Toro 22604, 22604THD Operator's Manual

Form No. 3366-779 Rev B

Brush Chipper

Model No. 22604-Serial No. 310000001 and Up

Model No. 22604THD-Serial No. 310000001 and Up

Register your product at www.Toro.com

Operator’s Manual

Original Instructions (EN)

This product complies with the US National Highway Traffic

Safety Administration (NHTSA) regulations for street legal

trailers.

WARNING

The engine exhaust from this product contains chemicals

known to the State of California to cause cancer, birth

defects, or other reproductive harm.

This spark ignition system complies with Canadian

ICES-002.

In some areas, there are local, state, or federal regulations

requiring that a spark arrester be used on the engine of this

machine. A spark arrester is not incorporated with the muffler

assembly.

Important This engine is not equipped with a spark arrester

muffler. It is a violation of California Public Resource Code

Section 4442 to use or operate the engine on any forestcovered, brush-covered, or grass-covered land without a spark

arrester muffler maintained in working order, or the engine

constricted, equipped, and maintained for the prevention of

fire. Other states or federal areas may have similar laws.

The enclosed Engine Owner’s Manual is supplied for

information regarding the US Environmental Protection

Agency (EPA) and the California Emission Control

Regulation of emission systems, maintenance, and

warranty. Replacements may be ordered through the

engine manufacturer.

This Manual identifies potential hazards and has safety

messages identified by the safety alert symbol, (Figure 1)

which signals a hazard that may cause serious injury or death

if you do not follow the recommended precautions.

Figure 1

1. Safety alert symbol

This manual uses two other words to highlight information.

Important calls attention to special mechanical information

and Note emphasizes general information worthy of special

attention.

Tire Information

The tire identification number (TIN) is branded into the

sidewall of all street legal tires (Figure 2).

Figure 2

1. Tire identification number (TIN)

INTRODUCTION

This brush chipper is designed to chip branches, vines, leaves,

and small tree limbs up to 6 in. (15.24 cm) in diameter. It is

not intended to chip rocks, wire, metal, or any materials other

than wood. The brush chipper can be towed behind a vehicle

equipped with an appropriate ball hitch .

You may contact Toro directly at www.Toro.com

and accessory information, help finding a dealer, or to register

your product.

Read this information carefully to learn how to operate and

maintain your product properly and to avoid injury and

product damage. You are responsible for operating the

product properly and safely.

Whenever you need service, genuine Toro parts, or additional

information, contact an Authorized Service Dealer or Toro

Customer Care and have the model and serial numbers of

your product ready. Write the numbers in the space provided.

for product

SAFETY

Hazard control and accident prevention are dependent

upon the awareness, concern, and proper training of the

personnel involved in the operation, transport,

maintenance, and storage of the machine. Improper use or

maintenance of the machine can result in injury or death.

To reduce the potential for injury or death, comply with

the following safety instructions.

Safe Operating Practices

This product is capable of crushing and amputating hands and

feet. Always follow all safety instructions to avoid serious

injury or death.

WARNING

Engine exhaust contains carbon monoxide, an odorless,

deadly poison that can kill you.

Do not run the engine indoors or in an enclosed area.

If you believe that your vehicle* has a defect which could

cause a crash or could cause injury or death, you should

immediately inform the National Highway Traffic Safety

Administration (NHTSA) in addition to notifying The Toro

Company.

If NHTSA receives similar complaints, it may open an

investigation, and if it finds that a safety defect exists in a

2

group of vehicles*, it may order a recall and remedy

campaign. However, NHTSA cannot become involved in

individual problems between you, your dealer, or The Toro

Company.

To contact NHTSA, you may call the Vehicle Safety Hotline

toll-free at 1–888–327–4236 (TTY: 1–800–424–9153); go to

http://www.safercar.gov ; or write to: Administrator, NHTSA,

400 Seventh Street, SW., Washington, DC 20590. You can

also obtain other information about motor vehicle safety from

http://www.safercar.gov.

* brush chipper trailer

Training

• Read the Operator’s Manual and other training material. If

the operator(s) or mechanic(s) can not read English, it is the

owner’s responsibility to explain this material to them.

• Do not allow anyone to operate the machine who has not

read the Operator’s Manual or has not been instructed on the

safe use of the machine.

• Never let children or untrained people operate or service the

equipment. Local regulations may restrict the age of the

operator.

• All operators and mechanics should be trained. The owner is

responsible for training the users.

• Keep the operator zone and adjacent area clear for safe,

secure footing.

Towing

Check with your local county or state safety towing

regulations, in addition to meeting Department of

Transportation (DOT) Safety Towing Regulations, before

towing the machine.

• In order to reduce the possibility of an accident while

transporting the machine on public roads, ALWAYS make

sure the towing vehicle is mechanically sound and in good

operating condition.

• ALWAYS shutdown engine before transporting the

machine.

• ALWAYS inspect the hitch and coupling for wear. NEVER

tow the machine with defective hitches, couplings, chains,

etc.

• Check the tire air pressure on both towing vehicle and

machine. The tires should be inflated to 60 psi (410 kpa) cold.

• Check the tire tread for wear.

• ALWAYS properly attach the safety chains to towing

vehicle.

• ALWAYS make sure that the towing vehicle’s directional,

backup, and brake lights are working properly.

• Avoid sudden stops and starts. This can cause skidding, or

jack knifing. Smooth, gradual starts and stops will improve

towing.

• Avoid sharp turns to prevent rolling. Tow only with a

vehicle that has a hitch designed for towing. Do not attach

towed equipment except at the hitch point.

Before towing check to make certain your machine is

correctly and securely attached to the towing vehicle.

• Be sure that the ball hitch you are using is the proper size

for the hitch coupler on the machine.

• Be sure the safety chains are properly hooked to the vehicle

leaving enough slack for turning.

• Be sure the jack stand is secured in the UP position.

• Do not tow the machine faster than 45 mph (75 km/h).

• Use caution when backing up; use a spotter outsi de the

vehicle to guide you.

• Do not allow anyone to sit or ride on unit when towing.

• Never carry any cargo or wood on unit when towing.

• Always disconnect the unit from the tow vehicle before

using it.

• Place chock blocks underneath wheel to prevent rolling

while unit is parked.

Preparation

Become familiar with the safe operation of the equipment,

operator controls, and safety signs.

• Always wear safety glasses or safety goggles while

operating this machine.

• Wear tight fitting gloves without draw strings or loose cuffs.

• Never wear jewelry or loose clothing that might become

entangled in moving or rotating parts of the machine.

• Wear shoes with non-slip treads when using your machine.

If you have safety shoes, we recommend wearing them. Do

not use the machine while barefoot or wearing open sandals.

• Wear long pants while operating the machine.

• Use ear protectors or ear plugs to protect your hearing.

• Make sure the machine is on level surface before operating.

• Always operate the machine from the side of the hopper.

• Block the wheels of the machine to prevent unintended

movement.

• Use extra care when handling gasoline and other fuels. They

are flammable and vapors are explosive.

• Use only an approved fuel container.

• Never remove the gas cap or add fuel when the engine is

running. Allow the engine to cool be fo re ref u el i ng. D o not

smoke.

• Never refuel or drain the machine indoors.

• Replace gasoline cap and tighten securely.

• Keep container nozzle in contact with the tank during

filling.

• If gasoline is spilled, wipe it off the engine and equipment.

Operation

Before every use:

• Inspect the coupler, ball and hitch.

• Always use safety chains.

• Verify all lights are functioning properly.

• Verify the tires are properly inflated as recommended.

• Verify lug nuts are tight and torqued properly.

• Machine is properly secured.

• Before starting this machine, review the “Safety

Instructions.” Failure to follow these rules may result in

serious injury to the operator or bystanders.

3

• Never leave this machine unattended with the engine

running.

• Never operate machine while under the influence of alcohol,

drugs, or medication.

• Never allow anyone to operate this machine without proper

instruction.

• Always operate this machine with all safety equipment in

place and working.

• Do not change the engine governor setting or over speed the

engine.

• Never place your hands, feet, or any part of your body in the

hopper, discharge chute opening, or near or under any moving

part while the machine is running.

• Keep area of discharge clear of people, animals, buildings,

glass, or anything else that will obstruct clear discharge, cause

injury, or damage. Wind can also change discharge directi o n ,

so be aware. If it becomes necessary to push material into the

hopper, use a small diameter stick, not your hands.

• Never use the machine with the hopper or discharge chute

removed.

• Always operate the machine from along side the hopper.

Never pass or stand on the discharge side of the machine

when the engine is running or the flywheel is turning.

• Clear the area of objects such as wire, rope, etc. Inserting

these objects into the hopper could damage the flywheel

and/or cause injury.

• Keep your face and body back from the hopper to avoid

accidental bounce back of any material.

• If you hear or see material being kicked back against the

rubber flap shut the feeder chute door until the debris has

passed.

• When feeding material into the hopper, be extremely careful

that pieces of metal, rocks or other foreign objects are not

included. Personal injury or damage to the machine could

result.

• Whenever you leave the operating position or if you have to

remove processed material, leaves, or debris from the

machine, always shut off the engine and wait five minutes to

make certain the flywheel and all moving parts have come to

a complete stop and cool. Remove the key, disconnect the

spark plug wires and keep the wire away from the spark plug

to prevent accidental starting before adjusting the machine.

• If the cutting mechanism strikes a foreign object or if your

machine should start making an unusual noise or vibration,

stop the engine and wait five minutes for all moving parts to

come to a complete stop and cool. Vibration is generally a

warning of trouble. Disconnect the spark plug wires and

inspect for clogging or damage. Clean and repair and/or

replace damaged parts.

• Do not touch parts that may be hot from operation. Allow

them to cool before attempting to maintain, adjust, or service.

• Never run an engine in an enclosed area.

• Never move this machine while the engine is running.

• Lightning can cause severe injury or death. If lightning is

seen or thunder is heard in the area, do not operate the

machine; seek shelter.

• Do not touch the engine or muffler while the engine

is running or soon after it is stopped. These areas

could be hot enough to cause a burn.

Maintenance and Storage

• Stop the engine and remove the spark plug wires before

making any repairs. Wait for all movement to stop before

adjusting, cleaning, or repairing.

• Inspect the machine before each use. Make sure all nuts,

bolts, screws, hydraulic fittings, hose clamps, are securely

tightened.

• Clean debris from the muffler and engine to help prevent

fires. Clean up oil or fuel spillage.

• Let the engine cool before storing and do not store near

flame.

• Do not store fuel near flames or drain indoors.

• Park the machine on level ground. Never allow untrained

personnel to service the machine.

• Keep hands and feet away from moving parts. If possible,

do not make adjustments with the engine running.

• Keep all parts in good working condition and all hardware

tightened. Replace all worn or damaged decals.

• Use extra care when handling gasoline and other fuels. They

are flammable and vapors are explosive.

• Never store the machine or fuel container inside where there

is an open flame, such as near a water heater or furnace.

• Use only genuine Toro replacement parts to ensure that

original equipment standards are maintained.

4

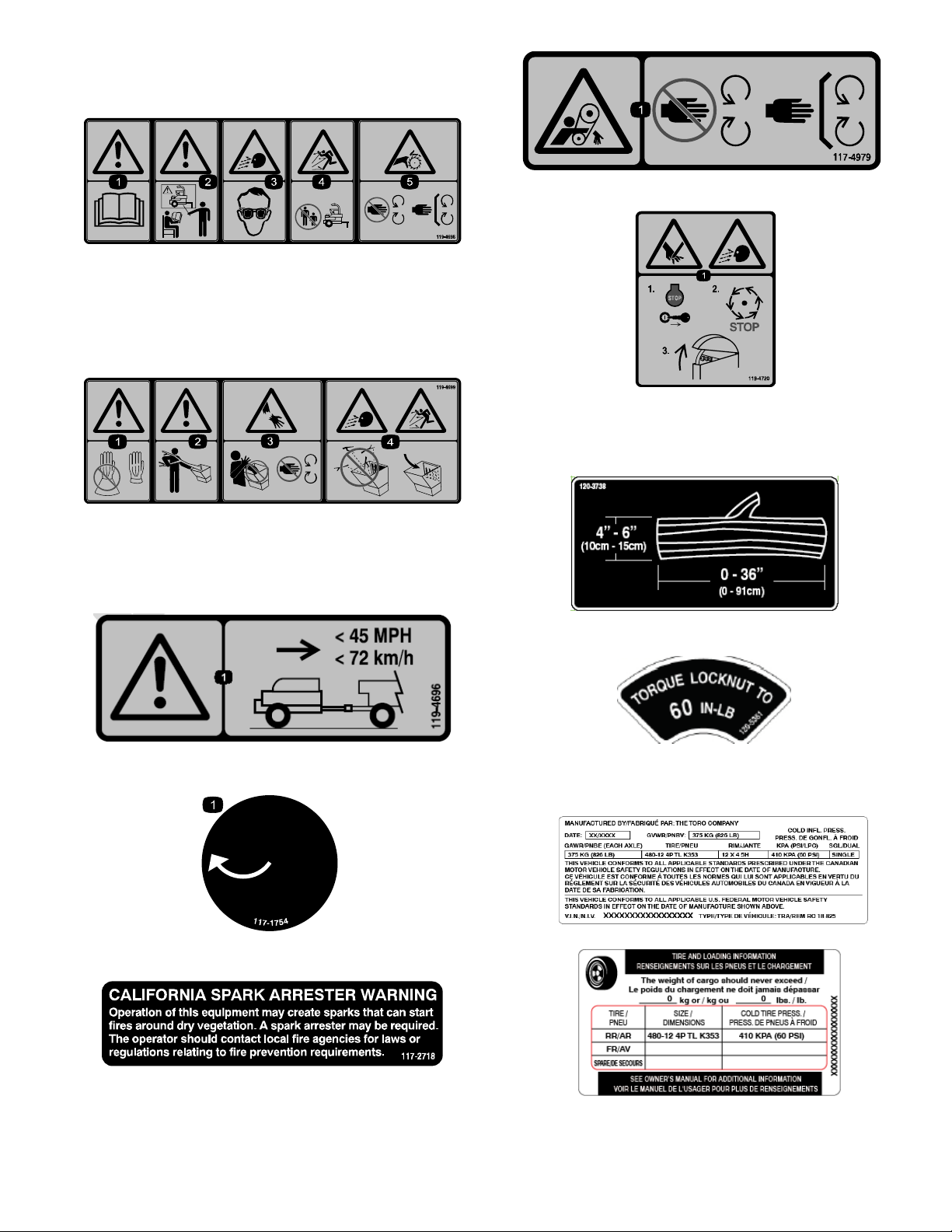

Safety and Instructional Decals

Safety decals and instructions are easily visible to the

operator and are located near any area of potential danger.

Replace any decal that is damaged or lost.

1. Warning – read the Operator’s Manual.

119-4698

2. Warning – do not operate the brush chipper unless you have

been trained.

3. Thrown object hazard – wear safety glasses.

4. Thrown object hazard – keep bystanders a safe distance from

the machine.

5. Rotating flywheel hazard – keep hands away from moving parts.

119-4699

1. Warning – wear leather gloves with narrow cuffs.

2. Warning – operate from the side of the hopper.

3. Severed hand hazard – keep hands out of the hopper

4. Thrown object hazard – keep bystanders a safe distance from

the machine.

1. Belt entanglement hazard – keep hands away from moving parts.

117-4979

119-4720

1. Cut hand hazard and thrown object hazard –

1 – stop the engine and remove the key

2 – wait for all moving parts to stop rotating

3 – before opening cover

120-3738

1. Maximum log size

1. Warning – do not exceed 45 mph (72 km/h) when transporting

119-4696

the machine.

1. Torque air filter nut to 60 in. lbs.

*Kohler Part Number 24 113 176

117-1754

1. Rotation – direction of flywheel.

117-2718

5

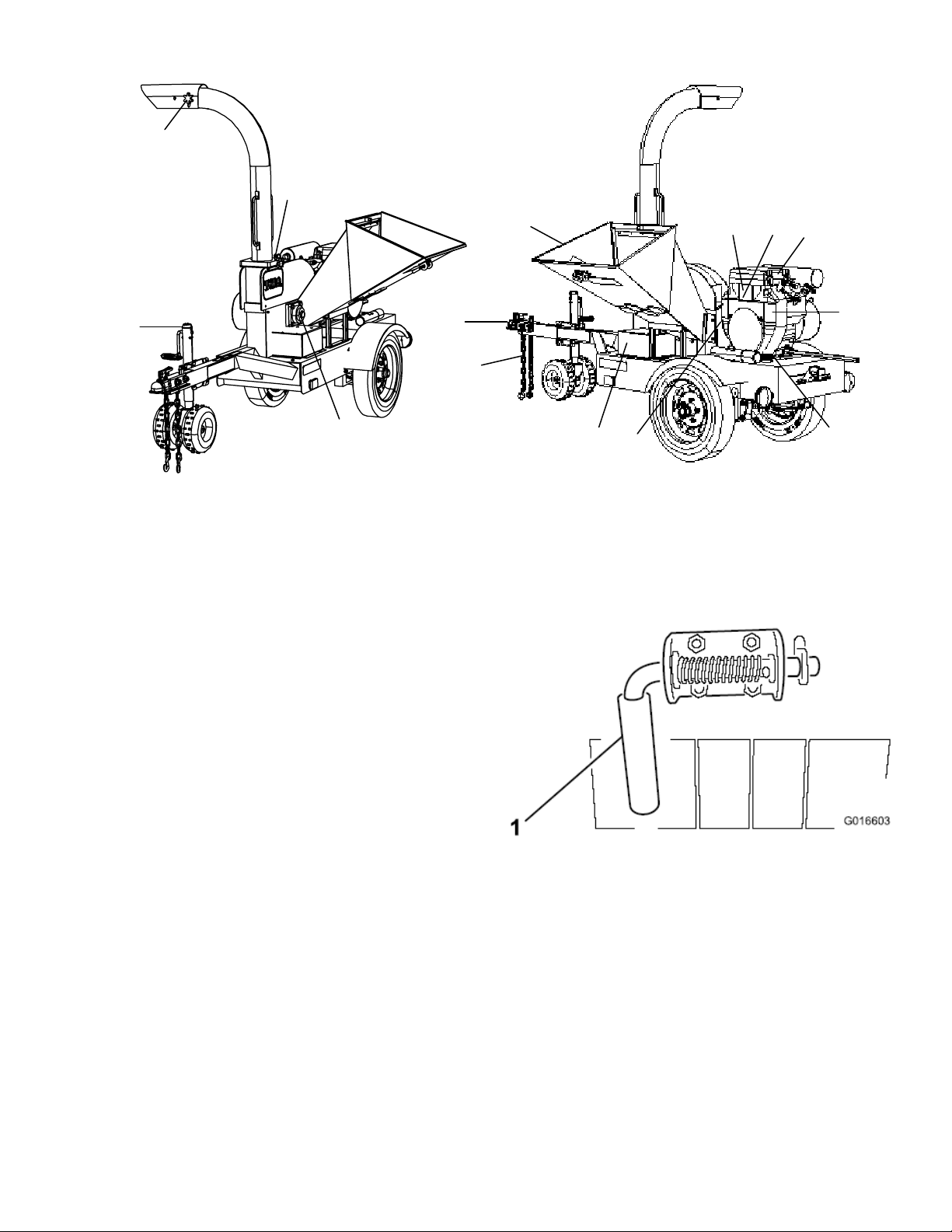

Product Overview

5

4

3

Controls

8

1

2

7

Figure 3

1. Coupler 8. Hopper

2. Safety Chains 9. Key switch

3. Jack stand 10. Fuel cap

4. Chute locking pin 11. Air filter

5. Deflector locking knob 12. Throttle

6. Battery box 13. Choke

7. Flywheel bearing 14. Fuel filter

6

14

12 13

11

9

10

Hopper Latch

The hopper, mounted on the side of the machine, swings

down for machine operation. The revolving blades mounted

on a flywheel behind the hopper turns branches fed into the

hopper into “chips”. The chipper can chip branches and vines

ranging in size up to 6” in diameter.

To release the hopper latch (Figure 4), pull on the handle and

rotate up or down to engage latch pin behind stop.

Pull hopper down to open.

6

1. Hopper latch

Figure 4

Loading...

Loading...