FormNo.3356-322RevB

VibratoryPlow

forCompactUtilityLoaders

ModelNo.22911—SerialNo.270000001andUp

Registeratwww.T oro.com.OriginalInstructions(EN)

Theremaybeburiedpower,gas,and/or

telephonelinesintheworkarea.Shockor

explosionmayoccurifyoudigintothem.

Havethepropertyorworkareamarkedfor

buriedlinesanddonotdiginmarkedareas.

Contactyourlocalmarkingserviceorutility

companytohavethepropertymarked(for

example,intheUnitedStates,call811forthe

nationwidemarkingservice).

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

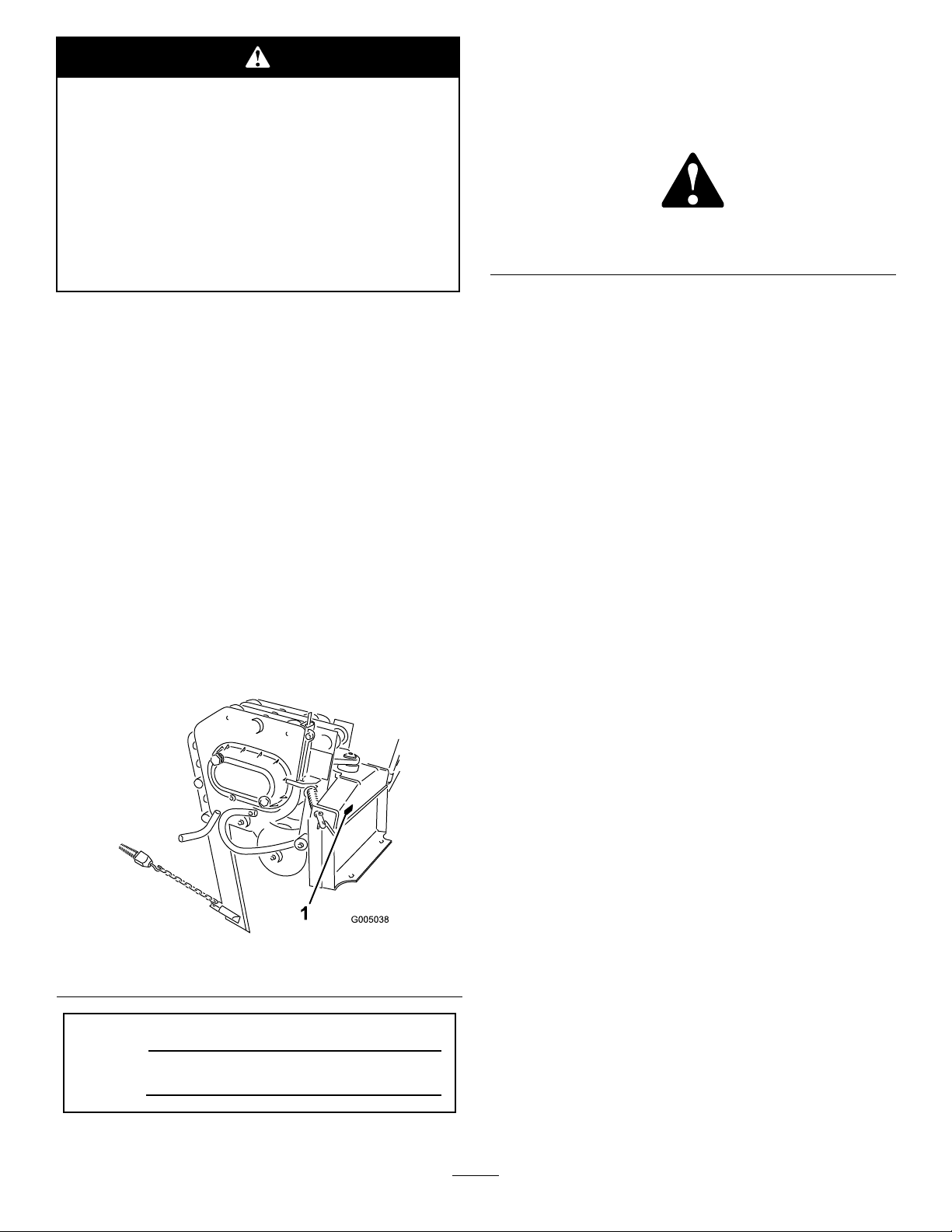

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Figure1

1.Modelandserialnumberlocation

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualalsouses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Introduction.................................................................2

Safety...........................................................................3

StabilityRatings....................................................4

SoundPressureLevel...........................................4

VibrationLevel.....................................................4

SafetyandInstructionalDecals.............................5

ProductOverview........................................................5

Specications.......................................................5

Attachments/Accessories.....................................5

Operation.....................................................................6

InstallingaBlade..................................................6

Plowing................................................................6

GaugingPlowDepth............................................7

TransportingthePlow..........................................8

RemovingthePlowfromtheTraction

Unit..................................................................8

OperatingTips.....................................................8

Maintenance.................................................................9

RecommendedMaintenanceSchedule(s)..................9

GreasingthePlow................................................9

ServicingtheGearLube.....................................10

ReplacingtheCoulter.........................................11

Storage.......................................................................11

Troubleshooting.........................................................12

ModelNo.

SerialNo.

©2007—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.T oreducethepotential

forinjury,complywiththesesafetyinstructionsand

thoseinthetractionunit

payattentiontothesafetyalertsymbol,which

means

safetyinstruction.Failuretocomplywiththe

instructionmayresultinpersonalinjuryordeath.

Caution

Contactwiththemovingplowcancuthands,

feet,orotherbodyparts.

•Keepyourhands,feet,andanyotherpart

ofyourbodyorclothingawayfrommoving

parts.

•Beforeadjusting,cleaning,repairing,and

inspectingtheplow,lowerittotheground,

stoptheengine,removethekey ,andwaitfor

allmovingpartstostop.

,

W ar ning

Operator’ s Man ual

,or

Danger

—personal

.Always

Whengoingupordownhill,themachinecould

overturniftheheavyendistowardthedownhill

side.Someonemaybepinnedorseriously

injuredbythemachineifitoverturns.

Operateupanddownslopeswiththeheavyend

ofthemachineuphill.Anattachedplowwill

makethefrontendheavy.

Ifyoudonotfullyseattheattachmentlocking

pinsintheattachmentmountplateholes,the

attachmentcouldfalloffofthetractionunit

severelyinjuringtheoperatororbystanders.

•Ensurethatyoufullyseattheattachment

lockingpinsthroughtheholesinthe

attachmentmountplatebeforeliftingthe

attachment.

•Ensurethattheattachmentmountplateis

freeofanydirtordebristhatmayhinder

theconnectionofthetractionunittothe

attachment.

Theremaybeburiedpower,gas,and/or

telephonelinesintheworkarea.Shockor

explosionmayoccurifyoudigintothem.

Havethepropertyorworkareamarkedfor

buriedlinesanddonotdiginmarkedareas.

Contactyourlocalmarkingserviceorutility

companytohavethepropertymarked(for

example,intheUnitedStates,call811forthe

nationwidemarkingservice).

Whentheengineisoff,attachmentsinthe

raisedpositioncangraduallylower.Someone

nearbymaybepinnedorinjuredbythe

attachmentasitlowers.

Alwayslowertheattachmentlifteachtimeyou

shutoffthetractionunit.

•Refertoyourtractionunit

Man ual

connectinganattachmenttoyourtraction

unit.

Theplowisveryloudduringoperation;

overtime,yourhearingmaybeimpairedif

unprotected.

Wearhearingprotectionduringoperation.

fordetailedinformationonsafely

Operator’ s

3

Whentheplowisoutoftheground,bystanders

couldbeinjuredbytheswingingplow,and/or

thetractionunitcouldbeoverturnedbythe

inertiaoftheswingingplow,crushingyouor

bystanders.

•Keeptheplowlowatalltimes.

•Usecautionwhenturninganddonotturn

quickly.

•Keepallbystandersatleast6ft.(2meters)

awaywhileoperating.

OrientationStabilityRating

FrontUphill

C

RearUphill

D

SideUphill

C

Hydrauliccouplers,hydrauliclines/valves,and

hydraulicuidmaybehotandcanburnyouif

youtouchthem.

•Weargloveswhenoperatingthehydraulic

couplers.

•Allowthetractionunittocoolbefore

touchinghydrauliccomponents.

•Donottouchhydraulicuidspills.

StabilityRatings

Todeterminethedegreeofslopeyoucantraversewith

theplowinstalledonatractionunit,ndthestability

ratingforthehillpositionyouwanttotravelinthe

appropriatetablebelow ,thenndthedegreeofslope

forthesameratingandhillpositionintheStabilityData

sectionofthetractionunitOperator’sManual.

SoundPressureLevel

Thisunithasamaximumsoundpressureatthe

operator’searof117dB(A),basedonmeasurements

whenoperatedonatractionunitperEN11201.The

soundpressurelevelwillvarydependingonconditions.

VibrationLevel

Thisunithasamaximumhand-armvibrationlevelof7

2

m/s

andwholebodyvibrationlevelof0.2m/s

onmeasurementsofidenticalmachinesperEN1033

andEN1032.

2

based

Exceedingthemaximumrecommendedslope

cancausethetractionunittotip,crushingyou

orbystanders.

Donotdrivethetractionunitonaslopesteeper

thanthemaximumrecommendedslope,as

determinedinthefollowingtablesandthe

tractionunit

Important:Ifyouhaveatractionunitotherthan

aTXcompactutilityloader,usethecounterweight

onthetractionunitwhenusingtheplow .Failureto

usethecounterweightwillcausethetractionunitto

becomeunstable.

Operator’ s Man ual

.

4

SafetyandInstructional

Decals

Safetydecalsandinstructionsareeasily

visibletotheoperatorandarelocated

nearanyareaofpotentialdanger.

Replaceanydecalthatisdamagedor

lost.

100-4649

1.Explosionandelectricshockhazards—donotdiginareas

withburiedgasorelectricallines,keepbystandersasafe

distancefromthemachine.

ProductOverview

1.Vibratoryplowbody

2.Blade(severaloptional

bladestylesareavailable)

3.Puller(severaloptional

pullerstylesareavailable)

Figure3

4.Gaugerodassembly

5.Coulter

6.Mountingplate

100-4650

1.Crushinghazardofhand—keepbystandersasafedistance

fromthemachine.

2.Crushinghazardoffoot—keepbystandersasafedistance

fromthemachine.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Width

Length

Height

Weight

Hydraulicmotordisplacement

Plowcycles2,000VPM

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

29inches(73.6cm)

35inches(89cm)

24inches(60cm)

400lb(181.5Kg)

1.27in3/rev(20.8cc)

5

Operation

RefertoyourtractionunitOperator’sManualformore

informationoninstallingandremovingattachments

onyourtractionunit.

Important:Alwaysusethetractionunittoliftand

movetheattachment.

InstallingaBlade

Torooffersseveraldifferentbladesandpullers.

PurchaseabladeandpullerfromyourTorodealer.

Plowing

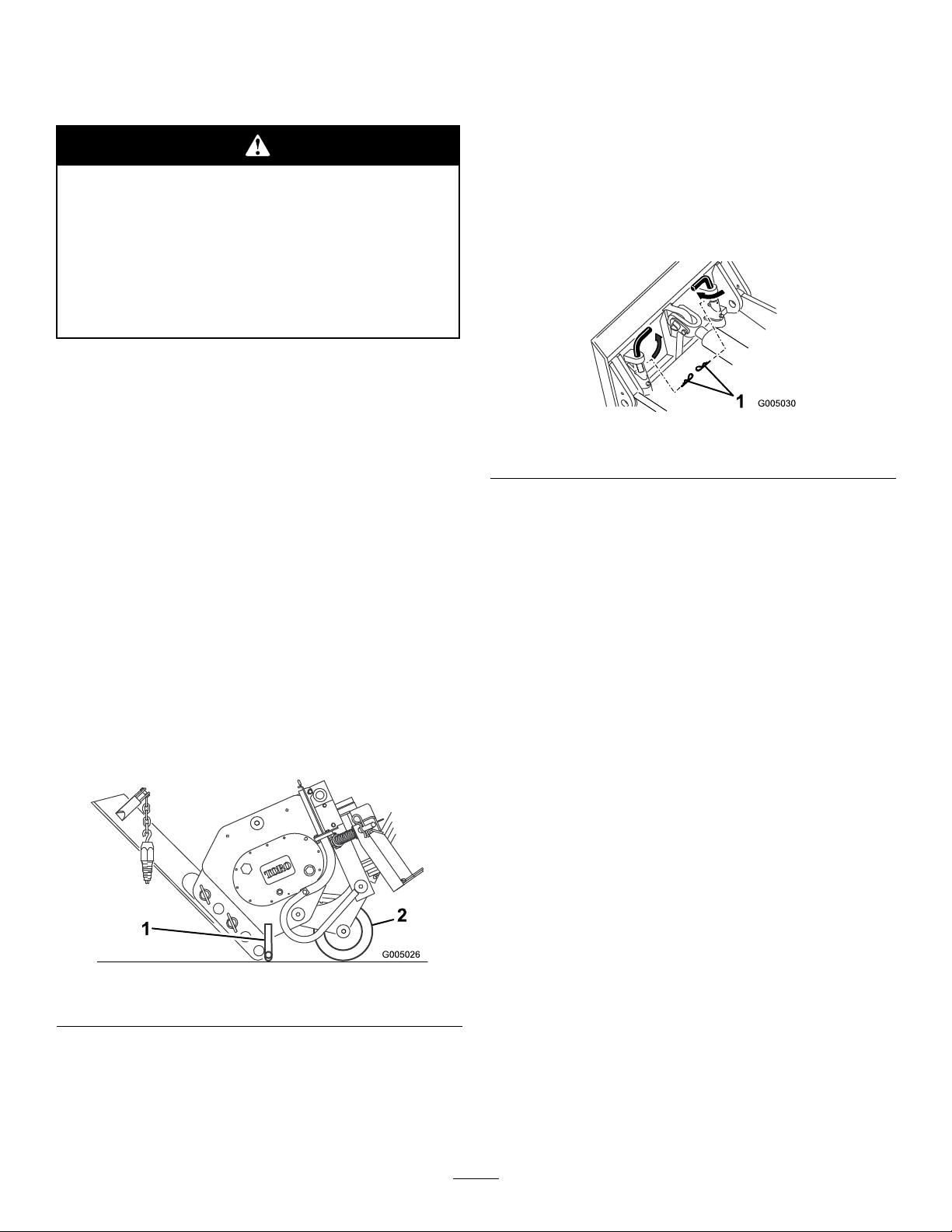

1.Movethelynchpinstotheoutsideholesonthe

springrodstoallowtheplowtomovefromside

toside(Figure5).

Thebladeissharpandcanswingduring

installationandremoval,cutting,pinching,or

crushinghandsorfeet.

Wearglovesandworkbootsandsecurelyhold

theblade.

1.Raisetheplowabout36inches(1m)offofthe

groundandinstallthecylinderlock(s).

2.Stoptheengineandremovethekey.

3.Removethetwoclickpinsfromtheclevispins

inthebladebracket,thenremovetheclevispins

(Figure4)andtheexistingblade(ifinstalled).

Figure5

1.Outerhole3.Springrod

2.Lynchpin(ininnerhole)

Whenyouremovethelynchpin,theplowcould

swingintoyouorabystander,orcausethe

tractionunittobecomeunstable.

Holdtheplowintheneutralpositionwhen

movingthelynchpins.

2.Connectthematerialbeinginstalledtotheplow.

3.Ifyourtractionunithasaspeedselector,moveitto

theslow(turtle)position.

4.Starttheengine.

5.Tilttheattachmentplatecompletelybacksothatthe

topoftheplowisparalleltotheground(Figure7).

6.Lowertheplowsothatitisrestingontheground.

Figure4

1.Clickpin

2.Clevispin

4.Slidethenewbladeintothebladebracketandsecure

itatthedesireddepth(achangeinmountingholes

willchangethedepthby3inches(7.6cm)),using

theclevispinsandclickpinsremovedpreviously

(Figure4).

3.Blade

Important:Alwaysensurethattheplowison

orinthegroundbeforeengagingtheauxiliary

hydraulicslever.Failuretodosowillcause

excessivevibrationofthetractionunit,possibly

resultingindamage.

Note:Ifyoudigaholetolowerthebladeinto

beforestarting,itwillreducetheriskofbending

theblade.

7.Pulltheauxiliaryhydraulicslevertotheoperator

griptoengagetheplow.

8.Slowlylowertheplowintothegroundtothedesired

depth,whilemovingthetractionunitbackward.

9.Whennished,releasetheauxiliaryhydraulicslever

tostoptheplow .

6

Whenplowingonahill,theplowcanswing

downhillwhenraisedoutofthesoil.Duetothe

weightoftheplow,ifitswingstoofast,theforce

couldtipthetractionunitinjuringyouorothers.

Whenplowingonahill,raisetheplowoutof

thegroundslowly,lettingitswingwhilethe

bulletisstillinthesoil.

10.Raisetheplowoutofthegroundfarenoughtopull

thepulleroutofthesoil.

11.Movethetractionunitrearwardtopullouta

workinglengthofmaterial,thenmoveforward

slightlytocreatesomeslackintheline.

12.Stoptheengine.

GaugingPlowDepth

Normally,youwillbeplowingatthemaximumdepth

setbytheblade;however,theplowisalsoequipped

withagaugetoallowyoutolifttheplowanddetermine

howhighabovemaximumdepthyouareplowing.

Thegaugeislocatedontheleftsideoftheplowfacing

thetractionunit.Arodassemblyrunsfromthegauge

totheground.Whentheplowislifted,theindicatoron

thegaugemovesdown.Marksonthegaugeshowthe

numberofincheslowerorhigherthanthemaximum

depththatyouareplowing.Thegaugereadsfrom

+2to-3inches(+5to-7.6cm),withzerobeingthe

maximumdepthonbaregroundand-3being3inches

(7.6cm)abovemaximumdepth.Figure6andFigure7

illustratethegauge.

Figure7

1.Gaugerodassembly

2.Paralleltotheground

Whenplowingbareground,maximumdepthis

indicatedonthegaugeasthezeromark.Youcan

plowdowntothe+1mark,butinthiscaseyouwillbe

contactingthegroundwiththecoulteraxle.Plowing

anylowermaydamagethecoulter.

Whenplowinggrasscoveredground,thegaugewill

readaboutaninchlowerthantheactualdepthbecause

ofthegrass.Inthiscase,lowertheplowtothedesired

coulterdepthandnotethereadingonthegauge.

Ifyouaretransportingtheploworareplowingrough

terrain,youcanlockthegaugeatthe+2position

tokeepitfrombeingdamaged.Tolockthegauge,

manuallyraiseittothe+2positionandmovethe

lockinglevertotheleft.

1.Depthgauge

Figure6

2.Gaugelockinglever

7

TransportingthePlow

1.Movethelynchpinstotheinsideholesonthespring

rodstopreventsidetosidemovement(Figure5).

Failuretosecuretheplowwillallowittoswing

sidetosideandunbalancetheplow.Duetothe

weightoftheplow,ifitswingstoofast,theforce

couldtipthetractionunitinjuringyouorothers.

Alwayssecuretheplowwiththelynchpins

intheinnerholesofthespringrodsbefore

transportingtheplow.

2.Raisetheloaderarmsjustenoughtoensurethatthe

bladeclearstheground.

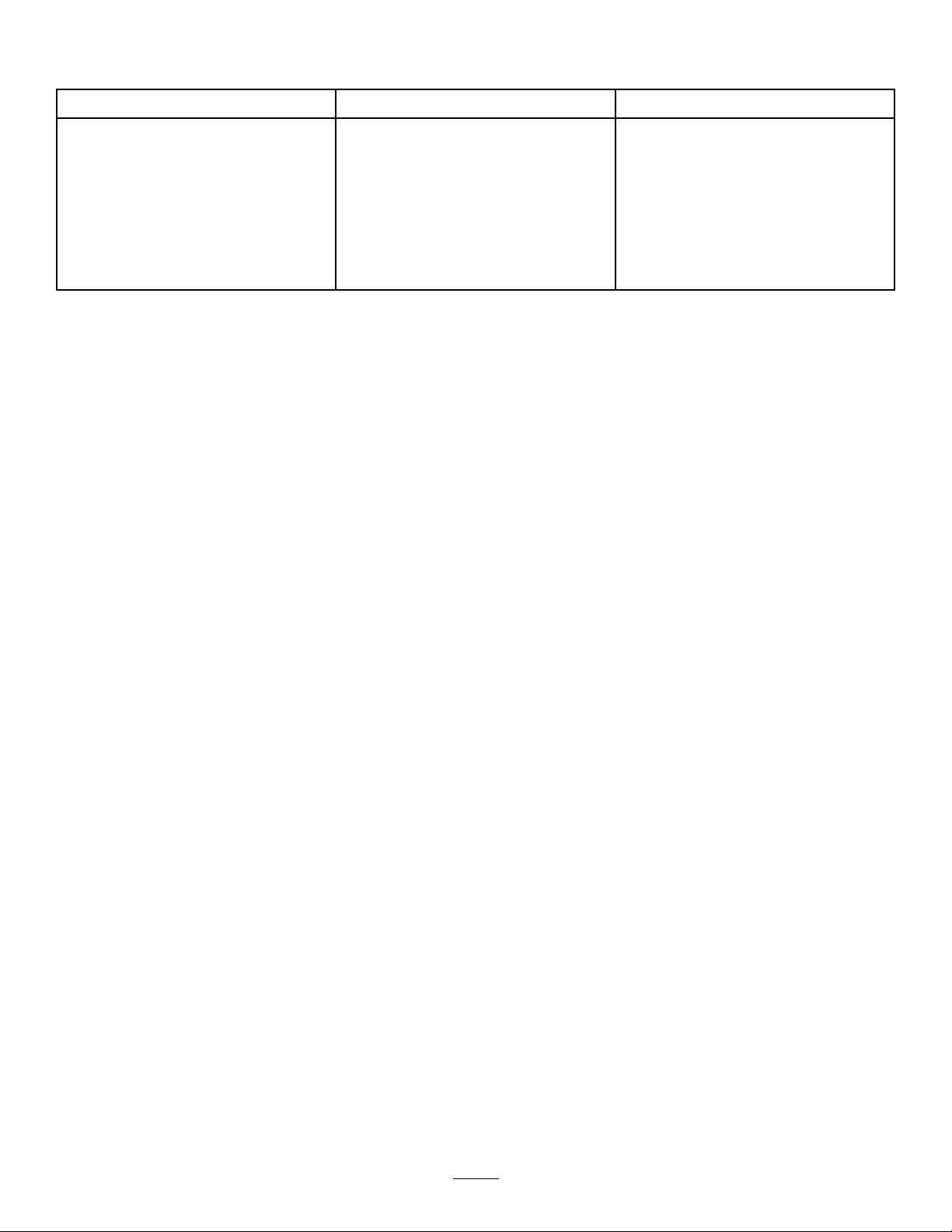

OperatingTips

•Someoldermodeltractionunitshaveholesthrough

thespringandquickattachpinsonthemountplate

(Figure9)toallowyoutoinstalltwohairpincotters

whenplowinglongruns.Thiswillensurethatthe

vibrationoftheplowwillnotcausethepinsto

comeloose.

Note:Thequickattachpinsonnewertraction

unitsnolongerneedthehairpincotters.

Important:Nevertransporttheplowwiththe

armsfullyraised.

RemovingthePlowfromthe

TractionUnit

RefertoyourtractionunitOperator’sManualfor

completeinstructionsonremovingattachmentsfrom

thetractionunitanddisconnectinghydraulichoses.

1.Withtheplowraisedabovetheground,stopthe

engine.

2.Removethelowerclickpinandclevispinsecuring

thebladetotheplow(tocompletelyremovethe

blade,removeboththeupperandlowerclickand

clevispins)(Figure4).

3.Swingthebladeupandsecureitasillustratedin

Figure8.

Figure9

1.Hairpincotters

•Toreducewearonthetractionunitdrivechain(if

yourmodelhasone),tightenthechainsothereis

only2inches(5cm)ofslackontheupperspan

(refertoyourtractionunitOperator’sManualfor

instructions).

•Cleantheareaoftrash,branchesandrocksbefore

plowingtopreventequipmentdamage.

•Alwaysbeginplowingwiththeslowestground

speedpossible.Increasespeedifconditionspermit,

butdonotallowthetiresortrackstospin.Spinning

thetracksortireswillcauseturfdamageandplace

stressonthetractionunit.

•Alwaysusefullthrottle(maximumenginespeed)

whenplowing.

•Alwaysplowbackwards(i.e.,inreverse).

•Ifyourtractionunithasaspeedselectorandaow

divider,movethespeedselectortoslow(turtle)and

theowdividertothe10o’clockposition.

Figure8

1.Stand2.Coulter

4.Tilttheplowforwardandlowerittothegroundor

trailer,withthestandandcoultersupportingthe

weightoftheplow(Figure8).

5.Stoptheengineandremovetheplowasdirectedin

yourtractionunitOperator’ sManual.

•Avoidsharpturnswhenplowingtoincrease

productivityandminimizegrounddisturbance.

•Ifyourtractionunithastiresandyouhavethe

agriculturalorSiteworkSystemstiresinstalledon

thetractionunit,removethetiresandmovethe

rightsidetirestotheleftandtheleftsidetiresto

theright.Thiswillensurethatthetiretreadpoints

tothereartogiveyouthemosttractionwhenusing

thevibratoryplow .

8

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Beforeeachuseordaily

Every25hours

Every200hours

Beforestorage

MaintenanceProcedure

•Greasetheplow .

•Checkthegearlubelevel.

•Changethegearlube.

•Greasetheplow .

•Checkthegearlubelevel.

•Paintchippedsurfaces.

Ifyouleavethekeyintheignitionswitch,someonecouldstarttheengine.Accidentalstartingofthe

enginecouldseriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionswitchbeforeyoudoanymaintenance.

GreasingthePlow

ServiceInterval:Beforeeachuseordaily

Beforestorage

Grease6ttings,asshowninFigure10through

Figure13,every8operatinghours.Greaseallttings

immediatelyaftereverywashing.

GreaseType:General-purposegrease

1.Stoptheengineandremovethekey.

2.Cleanthegreasettingswitharag.

3.Connectagreaseguntoeachtting.

4.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings.

5.Wipeupanyexcessgrease.

Figure11

Figure12

Figure10

9

Figure13

ChangingtheGearLube

ServiceInterval:Every200hours

1.Positionthetractionunitandplowonalevelsurface

andlowertheattachmentliftsothattheplowison

theground.

2.Stoptheengineandremovethekey.

3.Prepareanappropriatecontainertocatchtheused

oilundertheplow .

4.Removethedrainplug(Figure14),allowingtheoil

tospilloutintothecontainer.

ServicingtheGearLube

Checkthegearlubricationoillevelinthegearcaseevery

25operatinghoursandchangeitevery200operating

hoursoronceayear,whicheveroccursrst.

Gearlubetype:SAE90-140APIserviceGL-4orGL-5

Rellcapacity:3pints.

CheckingtheGearLubeLevel

ServiceInterval:Every25hours

Beforestorage

1.Positionthetractionunitandplowonalevelsurface

andlowertheattachmentliftsothattheplowison

theground.

2.Stoptheengineandremovethekey.

3.Checktheclearglassgaugeonthesideofthegear

case(Figure14).Thegearlubeshouldbeatthelevel

ofthereddotinthecenterofthegauge.

4.Ifthegearlubelevelislow,removethellplug

(Figure14)andllthecasewithgearlubeuntilitis

levelwiththereddotinthegauge.

5.Whennished,replacethedrainplug,ensuringthat

itistight.

6.Removethellplug(Figure14)andllthecasewith

gearlubeuntilitislevelwiththereddotinthegauge.

7.Replacethellplug.

1.Glassgauge

2.Drainplug

5.Replacethellplug.

Figure14

3.Fillplug

10

ReplacingtheCoulter

Ifthecoulterbecomesexcessivelywornordamaged,

replaceit.

1.Backoutthecoulterpinscrewabout0.5inch(1.3

cm),thenstrikeitseveraltimeswithahammerto

loosenthepin(Figure15).

Figure15

1.Coulterpin

2.Coulter5.Coulterpinscrew

3.Coulterbracket

4.Washer

Storage

1.Beforelongtermstorage,washtheattachmentwith

milddetergentandwatertoremovedirtandgrime.

2.Greasetheplow.

3.Checkgearcaselubrication.

4.Checkandtightenallbolts,nuts,andscrews.Repair

orreplaceanydamagedorwornpart.

5.Ensurethatallhydrauliccouplersareconnected

togethertopreventcontaminationofthehydraulic

system.

6.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDealer.

7.Storetheattachmentinaclean,drygarageorstorage

area.Coverittoprotectitandkeepitclean.

2.Completelyremovethecoulterpinscrew ,washer,

coulter,andcoulterpin(Figure15).

3.Putthenewcoulterintothecoulterbracket

(Figure15).

4.Slidethecoulterpinthroughthebracketandcoulter

andsecureitwiththecoulterpinscrewandwasher

(Figure15).

5.Torquethescrewto45ft-lb(61N-m).

11

Troubleshooting

Theplowdoesnotoperate.

Problem

1.Thehydrauliccouplerisnotcompletely

connected

2.Ahydrauliccouplerisdamaged.

3.Thereisanobstructioninahydraulic

hose.

4.Ahydraulichoseiskinked.4.Replacethekinkedhose

5.Theauxiliaryvalveonthetractionunit

isnotopening.

PossibleCauseCorrectiveAction

1.Checkandtightenallcouplers.

2.Checkthecouplersandreplaceany

thataredamaged.

3.Findandremovetheobstruction.

5.Repairthevalve.

12

Notes:

13

Notes:

14

Notes:

15

Compact Utility Loader

(CUL) Products

The Toro Compact Utility Loader Warranty

A One-Year Limited Warranty

The Toro® Company and its affi liate, Toro Warranty Company, pursuant

Conditions and Products Covered

to an agreement between them, jointly warrant your Toro Compact Utility

Loader (CUL) (“Product”) to be free from defects in materials or workmanship. The following time periods apply from the date the Product is delivered to the original retail purchaser:

The following time periods apply from the date of purchase:

Products Warranty Period

All CUL units and 1 year or 1000 operational

attachments hours, whichever occurs first

Kohler Engines 3 years

All other Engines 2 years

Where a warrantable condition exists, we will repair the Product at no cost

to you including diagnosis, labor, and parts.

Instructions for Obtaining Warranty Service

If you think that your Toro Product contains a defect in materials or workmanship, follow this procedure:

1. Contact any Authorized Toro CUL Service Dealer to arrange service

at their dealership. To locate a dealer convenient to you, access our

website at www.Toro.com. You may also call our Toro Customer Care

Department toll free at 888-577-7466 (U.S. customers) or 877-484-9255

(Canadian customers).

2. Bring the product and your proof of purchase (sales receipt) to the

Service Dealer.

If for any reason you are dissatisfi ed with the Service Dealer’s analysis or

with the assistance provided, contact us at:

LCB Customer Service Department

Toro Warranty Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Toll Free: 888-577-7466 (U.S. customers)

Toll Free: 877-484-9255 (Canada customers)

Owner Responsibilities

You must maintain your Toro Product by following the maintenance procedures described in the Operator’s Manual. Such routine maintenance,

whether performed by a dealer or by you, is at your expense. Parts scheduled for replacement as required maintenance (“Maintenance Parts”), are

warranted for the period of time up to the scheduled replacement time for

that part. Failure to perform required maintenance and adjustments can be

grounds for disallowing a warranty claim.

Not all product failures or malfunctions that occur during the warranty period are defects in materials or workmanship. This express warranty does

not cover the following:

Product failures which result from the use of non-Toro replacement

•

parts, or from installation and use of add-on, modified, or unapproved

accessories

Product failures which result from failure to perform required mainte-

•

nance and/or adjustments

Product failures which result from operating the Product in an abusive,

•

negligent or reckless manner

Parts subject to consumption through use unless found to be defec-

•

tive. Examples of parts which are consumed, or used up, during normal

Product operation include, but are not limited to, digging teeth, tines,

spark plugs, tires, tracks, filters, chains, etc.

Failures caused by outside influence. Items considered to be outside

•

influence include, but are not limited to, weather, storage practices,

contamination, use of unapproved coolants, lubricants, additives, or

chemicals, etc.

Normal “wear and tear” items. Normal “wear and tear” includes, but is

•

not limited to, worn painted surfaces, scratched decals or windows, etc

Any component covered by a separate manufacturer’s warranty

•

Pickup and delivery charges

•

Repair by an Authorized Toro CUL Service Dealer is your sole remedy

under this warranty. Neither The Toro® Company nor Toro Warranty

Company is liable for indirect, incidental or consequential damages

in connection with the use of the Toro Products covered by this warranty, including any cost or expense of providing substitute equipment or service during reasonable periods of malfunction or non-use

pending completion of repairs under this warranty. All implied warranties of merchantability and fitness for use are limited to the duration

of this express warranty. Some states do not allow exclusions of

incidental or consequential damages, or limitations on how long an

implied warranty lasts, so the above exclusions and limitations may

not apply to you. This warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

Except for the engine warranty coverage and the Emissions warranty refer-

enced below, if applicable, there is no other express warranty.

The Emissions Control System on your Product may be covered by a separate warranty meeting requirements established by the U.S. Environmental

Protection Agency (EPA) or the California Air Resources Board (CARB).

The hour limitations set forth above do not apply to the Emissions Control

System Warranty. Refer to the California Emission Control Warranty Statement printed in you operator’s manual or contained in the engine manufacturer’s documentation for details.

Items and Conditions Not Covered

General Conditions

Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer) to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfied with your Distributor’s service or have difficulty obtaining guarantee

information, contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty Company.

Countries Other than the United States or Canada

Part Number 374-0181 Rev. A

Loading...

Loading...