraulicFluid.............................39

CheckingtheHydraulicLines.............................40

TrencherMaintenance............................................40

ReplacingtheDiggingTeeth...............................40

CheckingandAdjustingtheDiggingChain

andBoom......................................................40

ReplacingtheDriveSprocket..............................41

Cleaning.................................................................42

RemovingDebrisfromtheMachine....................42

Storage.......................................................................43

Troubleshooting.........................................................44

Schematics.................................................................46

3

Page 4

Safety

Improperuseormaintenancebytheoperator

orownercanresultininjury.Toreducethe

potentialforinjury,complywiththesesafety

instructionsandalwayspayattentiontothesafety

alertsymbol,whichmeans:

Danger

complywiththeinstructionmayresultinpersonal

injuryordeath.

—personalsafetyinstruction.Failureto

Caution

SafeOperatingPractices

Thisproductiscapableofamputatinghandsandfeet.

Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.

,

W ar ning

•Inspecttheareawheretheequipmentistobeused

andremoveallobjectssuchasrocks,toys,andwire

whichcanbethrownbythemachine.

•Useextracarewhenhandlinggasolineandother

fuels.Theyareammableandvaporsareexplosive.

,or

–Useonlyanapprovedcontainer

–Neverremovethegascaporaddfuelwiththe

enginerunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

–Neverrefuelordrainthemachineindoors.

•Checkthattheoperatorpresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)can

notreadEnglish,itistheowner’sresponsibilityto

explainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmayrestrict

theageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludinghardhat,

safetyglasses,longpants,safetyshoes,andhearing

protection.Longhair,looseclothingorjewelrymay

gettangledinmovingparts.

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholes

andhiddenhazards.

•Besurealldrivesareinneutralandtheparkingbrake

isengagedbeforestartingtheengine.Onlystartthe

enginefromtheoperator’sposition.

•Slowdownanduseextracareonhillsides.Besure

totravelintherecommendeddirectiononhillsides.

Turfconditionscanaffectthemachine’sstability.

•Slowdownandusecautionwhenmakingturnsand

whenchangingdirectionsonslopes.

•Neveroperatewiththeguardsnotsecurelyinplace.

Besureallinterlocksareattached,adjustedproperly,

andfunctioningproperly.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Stoponlevelground,lowertheboom,disengage

thetrencherhydraulics,engagetheparkingbrake,

andshutofftheenginebeforeleavingtheoperator’ s

positionforanyreason.

•Keephandsandfeetawayfromthemovingchain,

diggingteeth,andspoilsauger.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

4

Page 5

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

•Ensurethattheareaisclearofotherpeoplebefore

operatingthemachine.Stopthemachineifanyone

entersthearea.

•Neverleavearunningmachineunattended.Always

lowertheboom,stoptheengine,settheparking

brake,andremovethekeybeforeleaving.

•Neverjerkthecontrols;useasteadymotion.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Removeobstaclessuchasrocks,treelimbs,etc.

fromtheworkarea.Watchforholes,ruts,orbumps,

asuneventerraincouldoverturnthemachine.Tall

grasscanhideobstacles.

•UseonlyToro-approvedaccessories.Accessoriescan

changethestabilityandtheoperatingcharacteristics

ofthemachine.Warrantymaybevoidedifusedwith

unapprovedaccessories.

•Keepallmovementsonslopesslowandgradual.Do

notmakesuddenchangesinspeedordirection.

•Avoidstartingorstoppingonaslope.Ifthemachine

losestraction,proceedslowly,straightdownthe

slope.

•Donottouchpartswhichmaybehotfrom

operation.Allowthemtocoolbeforeattemptingto

maintain,adjust,orservice.

•Ensurethatyouoperatethemachineinareaswhere

therearenoobstaclesincloseproximitytothe

operator.Failuretomaintainadequatedistancefrom

trees,walls,andotherbarriersmayresultininjury

asthemachinebacksupduringoperationifthe

operatorisnotattentivetothesurroundings.Only

operatetheunitinareaswherethereissufcient

clearancefortheoperatortosafelymaneuverthe

product.

•Beforedigging,havetheareamarkedfor

undergroundutilities,anddonotdiginmarkedareas.

•Locatethepinchpointareasmarkedonthemachine

andkeephandsandfeetawayfromtheseareas.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

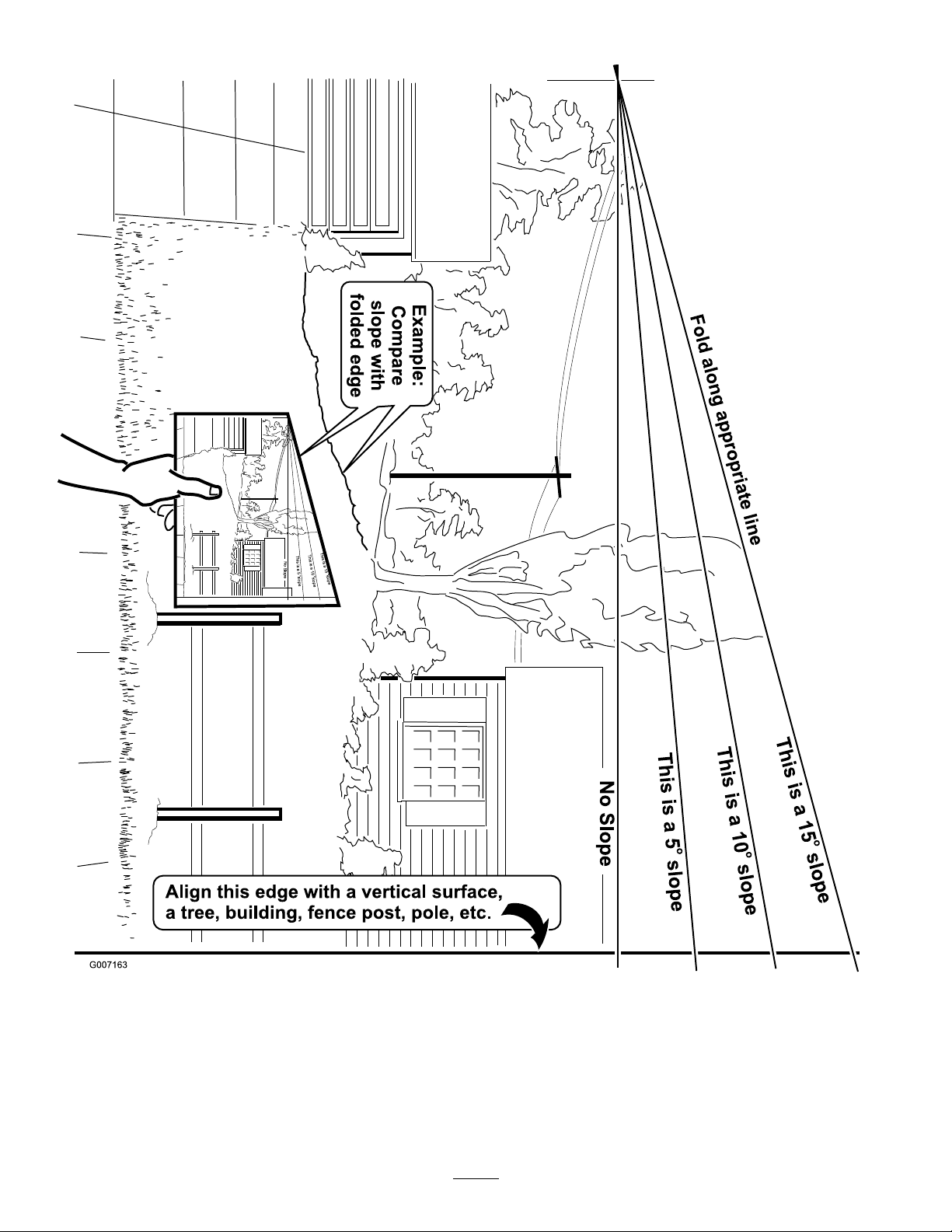

SlopeOperation

Slopesareamajorfactorrelatedtoloss-of-controland

tip-overaccidents,whichcanresultinsevereinjuryor

death.Allslopesrequireextracaution.

•Donotoperatethemachineonhillsidesorslopes

exceedingtheanglesrecommendedinthefollowing

table.

ModelFrontFacing

22970

22971

22974

Uphill

15°14°19°

13°14°19°

11°11°16°

Note:Seealsothe,page.

•Operateupanddownslopeswiththefrontend

ofthemachineuphill.

RearFacing

Uphill

SideFacing

Uphill

•Avoidturningonslopes.Ifyoumustturn,turn

slowlyandkeeptheheavyendofthemachineuphill.

•Donotoperateneardrop-offs,ditches,or

embankments.Themachinecouldsuddenlyturn

overifatrackgoesovertheedgeofaclifforditch,

orifanedgecavesin.

•Donotoperateonwetgrass.Reducedtractioncould

causesliding.

•Donotparkthemachineonahillsideorslope

withoutloweringtheboomtotheground,setting

theparkingbrake,andchockingthetracks.

MaintenanceandStorage

•Disengagethetrencherhydraulics,lowertheboom,

settheparkingbrake,stoptheengine,andremove

thekey .Waitforallmovementtostopbefore

adjusting,cleaning,orrepairing.

•Cleandebrisfromthechain,diggingteeth,boom,

trencherhead,drives,mufers,andenginetohelp

preventres.Cleanupoilorfuelspillage.

•Lettheenginecoolbeforestoringanddonotstore

nearame.

•Donotstorefuelnearamesordrainindoors.

•Parkthemachineonlevelground.Neverallow

untrainedpersonneltoservicethemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthebattery(electricstartmodelsonly)

orremovethesparkplugwiresbeforemaking

anyrepairs.Disconnectthenegativeterminalrst

andthepositivelast.Reconnectpositiverstand

negativelast.

5

Page 6

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Keepnutsandboltstight.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.

•Keepthemachinefreeofgrass,leaves,orother

debrisbuild-up.Cleanupoilorfuelspillage.Allow

themachinetocoolbeforestoring.

•Useextracarewhenhandlinggasolineandother

fuels.Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethegascaporaddfuelwhen

theengineisrunning.Allowtheenginetocool

beforerefueling.Donotsmoke.

–Neverrefuelthemachineindoors.

–Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasneara

waterheaterorfurnace.

–Neverllacontainerwhileitisinsideavehicle,

trunk,pick-upbed,oranysurfaceotherthanthe

ground.

–Keepcontainernozzleincontactwiththetank

duringlling.

•Stopandinspecttheequipmentifyoustrikean

object.Makeanynecessaryrepairsbeforerestarting.

•UseonlygenuineT ororeplacementpartstoensure

thatoriginalstandardsaremaintained.

•Batterysafety(electricstartmodelsonly):

–Chargebatteriesinanopen,wellventilated

area,awayfromsparkandames.Unplugthe

chargerbeforeconnectingordisconnectingit

fromthebattery.Wearprotectiveclothingand

useinsulatedtools.

–Batteryacidispoisonousandcancauseburns.

Avoidcontactwithskin,eyes,andclothing.

Protectyourface,eyes,andclothingwhen

workingwithabattery.

–Batterygasescanexplode.Keepcigarettes,

sparksandamesawayfromthebattery.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressurehydraulic

uid.Usecardboardorpapertondhydraulic

leaks;neveruseyourhands.Hydraulicuidescaping

underpressurecanpenetrateskinandcauseinjury

requiringsurgerywithinafewhoursbyaqualied

surgeonorgangrenemayresult.

SoundPressure

Model22970and22971

Thisunithasasoundpressurelevelattheoperator’s

earof91dBA,whichincludesanUncertaintyValue(K)

of1.0dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO11201.

Model22974

Thisunithasasoundpressurelevelattheoperator’s

earof92dBA,whichincludesanUncertaintyValue(K)

of1.0dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO11201.

SoundPower

Model22970and22971

Thisunithasaguaranteedsoundpowerlevelof105

dBA,whichincludesanUncertaintyValue(K)of3.75

dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO3744.

Model22974

Thisunithasaguaranteedsoundpowerlevelof107

dBA,whichincludesanUncertaintyValue(K)of3.75

dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO3744.

Vibration

Model22970and22971

Measuredvibrationlevelforrighthand=2.5m/s

Measuredvibrationlevelforlefthand=2.5m/s

UncertaintyValue(K)=1.25m/s

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinENISO20643.

2

Model22974

Measuredvibrationlevelforrighthand=1.8m/s

Measuredvibrationlevelforlefthand=2.0m/s

UncertaintyValue(K)=1.00m/s

2

2

2

2

2

6

Page 7

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinENISO20643.

7

Page 8

SlopeIndicator

8

Page 9

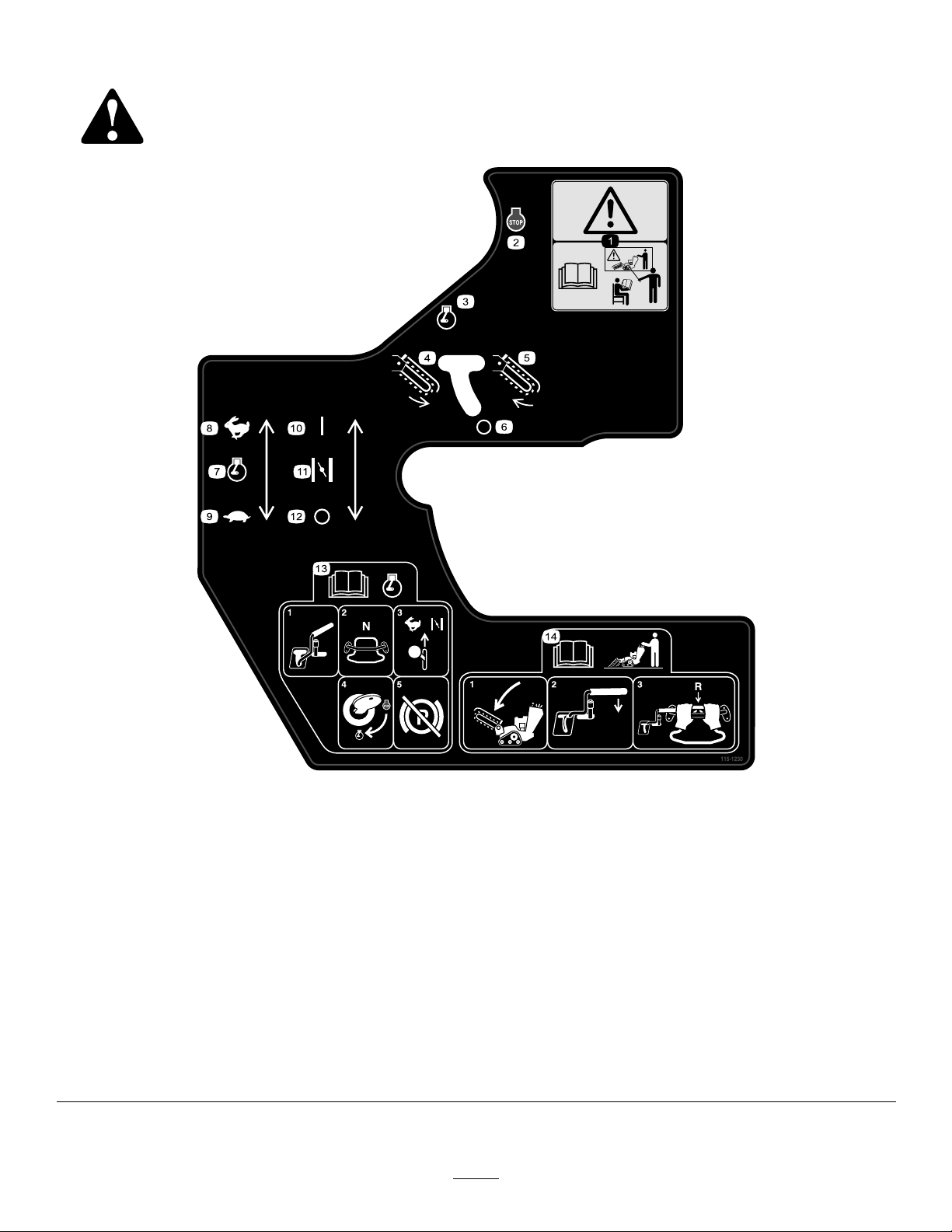

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

115-1230

1.Warning—donotoperatethismachineunlessyouaretrained.

2.Engine—stop

3.Engine—run

4.Trencherchain—reverse

5.Trencherchain—forward

6.Trencherchain—off

7.Enginethrottle

8.Fast

9.Slow

10.Choke

11.On/Closed

12.Off/Open

13.ReadtheOperator’sManualbeforestartingtheengine;tostarttheengine,movethetrenchercontrolleverintotheOffposition,

placethetractioncontrolinNeutral,movetheenginespeedtoFastandthechoketoOn/Closed,turntheignitionkeytorun,

andreleasetheparkingbrakeoncetheenginehasstarted.

14.ReadtheOperator’sManualbeforeoperatingthetrencher;tooperatethetrencher ,lowertheboom,movethetrenchercontrol

levertothereferencebar,pullthetractioncontrolrearwardtomoveinreverseanddigthetrench.

9

Page 10

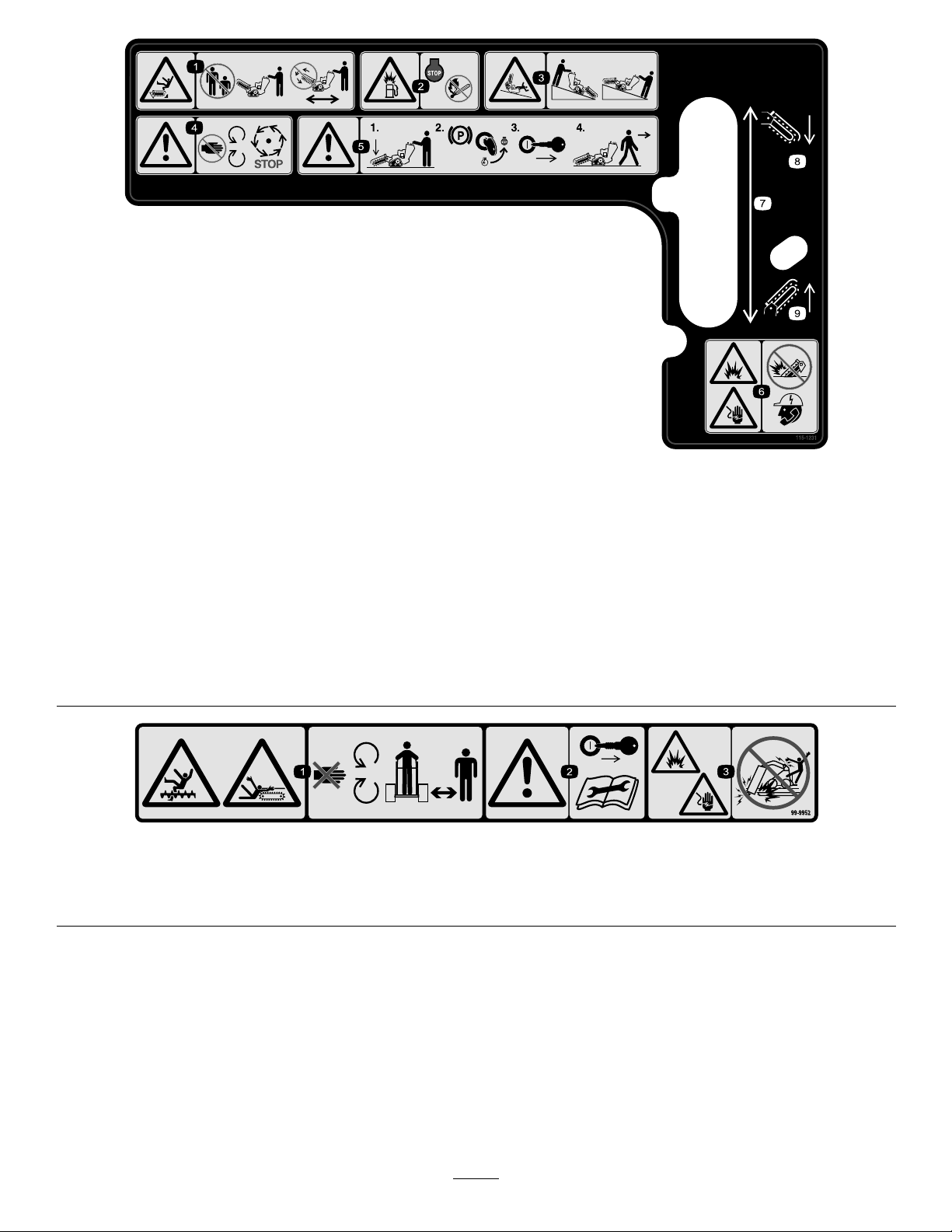

115-1231

1.Cutting/dismembermenthazardofbystanders,

trencher—keepbystandersasafedistancefromthemachine;

donotoperatethetrencherchainwhiletransportingthe

machine.

2.Explosionhazard,fueling—stoptheengineandextinguish

allameswhenfueling.

3.Tipping/crushinghazard—lowerthetrencherheadwhen

operatingonslopes.

4.Warning—stayawayfrommovingparts;waitforallmoving

partstostop

5.Warning—lowertheboom,engagetheparkingbrakeand

stoptheengine,removetheignitionkey ,beforeleavingthe

machine.

6.Explosionhazard;shockhazard—donotusemachinenear

buriedutilitylines;contacttheproperagenciesbeforedigging.

7.Boomelevation

8.Lowertheboom

9.Raisetheboom

99-9952

1.Cuttinghazard,chainandauger—stayawayfrommovingpartsandkeepbystandersawayfromthemachine.

2.Warning—stoptheengineandremovethekeybeforepreformingandmaintenanceorrepairs.

3.Explosionand/orelectricshockhazard—donotdiginareaswithburiedgasorpowerlines.

10

Page 11

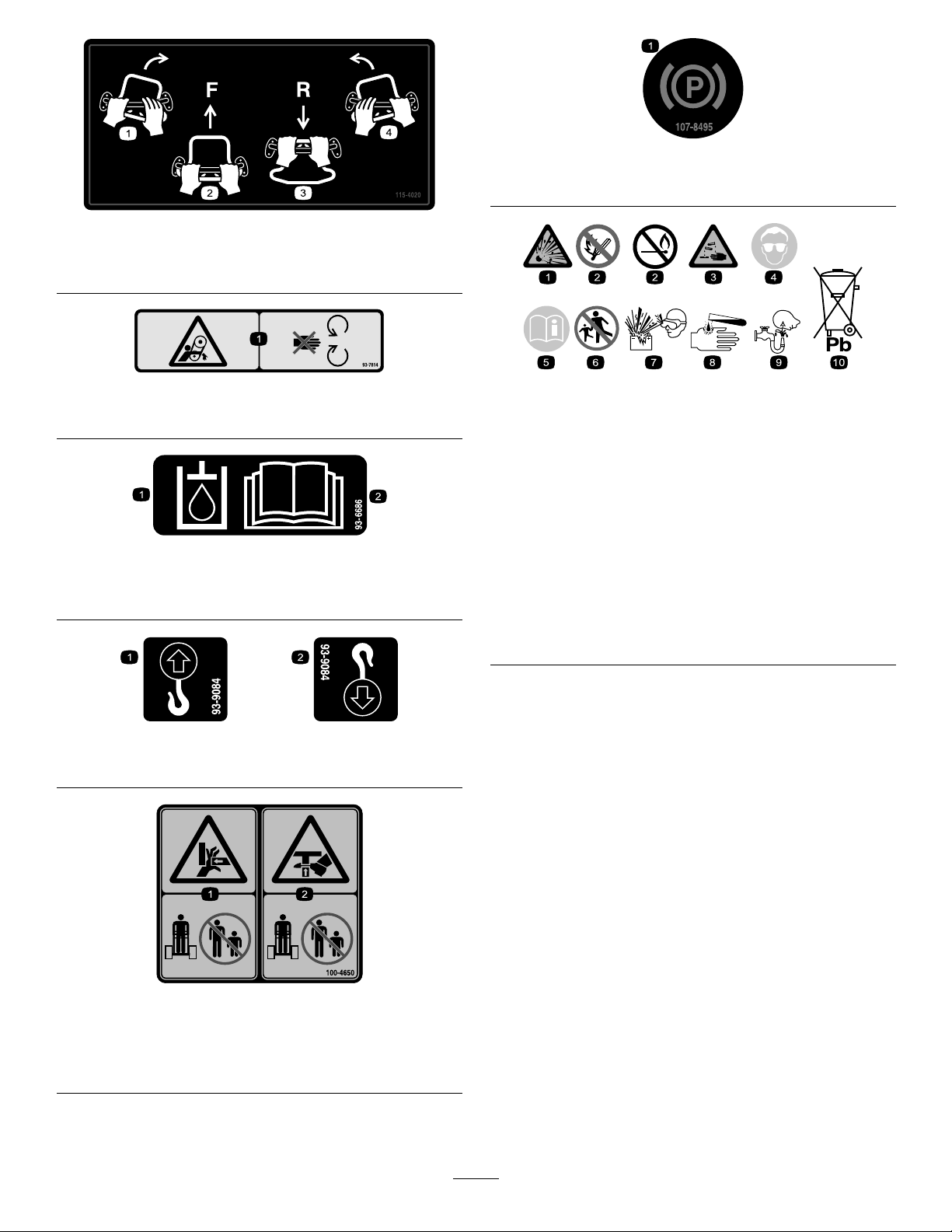

115-4020

1.Turnright3.Reverse

2.Forward

107-8495

1.Parkingbrake

4.Turnleft

93-7814

1.Entanglementhazard,belt—stayawayfrommovingparts.

93-6686

1.Hydraulicoil

2.ReadtheOperator’sManual.

93-9084

1.Liftpoint

2.Tie-downpoint

BatterySymbols

Someorallofthesesymbolsareonyourbattery(electric

startmodelsonly)

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator’s

Manual.

6.Keepbystandersasafe

distancefromthebattery .

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

100-4650

1.Crushinghazardofhand—keepbystandersasafedistance

fromthemachine.

2.Crushinghazardoffoot—keepbystandersasafedistance

fromthemachine.

11

Page 12

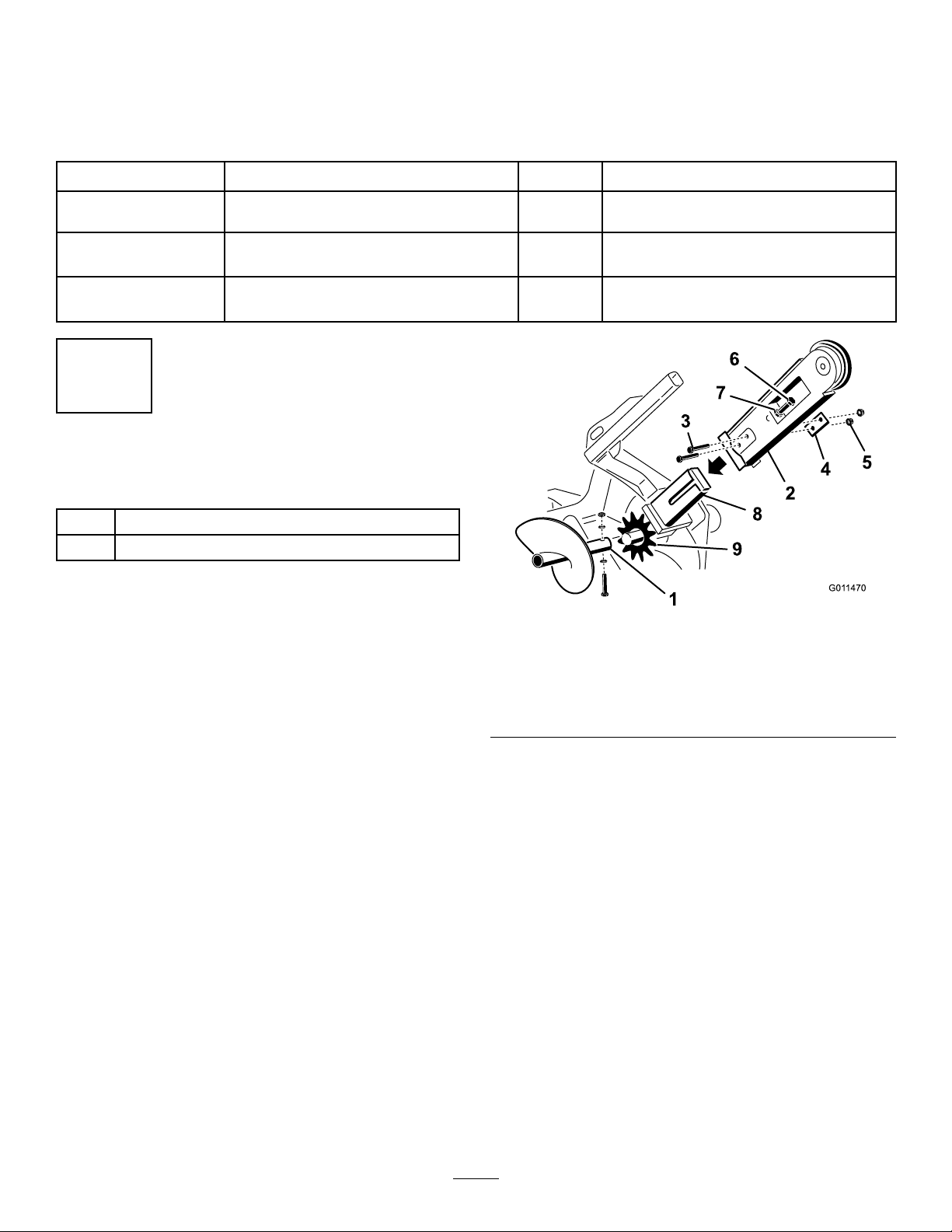

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Boom(soldseparately)

1

2

3

Chain(soldseparately)

Nopartsrequired

Nopartsrequired

1

InstallingtheBoomandChain

Partsneededforthisprocedure:

1

Boom(soldseparately)

1

Chain(soldseparately)

Procedure

Important:Thereareseveralboomandchainsize

congurationsavailable.RefertoyouAuthorized

ServiceDealertoobtaintheappropriateboomand

chaintomeetyourrequirements.

1.Stoptheengineandremovethekey.

Qty.

1

1

–

–

1.Spoilsauger

2.Boom7.Jamnut

3.Bolts8.Armonthedrivehead

4.Doublewasher9.Drivesprocket

5.Nuts

Installtheboomandchain.

Checktheuidlevels.

Chargethebattery .

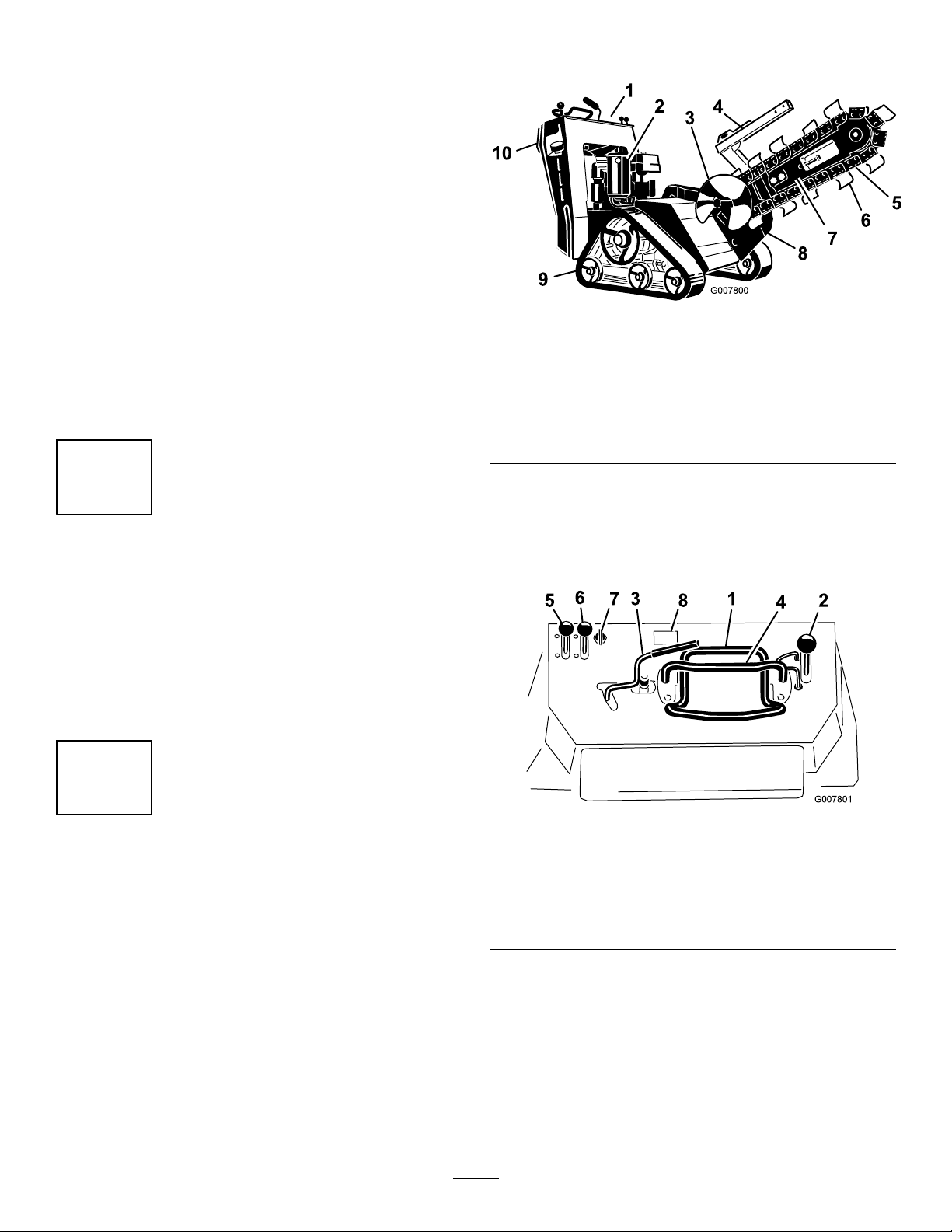

Figure3

Use

6.Adjustingbolt

2.Removethebolt,2saddlewashers,andnutsecuring

thespoilsaugerandremovetheauger(Figure3).

Savethefastenersforfutureuse.

3.Removethe2bolts,nuts,anddoublewashersfrom

thesidesoftheboom(Figure3).

4.Loosentheadjustingboltandjamnut(Figure3).

5.Slidetheboomoverthearmonthedrivehead.

6.Installthe2bolts,nuts,anddoublewashersremoved

instep3throughtheboomandarm,butdonot

tightenthem.

7.Ifthechainisnotconnected,connectthelinksby

pressingorhammeringtheclevispinsuppliedwith

thechainthroughthelinks.

Important:T oavoidbendingthechainlinks,

placeblocksunderandbetweenthelinkswhen

hammeringtheclevispinthrough.

8.Securetheclevispinwiththecotterpinsupplied

withthechain.

12

Page 13

9.Loopthediggingchainovertheaugerdriveshaftand

G007801

5

6

783

4

1

2

ontothedrivesprocket,ensuringthatthedigging

teethpointforwardontheupperspan.

10.Settheupperspanofthechainintoplaceonthe

trencherboom,thenwrapthechainaroundthe

rollerattheendoftheboom.

11.Threadtheadjustmentboltintotheboomandturn

itinuntilthereis1-1/2to2-1/2inches(3.8to6.3

cm)ofslackinthechainonthebottomspan.

12.Threadthejamnutdowntheadjustingboltand

tightenitsecurelyagainsttheboom.

ProductOverview

13.Torquethe2boltsandnutssecuringtheboomto

135to165ft-lb(183to223N-m).

14.Installthespoilsaugerusingthebolt,2saddle

washer,andnutyouremovedpreviously.

15.Torquetheboltandnutto75ft-lb(101N-m).

2

CheckingFluidLevels

NoPartsRequired

Procedure

Beforestartingtheengineforthersttime,checkthe

engineoilandhydraulicuidlevels;refertoOperation

formoreinformation.

Figure4

1.Control

panel

2.Engine

3.Spoils

auger

4.Chain

guard

5.Chain

6.Digging

teeth

7.Boom10.Reverse

8.Trencher

head

9.Track

Controls

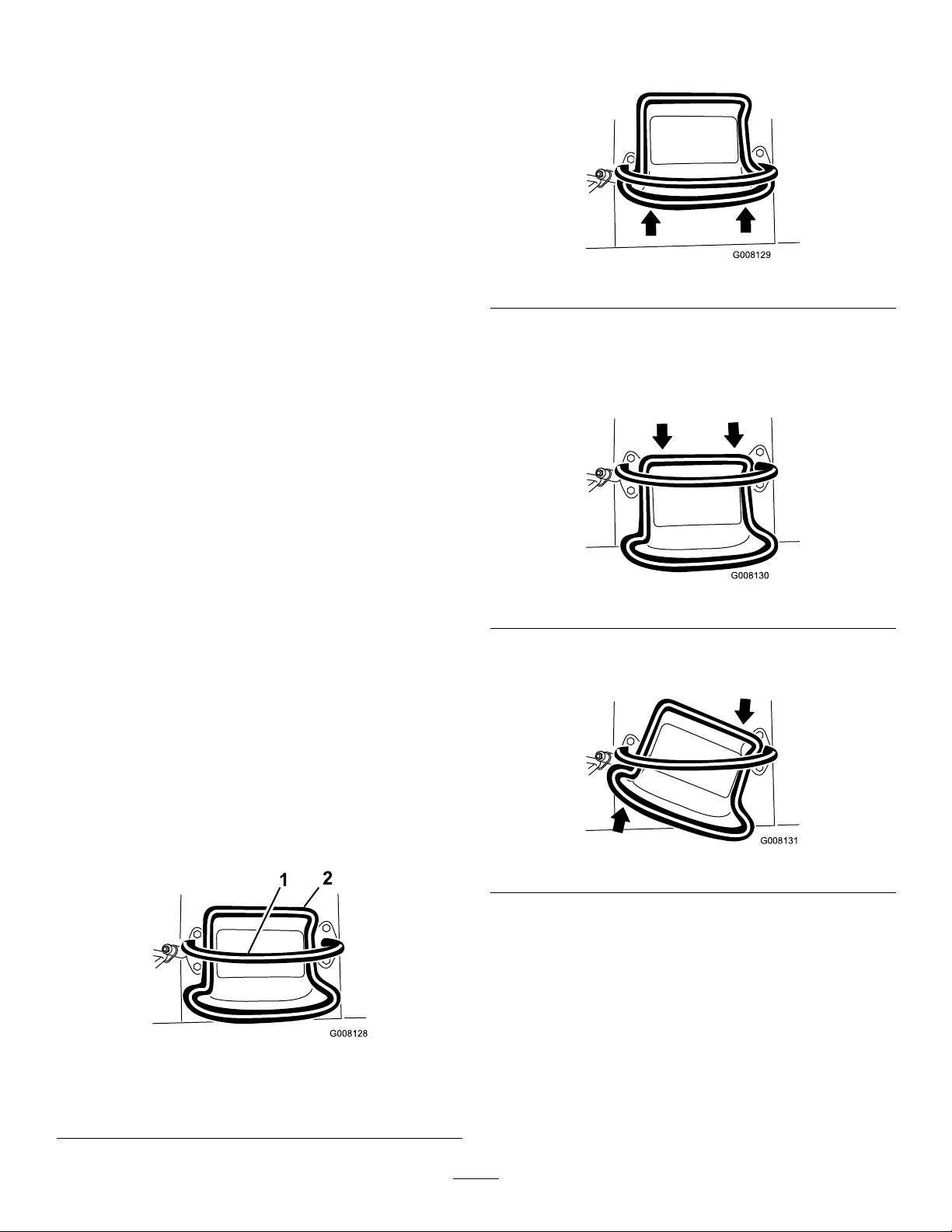

Becomefamiliarwithallthecontrols(Figure5)before

youstarttheengineandoperatethemachine.

safety

plate

3

ChargingtheBattery(Electric

StartModelsOnly)

NoPartsRequired

Procedure

Chargethebattery;refertoServicingtheBatteryin

Maintenanceformoreinformation.

Figure5

1.Tractioncontrol5.Throttlelever

2.Boomelevationlever

3.Trenchercontrollever7.Keyswitch

4.Referencebar8.Hourmeter(optional

6.Chokelever

KeySwitch,Model22970

Thekeyswitchhas2positions:offandrun.

Tostarttheengine,rotatethekeytotherunposition,

thenpulltherecoilhandleontheengine.

Tostoptheengine,rotatethekeytotheoffposition.

13

accessoryonmodel

22970)

Page 14

KeySwitch,ElectricStartModels

G008131

Thekeyswitchhasthreepositions:off,run,andstart.

Tostarttheengine,rotatethekeytothestartposition.

Releasethekeywhenenginestartsanditwillmove

automaticallytotherunposition.

Tostoptheengine,rotatethekeytotheoffposition.

ThrottleLever

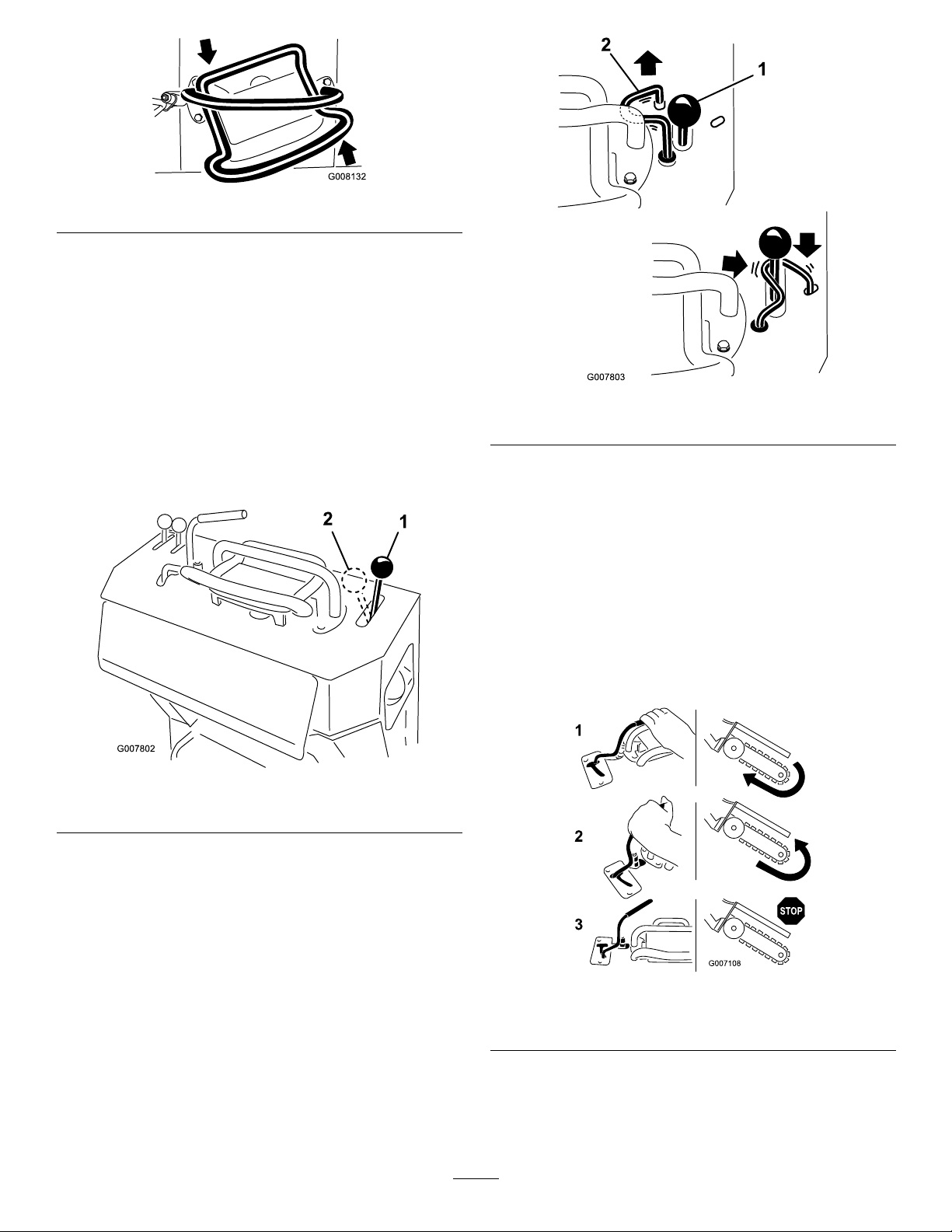

•Tomoveforward,movethetractioncontrolforward

(Figure7).

Movethecontrolforwardtoincreasetheenginespeed

andrearwardtodecreasespeed.

ChokeLever

Beforestartingacoldengine,movethechokelever

forward.Aftertheenginestarts,regulatethechoketo

keeptheenginerunningsmoothly.Assoonaspossible,

movethechokeleverallthewayrearward.

Note:Awarmenginerequireslittleornochoking.

HourMeter

Whentheengineisoff,thehourmeterdisplaysthe

numberofhoursofoperationthathavebeenlogged

onthemachine.

Note:Thehourmeterisanoptionalaccessoryon

model22970.

ReferenceBar

Figure7

•Tomoverearward,movethetractioncontrol

rearward(Figure8).Whenreversing,lookbehind

forobstructionsandkeepyourhandsonthe

referencebar(Figure6).

Figure8

•Toturnright,rotatethetractioncontrolclockwise

(Figure9).

Whendrivingthemachine,usethereferencebarasa

handleandaleveragepointforcontrollingthetraction

controlandthetrenchercontrollever.Toensure

smooth,controlledoperation,donottakebothhands

offofthereferencebarwhileoperatingthemachine.

TractionControl

Figure6

1.Referencebar(doesnotmovetogiveyouareferencepoint

andaxedhandletoholdwhileoperatingthetractionunit)

2.Tractioncontrol(movestocontrolthemachine)

Figure9

•Toturnleft,rotatethetractioncontrol

counterclockwise(Figure10).

14

Page 15

G008132

Figure10

•Tostop,releasethetractioncontrol(Figure6).

Note:Thefartheryoumovethetractioncontrolin

anydirection,thefasterthemachinewillmoveinthat

direction.

BoomElevationLever

Tolowertheboom,slowlymovetheleverforward

(Figure11).

Toraisetheboom,slowlymovetheleverrearward

(Figure11).

Figure11

1.Lowertheboom2.Raisetheboom

Figure12

1.Boomelevationlever2.Boomelevationlock

TrencherControlLever

Todigwiththetrencher,rotatetheleverrearwardand

pullitdowntothereferencebar(Figure13,number1).

Toreversethetrencherhead,rotatetheleverrearward,

thenmoveitleftintotheupperslot(Figure13,number

2).

Ifyoureleasethelever,itwillautomaticallyreturnto

theneutralposition(Figure13,number3),stoppingthe

chain.

BoomElevationLock

Theboomelevationlocksecurestheboomelevation

leversothatyoucannotpushitforward.Thishelpsto

ensurethatnoonewillaccidentallylowertheboom

duringmaintenance.Securetheboomwiththelock

anytimeyouneedtostopthemachinewiththeboom

raised.

Tosetthelock,liftuponitsoitclearstheholeinthe

controlpanelandswingittotherightinfrontofthe

boomelevationlever,pushingitdownintothelocked

position(Figure12).

Figure13

1.Forward3.Neutral

2.Reverse

15

Page 16

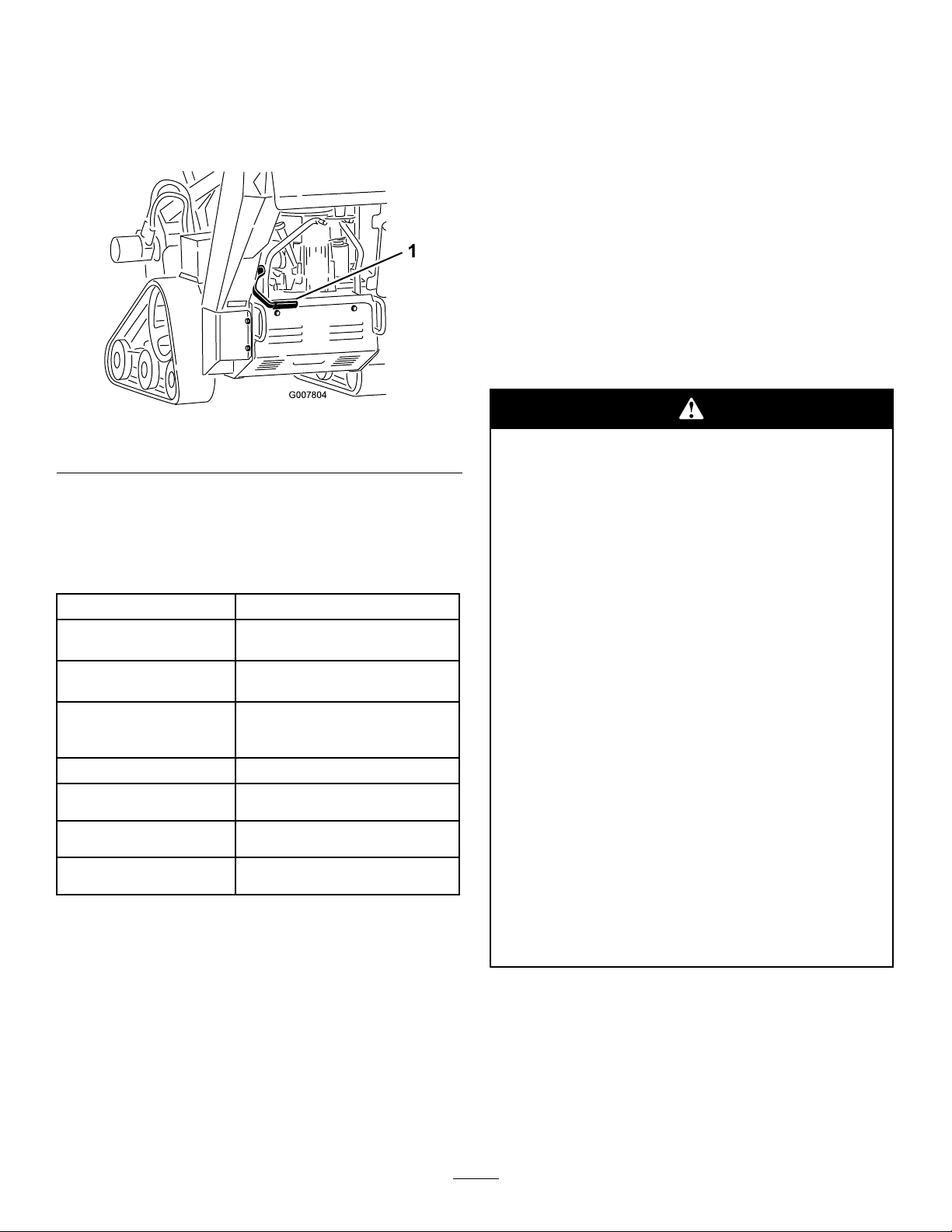

ParkingBrakeLever

G007804

1

•Tosettheparkingbrake,pullthebrakelever

rearwardandup(Figure14).

•Toreleasethebrake,pulltheleverrearwardandthen

down(Figure14).

Figure14

1.Parkingbrakelever(inthereleasedposition)

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Important:Beforeoperating,checkthefueland

oillevel,andremovedebrisfromthemachine.

Also,ensurethattheareaisclearofpeopleand

debris.Youshouldalsoknowandhavemarkedthe

locationsofallutilitylines.

AddingFuel

Useunleadedgasoline(87pumpoctaneminimum).

Leaded,regulargasolinemaybeusedifunleadedisnot

available.

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupany

gasolinethatspills.

Width

Length,with24inch(70

cm)boom

Length,with36inch(91.4

cm)boom

Length,with48inch(122

cm)boom(model22974

only)

Height

Weight(model22970)*1100lb(499Kg)

Weight(model22971)*1185lb(538Kg)

Weight(model22974)*1208lb(578Kg)

*A36inch(91.4cm)boomandchainwilladdabout60lbtothelistedweight.

33.8inches(86cm)

82.5inches(209.5cm)

92.6inches(235cm)

11 1.2inches(282.5cm)

46inches(117cm)

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

•Neverllthefueltankinsideanenclosed

trailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1/4

to1/2inch(6to13mm)belowthebottomof

thellerneck.Thisemptyspaceinthetank

allowsgasolinetoexpand.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Never

buymorethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

16

Page 17

Incertainconditionsduringfueling,static

G007806

1

electricitycanbereleasedcausingaspark

whichcanignitethegasolinevapors.Are

orexplosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowtheloss

ofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

chanceofvarnishdepositsinthefuelsystem,usefuel

stabilizeratalltimes.

FillingtheFuelTank

1.Parkthemachineonalevelsurface,lowerthe

boom,andstoptheengine.

2.Removethekeyandallowtheenginetocool.

3.Cleanaroundthefueltankcapandremoveit

(Figure15).

Figure15

1.Fueltankcap

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

Important:Donotusemethanol,gasoline

containingmethanol,orgasoholcontainingmore

than10%ethanolbecausethefuelsystemcouldbe

damaged.Donotmixoilwithgasoline.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysor

less.Forlongerstorageitisrecommendedthatthe

fueltankbedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

4.Addunleadedgasolinetothefueltank,untilthe

levelis1/4to1/2inchbelowthebottomofthe

llerneck.

Important:Thisspaceinthetankallows

gasolinetoexpand.Donotllthefueltank

completelyfull.

5.Installthefueltankcapsecurely.

6.Wipeupanygasolinethatmayhavespilled.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurface,lowerthe

boom,andstoptheengine.

2.Removethekeyandallowtheenginetocool.

3.Cleanaroundtheoildipstick(Figure16).

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditioner

tothegas.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.Tominimizethe

17

Page 18

Figure16

G007808

1

1.Oilllerhole

2.Oildipstick

3.Fullmark

4.Addmark

4.Removethedipstickandwipetheendclean

(Figure16).

5.Slidethedipstickfullyintothedipsticktubewithout

threadingitintothellerneck(Figure16).

6.Pullthedipstickoutandlookattheend.The

oilshouldbebetweentheAddandFullmarks

(Figure16).

7.IftheoilisbelowtheAddmark,add10w30engine

oiltothellerhole,checkingthelevelfrequently

withthedipstick,untiltheoillevelreachestheFull

mark.

8.Replacethedipstick.

CheckingtheHydraulicFluid

Level

Figure17

1.Hydraulicuidcheckbubble

4.Removethecoverplate;refertoRemovingthe

CoverPlate.

5.Cleantheareaaroundthellerneckofthehydraulic

tankandremovethecapandlterfromtheller

neckusingasocket(Figure18).

ServiceInterval:Every25hours

HydraulicTankCapacity:6USgallons(23l)

Use10W-30or15W -40detergent,dieselengineoil(API

serviceCH-4orhigher).

1.Parkthemachineonalevelsurfaceandlowerthe

boom.

2.Stoptheengine,removethekey ,andallowthe

enginetocool.

3.Lookintotheglassbubbleontherightsideofthe

machine.Ifyoucannotseehydraulicuidinthe

bubble,continuethisproceduretoadduid.

Figure18

1.Fillerneckcap

2.Hydraulicuidlter

6.Ifthelevelislow ,adduiduntilitisvisibleinthe

glassbubble.

7.Installthecapandlteronthellerneckandtorque

boltontopto110to140inch-lb(13to15.5N-m).

18

Page 19

StartingandStoppingthe

G007809

1

2

3

G007810

1

Engine

periodbetweenattempts.Failuretofollow

theseinstructionscanburnoutthestarter

motor.

StartingtheEngine

1.MovethethrottlelevermidwaybetweenSlowand

Fastpositions(Figure19).

Figure19

1.Throttlelever3.Key

2.Chokelever

2.MovethechokelevertotheOnposition(Figure19).

Note:Awarmorhotenginemaynotrequire

choking.

3.Starttheengineasfollowsforyourmodel:

•Formodel22970,turnthekeytotheOn

positionthenpulltherecoilhandletostartthe

engine(Figure20).

4.GraduallymovethechokelevertotheOffposition

(Figure19).Iftheenginestallsorhesitates,engage

thechokeagainuntiltheenginewarmsup.

5.Movethethrottlelevertothedesiredsetting

(Figure19).

Important:Iftheengineisrunathighspeeds

whenthehydraulicsystemiscold(i.e.,when

theambientairtemperatureisnearfreezingor

lower),hydraulicsystemdamagecouldoccur.

Whenstartingtheengineincoldconditions,

allowtheenginetoruninthemiddlethrottle

positionfor2to5minutesbeforemovingthe

throttletofast(rabbit).

Note:Iftheoutdoortemperatureisbelow

freezing,storethemachineinagaragetokeepit

warmerandaidinstarting.

StoppingtheEngine

1.MovethethrottlelevertotheSlowposition

(Figure19).

2.Lowertheboom(Figure21).

Figure20

1.Recoilhandle

•Foranelectricstartmodel,turnthekeytothe

Onposition(Figure19).Whentheenginestarts,

releasethekey .

Important:Donotengagethestarterfor

morethan10secondsatatime.Iftheengine

failstostart,allowa30secondcool-down

Figure21

3.Turnthekeyoff(Figure19).

Note:Iftheenginehasbeenworkinghardor

ishot,letitidleforaminutebeforeturningthe

ignitionkeyoff.Thishelpscooltheenginebefore

itisstopped.Inanemergency,theenginemaybe

stoppedimmediately .

4.Removethekey.

19

Page 20

StoppingtheMachine

G007816

1

Tostopthemachine,releasethetractioncontrol,move

thethrottlelevertoslow(turtle),lowertheboomto

theground,andstoptheengine.Settheparkingbrake

andremovethekey.

Achildoruntrainedbystandercouldattemptto

operatethemachineandbeinjured.

Removethekeyfromtheswitchwhenleaving

themachine,evenifjustforafewseconds.

MovingaNon-functioning

Machine

Important:Donottoworpullthemachine

withoutrstopeningthetowvalves,orthe

hydraulicsystemwillbedamaged.

1.Stoptheengine.

2.Removethebottomshield.

3.Usingawrench,turnthetowvalvesonthehydraulic

pumpstwicecounter-clockwise(Figure22).

2.Pullthetrenchercontrollevertothereferencebar

toengagethetrencher.

3.Slowlylowertheboomandchainintotheground.

Note:Toachievethemaximumdepth,youmay

needtolowertheboomasfarintothegroundas

itwillgowiththechainrunning.Then,stopthe

chainandloweritfully.Startthechainagainand

resumeoperation.

4.Oncethetrencherboomisinthegroundata45

to60degreeangle,slowlymovethetractionunit

rearwardtoextendthetrench.

Note:Ifyoumovetoofast,thetrencherwillstall.

Ifitstalls,raiseitslightly,slowlydriveforward,or

reversethechaindirectionmomentarily .

5.Whennished,raisetheboomoutofthetrench,

thenstopthetrencher.

SecuringtheMachinefor

Transport

Whentransportingthemachineonatrailer,alwaysuse

thefollowingprocedure:

Important:Donotoperateordrivethemachine

onroadways.

Figure22

1.Towvalves

4.Installthebottomshieldandtowthemachineas

required.

5.Whenthemachinehasbeenrepaired,closethetow

valvesbeforeoperatingit.

DiggingaTrench

1.Stoptheengine.

2.Lowertheboom.

3.Securethemachinetothetrailerwithchainsor

strapsusingthetie-down/liftloopsatthefrontand

rearofthemachine(Figure23andFigure24).Refer

toyourlocalordinancesfortrailerandtie-down

requirements.

Figure23

1.Fronttie-downloop

1.Starttheengine,raisetheboom,setthethrottle

levertotheFastposition,andmovethemachine

overtheareatobetrenched.

20

Page 21

1

G007818

Figure24

1.Reartie-downloops

LiftingtheMachine

Youcanliftthemachineusingthetie-down/liftloops

asliftpoints(Figure23andFigure24).

OperatingTips

•Cleantheareaoftrash,branchesandrocksbefore

trenchingtopreventequipmentdamage.

•Alwaysbegintrenchingwiththeslowestground

speedpossible.Increasespeedifconditionspermit.

Ifthechainspeedslowsdown,reducegroundspeed

tokeepthechainmovingatitsfastestrate.Donot

spinthetrackswhiletrenching.

•Alwaysusefullthrottle(maximumenginespeed)

whentrenching.

•Alwaystrenchbackwards(i.e.,inreverse).

•Trenchata45to60degreeangleforbestresults.

•Youwillbeabletodigatrenchfasterbycontrolling

thedepthwithperiodicadjustmentsoftheboom.

•Ifthetrencherbindsinthesoil,reversethechain

direction.Oncethechainisloose,changechain

directionsandcontinuetrenching.

•Ifyouneedthenishedtrenchtobecleanerthan

whatispossiblewiththetrencher,youcanpurchase

acrumberfromyourdealer.Thecrumbermounts

ontothetrencherheadandscrapesthetrenchclean

asyoudig.

•Toimprovethequalityoftrencheslessthan24inch

(60.9cm)deep,usea24inch(60.9cm)boom.

•Usethecorrectchainforthegroundconditions,as

listedinthefollowingtable:

SoilT ypeRecommendedChainType

SandySoilchain(re-congurewith

SandyLoam/Loam/Loamy

Clay

Wet,stickyclay

Hardsoils:dryclayand

compactedsoils

Rockysoil/gravel

extrateethforaddeddigging

speed;refertoyourAuthorized

ServiceDealer)

Soilchain

Soilchain

Combinationchain

Rockchain

21

Page 22

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Beforeeachuseordaily

Every25hours

Every40hours

Every50hours

Every100hours

MaintenanceProcedure

•Changetheengineoil.

•Checkandadjustthetracktension.

•Checktheengineoillevel.

•Greasethemachine.(Greaseimmediatelyaftereverywashing.)

•Checktheengineoillevel.

•Checktheconditionofandcleanthetracks.

•Checktheconditionofthediggingteethandreplaceanythatarewornordamaged.

•Removedebrisfromthemachine.

•Checkforloosefasteners.

•Checkthehydraulicuidlevel.

•Cleanthefoamaircleanerelement.(Models22970and22971)

•Checkthebatteryelectrolytelevel.

•Checkthediggingchainforexcessivewearandpropertension.

•Greasethetrencherhousing.

•Checkthepaperaircleanerelement.(Models22970and22971)

•Changetheengineoil.

•Checkthesparkplugs.

•Checkandadjustthetracktension.

•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,weather,andchemicaldeteriorationandrepairifnecessary.

•Replacethepaperaircleanerelement.(Models22970and22971)

Every200hours

Every250hours

Every400hours

Every1,500hours

Yearlyorbeforestorage

Important:Refertoyour

•Changetheoillter.

•Replacethefuellter .

•Replacethehydrauliclter.

•Replacetheprimaryairlterandcheckthecondtionofthesafetylter(Model22974)

•Checkandgreasetheroadwheels.

•Changethehydraulicuid.

•Replaceallmovinghydraulichoses.

•Checkandadjustthetracktension.

•Checkandadjustthechaintension.

•T ouchupchippedpaint

Engine Operator’ s Man ual

foradditionalmaintenanceprocedures.

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

22

Page 23

Premaintenance

Procedures

Beforeopeninganyofthecovers,stoptheengine,

removethekey,andallowtheenginetocool.

Important:Thefastenersonthecoversofthis

machinearedesignedtoremainonthecoverafter

removal.Loosenallofthefastenersoneachcovera

fewturnssothatthecoverisloosebutstillattached,

thengobackandloosenthemuntilthecover

comesfree.Thiswillpreventyoufromaccidentally

strippingtheboltsfreeoftheretainers.

RemovingtheCoverPlate

1.Lowertheboom,stoptheengine,andremovethe

key.

Thereisabeltunderthecoverthatismoving

whenthemachineisrunningandcancatch

ngers,hands,loosehair,andclothing,causing

seriousinjury,amputation,ordeath.

Alwaysstoptheengineandwaitforallmoving

partstostopbeforeremovingthecover.

InstallingtheCoverPlate

1.Lowertheboom,stoptheengine,andremovethe

key.

2.Slidethecoverplateintoplaceandsecureitwiththe

threeboltsyouloosenedpreviously(Figure25).

RemovingtheBottomShield

1.Lowertheboom,stoptheengine,andremovethe

key.

2.Loosenthetwoboltssecuringthebottomshield

sequentiallyuntiltheshieldisfree(Figure26).

Figure26

1.Bottomshield3.Tabs

2.Bolts

3.Pulltheshieldbackandoutofthemachine.

2.Loosentheboltattherearofthecoverplate.

3.Loosenthethreeboltssecuringthecoverplatetothe

framesequentiallyuntilthecoverisfree(Figure25).

Figure25

1.Coverplate

4.Pullupontherearofthecoverplateuntilitclears

theengineandthenpullitoffofthemachine.

2.Bolts

InstallingtheBottomShield

1.Lowertheboom,stoptheengine,andremovethe

key.

2.Slidethebottomshieldintothemachinesothatit

restsonall4tabs(Figure26).

Note:Youmayneedtoliftuponthebottomshield

toensurethatitrestsonthefronttabs.

3.Securetheshieldwiththeboltsyouloosened

previously.

23

Page 24

Lubrication

GreasingtheMachine

ServiceInterval:Beforeeachuseordaily(Grease

immediatelyaftereverywashing.)

GreaseType:General-purposegrease.

1.Lowertheboomandstoptheengine.Removethe

key.

2.Cleanthegreasettingswitharag.

3.Connectagreaseguntoeachtting(Figure27

throughFigure30).

4.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings(approximately3pumps).

5.Wipeupanyexcessgrease.

Figure29

Figure27

Figure28

Figure30

GreasingtheTrencher

Housing

ServiceInterval:Every40hours

GreaseType:General-purposegrease.

1.Lowertheboomandstoptheengine.Removethe

key.

2.Cleanthetrencherhousinggreasettingwitharag

andconnectagreaseguntoit(Figure31).

24

Page 25

Figure31

3.Pumpgreaseintothettinguntilgreasecomesout

ofthegreasevalvelocatednexttothetting.

EngineMaintenance

ServicingtheAirCleaner

(Models22970and22971)

ServiceInterval:Every25hours—Cleanthefoamair

cleanerelement.(Models22970and

22971)

Every50hours—Checkthepaperair

cleanerelement.(Models22970and

22971)

Every200hours/Yearly(whichever

comesrst)—Replacethepaperair

cleanerelement.(Models22970and

22971)

4.Wipeupanyexcessgrease.

Inspectthefoamandpaperelementsandreplacethem

iftheyaredamagedorexcessivelydirty.

Note:Servicetheaircleanermorefrequently(every

fewoperatinghours)iftheoperatingconditionsare

extremelydustyorsandy .

Important:Donotoilthefoamorpaperelement.

RemovingtheFoamandPaper

Elements

1.Lowertheboomandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Cleanaroundtheaircleanertopreventdirt

fromgettingintotheengineandcausingdamage

(Figure32).

4.Unscrewthecoverknobandremovetheaircleaner

cover(Figure32).

5.Removethe2wingnutsandremovetheaircleaner

assembly(Figure32).

6.Carefullypullthefoamelementoffthepaper

element(Figure32).

25

Page 26

2.Placetheaircleanerassemblyontotheaircleaner

G011475

1

2

3

4

5

baseandsecureitwiththe2wingnuts(Figure32).

3.Placetheaircleanercoverintopositionandtighten

thecoverknob(Figure32).

ServicingtheAirCleaner

(Model22974)

ServiceInterval:Every250hours

ServicingtheAirCleanerCoverand

Body

1.Stoptheengineandremovethekey.

2.Checktheaircleanerbodyfordamagewhichcould

causeanairleak.Checkthewholeintakesystem

forleaks,damage,orloosehoseclamps.Replaceor

repairanddamagedcomponents.

3.Releasethelatchesontheaircleanerandpulltheair

cleanercoveroffoftheaircleanerbody(Figure33).

Figure32

1.Engine4.Foamelement

2.Cover

3.Wingnut

5.Paperelement

6.Coverknob

CleaningtheFoamAirCleanerElement

1.Washthefoamelementinliquidsoapandwarm

water.Whentheelementisclean,rinseitthoroughly.

2.Drytheelementbysqueezingitinacleancloth.

Important:Replacethefoamelementifitis

tornorworn.

ServicingthePaperAirCleaner

Element

Donotcleanthepaperlter.Replaceitafter200

operatinghours(Figure32).Inspecttheelementfor

tears,anoilylm,ordamagetotherubberseal,and

replaceitifitisdamaged.

InstallingtheFoamandPaperElements

Important:Topreventenginedamage,always

operatetheenginewiththecompletefoamand

paperaircleanerassemblyinstalled.

1.Carefullyslidethefoamelementontothepaperair

cleanerelement(Figure32).

Important:Donotremovetheairltersyet.

Figure33

1.Airlterbody

2.Safetylter

3.Primarylter

4.Aircleanercover

5.Dustcap

4.Squeezethedustcapsidestoopenitandknockthe

dustout.

5.Cleantheinsideoftheaircleanercoverwith

compressedair.

ReplacingtheFilters

1.Gentlyslidetheprimarylteroutoftheaircleaner

body(Figure33).Avoidknockingthelterintothe

sideofthebody.

26

Page 27

Important:Donotattempttocleantheprimary

lter.

2.Checktheconditionofthesafetylterwithout

removingit.Ifitisdirtyordamaged,replaceit.

Important:Neverattempttocleanthesafety

lter.

3.Inspectthenewlter(s)fordamagebylookinginto

thelterwhileshiningabrightlightontheoutside

ofthelter.Holesinthelterwillappearasbright

spots.Inspecttheelementfortears,anoilylm,or

damagetotherubberseal.Ifthelterisdamaged

donotuseit.

4.Ifyouarereplacingthesafetylter,carefullyslide

thenewlterintothelterbody(Figure33).

Figure34

Important:T opreventenginedamage,always

operatetheenginewithbothairltersandcover

installed.

5.Carefullyslidetheprimarylteroverthesafetylter

(Figure33).Ensurethatitisfullyseatedbypushing

ontheouterrimofthelterwhileinstallingit.

Important:Donotpressonthesoftinsidearea

ofthelter.

6.Installtheaircleanercoverwiththedustcaporiented

asshowninFigure33andsecurethelatches.

ServicingtheEngineOil

ServiceInterval:Aftertherst8hours—Changethe

engineoil.

Beforeeachuseordaily—Checkthe

engineoillevel.

Every100hours—Changetheengine

oil.

Every200hours—Changetheoil

lter.

Note:Changetheoilmorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy.

OilType:Detergentoil(APIserviceSF,SG,SH,orSJ)

CheckingtheEngineOilLevel

1.Parkthemachineonalevelsurface.

2.Lowertheboomandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Cleanaroundtheoildipstick(Figure35)sothatdirt

cannotfallintothellerholeanddamagetheengine.

Figure35

1.Oildipstick

5.Unscrewtheoildipstickandwipetheendclean

(Figure35).

6.Slidetheoildipstickfullyintothellertube,butdo

notthreadontotube(Figure35).

2.Fillertube

CrankcaseCapacity:58ounces(1.7liter)withthelter

removed;51ounces(1.5liter)withoutthelterremoved

Viscosity:Refertothetable(Figure34).

7.Pullthedipstickoutandlookattheend.Iftheoil

levelislow ,slowlypouronlyenoughoilintotheller

tubetoraisetheleveltotheFullmark.

Important:Donotoverllthecrankcasewith

oilandruntheengine;enginedamagecan

result.

27

Page 28

ChangingtheOil

1.Starttheengineandletitrunveminutes.This

warmstheoilsoitdrainsbetter.

2.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoensurethattheoil

drainscompletely .

3.Lowertheboomandsettheparkingbrake.

4.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

5.Placeapanbelowthedrainhose.Rotatetheoildrain

valvetoallowoiltodrain(Figure36).

Figure37

1.Oillter

2.Adapter

3.Applyathincoatofnewoiltotherubbergasketon

thereplacementlter(Figure37).

4.Installthereplacementoilltertothelteradapter,

turntheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thentightenthelteran

additional3/4turn(Figure37).

5.Fillthecrankcasewiththepropertypeofnewoil;

refertoServicingtheEngineOil.

Figure36

Onmodel22974,theoildrainisontheoppositesideof

themachine.

1.Oildrainvalve2.Oildrainhose

6.Whenoilhasdrainedcompletely,closethedrain

valve.

7.Disposeoftheusedoilatarecyclingcenter

8.Slowlypourapproximately80%ofthespeciedoil

intothellertube(Figure35).

9.Checktheoillevel;refertoCheckingtheEngineOil

Level.

10.SlowlyaddtheadditionaloiltobringittotheFull

mark.

ChangingtheOilFilter

6.Runtheengineforabout3minutes,stoptheengine,

andcheckforoilleaksaroundtheoillteranddrain

valve.

7.Checktheengineoillevelandaddoilifneeded.

8.Wipeupanyspilledoil.

ServicingtheSparkPlug

ServiceInterval:Every100hours—Checkthespark

plugs.

Ensurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplug.

Useasparkplugwrenchforremovingandinstallingthe

sparkplugandagappingtool/feelergaugetocheckand

adjusttheairgap.Installanewsparkplugifnecessary.

Type:

•Models22970and22971—Champion®RCJ8Yor

equivalent;AirGap:0.030inch(0.75mm)

•Model22974—NGKBPR4Esorequivalent;Air

Gap:0.030inch(0.75mm)

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil.

2.Removetheoldlter(Figure37).

RemovingtheSparkPlug

1.Lowertheboomandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Disconnectthewirefromthesparkplug(Figure38).

28

Page 29

1

Figure38

1.Spark-plugwire/sparkplug

4.Cleanaroundthesparkplugtopreventdirtfrom

fallingintotheengineandpotentiallycausing

damage.

Note:Theheatshieldmayinterfereontheright

side;removeitifnecessaryandreplaceitwhen

nished.

Important:Alwaysreplacethesparkplugwhen

ithaswornelectrodes,anoilylmonit,orhas

cracksintheporcelain.

3.Checkthegapbetweenthecenterandsideelectrodes

(Figure39).Bendthesideelectrode(Figure39)if

thegapisnotcorrect.

InstallingtheSparkPlug

1.Installthesparkplugandthemetalwasher.Ensure

thattheairgapissetcorrectly.

2.Tightenthesparkplugto16ft-lb(22N-m).

3.Connectthewiretothesparkplug(Figure39).

5.Removethesparkplugandthemetalwasher.

CheckingtheSparkPlug

1.Lookatthecenterofthesparkplug(Figure39).

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeansthattheaircleanerisdirty.

2.Ifneeded,cleanthesparkplugwithawirebrushto

removecarbondeposits.

Figure39

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

29

Page 30

FuelSystem

Maintenance

DrainingtheFuelTank

Note:Nowisthebesttimetoinstallanewfuellter

becausethefueltankisempty .RefertoReplacing

theFuelFilter.

7.Installthefuellineontothefuelshut-offvalve.Slide

thehoseclampclosetothevalvetosecurethefuel

line.

8.Wipeupanyspilledfuel.

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopen

area.Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,and

stayawayfromanopenameorwherea

sparkmayignitethegasolinefumes.

1.Parkthemachineonalevelsurface,toensurethat

thefueltankdrainscompletely.

2.Lowertheboomandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Turnthefuelshut-offvalvetotheclosedposition

(Figure40).

ReplacingtheFuelFilter

ServiceInterval:Every200hours

Neverinstalladirtylterifitisremovedfromthefuel

line.

Note:Notehowthefuellterisinstalledinorderto

installthenewltercorrectly.

Note:Wipeupanyspilledfuel.

1.Lowertheboomandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Turnthefuelshut-offvalvetotheclosedposition

(Figure40).

4.Squeezetheendsofthehoseclampstogetherand

slidethemawayfromthelter(Figure41).

Figure40

1.Fuelshut-offvalve

5.Squeezetheendsofthehoseclampontheengine

sideoftheshut-offvalvetogetherandslideitupthe

fuellineawayfromvalve(Figure40).

6.Pullthefuellineoffthevalve(Figure40).Openthe

fuelshut-offvalveandallowthegasolinetodrain

intoagascanordrainpan.

Figure41

1.Hoseclamp3.Filter

2.Fuelline

5.Removethelterfromthefuellines.

6.Installanewlterandmovethehoseclampsclose

tothelter.

7.Turnthefuelshut-offvalvetotheopenposition

(Figure40).

8.Checkforfuelleaksandrepairifneeded.

9.Wipeupanyspilledfuel.

30

Page 31

ElectricalSystem

Maintenance

ServicingtheBattery(Models

22971and22974)

ServiceInterval:Every25hours—Checkthebattery

electrolytelevel.

Alwayskeepthebatterycleanandfullycharged.Use

apapertoweltocleanthebatterycase.Ifthebattery

terminalsarecorroded,cleanthemwithasolutionof

fourpartswaterandonepartbakingsoda.Applyalight

coatingofgreasetothebatteryterminalstoprevent

corrosion.

Voltage:12Vwith280coldcrankingAmps@0degrees

F(-18degreesC).

Warning

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

RemovingtheBattery

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponentscausing

sparks.Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,do

notallowthebatteryterminalstotouchany

metalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•AlwaysDisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•AlwaysReconnectthepositive(red)battery

cablebeforereconnectingthenegative

(black)cable.

Batteryelectrolytecontainssulfuricacidwhich

isadeadlypoisonandcausessevereburns.

Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

1.Lowertheboomandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Lifttheblackrubbercoveronthenegativecable.

Disconnectthenegativebatterycablefromthe

negative(-)batteryterminal(Figure42).

31

Page 32

Figure42

1.Negativecable7.Positivecable

2.Nut(1/4inch)

3.Nut(5/16inch)

4.Bolt10.J-bolt

5.Rubbercover(red)

6.Rubbercover(black)

8.Batteryholddownplate

9.Washer

11.Battery

CheckingtheBatteryElectrolyteLevel

Batteryelectrolytecontainssulfuricacidwhich

isadeadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontact

withskin,eyesorclothing.Wearsafety

glassestoshieldyoureyesandrubbergloves

toprotectyourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

1.Lookatthesideofthebattery.Theelectrolytemust

beuptotheupperline(Figure43).Donotallowthe

electrolytetofallbelowtheLowerline(Figure43).

Figure43

1.Ventcaps3.Lowerline

2.Upperline

4.Slidetheredterminalbootoffthepositive(red)

batteryterminal.Thenremovethepositive(red)

batterycable(Figure42).

5.Removetheholddownplate,j-bolts,andlocknuts

securingthebattery(Figure42)andremovethe

battery.

InstallingtheBattery

1.Placethebatteryontothemachine(Figure42).

2.Securethebatterywiththeholddownplate,j-bolts,

andlocknuts.

3.First,installthepositive(red)batterycableto

positive(+)batteryterminalwithanut,washerand

bolt(Figure42).Slidetherubbercoveroverthepost.

4.Theninstallthenegativebatterycableandground

wiretothenegative(-)batteryterminalwithanut,

washerandbolt(Figure42).Slidetherubbercover

overthepost.

2.Iftheelectrolyteislow ,addtherequiredamountof

distilledwater;refertoAddingWatertotheBattery.

AddingWatertotheBattery

Thebesttimetoadddistilledwatertothebatteryisjust

beforeyouoperatethemachine.Thisletsthewatermix

thoroughlywiththeelectrolytesolution.

1.Removethebatteryfromthemachine;referto

RemovingtheBattery.

Important:Neverllthebatterywithdistilled

waterwhilethebatteryisinstalledinthe

machine.Electrolytecouldbespilledonother

partsandcausecorrosion.

2.Cleanthetopofthebatterywithapapertowel.

3.Removetheventcapsfromthebattery(Figure43).

4.Slowlypourdistilledwaterintoeachbatterycell

untiltheelectrolytelevelisuptotheUpperline

(Figure43)onthebatterycase.

Important:Donotoverllthebatterybecause

electrolyte(sulfuricacid)cancausesevere

corrosionanddamagetothechassis.

32

Page 33

5.Waitvetotenminutesafterllingthebatterycells.

Adddistilledwater,ifnecessary,untiltheelectrolyte

levelisuptotheUpperline(Figure43)onthe

batterycase.

6.Installthebatteryventcaps.

ChargingtheBattery

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity).Thisisespeciallyimportant

topreventbatterydamagewhenthetemperatureis

below32°F(0°C).

1.Removethebatteryfromthechassis;referto

RemovingtheBattery.

2.Checktheelectrolytelevel;refertoCheckingthe

ElectrolyteLevel.

ReplacingtheFuses(Models

22971and22974)

Thereare4fusesintheelectricalsystem.Theyareunder

thecontrolpanelontheleftside(Figure45).

StartCircuit

ChargeCircuit

CoolerfanCircuit

Headlight(optional)

Figure45

1.Fuseblock

30amp

25amp

15amp

15amp

3.Makesurethellercapsareinstalledinbattery.

Connecta3to4ampbatterychargertothebattery

posts.Chargethebatteryatarateof3to4amperes

for4to8hours(12volts).Donotoverchargethe

battery.

4.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthe

chargerleadsfromthebatteryposts(Figure44).

5.Installthebatteryontothemachineandconnectthe

batterycables,refertoInstallingtheBattery.

Note:Donotrunthemachinewiththebattery

disconnected,electricaldamagemayoccur.

1.PositiveBatteryPost

2.NegativeBatteryPost

Figure44

3.Red(+)ChargerLead

4.Black(-)ChargerLead

33

Page 34

DriveSystem

Maintenance

ServicingtheTracks

CleaningtheTracks

ServiceInterval:Beforeeachuseordaily

Checkthetracksforexcessivewearandcleanthem

periodically.Ifthetracksareworn,replacethem.

1.Lowertheboomandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Usingawaterhoseorpressurewasher,removedirt

fromeachtracksystem.

Important:Ensurethatyouusehigh-pressure

watertowashonlythetrackarea.Donotuse

ahigh-pressurewashertocleantherestofthe

machine.High-pressurewashingcandamagethe

electricalsystemandhydraulicvalvesordeplete

grease.

Important:Ensurethatyoufullycleantheroad

wheelsandthedrivesprocket(Figure46).

thedrivesprocket.Thetrackshouldexnomorethan

1/4to3/8inch(0.6to1cm).Ifitdoes,adjustthetrack

tensionusingthefollowingprocedure:

Figure47

1.Stopthemachineinonalevelsurfaceandsetthe

parkingbrake.

2.Stoptheengine,lowertheboom,removethekey,

andwaitforallmovingpartstostopbeforeleaving

theoperatingposition.

3.Loosenthejamnutonthetracktensioningboltand

theclampboltsonthetensionarm(Figure48).

Figure46

1.Roadwheels3.Track

2.Drivesprocket

CheckingandAdjustingtheTrack

Tension

ServiceInterval:Aftertherst50hours

Every100hours

Tocheckthetensionofeachtrack,place45lb(20.4kg)

onthetrackmidwaybetweenthefrontroadwheeland

Figure48

1.Tensioningbolt

2.Jamnut

4.Torquethetensioningboltto24to30ft-lb(32.5to

40N-m)totightenthetrack(Figure48).

5.Ensurethatthetrackdeectslessthan1/4to3/8

inch(0.6to1cm)when45lb(20.6kg)offorceis

appliedtothetrackspan.Adjustthetorqueonthe

tensioningboltasneeded.

6.Tightenthejamnut.

7.Tightentheclampboltsandtorqueto75ft-lb(102

N-m).

34

3.Clampbolts

Page 35

ReplacingtheTracks

Whenthetracksarebadlyworn,replacethem.

1.Lowertheboomandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Lift/supportthesideoftheunittobeworkedon

sothatthetrackis3to4inches(7.6to10cm)off

oftheground.

4.Backoutthetensioningboltandjamnut(Figure48).

5.Loosentheclampbolts(Figure48).

6.Pushthefrontroadwheelrearwardasfarasitwill

go(Figure49).

Figure50

1.Snapring4.Gasket

2.Cap

3.Bolt

5.Wheelwithbearings

8.Whenthetrackisoffoftheroadwheel,removeit

fromthemachine(Figure49).

9.Beginningatthedrivesprocket,coilthenewtrack

aroundthesprocket,ensuringthatthelugson

thetracktbetweenthespacersonthesprocket

(Figure49).

Figure49

7.Beginremovingthetrackatthetopofthefrontroad

wheel,peelingitoffofthewheelwhilerotatingthe

trackforwards.

Note:Youmayneedtoremovethefront,outside

roadwheel.T oremovethiswheel,removethesnap

ringandcapfromthecenteroftheroadwheel

(Figure50).Nextremovetheboltandgasketfrom

thecenterofthewheelandpullthewheeloffofthe

machine.

10.Pushthetrackunderandbetweentherearandcenter

roadwheels(Figure49).

11.Startingatthebottomofthefrontroadwheel,install

thetrackaroundthewheelbyrotatingthetrack

rearwardwhilepushingthelugsintothewheel.

12.Ifyouremovedthefront,outsideroadwheel,install

itatthistimeusingtheboltandgasketremoved

previously.Torquetheboltto75ft-lb(102N-m)

andthenclean,grease,andinstallthecapandsnap

ringasinstructionintheCheckingandGreasingthe

RoadWheelssection.

13.Installthetensioningboltandjamnut.

14.Torquethetensioningboltto24to30ft-lb(32.5to

40N-m)totightenthetrack.

15.Ensurethatthetrackdeectslessthan1/4to3/8

inch(0.6to1cm)when45lb(20.6kg)offorceis

appliedtothetrackspan.Adjustthetorqueonthe

tensioningboltasneeded.

16.Tightenthejamnut.

17.Tightentheclampboltsandtorqueto75ft-lb(102

N-m).

18.Lowerthemachinetotheground.

19.Repeatsteps3through18toreplacetheothertrack.

35

Page 36

CheckingandGreasingtheRoad

Wheels

BeltMaintenance

ServiceInterval:Every250hours

1.Removethetracks;refertoReplacingtheTracks.

2.Removethesnapringandcapfromaroadwheel

(Figure51).

Figure51

1.Roadwheel

2.Roadwheelcap

3.Snapring

3.Checkthegreaseunderthecapandaroundthe

gasket(Figure51).Ifitisdirty,gritty,ordepleted,

cleanoutallofthegrease,replacethegasket,and

addnewgrease.

ReplacingthePumpDriveBelt

Ifthepumpdrivebeltbeginstosquealoriscracked,

worn,orfrayed,replaceit.ContactyouAuthorized

ServiceDealerforareplacementbelt.

1.Raisetheboomandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Raisethebackofthemachineandsupportitonjack

stands.

4.Removethebottomshield;refertoRemovingthe

BottomShield.

5.Loosenthetwopumpbolts(Figure52).

4.Ensurethattheroadwheelturnssmoothlyonthe

bearing.Ifitisfrozen,contactyourAuthorized

ServiceDealertoreplacetheroadwheel.

5.Placethegreasedroadwheelcapoverthebolthead

(Figure51).

6.Securetheroadwheelcapwiththesnapring

(Figure51).

7.Repeatsteps2through6forall12roadwheels.

8.Installthetracks;refertoReplacingtheTracks.

Figure52

1.Pump3.Belt

2.Pumpbolts4.Idlerpulleyspring

6.Twistthepumpcounterclockwiseandallowitto

dropdownawayfromthepulley(Figure52).Ensure

thatthespidercouplerdropsdownwiththepump.

7.Usingaspringpuller(contactyourAuthorized

ServiceDealer)orstiffmetalhook,pulltheendof

theidlerpulleysprintoffofthespringbolttorelease

tensiononthebelt(Figure52).

8.Removethebelt.

9.Routeanewbeltaroundthepulleys.

10.Installtheidlerpulleyspringonthebolt.

11.Ensurethatthespidercouplerisinplaceonthe

pumpandtheninsertitintothepulley,twistingit

clockwisetoseatitonthepumpbolts.

12.Torquethepumpboltsto50ft-lb(68N-m).

13.Installthebottomshield.

36

Page 37

ControlsSystem

Maintenance

Thefactoryadjuststhecontrolsbeforeshippingthe

machine.However,aftermanyhoursofuse,youmay

needtoadjustthetractioncontrolalignment,theneutral

positionofthetractioncontrol,andthetrackingofthe

tractioncontrolinthefullforwardposition.

Important:T oadjustthecontrolsproperly,

completeeachprocedureintheorderlisted.

AdjustingtheTractionControl

Alignment

Ifthetractioncontrolbardoesnotrestushand

squarewiththereferencebarwheninthefullbackward

position,immediatelycompletethefollowingprocedure:

1.Parkthemachineonaatsurfaceandlowerthe

boom.

2.Stoptheengineandremovethekey.

Figure54

1.Tractioncontrol

5.Adjustthetractioncontrolsothatitrestsush

againstthereferencebarwhenitispulledstraight

back(Figure54andFigure55).

2.Stem,boltandnut

3.Pullstraightbackonthetractioncontrolsothefront

ofthecontrolcontactsthereferencebar(Figure53).

Figure53

1.Frontofthecontrol,outof

alignment

4.Ifthefrontofthetractioncontroldoesnotrest

squareandushwiththereferencebar,loosenthe

angenutandboltinthestemofthetractioncontrol

(Figure54).

2.Referencebar

Figure55

6.Tightentheangenutandboltinthetraction

controlstem.

7.Starttheengine.

8.Drivethemachineinreversewiththetraction

controltighttothereferencebar.Ifthemachine

doesnotbackupstraight,completethefollowing

procedure:

A.Stoptheengine

B.Lift/supportthemachinesothatbothtracksare

offofthegroundandarefreetorun.

C.Loosentheangenutandboltinthestemofthe

tractioncontrol(Figure54).

D.Loosenthejamnutsonthetractionrods,under

thecontrolpanel(Figure56).

37

Page 38

G011476

1

1

2

2

Figure56

1.Tractionrod2.Jamnut

E.Startthemachineandsetthethrottletoabout

1/3openposition.

AdjustingtheTractionControl

NeutralPosition

Ifthemachinecreepsforwardorbackwardwhenthe

tractioncontrolisinneutralandtheunitiswarm,the

return-to-neutralmechanismonthepumpsmayneed

tobeadjusted;contactyouAuthorizedServiceDealer

forrepairs.

AdjustingtheTrackingofthe

TractionControl,FullForward

Position

Ifthemachinedoesnotdrivestraightwhenyouhold

thetractioncontrolforwardagainstthereferencebar,

completethefollowingprocedure:

1.Drivethemachinewiththetractioncontrolagainst

thereferencebar,notingwhichdirectionthe

machineveers.

2.Releasethetractioncontrol.

Whenthemachineisrunning,youcouldbe

caughtandinjuredinmovingpartsorburned

onhotsurfaces.

Stayawayfrompinchpoints,movingparts,

andhotsurfaceswhenadjustingtherunning

machine.

F.Haveahelperholdthetractioncontroltightto

thereferencebarinreverse.

G.Adjustthelengthofthetractionrodsuntilboth

tracksarerunningatthesamespeed.

Note:Youcanalsoadjustthemaximumreverse

speedofthetracksatthistime.

H.Tightenthejamnuts.

I.Adjustthetractioncontrolsothatitrestsush

againstthereferencebarwhenitispulledstraight

back(Figure54andFigure55).

J.Tightentheangenutandboltinthetraction

controlstem.

K.Stoptheengineandlowerthemachinetothe

ground.

L.Drivethemachineinfullreverse,checkingto

seeiftheunittracksstraight.Ifitdoesnot,

notethedirectionthemachineveers.Repeatthe

adjustmentpreviouslydescribedsothatittracks

straightinreverse.

3.Ifthemachineveerstotheleft,loosentherightjam

nutandadjustthetrackingsetscrewonthefrontof

thetractioncontrol(Figure57).

4.Ifthemachineveerstotheright,loosentheleftjam

nutandadjustthetrackingsetscrewonthefrontof

thetractioncontrol(Figure57).

Figure57

1.Setscrew3.Stop

2.Jamnut

5.Repeatsteps1through4untilthemachinedrives

straightinthefullforwardposition.

Important:Ensurethetrackingsetscrews

touchthestopsinthefullforwardpositionto

avoidoverstrokingthehydraulicpumps.

38

Page 39

HydraulicSystem

Maintenance

ReplacingtheHydraulicFilter

ServiceInterval:Every200hours

1.Positionmachineonalevelsurface.

2.Lowertheboomandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Removethetopcover.

5.Removeanddiscardtheoldlter(Figure58).

7.Placeadrainpancapableofhold10USGallons

(37.8l)underthehydraulictank.

8.Pinchthehoseclampandslidetheclampandhose

offofthettingonthehydraulictank,allowingthe

hydraulicuidtodrainfromthehoseandtankinto

thepan.

Figure58

1.Fillercap

2.Hydrauliclter

6.Installthereplacementhydrauliclterandllercap

(Figure58)andtorqueboltontopto110to140

in-lb(13to15.5N-m).

7.Cleanupanyspilleduid.

8.Installthetopcover.

ChangingtheHydraulicFluid

ServiceInterval:Every400hours/Yearly(whichever

comesrst)

1.Positionthemachineonalevelsurface.

2.Lowertheboomandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Allowthemachinetocoolcompletely.

5.Removethetopcover.

6.Removethehydraulictankllercapandlter

(Figure58).

Figure59

1.Hose

2.Hydraulictanktting

3.Hoseclamp

9.Whennished,installthehoseontothettingand

secureitwiththehoseclamp.

Note:Disposeoftheusedoilatacertiedrecycling

center.

10.Fillthehydraulictankwithapproximately6US

gallons(23l)of10W-30or15W -40detergent,diesel

engineoil(APIserviceCH-4orhigher);referto

CheckingHydraulicFluid.

11.Add8oz(236ml)ofAMSOIL

differentialadditiveoranequivalentdifferential

additivetothehydraulictank.

Note:AMSOILandSlip-Lockaretrademarksof

AMSOILInc.

12.Installthehydrauliclterandllercap(Figure58)

andtorqueboltontopto110to140in-lb(13to

15.5N-m).

13.Starttheengineandletitrunforafewminutes.

14.Stoptheengine.

®

Slip-Lock™

39

Page 40

15.Checkthehydraulicuidlevelandtopitoffif

necessary;refertoCheckingHydraulicFluid.

TrencherMaintenance

16.Cleanupanyspilleduid.

17.Installthetopcover.

CheckingtheHydraulicLines

ServiceInterval:Every100hours—Checkthe

hydrauliclinesforleaks,loose

ttings,kinkedlines,loosemounting

supports,wear,weather,andchemical

deteriorationandrepairifnecessary.

Every1,500hours/Every2years

(whichevercomesrst)—Replaceall

movinghydraulichoses.

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremovedwithin

afewhoursbyadoctorfamiliarwiththisform

ofinjuryorgangrenemayresult.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulic

leaks,neveruseyourhands.

ReplacingtheDiggingTeeth

ServiceInterval:Beforeeachuseordaily—Checkthe