Page 1

Form No. 3366-331 Rev A

9 hp Log Splitter

Model No. 22606-Serial No. 310000001 and Up

Operator’s Manual

Register your product at www.Toro.com

Original Instructions (EN)

Page 2

This product complies to the US National Highway Traffic

Safety Administration (NHTSA) for street legal trailer.

WARNING

The engine exhaust from this product contains chemicals

known to the State of California to cause cancer, birth

defects, or other reproductive harm.

This spark ignition system complies with Canadian ICES-

002.

In some areas there are local, state, or federal regulations

requiring that a spark arrester be used on the engine of this

machine, a spark arrester is incorporated with the muffler

assembly. Genuine Toro spark arresters are approved by the

USDA Forestry Service.

This engine is equipped with a spark arrester muffler. It is

a violation of California Public Resource Code Section

4442 to use or operate the engine on any forest-covered,

brush-covered, or grass-covered land without a spark

arrester muffler maintained in working order, or the

engine constricted, equipped, and maintained for the

prevention of fire. Other states or federal areas may have

similar laws.

The enclosed Engine Owner’s Manual is supplied for

information regarding the US Environmental Protection

Agency (EPA) and the California Emission Control

Regulation of emission systems, maintenance, and

warranty. Replacements may be ordered through the

engine manufacturer.

This Manual identifies potential hazards and has safety

messages identified by the safety alert symbol, (Figure 1)

which signals a hazard that may cause serious injury or death

if you do not follow the recommended precautions.

Figure 1

1. Safety alert symbol

This manual uses two other words to highlight information.

Important calls attention to special mechanical information

and Note emphasizes general information worthy of special

attention.

Tire Information

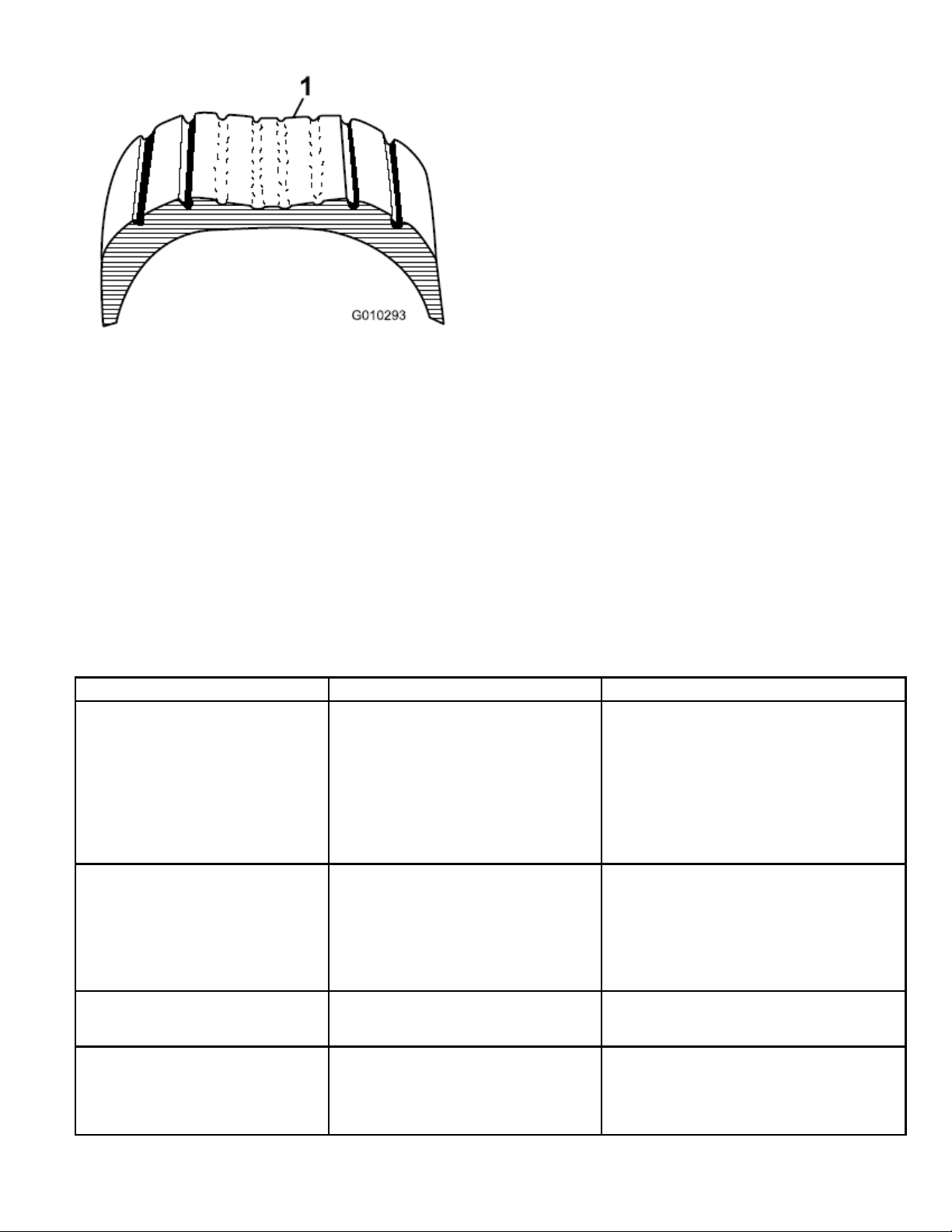

The tire identification number (TIN) is branded into the

sidewall of all street legal tires (Figure 2).

Figure 2

1. Tire identification number (TIN)

INTRODUCTION

This log splitter can operate in the horizontal or vertical

position. It is designed to split wood logs cut to a size to fit

within the machine splitting wedge opening. It is not intended

to split rock, metal, or any materials other than wood. The log

splitter can be towed behind a vehicle equipped with an

appropriate ball hitch.

You may contact Toro directly at www.Toro.com

and accessory information, help finding a dealer, or to register

your product.

Read this information carefully to learn how to operate and

maintain your product properly and to avoid injury and

product damage. You are responsible for operating the

product properly and safely.

Whenever you need service, genuine Toro parts, or additional

information, contact an Authorized Service Dealer or Toro

Customer Service and have the model and serial numbers of

your product ready. Write the numbers in the space provided.

for product

SAFETY

Hazard control and accident prevention are dependent

upon the awareness, concern, and proper training of the

personnel involved in the operation, transport,

maintenance, and storage of the machine. Improper use or

maintenance of the machine can result in injury or death.

To reduce the potential for injury or death, comply with

the following safety instructions.

Safe Operating Practices

This product is capable of crushing and amputating hands and

feet. Always follow all safety instructions to avoid serious

injury or death.

WARNING

Engine exhaust contains carbon monoxide, an odorless,

deadly poison that can kill you.

Do not run the engine indoors or in an enclosed area.

If you believe that your vehicle* has a defect which could

cause a crash or could cause injury or death, you should

immediately inform the National Highway Traffic Safety

Administration (NHTSA) in addition to notifying The Toro

Company.

2

Page 3

If NHTSA receives similar complaints, it may open an

investigation, and if it finds that a safety defect exists in a

group of vehicles*, it may order a recall and remedy

campaign. However, NHTSA cannot become involved in

individual problems between you, your dealer, or The Toro

Company.

To contact NHTSA, you may call the Vehicle Safety Hotline

toll-free at 1–888–327–4236 (TTY: 1–800–424–9153); go to

http://www.safercar.gov ; or write to: Administrator, NHTSA,

400 Seventh Street, SW., Washington, DC 20590. You can

also obtain other information about motor vehicle safety from

http://www.safercar.gov.

* log splitter

Training

• Read the Operator’s Manual and other training material. If

the operator(s) or mechanic(s) can not read English, it is the

owner’s responsibility to explain this material to them.

• Do not allow anyone to operate the machine who has not

read the Operator’s Manual or has not been instructed on the

safe use of the machine.

• Never let children or untrained people operate or service the

equipment. Local regulations may restrict the age of the

operator.

• Many accidents occur when more than one person operates

the machine. If a helper is assisting in loading logs, never

activate the control until the helper is a minimum of 10 feet

from the machine.

• All operators and mechanics should be trained. The owner is

responsible for training the users.

Hydraulic log splitters develop high fluid pressures during

operation. Hydraulic fluid escaping through a pin hole

opening can penetrate your skin and cause blood poisoning or

death. Follow these instructions at all times:

• Do not operate machine with frayed, kinked, cracked, or

damaged hoses, fitting, or tubing.

• Stop the engine and relieve hydraulic system pressure

before changing or adjusting fittings, hoses, tubing, or

other system components.

• Do not adjust the pressure settings of the pump or valve.

• Do not check for leaks with your hand.

• Leaks can be detected by passing cardboard or wood,

while wearing protective gloves and safety glasses, over

the suspected area. Look for discoloration of cardboard

or wood.

• Keep the operator zone and adjacent area clear for safe,

secure footing.

Towing

Check with your local county or state safety towing

regulations, in addition to meeting Department of

Transportation (DOT) Safety Towing Regulations, before

towing the log splitter.

• In order to reduce the possibility of an accident while

transporting the log splitter on public roads, ALWAYS make

sure the towing vehicle is mechanically sound and in good

operating condition.

• ALWAYS shutdown engine before transporting.

• ALWAYS inspect the hitch and coupling for wear. NEVER

tow the debris blower with defective hitches, couplings,

chains, etc.

• Check the tire air pressure on both towing vehicle and

debris blower. The log splitter tires should be inflated to 60

psi

(410 kpa) cold.

• Check the tire tread for wear.

• ALWAYS properly attach the safety chains to towing

vehicle.

• ALWAYS make sure that the towing vehicle’s directional,

backup, and brake lights are working properly.

• Avoid sudden stops and starts. This can cause skidding, or

jack knifing. Smooth, gradual starts and stops will improve

towing.

• Avoid sharp turns to prevent rolling. Tow only with a

vehicle that has a hitch designed for towing. Do not attach

towed equipment except at the hitch point.

Before towing check to make certain your log splitter is

correctly and securely attached to the towing vehicle.

• Be sure that the ball hitch you are using is the proper size

for the hitch coupler on the log splitter.

• Be sure the safety chains are properly hooked to the

vehicle leaving enough slack for turning.

• Always turn the fuel valve to the OFF position.

• Be sure the log splitter is secured in the horizontal

position.

• Be sure the jack stand is secured in the UP position.

• Do not tow machine faster than 45 mph (75 km/ h).

• Use caution when backing up; use a spotter outsi de the

vehicle to guide you.

• Do not allow anyone to sit or ride on unit when towing.

• Never carry any cargo or wood on unit when towing.

• Always disconnect the unit from the tow vehicle before

using it.

• Place chock blocks underneath wheel to prevent rolling

while unit is parked.

Preparation

Become familiar with the safe operation of the equipment,

operator controls, and safety signs.

• Always wear safety shoes or heavy boots.

• Always wear safety glasses or safety goggles during

operating this machine.

• Wear tight fitting gloves without draw strings or loose

cuffs.

• Never wear jewelry or loose clothing that might become

entangled in moving or rotating parts of the machine.

• Make sure machine is on level surface before operating.

• Always operate this machine from the operator zone

specified in the manual.

3

Page 4

• Logs should be cut with ends as square as possible prior to

splitting.

• Block the machine to prevent unintended movement, and

lock in either horizontal or vertical position.

• Use extra care when handling gasoline and other fuels. They

are flammable and vapors are explosive.

• Use only an approved fuel container.

• Never remove the gas cap or add fuel when the engine is

running. Allow the engine to cool before refueling. Do

not smoke.

• Never refuel or drain the machine indoors.

• Replace gasoline cap and tighten securely.

• Keep container nozzle in contact with the tank during

filling.

• If gasoline is spilled, wipe it off the engine and

equipment.

• Never attempt to split more than one log at a time.

• For logs which are not cut square, the least-square end and

the longest portion of the log should be placed toward the

beam and wedge, and the square end placed toward the end

plate.

• Keep the work area clean; remove split logs from around the

machine so you do not slip on them.

• Do not touch parts which may be hot from operation. Allow

them to cool before attempting to maintain, adjust, or service.

• Locate the pinch point areas marked on the machine and

keep hands and feet away from these areas.

• Never run an engine in an enclosed area.

• Never move this machine while the engine is running.

• Lightning can cause severe injury or death. If lightning is

seen or thunder is heard in the area, do not operate the

machine; seek shelter.

• Do not touch the engine or muffler while the engine

Operation

Before every use:

• Inspect the coupler, ball and hitch.

• Always use safety chains.

• Verify all lights are functioning properly.

• Verify the tires are properly inflated as recommended on

tires.

• Verify lug nuts are tight and torqued properly.

• Machine is properly secured.

• Before starting this machine, review the “Safety

Instructions” Failure to follow these rules may result in

serious injury to the operator or bystanders.

• Never leave this machine unattended with the engine

running.

• Never operate machine while under the influence of alcohol,

drugs, or medication.

• Never allow anyone to operate this machine without proper

instruction.

• Always operate this machine with all safety equipment in

place and working.

• Do not change the engine governor setting or over speed the

engine.

• Use only your hand to operate the control lever.

Always keep hands and feet clear of moving parts.

• Never place your hands or feet between the log and the

splitting wedge or between the log and the ram during the

forward or reverse stroke.

• When loading a log, place your hands on the sides of the

log, not on the ends. Never place your hands or any part of

your body between a log and any part of the log splitter.

is running or soon after it is stopped. These areas

could be hot enough to cause a burn.

Maintenance and Storage

• Stop the engine and remove the spark plug wire before

making any repairs. Wait for all movement to stop before

adjusting, cleaning, or repairing.

• Inspect the machine before each use. Make sure all nuts,

bolts, screws, hydraulic fittings, hose clamps, are securely

tightened.

• Clean debris from the muffler and engine to help prevent

fires. Clean up oil or fuel spillage.

• Let the engine cool before storing and do not store near

flame.

• Do not store fuel near flames or drain indoors.

• Park the machine on level ground. Never allow untrained

personnel to service the machine.

• Keep hands and feet away from moving parts. If possible,

do not make adjustments with the engine running.

• Keep all parts in good working condition and all hardware

tightened. Replace all worn or damaged decals.

• Use extra care when handling gasoline and other fuels. They

are flammable and vapors are explosive.

• Never store the machine or fuel container inside where there

is an open flame, such as near a water heater or furnace.

• Use only genuine Toro replacement parts to ensure that

original equipment standards are maintained.

• Do not straddle or reach across the log splitting area when

operating the machine.

4

Page 5

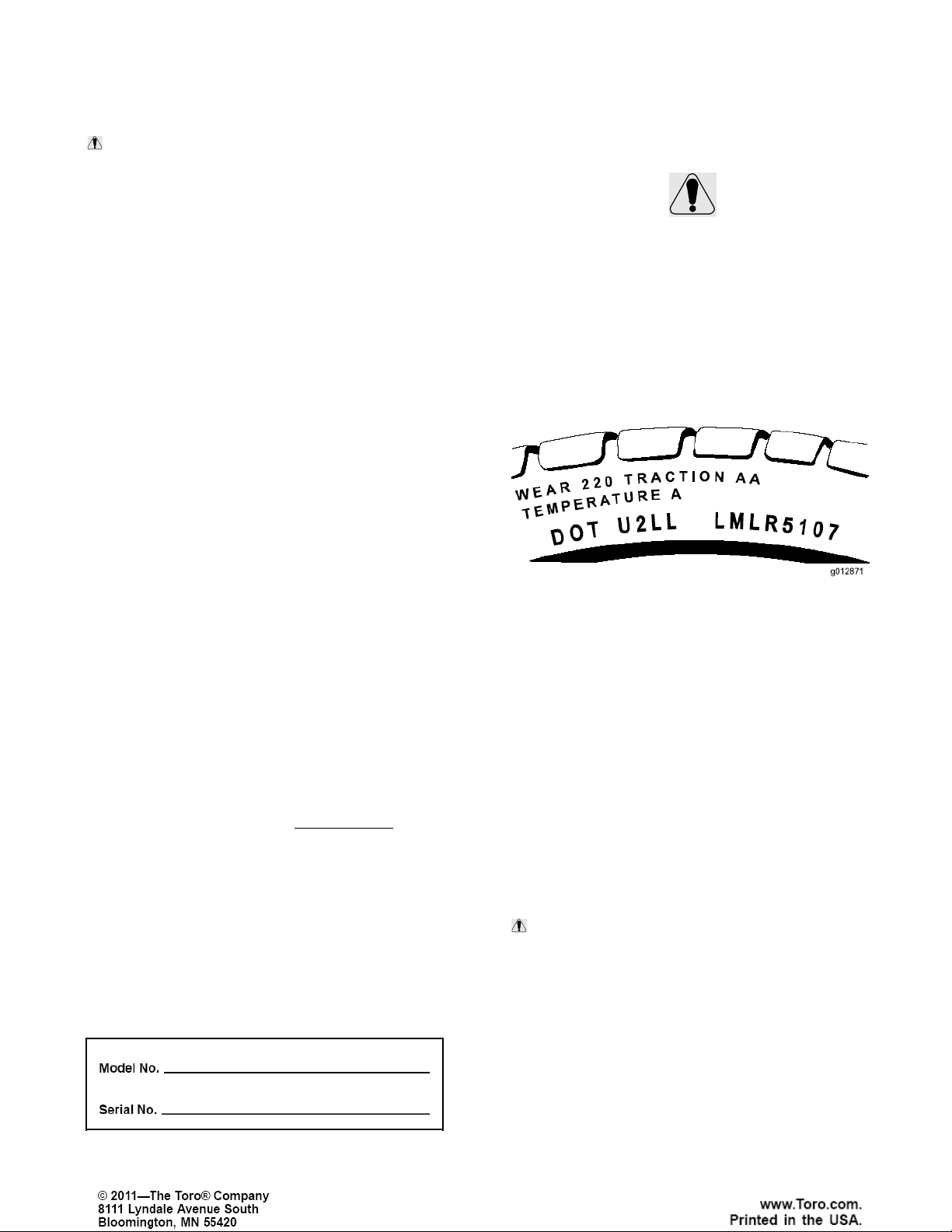

Safety and Instructional Decals

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any

decal that is damaged or lost.

1. Warning – read the Operator’s Manual. 4. Thrown object hazard – keep bystanders a safe distance from

the machine.

2. Warning – lower splitter to lock position. 5. Broken hydraulic lines hazard – do not use machine if lines are

cracked, broken or leaking.

3. Pinch point, hand – stay away from moving parts; keep all 6. Split logs with the grain – not across the grain.

guards in place.

119-4696

119-4695

1. Warning – do not exceed 45 mph (72 km/h) when transporting

the machine.

119-4697

1. To operate 1 - start the engine, 2 - move the lever to engage the

machine 3 - release the lever to disengage the machine.

2. Cutting/dismemberment of hand, blade – do not place hands on

the wood when engaging the splitter.

119-4694

1. Warning – read the Operator’s Manual.

2. Warning – learn how to lower splitter to lock position

3. Thrown object hazard – wear safety glasses.

4. Thrown object hazard – keep bystanders a safe distance from

the machine.

5. Pinch point hazard – keep hands away from moving parts.

117-2718

120-1853

120-1854

5

Page 6

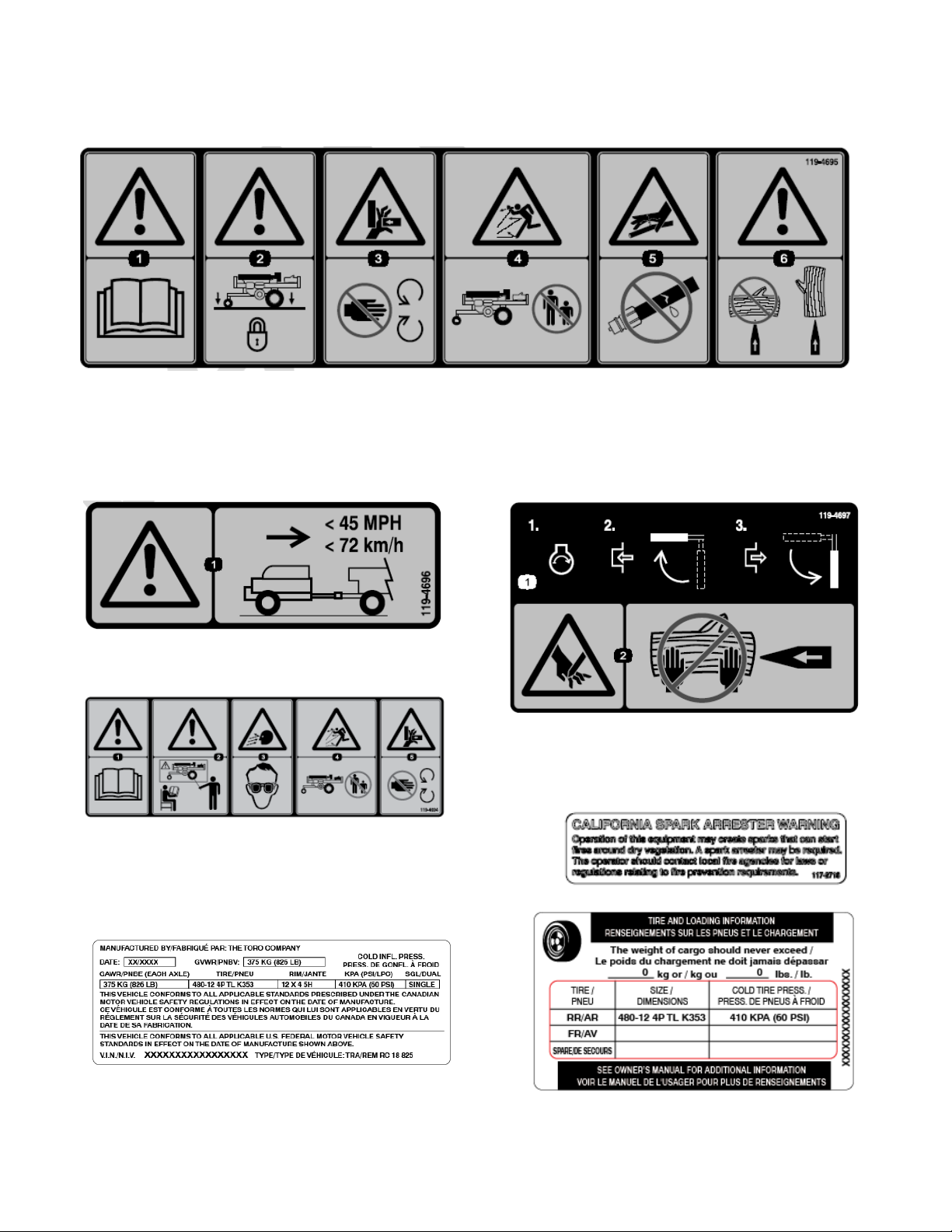

Product Overview

7

5

8

6

3

1

2

9

Figure 3

1. Coupler 9. Hydraulic filter

2. Safety Chains 10. Fuel cap

3. Jack stand 11. Air filter

4. Rail locking pin 12. Throttle

5. Control lever 13. Choke

6. Splitting wedge 14. Starter

7. End plate 15. Fuel valve

8. Hydraulic reservoir 16. Fuel filter

4

13

15

16

10

12

14

Controls

Control Lever

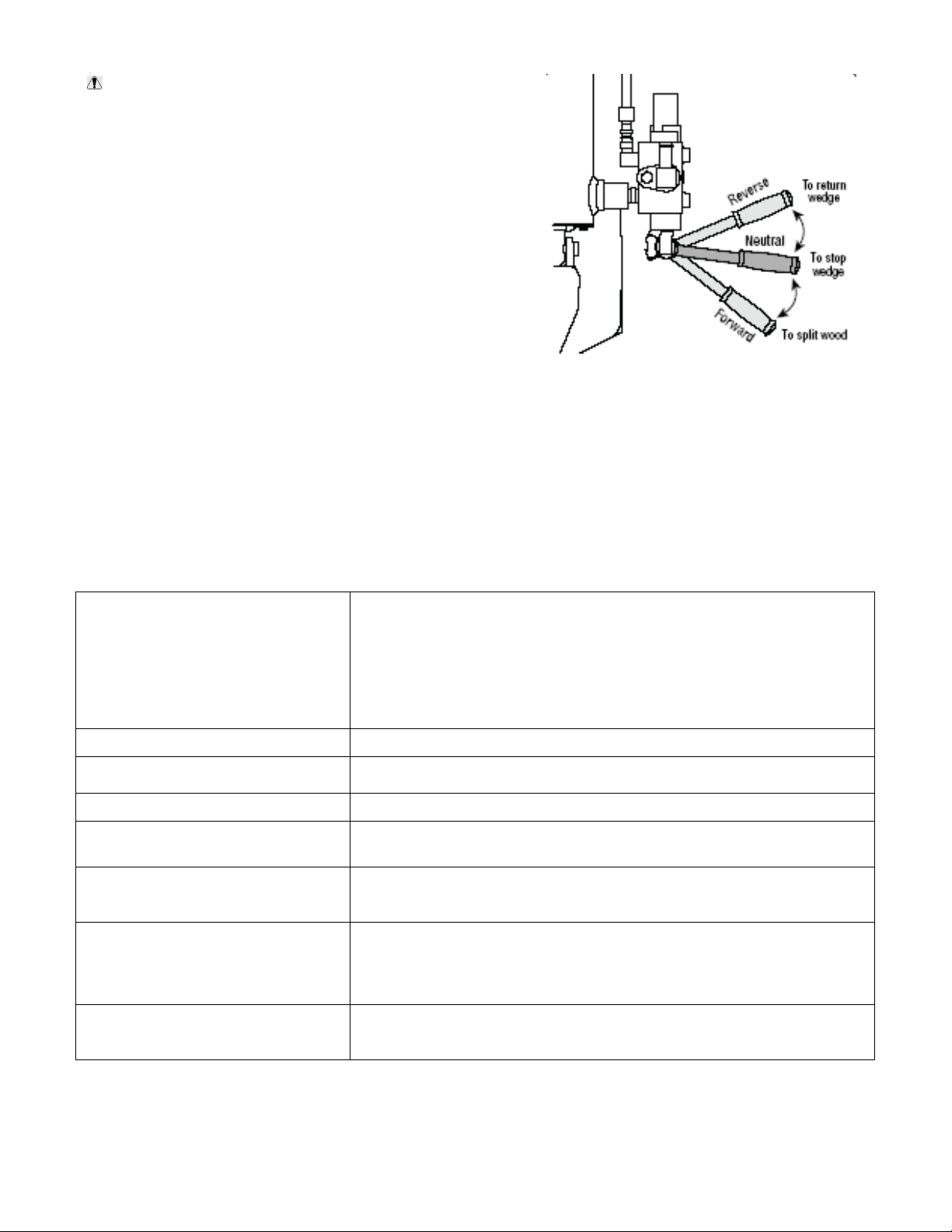

The control lever (Figure 4) actuates the hydraulic valve that

moves the splitting wedge forward (out) and reverse (back)

during the log splitting process.

Holding the control lever toward the end plate moves the

splitting wedge forward (out).

Releasing the control lever stops wedge movement.

Moving the control lever to the reverse (back) position

retracts the wedge. Moving the lever to the fully retracted

position causes the spitting wedge to retract automatically all

the way.

Figure 4

1. Control lever

6

Page 7

Specifications

Operating Positions .............................. Vertical/Horizontal

Slide Rail .................... 6 inch (15 cm) heavy-duty, I-beam

Wedge ................... 9 inch (22.5 cm) with compound angle

Engine .................................. 9 HP (6.7 kW) Robin/Subaru

Force/Tonnage ..................................... 28 ton (30.9 m ton)

Cylinder Stroke ...................................... 24 inches (60 cm)

Log Opening ......................... 25 inch (62.5 cm) maximum

Cycle Time ........................................ 12 seconds (approx.)

Wheels & Tires ............................... High-Speed, 4.80 x 12

Hitch Coupler ................................................ 2 inch (5 cm)

Safety Chains ........................................................ Standard

Jack Stand with two caster wheels ................. 4.10/3.50 x 4

Length .................................................. 97 inches (246 cm)

Width ............................................... 53.1 inches (135 cm)

Height .............................................. 45.5 inches (115 cm)

Weight ..................................................... 826 lbs (375 Kg)

• If coupler hitch is too loose on the ball: Turn adjustment

nut one turn clockwise.

WARNING

Failure to properly engage the hitch ball in the coupler

ball socket and securely lock the coupler latch mechanism

can cause the unit to become detached from the tow

vehicle while traveling, which may cause serious injury

and property damage.

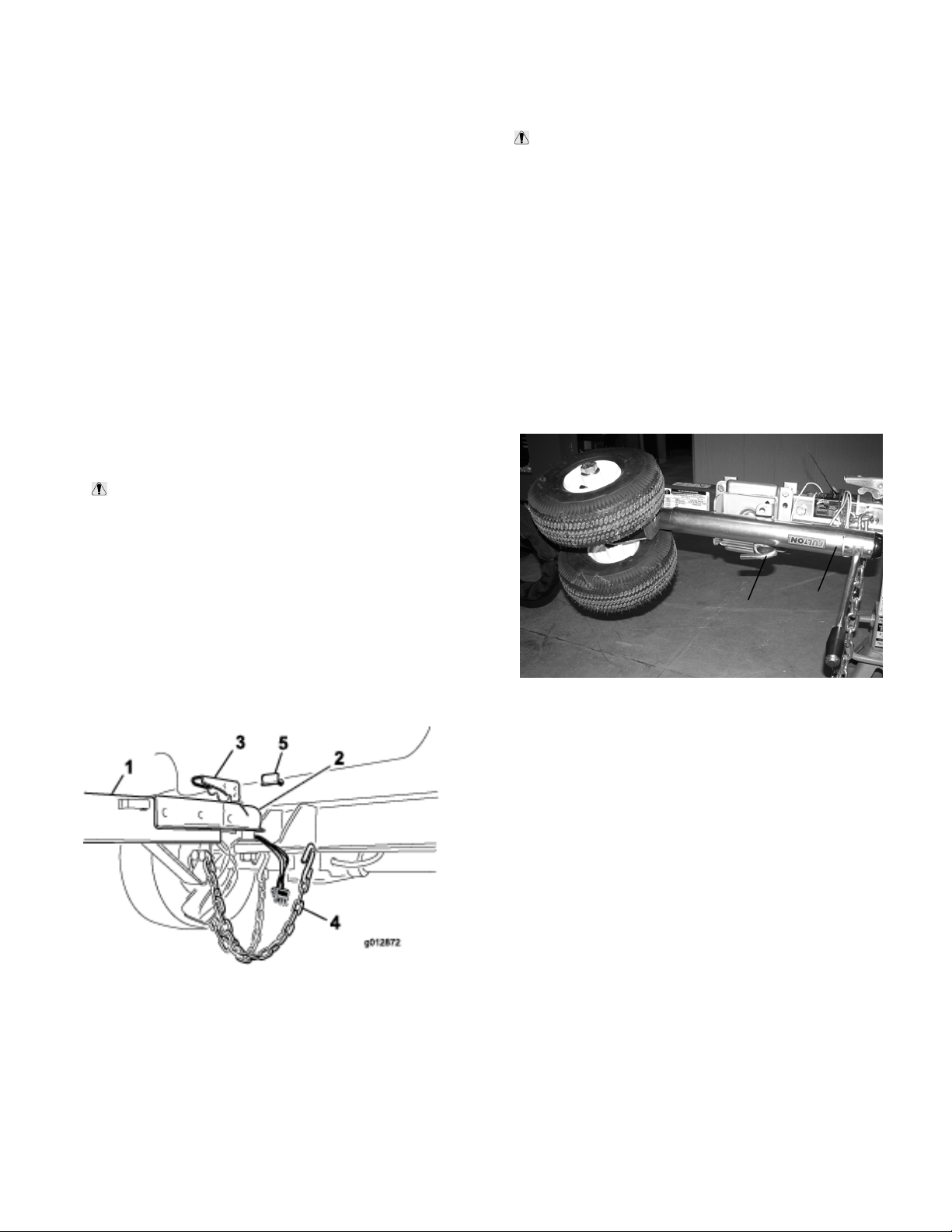

Install the locking pin to secure the lever (Figure 5).

Cross or “X” the safety chains and attach them to the holes on

the hitch.

Plug tail light wire harness connector to the tow vehicle

connector. Check to make sure the brake lights illuminate

properly with the brake pedal applied and the taillights flash

when the turning signals are use.

Towing

WARNING

Do not tow over 45 mph (75 km/h).

IMPORTANT Always turn fuel valve to the OFF position

before transporting the log splitter.

Lower the rail I-beam of the log splitter to the horizontal

position and lock with rail locking pin.

Crank the handle of the lift jack to align the coupler with the

ball of the tow vehicle.

Remove the locking pin from the lever, squeeze the latch lock

and lift the lever up to open the coupler (Figure 5).

Figure 5

1. Tongue 4. Safety chains

2. Coupler 5. Locking pin

3. Lever in locked position

Attach coupler to a class I or higher 2 inch

(50.8 cm) ball on a towing vehicle and latch securely.

• If coupler does not fit over the ball: Turn adjustment nut

one turn counter-clockwise.

2

Figure 6

1. Jack stand 2. Release pin

Raise jack stand (Figure 6) so caster wheels are free of the

ground, pull the release pin and rotate wheels rearward and

lock in the horizontal position.

1

Tires and Wheels

The most common cause of tire trouble is under-inflation. It is

important that you maintain full air pressure as indicated by

the tire manufacturer on the tire’s sidewall or on the trailer

manufacturer’s certification label.

Inflate main axle tires to ....................... 60 psi (410 kpa)

Check the torque of the wheel lug nuts initially and after the

first 10 hours of operation.

Torque wheel lug nuts to .... 80-90 ft. lbs (108-122 N·m)

7

Page 8

• When practical, remove gas-powered equipment from

Operation

Before You Start

Review all the machine’s safety decals.

Disconnect the unit from the tow vehicle, position it on a

level location and block the wheels front and back to prevent

it from moving.

Ensure you are familiar with safety regulations and shutdown

procedures described in the Operator’s Manual.

Before loading and operating the log splitter, always wear

protective gear, such as safety goggles, face shield, hearing

protection, tight fitting gloves without draw strings or loose

cuffs, and steel-toed shoes.

Ensure that the work area is free of wood and debris that you

could trip and fall over.

Check the fuel and oil level of the engine, and the hydraulic

fluid in the reservoir.

Adding Fuel

Use unleaded gasoline (87 pump octane minimum). Leaded,

regular gasoline may be used if unleaded us not available.

WARNING

In certain conditions, gasoline is extremely flammable

and highly explosive. A fire or explosion from gasoline

can burn you and others and can damage property.

• Fill the fuel tank outdoors, in an open area, when the

engine is cold. Wipe up any gasoline that spills.

• Never fill the fuel tank inside an enclosed trailer.

• Do not fill the fuel tank completely full. Add gasoline to

the fuel tank until the level is 1/4 to 1/2 inch (6 to 13 mm)

below the bottom of the filler neck. This empty space in

the tank allows gasoline to expand.

• Never smoke when handling gasoline, and stay away

from an open flame or where gasoline fumes may be

ignited by a spark.

• Store gasoline in an approved container and keep it out

of the reach of children. Never buy more than a 30-day

supply of gasoline.

• Do not operate without entire exhaust system in place

and in proper working condition.

the truck or trailer and refuel the equipment with its

wheels on the ground.

• If this is not possible, then refuel such equipment on a

truck or trailer from a portable container, rather than

from a gasoline dispenser nozzle.

• If a gasoline dispenser nozzle must be used, keep the

nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is complete.

Do not use methanol, gasoline containing methanol, or

gasohol containing more than 10% ethanol because the fuel

system could be damaged. Do not mix oil with gasoline.

Using Stabilizer/Conditioner

Use a fuel stabilizer/conditioner in the machine to provide the

following benefits:

• Keeps gasoline fresh during storage of 90 days or less. For

longer storage it is recommended that the fuel tank be

drained.

• Cleans the engine while it runs.

• Eliminates gum-like varnish buildup in the fuel system,

which causes hard starting.

Do not use fuel additive s containing methanol or ethanol.

Add the correct amount of gas stabilizer/conditioner to the

gas.

A fuel stabilizer/conditioner is most effective when mixed

with fresh gasoline. To minimize the chance of varnish

deposits in the fuel system, use fuel stabilizer at all times.

Filling the Fuel Tank

1. Park the machine on a level surface and stop the engine.

2. Allow the engine to cool.

3. Clean around the fuel tank cap and remove it

(Figure 7).

1

WARNING

In certain conditions during fueling, static electricity can

be released causing a spark which can ignite the gasoline

vapors. A fire or explosion from gasoline can burn you

and others and can damage property.

• Always place gasoline containers on the ground away

from your vehicle before filling.

• Do not fill gasoline containers inside a vehicle or on a

truck or trailer bed because interior carpets or plastic

truck bed liners may insulate the container and slow the

loss of any static charge.

8

1. Fuel tank cap

4. Only fill tank to bottom of the fill neck tube, do not

overfill.

Figure 7

Page 9

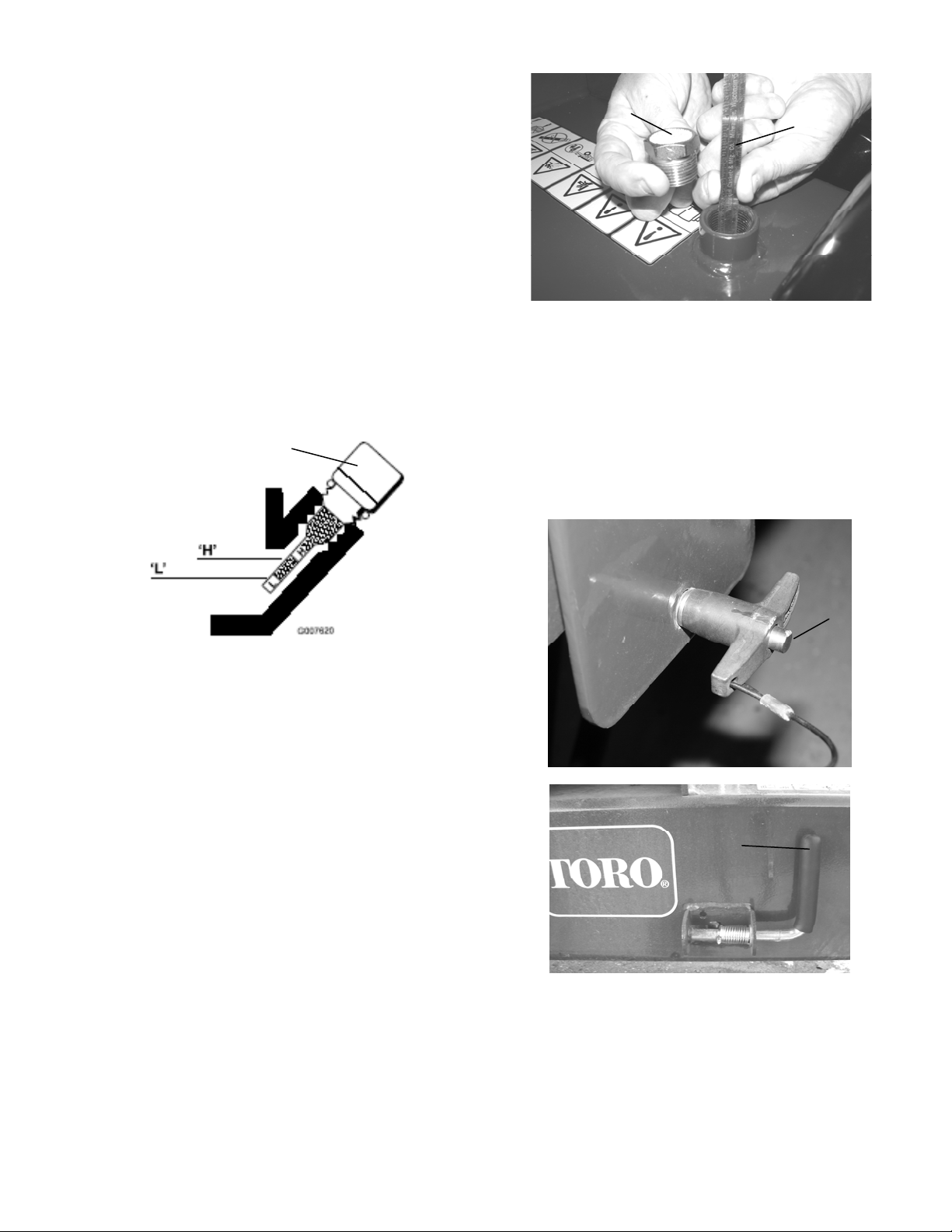

Checking the Engine Oil Level

The best time to check the engine oil is when the engine is

cool before it has been started for the day. If it has already

been run, allow the oil to drain back down to the sump for at

least 10 minutes before checking. If the oil level is at or

below the “L” mark on the dipstick, add oil to bring the oil

level to the “H” mark. Do not overfill. If the oil level is

between the “H” and “L” marks, no oil addition is required.

1. Place the machine on a flat level surface, and stop the

engine.

2. Allow the engine to cool.

3. Clean around the oil dipstick.

4. Remove the dipstick and wipe the end clean.

5. Slide the dipstick fully into the dipstick tube without

threading it into the filler neck.

6. Pull the dipstick out and look at the end. The oil should be

to the top of the upper limit range (Figure 8).

1

1. Vent plug 2. Ruler

Changing the Rail Position

The rail I-beam on this machine can be rotated to use in the

horizontal or vertical position.

1. To move the rail into the vertical position, press the springloaded button on the rail locking pin handle IN and pull the

rail locking pin from the lock down plate (Figure 10).

2. Set the vertical lock lever in the open position.

3. Lift and rotate the rail I-beam into the vertical position.

1

Figure 9

2

1

1. Oil dipstick

Running the engine with low o il level can cause engine

damage. This type of damage is not covered by warranty.

7. If the oil level is low, slowly pour only enough oil into the

crankcase to raise the level to the upper limit. See

Maintenance section for oil specifications.

Do not overfill the crankcase with oil because the engine

may be damaged.

8. Replace the dipstick.

Figure 8

2

Checking the Hydraulic Fluid

Level

Check the hydraulic fluid level daily, before each use. The

best time to check the hydraulic fluid is when the unit is cool

before it has been started for the day.

1. Place the machine on a flat level surface.

2. Clean around the hydraulic vent plug (Figure 9).

3. Remove the hydraulic vent plug and measure the hydraulic

fluid level.

4. Maintain fluid level 3 inch (7.6 cm) below the top of the

tank fitting, with the cylinder retracted. If the hydraulic

fluid is low, add SAE 10W30 or 15W40 Diesel Engine

Oil, API Service CH-4 or higher.

9

1. Rail Locking Pin - Button 2. Vertical locking pin

4. Rotate the handle or the vertical locking lever so it engages

the lower rail of the I-beam locking to secure it in the

vertical position (Figure 10).

Figure 10

Page 10

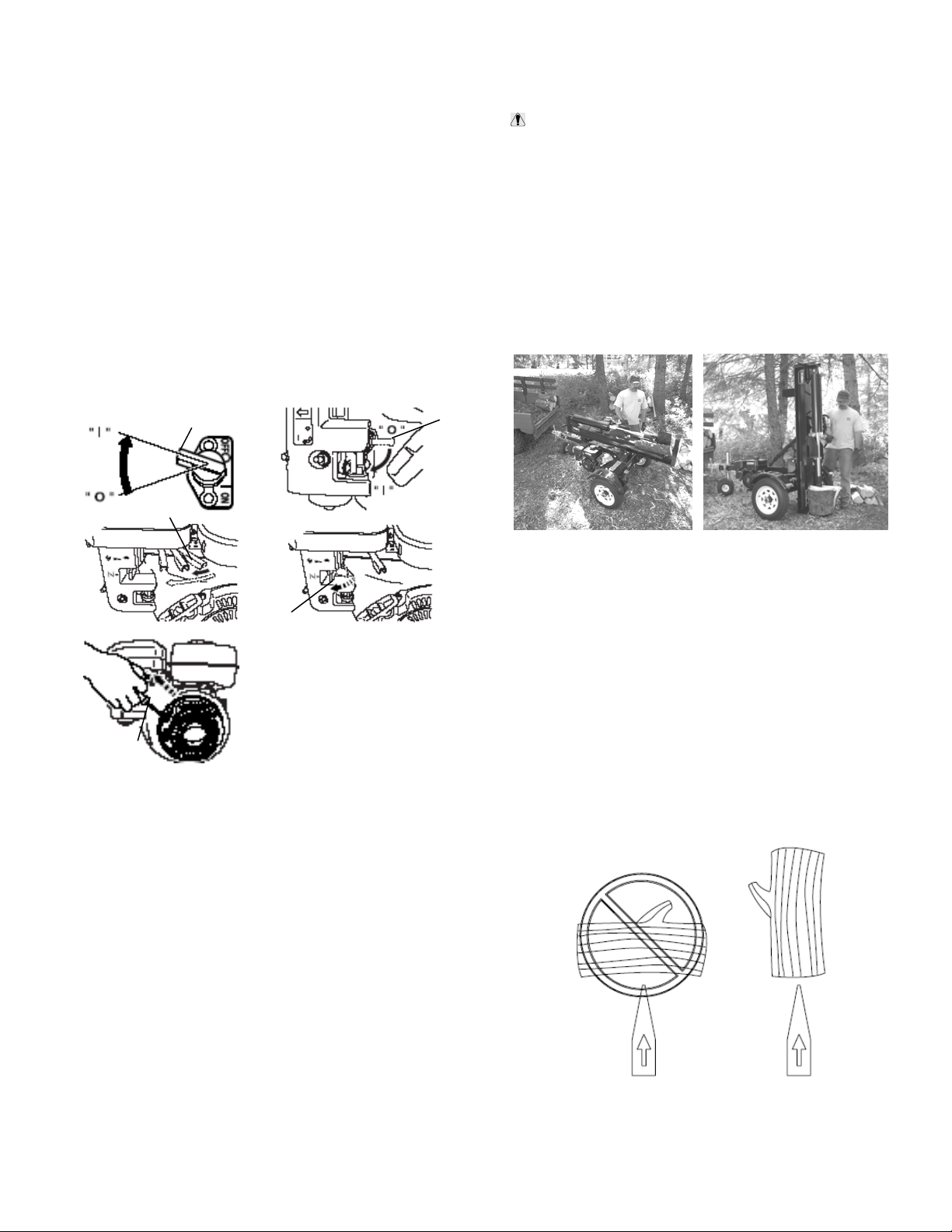

Starting and Stopping the

Engine

Starting the Engine

1. Turn the engine ON/OFF switch to the “I” ON position

(Figure 11-1).

2. Move the choke lever left to the ON position if you are

starting a cold engine (Figure 11-2). A warm or hot

engine may not require choking.

3. Move the throttle lever 1/3 way to the FAST position

(Figure 11-3).

4. Move the fuel valve to the Open position, all the way to

the right (Figure 11-4).

5. Pull the starter handle lightly until you feel resistance, then

pull the handle briskly (Figure 11-5). Return the starter

handle gently.

2

3

1

Using the Log Splitter

WARNING

Do not attempt to operate the log splitter without fully

understanding all instructions, safety precautions, and/or

warnings.

• Always wear protective gear, such as safety goggles, face

shield, hearing protection, tight-fitting gloves without

draw strings or loose cuffs, and steel-toed shoes, when

using the machine.

• Make sure you are standing in the safe operating area,

as shown in these pictures. You must stay in the safe

operating area at all times when the splitting wedge is in

motion (whether extending or retracting).

• Never place any part of your body into a position that

causes an unsafe operating condition.

4

5

1. ON/OFF Switch 4. Fuel Valve

2. Choke 5. Starter

3. Throttle

6. After the engine starts, gradually move the choke lever

back to the Off position. If the engine stalls or hesitates,

move the choke back to On again until the engine warms

up. Then move it to the Off position.

7. Move the throttle lever to the FAST position.

Figure 11

Stopping the Engine

1. Move the throttle lever to the SLOW position. If the engine

has been working hard or is hot, let it run for a minute

before turning off. This helps to cool the engine before

stopping. In an emergency, the engine may be stopped

immediately.

2. Turn the engine ON/OFF switch to the “O” OFF position.

3. Move the fuel valve to the Closed position, all the way to

the left.

1. Place the log splitter on level, dry ground and block the

front and back of both wheels to prevent any movement.

2. Make sure you read all the recommendations from the

“Safety” section before using the log splitter.

3. Adjust the rail position horizontal or vertical as desired and

lock in position.

4. Start the engine; refer to Starting the Engine and allow

engine to warm up at idle for two minutes.

5. Make sure both ends of the log you are splitting are cut as

square as possible. This will prevent the log from sliding

out of position while under pressure. All logs should be

shorter than 24 inches (60 cm) long.

6. Place the log against the end plate and only split wood in

the direction of the grain.

Figure 12

IMPORTANT Never attempt to split logs across the grain

(Figure 12).

10

Page 11

CAUTION

Do not place your hands on the ends of the log when

loading the log splitter. This is a very UNSAFE method

and could result in injury to your hands.

• Only use your hand to push the control lever forward

(towards the log). If the log moves before it is contacted by

the splitting wedge, do not touch it while the wedge is

moving. Release the control lever, then reposition the log.

• Operate the log splitter only when standing in the safe

operating zone by the control lever (Figure 13).

Figure 13

1. Control lever

7. Only one adult should stabilize the log and operate the

control handle, to ensure full control over the log and the

splitting wedge.

8. To stop the machine; refer to Stopping the Engine.

Maintenance

Maintenance Schedule

Daily - before each use Check the engine oil level

Check the hydraulic fluid level

Grease the rail I-beam

Remove debris from the unit

Check for loose fasteners or damaged components

Initial 20 hours Change the engine oil

Every 25 hours Check the hydraulic lines for leaks, loose fittings, kinked lines, loose mounting

supports, wear, weather, and chemical deterioration

Every 50 hours Clean the air filter

Every 100 hours - after the initial oil

change

Every 100 hours Change the hydraulic fluid

Every 200 hours Change the air filter

Change the engine oil

Change the hydraulic filter

Clean the fuel filter

Clean and adjust the spark plug

Every 500 hours Change the spark plug

Lubricate the wheel bearings

11

Page 12

Servicing the Air Cleaner

Service Interval: Every 50 hours

Clean the air filter. Replace the air filter every 200 hours or

once a month.

1. Make sure wire is off spark plug.

2. Remove cover over the air cleaner and clean cover

thoroughly (Figure 14).

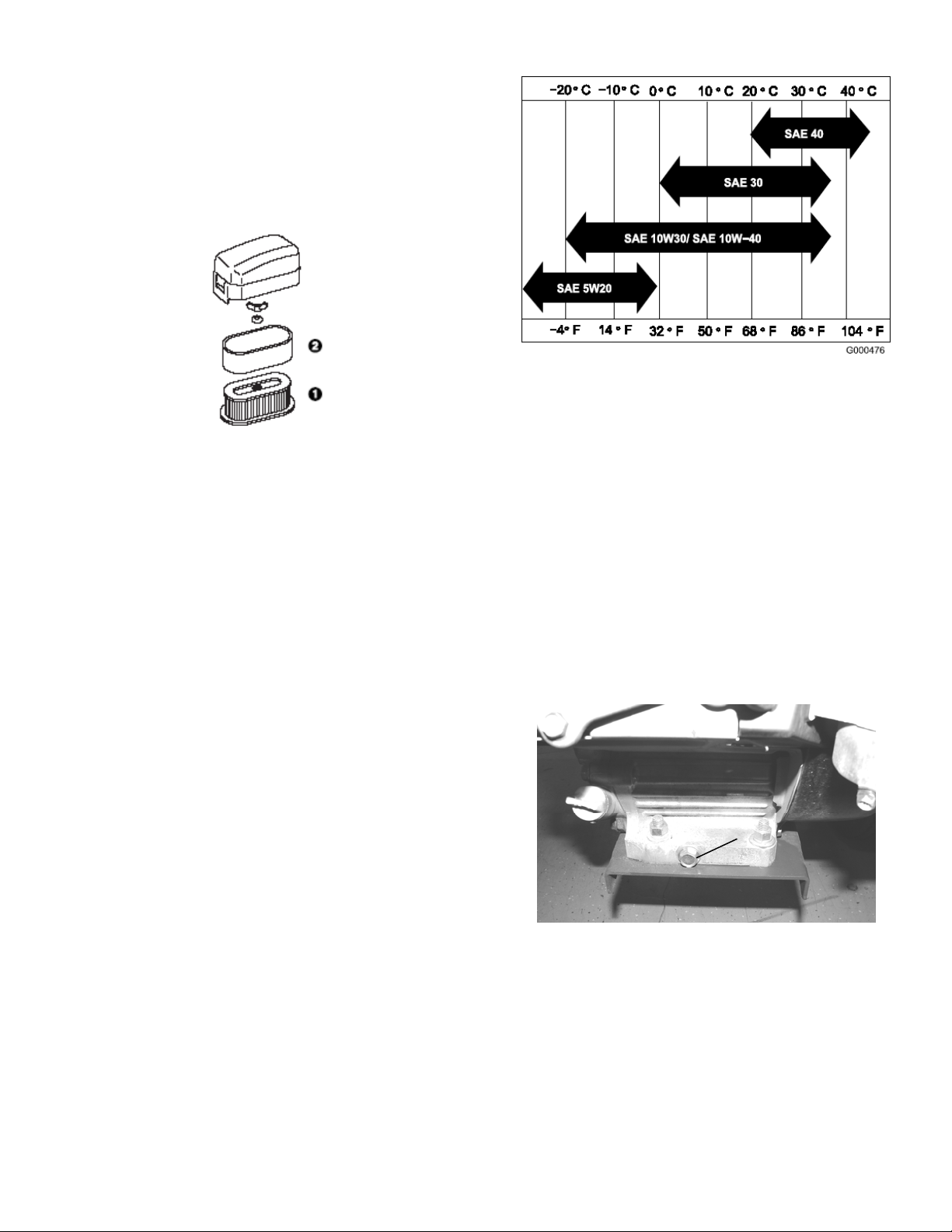

Figure 15

Using multi-grade oils (5W-20, 10W-30, and 10W-40) will

Figure 14

1. Foam element 2. Paper element

3. If foam element is dirty, remove it from paper element

(Figure 14). Clean thoroughly as follows:

• Wash foam element in a solution of liquid soap and warm

water. Squeeze to remove dirt, but do not twist because

the foam may tear.

• Dry by wrapping in a clean rag. Squeeze rag and foam

element to dry, but do not twist because the foam may

tear.

• Saturate element with clean engine oil. Squeeze element to

remove excess oil and to distribute oil thoroughly. An oil

damp element is desirable.

4. When servicing foam element, check condition of paper

element. Replace as required. Do not use compressed air

to clean the paper element.

5. Install foam element, paper element, and air cleaner cover.

Do not operate the engine without the air cleaner element

because extreme engine wear and damage will likely result.

increase oil consumption. Check the oil level more

frequently when using them.

Changing the Engine Oil

Service Interval: After the initial 20hours, then every 100

hours after the initial oil change.

1. Start the engine and let it run five minutes. This warms

the oil so it drains better.

2. Place a pan under the oil drain hole.

3. Remove the drain plug and drain the oil.

Dispose of the used oil at a certified recycling center.

5. Install the drain plug and refill the crankcase with the

specified oil. Refer to Checking the Engine Oil Level

(Figure 16).

Servicing the Engine Oil

The crankcase must be filled with approximately 34 fl oz (1

L) of proper viscosity oil before starting. The engine uses

any high-quality oil having the American Petroleum

Institute - API - “service classification" SF, SG, SH or SJ.

Oil viscosity - weight - must be selected according to

ambient temperature. (Figure 15) illustrates the

temperature/viscosity recommendations.

12

1. Oil drain plug

Figure 16

1

Page 13

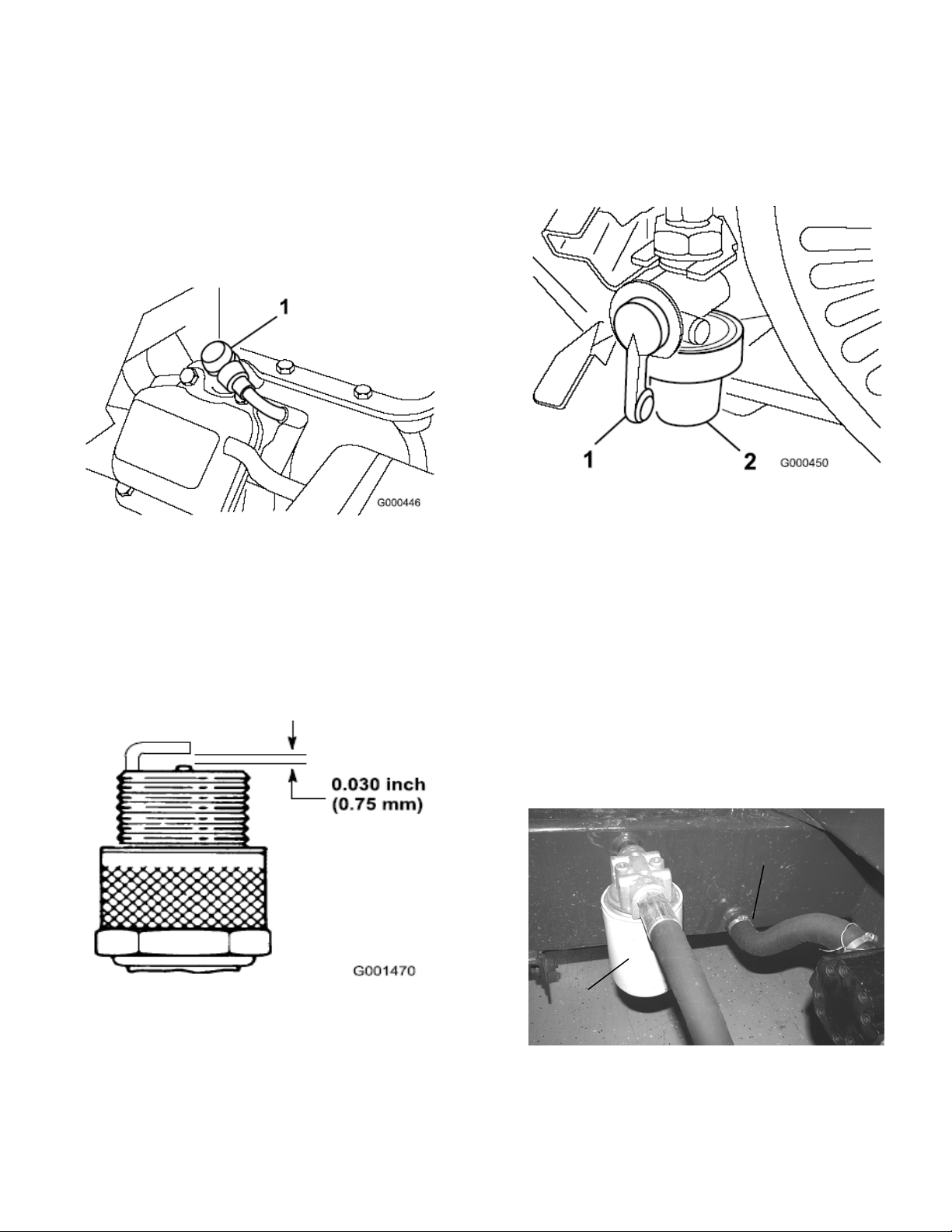

Replacing the Spark Plug

Service Interval: Clean the spark plug every 50 hours.

Replace the spark plug every 500 hours.

Type: NGK BR 6HS or equivalent

Air Gap: 0.28–0.032 inch (0.70-0.80 mm)

1. Pull molded wire off spark plug (Figure 17).

Figure 17

1. Spark plug wire

2. Clean around spark plug and remove plug from cylinder

head.

Replace a cracked, fouled, or dirty spark plug. Do not

sand blast, scrape, or clean electrodes because engine

damaged could result from grit entering the cylinder.

3. Set air gap at 0.028-0.032 inch (Figure 18). Install

correctly gapped spark plug and tighten firmly to

17 ft.-lb (23 N-m).

Cleaning the Fuel Filter

Service Interval: Clean the fuel filter every 200 hours.

1. Close the fuel shut off valve and unscrew the bowl from

the filter body (Figure 19).

Figure 19

1. Shut-off valve 2. Bowl

2. Clean the bowl and filter in clean gasoline.

3. Install the bowl and filter.

Replacing the Hydraulic Filter

Service Interval: Every 100 hours.

1. Place a pan under the hydraulic filter and slowly loosen it,

catching the oil as it runs out.

2. Remove the hydraulic filter and clean the mounting

flange (Figure 20).

3. Wipe hydraulic fluid on the gasket of the new hydraulic

filter.

4. Install new hydraulic filter until just tight, then turn ¾

turn more.

2

Figure 18

1. Hydraulic filter 2. Suction hose

13

1

Figure 20

Page 14

Replacing the Hydraulic Fluid

Service Interval: Every 100 hours.

Contaminants in fluid may damage the hydraulic

components. Flushing the reservoir tank and hoses with

kerosene after repairs are performed on the tank, hydraulic

pump, or valve is recommended. Contact an authorized

service dealer for hydraulic system repairs.

1. Disconnect the suction hose from the bottom of the

reservoir tank. Next to the hydraulic filter (Figure 20).

2. Allow the fluid to drain into a suitable container.

3. Tilt unit down in front to completely drain reservoir.

4. Install the suction hose and secure with clamp.

5. Refill the reservoir with approximately 10 gallons

(38 L) of SAE 10W30 or 15W40 Diesel Engine Oil, API

Service CH-4 or higher.

6. Maintain fluid level 1 inch (2.5 cm) below the top of the

tank, with the cylinder retracted (Figure 9).

NOTE: Always dispose of used hydrauli c fl ui d a n d engine

oil at approved recycling centers only.

Lubricate the Rail I-beam

Service Interval: Lubricate before every use.

The rail I-beam area where the splitting wedge slides should

be lubricated with general purpose grease. Make sure to

lubricate both the front and the back of the beam face.

Lubricate the Wheel Bearings

Service Interval: Every 500 hours.

1. The wheel bearing grease zerk is accessible behind the

rubber plug of the dust cover (Figure 21).

2. Lubricate the bearings with No. 2 General Purpose

lithium base grease.

3. Connect the grease gun to the grease zerk and pump

several times until grease comes out around the bearing.

4. Replace rubber plug.

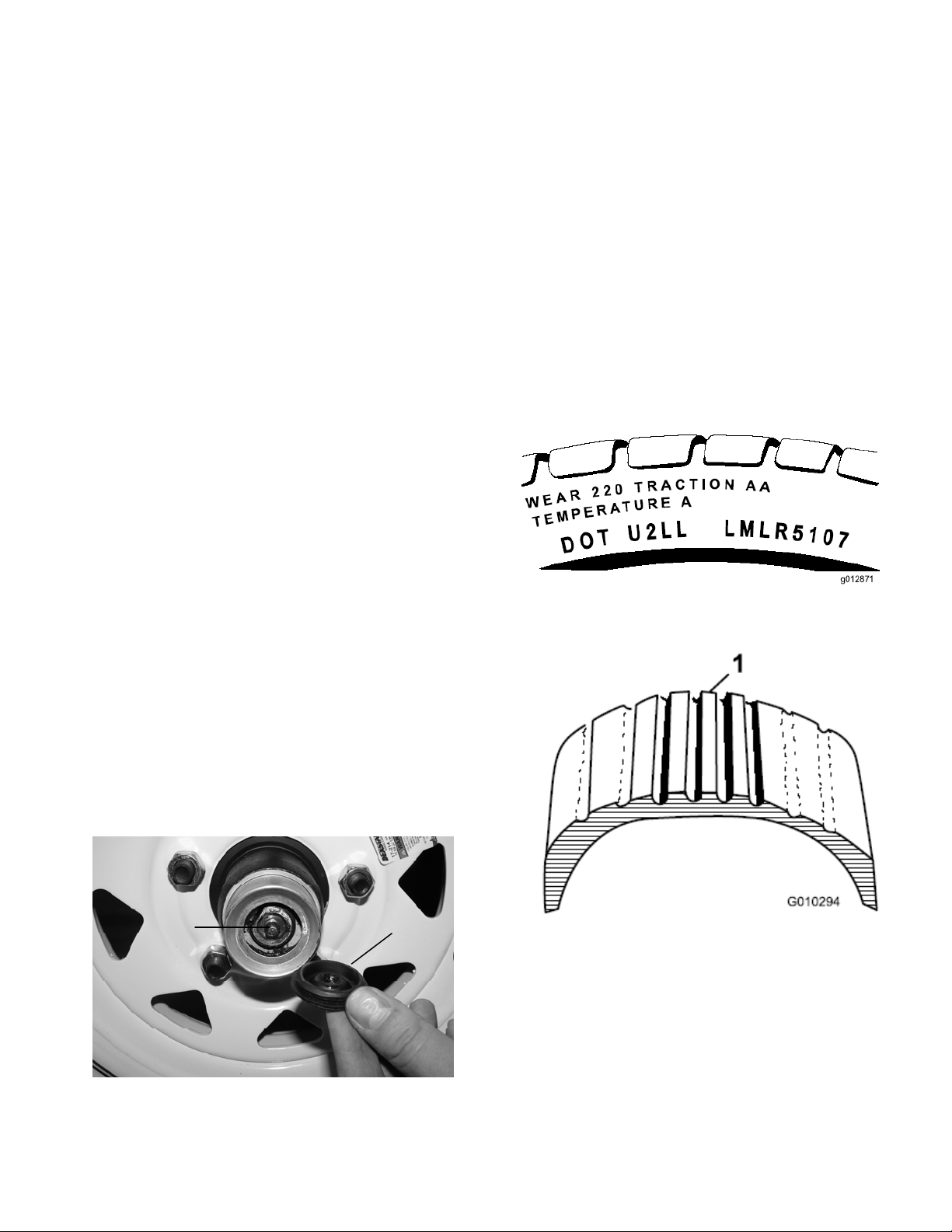

Inspecting the Tires

Service Interval: Every 100 hours.

IMPORTANT Keep tires properly inflated. Failure to

maintain correct pressure may result in tire failure and loss

of control resulting in serious injury and property damage.

Operating accidents can damage a tire or rim, so inspect tire

condition after an accident.

Check the tire pressure frequently to ensure proper inflation.

If the tires are not inflated to the correct pressure, the tires

will wear prematurely.

Always replace worn or damaged tires with DOT approve d

tires.

See (Figure 22) for the location of the tire identification

numbers.

Figure 22

Figure 23 is an example of tire wear caused by under

inflation.

2 1

1. Under inflated tire

Figure 24 is an example of tire wear caused by over

inflation.

Figure 21

1. Rubber plug 2. Grease zerk

14

Figure 23

Page 15

IMPORTANT: Do not store stabilizer/conditioned

gasoline over 90 days.

3. Run the engine to distribute conditioned fuel through the

fuel system (5 minutes).

4. Stop the engine, allow it to cool and drain the fuel tank

using a pump type siphon. Dispose of fuel properly.

Recycle as per local codes.

5. Restart the engine and run it until it stops.

6. Choke the engine.

7. Start and run the engine until it will not start again.

8. Clean the fuel filter; refer to Cleaning the Fuel Filter.

9. Service the air cleaner; refer to Servicing the Air Filter.

10. Change the engine crankcase oil; refer to Changing the

Figure 24

1. Over inflated tire

Storage

For storage over 30 days, prepare the unit as follows:

1. Remove dirt and grime from the external parts of the

entire unit, especially the engine. Clean dirt and wood

chips from the outside of the engine cylinder head fins

and blower housing.

2. Add a petroleum based stabilizer/conditioner to fuel in

the tank. Follow mixing instructions from stabilizer

manufacturer. (1 oz per US gallon). Do not use an

alcohol based stabilizer (ethanol or methanol).

NOTE: Fuel stabilizer/conditioner is most effective when

mixed with fresh gasoline and used at all times.

Engine Oil.

11. Remove the spark plug and check the condition; refer to

Servicing the Spark Plug.

12. With the spark plug removed from the engine, pour two

tablespoons of engine oil into the spark plug hole.

13. Pull the starter slowly to crank the engine and distribute

the oil inside the cylinder.

14. Install the spark plug, but do not install the wire on the

spark plug.

15. Check and tighten all bolts, nuts, and screws. Repair or

replace any damaged parts.

16. Paint all scratched or bare metal surfaces. Paint is

available from your Authorized Service Dealer.

17. Store the unit in a clean, dry garage or storage area.

19. Cover the unit to protect it and keep it clean.

Troubleshooting

Problem Cause Remedy

The engine will not start. 1. The engine switch is in the Off

position.

2. The fuel shutoff valve is closed.

3. The choke is open.

4. The fuel tank is empty.

5. Throttle is not in correct position

6. The spark plug is fouled, wire is

loose or disconnected.

The engine runs rough. 1. The choke is on.

2. The air filter is clogged.

3. The fuel filter is clogged.

4. There is water or contaminants in the

fuel.

5. The spark plug is worn or has

buildup on the electrodes.

Splitting wedge does not move. 1. Hydraulic fluid level may be low.

2. Blocked or damaged directional

control valve or pump.

Splitting wedge moves slowly. 1. Engine speed set on idle.

2. Contaminated hydraulic fluid.

3 Damage to pump, cylinder, or

directional valve.

1. Turn the engine switch is in the ON

position.

2. Open the fuel valve.

3. Close the choke when starting a cold

engine.

4. Fill tank with fresh fuel.

5. Move throttle to correct position.

6. Check the electrode gap and clean or

replace the spark plug.

1. Open the choke.

2. Clean or replace the air filter.

3. Clean the fuel filter.

4. Drain and fill the tank with fresh fuel.

Clean the fuel filter.

5. Check electrode gap and clean or replace

the spark plug.

1. Add hydraulic fluid until reservoir is full.

2. See Authorized Service Dealer

1. Move throttle to FAST.

2. Change hydraulic fluid and hydraulic filter.

3. See Authorized Service Dealer

15

Page 16

ToroCompactUtilityEquipmentWarranty

AOne-YearLimitedWarranty

CUEProducts

ConditionsandProductsCovered

TheToro®Companyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCompactUtility

Equipment(“Product”)tobefreefromdefectsinmaterialsorworkmanship.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

Loaders,Trenchers,StumpGrinders,

Chippers,LogSplitters,andAttachments

KohlerEngines3years

AllotherEngines2years

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

1yearor1000operating

hours,whicheveroccursrst

InstructionsforObtainingWarrantyService

IfyouthinkthatyourToroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.ContactanyAuthorizedT oroCompactUtilityEquipment(CUE)

ServiceDealertoarrangeserviceattheirdealership.T olocatea

dealerconvenienttoyou,accessourwebsiteatwww.T oro.com.

YoumayalsocallourT oroCustomerCareDepartmenttollfree

at888-865-5676(U.S.customers)or888-865-5691(Canadian

customers).

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.

3.IfforanyreasonyouaredissatisedwiththeServiceDealer’s

analysisorwiththeassistanceprovided,contactusat:

LCBCustomerCareDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1 196

TollFree:888-865-5676(U.S.customers)

TollFree:888-865-5691(Canadacustomers)

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutine

maintenance,whetherperformedbyadealerorbyyou,isatyourexpense.

Partsscheduledforreplacementasrequiredmaintenance(“Maintenance

Parts”),arewarrantedfortheperiodoftimeuptothescheduled

replacementtimeforthatpart.Failuretoperformrequiredmaintenance

andadjustmentscanbegroundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thisexpresswarranty

doesnotcoverthefollowing:

•Productfailureswhichresultfromtheuseofnon-Tororeplacement

parts,orfrominstallationanduseofadd-on,modied,orunapproved

accessories

•Productfailureswhichresultfromfailuretoperformrequired

maintenanceand/oradjustments

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligentorrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,during

normalProductoperationinclude,butarenotlimitedto,teeth,tines,

blades,sparkplugs,tires,tracks,lters,chains,etc.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,or

chemicals,etc.

•Normal“wearandtear”items.Normal“wearandtear”includes,butis

notlimitedto,wornpaintedsurfaces,scratcheddecalsorwindows,

etc.

•Anycomponentcoveredbyaseparatemanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

RepairbyanAuthorizedToroCompactUtilityEquipment(CUE)Service

Dealerisyoursoleremedyunderthiswarranty.

NeitherTheToro®CompanynorToroWarrantyCompanyisliable

forindirect,incidentalorconsequentialdamagesinconnectionwith

theuseoftheToroProductscoveredbythiswarranty,including

anycostorexpenseofprovidingsubstituteequipmentorservice

duringreasonableperiodsofmalfunctionornon-usepending

completionofrepairsunderthiswarranty.Allimpliedwarranties

ofmerchantabilityandtnessforusearelimitedtotheduration

ofthisexpresswarranty.Somestatesdonotallowexclusionsof

incidentalorconsequentialdamages,orlimitationsonhowlong

animpliedwarrantylasts,sotheaboveexclusionsandlimitations

maynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

ExceptfortheenginewarrantycoverageandtheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .The

EmissionsControlSystemonyourProductmaybecoveredbyaseparate

warrantymeetingrequirementsestablishedbytheU.S.Environmental

ProtectionAgency(EPA)ortheCaliforniaAirResourcesBoard(CARB).

ThehourlimitationssetforthabovedonotapplytotheEmissions

ControlSystemWarranty.RefertotheCaliforniaEmissionControl

WarrantyStatementsuppliedwithyourProductorcontainedintheengine

manufacturer’sdocumentationfordetails.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedToroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirToroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor’sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany.

374-0261RevB

Page 17

Impreso Nº 3366-331 Rev A

Partidora de troncos de 9 cv

Modelo Nº 22606- Nº de Serie 310000001 y superiores

Manual del Operador

Registre su producto en www.Toro.com

Traducción del original (ES)

Page 18

Este producto cumple las normas de la Administración de seguridad

nacional del tránsito en carreteras (National Highway Traffic Safety

Administration/NHTSA) de EE.UU. para remolques homologados.

ADVERTENCIA

Los gases de escape del motor de este producto contienen

sustancias químicas que en el estado de California se consideran

causantes de cáncer, defectos congénitos y otros trastornos del

sistema reproductor.

Este sistema de encendido por chispa cumple la norma canadiense

ICES-002.

Puesto que en algunas zonas existen normas locales, estatales o

federales que requieren el uso de un parachispas en el motor de esta

máquina, se ha incorporado un parachispas en el conjunto de

silenciador. Los parachispas genuinos de Toro están homologados

por el Servicio Forestal del Departamento de Agricultura de EE.UU.

(USDA Forestry Service).

Este motor está equipado con un silenciador de parachispas. El

uso o la operación del motor en cualquier terreno forestal, de

monte o cubierto de hierba con el motor obstruido o sin

silenciador con parachispas mantenido en buenas condiciones de

funcionamiento, equipado y mantenido para la prevención de

incendios, constituye una infracción de la legislación de

California (California Public Resource Code Section 4442).

Otros estados o zonas federales pueden tener una legislación

similar.

El Manual del usuario del motor adjunto ofrece información

sobre las normas de la Agencia de protección ambiental de

EE.UU. (U.S. Environmental Protection Agency/EPA) y de la

norma de control de emisión de California (California Emission

Control Regulation) sobre sistemas de emisiones, mantenimiento

y garantía. Puede solicitarse un manual nuevo al fabricante del

motor.

INTRODUCCIÓN

Esta partidora de troncos puede funcionar en posición horizontal o

vertical. Se ha diseñado para partir troncos cortados con un tamaño

acorde a la abertura de la cuña de corte de la máquina. No se ha

diseñado para partir piedras, metales ni ningún otro material que no

sea madera. La partidora de troncos puede remolcarse detrás de un

vehículo equipado con un enganche de bola adecuado.

Usted puede ponerse en contacto directamente con Toro en

www.Toro.com

si necesita localizar un distribuidor o registrar su producto.

Lea este manual detenidamente para aprender a utilizar y mantener

correctamente su producto, y para evitar lesiones y daños al

producto. Usted es el responsable de utilizar el producto de forma

correcta y segura.

Cuando necesite asistencia técnica, piezas genuinas Toro o

información adicional, póngase en contacto con un Servicio Técnico

Autorizado o con Asistencia al Cliente Toro, y tenga a mano los

números de modelo y serie de su producto. Escriba los números en el

espacio provisto.

si desea información sobre productos y accesorios, o

Este manual identifica posibles peligros y contiene mensajes de

seguridad identificados por el símbolo de alerta de seguridad (Figura

1), que señala un peligro que puede causar lesiones graves o la

muerte si usted no sigue las precauciones recomendadas.

Figura 1

1. Símbolo de alerta de seguridad

Este manual utiliza dos palabras más para resaltar información.

Importante llama la atención sobre información mecánica especial,

y Nota resalta información general que merece una atención

especial.

Información sobre los neumáticos

El número de identificación de neumático (TIN, por sus siglas en

inglés) está marcado en la pared externa de todos los neumáticos

homologados (Figura 2).

Figura 2

1. Número de identificación de neumático (TIN)

SEGURIDAD

El control de riesgos y la prevención de accidentes dependen de

los conocimientos, la atención y la correcta formación del

personal implicado en el manejo, el mantenimiento y el

almacenamiento de la máquina. El uso o el mantenimiento

inadecuado de la máquina puede causar lesiones o la muerte.

Para reducir la posibilidad de lesiones o la muerte, observe las

siguientes instrucciones de seguridad.

Prácticas de operación segura

Este producto es capaz de aplastar y amputar manos y pies. Siga

siempre todas las instrucciones de seguridad con el fin de evitar

lesiones físicas graves e incluso la muerte.

ADVERTENCIA

Los gases de escape del motor contienen monóxido de carbono,

que es un veneno inodoro que puede matarle.

No haga funcionar el motor dentro de un edificio o en un lugar

cerrado.

Si considera que su vehículo* presenta un defecto que podría

provocar un accidente, lesiones o incluso la muerte, debe informar

de inmediato a la Administración de seguridad nacional del tránsito

en carreteras (National Highway Traffic Safety

Administration/NHTSA) y notificar a The Toro Company.

2

Page 19

Si la NHTSA recibe quejas similares, podría iniciar una

investigación y si determina que existe un defecto de seguridad en

un grupo de vehículos*, podría ordenar una campaña de retirada y

corrección. Sin embargo, la NHTSA no puede intervenir en

problemas individuales entre usted, su distribuidor o The Toro

Company.

Para ponerse en contacto con la NHTSA, puede llamar a la línea

gratuita de seguridad vehicular 1–888–327–4236 (TTY: 1–800–424–

9153); visitar el sitio http://www.safercar.gov ; o escribir a:

Administrator, NHTSA, 400 Seventh Street, SW., Washington, DC

20590, EE. UU. Asimismo, puede obtener más información sobre la

seguridad de vehículos en http://www.safercar.gov.

* partidora de troncos

Formación

• Lea el Manual del operador y otros materiales de formación. Si el

o los operadores o mecánicos no saben leer el español, es la

responsabilidad del propietario explicarles este material.

• Evite el uso de la máquina por parte de operadores que no hayan

leído el Manual del operador o que no hayan recibido una adecuada

formación sobre el uso seguro de la máquina.

•No deje nunca que el equipo sea utilizado o mantenido por niños o

por personas que no hayan recibido la formación adecuada al

respecto. La normativa local puede imponer límites sobre la edad del

operador.

• Se producen muchos accidentes cuando más de una persona utiliza

la máquina. Si un asistente ayuda a cargar los troncos, no active

nunca el control hasta que el asistente se haya alejado de la máquina

y se encuentre a unos 3 metros (10 pies) de la máquina.

•Todos los operadores y mecánicos deben recibir una formación

adecuada. El propietario es responsable de proporcionar formación a

los usuarios.

Durante su funcionamiento, las partidoras hidráulicas de troncos

alcanzan presiones elevadas. El aceite hidráulico que sale por un

orificio pequeño puede penetrar en la piel y provocar una

intoxicación sanguínea o incluso la muerte. Siga siempre estas

instrucciones:

• No utilice la máquina si presenta mangueras, accesorios o tubos

deshilachados, doblados, fisurados o dañados.

• Pare el motor y libere la presión del sistema hidráulico antes de

cambiar o ajustar accesorios, mangueras, tubos u otros

componentes del sistema.

• No ajuste los parámetros de la presión de la bomba o válvula.

• Inspeccione SIEMPRE el enganche y el acoplamiento para ver si

están desgastados. No remolque NUNCA el soplador de residuos

con enganches, acoplamientos, cadenas, etc. defectuosos.

• Controle la presión de aire de los neumáticos del vehículo de

remolque y el soplador de residuos. Los neumáticos de la partidora

de troncos deben inflarse a 60 psi

(410 kpa) en frío.

• Inspeccione el dibujo de los neumáticos para ver si está gastado.

• Conecte SIEMPRE de forma adecuada la cadenas de seguridad al

vehículo de remolque.

• Compruebe SIEMPRE que funcionan correctamente las luces

direccionales, de marcha atrás y del freno del vehículo de remolque.

• Evite las paradas y los arranques repentinos, ya que podría patinar

la máquina o desviarse el patín. Los arranques y paradas suaves y

graduales mejorarán el remolque.

• Evite los giros bruscos para no volcar. Utilice únicamente un

vehículo equipado con un enganche diseñado para remolque.

Únicamente conecte el equipo remolcado en el punto de enganche.

Antes de remolcar la partidora de troncos, compruebe que está

conectada de forma correcta y segura al vehículo de remolque.

• Compruebe que el enganche de bola en uso tenga el tamaño

adecuado para el acoplador de la partidora de troncos.

• Compruebe que las cadenas de seguridad están debidamente

enganchadas al vehículo y que se haya dejado la holgura

necesaria para los giros.

• Coloque siempre la válvula de combustible en la posición de

cerrado (OFF).

• Compruebe que la partidora de troncos está bien ubicada en

posición horizontal.

• Compruebe que el soporte del patín está bien ubicado en

posición de elevado.

• No remolque la máquina a una velocidad superior a los 75 km/h

(45 mph).

• Proceda con cautela al dar marcha atrás; hágase ayudar por un

observador fuera del vehículo para que le guíe.

• No permita que ninguna persona se siente o viaje en la unidad

mientras la remolca.

• No lleve nunca ninguna carga ni madera en la unidad mientras la

remolca.

• Desconecte siempre la unidad del vehículo de remolque antes de

utilizarla.

• Ponga cuñas debajo de las ruedas para evitar que la unidad se

mueva mientras está aparcada.

• Absténgase de controlar con las manos si hay fugas.

• Para detectar fugas, póngase guantes y gafas de seguridad, y

pase un trozo de cartón o madera por la zona que podría

presentar fugas. Observe si se decolora el cartón o la madera.

• Mantenga despejadas la zona del operador y el espacio adyacente

para garantizar un desplazamiento seguro.

Remolque

Consulte la normativa de seguridad estatal o local y cumpla las

normas de seguridad del Departamento de Transporte (Department

of Transportation/DOT), antes de remolcar la partidora de troncos.

• Para reducir las posibilidades de accidente mientras transporta la

partidora de troncos por carreteras públicas, compruebe SIEMPRE

que el vehículo de remolque se encuentra en buen estado mecánico y

de funcionamiento.

• Pare SIEMPRE el motor antes de transportar la máquina.

Preparación

Familiarícese con la operación segura del equipo, los controles del

operador y las señales de seguridad.

• Póngase siempre zapatos de seguridad o botas reforzadas.

• Póngase siempre anteojos o gafas de seguridad al utilizar esta

máquina.

• Póngase guantes ajustados sin cordones ni puños sueltos.

• No se ponga nunca alhajas ni prendas sueltas que podrían

enredarse en las piezas móviles o giratorias de la máquina.

• Compruebe que la máquina está situada en una superficie nivelada

antes de usarla.

• Utilice siempre la máquina desde la zona del operador que se

especifica en el manual.

• Los troncos deben cortarse con los extremos lo más rectos posible

antes de partirlos.

3

Page 20

• Bloquee la máquina para evitar su movimiento accidental y trábela

en posición horizontal o vertical.

•Extreme las precauciones cuando maneje gasolina y otros

combustibles. Son inflamables y sus vapores son explosivos.

• Utilice solamente un recipiente de combustible homologado.

• No retire nunca el tapón de combustible ni añada combustible

con el motor en marcha. Deje que se enfríe el motor antes de

repostar combustible. No fume.

• No añada ni drene nunca el combustible dentro de un edificio.

• Vuelva a colocar el tapón de combustible y apriételo

firmemente.

• Mantenga la boquilla del recipiente en contacto con el depósito

durante el repostaje.

• Si se derrama combustible, límpielo del motor y el equipo.

Operación

Antes de cada uso:

• Inspeccione el acoplador, la bola y el enganche.

• Utilice siempre las cadenas de seguridad.

• Compruebe que todas las luces funcionan correctamente.

• Compruebe que los neumáticos están bien inflados según lo

recomendado.

• Compruebe que las tuercas están bien apretadas.

• Compruebe que la máquina está bien ubicada.

• Antes de poner en marcha la máquina, lea las "Instrucciones de

seguridad". Si no sigue estas reglas, podría provocarse una lesión

grave al operador o a otras personas cercanas.

• No deje nunca la máquina sin atención de un operador cuando el

motor está en marcha.

• No utilice nunca la máquina bajo la influencia de alcohol, drogas o

medicamentos.

• Nunca permita que una persona utilice la máquina si no ha recibido

la debida formación.

• Utilice siempre la máquina con todos los equipos de seguridad

instalados y en funcionamiento.

• No cambie los ajustes del regulador del motor ni haga funcionar el

motor a una velocidad excesiva.

• Únicamente use la mano para utilizar la palanca de mando.

Mantenga siempre las manos y los pies alejados de las piezas

móviles.

• No coloque nunca las manos o los pies entre el tronco y la cuña de

corte ni entre el tronco y el ariete durante el golpe hacia adelante o

hacia atrás.

• Al cargar un tronco, coloque las manos en los lados del tronco y no

en los extremos. No ponga nunca las manos ni ninguna parte del

cuerpo entre un tronco y cualquier pieza de la partidora de troncos.

• No trate de estirarse ni de pasar por encima de la zona de corte de

troncos para alcanzar algo que está del otro lado mientras la máquina

está en funcionamiento.

• No trate nunca de partir más de un tronco por vez.

• Si los troncos no están cortados en ángulo recto, el extremo menos

recto y la parte más larga del tronco deben situarse entre la viga y la

cuña, y el extremo recto debe ubicarse hacia la placa de extremo.

• Mantenga limpia la zona de trabajo; retire los troncos partidos de

la zona alrededor de la máquina para no tropezarse con ellos.

•No toque piezas que pueden estar calientes después de estar en

funcionamiento. Deje que se enfríen antes de realizar cualquier

operación de mantenimiento, ajuste o revisión.

• Localice las zonas peligrosas señaladas en la máquina, y mantenga

alejados los pies y las manos de estas zonas.

• No haga funcionar nunca el motor en un lugar cerrado.

• No mueva nunca la máquina mientras el motor está en marcha.

•Los rayos pueden causar graves lesiones o incluso la muerte. Si se

ven relámpagos o rayos, o se oyen truenos en la zona, no utilice la

máquina; busque un lugar donde resguardarse.

• No toque el motor ni el silenciador mientras el motor

está en marcha ni poco después de su parada. Estas zonas

podrían estar muy calientes y provocar quemaduras.

Mantenimiento y almacenamiento

• Pare el motor y retire el cable de la bujía antes de efectuar

cualquier reparación. Deje que se detenga todo movimiento antes de

ajustar, limpiar o reparar.

• Inspeccione la máquina antes de cada uso. Compruebe que todas

las tuercas, pernos, tornillos, acoplamientos hidráulicos y

abrazaderas de mangueras están bien apretados.

• Limpie cualquier residuo del silenciador y el motor para ayudar a

prevenir incendios. Limpie cualquier aceite o combustible

derramado.

• Espere a que se enfríe el motor antes de guardar la máquina, y no

la guarde cerca de una llama.

• No almacene el combustible cerca de una llama, y no lo drene

dentro de un edificio.

•Aparque la máquina en una superficie nivelada. No permita jamás

que la máquina sea revisada o reparada por personal no debidamente

formado.

•Mantenga las manos y los pies alejados de las piezas en

movimiento. Si es posible, no haga ajustes mientras el motor está

funcionando.

•Mantenga todas las piezas en buenas condiciones de

funcionamiento, y todos los herrajes bien apretados. Sustituya

cualquier pegatina desgastada o deteriorada.

•Extreme las precauciones cuando maneje gasolina y otros

combustibles. Son inflamables y sus vapores son explosivos.

• No guarde nunca la maquina o un recipiente de combustible dentro

de un edificio cerca de una llama desnuda, por ejemplo, cerca de un

calentador de agua o una caldera.

• Utilice solamente piezas de repuesto genuinas Toro para asegurar

que se mantengan los niveles de calidad de los equipos originales.

4

Page 21

Pegatinas de seguridad e instrucciones

Las pegatinas de seguridad e instrucciones están a la vista del operador y están ubicadas cerca de cualquier zona de peligro potencial. Sustituya

cualquier pegatina que esté dañada o que falte.

119-

1. Advertencia – Lea el Manual del operador. 4. Peligro de objetos arrojados – Mantenga a otras personas a una distancia

prudencial de la máquina.

2. Advertencia – Baje la partidora a la posición de bloqueo. 5. Peligro de tubos hidráulicos rotos – No use la máquina si los tubos están

fisurados, rotos o presentan fugas.

3. Peligro de agarre para las manos – Manténgase alejado de las piezas 6. Partir los troncos en el sentido de las vetas y no de forma transversal a ellas.

móviles; mantenga todas las protecciones instaladas.

119-4696

4695

1. Advertencia – No supere la velocidad de 72 km/h (45 mph) al transportar

la máquina.

119-4697

1. Para utilizar la máquina 1 - ponga en marcha el motor, 2 - mueva la

palanca para activar la máquina 3 - libere la palanca para desactivar la

máquina.

2. Corte/desmembramiento de manos, cuchilla – No ponga las manos en la

madera al activar la partidora.

119-4694

1. Advertencia – Lea el Manual del operador.

2. Advertencia – Aprenda a bajar la partidora a la posición de bloqueo.

3. Peligro de objetos arrojados – Póngase gafas de seguridad.

4. Peligro de objetos arrojados – Mantenga a otras personas a una distancia

prudencial de la máquina.

5. Peligro de agarre – Mantenga alejadas las manos de las piezas móviles.

117-2718

120-1853

120-1854

5

Page 22

Descripción general del producto

5

7

8

6

10

3

12

1

2

9

1. Acoplador 9. Filtro hidráulico

2. Cadenas de seguridad 10. Tapón de combustible

3. Soporte del patín 11. Filtro de aire

4. Pasador de bloqueo del riel 12. Acelerador

5. Palanca de control 13. Estárter

6. Cuña de corte 14. Arrancador

7. Placa de extremo 15. Válvula de combustible

8. Depósito hidráulico 16. Filtro de combustible

Figura 3

4

15

13

16

14

Controles

Palanca de mando

La palanca de mando (Figura 4) acciona la válvula hidráulica que

mueve la cuña de corte hacia adelante (afuera) y hacia atrás durante

el proceso de corte de troncos.

Para mover la cuña de corte hacia adelante (afuera) debe mantenerse

la palanca de mando hacia la placa de extremo.

Al liberarse la palanca se detiene el movimiento de la cuña.

Para retraer la cuña, deberá moverse la palanca de mando hacia

atrás. La cuña de corte se retraerá por completo de forma automática

al moverse la palanca a la posición totalmente retraída.

Figura 4

1. Palanca de mando

6

Page 23

Especificaciones

Posiciones de operación ................................. Vertical/Horizontal

Riel de deslizamiento . Viga en I reforzada de 15 cm (6 pulgadas)

Cuña ................. De 22.5 cm (9 pulgadas ) con ángulo compuesto

Motor .......................................... Robin/Subaru de 9 cv (6.7 kW)

Tonelaje de fuerza ........... 30.9 toneladas métricas (28 toneladas)

Carrera del cilindro ...................................... 60 cm (24 pulgadas)

Abertura del área donde se

coloca el tronco ........................... 62.5 cm (25 pulgadas), máximo

Duración del ciclo operativo ........................ 12 segundos (aprox.)

Ruedas y neumáticos ......................... 4.80 x 12 de alta velocidad

Acoplador de enganche .................................... 5 cm (2 pulgadas)

Cadenas de seguridad ..................................................... Estándar

Soporte de patín con dos ruedas giratorias ............... 4.10/3.50 x 4

Longitud ..................................................... 246 cm (97 pulgadas)

Ancho ...................................................... 135 cm (53.1 pulgadas)

Altura ...................................................... 115 cm (45.5 pulgadas)

Peso ................................................................ 375 kg (826 libras)

• Si el enganche del acoplador está muy flojo en la bola: Haga girar

la tuerca de ajuste una vuelta hacia la derecha.

ADVERTENCIA

Si no se engancha de forma correcta la bola del enganche en el

zócalo de bola del acoplador y no se traba bien el mecanismo de

bloqueo del acoplador, la unidad podría separarse del vehículo

de remolque durante su transporte, lo que podría provocar

lesiones físicas graves y daños materiales.

Instale el pasador de bloqueo para sujetar la palanca (Figura 5).

Verifique las cadenas de seguridad y conéctelas a los orificios del

enganche.

Coloque el conector para arnés de cables de luces traseras al

conector del vehículo de remolque. Compruebe que las luces de

freno se encienden correctamente cuando se presiona el pedal del

freno y que las luces traseras parpadean cuando se usan las señales

de giro.

Remolque

ADVERTENCIA

No remolque la máquina a una velocidad superior a los 75 km/h

(45 mph).

IMPORTANTE Antes de transportar la partidora de troncos,

coloque siempre la válvula de combustible en la posición de cerrado

(OFF).

Baje la viga en I del riel de la partidora de troncos a la posición

horizontal y trábela con el pasador de bloqueo del riel.

Haga girar la manija del elevador para alinear el acoplador con la

bola del vehículo de remolque.

Extraiga el pasador de bloqueo de la palanca, presione la traba y

levante la palanca para abrir el acoplador (Figura 5).

Figura 6

1. Soporte del patín 2. Pasador de liberación

Levante el soporte del patín (Figura 6) para que las ruedas giratorias

queden separadas del suelo, tire del pasador de liberación y haga

girar las ruedas hacia atrás y trábelas en posición horizontal.

2

1

Neumáticos y ruedas

La causa más común de los problemas de los neumáticos es que se

inflan a una presión inferior a la especificada. Es importante

mantener toda la presión de aire indicada por el fabricante de los

neumáticos en la pared externa o en la etiqueta de certificación del

fabricante del remolque.

Infle los neumáticos del eje principal a .......... 60 psi (410 kpa).

Figura 5

1. Enganche 4. Cadenas de seguridad

2. Acoplador 5. Pasador de bloqueo

3. Palanca en la posición de trabada

Conecte el acoplador a una bola clase I o superior de 50.8 cm

(2 pulgadas) del vehículo de remolque y trábelo de forma segura.

• Si el acoplador no encaja en la bola: Haga girar la tuerca de ajuste

una vuelta hacia la izquierda.

7

Compruebe si las tuercas de las ruedas están bien apretadas antes de

comenzar y después de las primeras 10 horas de funcionamiento.

Ajuste las tuercas a ............... 80-90 libras pies (108-122 N·m)

Page 24

• Cuando sea posible, retire el equipo a repostar del camión o

Operación

Antes de comenzar

Revise todas las pegatinas de seguridad de la máquina.

Desconecte la unidad del vehículo de remolque, sitúela en un lugar

nivelado y bloquee las ruedas adelante y atrás para evitar su

movimiento.

Asegúrese de que está familiarizado con las normas de seguridad y

los procedimientos de parada descritos en el Manual del operador.

Antes de cargar y utilizar la partidora de troncos, póngase siempre

equipos de protección, como gafas de seguridad, protector facial,

protección auditiva, guantes ajustados sin cordones ni puños sueltos

y zapatos con punta de acero.

Compruebe que en la zona de trabajo no haya ni maderas ni residuos

con los que podría tropezarse y caerse.

Controle el nivel de combustible y aceite del motor, y el aceite

hidráulico en el depósito.

Cómo añadir combustible

Utilice gasolina sin plomo (87 octanos mínimo) Se puede utilizar

gasolina normal con plomo si no hubiera gasolina sin plomo

disponible.

ADVERTENCIA

En ciertas condiciones la gasolina es extremadamente

inflamable y altamente explosiva. Un incendio o una explosión

provocados por la gasolina puede causarle quemaduras a usted

y a otras personas así como daños materiales.

•Llene el depósito de combustible en el exterior, en una zona

abierta y con el motor frío. Limpie la gasolina derramada.

• No llene nunca el depósito de combustible dentro de un

remolque cerrado.

• No llene completamente el depósito de combustible. Añada

gasolina al depósito de combustible hasta que el nivel esté entre

6 y 13 mm (1/4 - 1/2 pulg.) por debajo del extremo inferior del

cuello de llenado. Este espacio vacío en el depósito permitirá la

dilatación de la gasolina.

• No fume nunca mientras maneja gasolina y manténgase

alejado de llamas desnudas o de lugares donde una chispa

pudiera inflamar los vapores de gasolina.

•Almacene la gasolina en un recipiente homologado y

manténgala fuera del alcance de los niños. No compre nunca

gasolina para más de 30 días de consumo normal.

• No utilice la máquina a menos que esté instalado un sistema

completo de escape en buenas condiciones de funcionamiento.

ADVERTENCIA

En determinadas condiciones durante el repostaje, puede tener

lugar una descarga de electricidad estática, produciendo una

chispa que puede prender los vapores de la gasolina. Un

incendio o una explosión provocados por la gasolina puede

causarle quemaduras a usted y a otras personas así como daños

materiales.

• Coloque siempre los recipientes de gasolina en el suelo, lejos

del vehículo que está repostando.

• No llene los recipientes de gasolina dentro de un vehículo,

camión o remolque ya que las alfombras o los revestimientos

de plástico del interior de los remolques podrían aislar el

recipiente y retrasar la pérdida de la carga estática.

remolque y reposte con las ruedas del equipo sobre el suelo.

• Si esto no es posible, reposte el equipo sobre el camión o

remolque desde un recipiente portátil, en vez de usar un

surtidor de gasolina.

• Si es imprescindible el uso de un surtidor, mantenga la

boquilla en contacto con el borde del depósito de combustible o

la abertura del recipiente en todo momento hasta que termine

de repostar.

No use metanol, gasolina que contenga metanol o gasohol con más

del 10% etanol porque se podrían producir daños en el sistema de

combustible del motor. No mezcle aceite con la gasolina.

Uso del estabilizador/acondicionador

Use un estabilizador/acondicionador en la máquina para conseguir

los beneficios siguientes:

•Mantiene la gasolina fresca durante un período de almacenamiento

de 90 días o menos. Para un almacenamiento más largo, se

recomienda drenar el depósito de combustible.

• Limpia el motor durante el funcionamiento.

• Elimina la acumulación de depósitos pegajosos, con aspecto de

barniz, del sistema de combustible, que pueden dificultar el

arranque.

No utilice aditivos de combustible que contengan metanol o

etanol.

Agregue la cantidad adecuada de estabilizador/acondicionador a la

gasolina.

Un estabilizador/acondicionador de combustible es más eficaz

cuando se mezcla con gasolina fresca. Para reducir al mínimo los

depósitos de barniz en el sistema de combustible, utilice siempre un

estabilizador de combustible.

Cómo llenar el depósito de

combustible

1. Coloque la máquina en una superficie nivelada y pare el motor.

2. Deje que el motor se enfríe.

3. Limpie alrededor del tapón del depósito de combustible y retire el

tapón (Figura 7).

1

Figura 7

1. Tapón del depósito de combustible

4. Únicamente llene el depósito hasta el extremo inferior del cuello

de llenado; no lo llene en exceso.

8

Page 25

Verificación del nivel de aceite del

para motores diesel SAE 10W30 o 15W40, servicio API CH-4 o

superior.

motor

El mejor momento para controlar el aceite del motor es cuando el

motor está frío antes de ponerlo en marcha para las tareas del día. Si

ya estuvo en funcionamiento, deje fluir el aceite en el cárter durante

10 minutos, como mínimo, antes de realizar la verificación. Si el

nivel de aceite alcanza la marca “L” de la varilla de aceite o se

encuentra por debajo de ella, añada aceite hasta que el nivel de