Page 1

Form No. 3366-325 Rev A

13 hp Stump Grinder

Model No. 22602-Serial No. 310000001 and Up

Operator’s Manual

Register your product at www.Toro.com

Original Instructions (EN)

Page 2

Introduction

Because in some areas there are local, state, or federal regulations requiring that a spark arrester

be used on the engine of this machine, a spark arrester is available as an option. If you require a

spark arrester, contact your Authorized Toro Service Dealer.

Genuine Toro spark arresters are approved by the USDA Forestry Service.

Important: It is a violation of California Public Resource Code Section 4442 to use or

operate the engine on any forest-covered, brush-covered, or grass-covered land without a

spark arrester muffler maintained in working order, or the engine constricted, equipped,

and maintained for the prevention of fire. Other states or federal areas may have similar

laws.

This spark ignition system complies with Canadian ICES-002.

Important: The enclosed Engine Owner’s Manual is supplied for information regarding

the US Environmental Protection Agency (EPA) and the California Emission Control

Regulation of emission systems, maintenance, and warranty. Replacements may be ordered

through the engine manufacturer.

© 2010—The Toro® Company Contact us at www.Toro.com

8111 Lyndale Avenue South All Rights Reserved

Bloomington, MN 55420 Printed in the USA

1

Page 3

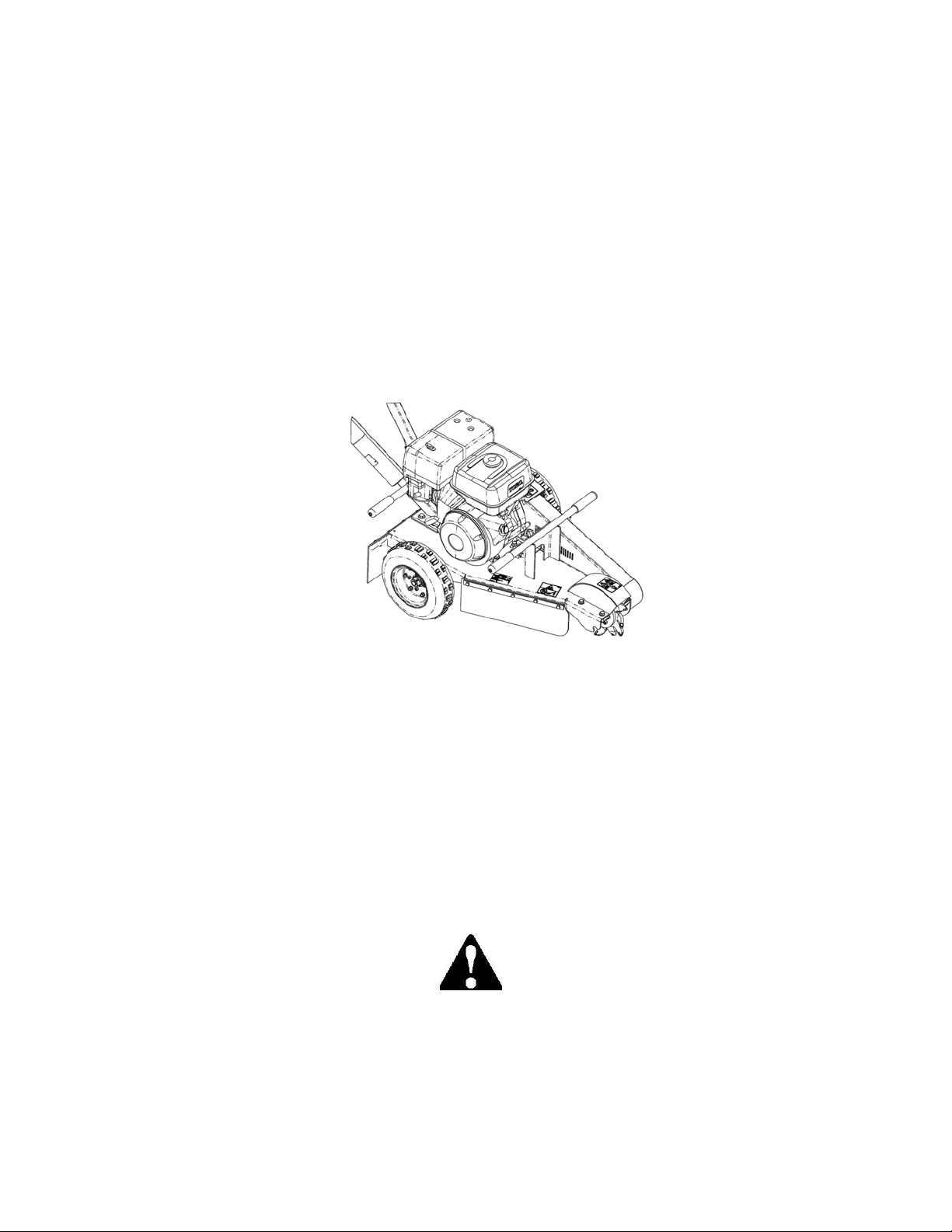

The Stump Grinder is used to remove tree stumps. By moving the machine in sweeping

movements laterally over the top and front of the stump, the blade gradually grinds it away.

Only use the machine for removing tree stumps and exposed root systems. It is not intended for

any other use. Read this information carefully to learn how to operate and maintain your product

properly and to avoid injury and product damage. You are responsible for operating the product

properly and safely.

You may contact Toro directly at www.Toro.com for product and accessory information, help

finding a dealer, or to register your product.

Whenever you need service, genuine Toro parts, or additional information, contact an

Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of

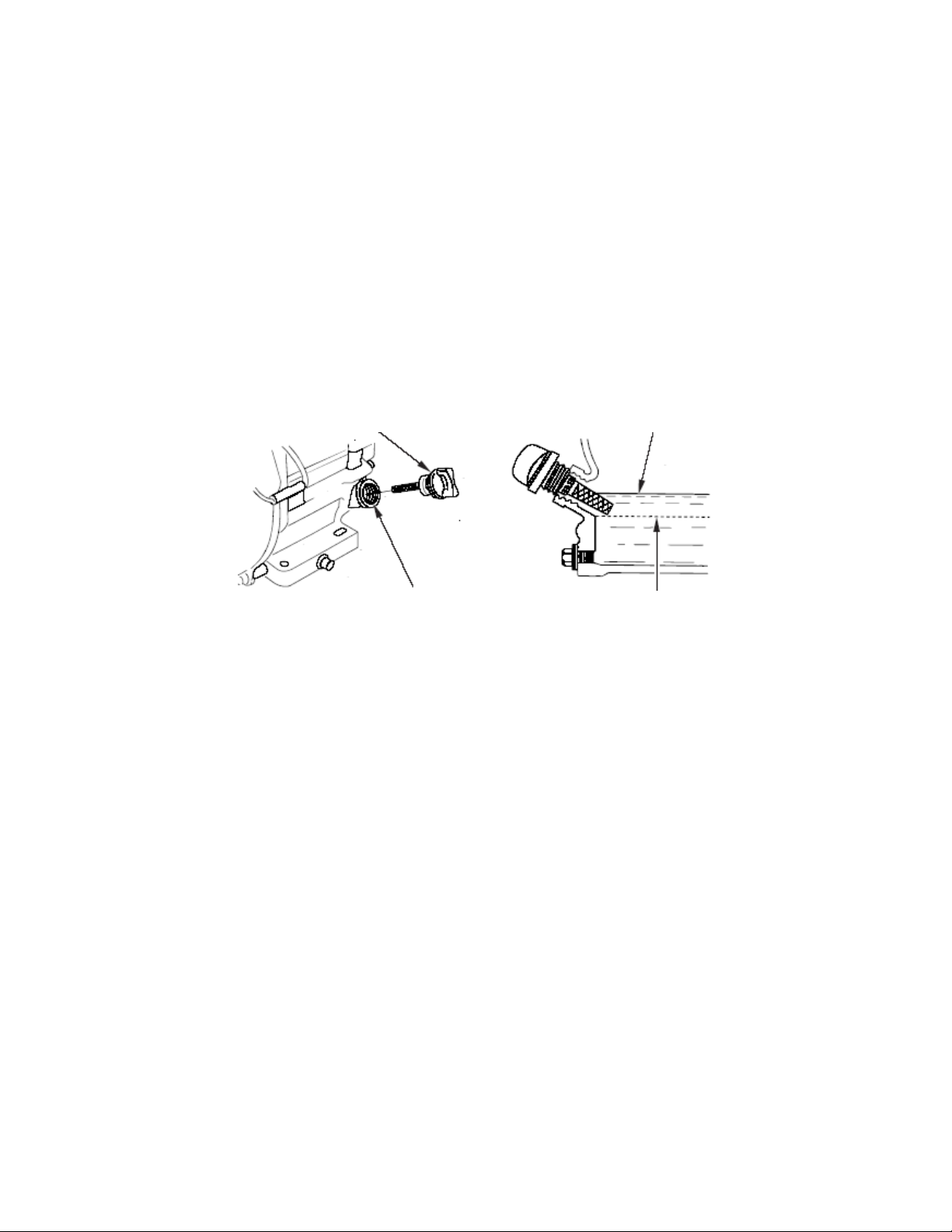

your product ready. Figure 1 identifies the location of the model and serial numbers on the

product. Write the numbers in the space provided.

1

Figure 1

1. Model and serial number location

Model No. ____________________________________________

Serial No. ____________________________________________

This manual identifies potential hazards and has safety messages identified by the safety alert

symbol (Figure 2), which signals a hazard that may cause serious injury or death if you do not

follow the recommended precautions.

Figure 2

1. Safety alert symbol

2

Page 4

Contents

Introduction ................................................1

Safety ...........................................................4

Safe Operating Practices .........................4

Training ...................................................4

Preparation ...............................................4

Operating .................................................5

Slope Operation .......................................6

Maintenance and Storage ........................6

Safety and Instructional Decals ................8

Controls .......................................................9

Throttle ....................................................9

Safety Bail ...............................................9

Parking Brake ..........................................9

Hour Meter ..............................................9

Specifications ............................................10

Operating ..................................................11

Before you Start .....................................11

Adding Fuel ..............................................12

Using Stabilizer/Conditioner .................13

Filling the Fuel Tank .............................13

Checking the Engine Oil Level ...............14

Starting and Stopping the Engine .........15

Starting the Engine ................................15

Stopping the Engine ..............................16

Grinding the Stump .................................16

Maintenance .............................................19

Recommended Maintenance Schedule ..19

Cleaning the Cyclone Air Filter ............20

Replacing the Air Filter .........................21

Changing the Engine Oil .......................23

Changing the Oil ...................................23

Cleaning the Sediment Cup ...................24

Servicing the Spark Plug .......................25

Removing the Spark Plug ......................25

Installing the Spark Plug .......................25

Cutting Blade .........................................26

Replacing Cutting Blades ......................26

Parking Brake Adjustment ....................27

Cleaning and Washing ...........................27

Lubricating the Bearings .......................27

Drive Belt ..............................................28

Belt Drive Adjustment ...........................28

Storage ......................................................29

Troubleshooting .......................................30

Warranty ................................. Back Cover

3

Page 5

Safety

Improper use or maintenance by the operator or owner can result in injury. To

reduce the potential for injury, comply with these safety instructions and always pay

attention to the safety

personal safety instruction. Failure to comply with the instruction may result in

personal injury or death.

Safe Operating Practices

This product is capable of amputating hands and feet. Always follow all safety

instructions to avoid serious injury or death.

Engine exhaust contains carbon monoxide, an odorless deadly poison that can kill

you. Do not run the engine indoors or in an enclosed area.

Training

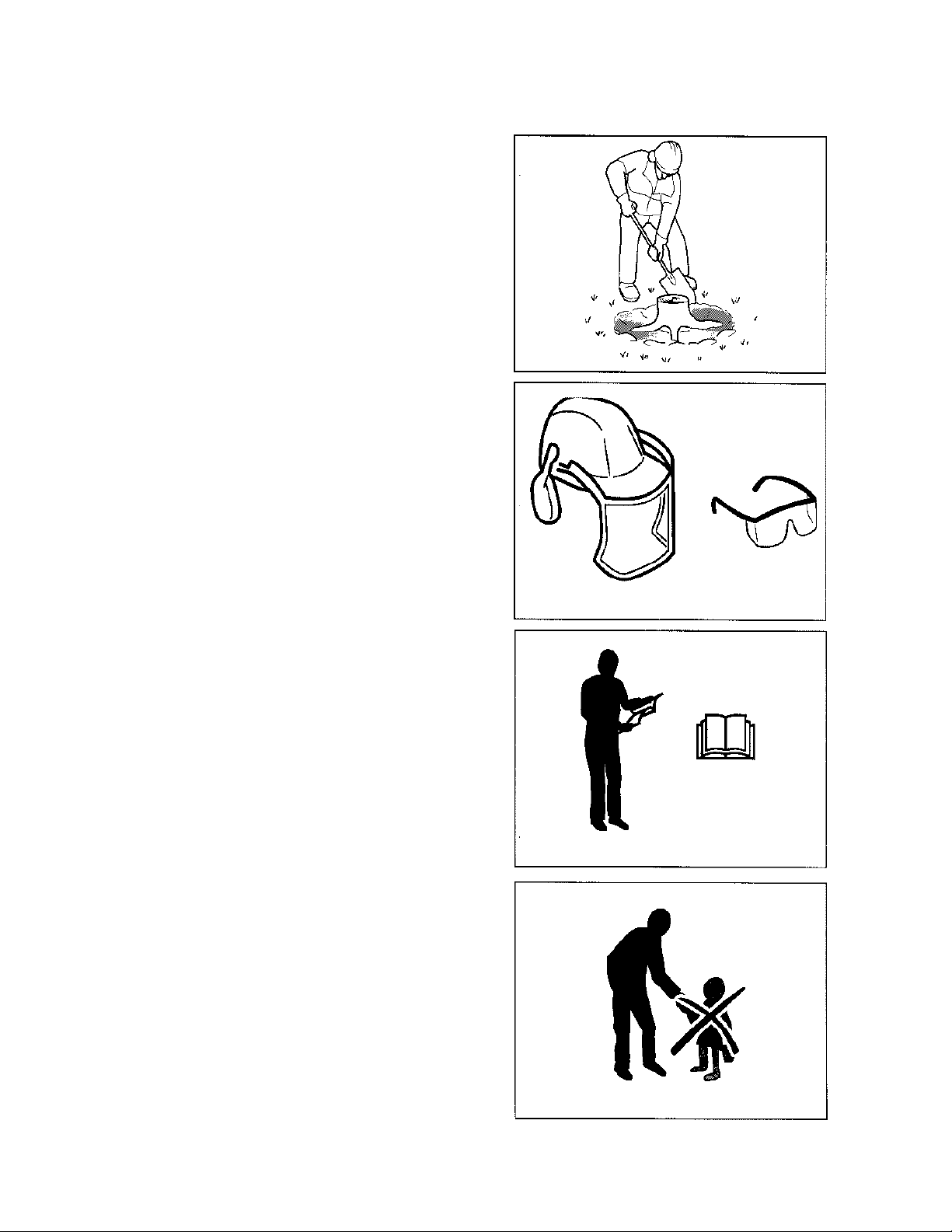

• Read the Operator’s Manual and other training material. If the operator(s) or

mechanic(s) can not read English, it is the owner’s responsibility to explain this

material to them.

• Become familiar with the safe operation of the equipment, operator controls, and

safety signs.

• All operators and mechanics should be trained. The owner is responsible for training

the users.

• Never let children or untrained people operate or service the equipment. Local

regulations may restrict the age of the operator.

• The owner/user can prevent and is responsible for accidents or injuries occurring to

himself or herself, other people or property.

Preparation

alert symbol, which means: Caution, Warning, or Danger—

• Inspect the area where the equipment is to be used and remove all objects such as

rocks, toys, and wire which can be thrown by the machine.

• Use extra care when handling gasoline and other fuels. They are flammable and

vapors are explosive.

- Use only an approved container

- Never remove the gas cap or add fuel with the engine running. Allow the engine

to cool before refueling. Do not smoke.

- Never refuel or drain the machine indoors.

• Check that the operator presence controls, safety switches, and shields are attached

and functioning properly.

• Check that the cutting blade stop rotating when you reduce the throttle.

• Do not operate unless all safety devises are attached and functioning properly.

4

Page 6

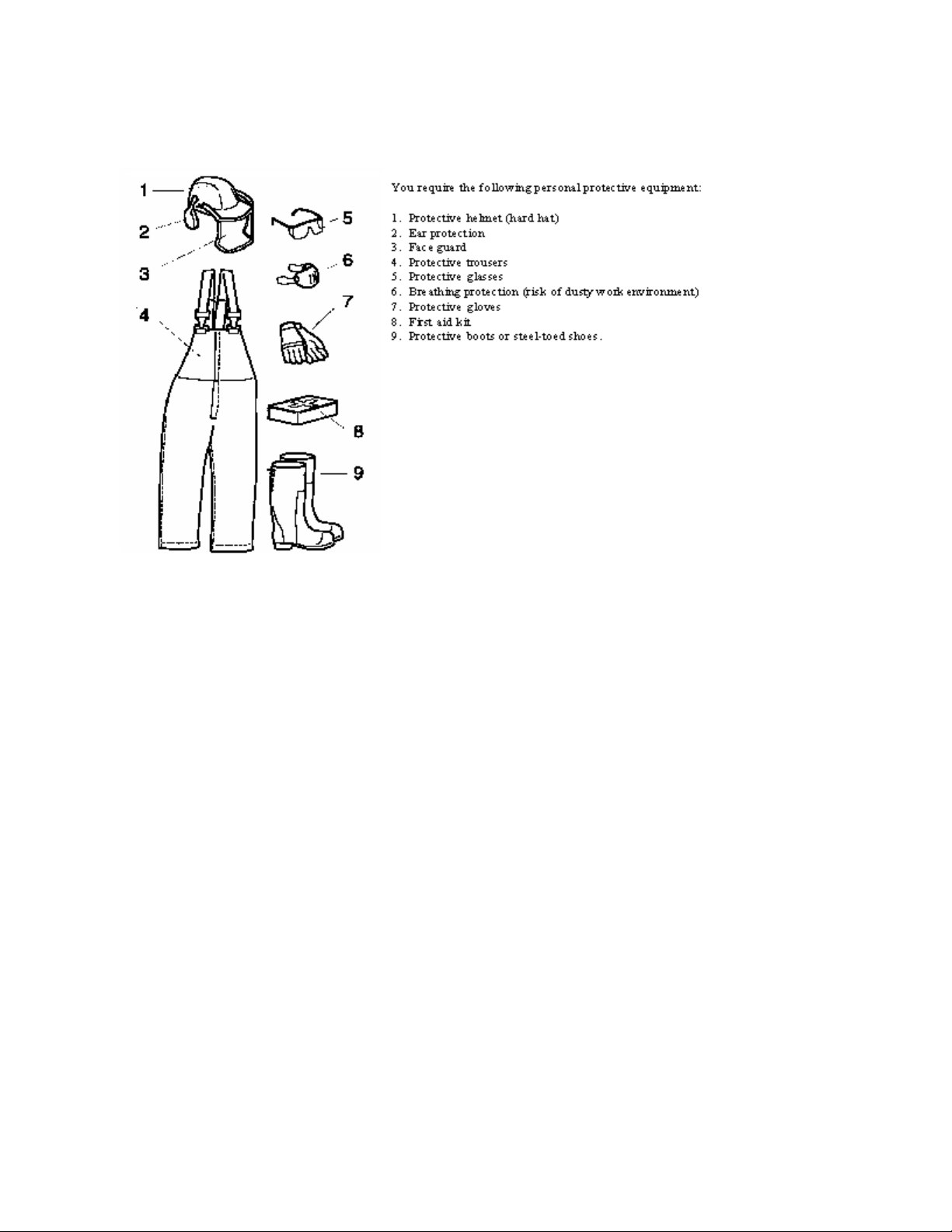

• Wear appropriate clothing including hardhat, safety glasses, long pants, safety shoes,

and hearing protection. Long hair, loose clothing or jewelry may get tangled in

moving parts.

Operation

• Never run an engine in an enclosed area.

• Only operate in daylight, keeping away from holes and hidden hazards.

• Be sure the parking brake is engaged before starting the engine. Only start the

engine from the operator’s position.

• Never operate with the guards not securely in place. Be sure all interlocks are

attached, adjusted properly, and functioning property.

• Do not change the engine governor setting or over speed the engine.

• Engage the parking brake and shut off the engine before leaving the operator’s

position for any reason.

• Keep hands and feet away from moving blades.

• Make sure you have a proper foothold when using the machine, particularly when

backing.

• Walk, don’t run when moving machine on location.

• Never work on wet grass. Poor traction may cause you to slip.

• Look behind and down before backing up to be sure of a clear path.

• Keep pets and bystanders away.

• Do not operate the machine under the influence of alcohol or drugs.

• Use care when loading or unloading the machine into a trailer or truck.

• Use care when approaching blind corners, shrubs, trees, or other objects that may

obscure vision.

• Ensure that the area is clear of other people before operating the unit. Stop the unit if

anyone enters the area.

5

Page 7

• Never leave a running unit unattended. Always stop the engine, set the parking

brake, before leaving.

• Watch for traffic when operating near or crossing roadways.

• Do not touch parts which may be hot from operation. Allow them to cool before

attempting to maintain, adjust, or service.

• Only operate the unit in areas where there is sufficient clearance for the operator to

safely maneuver the product.

• Before removing a stump, have the area marked for underground utilities, and do not

dig in marked areas.

• Locate the pinch point areas marked on the unit and keep hands and feet away from

these areas.

• Lightning can cause severe injury or death. If lightning is seen or thunder is heard in

the area, do not operate the machine; seek shelter.

Slope Operation

Slopes are a major factor related to loss-of-control and accidents, which can result in

severe injury or death. All slopes require extra caution.

• Do not operate the unit on hillsides or slopes exceeding 10 degrees.

• Remove obstacles such as rocks, tree limbs, etc. from the work area. Watch for

holes, ruts, or bumps, as uneven terrain could overturn the unit. Tall grass can hide

obstacles.

• Keep all movements on slopes slow and gradual. Do not make sudden changes in

direction.

• Do not operate near drop-offs, ditches, or embankments. The unit could suddenly

turn over if a wheel goes over the edge of a cliff or ditch, or if an edge caves in.

• Do not operate on wet grass. Reduced traction could cause sliding.

Maintenance and Storage

• Set the parking brake, stop the engine. Wait for all movement to stop before

adjusting, cleaning, or repairing.

• Clean debris from unit, drives, mufflers, and engine to help prevent fires. Clean up

oil or fuel spillage.

• Let the engine cool before storing and do not store near flame.

• Do not store fuel near flames or drain indoors.

• Park the machine on level ground. Never allow untrained personnel to service the

machine.

• Carefully release pressure from components with stored energy.

• Remove the spark plug wire before making any repairs

• Keep hands and feet away from moving parts. If possible, do not make adjustments

with the engine running.

• Keep all parts in good working condition and all hardware tightened. Replace all

worn or damaged decals.

• Keep nuts and bolts tight. Keep equipment in good condition.

• Never tamper with safety devices.

6

Page 8

• Keep the unit free of grass, leaves, or other debris build-up. Clean up oil or fuel

spillage. Allow the unit to cool before storing.

• Use extra care when handling gasoline and other fuels. They are flammable and

vapors are explosive.

- Use only an approved container.

- Never remove the gas cap or add fuel when the engine is running. Allow the

engine to cool before refueling. Do not smoke.

- Never refuel the unit indoors.

- Never store the unit or fuel container inside where there is an open flame, such

as near a water heater or furnace.

- Never fill a container while it is inside a vehicle, trunk, pick-up bed, or any

surface other than the ground.

- Keep container nozzle in contact with the tank during filling.

- Close the fuel valve for storage or transport

• Stop and inspect the equipment if you strike an object. Make any necessary repairs

before restarting.

• Use only genuine Toro replacement parts to ensure that original standards are

maintained.

7

Page 9

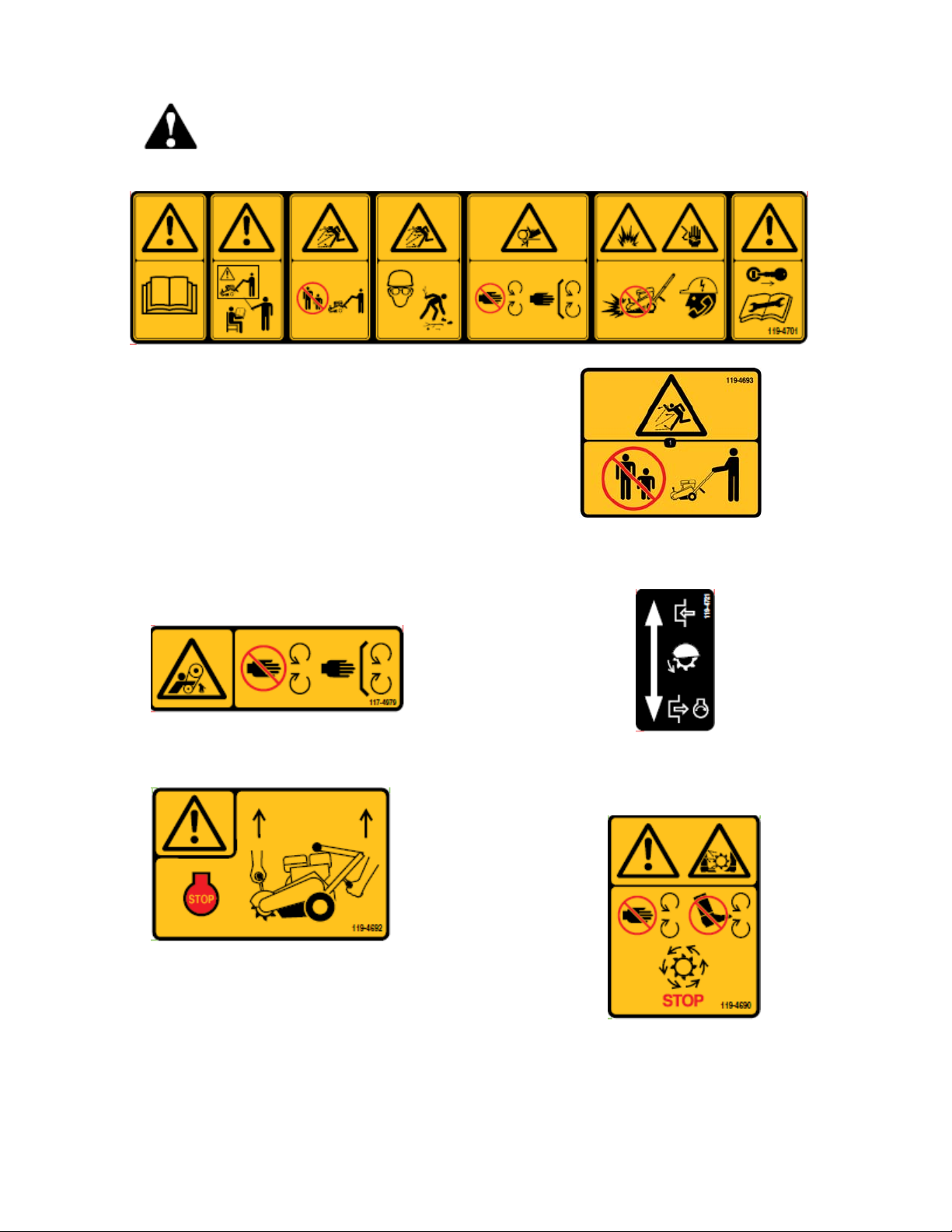

Safety and Instructional Decals

Safety decals and instructions are easily visible to the operator and are located

near any areas of potential danger. Replace any decal that is damaged of lost.

119-4701

- Warning - Read Operator’s Manual

- Warning - Train all product users

- Thrown objects - Keep bystanders away

- Thrown objects - Wear hard hat and

safety glasses, clean area of debris

- Rotating belt - Keep guard in place

- Explosion and electric shock hazard

- Call utilities to mark underground

hazards

- Warning - Stop engine before performing

maintenance operations

117-4979

- Rotating belt - Keep guard in place

119-4692

- Warning - Stop engine before lifting

- Thrown objects - Keep by-standers away

- Move throttle to engage/disengage blade

- Warning, - Rotating blade

- Keep and hands and feet clear

- Stop rotating blade before servicing

119-4693

119-4721

119-4690

8

Page 10

Controls

Throttle:

The throttle lever controls engine speed.

With the lever down, in the DISENGAGED position the

engine runs at idle. This is also the starting position.

When the engine speed increases, to the ENGAGED

position, the centrifugal clutch engages and the cutting

blade rotates.

Safety Bail:

Hold the safety bail against the handle to deactivate the

engine kill switch so the engine will start. Releasing the

bail stops the engine.

Parking Brake:

The parking brake holds the left wheel from turning to

secure the machine and for easy movement of the

machine from side to side when grinding the stump.

Hour Meter:

The hour meter shows the hours the unit has been used

and runs only when the engine is running.

9

Page 11

Specifications

Model

Engine

Idling speed

Spark plug

Fuel tank volume

Tires

Brake

Drive Belt

Clutch

Cutters

Cutting depth

Length

Width

Height

Weight

22602

Honda GX390QXC9

1250-1550 RPM

NKG BPR6ES

6.5 liters/1.72 US Gal

13 x 5.00 - 6 (pneumatic)

Disk - Lever activated Direct

Double-banded - 3V section

Centrifugal clutch

12 - Tungsten carbide tips

Approx 12" (30.48 cm)

76" (193 cm)

29.5 (75 cm)

42" (107 cm)

240 lbs. (109 kg)

10

Page 12

Operation

Note: Determine the left and right sides of the

machine from the normal operating position.

Important: Before operating, check the fuel

and oil level, and remove debris from the

traction unit. Also, ensure that the area is clear

of people and debris. You should also know and

have marked the locations of all utility lines.

Before you start:

Dig away the earth and remove any stones near the

tree stump that may interfere with your work.

Check that the ground is free of foreign objects,

such as electrical cables, barbed wire, etc.

Cut or trim the stump as necessary using a power

saw.

Review all the machine’s safety decals.

Use a hard-hat, hearing, and eye protection. A

mesh visor alone does not provide sufficient eye

protection; supplement with protective glasses.

Make sure that you are familiar with safety

regulations and shutdown procedures described in

the Operator’s Manual.

Make sure that all guards are in place and in good

condition.

Make sure that the blades and cutters are in place

and in good condition.

Make sure that the work area, cutter, and stump in

particular are free from metallic objects such as

wire, nails, etc. that could be thrown out and injure

persons in the vicinity and damage the equipment.

Make sure that everyone, including children and

animals, maintain a distance of at least 50 feet

(15 m) from the machine. Debris can be thrown

out and injure people and animals.

11

Page 13

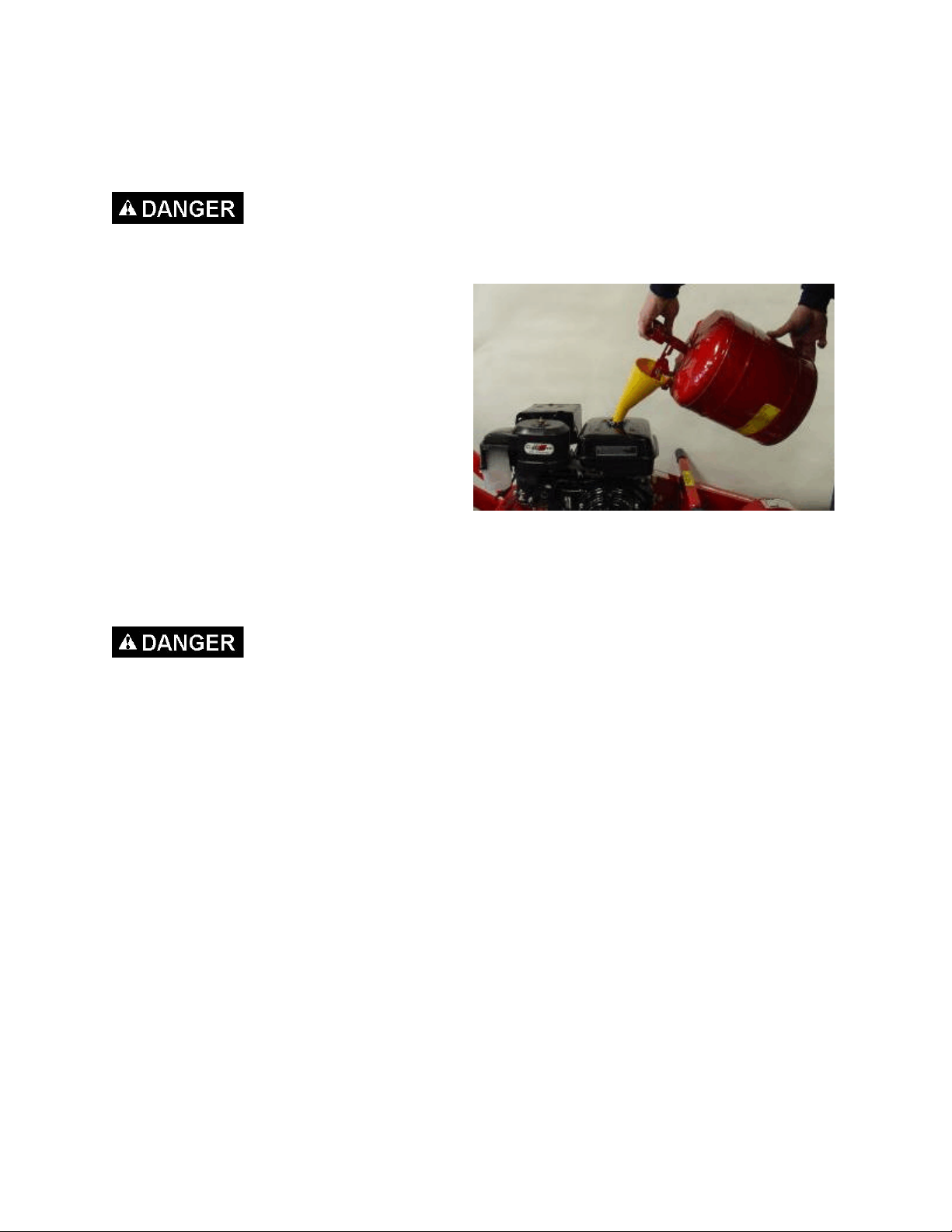

Adding Fuel

Use unleaded gasoline (87 pump octane minimum). Leaded, regular gasoline may be used if

unleaded is not available.

In certain conditions, gasoline is extremely flammable and highly explosive. A fire or

explosion from gasoline can burn you and others and can damage property.

• Fill the fuel tank outdoors, in an open

area, when the engine is cold. Wipe up

any gasoline that spills.

• Never fill the fuel tank inside an

enclosed trailer.

• Do not fill the fuel tank completely full.

Add gasoline to the fuel tank until the

level is below the bottom of the strainer

neck. This empty space in the tank

allows gasoline to expand.

• Never smoke when handling gasoline,

and stay away from an open flame or where gasoline fumes may be ignited by a spark.

• Store gasoline in an approved container and keep it out of the reach of children. Never

buy more than a 30-day supply of gasoline.

• Do not operate without entire exhaust system in place and in proper working condition.

In certain conditions during fueling, static electricity can be released causing a spark

which can ignite the gasoline vapors. A fire or explosion from gasoline can burn you and

others and can damage property.

• Always place gasoline containers on the ground away from your vehicle before filling.

• Do not fill gasoline containers inside a vehicle or on a truck or trailer bed because

interior carpets or plastic truck bed liners may insulate the container and slow the loss

of any static charge.

• When practical, remove gas-powered equipment from the truck or trailer and refuel the

equipment with its wheels on the ground.

• If this is not possible, then refuel such equipment on a truck or trailer from a portable

container, rather than from a gasoline dispenser nozzle.

• If a gasoline dispenser nozzle must be used, keep the nozzle in contact with the rim of the

fuel tank or container opening at all times until fueling is complete.

Important: Do not use methanol, gasoline containing methanol, or gasohol containing

more than 10% ethanol because the fuel system could be damaged. Do not mix oil with

gasoline.

12

Page 14

Using Stabilizer/Conditioner

Use a fuel stabilizer/conditioner in the traction unit to provide the following benefits:

• Keeps gasoline fresh during storage of 90 days or less. For longer storage it is recommended

that the fuel tank be drained.

• Cleans the engine while it runs

• Eliminates gum-like varnish buildup in the fuel system, which causes hard starting

Important: Do not use fuel additives containing methanol or ethanol.

Add the correct amount of gas stabilizer/conditioner to the gas.

Note:

A fuel stabilizer/conditioner is most effective when mixed with fresh gasoline. To

minimize the chance of varnish deposits in the fuel system, use fuel stabilizer at all times.

Filling the Fuel Tank

1. Park the traction unit on a level surface and stop the engine.

2. Allow the engine to cool.

3. Clean around the fuel tank cap and remove it.

Note: The cap is tethered to the fuel tank.

4. Add unleaded gasoline to the fuel tank, until the level is just below the bottom of the

strainer neck.

Important: This space in the tank allows gasoline to expand. Do not fill the fuel tank

completely full. 1 2

1. Maximum fuel level 2. Fuel tank top

5. Install the fuel tank cap securely, turning it until it clicks.

6. Wipe up any gasoline that may have spilled.

13

Page 15

Checking the Engine Oil Level

1. Park the unit on a level surface and stop the engine.

2. Clean around the oil dipstick

3. Unscrew the oil dipstick and wipe the end clean.

4. Slide the oil dipstick fully into the crankcase. Do not thread it in.

5. Pull the oil dipstick out and look at the end. Oil should be to the top of the upper limit range.

Note: Running the engine with low oil level can cause engine damage. This type of damage is

not covered by Warranty.

The engine is equipped with and Oil Alert system that will automatically stop the engine before

the oil level falls below the safe limit. To avoid the inconvenience of an unexpected shutdown,

fill to the upper limit, and check the oil level regularly.

1 3

2 4

1. Oil dipstick 2. Oil fill hole 3. Upper limit 4. Lower limit

6. If the oil level is low, slowly pour only enough oil into crankcase to raise the level to the upper

limit.

Important: Do not overfill the crankcase with oil because the engine may be damaged.

7. Replace the oil dipstick.

14

Page 16

Starting and Stopping the Engine

Starting the Engine

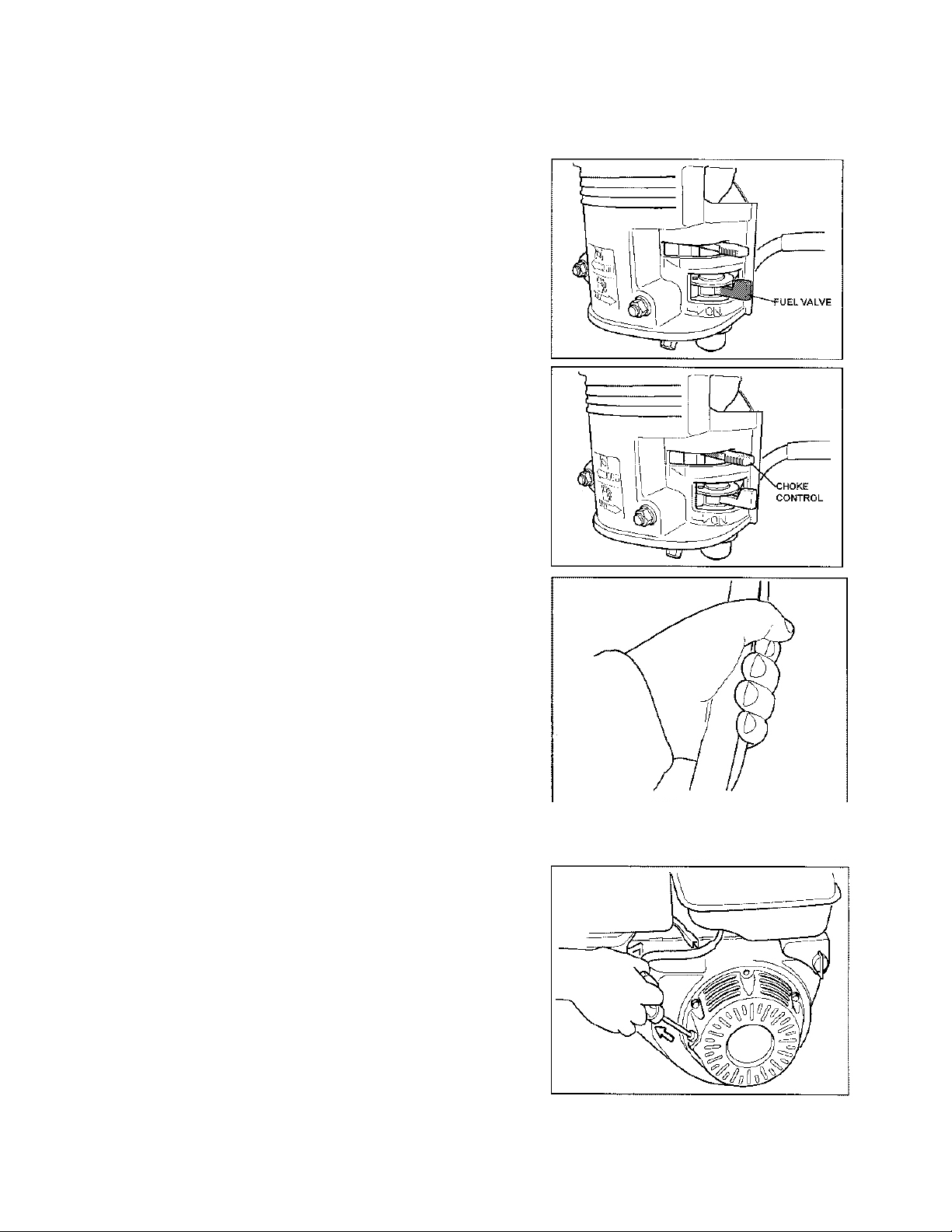

1. Move the fuel valve to the OPEN position, all the

way to the right.

2. Move the choke lever left to the ON position if you

are starting a cold engine.

Note: A warm or hot engine may not require choke.

3. Move the throttle to the DISENGAGE position.

4. Hold the safety bail against the handle and push the

handle down enough to raise the cutting wheel off

the ground.

5. Pull the starter handle lightly until you feel resistance, then pull briskly in the direction the

arrow show. Return the starter grip gently.

6. After the engine starts, gradually move the choke

lever back to the OFF position. If the engine stalls

or hesitates, move the choke back to the ON again

until the engine warms up. Then move to the full

OFF position.

15

Page 17

Stopping the Engine

1. Move the throttle to the DISENGAGE positions.

Note: If the engine has been working hard or is hot,

let it run for a minute before releasing the safety bail.

This helps to cool the engine before stopping. In an

emergency, the engine may be stopped immediately.

2. Release the safety bail to stop the engine.

3. Move the fuel valve to the CLOSED position, all

the way to the left.

Grinding a Stump

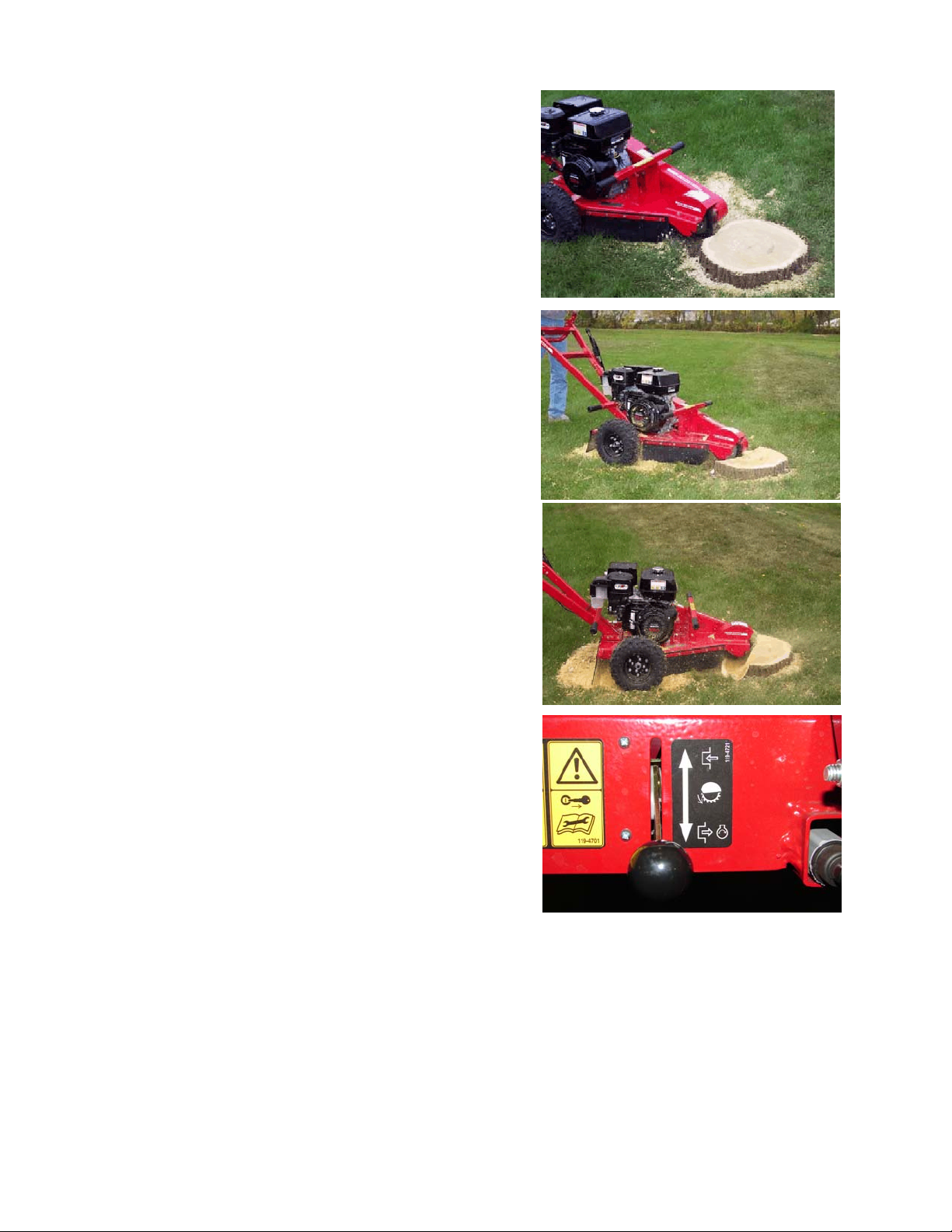

Place the stump grinder into position with cutting

blade near the front-top edge of the stump.

A rotating cutting blade is very DANGEROUS!

Keep bystanders away from thrown debris.

Set the parking brake to the lock position.

1. Set throttle to the DISENGAGE position.

1. Start the engine; refer to Starting the Engine.

2. Allow engine to warm up at idle for two minutes.

3. Push the handle down enough to raise the cutting

wheel off the ground.

4. Move throttle up to the ENGAGE position, this

will engage the centrifugal clutch and the cutting

blade rotates.

16

Page 18

5. Swing the cutting blade to one side, then lower it

approximately 1/2" to 1" into the front-top corner

of the stump. Swing the cutting blade back and

forth, lowering the cutting blade approximately

1/2" to 1" before each sweep, until you have

removed the front portion of the stump to ground

level.

6. Raise the cutting blade until center of cutting blade

is just above top of the stump.

7. With the cutting blade off to one side, release the

parking brake and advance the machine forward,

reset the parking brake.

8. Sweep the cutting blade across the stump, cutting

away 1/2" to 1" of stump.

9. Advance the machine forward 1/2" to 1", and

sweep across the stump in the opposite direction.

10. Continue sweeping and cutting blade left and right

across stump, advancing the machine before each

sweep, cutting 1/2" to 1" depth of cut with each

sweep.

11. Continue cutting until top level of stump is all

removed, making sure not to cut stump deeper than

ground level during this first stage.

12. Move throttle to the DISENGAGE position, push

the handle down enough to raise the cutting wheel

off the ground. Wait ten seconds for blade to stop

rotating then release brake and retract machine

from stump.

17

Page 19

Pull machine away from stump, and rake chips away

from stump.

13. Place stump machine into position with cutting

blade near the front-top edge of the stump.

14. Set brake to the lock position.

15. Move the throttle up to the ENGAGE position.

16. Complete cutting stump by repeating step 12 again

and again until entire stump is cut to desired depth.

17. Stop the machine; refer to Stopping the Engine.

DO NOT let front of unit touch ground until you are sure cutting wheel has stopped turning.

A rotating cutting blade is very DANGEROUS!

Stay at the operating position and be sure that the blade comes to a complete stop before doing

anything else.

18

Page 20

Maintenance

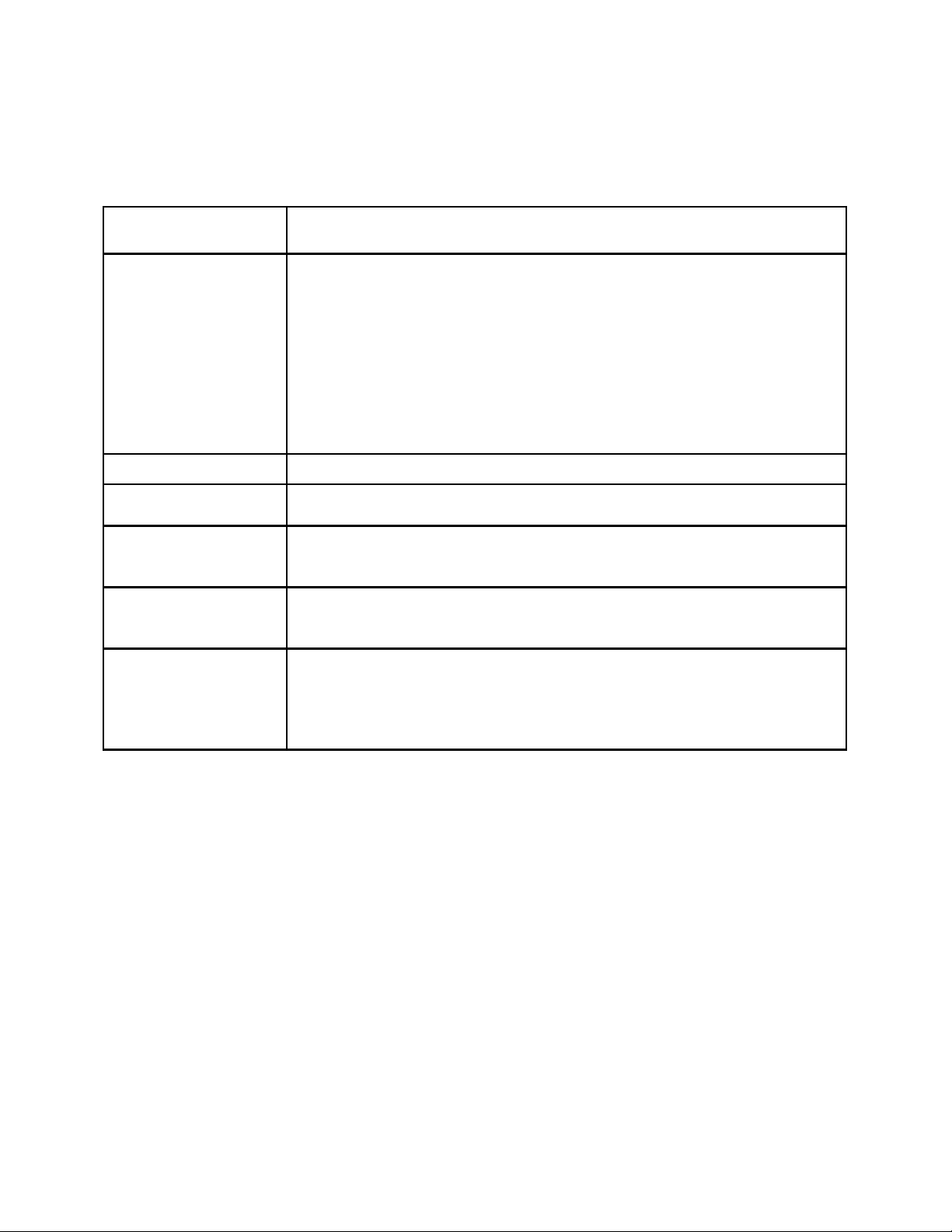

Recommended Maintenance Schedule

Maintenance

Service Interval

Before each use or daily

After the first 20 hours • Change the engine oil

Every 50 hours

Every 100 hours

Every 300 hours

Yearly or before

storage

(1) More frequently in dusty conditions

Important: Refer to your Engine Operator’s Manual for additional maintenance

procedures.

Maintenance Procedure

• Check the engine oil level.

• Lubricate the cutting blade bearings. (Lubricate immediately after every

washing.)

• Check the air filter

• Check the safety bail switch

• Check the cutter blades for sharpness and missing or bent teeth

• Inspect the drive belt for wear and tension

• Remove debris from the unit

• Check for loose fasteners

• Check/replace safety and instructional decals

• Check/Replace the air filter (1)

• Inspect the drive belt for wear or damage

• Change the engine oil (1)

• Clean the sediment cup

• Check/adjust the spark plug

• Replace the air filter paper element

• Replace the spark plugs

• Replace the drive belt

• Change the engine oil

• Check/Replace the air filter

• Clean the sediment cup

• Check/adjust the spark plug

• Touch up chipped paint

19

Page 21

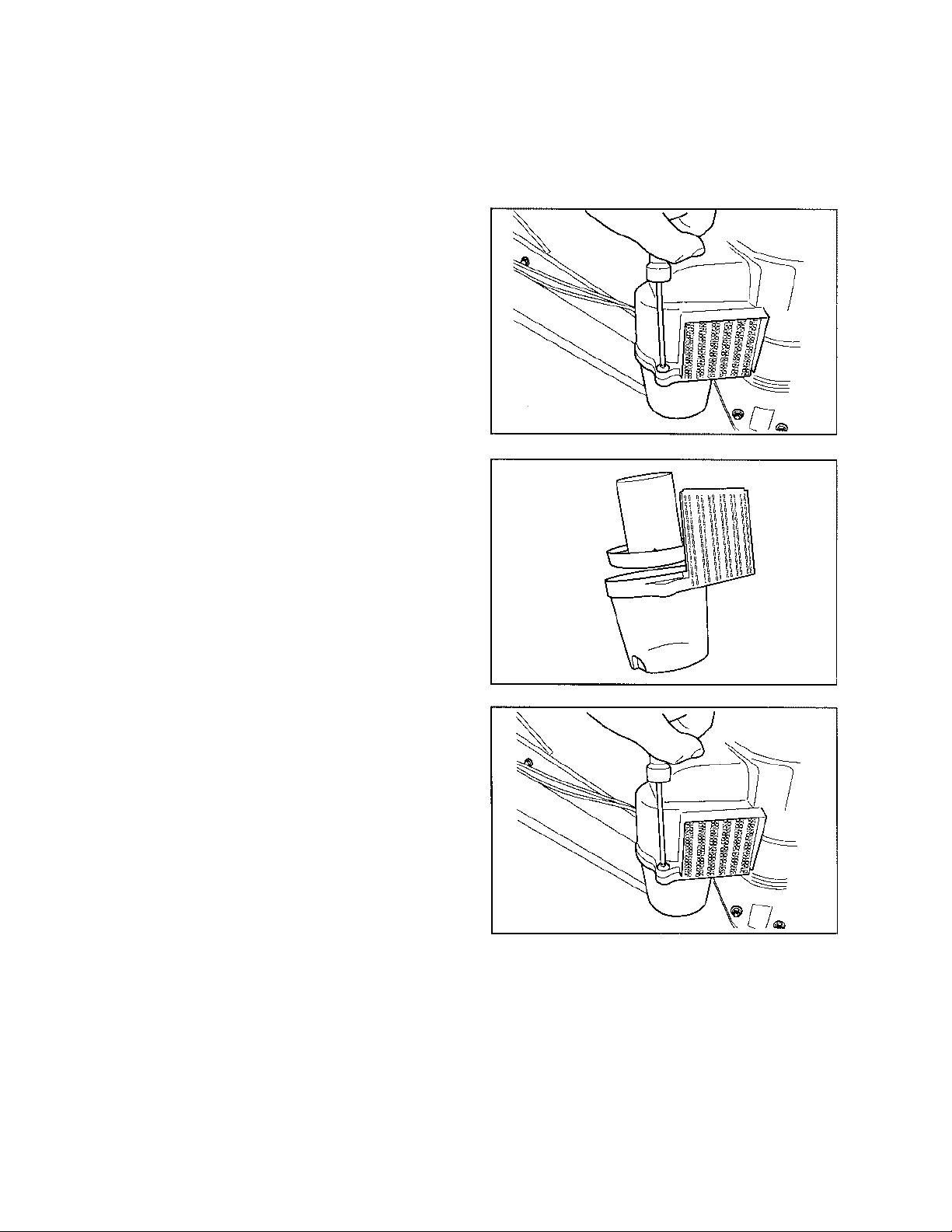

Cleaning the Cyclone Air Filter

The cyclone air filter collects the largest contaminant particles, which collect in the container.

When you can see a layer of dirt at the bottom of the container, the cyclone housing (4), air

channels and air intake screen (3) must be cleaned.

1. Remove the three screws holding the

cyclone housing.

2. Remove the housing with the air intake

screen and remove the air channels.

Note: The air channels may remain in the upper

portion or follow along with the housing when

removed.

3. Clean the components. Use water, detergent

and a brush. Dry carefully.

4. Place the air channels in the cyclone

housing.

5. Insert cyclone housing into position and

make sure it fits in the upper portion.

DO NOT use force; align it in place before

fitting the screws.

20

Page 22

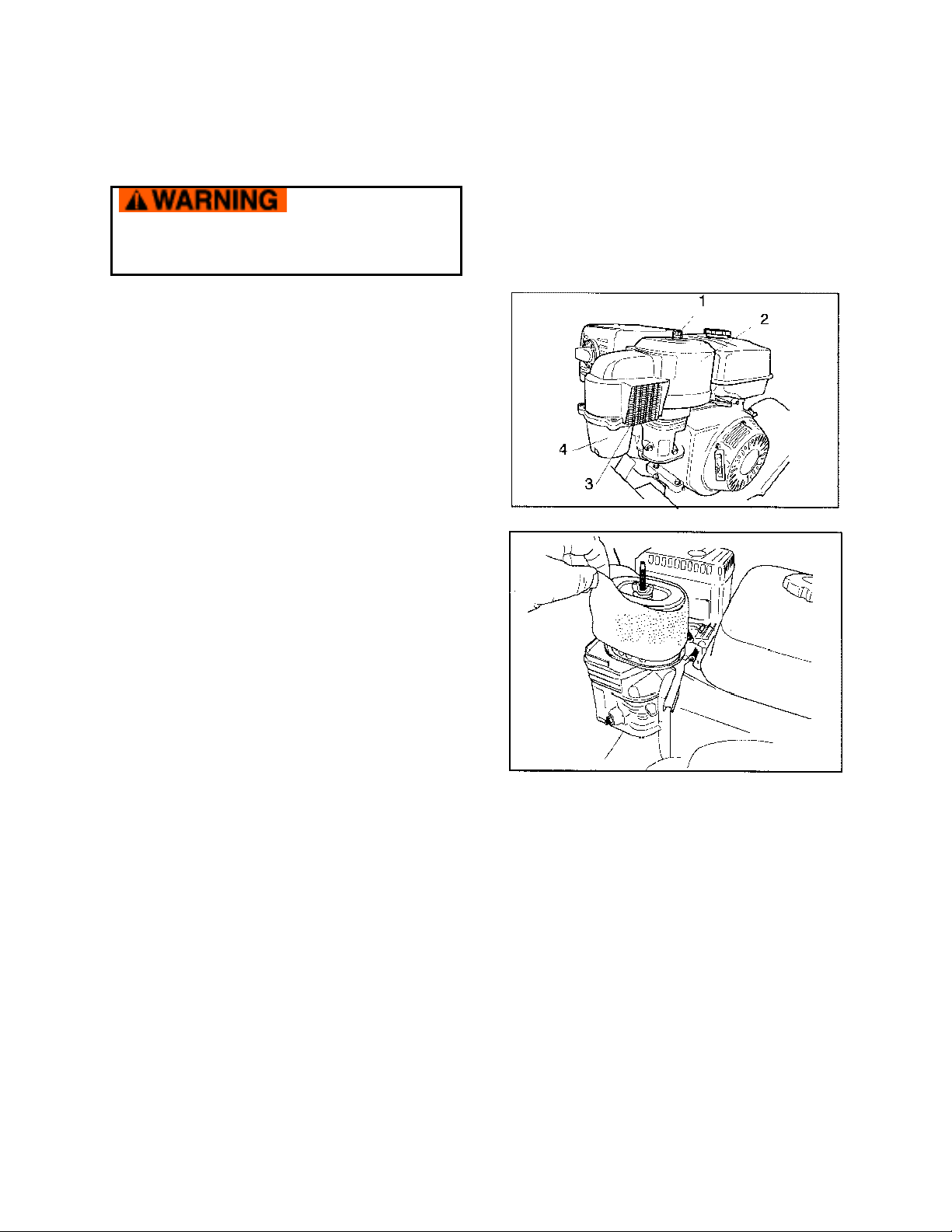

Replacing the Air Filter

If the engine is low on power, produces black smoke or runs unevenly, the air filter may be

clogged. For this reason, it is important to clean and replace the air filter regularly (see the

maintenance schedule for the proper service interval).

Allow the exhaust system to cool before

performing service. Risk for burns.

1. Remove the wing nut (1) and lift off the

cyclone filter with the air filter cowling (2).

2. Remove the foam pre-filter and clean using a

mild detergent and water.

- Squeeze it dry with a clean cloth.

- Soak it with new engine oil. Wind the filter

in an absorbent cloth and squeeze out excess

oil.

21

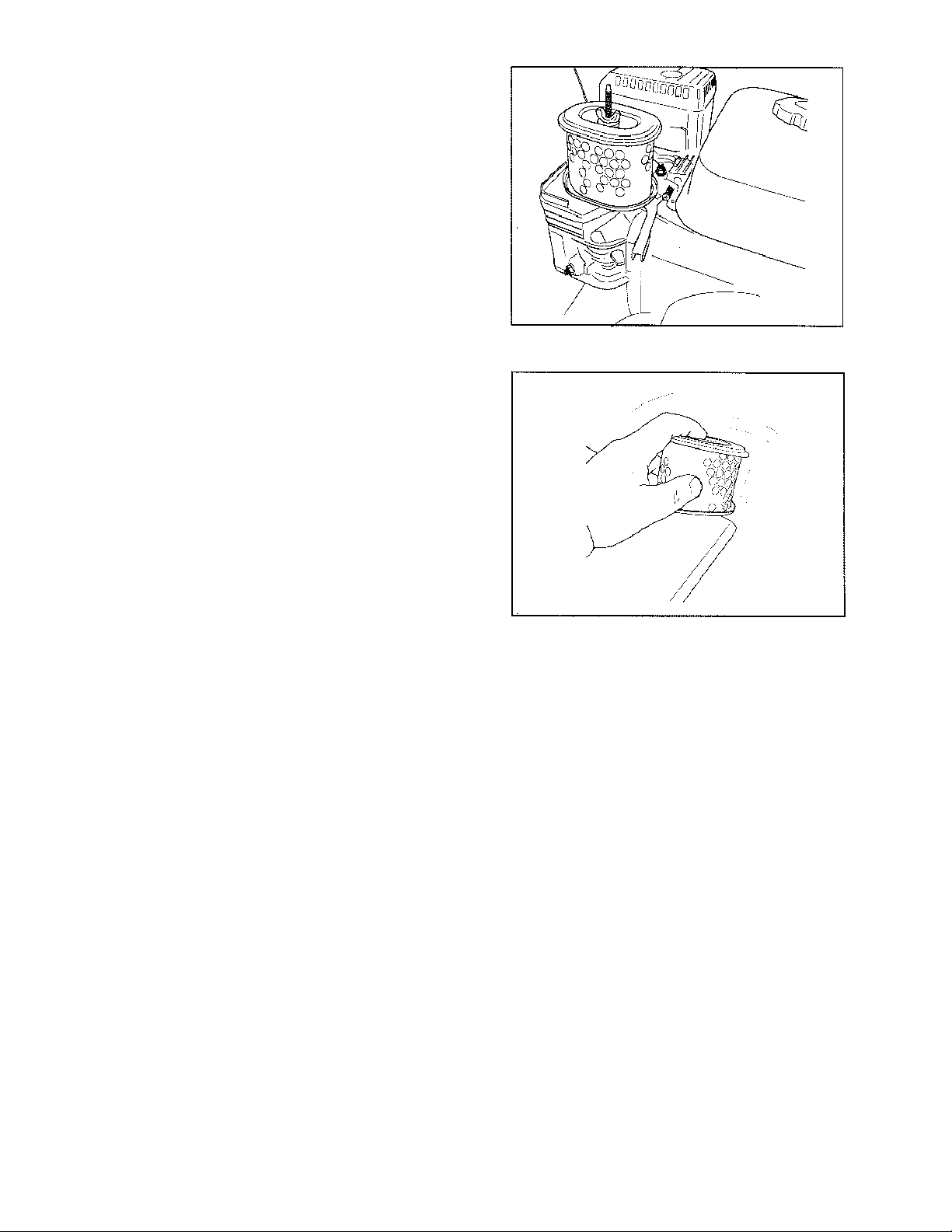

Page 23

3. Remove the wing nut on top of the air filter

and remove the paper filter.

4. Tap the paper filter against a fixed surface to

remove dust. If the paper filter is still dirty or

damaged, replaced it.

Important: Do not us compressed air to blow

out paper element, this can damage paper

element.

Assemble the air filter as follows:

5. Mount the paper filter in the air filter housing

and tighten the wing nut.

6. Position the foam pre-filter over the paper

filter.

7. Install the cyclone filter with the air filter cover.

22

Page 24

Changing the Engine Oil

Note: Change oil more frequently when operating

conditions are extremely dusty.

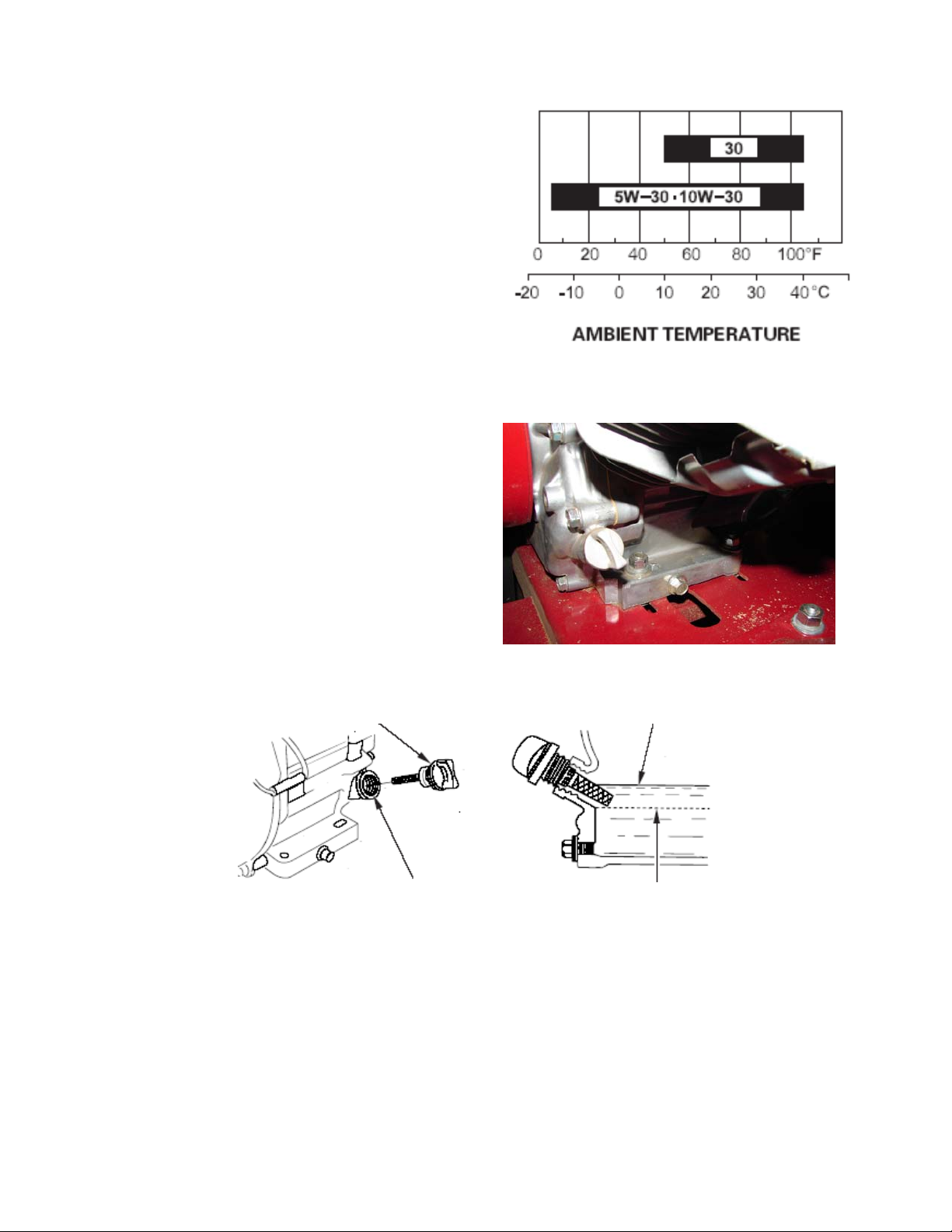

Oil Type: Detergent oil with an API service rating

of SJ, or higher.

Crankcase Capacity: 2.1 qt. (2 l)

Viscosity: SAE 10W-30 is recommended for

general use. Other viscosities show in the chart

may be used when the average temperature in your

area is within the indicated range

Changing the Oil

1. Start the engine and let it run for five minutes.

This warms the oil so it drains better.

2. Park the unit so that the drain is slightly lower

than the opposite side to ensure that the oil

drains completely.

3. Set the parking brake and stop the engine.

4. Remove the drain plug and catch oil drained

through the slot in frame.

5. When the oil has drained completely, replace

the plug.

Note: Dispose of the used oil at a certified recycling center.

1 3

2 4

1. Oil dipstick 2. Oil fill hole 3. Upper limit 4. Lower limit

6. Remove the oil fill cap and slowly pour approximately 80% of the specified amount of oil

into the engine.

8. Slowly add additional oil to bring the level to the upper limit mark on the dipstick.

9. Replace the oil fill cap.

23

Page 25

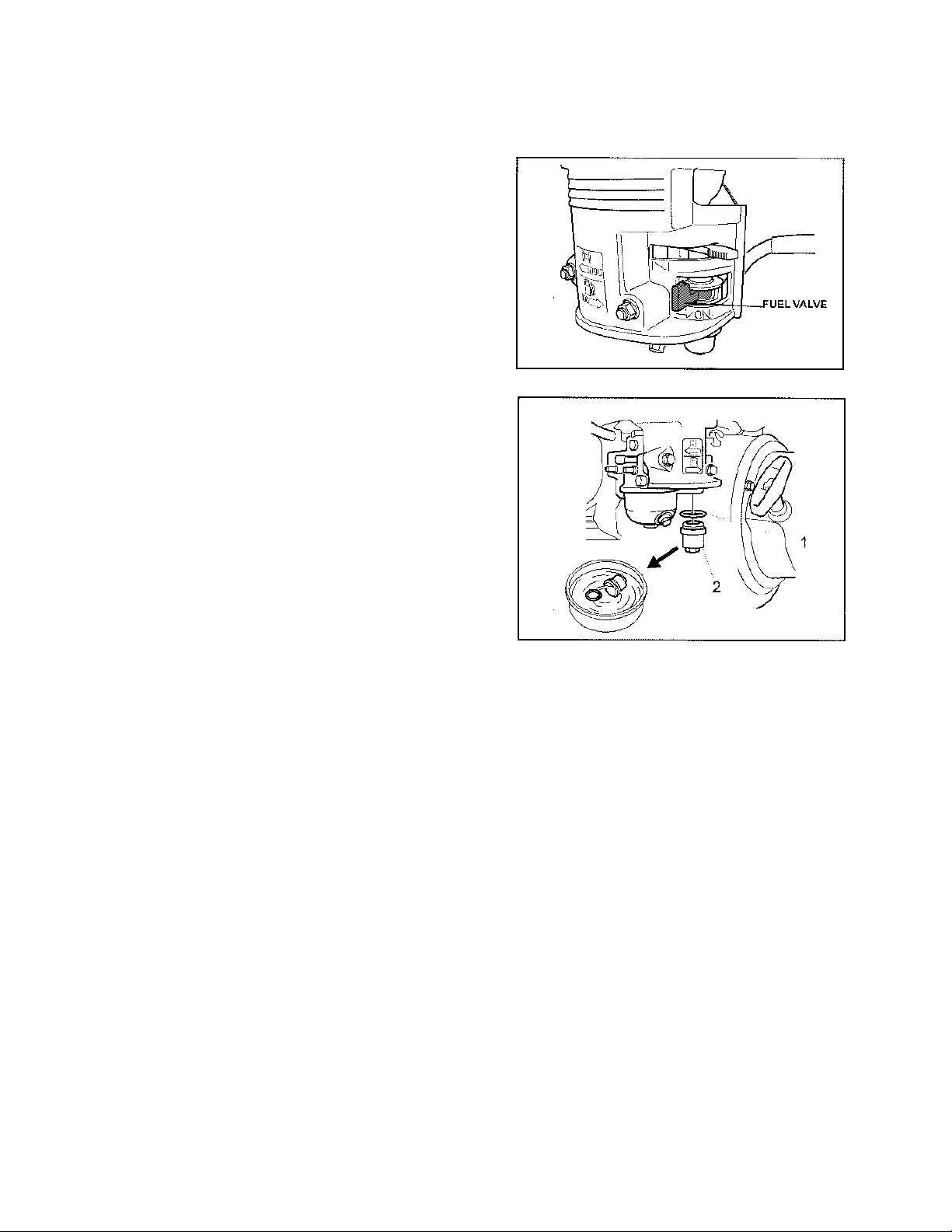

Cleaning the Sediment Cup

Underneath the fuel valve is a sediment cup to catch dirt in the fuel.

1. Move the fuel valve to the OFF position, all the

way to the left.

2. Unscrew the sediment cup (2). Make sure not to

misplace the o-ring (1).

3. Clean the reservoir and the o-ring using a

cleaning solvent and dry carefully.

4. Put the o-ring in place in its groove and replace

the sediment cup (2).

Note: Make sure not to misplace the o-ring (1).

5. Turn the fuel valve to the ON position, all the

way to the right, and check for leaks. If it leaks,

replace the o-ring.

24

Page 26

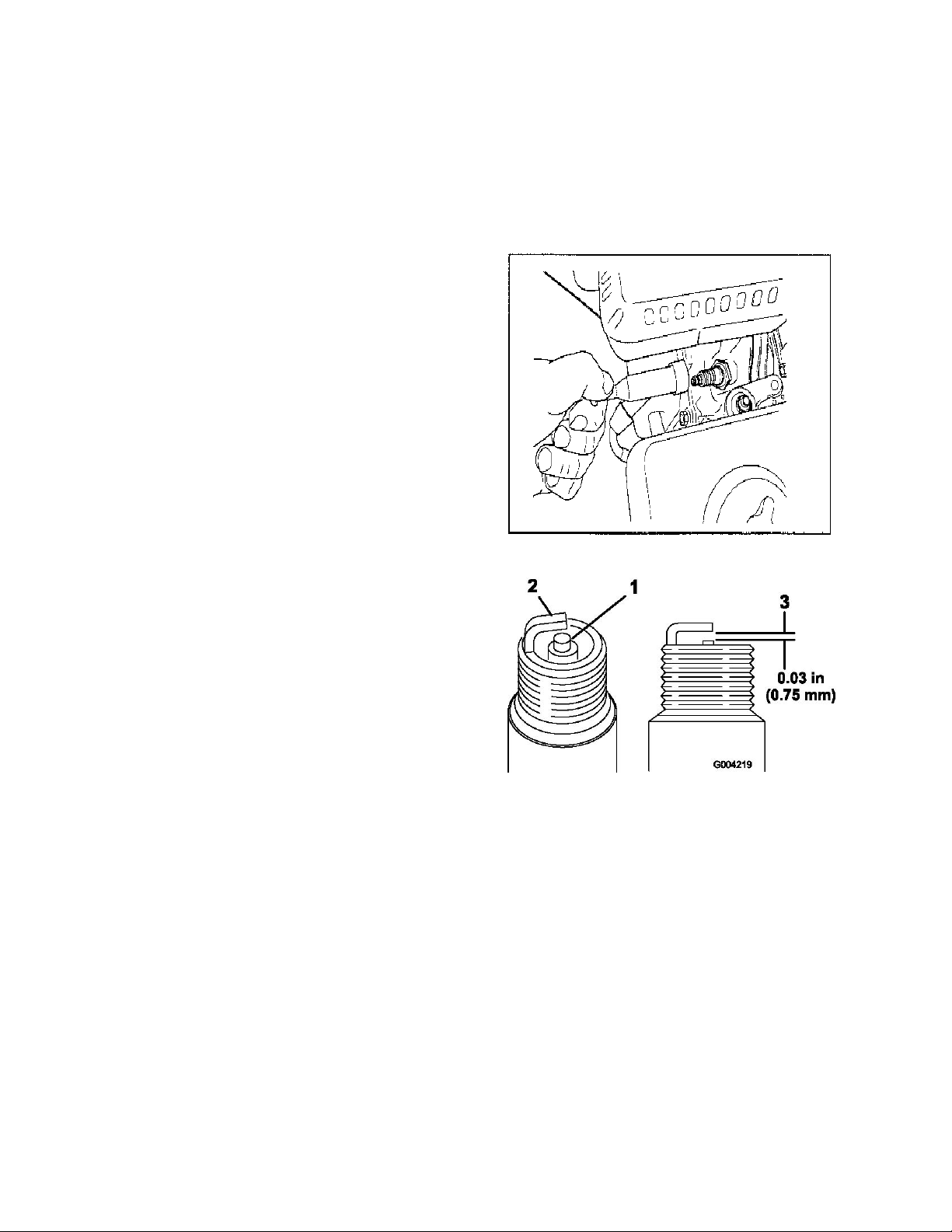

Servicing the Spark Plug

Ensure that the air gap between the center and side electrodes is correct before installing the

spark plug. Use a spark plug wrench for removing and installing the spark plugs and a gapping

tool/feeler gauge to check and adjust the air gap. Install a new spark plug if necessary.

Type: BPR6ES (NKG) or equivalent. Air Gap: 0.28-0.031 inch (0.70-0.80 mm)

Removing the Spark Plugs

1. Pull the wire off of the spark plug

2. Clean around the spark plug.

3. Remove spark plugs and metal washer

Checking the Spark Plugs

1. Look at the center of the spark plug. If you see

light brown or gray on the insulator, the engine

is operating properly. A black coating on the

insulator usually means the air cleaner is dirty.

Important: Never clean the spark plug. Always

replace the spark plug when it has a black

coating, worn electrodes, an oily film, or cracks.

2. Check the gap between the center and side

electrodes.

3. Bend the side electrode if the gap is not

correct.

Installing the Spark Plugs

1. Thread the spark plugs into the spark plug

hole.

2. Tighten the spark plugs to 20 ft-lb (27 N-m).

3. Push the wire onto the spark plug

1 Center electrode insulator

2. Side electrode

3. Air gap (not to scale)

25

Page 27

Cutting Blades

Among the most critical elements of the Stump Grinder is the cutting blades. It is also the most

subject to damage and wear. In the course of grinding stumps it not only makes contact with the

wood, but also encounters numerous abrasives and objects in the stump’s environment, such as

dirt, stones, and occasionally a large rock or buried scrap.

The wear and loss of cutting teeth can significantly impair the efficiency and performance of the

stump grinder. Therefore, it is important to make frequent checks of the condition of all of the

cutting teeth and replace any damaged or worn blade sections.

Replacing Cutting Blades

1. Clean all dirt from the cutting blade and

mounting flanges.

2. Remove the two bolts that hold each cutting

blade section. Use care not to let a section drop

and chip when they become loose.

3. Check each section for cracks. Replace blade

section if it is cracked or has missing or worn

teeth.

4. When replacing cutting blade sections, make

sure blade section is placed in correct

alignment with blade rotation.

5. Insert blade section between the blade

mounting flanges.

6. Slide bolt through one side of flange, and

through flange on other side. Install lock

washer and nut on each bolt.

7. Tighten securely. Torque to 27-33 ft-lb (37-45

N-m).

26

Page 28

Parking Brake Adjustment

1. Loosen the setscrew on side of brake lever knob.

Turn knob clockwise to tighten brake; adjust

counter clockwise to loosen brake. Left wheel

should lock completely when brake is set.

2. Tighten the setscrew.

Important: The machine may be tipped

backward or on its side to facilitate access for

cleaning or service, but no longer than 2 minutes.

If the machine is held in this position for too

long, the engine can be damaged by gasoline

draining into the crankcase. Should this happen,

perform an extra oil change on the engine. Then

turn the engine over a few revolutions with the

starter handle before starting the engine again.

Cleaning and Washing

Regular cleaning and washing will increase the machine’s life span. Clean the machine directly

after use, before the dirt hardens.

Check before cleaning that the fuel tank cap is properly in place to avoid getting water in the

tank.

Use care when using high-pressure sprayer because warning decals, instruction signs and the

engine can be damaged.

Important: Lubricate the cutting blade bearings after cleaning. This is particularly

important if the machine is to be stored.

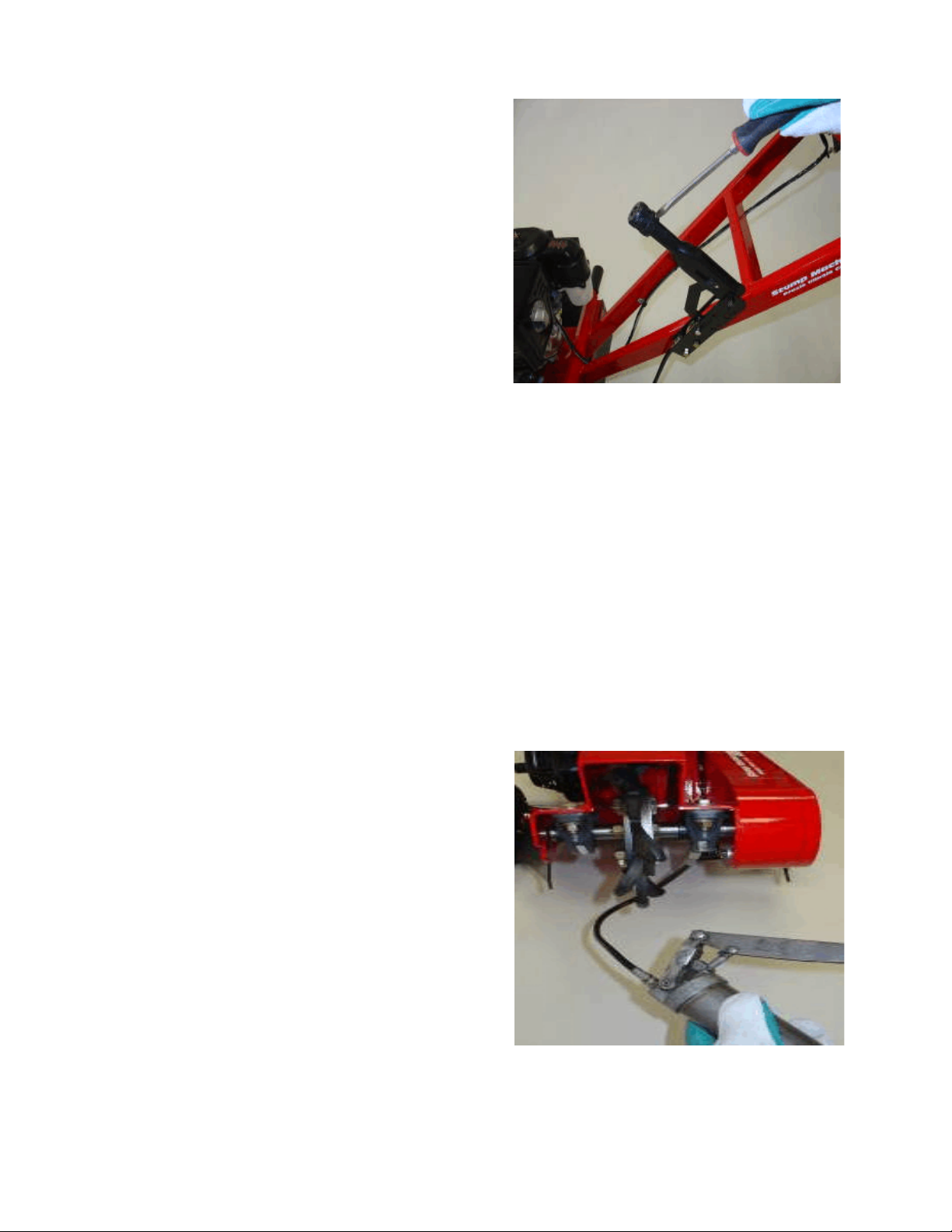

Lubricating the Bearings

Cutting blade bearings should be greased after every

10 hours of operation.

Grease Type: General-purpose grease.

1. Clean the grease fittings with a rag.

2. Connect a grease gun to each fitting.

3. Lubricate two fittings one on each cutting blade

bearing.

4. Pump grease into the fittings until grease begins

to ooze out of the bearings (approximately 3

pumps).

5. Wipe up any excess grease.

Important: Pump grease in slowly and carefully to prevent damage to the bearing seals.

27

Page 29

Drive Belt

The drive belt of the stump grinder is a double-banded 3V-belt.

Note: The belt tension should be checked daily.

Replace the belt if it shows any signs of wear,

cracks, or damage.

1. Shut off the engine and wait for all rotating

parts to stop.

2. Remove belt guard retaining screws.

3. To check belt tension, gently squeeze together.

You should be able to depress the belt down

about 1/4 - 3/8" (6-10mm) from the original

position.

Note: To extend belt life, proper tension must be

maintained. A loose belt will cause excessive

cutting blade slippage and early belt failure. A belt

that is too tight can cause bearing and shaft failure,

and rapid belt wear.

Drive Belt Adjustment

1. Loosen the 2 bolts behind the centrifugal

clutch.

2. Loosen the 4 engine mounting bolts.

3. Turn square head adjusting bolt on the frame

clockwise to tighten the belt, counter clockwise

to loosen the belt.

Important: Make sure to tighten all 6 bolts

after proper belt adjustment is achieved.

3. Install the belt guard and secure with

previously removed hardware.

28

Page 30

Storage

For storage over 30 days, prepare the unit as follows:

1. Remove dirt and grime from the external parts of the entire unit, especially the engine. Clean

dirt and sawdust chips from the outside of the engine cylinder head fins and blower housing.

Important: You can wash the unit with mild detergent and water. Do not pressure wash

the unit. Avoid excessive use of water, especially near the control panel and engine.

2. Add a petroleum based stabilizer/conditioner to fuel in the tank. Follow mixing instructions

from stabilizer manufacturer. (1 oz. per US gallon). Do not use an alcohol based stabilizer

(ethanol or methanol).

Note:

used at all times.

Important: Do not store stabilizer/conditioned gasoline over 90 days.

3. Run the engine to distribute conditioned fuel through the fuel system (5 minutes).

4. Stop the engine, allow it to cool and drain the fuel tank using a pump type siphon. Dispose of

5. Restart the engine and run it until it stops.

6. Choke the engine.

7. Start and run the engine until it will not start again.

8. Clean the sediment cup; refer to Cleaning the Sediment Cup.

9. Service the air cleaner; refer to Cleaning the Cyclone Air Filter and Replacing the Air Filter.

10. Change the engine crankcase oil; refer to Changing the Engine Oil.

11. Remove the spark plug and check the condition; refer to Servicing the Spark Plug.

12. With the spark plug removed from the engine, pour two tablespoons of engine oil into the

13. Pull the starter slowly to crank the engine and distribute the oil inside the cylinder.

14. Install the spark plug, but do not install the wire on the spark plug.

15. Grease the cutter blade bearings; refer to Lubricating Bearings.

16. Check and tighten all bolts, nuts, and screws. Repair or replace any part that is damaged.

17. Paint all scratched or bare metal surfaces. Paint is available from your Authorized Service

18. Store the unit in a clean, dry garage or storage area.

19. Cover the unit to protect it and keep it clean.

Fuel stabilizer/conditioner is most effective when mixed with fresh gasoline and

fuel properly. Recycle as per local codes.

spark plug hole.

Dealer.

29

Page 31

Troubleshooting

Symptom Cause Action

The engine will not

start.

Engine runs rough.

Belt slips or comes off

pulleys.

The cutting wheel

does not rotate.

The cutting wheel

continues to rotate.

The parking brake

does not hold.

Engine switch in OFF position.

Fuel valve closed.

Choke valve open.

Fuel tank empty.

Spark plug fouled.

Choke is left on.

Clogged air filter.

Clogged fuel line.

Water or contaminants in fuel.

Worn spark plug or buildup on

electrodes.

Belt tension is insufficient.

Engine speed is insufficient to

activate the centrifugal clutch.

Belt tension is insufficient.

Clutch shoes are worn.

Engine speed is excessive.

Belt is off pulleys or broken.

Clutch springs are weak or

broken.

Parking brake out of adjustment.

Brake pads worn.

Hold safety bail against handle.

Open the fuel valve.

Close the choke when starting a

cold engine.

Fill tank with fresh fuel.

Check electrode gap and clean or

replace spark plug.

Open the choke valve.

Clean or replace the air filter.

Clean sediment cup.

Drain and fill the tank with fresh

fuel.

Check electrode gap and clean or

replace spark plug.

Adjust belt tension.

Reduce cutting depth.

Move throttle to the ENGAGED

position.

Adjust belt tension.

Replace the clutch.

Move throttle to the

DISENGAGED position.

Replace drive belt.

Replace the clutch.

Adjust the parking brake.

Replace brake pads.

30

Page 32

ToroCompactUtilityEquipmentWarranty

AOne-YearLimitedWarranty

CUEProducts

ConditionsandProductsCovered

TheT oro®Companyanditsafliate,T oroWarrantyCompany ,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCompactUtility

Equipment(“Product”)tobefreefromdefectsinmaterialsorworkmanship.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

Loaders,Trenchers,StumpGrinders,

Chippers,LogSplitters,andAttachments

KohlerEngines3years

AllotherEngines2years

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

1yearor1000operating

hours,whicheveroccursrst

InstructionsforObtainingWarrantyService

IfyouthinkthatyourToroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.ContactanyAuthorizedT oroCompactUtilityEquipment(CUE)

ServiceDealertoarrangeserviceattheirdealership.Tolocatea

dealerconvenienttoyou,accessourwebsiteatwww.T oro.com.

YoumayalsocallourToroCustomerCareDepartmenttollfree

at888-865-5676(U.S.customers)or888-865-5691(Canadian

customers).

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.

3.IfforanyreasonyouaredissatisedwiththeServiceDealer’s

analysisorwiththeassistanceprovided,contactusat:

LCBCustomerCareDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFree:888-865-5676(U.S.customers)

TollFree:888-865-5691(Canadacustomers)

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutine

maintenance,whetherperformedbyadealerorbyyou,isatyourexpense.

Partsscheduledforreplacementasrequiredmaintenance(“Maintenance

Parts”),arewarrantedfortheperiodoftimeuptothescheduled

replacementtimeforthatpart.Failuretoperformrequiredmaintenance

andadjustmentscanbegroundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thisexpresswarranty

doesnotcoverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,modied,orunapproved

accessories

•Productfailureswhichresultfromfailuretoperformrequired

maintenanceand/oradjustments

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligentorrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,during

normalProductoperationinclude,butarenotlimitedto,teeth,tines,

blades,sparkplugs,tires,tracks,lters,chains,etc.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,or

chemicals,etc.

•Normal“wearandtear”items.Normal“wearandtear”includes,butis

notlimitedto,wornpaintedsurfaces,scratcheddecalsorwindows,

etc.

•Anycomponentcoveredbyaseparatemanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

RepairbyanAuthorizedToroCompactUtilityEquipment(CUE)Service

Dealerisyoursoleremedyunderthiswarranty .

NeitherTheToro®CompanynorToroWarrantyCompanyisliable

forindirect,incidentalorconsequentialdamagesinconnectionwith

theuseoftheToroProductscoveredbythiswarranty ,including

anycostorexpenseofprovidingsubstituteequipmentorservice

duringreasonableperiodsofmalfunctionornon-usepending

completionofrepairsunderthiswarranty.Allimpliedwarranties

ofmerchantabilityandtnessforusearelimitedtotheduration

ofthisexpresswarranty .Somestatesdonotallowexclusionsof

incidentalorconsequentialdamages,orlimitationsonhowlong

animpliedwarrantylasts,sotheaboveexclusionsandlimitations

maynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

ExceptfortheenginewarrantycoverageandtheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.The

EmissionsControlSystemonyourProductmaybecoveredbyaseparate

warrantymeetingrequirementsestablishedbytheU.S.Environmental

ProtectionAgency(EPA)ortheCaliforniaAirResourcesBoard(CARB).

ThehourlimitationssetforthabovedonotapplytotheEmissions

ControlSystemWarranty.RefertotheCaliforniaEmissionControl

WarrantyStatementsuppliedwithyourProductorcontainedintheengine

manufacturer’sdocumentationfordetails.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor’sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheToroimporter.Ifallotherremediesfail,youmaycontactusatToroWarrantyCompany.

374-0261RevB

Page 33

Impreso Nº 3366-325 Rev A

Debastador de troncones 13 cv

Modelo Nº 22602- Nº de Serie 310000001 y superiores

Manual del Operador

Registre su producto en www.Toro.com

Traducción del original (ES)

Page 34

Introducción

Puesto que en en algunas zonas existen normas locales, estatales o federales que requieren el uso

de un parachispas en el motor de esta máquina, está disponible un parachispas como opción. Si

usted desea adquirir un parachispas, póngase en contacto con un Distribuidor Autorizado de

Toro.

Los parachispas genuinos de Toro están homologados por el USDA Forestry Service (Servicio

Forestal del Departamento de Agricultura de EE.UU.).

Importante: El uso o la operación del motor en cualquier terreno forestal, de monte o

cubierto de hierba con el motor obstruido o sin silenciador con parachispas mantenido en

buenas condiciones de funcionamiento, equipado y mantenido para la prevención de

incendios, constituye una infracción de la legislación de California (California Public

Resource Code Section 4442). Otros estados o zonas federales pueden tener una legislación

similar.

Este sistema de encendido por chispa cumple la norma canadiense ICES -002.

Importante: El Manual del propietario del motor adjunto ofrece información sobre las

normas de la U.S. Environmental Protection Agency (EPA) y de la California Emission

Control Regulation sobre sistemas de emisiones, mantenimiento y garantía. Puede

solicitarse un manual nuevo al fabricante del motor.

© 2010—The Toro® Company Contacto: www.Toro.com

8111 Lyndale Avenue South Reservados todos los derechos

Bloomington, MN 55420 Impreso en EE.UU.

1

Page 35

El Desbastador de tocones se utiliza para eliminar troncos de árboles. Al desplazar la máquina

lateralmente sobre la cara superior y delantera del tocón, la cuchilla lo va moliendo poco a poco.

Utilice la máquina únicamente para eliminar troncos de árboles y raíces expuestas. No está

diseñada para ningún otro uso. Lea este manual detenidamente para aprender a utilizar y

mantener correctamente su producto, y para evitar lesiones y daños al producto. Usted es el

responsable de utilizar el producto de forma correcta y segura.

Usted puede ponerse en contacto directamente con Toro en www.Toro.com si desea

información sobre productos y accesorios, o si necesita localizar un distribuidor o registrar su

producto.

Cuando necesite asistencia técnica, piezas genuinas Toro o información adicional, póngase en

contacto con un Distribuidor de Servicio Autorizado o con Asistencia al Cliente Toro, y tenga a

mano los números de modelo y serie de su producto. La Figura 1 identifica la ubicación de los

números de modelo y serie en el producto. Escriba los números en el espacio provisto.

1

Figura 1

1. Ubicación de los números de modelo y de serie

Nº de modelo _________________________________________

Nº de serie ___________________________________________

Este manual identifica peligros potenciales y contiene mensajes de seguridad identificados por el

símbolo de alerta de seguridad (Figura 2), que señala un peligro que puede causar lesiones

graves o la muerte si usted no sigue las precauciones recomendadas.

Figura 2

1. Símbolo de alerta de seguridad

2

Page 36

Contenido

Introducción ...............................................1

Seguridad ....................................................4

Prácticas de operación segura .................4

Formación ................................................4

Preparación ..............................................4

Operación ................................................5

Operación en pendientes .........................6

Mantenimiento y almacenamiento ..........6

Pegatinas de seguridad e instrucciones ....8

Controles .....................................................9

Acelerador ...............................................9

Barra de seguridad ...................................9

Freno de estacionamiento ........................9

Contador de horas ....................................9

Especificaciones ........................................10

Operación .................................................11

Antes de empezar ..................................11

Cómo añadir combustible .......................12

Uso del estabilizador/acondicionador ...13

Cómo llenar el depósito de

combustible .......................................13

Verificación del nivel de aceite del motor14

Arranque y parada del motor .................15

Cómo arrancar el motor .........................15

Cómo parar el motor ..............................16

Cómo desbastar el tocón ..........................16

Mantenimiento .........................................19

Calendario recomendado de

mantenimiento .......................................19

Limpieza del filtro de aire ciclónico .....20

Cómo cambiar el filtro de aire ...............21

Cómo cambiar el aceite del motor .........23

Cómo cambiar el aceite .........................23

Limpieza de la taza de sedimentos ........24

Mantenimiento de la bujía .....................25

Desmontaje de la bujía ..........................25

Instalación de la bujía ............................25

Cuchilla .................................................26

Sustitución de las cuchillas ...................26

Ajuste de los frenos de

estacionamiento .....................................27

Limpieza y lavado .................................27

Lubricación de los cojinetes ..................27

Correa de transmisión ............................28

Ajuste de la correa de transmisión ........28

Almacenamiento .......................................29

Solución de problemas .............................30

Garantía .............................. Contraportada

3

Page 37

Seguridad

El uso o mantenimiento indebido por parte del operador o el propietario puede

causar lesiones. Para reducir el peligro de lesiones, cumpla estas instrucciones de

seguridad y preste atención siempre al símbolo de alerta de seguridad

significa: Cuidado, Advertencia o Peligro—instrucción relativa a la seguridad

personal. El incumplimiento de estas instrucciones puede dar lugar a lesiones

personales e incluso la muerte.

Prácticas de operación segura

Este producto es capaz de amputar manos y pies. Siga siempre todas las instrucciones de

seguridad con el fin de evitar lesiones corporales graves e incluso la muerte.

Los gases de escape del motor contienen monóxido de carbono, que es un veneno

inodoro que puede matarle. No haga funcionar el motor dentro de un edificio o en

un lugar cerrado.

Formación

, que

• Lea el Manual del operador y otros materiales de formación. Si el o los operadores o

mecánicos no saben leer el español, es responsabilidad del propietario explicarles

este material.

• Familiarícese con la operación segura del equipo, los controles del operador y las

señales de seguridad.

• Todos los operadores y mecánicos deben recibir una formación adecuada. El

propietario es responsable de proporcionar formación a los usuarios.

• No deje nunca que el equipo sea utilizado o mantenido por niños o por personas que

no hayan recibido la formación adecuada al respecto. La normativa local puede

imponer límites sobre la edad del operador.

• El propietario/usuario puede prevenir, y es responsable de, los accidentes o lesiones

sufridos por él mismo, o por otras personas o bienes.

Preparación

• Inspeccione el área donde se va a utilizar el equipo y retire todos los objetos, como por

ejemplo piedras, juguetes y alambres, que puedan ser arrojados por la máquina.

• Extreme las precauciones cuando maneje gasolina y otros combustibles. Son

inflamables y sus vapores son explosivos.

- Utilice solamente un recipiente homologado

- Nunca retire el tapón de combustible ni añada combustible con el motor en marcha.

Deje que se enfríe el motor antes de repostar combustible. No fume.

- No añada ni drene nunca el combustible dentro de un edificio.

• Compruebe que los controles de presencia del operador, los interruptores de seguridad

y los protectores de seguridad están instalados y que funcionan correctamente.

• Compruebe que las cuchillas dejan de girar cuando usted reduce la velocidad.

• No utilice la máquina a menos que todos los dispositivos de seguridad estén colocados

y funcionen correctamente.

• Lleve ropa adecuada, incluyendo casco, gafas de seguridad, pantalón largo, calzado de

4

Page 38

seguridad y protección auricular. El pelo largo y las prendas o joyas sueltas pueden

enredarse en piezas en movimiento.

Operación

• No haga funcionar nunca el motor en un lugar cerrado.

• Utilice el equipo únicamente con luz solar natural, alejándose de hoyos y peligros

ocultos.

• Asegúrese de que el freno de estacionamiento está puesto antes de arrancar el motor.

Arranque el motor sólo desde la posición del operador.

• No utilice el equipo nunca si no están colocados firmemente los protectores de

seguridad. Asegúrese de que todos los interruptores de seguridad están conectados,

correctamente ajustados y que funcionan correctamente.

• No cambie los ajustes del regulador del motor ni haga funcionar el motor a una

velocidad excesiva.

• Antes de abandonar el puesto del operador por cualquier motivo, ponga el freno de

estacionamiento y pare el motor.

• Mantenga las manos y los pies alejados de las cuchillas en movimiento.

• Asegúrese de pisar firmemente mientras utiliza la máquina, sobre todo al conducir en

marcha atrás.

• Camine, no corra al desplazar la máquina en el lugar de trabajo.

• No trabaje nunca sobre hierba mojada. Una mala tracción puede hacer que se resbale.

• Mire hacia atrás y hacia abajo antes de poner marcha atrás para asegurarse de que el

camino está despejado.

• Mantenga alejadas a otras personas y a animales domésticos.

• No utilice la máquina bajo la influencia de alcohol o drogas.

• Tenga cuidado al cargar o descargar la máquina en/desde un remolque o un camión.

• Tenga cuidado al acercarse a esquinas ciegas, arbustos, árboles u otros objetos que

puedan dificultar la visión.

5

Page 39

• Asegúrese de que no haya otras personas en la zona antes de utilizar la unidad. Pare la

unidad si alguien entra en la zona.

• No deje nunca desatendida la unidad si está funcionando. Pare siempre el motor y

ponga el freno de estacionamiento antes de alejarse.

• Vigile el tráfico cuando esté cerca de una calle o carretera o cuando cruce una.

• No toque piezas que pueden estar calientes después de estar en funcionamiento. Deje

que se enfríen antes de realizar cualquier operación de mantenimiento, ajuste o

revisión.

• Sólo utilice la unidad en áreas en las que hay suficiente espacio para que el operador

maniobre el producto con seguridad.

• Antes de eliminar un tronco, haga que se señale cualquier conducción subterránea

(gas, agua, etc.) de la zona y no excave en las zonas marcadas.

• Localice los puntos de aprisionamiento señalados en la máquina y los accesorios y

mantenga alejados los pies y las manos de estas zonas.

• Los rayos pueden causar graves lesiones o incluso la muerte. Si se ven relámpagos o

rayos, o se oyen truenos en la zona, no utilice la máquina; busque un lugar donde

resguardarse.

Operación en pendientes

Las pendientes son una de las principales causas de accidentes por pérdida de control, que

pueden causar lesiones graves o la muerte. En todas las pendientes y cuestas se necesita

tener un cuidado especial.

• No utilice la máquina en cuestas o pendientes de más de 10 grados.

• Retire cualquier obstáculo, como por ejemplo piedras, ramas de árboles, etc., de la

zona de trabajo. Esté atento a baches, surcos o montículos, puesto que un terreno

desigual puede hacer que la unidad vuelque. La hierba alta puede ocultar obstáculos.

• Haga todos los movimientos en cuestas y pendientes de forma lenta y gradual. No

haga cambios bruscos de dirección.

• No utilice la máquina cerca de terraplenes, fosas o taludes. La unidad podría volcar

repentinamente si una rueda pasa por el borde de un terraplén o fosa, o si se socava un

talud.

• No utilice la máquina sobre hierba mojada. Una reducción en la tracción podría causar

derrapes.

Mantenimiento y almacenamiento

• Ponga el freno de estacionamiento y pare el motor. Deje que se detenga todo

movimiento antes de ajustar, limpiar o reparar.

• Limpie cualquier residuo de la unidad, las transmisiones, los silenciadores y el motor

para ayudar a prevenir incendios. Limpie cualquier aceite o combustible derramado.

• Espere a que se enfríe el motor antes de guardar el cortacésped, y no lo guarde cerca

de una llama.

• No almacene el combustible cerca de una llama, y no lo drene dentro de un edificio.

• Aparque la máquina en una superficie nivelada. No permita jamás que la máquina sea

revisada o reparada por personal no debidamente formado.

• Alivie con cuidado la tensión de aquellos componentes que tengan energía

almacenada.

• Retire el cable de la bujía antes de efectuar reparación alguna.

6

Page 40

• Mantenga las manos y los pies alejados de las piezas en movimiento. Si es posible, no

haga ajustes mientras el motor está funcionando.

• Mantenga todas las piezas en buenas condiciones de funcionamiento, y todos los

herrajes bien apretados. Sustituya cualquier pegatina desgastada o deteriorada.

• Mantenga apretados los pernos y las tuercas. Mantenga el equipo en buenas

condiciones de funcionamiento.

• No manipule nunca los dispositivos de seguridad.

• Mantenga la unidad libre de hierba, hojas u otros residuos acumulados. Limpie

cualquier aceite o combustible derramado. Deje que la unidad se enfríe antes de

almacenarla.

• Extreme las precauciones cuando maneje gasolina y otros combustibles. Son

inflamables y sus vapores son explosivos.

- Utilice solamente un recipiente homologado.

- No retire nunca el tapón de combustible ni añada combustible con el motor en

marcha. Deje que se enfríe el motor antes de repostar combustible. No fume.

- No reposte nunca la unidad en un recinto cerrado.

- No guarde nunca la unidad o un recipiente de combustible dentro de un edificio

cerca de una llama desnuda, por ejemplo, cerca de un calentador de agua o una

caldera.

- No llene nunca un recipiente con el recipiente dentro de un vehículo, maletero, la

caja de una camioneta ni ninguna otra superficie que no sea el suelo.

- Mantenga la boquilla del recipiente en contacto con el depósito durante el

repostaje.

- Cierre la válvula de combustible antes del almacenamiento o el transporte

• Pare e inspeccione el equipo si golpea un objeto. Haga cualquier reparación necesaria

antes de volver a arrancar.

• Utilice solamente piezas de repuesto genuinas Toro para asegurar que se mantengan

los niveles de calidad originales.

7

Page 41

Pegatinas de seguridad e instrucciones

Las pegatinas de seguridad e instrucciones están a la vista del operador y están

ubicadas cerca de cualquier zona de peligro potencial. Sustituya cualquier pegatina

que esté dañada o que falte.

119-4701

- Advertencia – Lea el Manual del operador

- Advertencia – Forme a todos los usuarios

del producto

- Objetos arrojados – Mantenga alejadas a

otras personas

- Objetos arrojados – Lleve casco y gafas de

seguridad, y limpie la zona de residuos

- Correa móvil – Mantenga colocado el

protector

- Peligro de explosión y descarga eléctrica

- Llamar a las compañías de

electricidad/gas/agua para que señalen los

conductos subterráneos

- Advertencia – Pare el motor antes de

realizar operaciones de mantenimiento

117-4979

- Correa móvil – Mantenga colocado el

protector

119-4692

- Advertencia – pare el motor antes de

levantar la máquina

119-4693

- Objetos arrojados – Mantenga alejadas a

otras personas

119-4721

- Mueva el acelerador para engranar y

desengranar la cuchilla

119-4690

- Advertencia – Cuchilla en rotación

- Mantenga alejadas las manos y los pies

- Pare la cuchilla en rotación antes de

realizar tareas de mantenimiento

8

Page 42

Controles

Acelerador

La palanca del acelerador controla la velocidad del

motor.

Con la palanca hacia abajo, en la posición de

DESENGRANADO, el motor funciona a velocidad de

ralentí. Ésta es también la posición de arranque. Al

aumentar la velocidad del motor hasta la posición de

ENGRANADO, se engrana el embrague centrífugo y la

cuchilla gira.

Barra de seguridad

Sujete la barra de seguridad contra el manillar para

desactivar el interruptor de parada del motor y poder

arrancar el motor. Si usted suelta la barra, el motor se

para.

Freno de estacionamiento

El freno de estacionamiento impide que gire la rueda

izquierda para inmovilizar la máquina, y facilita el

desplazamiento de la máquina de un lado a otro mientras

se desbasta el tocón.

Contador de horas

El contador de horas muestra el número de horas de uso

de la máquina, y funciona solamente cuando el motor está

en marcha.

9

Page 43

Especificaciones

Modelo

Motor

Velocidad de ralentí

Bujía

Volumen del depósito de combustible

Neumáticos

Freno

Correa de transmisión

Embrague

Dientes

Profundidad de corte

Longitud

Anchura

Altura

Peso

22602

Honda GX390QXC9

1250-1550 rpm

NKG BPR6ES

6,5 litros/1,72 galones US

13 x 5,00 – 6 (neumáticos)

Disco - Palanca de activación directa

Doble banda - sección 3V

Embrague centrífugo

12 - Puntas de carburo de tungsteno

Aprox 12" (30,48 cm)

76" (193 cm)

29,5" (75 cm)

42" (107 cm)

240 libras (109 kg)

10

Page 44

Operación

Nota : Los lados derecho e izquierdo de la

máquina se determinan desde la posición normal

del operador.

Importante Antes del uso, compruebe el nivel

de combustible y de aceite, y retire cualquier

residuo de la unidad de tracción. Asegúrese

también de que no hay otras personas o

residuos en la zona. Usted también debe

conocer y haber señalado la posición de

cualquier conducción subterránea.

Antes de empezar

Excave la tierra y retire cualquier piedra de las

proximidades del tocón que pueda interferir con su

trabajo. Compruebe que el terreno está libre de

objetos extraños, tales como cables eléctricos,

alambre de espinas, etc.

Tale o recorte el tocón según sea necesario usando

una sierra mecánica.

Revise todas las pegatinas de seguridad de la

máquina.

Utilice un casco y protección auditiva y ocular.

Una pantalla de malla por sí sola no proporciona

protección ocular suficiente; utilice gafas

protectoras también.

Asegúrese de que está familiarizado con las

normas de seguridad y los procedimientos de

parada descritos en el Manual del operador.

Asegúrese de que todos los protectores están

colocados y que están en buen estado de uso.

Compruebe que las cuchillas y los dientes están

colocados y que están en buen estado de uso.

Asegúrese de que la zona de trabajo, el cortador y

el tocón en particular están libres de objetos

metálicos, como por ejemplo alambres o clavos,

etc., que podrían ser arrojados y lesionar a

cualquier persona que esté cerca, o dañar el

equipo.

Asegúrese de que no hay nadie, incluyendo niños

y animales, en un radio de al menos 50 pies (15 m)

de la máquina. La máquina puede arrojar residuos

que podrían lesionar a otras personas y animales.

11

Page 45

Cómo añadir combustible

Utilice gasolina sin plomo (87 octanos mínimo) Se puede utilizar gasolina normal con plomo si

no hubiera gasolina sin plomo disponible.

En ciertas condiciones la gasolina es extremadamente inflamable y altamente explosiva. Un

incendio o una explosión provocados por la gasolina puede causarle quemaduras a usted y

a otras personas así como daños materiales.

• Llene el depósito de combustible en el

exterior, en una zona abierta y con el

motor frío. Limpie la gasolina

derramada.

• No llene nunca el depósito de

combustible dentro de un remolque

cerrado.

• No llene completamente el depósito de

combustible. Añada gasolina al depósito

de combustible hasta que el nivel esté

por debajo de la parte inferior del cuello

del filtro. Este espacio vacío en el depósito permitirá la dilatación de la gasolina.

• No fume nunca mientras maneja gasolina y manténgase alejado de llamas desnudas o de

lugares donde una chispa pudiera inflamar los vapores de gasolina.

• Almacene la gasolina en un recipiente homologado y manténgala fuera del alcance de los

niños. No compre nunca gasolina para más de 30 días de consumo normal.

• No utilice la máquina a menos que esté instalado un sistema completo de escape en

buenas condiciones de funcionamiento.

En determinadas condiciones durante el repostaje, puede tener lugar una descarga de

electricidad estática, produciendo una chispa que puede prender los vapores de la

gasolina. Un incendio o una explosión provocados por la gasolina puede causarle

quemaduras a usted y a otras personas así como daños materiales.

• Coloque siempre los recipientes de gasolina en el suelo, lejos del vehículo que está

repostando.

• No llene los recipientes de gasolina dentro de un vehículo, camión o remolque ya que las

alfombras o los revestimientos de plástico del interior de los remolques podrían aislar el

recipiente y retrasar la pérdida de la carga estática.

• Cuando sea posible, retire el equipo a repostar del camión o remolque y reposte con las

ruedas del equipo sobre el suelo.

• Si esto no es posible, reposte el equipo sobre el camión o remolque desde un recipiente

portátil, en vez de usar un surtidor de gasolina.

• Si es imprescindible el uso de un surtidor, mantenga la boquilla en contacto con el borde

del depósito de combustible o la abertura del recipiente en todo momento hasta que

termine de repostar.

Importante: No use metanol, gasolina que contenga metanol o gasohol con más del 10% de

etanol porque se podrían producir daños en el sistema de combustible. No mezcle aceite

con la gasolina.

12

Page 46

Uso del estabilizador/acondicionador

Use un estabilizador/acondicionador en la unidad de tracción para conseguir los beneficios

siguientes:

• Mantiene la gasolina fresca durante un período de almacenamiento de 90 días o menos. Para

un almacenamiento más largo, se recomienda drenar el depósito de combustible.

• Limpia el motor durante el funcionamiento.

• Elimina la formación de depósitos pegajosos, con aspecto de barniz, en el sistema de

combustible, que pueden dificultar el arranque.

Importante: No utilice aditivos de combustible que contengan metanol o etanol.

Agregue la cantidad adecuada de estabilizador/acondicionador a la gasolina.

Nota: Un estabilizador/acondicionador de combustible es más eficaz cuando se mezcla con

gasolina fresca, Para reducir al mínimo los depósitos de barniz en el sistema de combustible,

utilice siempre un estabilizador de combustible.

Cómo llenar el depósito de combustible

1. Aparque la unidad de tracción sobre una superficie nivelada y pare el motor.

2. Deje que el motor se enfríe.

3. Limpie alrededor del tapón del depósito de combustible y retire el tapón.

Nota: El tapón está sujeto al depósito de combustible.

4. Añada gasolina sin plomo al depósito de combustible hasta que el nivel esté justo por

debajo del extremo inferior del cuello del filtro.

Importante: Este espacio vacío en el depósito permitirá la dilatación de la gasolina. No

llene completamente el depósito de combustible.

1 2

1. Nivel máximo de combustible 2. Parte superior del depósito de combustible

5. Instale el tapón del depósito de combustible firmemente, girándolo hasta que encaje con un

clic.

6. Limpie cualquier gasolina que se haya derramado.

13

Page 47

Verificación del nivel de aceite del motor

1. Coloque la máquina en una superficie nivelada y pare el motor.

1. Limpie alrededor de la varilla de aceite.

3. Desenrosque la varilla de aceite y limpie el extremo.

4. Introduzca la varilla a fondo en el tubo de llenado. No la enrosque.

5. Retire la varilla y observe el extremo. El aceite debe llegar al límite superior.

Nota: Si se pone en marcha el motor con un nivel bajo de aceite, puede dañarse el motor. Este

tipo de daño no está cubierto por la Garantía.

El motor incorpora un sistema de alerta de aceite que para el motor antes de que el nivel de

aceite descienda por debajo del límite de seguridad. Para evitar los inconvenientes de una parada

por alarma, rellene hasta el límite superior y compruebe frecuentemente el nivel de aceite.

1 3

2 4

1. Varilla de aceite 2. Orificio de llenado de aceite 3. Límite superior 4. Límite inferior

6. Si el nivel de aceite es bajo, vierta lentamente en el cárter sólo la cantidad de aceite suficiente

para que el nivel llegue al límite superior.

Importante: No llene excesivamente el cárter de aceite ya que podría dañar el motor.

7. Vuelva a colocar la varilla.

14

Page 48

Arranque y parada del motor

Cómo arrancar el motor

1. Mueva la válvula de combustible hacia la derecha

hasta la posición de ABIERTO.

2. Mueva la palanca del estárter hacia la izquierda a la

posición de ACTIVADO si el motor está frío.

Nota: Si el motor está caliente, puede no ser necesario

usar el estárter.

3. Mueva el acelerador a la posición de

DESENGRANADO.

4. Sujete la barra de seguridad contra el manillar, y

empuje el manillar hacia abajo para levantar la

rueda de corte del suelo.

5. Tire suavemente del arrancador hasta que note

resistencia, luego tire con fuerza en el sentido de la

flecha. Deje que el arrancador vuelva lentamente a

su posición inicial.

6. Cuando el motor arranque, mueva la palanca del

estárter poco a poco a la posición de Desactivado.

Si el motor se cala o funciona de forma irregular,

mueva el estárter a Activado de nuevo hasta que el

motor se caliente. Luego muévalo a la posición de

Desactivado.

15

Page 49

Cómo parar el motor

1. Mueva el acelerador a la posición de

DESENGRANADO.

Nota: Si el motor ha estado trabajando duro o si está

muy caliente, déjelo funcionar durante un minuto

antes de soltar la barra de seguridad. Esto ayuda a

enfriar el motor antes de pararlo. En una emergencia,

se puede parar el motor inmediatamente.

2. Suelte la barra de seguridad para parar el motor.

3. Mueva la válvula de combustible a la posición de

CERRADO, totalmente hacia la izquierda.

Cómo desbastar un tocón

Coloque el desbastador de tocones con la cuchilla

cerca del borde superior delantero del tocón.

¡La cuchilla en rotación es muy PELIGROSA!

Mantenga a otras personas alejadas de los

residuos arrojados.

Ponga el freno de estacionamiento en la posición de

bloqueo.

1. Ponga el acelerador en la posición de

DESENGRANADO.

2. Arranque el motor; consulte Arranque del motor.

3. Deje que el motor se caliente a velocidad de

ralentí durante dos minutos.

4. Empuje el manillar hacia abajo lo suficiente para

levantar la rueda de corte del suelo.

5. Mueva el acelerador hacia arriba, a la posición de

ENGRANADO; de esta manera se engrana el

embrague centrífugo y la cuchilla empieza a girar.

16

Page 50

6. Mueva la cuchilla a un lado, luego bájela para que

penetre de 1/2" a 1" aproximadamente en el borde

delantero superior del tocón. Mueva la cuchilla

hacia un lado y otro, bajando la cuchilla de 1/2" a

1" aproximadamente antes de cada pasada, hasta

que haya eliminado la parte delantera del tocón

hasta el nivel del suelo.

7. Levante la cuchilla hasta que el centro de la

cuchilla esté justo por encima de la parte superior

del tocón.

8. Con la cuchilla desplazada a un lado, quite el freno

de estacionamiento y desplace la máquina hacia

adelante; luego ponga el freno de estacionamiento.

9. Pase la cuchilla por el tocón, eliminando de 1/2" a

1" del tocón.

10. Mueva la máquina hacia adelante de 1/2" a 1", y

pásela por el tocón en el sentido opuesto.

11. Continúe pasando la cuchilla de una lado a otro por

del tocón, moviendo la máquina hacia adelante

antes de cada pasada, y cortando una altura de 1/2"

a 1" con cada pasada.

12. Siga cortando hasta eliminar por completo la parte

superior del tocón, asegurándose de no cortar por

debajo del nivel del suelo en esta primera fase.

13. Ponga el acelerador en la posición de

DESENGRANADO, y empuje el manillar hacia

abajo lo suficiente para levantar la rueda de corte

del suelo. Espere diez segundos para que la

cuchilla deje de girar, luego quite el freno y retire

la máquina del tocón.

17

Page 51

Aleje la máquina del tocón, y recoja con un rastrillo las

astillas que estén cerca del tocón.

14. Coloque el desbastador con la cuchilla cerca del

borde superior delantero del tocón.

15. Ponga el freno en la posición de bloqueo.

16. Mueva el acelerador hacia arriba, a la posición de

ENGRANADO.