Page 1

FormNo.3421-305RevA

LogSplitter

ModelNo.22618—SerialNo.402000000andUp

ModelNo.22618HD—SerialNo.402000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3421-305*A

Page 2

WARNING

registeryourproduct.

accessoryinformation,helpndingadealer,orto

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

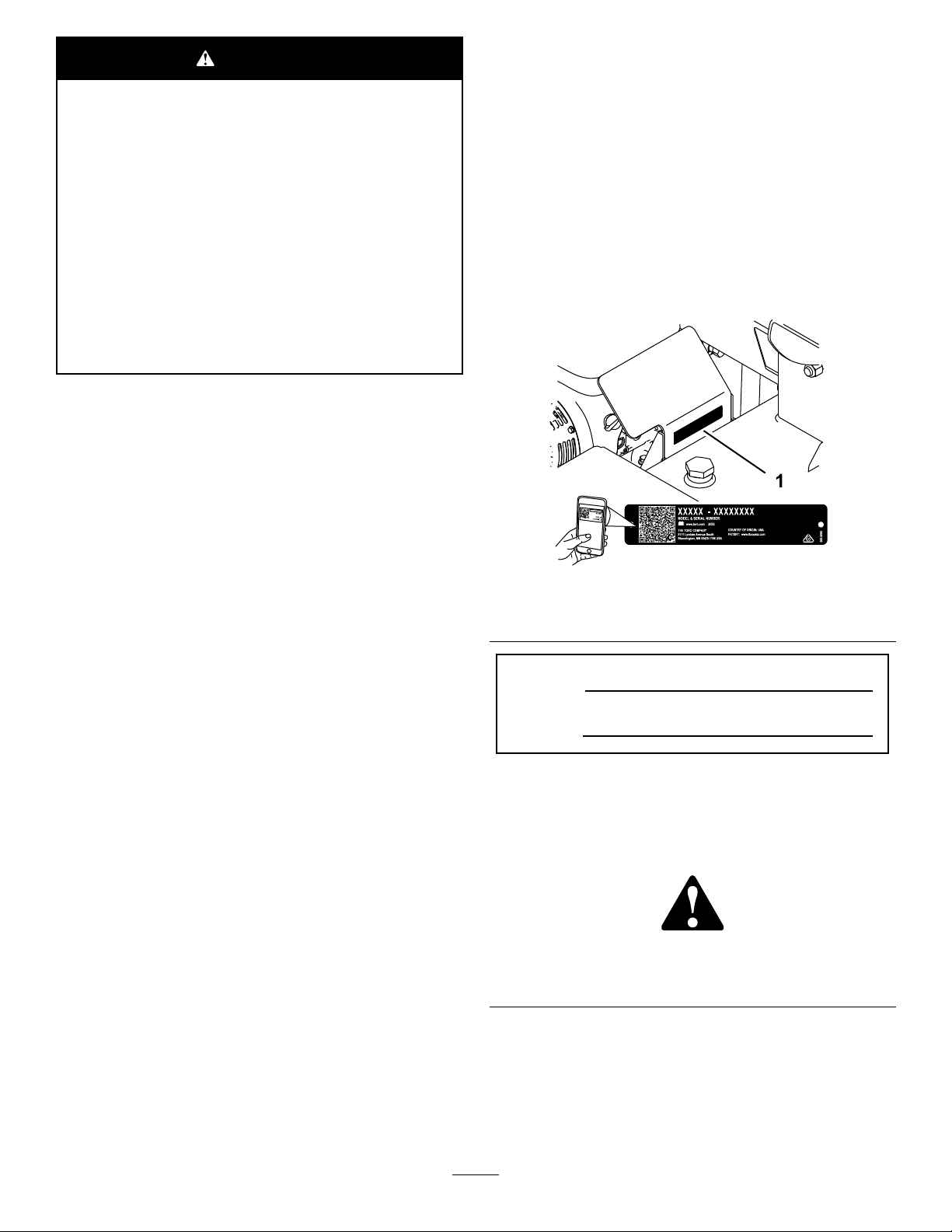

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

TheDOTtireinformationislocatedonthesideof

eachtire.Thisinformationgivesloadandspeed

ratings.Replacementtiresshouldhavethesame

orbetterratings;refertoSpecications(page7)to

ensurethatthetiresonyourmachinemeetorexceed

theweightrequirementsofyourmachine.

Introduction

Thismachineisdesignedtosplitwoodlogscuttoa

sizetotwithinthemachinesplittingwedgeopening.

Itcanoperateinthehorizontalorverticalposition.It

isnotintendedtosplitrock,metal,oranymaterials

otherthanwood.Thelogsplittercanbetowedbehind

avehicleequippedwithanappropriateballhitch.

g243187

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactTorodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

2

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety

Safety.......................................................................3

GeneralSafety...................................................3

SafetyandInstructionalDecals..........................4

ProductOverview.....................................................6

Controls.............................................................6

EngineControls..............................................6

Specications....................................................7

BeforeOperation...................................................8

BeforeOperationSafety.....................................8

AddingFuel........................................................8

PreparingtoUsetheMachine.............................9

DuringOperation.................................................10

DuringOperationSafety...................................10

StartingtheEngine............................................11

ShuttingofftheEngine.......................................11

ChangingtheRailPosition.................................11

SplittingaLog...................................................12

AfterOperation....................................................13

AfterOperationSafety......................................13

TowingSafety...................................................13

TowingtheMachine..........................................14

Maintenance...........................................................17

RecommendedMaintenanceSchedule(s)...........17

Pre-MaintenanceProcedures..............................18

MaintenanceSafety..........................................18

DisconnectingtheSpark-plugWire...................18

Lubrication..........................................................19

GreasingtheRail..............................................19

GreasingtheWheelBearings...........................19

EngineMaintenance...........................................20

EngineSafety...................................................20

ServicingtheAirCleaner..................................20

ServicingtheEngineOil....................................21

ServicingtheSparkPlug...................................23

FuelSystemMaintenance...................................24

CleaningtheFuel-SedimentCup......................24

DriveSystemMaintenance..................................25

CheckingtheTirePressure...............................25

CheckingtheWheelLugNuts...........................25

HydraulicSystemMaintenance...........................26

HydraulicSystemSafety...................................26

HydraulicFluidSpecications...........................26

CheckingtheHydraulic-FluidLevel...................26

ReplacingtheHydraulicFilter...........................27

ReplacingtheHydraulicFluid...........................27

Storage...................................................................28

StorageSafety..................................................28

Storage.............................................................28

Troubleshooting......................................................29

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.T oreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafety-alert

symbol

Danger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

,whichmeans:Caution,Warning,or

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepclearofanydischargeopening.Keep

bystandersandpetsasafedistanceawayfrom

themachine.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Stopthemachineandshutofftheenginebefore

servicing,fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthisOperator’sManual.

3

Page 4

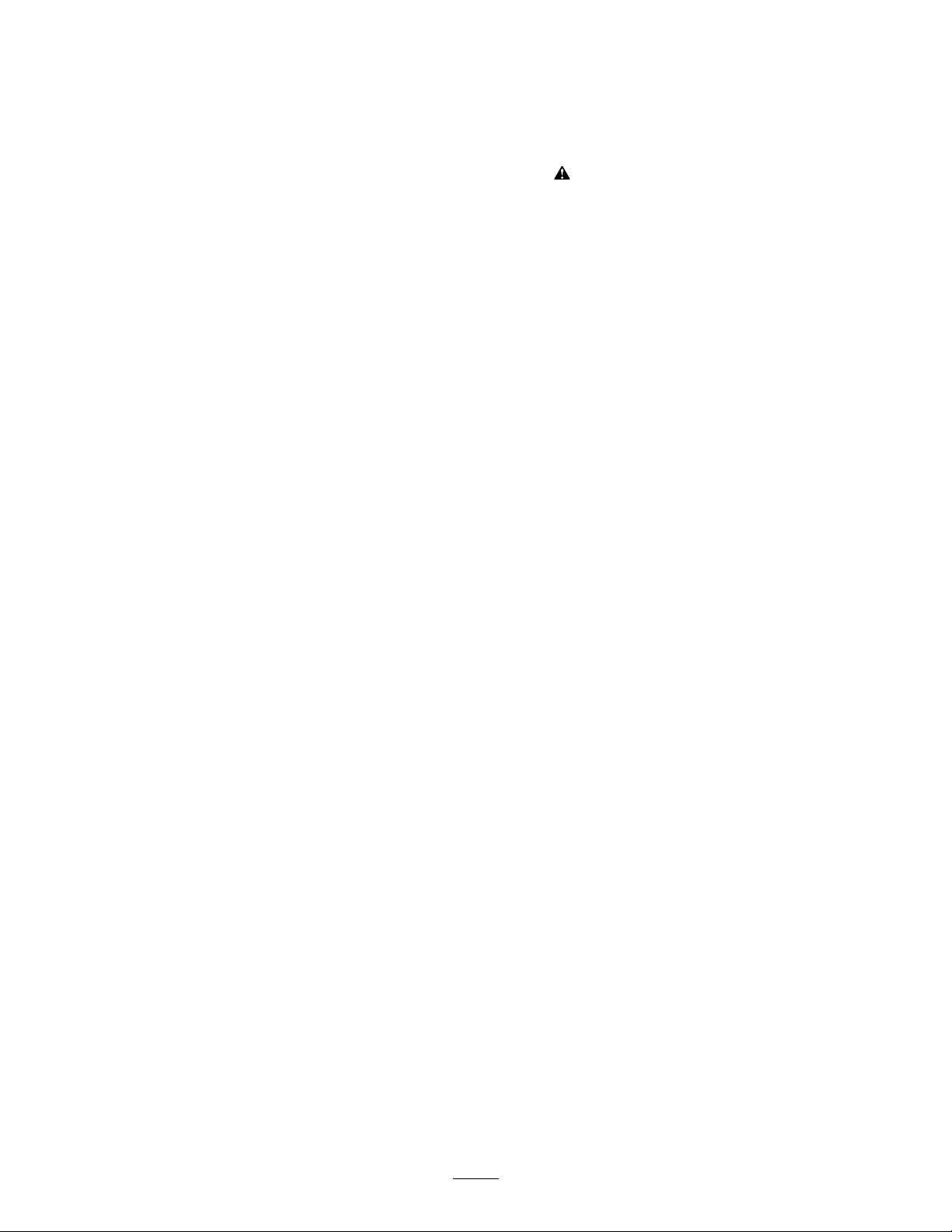

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

120-0625

1.Pinchpoint,hand—keephandsaway.

130-8322

decal120-0625

decal137-0555

137-0555

1.Cuttinghazard—keepawayfrommovingparts.

decal130-8322

1.Useonlyfuelwithan

alcoholcontentbyvolume

under10%.

3.Donotusefuelwithan

alcoholcontentbyvolume

greaterthan10%.

2.ReadtheOperator's

Manualformore

informationonfuel.

133-8056

137-0554

1.Warning—donotexceed88km/h(55mph)when

transportingthemachine.

decal137-0564

137-0564

1.Warning—readtheOperator’sManual;keepawayfromthe

machinewhileinoperation.

decal133-8056

decal137-0587

137-0587

decal137-0554

1.1)Starttheengine;2)

Movetheleverforwardto

splitthelog;3)Movethe

leverbackwardtoreturn

thesplittingwedge.

2.Cuttinghazard—keep

handsoffofthelog.

4

Page 5

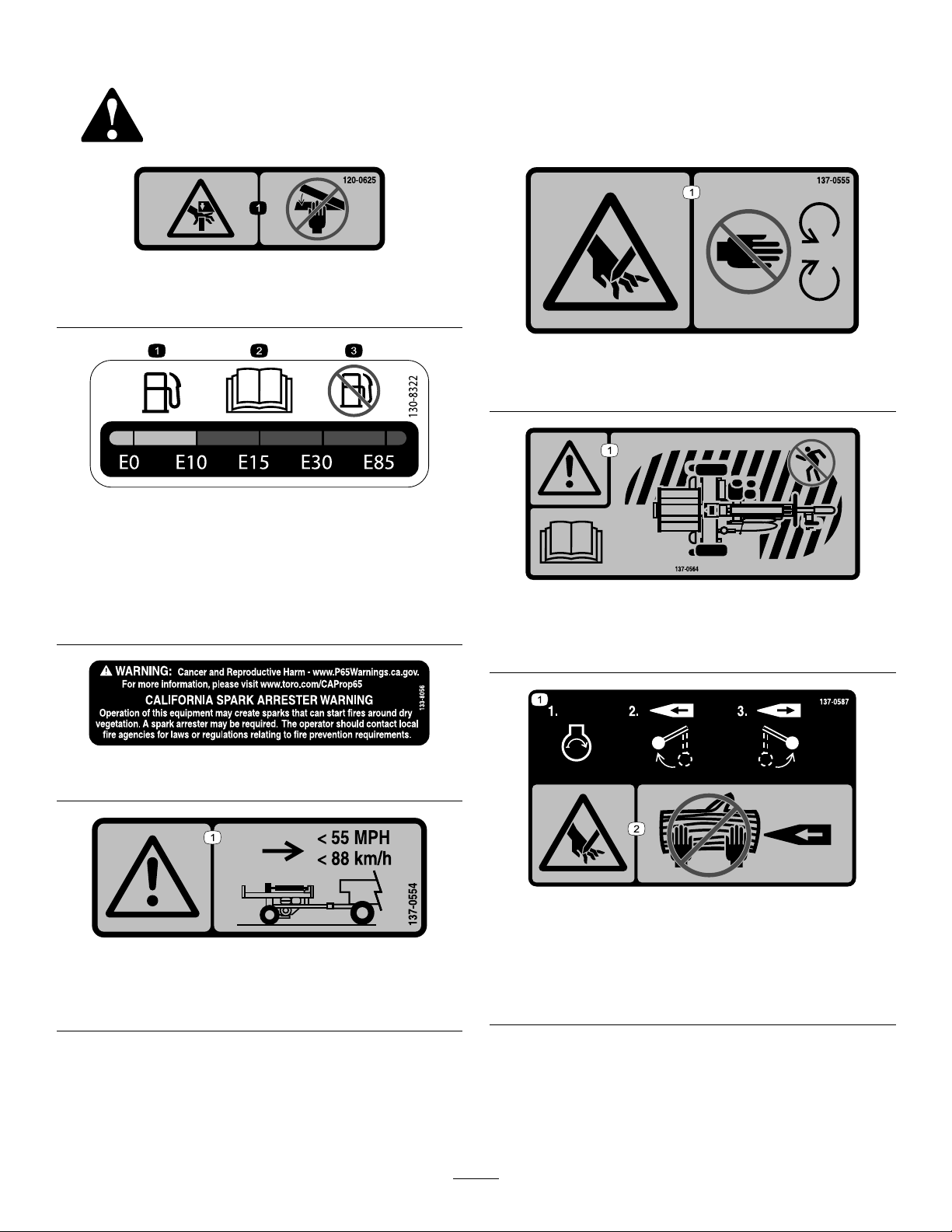

decal137-0588

137-0588

1.Warning—readthe

Operator’sManual.

2.Toraisetherail,1)

Removethelockpin;2)

Raisetherail;3)Turnthe

locklever.

3.Tolowertherail,1)Turn

thelocklever;2)Lower

therail;3)Insertthelock

pin.

decal137-0551

137-0551

1.Warning—readtheOperator’sManual.4.Cuttinghazard—keepawayfrommovingparts.

2.Thrownoryingobjectshazard—weareyeprotection.5.Thrownobjecthazard—keepbystandersawayfromthe

machine.

3.Warning—wearprotectivegloves.

5

Page 6

ProductOverview

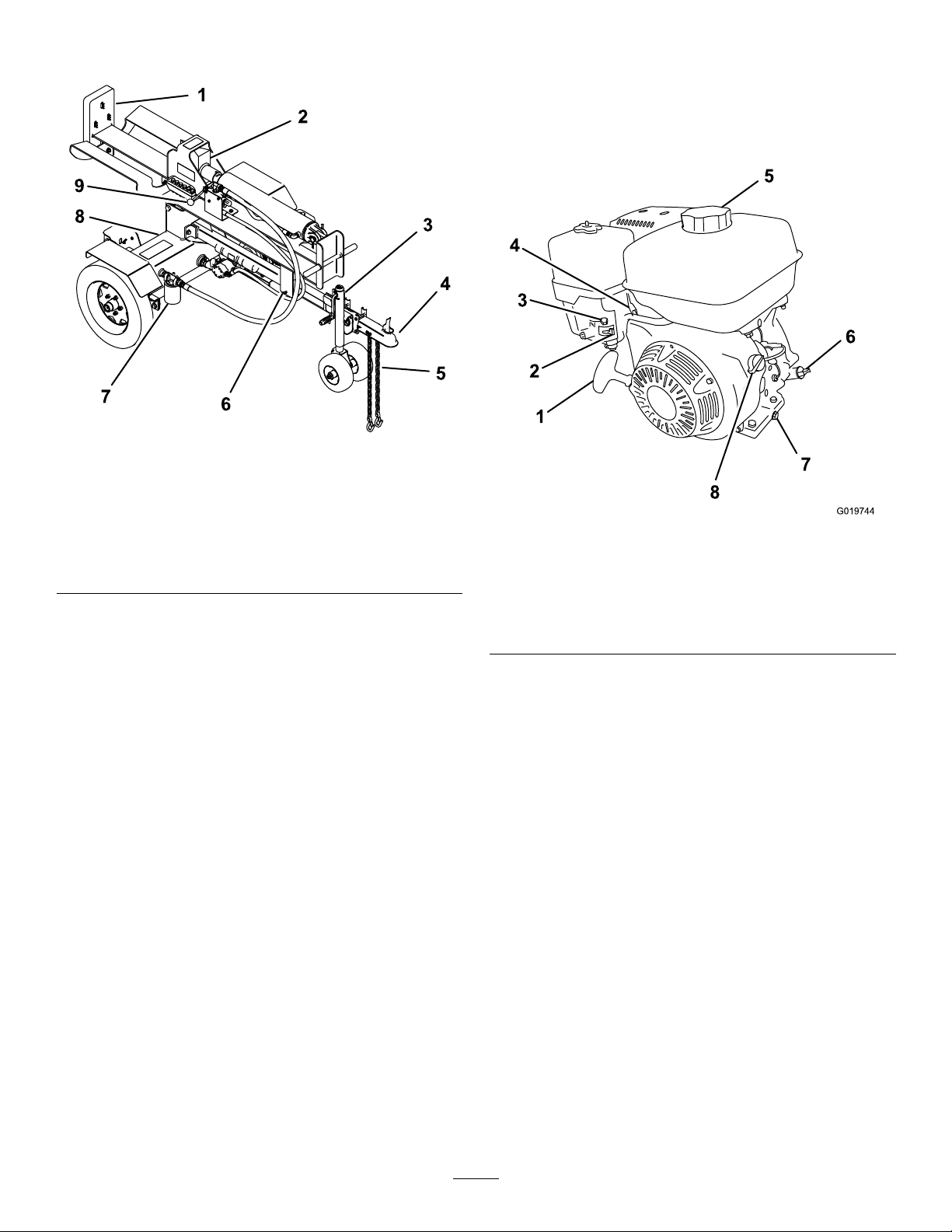

Figure3

1.Endplate6.Raillockingpin

2.Spittingwedge7.Hydrauliclter

3.Jacklift

4.Hitchreceiver

5.Safetychains

8.Hydraulicreservoir

9.Controllever

Controls

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine.

EngineControls

g205930

g019744

Figure4

1.Recoil-starthandle5.Fuelcap

2.Fuelvalve

3.Chokelever7.Oil-drainplug

4.Throttlelever

6.Oildipstick

8.ON/OFFswitch

FuelValve

Thefuelvalve(Figure4)islocatedunderneaththe

chokelever.Movetheleverforthefuelvalvetothe

ONpositionbeforeattemptingtostarttheengine.

Whenyouhavenishedusingthemachine,shutoff

theengineandmovethefuel-valvelevertotheOFF

position.

ChokeLever

Usethechokelever(Figure4)tostartacoldengine.

Beforepullingtherecoil-starthandle,movethechoke

levertotheCLOSEDposition.Oncetheengineis

running,movethechokelevertotheOPENposition.

Donotusethechokeiftheengineisalreadywarmed

uporiftheairtemperatureishigh.

ThrottleLever

Thethrottlelever(Figure4)controlsthespeed(rpm)

oftheengine.Itislocatednexttothechokelever.

EngineON/OFFSwitch

TheON/OFFswitchislocatedonthefrontofthe

engine.

6

Page 7

•RotateittotheONpositiontostartandrunthe

engine.

•RotateittotheOFFpositiontoshutofftheengine.

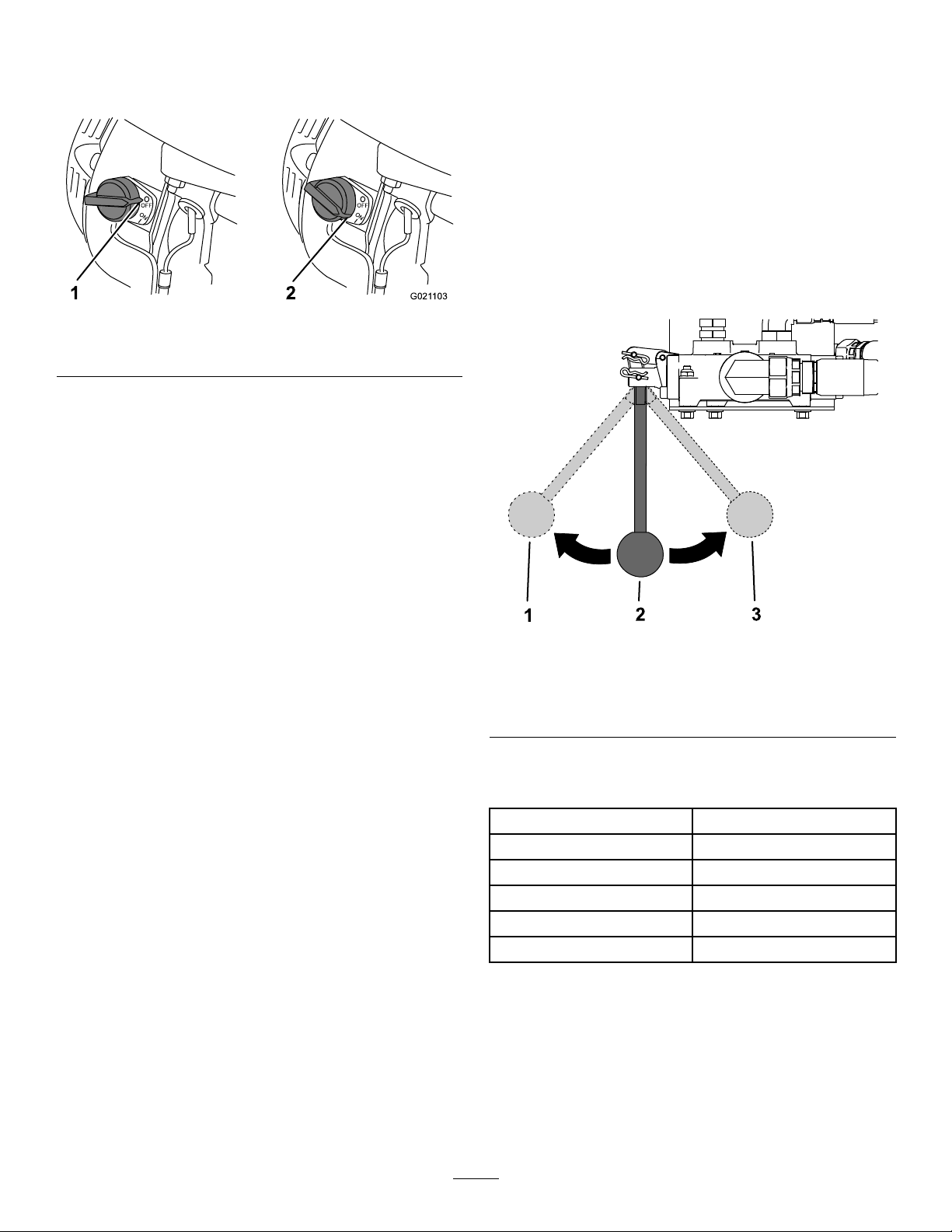

Figure5

1.Offposition2.Onposition

Recoil-StartHandle

Tostarttheengine,pulltherecoil-starthandle(Figure

4)quicklytoturntheengineover.Theenginecontrols

describedabovemustallbesetcorrectlyforthe

enginetostart.

WedgeControlLever

Thewedgecontrolleveractuatesthehydraulicvalve

thatmovesthesplittingwedgeforwardandreverse

duringthelogsplittingprocess.

•Holdthecontrollevertowardtheendplateto

movethesplittingwedgeforward.

•Releasethecontrollevertostopthesplitting

wedgemovement.

•Movethecontrollevertothereversepositionto

retractthesplittingwedge.Movingtheleverto

thefullreversepositionautomaticallyretractsthe

g021103

splittingwedgealltheway.

1.Movethewedgeforward.

2.Controllever(neutral

position)

Specications

Length

Width

Height

Weight

Maximumlogopening

Hitchreceiver

g206049

Figure6

3.Movethewedgerearward.

246cm(97inches)

130cm(51inches)

115cm(46inches)

412kg(909lb)

63cm(25inches)

5cm(2inches)

7

Page 8

Operation

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Knowhowtostopthemachineandenginequickly.

•Checkthatoperator-presencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

FuelSafety

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlingfuel.Fuelvaporsare

ammableandexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfueltothefuel

tankwhiletheengineisrunningorwhilehot.

•Donotrefuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

•Donotllcontainersinsideavehicleoronatruck

ortrailerbedwithaplasticliner.Alwaysplace

containersontheground,awayfromyourvehicle

beforelling.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately.Wipeupanyspilledfuel.

•Neveroverllthefueltank.Replacethefuelcap

andtightenitsecurely.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymorethan

a30-daysupplyoffuel.

•Donotllthefueltankcompletelyfull.Addfuelto

thefueltankuntilthelevelisatthebottomofthe

llernecktube..

–Avoidprolongedbreathingofvapors.

–Keepyourfaceawayfromthenozzleandfuel

tankopening.

–Avoidcontactwithskin;washoffspillswith

soapandwater.

AddingFuel

FuelRecommendations

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorinfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

•Removetheequipmentfromthetruckortrailer

andrefuelitwhileitisontheground.Ifthisisnot

possible,thenrefuelfromaportablecontainer

ratherthanafuel-dispensernozzle.

•Donotoperatethemachinewithouttheentire

exhaustsysteminplaceandinproperworking

condition.

•Keepthefuel-dispensernozzleincontactwith

therimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.Donotusea

nozzlelock-opendevice.

Important:T oreducestartingproblems,addfuel

stabilizertothefuelallseason,mixingitwithfuel

lessthan30daysold;runthemachinedrybefore

storingitformorethan30days.

Donotusefueladditivesotherthanafuel

stabilizer/conditioner.Donotusefuelstabilizers

withanalcoholbasesuchasethanol,methanol,

orisopropanol.

8

Page 9

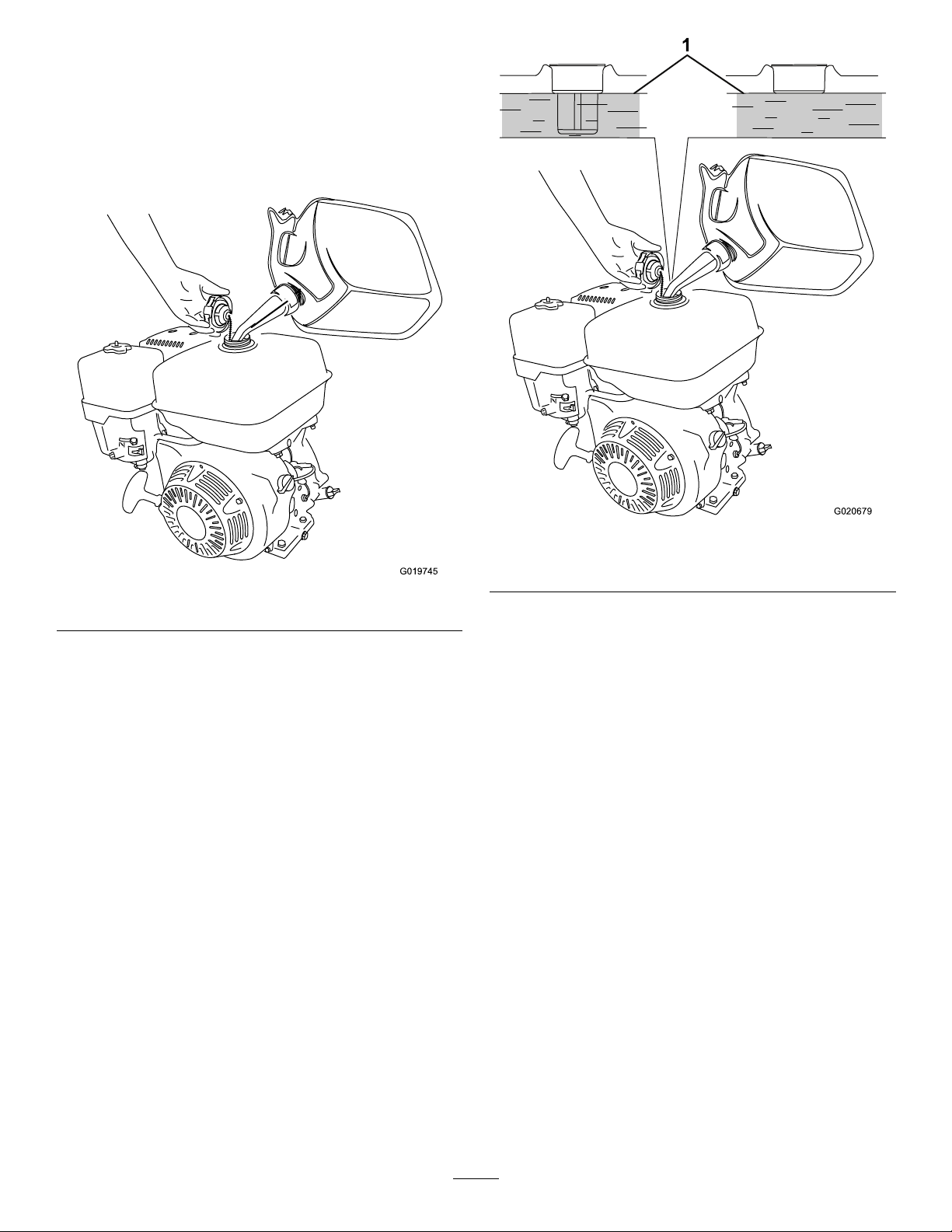

FillingtheFuelTank

FuelTankCapacity:1.1L(1.2USqt)

1.Parkthemachineonalevelsurface,shutoffthe

engine,andallowtheenginetocool.

2.Cleanaroundthefuelcapandremoveit(Figure

7).

Figure7

3.Addfueltothefueltankuntilthelevelisatthe

maximumfuellevel(Figure8).

Important:Thisspaceinthetankallows

fueltoexpand.Donotllthefueltank

completelyfull.

g020679

Figure8

g019745

1.Maximumfuellevel

4.Installthefuelcapsecurely(Figure7).

5.Wipeupanyspilledfuel.

PreparingtoUsethe Machine

1.Parkthemachineonalevelsurfaceand

disconnectthemachinefromthetowvehicle.

2.Chockthefrontandbackofthetirestoprevent

themachinefrommoving.

3.Ensurethatallguardsareinplaceandingood

condition.

4.Ensurethattheworkareaisfreeofwoodand

debris.

5.Performalldailymaintenanceprocedures

describedinMaintenance(page17).

9

Page 10

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;handprotection;longpants;

slip-resistant,substantialfootwear;andhearing

protection.Tiebacklonghairanddonotwear

looseclothingorloosejewelry.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Nevercarrypassengersonthemachineandkeep

bystandersandpetsawayfromthemachine

duringoperation.

•Beforeyoustarttheengine,ensurethatthe

machineissecurefrommovement,therailis

lockedinthehorizontalorverticalposition,and

youareintheoperatingposition.

•Alwaysoperatethemachinefromtheoperator

zonespeciedinSplittingaLog(page12).Keep

theoperator’sareaandadjacentareasclearfor

safe,securefooting.

SplittingSafety

•Placeyourhandsonthesidesofthelog,notonthe

ends.Neverplaceyourhandsoranypartofyour

bodybetweenalogandanypartofthemachine.

•Donotstraddleorreachacrossthelog-splitting

areawhenoperatingthemachine.

•Useyouronlyhandtopushthecontrollever

forward(towardthelog).Ifthelogmovesbefore

thesplittingwedgecontactsit,donottouchthe

splittingwedgewhileinmotion.Releasethe

controllever,thenpositionthelog.

•Operatethemachineonlyfromtheoperating

positionbythecontrollever.

•Only1adultshouldstabilizethelogandoperate

thecontrolhandletoensurefullcontroloverthe

logandsplittingwedge.

•Neverattempttosplitmorethan1logatatime.

•Keeptheworkareaclean;removesplitlogsfrom

aroundthemachinesothatyoudonotslipon

them.

•Logsshouldbecutwithendsassquareas

possiblepriortosplitting.Forlogsthatarenotcut

square,theleast-squareendandlongestportion

ofthelogshouldbeplacedtowardthesplitting

wedgeandthesquareendplacedtowardtheend

plate.

•Keepyourhandsandfeetawayfrommovingparts.

Keepclearofthesplittingwedgeatalltimes.

•Ifahelperisassistinginloadinglogs,never

activatethecontrolsuntilthehelperisatleast3m

(10ft)awayfromthemachine.

•Stopthemachine,shutofftheengine,waitfor

allmovingpartstostop,andinspectthesplitting

wedgeafterstrikinganobjectorifthereisan

abnormalvibrationinthemachine.Makeall

necessaryrepairsbeforeresumingoperation.

•Neverrunanengineinanareawhereexhaust

gassesareenclosed.

•Neverleavearunningmachineunattended.

•Beforeleavingtheoperatingposition,dothe

following:

–Fullyretractthesplittingwedge.

–Shutofftheengine.

–Waitforallmovingpartstostop.

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Useaccessories,attachments,andreplacement

partsapprovedbyTheT oro®Companyonly.

10

Page 11

StartingtheEngine

1.TurntheengineOn/OffswitchtotheONposition

(Figure5).

2.MovethefuelvalvetotheOPENposition(Figure

7).

ChangingtheRailPosition

WARNING

Therailisheavyandcansuddenlyfallonto

themachineframeifyoureleasethehandle

whenraisingorloweringtherail.

Controltherailbythehandle,andkeepyour

handsawayfromthemachineframeand

pinchpointswhenraisingorloweringtherail.

RaisingtheRailtotheVertical Position

Youcanrotatetherailanduseitinthehorizontalor

verticalposition.

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

2.Chockthefrontandbackofthetirestoprevent

themachinefrommoving.

3.Removethelockpin(Figure10).

Figure9

1.Chokelever

2.Fuelvalve4.Recoil-starthandle

3.MovethechokelevertotheCLOSEDposition

(Figure7).

3.Throttlelever

Note:Awarmorhotenginemaynotrequire

choking.

4.MovethethrottlelevertotheFASTposition

(Figure7).

5.Pullthestarterhandlelightlyuntilyoufeel

resistance,thenpullthehandlebriskly(Figure

7).Returnthestarterhandlegently .

6.Aftertheenginestarts,graduallymovethe

chokeleverbacktotheOFFposition.Ifthe

enginestallsorhesitates,movethechokeback

totheONpositionagainuntiltheenginewarms

up.ThenmoveittotheOFFposition.

4.Rotatetherailsothatitisvertical,againstthe

baseofthemachine(Figure10).

g205921

5.Rotatetheverticallocklevertotheclosed

positiontosecurethelowerrailinplace(Figure

10).

ShuttingofftheEngine

1.MovethethrottlelevertoSLOWposition.

2.TurntheengineOn/OffswitchtotheOFF

position.

3.MovethefuelvalvetotheCLOSEDposition.

g206125

Figure10

11

Page 12

LoweringtheRailtotheHorizontal Position

SplittingaLog

1.Rotatetheverticallocklevertotheopenposition

(Figure11).

2.Carefullyrotatetherailintothehorizontal

position(Figure11).

3.Installthelockpintosecuretherail(Figure11).

WARNING

Thismachineiscapableofamputatinghands

andfeet.

Alwaysstandintheoperatingareashownin

Figure12.

g206500

Figure12

1.Operatingarea

Figure11

g206124

1.Parkthemachineonalevelsurface.

2.Chockthefrontandbackofthetirestoprevent

themachinefrommoving.

3.Changetherailposition,ifdesired,andlockit

intoposition;refertoChangingtheRailPosition

(page11).

4.Starttheengine.

5.Ensurethatthelogsyouaresplittingareless

than60cm(24inches)longandthatbothends

arecutasataspossible.

Note:Thispreventsthelogfromslidingoutof

positionwhileunderpressure.

6.Placethelogagainsttheendplatesothatthe

directionofthegrainmatchesthedirectionof

movementforthesplittingwedge.

12

Page 13

Figure13

1.Log3.Endplate—Railvertical

position

2.Endplate—Railhorizontal

position

AfterOperation

AfterOperationSafety

•Cleandebrisfromthemuferandenginetohelp

preventres.Cleanupoilorfuelspills.

•Allowtheenginetocoolbeforestoringthemachine

inanyenclosure.

•Shutoffthefuelbeforestoringortransportingthe

machine.

•Neverstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

g206746

asonawaterheateroronotherappliances.

•Keepallpartsofthemachineingoodworking

conditionandallhardwaretightened.

•Replaceallwornordamageddecals.

TowingSafety

Important:Neverattempttosplitlogs

acrossthegrain.

Figure14

7.MovethecontrollevertotheFORWARDposition

tosplitthelog.

8.MovethecontrollevertotheREVERSEposition

toreturnthesplittingwedge.

9.Shutofftheenginewhenyouarenished

splittinglogs.

Checkwithyourlocalcountyorstatetowingsafety

regulationsbeforetowingthemachine.

•Inordertoreducethepossibilityofanaccident

whiletransportingthemachineonpublicroads,

ensurethatthetowingvehicleismechanically

soundandingoodoperatingcondition.

•Shutofftheenginebeforetransportingthe

machine.

•Ensurethattheballhitchyouareusingisthe

propersizeforthehitchreceiveronthemachine.

•Inspectthehitchandcouplingforwear.Nevertow

themachinewithdamagedordefectivehitches,

couplings,chains,orothercomponents.

•Checkthetireairpressureonthetowingvehicle

g206160

andthemachine.

•Checkthetiretreadandsidewallfordamageand

wear.

•Properlyattachthesafetychainstothetowing

vehicle.

•Ensurethatthedirectionalandbrakelightsare

workingproperly.

•Ensurethatthedirectional,backup,andbrake

lightsofthetowvehicleareworkingproperly(if

equipped).

•Beforetowing,ensurethatyourmachineis

correctlyandsecurelyattachedtothetowing

vehicle.

•Ensurethatthesafetychainsareproperlysecured

tothevehicle,andleaveenoughslackforturning.

•Donotcarryanymaterialinthemachinewhen

towing.

•Avoidsuddenstopsandstarts.Thiscancause

skidding,orjackkning.Smooth,gradualstarts

andstopswillimprovetowing.

13

Page 14

•Avoidsharpturnstopreventrolling.T owonlywith

avehiclethathasahitchdesignedfortowing.Do

notattachtowedequipmentexceptatthehitch

point.

•Donottowthemachinefasterthan88km/h(55

mph).

•Usecautionwhenbackingup;useaspotter

outsidethevehicletoguideyou.

•Donotallowanyonetositorrideonthemachine.

•Disconnectthemachinefromthetowvehicle

beforeusingit.

•Securethemachinefrommovementbeforeyou

towit.

TowingtheMachine

Beforetowingthemachine,readalloftheinformation

andperformalloftheapplicableproceduresinthis

sectiontoensuresafeandpropertowing.

WARNING

Towingthemachineathighspeedincreases

theriskofahitchmalfunctionandtirefailure.

Higherspeedsalsoincreasethemomentum

ofthemachineandbrakingdistance.Ifthe

machinedetachesfromthetowvehicleathigh

speed,itcouldcausedamagetoproperty,or

injuryordeathtobystanders.

•Placechockblocksunderneaththetirestoprevent

themfromrollingwhilethemachineisparked.

Donotexceed88km/h(55mph)whentowing

themachine.Forpoorroadconditionsor

inclementweather,reducespeedaccordingly.

•ReviewandunderstandtheTowingSafety(page

13).

•Testthebrakesofthetowvehiclebeforetowing.

•Avoidsuddenstartsandstopswhiletowingthe

machine.

TowVehicleRequirements

Beforeconnectingthemachinetoyourtowvehicle,

ensurethatyourvehicleispreparedasfollows:

•Ensurethatyourtowvehiclehastowing

capacityfortheweightofthemachine;referto

Specications(page7).

•UseaClass2orlargerreceiver.

•Ensurethatyourtowvehiclehastheappropriate

hitchtotowthemachine;optionsincludea50mm

(2inch)ballhitchorapintlehitch.

•Ensurethattheelectricalconnectorofthetow

vehicleiscompatiblewiththeelectricalconnector

ofthemachine.Themachineusesastandard

4-pin,atplug.Ifyourtowvehiclehasadifferent

typeofplug,obtainanadapterfromanautomotive

partsstore.

14

Page 15

HitchingtheMachinetoaTow

ConnectingtheSafetyChainsto

Vehicle

1.Shut-offtheengineandfuelvalve.

2.Lowertherailtothehorizontalpositionand

secureitwiththelockpin;refertoLoweringthe

RailtotheHorizontalPosition(page12).

3.Inspectthetires;refertoCheckingtheTire

Pressure(page25).

4.Applychassisgreasetothesocketofthehitch

receiverandtheareaoftheclampthatcontacts

theball.

5.Oilthepivotpointsandslidingsurfacesofthe

hitchreceiverwithSAE30motoroil.

6.Crankthehandleofthejacklifttoalignthehitch

receiverwiththeballofthetowvehicle.

7.HitchthemachineasshowninFigure15.

theTowVehicle

1.Pullthesafetychainthroughtheslotsinthe

keyholes,sothatthelengthsoneachsideare

equal.

2.Crossbothlengthsofchainunderthehitch

receiver.

Note:Crossingthechainsdecreasesthe

chancesofthefrontofthemachinedropping

tothegroundifthehitchdoesnotholdthe

connection.

Figure16

1.Connectinglinks2.Chainscrossedunder

hitchreceiver

3.Connecteachlengthofchaintothesafety

chainmountingpointonthetowvehiclewiththe

connectinglinks(Figure16).

Important:Ensurethatthechainhas

enoughslackforturningaroundcorners

whentowingthemachine.

g206325

Figure15

8.Crankthehandleonthejacklifttoraisethe

casterwheelsofftheground.

g035113

15

Page 16

ConnectingandCheckingthe Lights

1.Connecttheelectricalplugofthemachinewith

theelectricalplugofthetowvehicle(Figure17).

Figure17

Note:Themachineusesastandard4-pin,at

plug.Ifyourtowvehiclehasadifferenttype

ofplug,obtainanadapterfromanautomotive

partsstore.

2.EnsurethatthetowvehicleisinNEUTRAL,

engagetheparkingbrake,andstarttheengine.

3.Testthelightsasfollows:

A.Turnontheheadlightsofthetowvehicle.

g020828

Note:Thetaillightsofthemachineshould

illuminate.

B.Pressthebrakepedalofthetowvehicle.

Note:Thebrakelightsofthemachine

shouldilluminate.

C.Operateeachturnsignalofthetowvehicle

inturn.

Note:Thecorrespondingturn-signallights

ofthemachineshouldilluminate.

16

Page 17

Maintenance

Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Afterthersthour

Aftertherst10hours

Aftertherst20hours

Beforeeachuseordaily

Every50hours

Every100hours

Every300hours

Every500hours

Yearly

MaintenanceProcedure

•Checkthewheellugnuts.

•Checkthewheellugnuts.

•Changetheengineoil.

•Inspecttheair-cleanerelements.

•Checktheengine-oillevel.

•Checkthetirepressure.

•Checkthehydraulic-uidlevel.

•Cleantheair-cleanerelements.Cleanthemmorefrequentlyindustyoperating

conditions.

•Changetheengineoil(moreofteninextremelydustyorsandyconditions).

•Checkthesparkplug.

•Cleanthefuel-sedimentcup.

•Replacethehydrauliclter.

•Replacethehydraulicuid.

•Replacethepaperair-cleanerelement.Replaceitmorefrequentlyindusty

operatingconditions.

•Replacethesparkplug.

•Greasethewheelbearings.

•Checkthewheellugnuts.

Yearlyorbeforestorage

•Changetheengineoil.

•Cleanthefuel-sedimentcup.

Note:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

17

Page 18

Pre-Maintenance

Disconnectingthe

Procedures

MaintenanceSafety

•Beforerepairingthemachinedothefollowing:

–Parkthemachineonalevelsurface.

–Fullyretractthesplittingwedge.

–Shutofftheengine.

–Disconnectthespark-plugwire.

•Cleangrassanddebrisfromthemuferand

enginetohelppreventres.

•Cleanupoilorfuelspills.

•Donotallowuntrainedpersonneltoservicethe

machine.

•Usejackstandstosupportthemachineand/or

componentswhenrequired.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Removethespark-plugwirebeforemakingany

repairs.

Spark-plugWire

Pullthespark-plugwireofftheterminalofthespark

plug(Figure18).

g019281

Figure18

1.Sparkplug

•Keepyourhandsandfeetawayfrommoving

parts.Ifpossible,donotmakeadjustmentswith

theenginerunning.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Neverinterferewiththeintendedfunctionofa

safetydeviceorreducetheprotectionprovided

byasafetydevice.Checktheirproperoperation

regularly.

•Toensureoptimumperformanceandcontinued

safetycerticationofthemachine,useonly

genuineT ororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadeby

othermanufacturerscouldbedangerous,and

suchusecouldvoidtheproductwarranty.

18

Page 19

Lubrication

GreasingtheRail

Greasetype:General-purposegrease

Ifthesplittingwedgegetsstuckontherail,ensurethat

thebeamisnotbentandthereisnothingobstructing

thepathofthewedge,thengreasetherail.Lubricate

bothsidesofthebeamface.

g206422

Figure20

1.Rubberplug

2.Connectagreaseguntothegreasettings

andpumpgreaseintothettingsontheaxle

(Figure20)andthecasterwheels(Figure21)

untilgreasebeginstooozeoutofthebearings.

Figure19

1.Rail

GreasingtheWheel Bearings

ServiceInterval:Every500hours

Greasetype:General-purposegrease

1.Removetherubberplugsfromtheaxle(Figure

20).

g206411

g206425

Figure21

1.Greasetting

3.Installtherubberplugs(Figure20).

19

Page 20

EngineMaintenance

EngineSafety

•Shutofftheenginebeforecheckingtheoilor

addingoiltothecrankcase.

•Donotchangethegovernorspeedoroverspeed

theengine.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Inspect

theair-cleanerelements.

Every50hours—Cleantheair-cleaner

elements.Cleanthemmorefrequentlyindusty

operatingconditions.

Every300hours/Y early(whichevercomes

rst)—Replacethepaperair-cleanerelement.

Replaceitmorefrequentlyindustyoperating

conditions.

Important:Donotoperatetheenginewithout

theair-lterassembly;extremeenginedamage

willoccur.

1.Shutofftheengineandwaitforallmovingparts

tostop.

2.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-plugWire(page18).

3.Removethenutthatsecuresthecover(Figure

22).

Figure22

1.Covernut

2.Cover

3.Wingnut6.Base

4.Removethecover.

4.Foamelement

5.Paperelement

Note:Becarefultopreventdirtanddebrisfrom

fallingintothebase.

5.Removethefoamandpaperelementsfromthe

base(Figure22).

6.Removethefoamelementfromthepaper

element(Figure22).

7.Inspectthefoamandpaperelementsand

replacethemiftheyaredamagedorexcessively

dirty.

g019728

Note:Nevertrytobrushdirtoffthepaper

element;brushingforcesthedirtintothebers.

8.Cleanthefoamelementinwarm,soapywater

orinanonammablesolvent.

Note:Donotusefueltocleanthefoamelement

becauseitcouldcreateariskofreorexplosion.

20

Page 21

9.Rinseanddrythefoamelementthoroughly .

10.Dipthefoamelementincleanengineoil,then

squeezeouttheexcessoil.

Note:Excessoilinthefoamelementrestricts

theairowthroughtheelementandmayreach

thepaperlterandclogit.

11.Wipedirtfromthebaseandthecoverwitha

moistrag.

ServicingtheEngineOil

Note:Changetheoilmorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy .

Engine-OilSpecications

ToroPremiumEngineOilisavailablefromyour

AuthorizedT oroDealer.

Note:Becarefultopreventdirtanddebrisfrom

enteringtheairductleadingtothecarburetor.

12.Installtheair-cleanerelementsandensurethat

theyareproperlypositioned.

13.Securelyinstallthecoverwiththenut.

OilType:DetergentoilwithanAPIserviceofSJor

higher.

CrankcaseCapacity:1.1L(1.2USqt)

Viscosity:Refertothetablebelow.

g013375

Figure23

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

2.Allowtheenginetocool.

3.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-plugWire(page18).

4.Cleanaroundthedipstick.

5.ChecktheoillevelasshowninFigure24.

21

Page 22

Figure25

5.Slowlypourapproximately80%ofthespecied

oilintothellertubeandslowlyaddthe

additionaloiltobringittotheFullmark(Figure

26).

g206641

g031623

Figure24

ChangingtheEngineOil

ServiceInterval:Aftertherst20hours—Change

theengineoil.

Every100hours—Changetheengineoil(more

ofteninextremelydustyorsandyconditions).

Yearlyorbeforestorage—Changetheengine

oil.

Note:Disposeoftheusedoilatarecyclingcenter.

1.Starttheengineandletitrunfor5minutes.

Note:Thiswarmstheoilsothatitdrainsbetter.

2.Parkthemachineonalevelsurfaceandshut

offtheengine.

3.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-plugWire(page18).

4.ChangetheoilasshowninFigure25.

g035136

g206640

Figure26

22

Page 23

ServicingtheSparkPlug

SparkPlugSpecications

Type:NGKBPR6ESorequivalent

Gap:0.7to0.8mm(0.028to0.031inch)

Note:Usea21mm(13/16inch)spark-plugwrench

forremovingandinstallingthesparkplug.

RemovingtheSparkPlug

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

2.Locateandremovethesparkplugs(Figure27).

CheckingtheSparkPlug

ServiceInterval:Every100hours/Every6months

(whichevercomesrst)

Every300hours/Yearly(whichevercomesrst)

Important:Donotcleanthesparkplug(s).

Alwaysreplacethesparkplug(s)whenithas:a

blackcoating,wornelectrodes,anoilylm,or

cracks.

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty .

Setthegapto0.70to0.80mm(0.28to0.031inch).

g206628

Figure28

Figure27

InstallingtheSparkPlug

Tightenthesparkplug(s)to27N∙m(20ft-lb).

g019749

g027478

g027735

Figure29

23

Page 24

FuelSystem

Maintenance

CleaningtheFuel-Sediment Cup

ServiceInterval:Every100hours/Every6months

(whichevercomesrst)—Cleanthe

fuel-sedimentcup.

Yearlyorbeforestorage—Cleanthe

fuel-sedimentcup.

Underneaththefuelvalveisasedimentcuptocatch

dirtinthefuel.

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

2.Allowtheenginetocool.

3.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-plugWire(page18).

4.MovetheleverofthefuelvalvetotheOFF

position,allthewaytotheleft(Figure30).

5.Unscrewthefuel-sedimentcup(Figure30).

6.RemoveandretainthefuellterandO-ring

(Figure30).

10.AligntheO-ringintothegrooveinthesediment

cupandinstallthesedimentcuptothefuel-valve

housing.

11.MovetheleverofthefuelvalvetotheON

position(allthewaytotheright)andcheckfor

leaks.Ifitleaks,replacetheO-ring.

Note:DonotcleantheO-ringinsolvent.

Figure30

1.Fuelvalve—OFFposition3.Fuellter

2.O-ring

4.Fuel-sedimentcup

g019333

7.Cleanthefuellterandsedimentcupusinga

nonammablesolvent,anddryitcarefully.

8.WipetheO-ringwithaclean,drycloth.

9.Installthefuellterinthebottomofthe

carburetor(Figure30).

24

Page 25

DriveSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

2.Ensurethatthetiresareinatedto410kPa(60

psi).

CheckingtheWheelLug Nuts

ServiceInterval:Afterthersthour

WARNING

Failuretomaintaincorrecttirepressure

mayresultintirefailureandlossofcontrol,

resultinginpropertydamageandserious

injuryordeath.

•Checkthetirepressurefrequentlyto

ensureproperination.Ifthetiresarenot

inatedtothecorrectpressure,theywill

wearprematurely .

•Inspectthetireconditionbeforetowing

andafteranyoperatingaccident.

TheDOTtireinformationislocatedonthesideof

eachtire.Thisinformationgivesloadandspeed

ratings.Replacementtiresshouldhavethesame

orbetterratings.Formoreinformationgoto

http://www.nhtsa.gov/Vehicle+Safety/Tires.

1.Visuallyinspectthetiresfordamageandwear

(Figure31andFigure32).

Aftertherst10hours

Yearly

Checkandtorquethewheellugnutsto108to122

N∙m(80to90ft-lb).

1.Exampleoftirewearcausedbyunderination

1.Exampleoftirewearcausedbyoverination

g020836

Figure31

g010293

Figure32

25

Page 26

HydraulicSystem

Maintenance

HydraulicSystemSafety

•Seekimmediatemedicalattentionifuidisinjected

intoskin.Injecteduidmustbesurgicallyremoved

withinafewhoursbyadoctor.

•Ensurethatallhydraulic-uidhosesandlinesare

ingoodconditionandallhydraulicconnections

andttingsaretightbeforeapplyingpressureto

thehydraulicsystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthigh-pressurehydraulic

uid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

HydraulicFluid

Specications

Hydraulictankcapacity:30L(8USgallons)

Hydraulicuidtype:T oroAllSeasonHydraulicFluid

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditivefor

thehydraulicsystemuidisavailablein20ml(0.67

oz)bottles.Onebottleissufcientfor15to22L

(4to6USgallons)ofhydraulicuid.OrderPartNo.

44-2500fromyourAuthorizedT oroDealer.

g206553

Figure33

1.Uppernotch2.Breathercap

5.Removethebreathercap(Figure33).

6.Wipethedipstickoffandthreadthebreather

capintothereservoir.

7.Removethedipstickandverifythattheuidisat

theuppernotch(Figure33).Installthebreather

cap.

8.Iftheuidlevelislow,removethellerplugand

slowlyaddhydraulicuidintothereservoirto

raisetheleveltotheuppernotchonthedipstick

(Figure34).

Checkingthe Hydraulic-FluidLevel

ServiceInterval:Beforeeachuseordaily

Note:Thebesttimetocheckthehydraulic-uidlevel

iswhenthemachineiscool,beforeyoustartitfor

theday.

1.Parkthemachineonalevelsurfaceandfully

retractthesplittingwedge.

2.Shutofftheengine.Allowthemachinetocool

completely.

3.Lowertherailtothehorizontalposition;refer

toLoweringtheRailtotheHorizontalPosition

(page12)

4.Cleanaroundthebreathercap(Figure33).

g207827

Figure34

1.Fillerplug

9.Installthellerplug.

26

Page 27

ReplacingtheHydraulic

ReplacingtheHydraulic

Filter

ServiceInterval:Every100hours

1.Parkthemachineonalevelsurface,fullyretract

thesplittingwedge,andshutofftheengine.

2.Placeadrainpanunderthelterandreplace

thelter(Figure35).

Fluid

ServiceInterval:Every100hours

1.Parkthemachineonalevelsurface,fullyretract

thesplittingwedge,andshutofftheengine.

Allowthemachinetocoolcompletely .

2.Placeadrainpanunderthesuctionhose

connectedtothereservoirtank(Figure36).

g206497

Figure36

3.Cleanupanyspilleduid.

Figure35

1.Hydrauliclter

2.Hoseclamp

3.Crankthehandleofthejacklifttolowerthefront

ofthemachine.

4.Disconnectthesuctionhoseandallowuidto

drainintothedrainpan.

g206495

5.Installthesuctionhoseandsecureitwiththe

hoseclamp.

6.Crankthehandleofthejacklifttoraisethe

machinesothatitislevel.

7.Removethellerplugandllthereservoirwith

hydraulicuidasspeciedinHydraulicFluid

Specications(page26).

3.Hose

Note:Theuidlevelshouldbeattheupper

notchonthedipstickonthebreathercap(Figure

33)

27

Page 28

Storage

StorageSafety

•Allowthemachinetocoolbeforestoring.

•Donotstorethemachineorfuelnearames.

Storage

Forstorageover30days,preparethemachineas

follows:

1.Removedirtandgrimefromtheexternalparts

oftheentireunit,especiallytheengine.Clean

dirtandsawdustchipsfromtheoutsideofthe

enginecylinderheadnsandblowerhousing.

Important:Youcanwashtheunitwithmild

detergentandwater.

2.Addapetroleum-basedstabilizer/conditionerto

fuelinthetank.Followmixinginstructionsfrom

stabilizermanufacturer.(7.8mlperLor1oz

perUSgallon).

15.Checkandtightenallbolts,nuts,andscrews.

Repairorreplaceanypartthatisdamaged.

16.Paintallscratchedorbaremetalsurfaces.Paint

isavailablefromyourAuthorizedServiceDealer.

17.Storethemachineinaclean,drygarageor

storagearea.

18.Coverthemachinetoprotectitandkeepitclean.

Note:Fuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuelandused

atalltimes.

Important:Donotuseanalcohol-based

stabilizer(ethanolormethanol).Donotstore

stabilizer/conditionedfuelover90days.

3.Runtheenginetodistributeconditionedfuel

throughthefuelsystem(5minutes).

4.Shutofftheengine,allowittocool,anddrain

thefueltankusingapumptypesiphon.Dispose

offuelproperly;recycleasperlocalcodes.

5.Starttheengineandrunituntilitshutsoff.

6.Engagethechokelever.

7.Startandruntheengineuntilitdoesnotstart.

8.Cleanthesedimentcup;refertoCleaningthe

Fuel-SedimentCup(page24).

9.Servicetheaircleaner;refertoServicingtheAir

Cleaner(page20).

10.Changetheengineoil;refertoChangingthe

EngineOil(page22).

11.Removethesparkplugandcheckthecondition;

refertoServicingtheSparkPlug(page23).

12.Withthesparkplugremovedfromtheengine,

pour2tablespoonsofengineoilintothespark

plughole.

13.Pullthestarterslowlytocranktheengineand

distributetheoilinsidethecylinder.

14.Installthesparkplug,butdonotinstallthewire

onthesparkplug.

28

Page 29

Troubleshooting

Problem

Theenginedoesnotstart.

Theenginerunsrough.

Thesplittingwedgedoesnotmove.

Thesplittingwedgemovesslowly .

PossibleCauseCorrectiveAction

1.TheengineOn/OffswitchisintheOFF

position.

2.Thefuel-shutoffvalveisclosed.2.Openthefuel-shutoffvalve.

3.Thechokeisopen.

4.Thefueltankisempty.4.Fillthetankwithfreshfuel.

5.ThethrottleisnotintheFASTposition.5.MovethethrottletotheFASTposition.

6.Thesparkplugwireislooseor

disconnected.

1.Thechokeisclosed.

2.Theairlterisclogged.2.Cleanorreplacetheairlter.

3.Thefuellineisclogged.3.Cleanthesedimentcup.

4.Thereiswaterorcontaminantsinthe

fuel.

5.Thesparkplugsarewornorhave

buildupontheelectrodes.

1.Thehydraulic-uidlevelmaybelow.1.Addhydraulicuid.

2.Thecontrolvalveorpumpisblocked

ordamaged.

1.Theenginespeedissetonidle.1.MovethethrottletotheFASTposition.

2.Thehydraulicuidiscontaminated.2.Changethehydraulicuidandlter.

3.Thehydraulicpump,cylinder ,or

directionalvalveisdamaged.

1.MovetheswitchtotheONposition.

3.Closethechokewhenstartingacold

engine.

6.Checktheelectrodegapandcleanor

replacethesparkplug.

1.Openthechoke.

4.Drainthefueltankandllitwithfresh

fuel.

5.Checktheelectrodegapandcleanor

replacethesparkplug.

2.ContactyourAuthorizedService

Dealer.

3.ContactyourAuthorizedService

Dealer.

29

Page 30

Notes:

Page 31

Notes:

Page 32

CaliforniaProposition65WarningInformation

Whatisthiswarning?

Youmayseeaproductforsalethathasawarninglabellikethefollowing:

WARNING:CancerandReproductiveHarm—www.p65Warnings.ca.gov.

WhatisProp65?

Prop65appliestoanycompanyoperatinginCalifornia,sellingproductsinCalifornia,ormanufacturingproductsthatmaybesoldinorbroughtinto

California.ItmandatesthattheGovernorofCaliforniamaintainandpublishalistofchemicalsknowntocausecancer,birthdefects,and/orother

reproductiveharm.Thelist,whichisupdatedannually,includeshundredsofchemicalsfoundinmanyeverydayitems.ThepurposeofProp65isto

informthepublicaboutexposuretothesechemicals.

Prop65doesnotbanthesaleofproductscontainingthesechemicalsbutinsteadrequireswarningsonanyproduct,productpackaging,orliteraturewith

theproduct.Moreover,aProp65warningdoesnotmeanthataproductisinviolationofanyproductsafetystandardsorrequirements.Infact,the

CaliforniagovernmenthasclariedthataProp65warning“isnotthesameasaregulatorydecisionthataproductis‘safe’or‘unsafe.’”Manyofthese

chemicalshavebeenusedineverydayproductsforyearswithoutdocumentedharm.Formoreinformation,gotohttps://oag.ca.gov/prop65/faqs-view-all

AProp65warningmeansthatacompanyhaseither(1)evaluatedtheexposureandhasconcludedthatitexceedsthe“nosignicantrisklevel”;or(2)

haschosentoprovideawarningbasedonitsunderstandingaboutthepresenceofalistedchemicalwithoutattemptingtoevaluatetheexposure.

Doesthislawapplyeverywhere?

Prop65warningsarerequiredunderCalifornialawonly .ThesewarningsareseenthroughoutCaliforniainawiderangeofsettings,includingbutnot

limitedtorestaurants,grocerystores,hotels,schools,andhospitals,andonawidevarietyofproducts.Additionally,someonlineandmailorder

retailersprovideProp65warningsontheirwebsitesorincatalogs.

.

HowdotheCaliforniawarningscomparetofederallimits?

Prop65standardsareoftenmorestringentthanfederalandinternationalstandards.TherearevarioussubstancesthatrequireaProp65warning

atlevelsthatarefarlowerthanfederalactionlimits.Forexample,theProp65standardforwarningsforleadis0.5μg/day,whichiswellbelow

thefederalandinternationalstandards.

Whydon’tallsimilarproductscarrythewarning?

•ProductssoldinCaliforniarequireProp65labellingwhilesimilarproductssoldelsewheredonot.

•AcompanyinvolvedinaProp65lawsuitreachingasettlementmayberequiredtouseProp65warningsforitsproducts,butothercompanies

makingsimilarproductsmayhavenosuchrequirement.

•TheenforcementofProp65isinconsistent.

•CompaniesmayelectnottoprovidewarningsbecausetheyconcludethattheyarenotrequiredtodosounderProp65;alackofwarningsfora

productdoesnotmeanthattheproductisfreeoflistedchemicalsatsimilarlevels.

WhydoesToroincludethiswarning?

Torohaschosentoprovideconsumerswithasmuchinformationaspossiblesothattheycanmakeinformeddecisionsabouttheproductstheybuyand

use.T oroprovideswarningsincertaincasesbasedonitsknowledgeofthepresenceofoneormorelistedchemicalswithoutevaluatingthelevelof

exposure,asnotallthelistedchemicalsprovideexposurelimitrequirements.WhiletheexposurefromToroproductsmaybenegligibleorwellwithinthe

“nosignicantrisk”range,outofanabundanceofcaution,T orohaselectedtoprovidetheProp65warnings.Moreover ,ifT orodoesnotprovidethese

warnings,itcouldbesuedbytheStateofCaliforniaorbyprivatepartiesseekingtoenforceProp65andsubjecttosubstantialpenalties.

RevA

Loading...

Loading...