Page 1

FormNo.3382-929RevA

G017901

BC-25BrushChipper

ModelNo.22614—SerialNo.314000001andUp

ModelNo.22614G—SerialNo.314000001andUp

ModelNo.32614—SerialNo.314000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3382-929*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

YoumaycontactTorodirectlyatwww .T oro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Writethenumbersinthespaceprovided.

ModelNo.

SerialNo.

DANGER

Watchforoverheadpowerlinesintheworkarea.

Shockorexplosionmayoccurifyoucomeinto

contactwiththem.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Theenclosed

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Engine Owner's Man ual

issuppliedfor

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure1

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

TireInformation

TheDOTtireidenticationnumber(TIN)isbrandedinto

thesidewallofallstreetlegaltires(Figure2).

Introduction

Thisbrushchipperisdesignedtochipbranches,vines,leaves,

andsmalltreelimbsupto15.24cm(6inches)indiameter.It

isnotintendedtochiprocks,wire,metal,oranymaterials

otherthanwood.Thebrushchippercanbetowedbehinda

vehicleequippedwithanappropriateballhitch.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure2

Contents

Safety...........................................................................3

SafeOperatingPractices...........................................3

SafetyandInstructionalDecals.................................6

ProductOverview..........................................................7

Controls................................................................7

Specications.........................................................7

Operation.....................................................................8

TowingtheMachine................................................8

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

MaintainingtheTiresandWheels..............................9

PreparingtoStarttheMachine..................................9

AddingFuel............................................................9

CheckingtheHourMeter........................................10

CheckingtheEngine-OilLevel.................................10

ChangingtheChutePosition....................................11

ChangingtheDeectorPosition...............................11

StartingandStoppingtheEngine..............................11

UsingtheBrushChipper.........................................12

Maintenance.................................................................14

RecommendedMaintenanceSchedule(s)......................14

Lubrication...............................................................14

LubricatetheCutterWheelBearings.........................14

LubricatetheWheelBearings...................................15

EngineMaintenance..................................................15

ServicingtheAirCleaner.........................................15

ServicingtheEngineOil..........................................16

ServicingtheSparkPlug..........................................17

FuelSystemMaintenance...........................................18

ChangingtheFuelFilter..........................................18

BeltMaintenance......................................................18

AdjustingtheDriveBeltTension..............................18

ReplacingtheDriveBelt..........................................19

CutterMaintenance....................................................19

InspectingtheCutterBlock......................................19

ReplacingtheCutterBlades.....................................19

ChargingtheBattery...................................................20

InspectingtheTires....................................................21

InspectingtheTires................................................21

Storage........................................................................22

Troubleshooting...........................................................23

Safety

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafetyalertsymbol

means:

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

Caution

,

W ar ning

,or

Danger

SafeOperatingPractices

Thisproductiscapableofamputatinghandsandfeet.Always

followallsafetyinstructionstoavoidseriousinjuryordeath.

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Ifyoubelievethatyourmachinehasadefectwhichcould

causeacrashorcouldcauseinjuryordeath,youshould

immediatelyinformtheNationalHighwayTrafcSafety

Administration(NHTSA)inadditiontonotifyingTheToro

Company.

IfNHTSAreceivessimilarcomplaints,itmayopenan

investigation,andifitndsthatasafetydefectexistsina

groupofmachines,itmayorderarecallandremedycampaign.

However,NHTSAcannotbecomeinvolvedinindividual

problemsbetweenyou,yourdealer,orTheT oroCompany.

,which

—personalsafety

TocontactNHTSA,youmaycalltheVehicleSafetyHotline

toll-freeat1–888–327–4236(TTY :1–800–424–9153);go

tohttp://www .safercar.gov;orwriteto:Administrator,

NHTSA,400SeventhStreet,SW .,Washington,DC20590.

Youcanalsoobtainotherinformationaboutmotorvehicle

safetyfromhttp://www .safercar.gov.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglish,itis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeople,ordamageto

property.

3

Page 4

TowingtheMachine

Checkwithyourlocalcountyorstatesafetytowing

regulations,inadditiontomeetingtheDepartmentof

Transportation(DOT)SafetyTowingRegulations,before

towingthemachine.

•Inordertoreducethepossibilityofanaccidentwhile

transportingthemachineonpublicroads,makesurethat

thetowingvehicleismechanicallysoundandingood

operatingcondition.

•Shutdowntheenginebeforetransportingthemachine.

•Inspectthehitchandcouplingforwear.Nevertowthe

machinewithdefectivehitches,couplings,chains,etc.

•Checkthetireairpressureonbothofthetowingvehicle

andthemachine.Thechippertiresshouldbeinatedto

410kPa(60ps)cold.

•Checkthetiretreadforwear.

•Properlyattachthesafetychainstothetowingvehicle.

•Ensurethatthetowingvehicle’sdirectional,backup,and

brakelightsareworkingproperly .

•Avoidsuddenstopsandstarts.Thiscancauseskidding,

orjackkning.Smooth,gradualstartsandstopswill

improvetowing.

•Avoidsharpturnstopreventrolling.T owonlywitha

vehiclethathasahitchdesignedfortowing.Donot

attachtowedequipmentexceptatthehitchpoint.

Beforetowingchecktomakecertainyourmachineiscorrectly

andsecurelyattachedtothetowingvehicle.

•Ensurethattheballhitchyouareusingisthepropersize

forthehitchcoupleronthemachine.

•Ensurethatthesafetychainsareproperlyhookedtothe

vehicle,leavingenoughslackforturning.

•EnsurethatthejackstandissecuredintheUpposition.

•Donottowthemachinefasterthan75km/h(45mph).

•Usecautionwhenbackingup;useaspotteroutsidethe

vehicletoguideyou.

•Donotallowanyonetositorrideonthemachine.

•Donotcarryanycargoorwoodonthemachinewhen

towing.

•Disconnectthemachinefromthetowvehiclebefore

usingit.

•Placechockblocksunderneaththewheeltoprevent

rollingwhilethemachineisparked.

PreparingtheMachine

Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludinghardhat,faceshield,

safetyglasses,longpants,substantialslip-resistantsafety

shoes,andhearingprotection.Longhair,looseclothing

orjewelrymaygettangledinmovingparts.W eartight

ttinggloveswithoutdrawstringsorloosecuffs.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer

–Neverremovethegascaporaddfuelwiththeengine

running.Allowtheenginetocoolbeforerefueling.

Donotsmoke.

–Neverrefuelordrainthemachineindoors.

–Replacethegasolinecapandtightenitsecurely.

–Keepthecontainernozzleincontactwiththetank

duringlling.

–Ifgasolineisspilled,wipeitofftheengineand

equipment.

•Ensurethatthemachineisonalevelsurfacebefore

operating.

•Alwaysoperatethemachinefromthesideofthehopper.

•Blockthewheelsofthemachinetopreventunintended

movement.

OperatingtheMachine

•Beforestartingthismachine,reviewtheSafety(page3)

section.Failuretofollowtheserulesmayresultinserious

injurytotheoperatororbystanders.

•Neverrunanengineinanenclosedarea.

•Onlyoperatethemachineingoodlight,keepingaway

fromholesandhiddenhazards.

•Onlystarttheenginefromtheoperator'sposition.

•Donotpassorstandonthedischargesideofthemachine

whentheengineisrunningorwhentheywheelis

turning.

•Ensurethatalltheguardsandshieldsaresecurelyinplace

beforeoperating.

•Ensurethatallinterlocksareattached,adjustedproperly,

andfunctioningproperly.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelground,andshutofftheenginebefore

leavingtheoperator'spositionforanyreason.

•Chockthemachineorkeepitattachedtothetowing

vehiclewhennotinusetopreventthemachinefrom

rolling.

•Keephandsandfeetawayfromanymovingparts.

•Nevercarrypassengers,andkeeppetsandbystanders

away.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Ensurethattheareaisclearofotherpeoplebefore

operatingthemachine.Stopthemachineifanyoneenters

thearea.

4

Page 5

•Neverleavearunningmachineunattended.Alwaysstop

theengineandverifythechipperywheelhasstopped

rotating.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservicethemachine.

–Ensurethatthetiresareproperlyinatedas

recommended.

–Ensurethatthelugnutsaretightandtorqued

properly.

–Ensurethatthemachineisproperlysecured.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Donotallowanyonetooperatethismachinewithout

properinstruction.

•Keepareaofdischargeclearofpeople,animals,buildings,

glass,oranythingelsethatwillobstructcleardischarge,

causeinjury,ordamage.Windcanalsochangedischarge

direction.Ifitbecomesnecessarytopushmaterialinto

thehopper,useasmalldiameterwoodstick,notyour

hands.

•Donotusethemachinewiththehopperordischarge

chuteremoved.

•Cleartheareaofobjectssuchaswire,rope,etc.Inserting

theseobjectsintothehoppercoulddamagetheywheel

and/orcauseinjury.

•Keepyourfaceandbodyawayfromthehoppertoavoid

accidentalbouncebackofanymaterial.

•Ifyouhearorseematerialbeingkickedbackagainstthe

rubberap,shutthefeederchutedooruntilthematerial

haspassed.

•Whenfeedingmaterialintothehopper,beextremely

carefulthatpiecesofmetal,rocks,orotherforeign

objectsarenotincluded.Personalinjuryordamageto

themachinecouldresult.

•Shutofftheengineandwaitforthemovingpartstocome

toacompletestopbeforeremovingprocessedmaterial,

leaves,ordebrisfromthemachine.

•Removethekey ,disconnectthesparkplugwiresandkeep

thewireawayfromthesparkplugtopreventaccidental

startingwhileadjustingthemachine.

•Ifthecuttingmechanismstrikesaforeignobjectorif

yourmachineshouldstartmakinganunusualnoiseor

vibration,stoptheengineandwaitveminutesforall

movingpartstocometoacompletestopandcool.

Vibrationisgenerallyawarningoftrouble.Disconnect

thesparkplugwiresandinspectforcloggingordamage.

Cleanandrepairand/orreplacedamagedparts.

•Donottouchpartsthatmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservicethemachine.

MaintainingandStoringtheMachine

•Stoptheengine.W aitforallmovementtostopbefore

adjusting,cleaning,orrepairing.

•Cleanthedebrisfromthemufersandenginetohelp

preventres.Cleanupanyoilorfuelspillage.

•Lettheenginecoolbeforestoring.

•Donotstorefuelnearamesordrainindoors.

•Parkthemachineonlevelground.Neverallowuntrained

personneltoservicethemachine.

•Removethesparkplugwirebeforemakinganyrepairs.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Keepallnuts,bolts,screws,hydraulicttings,andhose

clampssecurelytightened.Keepequipmentingood

condition.

•Donottamperwithsafetydevices.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethegascaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

–Neverrefuelthemachineindoors.

–Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Neverllacontainerwhileitisinsideavehicle,trunk,

pick-upbed,oranysurfaceotherthantheground.

–Keepcontainernozzleincontactwiththetankduring

lling.

•Stopandinspectthemachineifyoustrikeanobject.

Makeanynecessaryrepairsbeforerestarting.

•UseonlygenuineT ororeplacementpartstoensurethat

theoriginalstandardsaremaintained.

•Nevermovethismachinewhiletheengineisrunning.

•Beforeeveryuse:

–Inspectthecoupler,ballandhitch.

–Ensurethatalllightsarefunctioningproperly.

5

Page 6

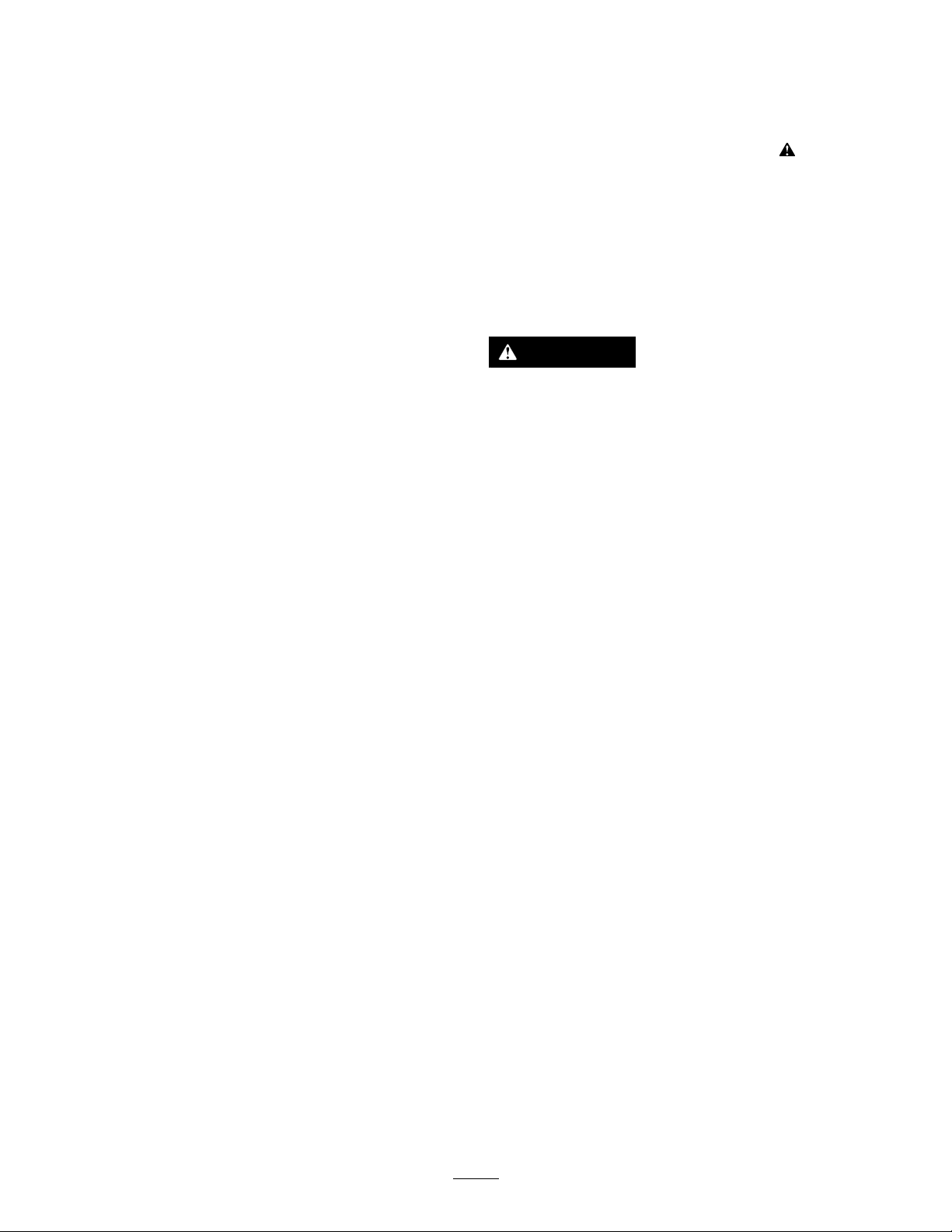

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasily

visibletotheoperatorandarelocatednear

anyareaofpotentialdanger.Replaceany

decalthatisdamagedorlost.

117–2718

119-4696

1.Warning—donotexceed72kmh(45mph)when

transportingthemachine.

119-4698

1.Warning—readtheOperator'sManual.

2.Warning—readtheOperator'sManual,donotoperatethis

machineunlessyouaretrained.

3.Thrownobjecthazard,face—weareyeprotection.

4.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

5.Cutting/dismembermenthazardofhand,blade—stayaway

frommovingparts,keepallguardsandshieldsinplace.

119-4699

119-4720

1.Cutting/dismembermenthazardofhand;thrownobject

hazard,face—stoptheengine,removethekeyandwaitfor

allmovingpartstostopbeforeopeningtheguard.

1.Warning—donotoperatewearinggloveswithloose

gauntlets,usegloveswithoutloosematerial.

2.Warning—donotentanglebodywithmaterialwhenusing

machine.

3.Cutting/dismembermenthazardarm—donotplacearmin

hopper;stayawayfrommovingparts,keepallguardsand

shieldsinplace.

4.Thrownobjecthazard,faceandbody—donotletloose

materialescapefromthehopper ,puttheshroudinplace.

117–4979

1.Rotatingbelt—Keepguardinplace

1.Rotationaldirectionandspinindicator

117-1754

120-3738

1.Whenchippingbrancheswithwidthsof4to6inches,cut

thebranchestolengthsof36inchesorlesstoprevent

cloggingofthechipper.

6

Page 7

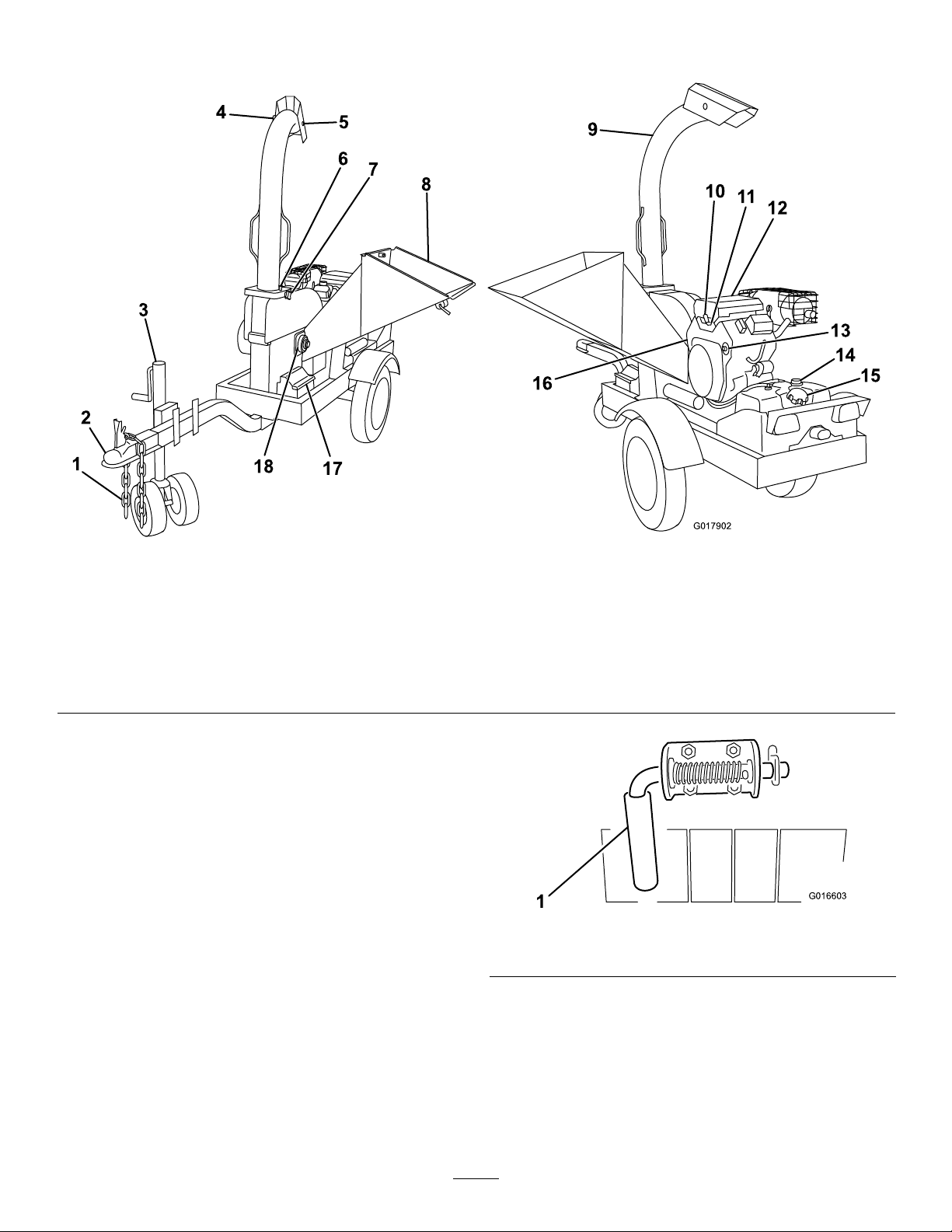

ProductOverview

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

G017902

G016603

Figure3

1.Safetychains7.Chutelockingknob

2.Coupler

3.Jackstand9.Dischargechute15.Fuelcap

4.Deectorlockingknob10.Choke16.Fuellter

5.Deector

6.Chutelockingpin12.Airlter

8.Hopper14.Fuellevelgauge

11.Throttle17.Battery

13.Keyswitch

18.Flywheelbearing

Controls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine.

HopperLatch

Thehopper,mountedonthesideofthemachine,swings

downformachineoperation.Therevolvingbladesmounted

onaywheelbehindthehopperturnbranchesfedintothe

hopperintochips.Thechippercanchipbranchesandvines

ranginginsizeupto15cm(6inches)indiameterandup

to1meter(3feet)inlength.

Toreleasethehopperorhopperlatch(Figure4),pullon

thehandleandrotateitupordowntoengagethelatchpin

behindthestop.

Pullhopperdowntoopen.

Figure4

1.Hopperlatch

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

7

Page 8

HopperOpening15cm(6inches)maximum

3

4

G016604

Length

Width

Height

Weight

EngineKohler725cc,V-Twin,gas

TirePressure

FuelT ankCapacity20.8L(5.5USgallons)

282cm(1 11inches)

89cm(35inches)

206cm(81inches)

478Kg(1056lbs)

413.5kPa(60psi)

diameter

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Important:Beforeoperating,checkthefuelandoil

level,andremovedebrisfromthemachine.Ensurethat

theareaisclearofpeople.

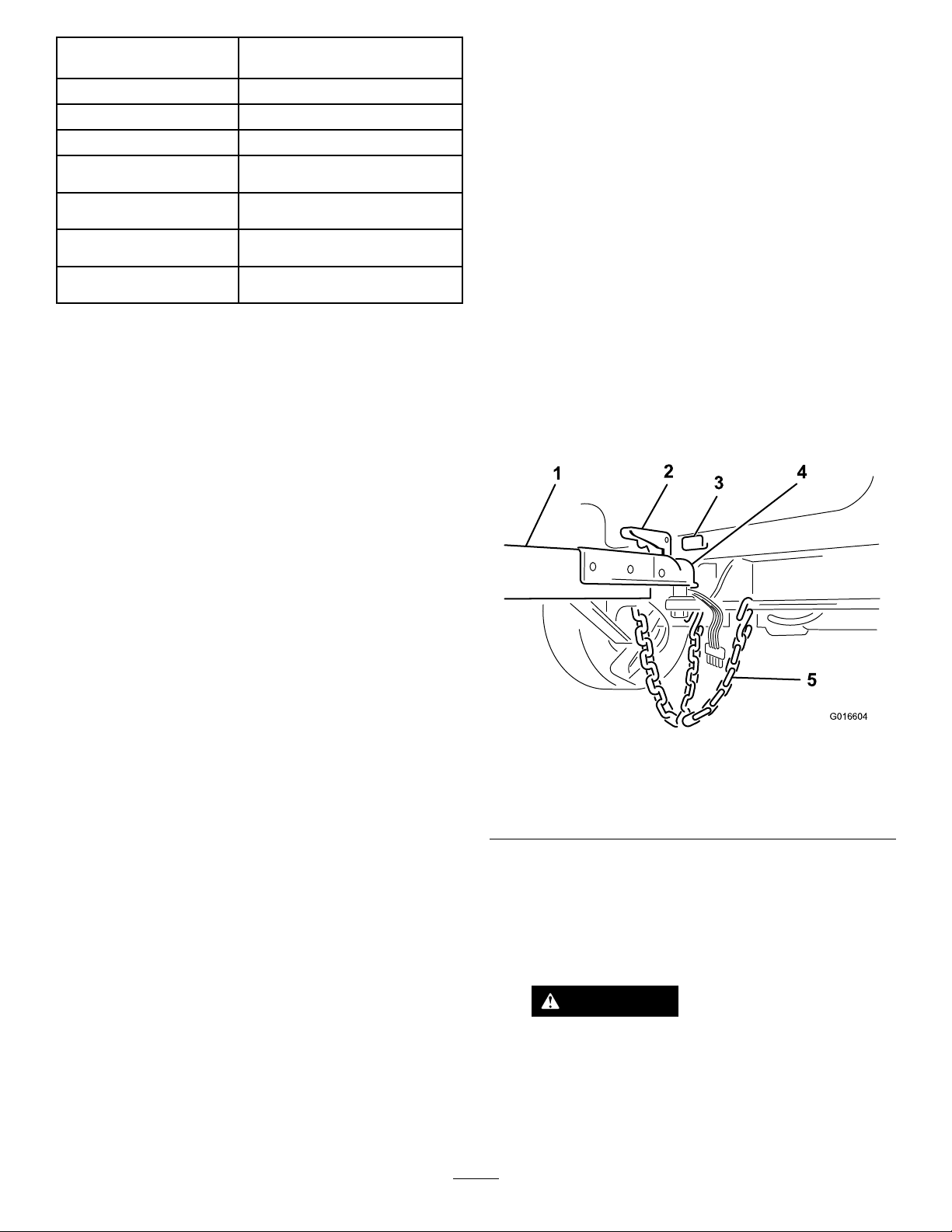

TowingtheMachine

Important:Donottowover72km/h(45mph).

1.Raisehopperandlockitintheupposition.Rotate

thechutetowardtherearofthemachine,lockitin

positionwiththechutelockingpinandtightenchute

lockingknob(Figure3).

2.Crankthehandleoftheliftjacktoalignthecoupler

withtheballofthetowvehicle.

3.Removethelockingpinfromthelever,squeezethe

latchlock,andlifttheleveruptoopenthecoupler

(Figure4).

Figure5

1.Tongue

2.Leverinlockedposition

3.Lockingpin

4.Coupler

5.Safetychain

4.AttachcouplertoaclassIorhigher50.8mm(2inch)

ballonatowingvehicleandlatchsecurely.

•Ifcouplerdoesnottovertheball,turnthe

adjustmentnut1turncounter-clockwise.

•Ifcouplerhitchistoolooseontheball,turnthe

adjustmentnut1turnclockwise.

WARNING

Failuretoproperlyengagethehitchballin

thecouplerballsocketandsecurelylockthe

couplerlatchmechanismcancausetheunitto

becomedetachedfromthetowvehiclewhile

traveling,whichmaycauseseriousinjuryand

propertydamage.

8

Page 9

5.Installthelockingpintosecurethelever(Figure5).

G016605

6.Crossor“X”thesafetychainsandattachthemtothe

holesonthehitch.

7.Plugthetaillightwireharnessconnectortothetow

vehicleconnector.Checktomakesurethatthebrake

lightsilluminateproperlywiththebrakepedalapplied

andthetaillightsashwhentheturningsignalsareuse.

8.Raisethejackstandsothatthecasterwheelsarefreeof

theground,pullthereleasepinandrotatethewheels

rearwardandlockitinthehorizontalposition(Figure

6).

Figure6

1.Releasepin2.Jackstand

MaintainingtheTiresand Wheels

Themostcommoncauseoftiretroubleisunder-ination.It

isimportantthatyoumaintainfullairpressure.

Inatemainaxletiresto410kPa(60psi).

•Ensurethattheworkareasandbladesarefreefrom

metallicobjectssuchaswire,nails,etc.thatcouldbe

thrownoutandinjurepersonsinthevicinityanddamage

theequipment.

•Ensurethateveryone,includingchildrenandanimals,

maintainadistanceofatleast15meters(50feet)from

themachine.Debriscanbethrownoutandinjurepeople

andanimals.

•Disconnectthemachinefromthetowvehicle,positionit

onalevellocationandblockthewheelsfrontandback

topreventitfrommoving.

•Checkthefuelandoilleveloftheengine.

AddingFuel

Useunleadedgasoline(87pumpoctaneminimum).Leaded,

regulargasolinemaybeusedifunleadedisnotavailable.

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

Checkthetorqueofthewheellugnutsinitiallyandafterthe

rst10hoursofoperation.

Torquewheellugnutsto108-122Nm(80-90ft.-lbs).

PreparingtoStarttheMachine

•Reviewallthemachine’ssafetydecals.

•Useahard-hat,hearingprotection,tightttinggloves

withoutdrawstringsorloosecuffs,andeyeprotection.

Ameshvisoralonedoesnotprovidesufcienteye

protection;supplementwithprotectiveglasses.

•Ensurethatyouarefamiliarwithsafetyregulations

andshutdownproceduresdescribedinthismachine’s

Operator’sManualandEngineOwner’sManual.

•Ensurethatallguardsareinplaceandingoodcondition.

•Ensurethatthebladesareinplaceandingoodcondition.

9

Page 10

DANGER

G016607

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

Figure7

1.Fueltankcap

4.Addunleadedgasolinetothefueltank,untilthelevel

is6to13mm(1/4to1/2inch)belowthebottomof

thellerneck.

Important:Thisspaceinthetankallowsgasoline

toexpand.Donotllthefueltankcompletelyfull.

5.Installthefueltankcapsecurely ,turningituntilitclicks.

6.Wipeupanygasolinethatmayhavespilled.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

Important:Donotusemethanol,gasolinecontaining

methanol,orgasoholcontainingmorethan10%ethanol

becausethefuelsystemcouldbedamaged.Donotmix

oilwithgasoline.

CheckingtheHourMeter

Thehourmeterrecordsthenumberofhourstheenginehas

operated.Itoperateswhentheengineisrunning.

Figure8

1.Hourmeter

CheckingtheEngine-OilLevel

FillingtheFuelTank

1.Parkthemachineonalevelsurface,andstopthe

engine.

2.Allowtheenginetocool.

3.Cleanaroundthefueltankcapandremoveit(Figure7).

ServiceInterval:Beforeeachuseordaily

1.Placethemachineonaatlevelsurface,andstopthe

engine.

2.Allowtheenginetocool.

3.Cleanaroundtheoildipstick.

10

Page 11

4.Removethedipstickandwipetheendclean.

G016608

1

2

G017903

5.Slidethedipstickfullyintothedipsticktubewithout

threadingitintothellerneck.

6.Pullthedipstickoutandlookattheend.Theoil

shouldbetothetopoftheupperlimitrange(Figure9).

Figure10

Figure9

1.Oildipstick

2.Oilllcap

Important:Runningtheenginewithlowoillevel

cancauseenginedamage.Thistypeofdamageis

notcoveredbywarranty.

7.Iftheoillevelislow ,slowlypouronlyenoughoilinto

thecrankcasetoraisetheleveltotheupperlimit.

Important:Donotoverllthecrankcasewithoil

becausetheenginemaybedamaged.

8.Replacethedipstick.

3.Valvecover

4.Metalend

ChangingtheChutePosition

Thedischargechuteonthismachinecanberotatedtousein

variouspositions.Rotatethechutetotheside,awayfromthe

hopper,whenusingthemachine.

1.Torotate,loosentheclampknob,thenpressthe

spring-loadedbuttononthelockingpinhandlein,and

pullthelockingpinfromthechuteplate(Figure10).

1.Lockingpinbutton

2.Rotatethechuteintothepositiondesiredandsecure

withclampknob.

2.Clampknob

ChangingtheDeector

Position

Thedeectorontheendofthechutecanberotatedupand

downtodirectthedischargeofchips.

1.Loosenthedeectorknobandrotatethechuteinto

thedesiredposition(Figure11).

Figure11

1.Chutedeector

2.Knob

2.Tightenthedeectorknob.

StartingandStoppingthe Engine

StartingtheEngine

1.MovethechokelevertotheOnposition(Figure12).

11

Page 12

Note:Awarmorhotenginemaynotrequirechoking.

G016610

G01661 1

2

3

4

tocooltheenginebeforestopping.Inanemergency,

theenginemaybestoppedimmediately .

2.TurntheignitionswitchtotheOffposition(Figure13).

UsingtheBrushChipper

ServiceInterval:Beforeeachuseordaily—Cleantheinside

ofthecuttingchambercover.

DANGER

Figure12

1.Choke

2.MovethethrottleleveronethirdofthewaytotheFast

position(Figure12).

3.TurntheengineignitionswitchtotheStartposition

(Figure13).

2.Throttle

Themachinewillcutandamputatehandsandfeet.

•Stayintheoperator'spositionwhilethemachine

isrunning.

•Keepallbystandersasafedistancefromthe

machine.

•Stopthemachineimmediatelyifanypeopleor

animalsentertheworkarea.

•Neverplaceanypartofyourbodyintoaposition

thatcausesanunsafeoperatingcondition.

WARNING

Usingthebrushchippermaythrowwoodchips,

soil,andotherdebrisintotheairwhichcouldinjure

youorbystanders.

•Alwayswearprotectivegear,suchassafety

gogglesorfaceshield,hearingprotection,

tight-ttinggloveswithoutdrawstringsorloose

cuffswhenusingthemachine.

Figure13

1.Ignitionswitch3.Run

2.Off4.Start

4.Aftertheenginestarts,releasekeytotheRunposition

(Figure13).

5.GraduallymovethechokeleverbacktotheOff

position.

Note:Iftheenginestallsorhesitates,movethechoke

backtoOnagainuntiltheenginewarmsup.Then

moveittotheOffposition.

6.MovethethrottlelevertotheFastpositiontobegin

chipping.

StoppingtheEngine

1.Movethethrottlelevertothemid-rangeposition.

Note:Iftheenginehasbeenworkinghardorishot,

letitrunforaminutebeforeturningitoff.Thishelps

•Keepfaceandbodyawayfromthefeedopening.

Donotoverreach.Keepproperbalanceand

footingatalltime.

•Keepallbystandersatleast15meters(50feet)

fromthemachineduringoperation.

1.Placethebrushchipperonlevel,dryground,

disconnectitfromthetowvehicle,andblockthefront

andbackofbothwheelstopreventanymovement.

2.Makesurethatyoureadalltherecommendationsfrom

theSafety(page3)sectionbeforeusingthebrush

chipper.

3.Starttheengine;refertoStartingtheEngine(page11)

andallowenginetowarmupatidlefortwominutes.

4.Lowerthehopper(Figure14).

12

Page 13

G016612

G016613

•Tomoveapileofprocessedmaterial,useaspade,

rake,orlonghandletool.Neveruseyourhands

orfeet!

•Limitthelengthoflargebranchesto3feetlong

orless;longerlengthscouldcausethechipperto

slowandjam.

•Washoutthecuttingchamberaftereachuseby

sprayingwaterfromagardenhoseintothehopper

whiletheengineisrunningatfullthrottle.Do

thisforafewminutestopreventaccumulationof

matterthatcandegradethechipperperformance.

Figure14

•Donotforcematerialintothechipper.Ifthe

machinedoesnotchipwell,thechipperknifeor

cutterblockmayneedtobesharpenedorreplaced.

•Extremelyhardknotsofwoodwillnotprocessvery

well.Shortstubsthathavenotself-fedthrough

thechippercanbepushedthroughwiththenext

branchtobechipped,otherwisesimplyclosethe

upperchute.

•Overloadingthehopperwillcausetherotorspeed

todecrease.IfyouheartheengineRPMdecreasing,

stopfeedingmaterialintothehopperuntilthe

enginehasreturnedtofullspeed(Figure15).

•Tostopthemachine;refertoStoppingtheEngine

(page12).

Figure15

•Ifyoujamthemachineanddonotstoptheengine,

itcandamagethemachine.Forthisreason,itis

importantthatyouimmediatelystoptheengineif

themachinebecomesjammed,wait5minutesto

makecertaintheywheelandallmovingpartshave

cometoacompletestopandcool.Disconnect

thesparkplugwires,keepingthemawayfromthe

sparkplugstopreventaccidentalstarting.

•Neverallowprocessedmaterialtobuildupwithin

76.2mm(3in)ofthedischargechuteopening.

Movethemachineorthepileasneeded.Failureto

dosocouldresultinunnecessaryjammingofthe

machine.

13

Page 14

Maintenance

G016615

Important:Beforeperforminganymaintenanceprocedures,rststoptheengine,wait5minutestoallowallmoving

partstocometoacompletestopandcool,anddisconnectthesparkplugwires.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst50hours

Beforeeachuseordaily

Every25hours

Every100hours

Every200hours

Every500hours

Yearlyorbeforestorage

Important:Refertoyour

MaintenanceProcedure

•Changetheengineoil.

•Checktheengineoillevel.

•Cleantheinsideofthecuttingchambercover.

•Greasethemachine.

•Checkthedrivebelttension.

•Checkthecutterblock.

•Inspectthecutterblades.

•Cleanthefoampre-lterontheairlter.

•Replacetheairlter.

•Changetheengineoil.

•Replacethedrivebelt.

•Inspectthetires.

•Checkthesparkplugs.

•Replacethefuellter.

•Lubricatewheelbearings.

•Replacethesparkplugs.

•Changetheengineoil.

Engine Operator's Man ual

foradditionalmaintenanceprocedures.

Lubrication

LubricatetheCutterWheel Bearings

ServiceInterval:Beforeeachuseordaily

GreaseType:General-purposegrease.

1.Cleanaroundgreasettingwitharagandlifttheplastic

capoffthegreasetting.

2.Pumpseveralshotsofgreaseintothettinguntilit

startstooozeoutofthebearing(Figure16).

Figure16

1.Greasetting2.Cutterwheelbearing

3.Wipeupanyexcessgrease.

Important:Pumpgreaseinslowlyandcarefully

topreventdamagetothebearingseals.

14

Page 15

LubricatetheWheelBearings

G016621

ServiceInterval:Every500hours

EngineMaintenance

LubricatethewheelbearingswithseveralpumpsofNo.2

generalpurposelithiumbasegrease(Figure17).

Figure17

1.Greasetting

ServicingtheAirCleaner

RemovingtheAirFilter

1.Unscrewtheknobandremovetheaircleanercover

(Figure18).

Figure18

1.Knob

2.Air-cleanercover

3.Covernut

4.Spacer

5.Cover

2.Carefullyslidethefoampre-lteroffofthepaper

element.

3.Unscrewthecovernutandremovethecover,spacer,

andpaperlter.

6.Foampre-lter

7.Paperlter

8.Rubberseal

9.Air–cleanerbase

CleaningtheFoamPre-Filter

ServiceInterval:Every25hours

1.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage.

2.Removethefoampre-lter;SeeRemovingtheAir

Filter(page15).

15

Page 16

3.Washthefoampre-lterinliquidsoapandwarmwater.

Whenclean,rinseitthoroughly .

4.Drythepre-lterbysqueezingitinacleanclothand

allowittoairdry.

5.Put1or2ouncesofengineoilonthepre-lter(Figure

19).

Figure19

Note:Thiswarmstheoilsoitdrainsbetter.

2.Parkthemachinesothatthedrainsideisslightlylower

thantheoppositesidetoensurethattheoildrains

completely.

3.Placeoneendofahoseonthedrainvalveandthe

otherendinapan(Figure20).

1.Foamelement

2.Oil

6.Squeezethepre-ltertodistributetheoil.

7.Carefullyslidethefoampre-lterontothepaperlter

(Figure18).

8.Installtheaircleanercoverandsecureitwiththeknob

(Figure18).

ReplacingtheAirFilter

ServiceInterval:Every100hours

Note:Donotcleanthepaperelement.Replacethepaper

elementifitisdirtyordamaged.

Topreventenginedamage,alwaysoperatetheenginewiththe

completefoamandpaperaircleanerassemblyinstalled.

1.Carefullyslidethefoampre-lterontothepaperlter

(Figure18).

2.Placetheaircleanerassemblyontotheaircleanerbase.

3.Installthecoverandspacerandsecureitwiththecover

nut.

4.Torquethenutto7N-m(60in-lb).

5.Installtheaircleanercoverandsecureitwiththeknob.

Figure20

1.Oildrainvalve

2.Hose

4.Openthedrainvalvebyturningitcounterclockwise,

pullingoutasyouturnit(Figure20).

5.Whentheoilhasdrainedcompletely,closethedrain

valvebypushinginandrotatingclockwise,andremove

thehose.Wipeupanyspilledoil.

Note:Disposeoftheusedoilatacertiedrecycling

center.

6.Removetheoldlterandwipethelteradaptergasket

surface(Figure21).

ServicingtheEngineOil

Note:Changetheoilmorefrequentlywhentheoperating

conditionsareextremelydustyorsandy.

OilType:DetergentoilwithanAPIserviceofSG,SH,SJ

orhigher.

CrankcaseCapacity:withlter1.9liters(2qt)

Viscosity:SAE10W -30isrecommendedforgeneraluse.

ChangingtheEngineOil

ServiceInterval:Aftertherst50hours

Every100hours

Yearlyorbeforestorage

1.Starttheengineandletitrunfor5minutes.

Figure21

1.Oillter

2.Gasket

3.Adapter

7.Pournewoilofthepropertypeinthroughthecenter

holeofthelter.Stoppouringwhentheoilreaches

thebottomofthethreads.

8.Allow1or2minutesfortheoiltobeabsorbedbythe

ltermaterial,thenpourofftheexcessoil.

9.Applyathincoatofnewoiltotherubbergasketon

thereplacementlter.

10.Installthereplacementoilltertothelteradapter.

Turntheoillterclockwiseuntiltherubbergasket

16

Page 17

contactsthelteradapter,thentightenthelteran

6

G017152

additional3/4turn.

11.Removetheoilllcapandslowlypourapproximately

80%ofthespeciedamountofoilinthroughthevalve

cover(Figure9).

CheckingtheSparkPlug

1.Lookatthecenterofthesparkplug(Figure23).Ifyou

seelightbrownorgrayontheinsulator,theengineis

operatingproperly .Ablackcoatingontheinsulator

usuallymeansthattheaircleanerisdirty.

12.Checktheoillevel;refertoCheckingtheEngine-Oil

Level(page10).

13.SlowlyaddadditionaloiltobringtheleveltotheFull

markonthedipstick.

14.Replacethellcap.

ServicingtheSparkPlug

ServiceInterval:Every200hours—Checkthesparkplugs.

Every500hours

Ensurethattheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingthesparkplug.Useasparkplug

wrenchforremovingandinstallingthesparkpluganda

gappingtool/feelergaugetocheckandadjusttheairgap.

Installanewsparkplugifnecessary.

Type:ChampionXC12YC(RFItype)orequivalent

AirGap:0.76mm(0.030inch)

RemovingtheSparkPlug

Important:Nevercleanthesparkplug.Always

replacethesparkplugwhenithasablackcoating,

wornelectrodes,anoilylm,orcracks.

Figure23

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

2.Checkthegapbetweenthecenterandsideelectrodes

(Figure23).Bendthesideelectrode(Figure23)ifthe

gapisnotcorrect.

1.Pullthewiresoffofthesparkplugs(Figure22).

Figure22

1.Sparkplugwire2.Sparkplug

2.Cleanaroundsparkplugs.

3.Removethesparkplugsandthemetalwashers.

InstallingtheSparkPlug

1.Threadthesparkplugintothesparkplughole.

2.Tightenthesparkplugto24.4–29.8N-m(18–22ft-lb).

3.Pushthewireontothesparkplug.

17

Page 18

FuelSystem

G016676

G016616

3

G016617

BeltMaintenance

Maintenance

ChangingtheFuelFilter

ServiceInterval:Every200hours

1.Clampthefuellinebetweenthecarburetorandthefuel

ltertoblockthefuelow.

2.Squeezetheendsofthehoseclampstogetherandslide

awayfromthefuellter(Figure24).

Figure24

1.Fuellter

2.Hoseclamp

3.Fuelhose

AdjustingtheDriveBelt Tension

ServiceInterval:Beforeeachuseordaily—Checkthedrive

belttension.

Note:Inspectthedrivebelttensionbyinsertingametal

scalethroughtheslotontopofthebeltcover(Figure25)

andpressingdownonthescalewithaforcegage.Theforce

shouldmeasure6.5-7.5kg(15±.75lbs)at1cm(0.40inch)

beltdeection.Adjustasrequired.

1.Removetheboltsandwasherssecuringthebeltguard

tomachine.

2.Removethebeltguard(Figure25).

3.Placeadrainpanunderthefuellinestocatchanyleaks,

thenremovethelterfromthefuellines(Figure24).

4.Installanewlter,witharrowpointingtowardthe

carburetor,andmovethehoseclampsclosetothelter.

5.Removetheclampblockingfuelow.

Figure25

1.Boltsandwashers3.Beltguard

2.Slotinbeltguard

3.Loosenthe4engineplatemountingboltsandthe4

boltssecuringtherearofthebeltguardtotheengine.

4.Loosenthebelttensionboltandjamnut(Figure26).

Figure26

1.Tensionboltandjamnut2.Engineplatemountingbolt

18

Page 19

5.Adjustthedrivebelttensionbylooseningthejam

G016618

G016620

nutandtighteningthetensionboltagainsttheengine

mountingplate,pushingtheenginerearward.

6.Layastraightedgeacrossclutchandywheelpulleys,

tightenbelttensionboltsothereis1cm(0.40inch)

ofexinthebeltwhenpushingdownwith6.8kg(15

lbs)force,atmid-span(whenre-tensioningabeltin

use)orwith8kg(18lbs)forcewheninstallinganew

belt(Figure27).

Figure27

1.Straightedge2.Flexof1cm(0.40inch)

CutterMaintenance

InspectingtheCutterBlock

ServiceInterval:Beforeeachuseordaily

Makesurethecutterblockhasacrispedgeandisnofarther

than3.2mm(1/8inch)awayfromtheblade.Ifthecutter

blockiswornorchippeditshouldbereplaced(Figure28).

Figure28

7.Ensurethatthepulleysarealignedandtheengineis

parallelwiththeframe(notangledtowardtheside),

thentightenthe4engineplatemountingbolts,the4

boltssecuringtherearofthebeltguardtotheengine,

andthejamnut.

8.Installthebeltguardandsecureitwiththepreviously

removedwashersandbolts.

ReplacingtheDriveBelt

ServiceInterval:Every100hours

Note:Replacethebeltifitshowsanysignsofwear,cracks,

glazing,ordamage.

1.Removetheboltsandwasherssecuringthebeltguard

tomachine.

2.Removethebeltguard(Figure25).

3.Loosenthe4engineplatemountingboltsandthe4

boltssecuringtherearofthebeltguardtotheengine.

4.Loosenthebelttensionboltandjamnut,slidethe

enginetowardtheywheelhousingtoloosenbelt

(Figure26).

5.Replacedrivebelt.

6.Adjusttensionofnewbeltto7.8-8.6kg(18±0.9lb)

forceat1cm(0.40inch)beltdeectionatmid-span.

7.Tightenthe4engineplatemountingbolts,the4bolts

securingtherearofthebeltguardtotheengine,and

thejamnut.

8.Installthebeltguardandsecureitwiththepreviously

removedwashersandbolts.

1.Blade

2.CutterBlock

ReplacingtheCutterBlades

ServiceInterval:Beforeeachuseordaily—Inspectthe

cutterblades.

Note:Usingadullbladewilldecreaseperformanceand

causeexcessivevibrationsthatwillcausedamagetotheBrush

Chipperorengine.

1.Removetheboltandwashersecuringtheywheel

housingcover,swingitforwardtoexposetheywheel.

2.Rotatetheywheelusingastickuntiltheboltsand

locknutsattachingthecutterbladestotheywheel

areaccessible(Figure29).

19

Page 20

G016619

Figure29

1

2

3

4

G003792

ChargingtheBattery

Important:Alwayskeepthebatteryfullycharged(1.265

specicgravity).Thisisespeciallyimportanttoprevent

batterydamagewhenthetemperatureisbelow32F

(05C).

Chargingthebatteryproducesgasesthatcanexplode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

1.Removethebatterycover.

2.Cleanthetopofthebatterywithapapertowel.

3.Chargethebatteryfor10to15minutesat25to30

ampsor30minutesat4to6amps.Donotovercharge

thebattery(Figure30).

1.Flywheel

2.Blade

3.Sequencefortightening

(3-1,3-2,3-3)

3.Removethedullordamagedcutterbladesandvisually

inspecttheywheelslots.Theblademountingareas

mustbecleansothereplacementbladeswillmount

ushagainsttheywheel.

Important:Itisveryimportanttoconsistently

maintainthe35-degreeangleforproperchipping

performance.

4.Reversethebladetousethesecondsharpedge,or

installneworsharpenedbladesandngertightenthe

boltsandlocknutstoholdthebladestotheywheel.

5.Tightenthecenterboltsandnutsrst,thentightenthe

outerboltsandnuts,andnallytightentheinnerbolts

andnut.Seesequencefortightening(Figure29).

6.Torquethebladeboltsto58-72N-m(43-53ft-lb).

7.Scrapeanysap,mulch,and/ordirtfrominsidethe

topcoverofthehousingtopreventtheywheelfrom

rubbingonit.

Figure30

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(-)chargerlead

4.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(Figure30).

5.Installthebatterycover.

20

Page 21

InspectingtheTires

InspectingtheTires

ServiceInterval:Every100hours

Note:Failuretomaintaincorrectpressuremayresultin

tirefailureandlossofcontrolresultinginseriousinjuryor

propertydamage.

•Operatingaccidentscandamageatireorrim,soinspect

tireconditionafteranaccident.

•Checkthetirepressurefrequentlytoensureproper

ination.Ifthetiresarenotinatedtothecorrect

pressure,thetireswillwearprematurely .

•AlwaysreplacewornordamagedtireswithDOT

approvedtires.

•LocatetheDOTtireidenticationnumbers(Figure31).

Figure33

Exampleoftirewearcausedbyover-ination.

1.Overinatedtire

Exampleoftirewearcausedbyunder-ination.

1.Underinatedtire

Figure31

Figure32

21

Page 22

Storage

Forstorageover30days,preparethemachineasfollows:

1.Removedirtandgrimefromtheexternalpartsofthe

entiremachine,especiallytheengine.Cleandirtand

sawdustchipsfromtheoutsideoftheenginecylinder

headnsandblowerhousing.

Important:Youcanwashthemachinewithmild

detergentandwater.

2.Addapetroleumbasedstabilizer/conditionertofuel

inthetank.Followmixinginstructionsfromstabilizer

manufacturer.(1oz.perUSgallon).Donotusean

alcoholbasedstabilizer(ethanolormethanol).

Note:Fuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasolineandusedatalltimes.

Important:Donotstorestabilizer/conditioned

gasolineover90days.

3.Runtheenginetodistributeconditionedfuelthrough

thefuelsystem(5minutes).

4.Stoptheengine,allowittocool,anddrainthefueltank

usingapumptypesiphon.Disposeoffuelproperly;

recycleasperlocalcodes.

5.Starttheengineandrunituntilitstops.

6.Choketheengine.

7.Startandruntheengineuntilitwillnotstartagain.

8.Changethefuellter;refertoChangingtheFuelFilter

(page18).

9.Servicetheaircleaner;refertoServicingtheAir

Cleaner(page15).

10.Changetheenginecrankcaseoil;refertoServicingthe

EngineOil(page16).

11.Removethesparkplugandchecktheconditionofthe

sparkplug;refertoServicingtheSparkPlug(page17).

12.Withthesparkplugremovedfromtheengine,pour

twotablespoonsofengineoilintothesparkplughole.

13.Pullthestarterslowlytocranktheengineanddistribute

theoilinsidethecylinder.

14.Installthesparkplug,butdonotinstallthewireon

thesparkplug.

15.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamaged.

16.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDealer.

17.Storethemachineinaclean,drygarageorstoragearea.

18.Coverthemachinetoprotectitandkeepitclean.

22

Page 23

Troubleshooting

Problem

Theenginewillnotstart.

Theenginerunsrough.

Chippingactionseemssloworthe

ywheelisstalling.

Theywheeldoesnotrotate.

PossibleCauseCorrectiveAction

1.Thechokeisopen.

2.Thefueltankisempty.2.Fillthetankwithfreshfuel.

3.Thesparkplugwireislooseor

disconnected.

1.Thechokeislefton.1.Openthechoke.

2.Theairlterisclogged.2.Cleanorreplacetheairlter.

3.Thefuellineisclogged.3.Cleanthesedimentcup.

4.Thereiswaterorcontaminantsinthe

fuel.

5.Thesparkplugsarewornorhave

buildupontheelectrodes.

1.Theenginespeedistooslowcausing

theclutchtoslip.

2.Checkforalooseordamageddrive

belt.

3.Checkfordullordamagedblades.

4.Theclutchshoesareworn.4.Replacetheclutch.

1.Build-upofchipsanddebrisaround

ywheel.

2.Thebeltislooseordamaged.

3.Theclutchoverheated,isdamaged,or

theshoesareworn.

1.Closethechokewhenstartingacold

engine.

3.Checktheelectrodegapandcleanor

replacethesparkplug.

4.Drainandllthetankwithfreshfuel.

5.Checktheelectrodegapandcleanor

replacethesparkplug.

1.Runtheengineatfullthrottle.

2.Tightenorreplacethedrivebelt.

3.Replacewithsharpblades.

1.Cleanoutthebuild-upofchipsand

debrisaroundtheywheel,onthe

outerdiameterofthewheel,upperlid

ofthegrinder,andinsidethehousing

cover.

2.Checkthedrivebelt.

3.Replacetheclutch.

Drivebeltisworn,burned,orjumpsoffof

pulley.

Themachinehasexcessivevibration.

1.Improperdrivebeltadjustment.

2.Thedrivebeltmaybestretched.2.Replacethedrivebelt.

3.Pulleysareoutofalignment.3.Aligntheengine/clutchpulleywith

1.Checkfordullordamagedblades.

2.Bladesmaynotbeproperlyseatedon

theywheel.

3.Gapbetweenthebladesandcutter

blockistoogreat.

1.Checkthedrivebelttension.

ywheel.

1.Replacewithsharpblades.

2.Loosentheblademountingscrews,

resetthebladesandtightenthe

screws.

3.Adjusttheywheelpositioninthe

housingtoattaina1/8inch(3mm)

clearancebetweenthebladeand

cutterblock.

23

Page 24

ToroCompactUtilityEquipmentWarranty

AOne-Y earLimitedWarranty

CompactUtilityEquipment

(CUE)Products

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,T oroWarrantyCompany,pursuantto

anagreementbetweenthem,jointlywarrantyourT oroCompactUtility

Equipment(“Product”)tobefreefromdefectsinmaterialsorworkmanship.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

ProSneak

CompactUtilityLoaders,

Trenchers,StumpGrinders,

andAttachments

KohlerEngines3years

AllotherEngines2years

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

*

SomeenginesusedonToroProductsarewarrantedbytheenginemanufacturer.

1yearor1000operatinghours,

whicheveroccursrst

*

*

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.ContactanyAuthorizedToroCompactUtilityEquipment(CUE)

ServiceDealertoarrangeserviceattheirdealership.Tolocatea

dealerconvenienttoyou,accessourwebsiteatwww.Toro.com.You

mayalsocallourToroCustomerCareDepartmenttollfreeatthe

numberbelow.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.

3.IfforanyreasonyouaredissatisedwiththeServiceDealer’s

analysisorwiththeassistanceprovided,contactusat:

SWSCustomerCareDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFree:888-384-9940

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutinemaintenance,

whetherperformedbyadealerorbyyou,isatyourexpense.Parts

scheduledforreplacementasrequiredmaintenance(“MaintenanceParts”),

arewarrantedfortheperiodoftimeuptothescheduledreplacementtime

forthatpart.Failuretoperformrequiredmaintenanceandadjustmentscan

begroundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarrantyperiod

aredefectsinmaterialsorworkmanship.Thisexpresswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,modied,orunapproved

accessories

•Productfailureswhichresultfromfailuretoperformrequired

maintenanceand/oradjustments

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligentorrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

productoperationinclude,butarenotlimitedto,belts,wipers,spark

plugs,tires,lters,gaskets,wearplates,seals,O-rings,drivechains,

clutches.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather ,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,or

chemicals,etc.

•Normal“wearandtear”items.Normal“wearandtear”includes,butis

notlimitedto,wornpaintedsurfaces,scratcheddecals,etc.

•Repairsnecessaryduetofailuretofollowrecommendedfuel

procedure(consultOperator'sManualformoredetails)

–Removingcontaminantsfromthefuelsystemisnotcovered

–Useofoldfuel(morethanonemonthold)orfuelwhichcontains

morethan10%ethanolormorethat15%MTBE

–Failuretodrainthefuelsystempriortoanyperiodofnon-use

overonemonth

•Anycomponentcoveredbyaseparatemanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

RepairbyanAuthorizedT oroCompactUtilityEquipment(CUE)Service

Dealerisyoursoleremedyunderthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletionof

repairsunderthiswarranty.Allimpliedwarrantiesofmerchantability

andtnessforusearelimitedtothedurationofthisexpresswarranty .

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sothe

aboveexclusionsandlimitationsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

ExceptfortheenginewarrantycoverageandtheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .The

EmissionsControlSystemonyourProductmaybecoveredbyaseparate

warrantymeetingrequirementsestablishedbytheU.S.Environmental

ProtectionAgency(EPA)ortheCaliforniaAirResourcesBoard(CARB).

ThehourlimitationssetforthabovedonotapplytotheEmissions

ControlSystemWarranty .RefertotheCaliforniaEmissionControl

WarrantyStatementsuppliedwithyourProductorcontainedintheengine

manufacturer’sdocumentationfordetails.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsoutsidetheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtainguarantee

policiesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguarantee

information,contacttheToroimporter .Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalToro

Dealer.

374-0261RevE

Loading...

Loading...