FormNo.3430-913RevA

VibratoryPlow

CompactToolCarrier

ModelNo.22911—SerialNo.404320000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3430-913*A

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

g245687

Figure1

1.Modelandserialnumberlocation

Thevibratoryplowisanattachmentdesignedforuse

onT orocompacttoolcarrierstopullexiblepipeand

cableintoandthroughsoil.Itisdesignedtobeused

bytrainedoperatorsprimarilyforroutingirrigationand

utilitylinesundergroundwithouthavingtodigatrench

fortheentirelengthofthepipeorcable.Usingthis

productforpurposesotherthanitsintendedusecould

provedangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Y ouareresponsiblefor

operatingtheproductproperlyandsafely .

Visitwww.Toro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

©2019—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................3

GeneralSafety...................................................3

SlopeSafety.......................................................4

VibratoryPlowSafety.........................................4

MaintenanceandStorageSafety........................4

SafetyandInstructionalDecals..........................5

ProductOverview.....................................................5

Specications....................................................5

Operation..................................................................6

InstallingtheAttachment....................................6

RemovingtheAttachment..................................6

InstallingaBlade................................................6

Plowing...............................................................7

GaugingPlowDepth...........................................7

TransportPosition..............................................8

TransportingthePlow.........................................9

OperatingTips...................................................9

Maintenance...........................................................10

RecommendedMaintenanceSchedule(s)...........10

GreasingthePlow............................................10

ServicingtheGearLube....................................11

ReplacingtheCoulter.......................................12

Storage...................................................................12

Troubleshooting......................................................13

Safety

DANGER

Theremaybeburiedutilitylinesinthework

area.Diggingintothemmaycauseashock

oranexplosion.

Havethepropertyorworkareamarkedfor

buriedlinesanddonotdiginmarkedareas.

Contactyourlocalmarkingserviceorutility

companytohavethepropertymarked(for

example,intheUS,call811orinAustralia,

call1100forthenationwidemarkingservice).

GeneralSafety

Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.

•Donottransportanattachmentwiththearms

raised.Alwaystransporttheattachmentcloseto

theground;refertoTransportPosition(page8).

•Havethepropertyorworkareamarkedforburied

linesandotherobjects,anddonotdiginmarked

areas.

•ReadandunderstandthecontentofthisOperator’s

Manualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Neverallowchildrenoruntrainedpeopleto

operatethemachine.

•Keepyourhandsandfeetawayfromthemoving

componentsandattachments.

•Donotoperatethemachinewithouttheguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepbystandersandpetsawayfromthemachine.

•Stopthemachine,shutofftheengine,andremove

thekeybeforeservicing,fueling,orunclogging

themachine.

Improperlyusingormaintainingthismachinecan

resultininjury.T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

,which

3

SlopeSafety

•Operatethemachineupanddownslopeswith

theheavyendofthemachineuphill.Weight

distributionchangeswithattachments.This

attachmentmakesthefrontofmachinetheheavy

end.

•Keeptheattachmentintheloweredposition

whenonslopes.Raisingtheattachmentona

slopeaffectsthestabilityofthemachine.

•Slopesareamajorfactorrelatedtolossofcontrol

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Operatingthemachineonany

slopeoruneventerrainrequiresextracaution.

•Establishyourownproceduresandrulesfor

operatingonslopes.Theseproceduresmust

includesurveyingthesitetodeterminewhich

slopesaresafeformachineoperation.Always

usecommonsenseandgoodjudgmentwhen

performingthissurvey.

•Slowdownanduseextracareonhillsides.Ground

conditionscanaffectthestabilityofthemachine.

•Avoidstartingorstoppingonaslope.Ifthe

machinelosestraction,proceedslowly ,straight

downtheslope.

•Avoidturningonslopes.Ifyoumustturn,turn

slowlyandkeeptheheavyendofthemachine

uphill.

•Keepallmovementsonslopesslowandgradual.

Donotmakesuddenchangesinspeedor

direction.

•Ifyoufeeluneasyoperatingthemachineona

slope,donotdoit.

•Watchforholes,ruts,orbumps,asuneventerrain

couldoverturnthemachine.T allgrasscanhide

obstacles.

•Usecautionwhenoperatingonwetsurfaces.

Reducedtractioncouldcausesliding.

•Evaluatetheareatoensurethatthegroundis

stableenoughtosupportthemachine.

•Usecautionwhenoperatingthemachinenearthe

following:

–Drop-offs

–Ditches

–Embankments

–Bodiesofwater

VibratoryPlowSafety

•Theplowisveryloudduringoperation.Wear

hearingprotection.

•Keeptheplowlowatalltimes.

•Usecautionwhenturninganddonotturnquickly.

•Keepallbystandersatleast2m(6ft)awaywhile

operating.

•Forwheeledtractionunits,usethecounterweight

onthetractionunitwhenusingtheattachment.

MaintenanceandStorage

Safety

•Checkfastenersatfrequentintervalsforproper

tightnesstoensurethattheequipmentisinsafe

operatingcondition.

•RefertotheOperator’sManualforimportant

detailsifyoustoretheattachmentforanextended

periodoftime

•Maintainorreplacesafetyandinstructionlabels,

asnecessary.

Themachinecouldsuddenlyrolloverifatrack

goesovertheedgeortheedgecavesin.Maintain

asafedistancebetweenthemachineandany

hazard.

•Donotremoveoraddattachmentsonaslope.

•Donotparkthemachineonahillsideorslope.

4

SafetyandInstructional

ProductOverview

Decals

Safetydecalsandinstructionsare

easilyvisibletotheoperatorandare

locatednearanyareaofpotential

danger.Replaceanydecalthatis

damagedormissing.

g005037

Figure3

100-4649

1.Explosionhazard;electricalshockhazard—donotoperate

ifpowerlinesmaybepresent;keepbystandersaway.

100-4650

1.Crushinghazardofhand—keepbystandersaway .

2.Crushinghazardoffoot—keepbystandersaway.

133-8061

1.Vibratory-plowbody

decal100-4649

2.Blade(severaloptional

bladestylesareavailable)

3.Puller(severaloptional

pullerstylesareavailable)

4.Gauge-rodassembly

5.Coulter

6.Mountingplate

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Width

Length

Height

Weight

decal100-4650

Hydraulicmotordisplacement

Plowcycles2,000VPM

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

decal133-8061

productwarranty.

73.6cm(29inches)

89cm(35inches)

60cm(24inches)

181.5kg(400lb)

1.27in3/rev(20.8cc)

5

Operation

InstallingtheAttachment

RefertotheOperator’sManualforthetractionunitfor

theinstallationprocedure.

Important:Beforeinstallingtheattachment,

positionthemachineonalevelsurface,ensure

thatthemountplatesarefreeofanydirtordebris,

andensurethatthepinsrotatefreely .Ifthepins

donotrotatefreely,greasethem.

Note:Alwaysusethetractionunittoliftandmove

theattachment.

WARNING

Ifyoudonotfullyseatthequick-attach

pinsthroughtheattachmentmountplate,

theattachmentcouldfalloffthemachine,

crushingyouorbystanders.

Ensurethatthequick-attachpinsarefully

seatedintheattachmentmountplate.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliarwith

thisformofinjury;otherwise,gangrenemay

result.

•Ensurethatallhydraulic-uidhoses

andlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretothehydraulic

system.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks;neveruseyourhands.

RemovingtheAttachment

1.Withtheplowraisedabovetheground,shutoff

theengineandremovethekey.

2.Removethelowerlynchpinandclevispin

securingthebladetotheplow.

Note:Tocompletelyremovetheblade,remove

boththeupperandlowerlynchandclevispins;

refertoFigure5.

3.Swingthebladeupandsecureitusingthelynch

andclevispinasshownin(Figure4).

Figure4

1.Lynchandclevispin

2.Stand

4.Tilttheplowforwardandlowerittotheground

ortrailer,withthestandandcoultersupporting

theweightoftheplow(Figure4).

5.Disconnectthehydraulichosesandremovethe

plowasdirectedinyourtractionunitOperator’s

Manual.

3.Coulter

InstallingaBlade

Torooffersseveraldifferentbladesandpullers.

PurchaseabladeandpullerfromyourAuthorized

ServiceDealer.

WARNING

Thebladeissharpandcanswingduring

installationandremoval,cutting,pinching,or

crushinghandsorfeet.

g247050

CAUTION

Hydrauliccouplers,hydrauliclines/valves,

andhydraulicuidmaybehot.Ifyoucontact

hotcomponents,youmaybeburned.

•Weargloveswhenoperatingthehydraulic

couplers.

•Allowthemachinetocoolbeforetouching

hydrauliccomponents.

•Donottouchhydraulicuidspills.

Wearglovesandworkbootsandsecurely

holdtheblade.

1.Parkthemachineonalevelsurfaceandengage

theparkingbrake(ifequipped)

2.Raisetheplowabout1m(39inches)offthe

groundandinstallthecylinderlock(s).

3.Shutofftheengineandremovethekey

4.Removethe2lynchpinsfromtheclevispinsin

thebladebracket,thenremovetheclevispins

(Figure5)andtheexistingblade(ifinstalled).

6

Figure5

1.Lynchpin3.Blade

2.Clevispin

5.Slidethenewbladeintothebladebracketand

secureitatthedesireddepth(achangein

mountingholeschangesthedepthby7.6cm

(3inches),usingtheclevispinsandlynchpins

removedpreviously(Figure5).

2.Connectthematerialbeinginstalledtotheplow.

3.Ifyourtractionunithasaspeedselector,move

ittotheSLOW(turtle)position.

4.Starttheengine.

5.Tilttheattachmentplatecompletelybackso

thatthetopoftheplowisparalleltotheground

(Figure8).

6.Lowertheplowsothatitisrestingontheground.

Important:Alwaysensurethattheplow

isonorinthegroundbeforeengagingthe

g005025

auxiliaryhydraulicslever.Failuretodoso

willcauseexcessivevibrationofthetraction

unit,possiblyresultingindamage.

Note:Ifyoudigaholetolowerthebladeinto

beforestarting,itwillreducetheriskofbending

theblade.

7.Pulltheauxiliary-hydraulicslevertotheoperator

griptoengagetheplow.

8.Slowlylowertheplowintothegroundtothe

desireddepth,whilemovingthetractionunit

backward.

Plowing

1.Movethelynchpinstotheoutsideholesonthe

springrodstoallowtheplowtomovefromside

toside(Figure6).

Figure6

1.Outerhole

2.Lynchpin(ininnerhole)

3.Springrod

9.Whennished,releasetheauxiliary-hydraulics

levertostoptheplow.

CAUTION

Whenplowingonahill,theplowcan

swingdownhillwhenraisedoutofthe

soil.Duetotheweightoftheplow,ifit

swingstoofast,theforcecouldtipthe

tractionunit,injuringyouorothers.

Whenplowingonahill,raisetheplow

outofthegroundslowly,lettingitswing

whilethebulletisstillinthesoil.

10.Raisetheplowoutofthegroundfarenoughto

pullthepulleroutofthesoil.

g005027

11.Movethetractionunitrearwardtopullouta

workinglengthofmaterial,thenmoveforward

slightlytocreatesomeslackintheline.

12.Shutofftheengineandremovethekey.

CAUTION

Whenyouremovethelynchpin,theplow

couldswingintoyouorabystander,

orcausethetractionunittobecome

unstable.

Holdtheplowintheneutralposition

whenmovingthelynchpins.

GaugingPlowDepth

Normally,youwillplowatthemaximumdepthsetby

theblade;however,theplowisalsoequippedwitha

gaugetoallowyoutolifttheplowanddeterminehow

highabovemaximumdepthyouareplowing.

Thegaugeislocatedontheleftsideoftheplowfacing

thetractionunit.Arodassemblyrunsfromthegauge

7

totheground(Figure8).Whenyoulifttheplow,the

indicatoronthegaugemovesdown.Marksonthe

gaugeshowthenumberofincheslowerorhigherthan

themaximumdepththatyouareplowing(Figure7).

Thegaugereadsfrom+2to-3.The+2onthegauge

representsa5.0cm(2inch)depthbelowthebare

surfaceandthe-3onthegaugerepresentsa7.6cm

(3inch)abovethebaresurface.The0onthegauge

indicatesthatnooffsetisappliedtothebladedepth.

Figure7

TransportPosition

1.Withtheplowraisedabovetheground,shutoff

theengineandremovethekey.

2.Removethelowerlynchpinandclevispin

securingthebladetotheplow.

Note:Tocompletelyremovetheblade,remove

boththeupperandlowerlynchandclevispins;

refertoFigure5.

3.Swingthebladeupandsecureitusingthelynch

andclevispinasshowninFigure4.

4.Whentransportingtheattachment,keepitas

closetothegroundaspossible,nomorethan15

cm(6inches)abovetheground.Tiltitrearward.

g005028

1.Depthgauge

1.Gauge-rodassembly

2.Gauge-lockinglever

Figure8

2.Paralleltotheground

Whenplowingbareground,themaximumdepth

indicatedonthegaugeisthe0mark.Y oucanplow

downtothe+1mark,butyouwillcontacttheground

withthecoulteraxle.Plowinganylowermaydamage

thecoulter.

g245785

Figure9

g005029

1.Nomorethan15cm(6

inches)abovetheground

2.Tilttheattachment

rearward.

Whenplowinggrasscoveredground,thegauge

willreadaboutaninchlowerthantheactualdepth

becauseofthegrass.Inthiscase,lowertheplowto

thedesiredcoulterdepthandnotethereadingon

thegauge.

Ifyoutransporttheploworplowroughterrain,youcan

lockthegaugeatthe+2positiontokeepitfrombeing

damaged.Tolockthegauge,manuallyraiseittothe

+2positionandmovethelockinglevertotheleft.

8

TransportingthePlow

OperatingTips

1.Movethelynchpinstotheinsideholesonthe

springrodstopreventside-to-sidemovement

(Figure6).

CAUTION

Failuretosecuretheplowallowsitto

swingside-to-sideandunbalancethe

plow.Duetotheweightoftheplow,ifit

swingstoofast,theforcecouldtipthe

tractionunit,injuringyouorbystanders.

Alwayssecuretheplowwiththelynch

pinsintheinnerholesofthespringrods

beforetransportingtheplow.

2.Raisetheloaderarmsjustenoughtoensure

thatthebladeclearstheground.

Important:Important:Nevertransportthe

plowwiththearmsfullyraised.

•Someoldermodeltractionunitshaveholes

throughthespringandquick-attachpinsonthe

mountplate(Figure10)toallowyoutoinstall

2hairpincotterswhenplowinglongruns.This

ensuresthatthevibrationoftheplowdoesnot

causethepinstocomeloose.

Note:Thequick-attachpinsonnewertraction

unitsnolongerneedthehairpincotters.

g005030

Figure10

1.Hairpincotters

•Toreducewearonthetractionunitdrivechain(if

yourmodelhasone),tightenthechainsothereis

only5cm(2inches)ofslackontheupperspan

(refertoyourtractionunitOperator’sManualfor

instructions).

•Cleantheareaoftrash,branches,androcks

beforeplowingtopreventequipmentdamage.

•Alwaysbeginplowingwiththeslowestground

speedpossible.Increasespeedifconditions

permit,butdonotallowthetiresortrackstospin.

Spinningthetracksortirescausesturfdamage

andplacesstressonthetractionunit.

•Alwaysusefullthrottle(maximumenginespeed)

whenplowing.

•Alwaysplowbackward(inreverse).

•Ifyourtractionunithasaspeedselectoranda

owdivider,movethespeedselectortotheSLOW

(turtle)positionandtheowdividertothe10

o’clockposition.

•Avoidsharpturnswhenplowingtoincrease

productivityandminimizegrounddisturbance.

•Ifyourtractionunithastiresandyouhavethe

agriculturalorSiteworkSystemstiresinstalledon

thetractionunit,removethetiresandmovethe

right-sidetirestotheleftandtheleft-sidetiresto

theright.

Note:Thisensuresthatthetiretreadpointsto

thereartogiveyouthemosttractionwhenusing

thevibratoryplow.

9

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Beforeeachuseordaily

Every25hours

Every200hours

Beforestorage

MaintenanceProcedure

•Greasetheplow.

•Checkthegear-lubelevel.

•Changethegearlube.

•Greasetheplow.

•Checkthegear-lubelevel.

•Paintchippedsurfaces.

CAUTION

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheswitchbeforeyouperformanymaintenance.

GreasingthePlow

ServiceInterval:Beforeeachuseordaily

Beforestorage

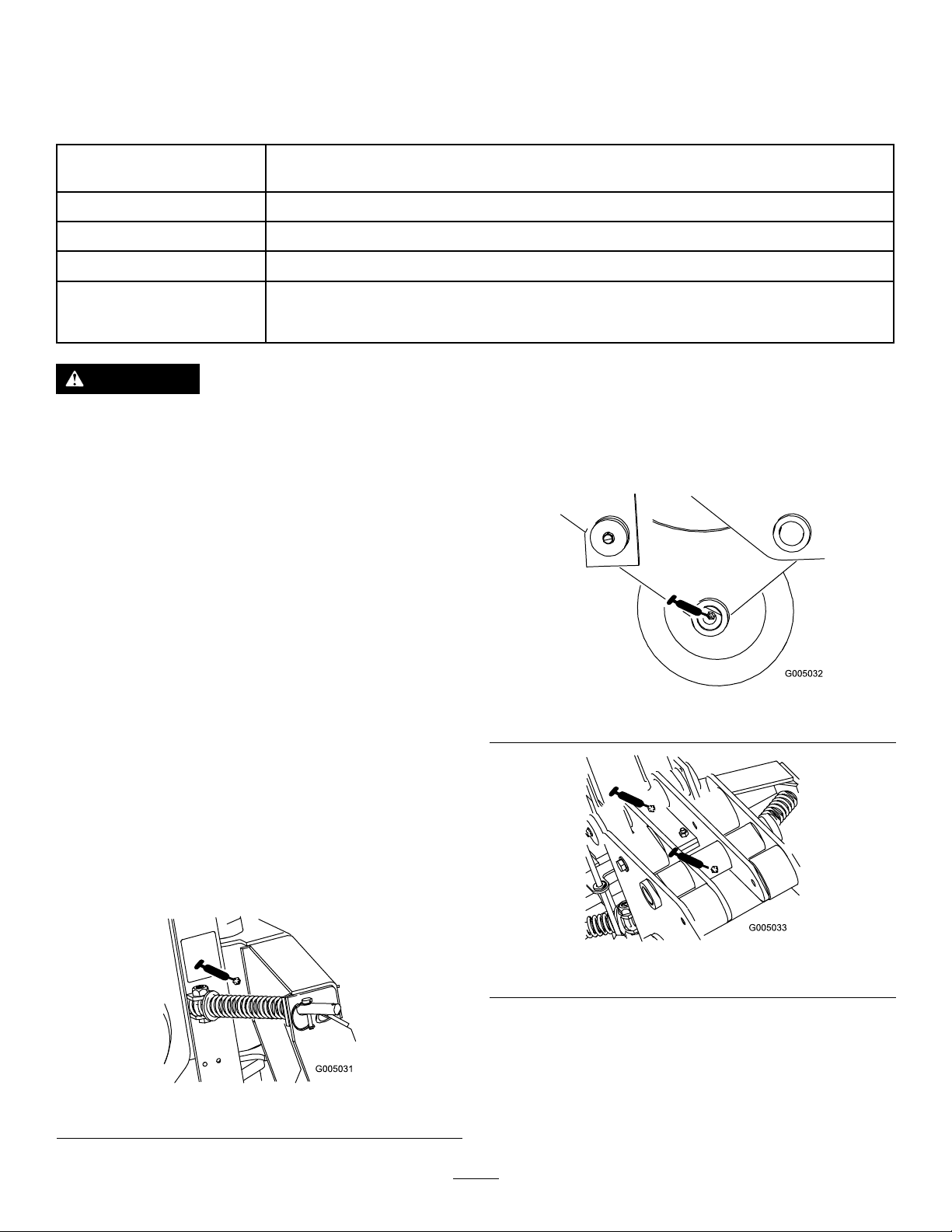

Greasethe6ttings,asshowninFigure11through

Figure14,every8operatinghours.Greaseallttings

immediatelyaftereverywashing.

GreaseType:General-purposegrease

1.Parkthemachineonalevelsurface,disengage

theauxiliaryhydraulicslever,lowerthe

attachment,andengagetheparkingbrake(if

equipped).

2.Shutofftheengineandremovethekey

3.Connectagreaseguntoeachtting.

4.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings.

5.Wipeupanyexcessgrease.

g005032

Figure12

g005033

Figure13

Figure11

g005031

10

ChangingtheGearLube

ServiceInterval:Every200hours/Yearly(whichever

comesrst)

1.Parkthemachineonalevelsurface,disengage

theauxiliaryhydraulicslever,andlowerthe

attachmentsothattheplowisontheground.

Engagetheparkingbrake(ifequipped).

Figure14

ServicingtheGearLube

Gear-lubetype:SAE90-140APIserviceGL-4orGL-5

Capacity:1.4L(47oz)

CheckingtheGear-LubeLevel

ServiceInterval:Every25hours

Beforestorage

1.Parkthemachineonalevelsurface,disengage

theauxiliaryhydraulicslever,andlowerthe

attachmentsothattheplowisontheground.

Engagetheparkingbrake(ifequipped).

2.Stoptheengineandremovethekey.

3.Checktheclearglassgaugeonthesideofthe

gearcase(Figure15).

g005034

2.Stoptheengineandremovethekey.

3.Prepareanappropriatecontainertocatchthe

usedoilundertheplow.

4.Removethedrainplug(Figure15),allowingthe

oiltospilloutintothecontainer.

5.Whennished,replacethedrainplug,ensuring

thatitistight.

6.Removethellplug(Figure15)andllthecase

withgearlubeuntilitislevelwiththereddotin

thegauge.

7.Replacethellplug.

Note:Thegearlubeshouldbeatthelevelof

thereddotinthecenterofthegauge.

4.Ifthegear-lubelevelislow,removethellplug

(Figure15)andllthecasewithgearlubeuntilit

islevelwiththereddotinthegauge.

Figure15

1.Glassgauge

2.Drainplug

5.Replacethellplug.

3.Fillplug

g005035

11

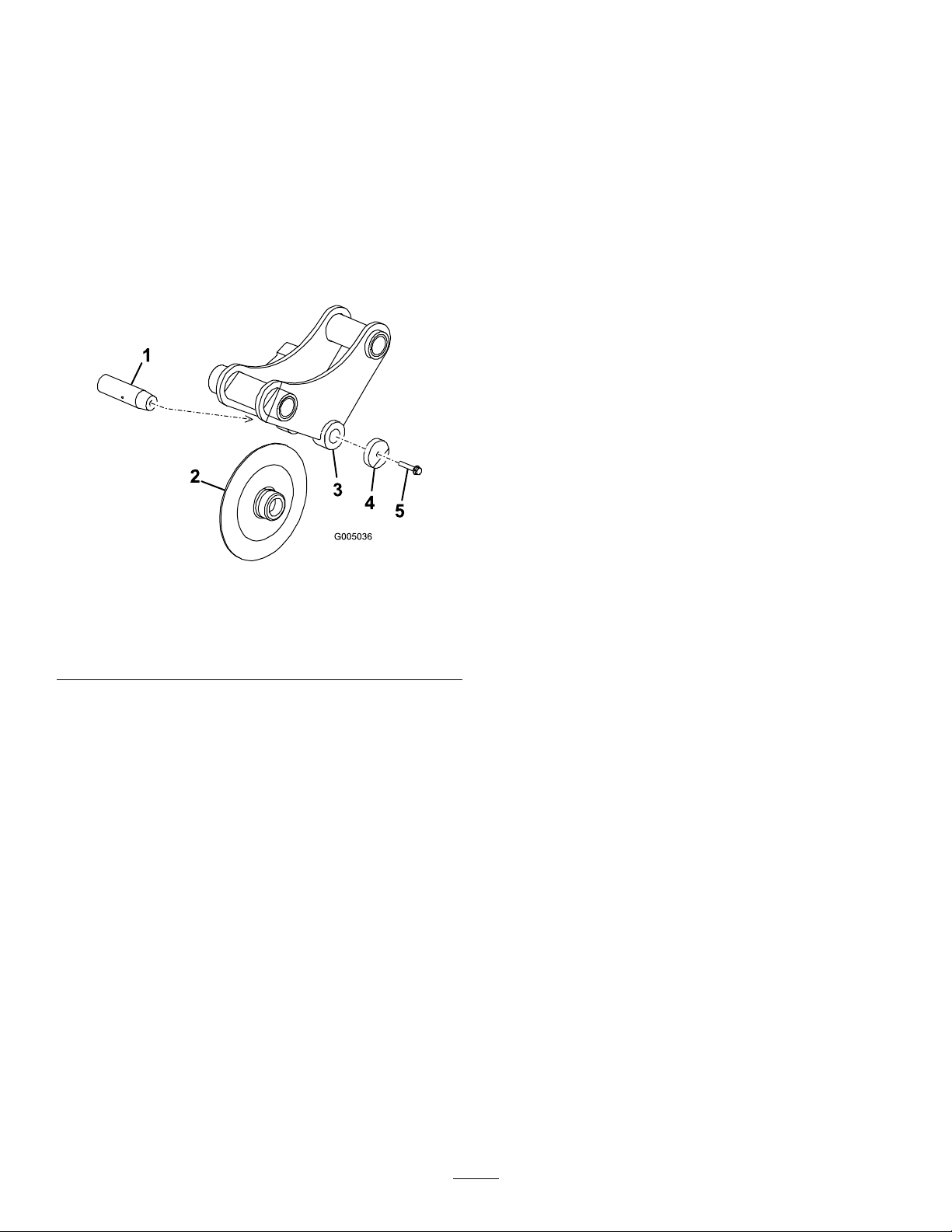

ReplacingtheCoulter

Ifthecoulterbecomesexcessivelywornordamaged,

replaceit.

1.Parkthemachineonalevelsurface,disengage

theauxiliaryhydraulicslever,lowerthe

attachment,andengagetheparkingbrake(if

equipped).

2.Shutofftheengineandremovethekey.

3.Backoutthecoulter-pinscrewabout1.3cm(0.5

inch),thenstrikeitseveraltimeswithahammer

toloosenthepin(Figure16).

Storage

1.Beforelong-termstorage,washtheattachment

withmilddetergentandwatertoremovedirtand

grime.

2.Greasetheplow.

3.Checkgear-caselubrication.

4.Checkandtightenallbolts,nuts,andscrews.

Repairorreplaceanydamagedorwornpart.

5.Ensurethatallhydrauliccouplersareconnected

togethertopreventcontaminationofthe

hydraulicsystem.

6.Paintallscratchedorbaremetalsurfaces.Paint

isavailablefromyourAuthorizedServiceDealer.

7.Storetheattachmentinaclean,drygarageor

storagearea.Coverittoprotectitandkeepit

clean.

Figure16

1.Coulterpin

2.Coulter5.Coulter-pinscrew

3.Coulterbracket

4.Completelyremovethecoulter-pinscrew,

washer,coulter,andcoulterpin(Figure16).

5.Putthenewcoulterintothecoulterbracket

(Figure16).

6.Slidethecoulterpinthroughthebracketand

coulterandsecureitwiththecoulter-pinscrew

andwasher(Figure16).

7.T orquethescrewto61N∙m(45ft-lb).

4.Washer

g005036

12

Troubleshooting

Theplowdoesnotoperate.

Problem

1.Thehydrauliccouplerisnotcompletely

connected.

2.Ahydrauliccouplerisdamaged.

3.Thereisanobstructioninahydraulic

hose.

4.Ahydraulichoseiskinked.4.Replacethekinkedhose

5.Theauxiliaryvalveonthetractionunit

isnotopening.

PossibleCauseCorrectiveAction

1.Checkandtightenallcouplers.

2.Checkthecouplersandreplaceany

thataredamaged.

3.Findandremovetheobstruction.

5.Repairthevalve.

13

DeclarationofIncorporation

TheT oroCompany,8111LyndaleAvenueSouth,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.

22911404320000andUpVibratoryPlow

SerialNo.

ProductDescriptionInvoiceDescription

VIBRATORYPLOW

ATT ACHMENTCE

GeneralDescription

VibratoryPlow

Directive

2006/42/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedToromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:

JoeHager

Sr.EngineeringManager

811 1LyndaleAve.South

Bloomington,MN55420,USA

February28,2019

AuthorizedRepresentative:

MarcelDutrieux

ManagerEuropeanProductIntegrity

ToroEuropeNV

Nijverheidsstraat5

2260Oevel

Belgium

EuropeanPrivacyNotice

TheInformationToroCollects

ToroWarrantyCompany(T oro)respectsyourprivacy.Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalT orocompanyordealer.

TheT orowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIV ACYNOTICE.

TheWayT oroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.ToromayshareyourinformationwithT oro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany.Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw .

Toro'sCommitmenttoSecurityofYourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailatlegal@toro.com.

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalToroDealer.

374-0282RevC

CaliforniaProposition65WarningInformation

Whatisthiswarning?

Youmayseeaproductforsalethathasawarninglabellikethefollowing:

WARNING:CancerandReproductiveHarm—www.p65Warnings.ca.gov.

WhatisProp65?

Prop65appliestoanycompanyoperatinginCalifornia,sellingproductsinCalifornia,ormanufacturingproductsthatmaybesoldinorbroughtinto

California.ItmandatesthattheGovernorofCaliforniamaintainandpublishalistofchemicalsknowntocausecancer,birthdefects,and/orother

reproductiveharm.Thelist,whichisupdatedannually,includeshundredsofchemicalsfoundinmanyeverydayitems.ThepurposeofProp65isto

informthepublicaboutexposuretothesechemicals.

Prop65doesnotbanthesaleofproductscontainingthesechemicalsbutinsteadrequireswarningsonanyproduct,productpackaging,orliteraturewith

theproduct.Moreover,aProp65warningdoesnotmeanthataproductisinviolationofanyproductsafetystandardsorrequirements.Infact,the

CaliforniagovernmenthasclariedthataProp65warning“isnotthesameasaregulatorydecisionthataproductis‘safe’or‘unsafe.’”Manyofthese

chemicalshavebeenusedineverydayproductsforyearswithoutdocumentedharm.Formoreinformation,gotohttps://oag.ca.gov/prop65/faqs-view-all

AProp65warningmeansthatacompanyhaseither(1)evaluatedtheexposureandhasconcludedthatitexceedsthe“nosignicantrisklevel”;or(2)

haschosentoprovideawarningbasedonitsunderstandingaboutthepresenceofalistedchemicalwithoutattemptingtoevaluatetheexposure.

Doesthislawapplyeverywhere?

Prop65warningsarerequiredunderCalifornialawonly.ThesewarningsareseenthroughoutCaliforniainawiderangeofsettings,includingbutnot

limitedtorestaurants,grocerystores,hotels,schools,andhospitals,andonawidevarietyofproducts.Additionally ,someonlineandmailorder

retailersprovideProp65warningsontheirwebsitesorincatalogs.

.

HowdotheCaliforniawarningscomparetofederallimits?

Prop65standardsareoftenmorestringentthanfederalandinternationalstandards.TherearevarioussubstancesthatrequireaProp65warning

atlevelsthatarefarlowerthanfederalactionlimits.Forexample,theProp65standardforwarningsforleadis0.5μg/day,whichiswellbelow

thefederalandinternationalstandards.

Whydon’tallsimilarproductscarrythewarning?

•ProductssoldinCaliforniarequireProp65labellingwhilesimilarproductssoldelsewheredonot.

•AcompanyinvolvedinaProp65lawsuitreachingasettlementmayberequiredtouseProp65warningsforitsproducts,butothercompanies

makingsimilarproductsmayhavenosuchrequirement.

•TheenforcementofProp65isinconsistent.

•CompaniesmayelectnottoprovidewarningsbecausetheyconcludethattheyarenotrequiredtodosounderProp65;alackofwarningsfora

productdoesnotmeanthattheproductisfreeoflistedchemicalsatsimilarlevels.

WhydoesToroincludethiswarning?

Torohaschosentoprovideconsumerswithasmuchinformationaspossiblesothattheycanmakeinformeddecisionsabouttheproductstheybuyand

use.T oroprovideswarningsincertaincasesbasedonitsknowledgeofthepresenceofoneormorelistedchemicalswithoutevaluatingthelevelof

exposure,asnotallthelistedchemicalsprovideexposurelimitrequirements.WhiletheexposurefromT oroproductsmaybenegligibleorwellwithinthe

“nosignicantrisk”range,outofanabundanceofcaution,T orohaselectedtoprovidetheProp65warnings.Moreover ,ifTorodoesnotprovidethese

warnings,itcouldbesuedbytheStateofCaliforniaorbyprivatepartiesseekingtoenforceProp65andsubjecttosubstantialpenalties.

RevA

Loading...

Loading...