Page 1

FormNo.3366-323RevA

g014867

6.5hpStumpGrinder

ModelNo.22601—SerialNo.310000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

WARNING

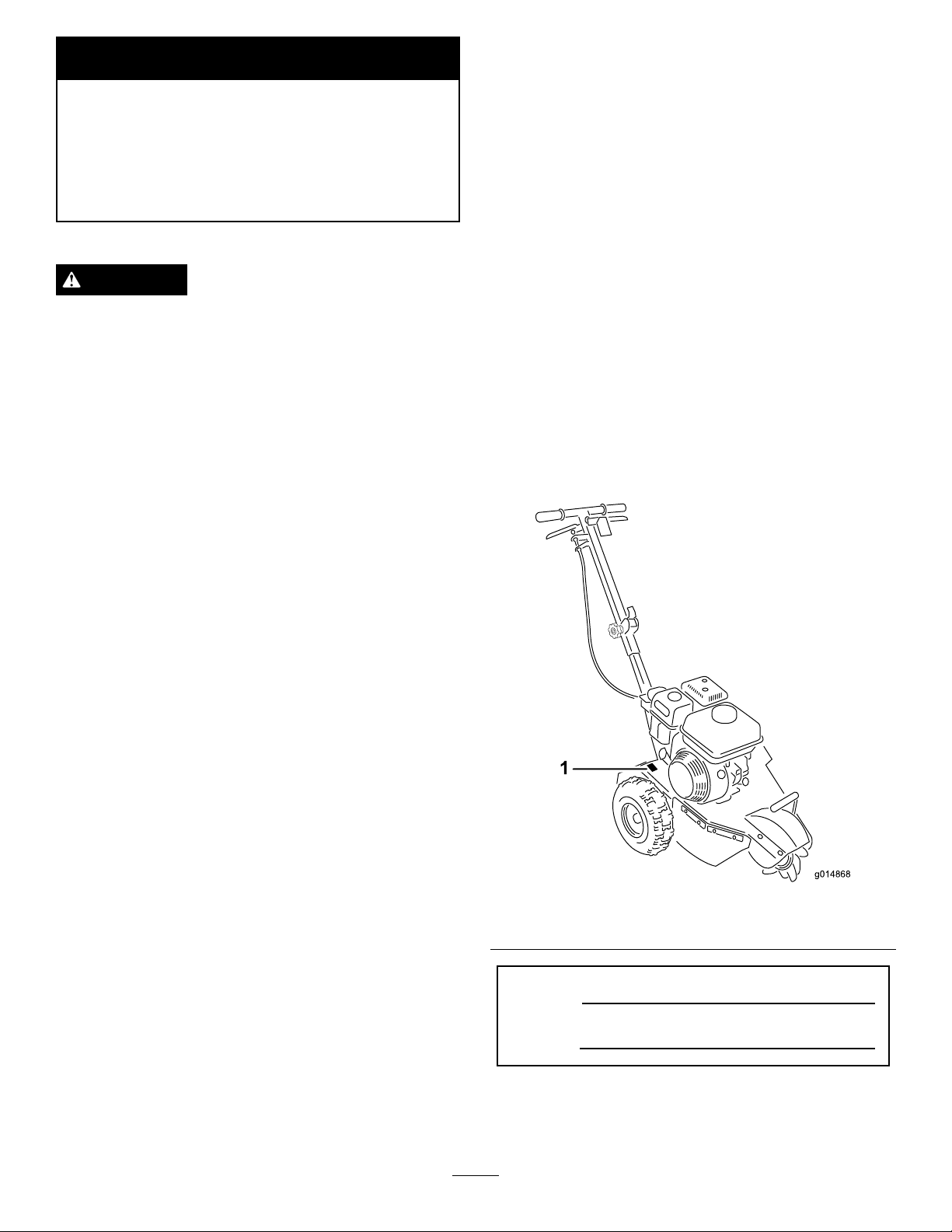

g014868

1

Introduction

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

DANGER

Theremaybeburiedpower,gas,and/ortelephone

linesintheworkarea.Shockorexplosionmay

occurifyoudigintothem.

Havethepropertyorworkareamarkedforburied

linesanddonotdiginmarkedareas.Contactyour

localmarkingserviceorutilitycompanytohavethe

propertymarked(forexample,intheUnitedStates,

call811forthenationwidemarkingservice).

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Thismachineisdesignedtogrindandremovetree

stumpsandsurfaceroots.Itisnotintendedtocutrock

oranyothermaterialotherthanwoodandthesoil

aroundastump.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.

Figure1

illustratesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrestor,contactyour

AuthorizedToroServiceDealer.

GenuineTorosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,

orgrass-coveredlandwithoutasparkarrester

mufermaintainedinworkingorder,ortheengine

constricted,equipped,andmaintainedforthe

preventionofre.Otherstatesorfederalareasmay

havesimilarlaws.

Theenclosed

Engine Owner’ s Man ual

issupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCalifornia

EmissionControlRegulationofemissionsystems,

maintenance,andwarranty.Replacementsmaybe

orderedthroughtheenginemanufacturer.

Figure1

1.Modelandserialnumberplate

ModelNo.

©2010—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(

Figure2),whichsignalsahazardthatmaycauseserious

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety

Improperuseormaintenancebytheoperator

orownercanresultininjury.Toreducethe

potentialforinjury,complywiththesesafety

instructionsandalwayspayattentiontothesafety

alertsymbol

or

Danger

complywiththeinstructionmayresultinpersonal

injuryordeath.

,whichmeans:

—personalsafetyinstruction.Failureto

SafeOperatingPractices

Thisproductiscapableofamputatinghandsandfeet.

Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.

Caution

,

W ar ning

,

Introduction.................................................................2

Safety...........................................................................3

SafeOperatingPractices.......................................3

SafetyandInstructionalDecals.............................5

ProductOverview........................................................6

Controls...............................................................6

Specications.......................................................8

Attachments/Accessories.....................................8

Operation.....................................................................9

BeforeyouStart...................................................9

AddingFuel.........................................................9

CheckingtheEngineOilLevel............................10

StartingandStoppingtheEngine........................11

GrindingaStump...............................................11

Maintenance...............................................................13

RecommendedMaintenanceSchedule(s)................13

Lubrication.............................................................13

GreasingtheMachine.........................................13

EngineMaintenance...............................................14

ServicingtheAirCleaner....................................14

ServicingtheEngineOil.....................................15

ServicingtheSparkPlug.....................................16

BeltMaintenance....................................................17

CheckingtheDriveBeltTension.........................17

AdjustingtheDriveBelt.....................................17

GrinderMaintenance..............................................18

CheckingtheCuttingWheelBlades.....................18

ReplacingtheCuttingWheelBlades....................18

Cleaning.................................................................19

RemovingDebrisfromtheMachine....................19

Storage.......................................................................20

..........................................................................20

Troubleshooting.........................................................21

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)can

notreadEnglish,itistheowner’sresponsibilityto

explainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmayrestrict

theageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludinghardhat,face

shield,safetyglasses,longpants,safetyshoes,and

hearingprotection.Longhair,looseclothingor

jewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeused

andremoveallobjectssuchasrocks,toys,andwire

whichcanbethrownbythemachine.

3

Page 4

•Useextracarewhenhandlinggasolineandother

fuels.Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer

–Neverremovethegascaporaddfuelwiththe

enginerunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

–Neverrefuelordrainthemachineindoors.

•Checkthattheoperatorpresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

•Donottouchpartswhichmaybehotfrom

operation.Allowthemtocoolbeforeattemptingto

maintain,adjust,orservice.

•Ensurethatyouoperatethemachineinareaswhere

therearenoobstaclesincloseproximitytothe

operator.Failuretomaintainadequatedistancefrom

trees,walls,andotherbarriersmayresultininjury

asthemachinebacksupduringoperationifthe

operatorisnotattentivetothesurroundings.Only

operatetheunitinareaswherethereissufcient

clearancefortheoperatortosafelymaneuverthe

product.

•Checkthatthecuttingwheelhasstoppedrotating

whenyoureducethethrottle.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholes

andhiddenhazards.

•Besurealldrivesareinneutralbeforestartingthe

engine.Onlystarttheenginefromtheoperator’s

position.

•Neveroperatewiththeguardsnotsecurelyinplace.

Besureallinterlocksareattached,adjustedproperly,

andfunctioningproperly.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Stoponlevelground,lowerthegrinder,andshut

offtheenginebeforeleavingtheoperator’sposition

foranyreason.

•Keephandsandfeetawayfromthemovinggrinder

wheelandteeth.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

•Keeppetsandbystandersaway.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Ensurethattheareaisclearofotherpeoplebefore

operatingthemachine.Stopthemachineifanyone

entersthearea.

•Beforegrinding,havetheareamarkedfor

undergroundutilities,anddonotgrindinmarked

areas.

•Locatethepinchpointareasmarkedonthemachine

andkeephandsandfeetawayfromtheseareas.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

MaintenanceandStorage

•Stoptheengine.Waitforallmovementtostop

beforeadjusting,cleaning,orrepairing.

•Cleandebrisfromthegrinder,drives,mufers,and

enginetohelppreventres.Cleanupoilorfuel

spillage.

•Lettheenginecoolbeforestoringanddonotstore

nearame.

•Donotstorefuelnearamesordrainindoors.

•Parkthemachineonlevelground.Neverallow

untrainedpersonneltoservicethemachine.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Removethesparkplugwirebeforemakingany

repairs.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Neverleavearunningmachineunattended.Always

stoptheengineandverifythecuttingwheelshas

stoppedrotating.

•Neverjerkthecontrols;useasteadymotion.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Keepnutsandboltstight.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.

•Keepthemachinefreeofgrass,leaves,orother

debrisbuild-up.Cleanupoilorfuelspillage.Allow

themachinetocoolbeforestoring.

4

Page 5

•Useextracarewhenhandlinggasolineandother

fuels.Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethegascaporaddfuelwhen

theengineisrunning.Allowtheenginetocool

beforerefueling.Donotsmoke.

–Neverrefuelthemachineindoors.

–Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasneara

waterheaterorfurnace.

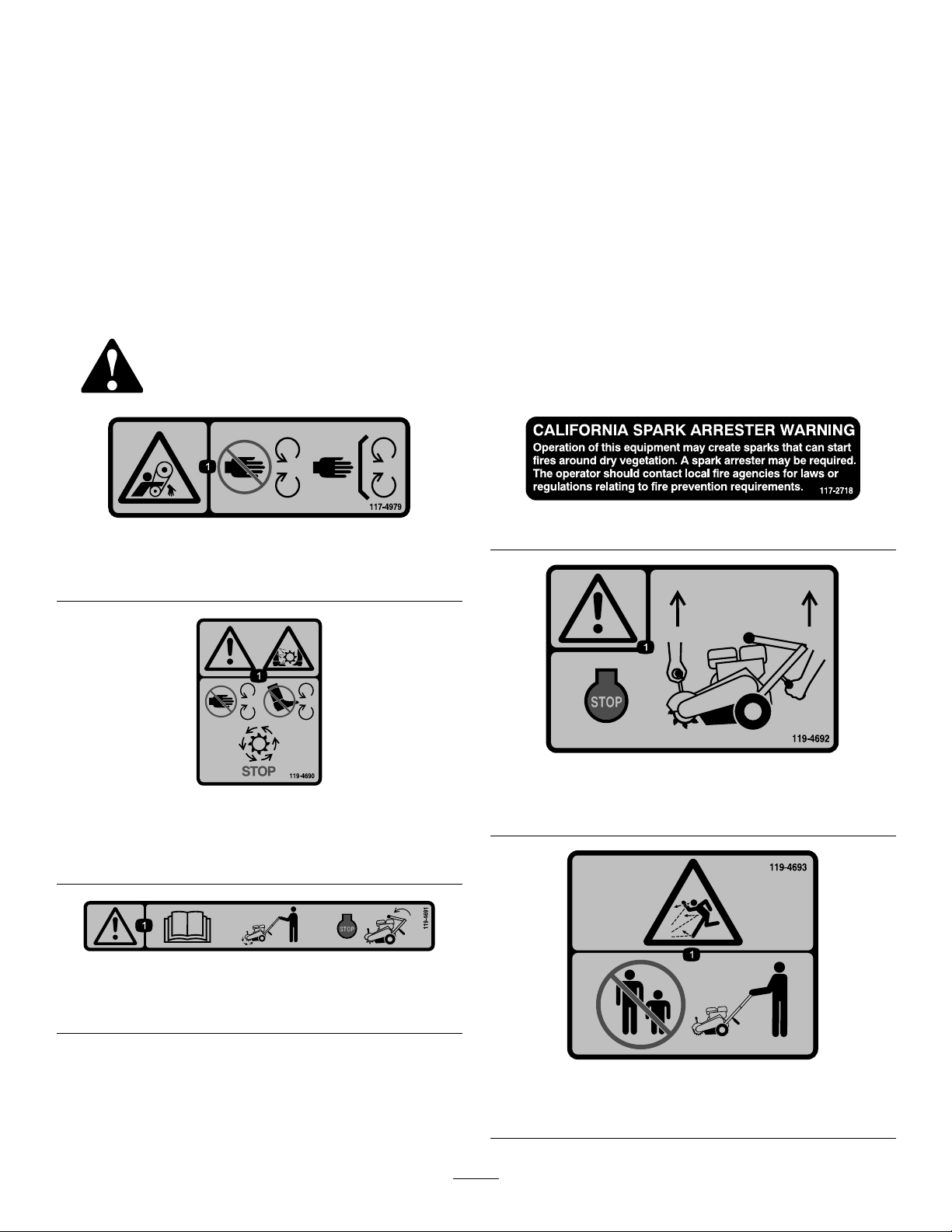

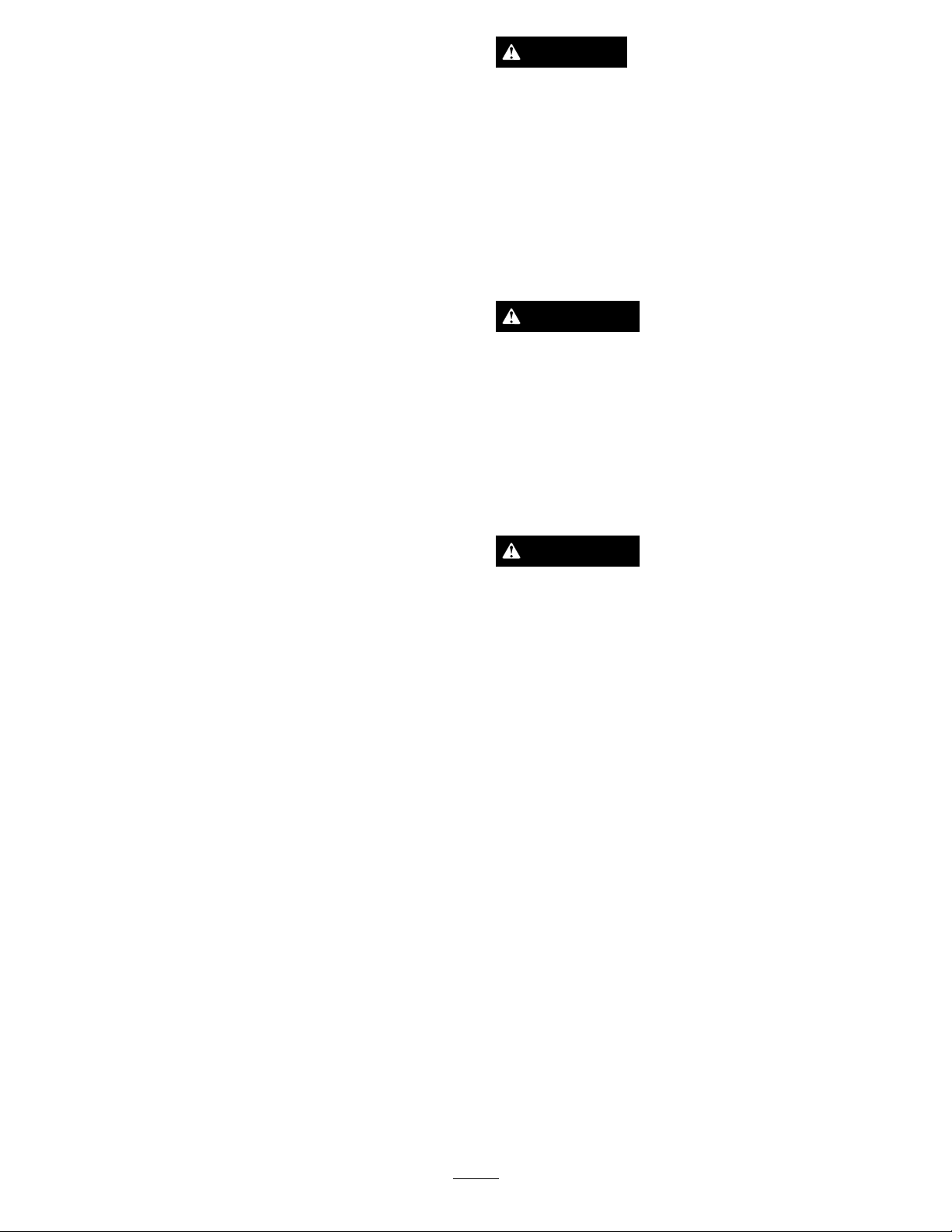

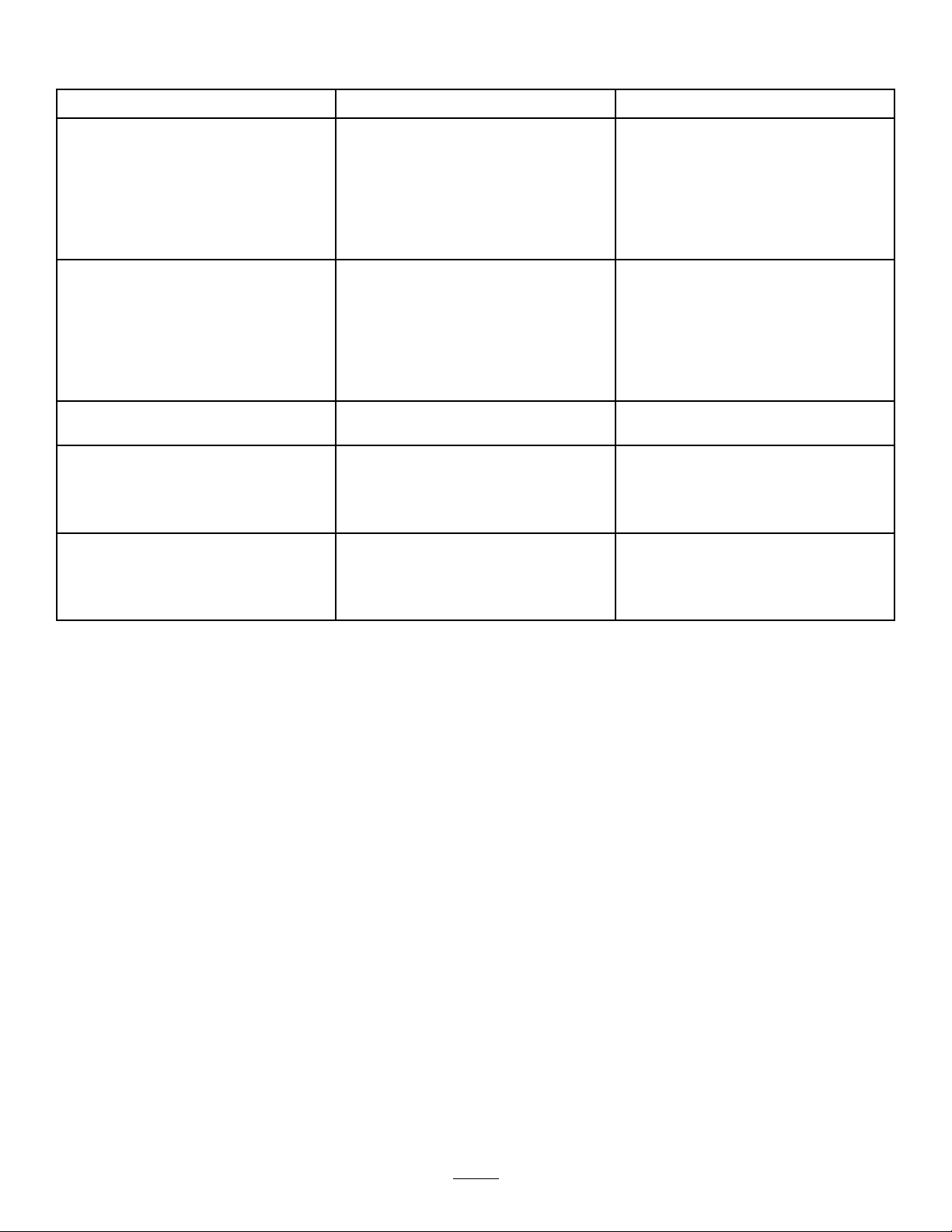

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

–Neverllacontainerwhileitisinsideavehicle,

trunk,pick-upbed,oranysurfaceotherthanthe

ground.

–Keepcontainernozzleincontactwiththetank

duringlling.

•Stopandinspecttheequipmentifyoustrikean

object.Makeanynecessaryrepairsbeforerestarting.

•UseonlygenuineTororeplacementpartstoensure

thatoriginalstandardsaremaintained.

117–4979

1.Entanglementhazard,belt—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

119-4690

1.Warning;cutting/dismembermenthazard,grinding

blade—keephandsandfeetawayfromallmovingparts,

keepallshieldsinplace;waitforallmovingpartstostop.

119-4691

1.Warning—readtheOperator’sManual;waitforgrinder

bladetostop,stoptheengineandfoldthehandle.

117–2718

119-4692

1.Warning—stoptheengine;usebothhandholdstoliftthe

grinder.

119-4693

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

5

Page 6

ProductOverview

g014869

3

9

1

2

4

5

6

7

8

10

11

12

13

119-4722

1.Engine—run

2.Grinderblade—engage

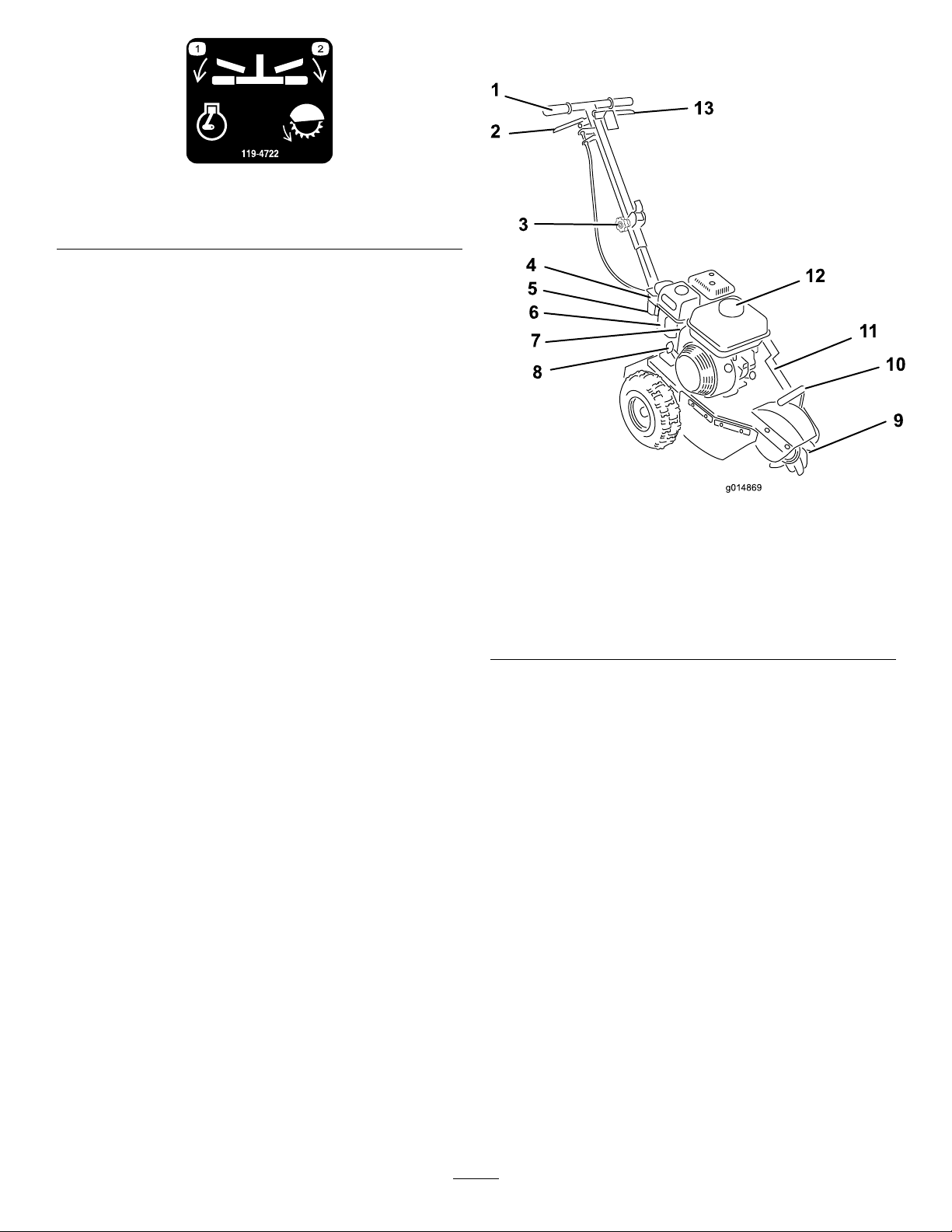

Figure3

1.Handle

2.Throttlelever

3.Handlereleaseknob

4.Airlter

5.Sedimentcup

6.Fuelvalve

7.Choke

8.Starter

9.Cuttingwheel

10.Lift

11.Beltcover

12.Fuelcap

13.Safetybail

Controls

Becomefamiliarwithallthecontrols(Figure3and

Figure6)beforeyoustarttheengineandoperatethe

machine.

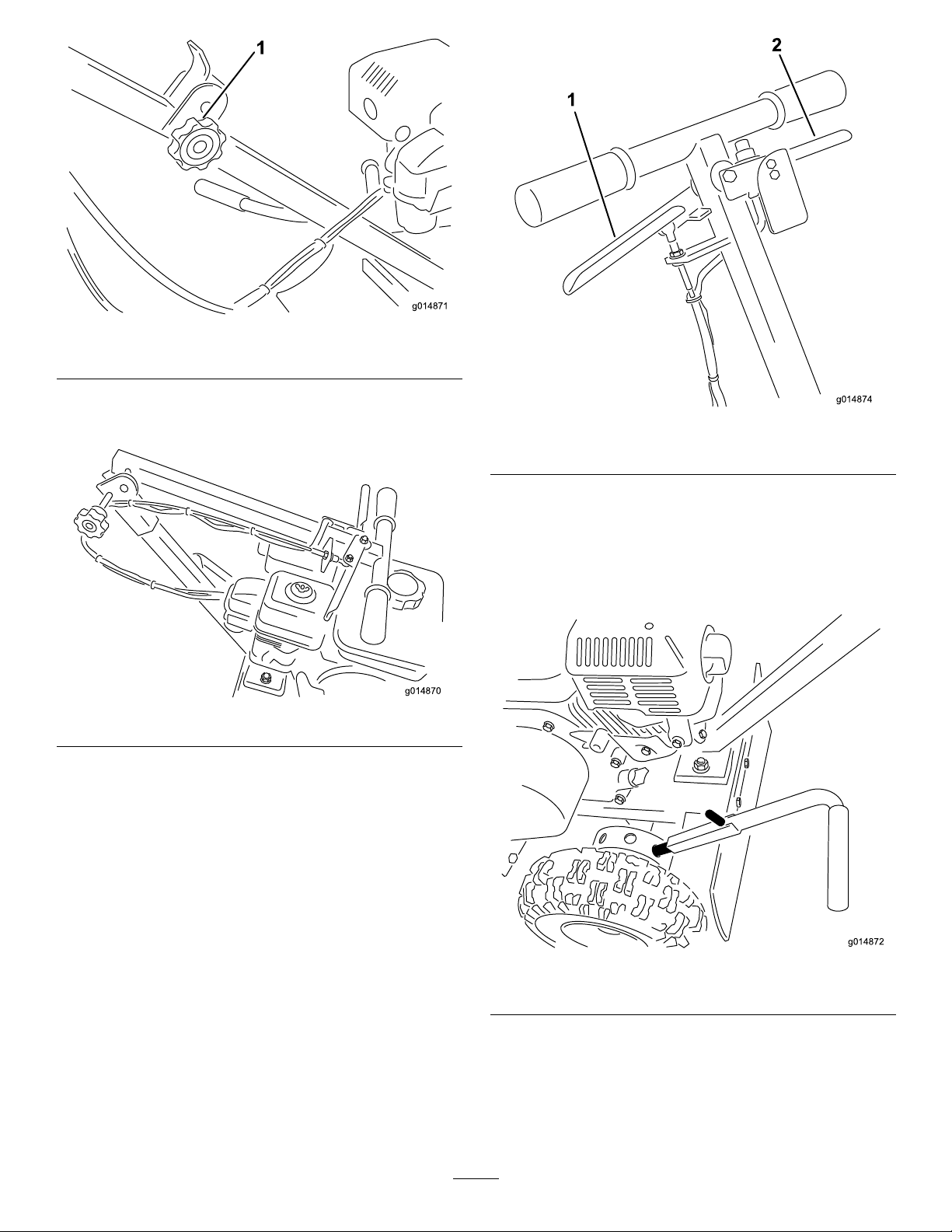

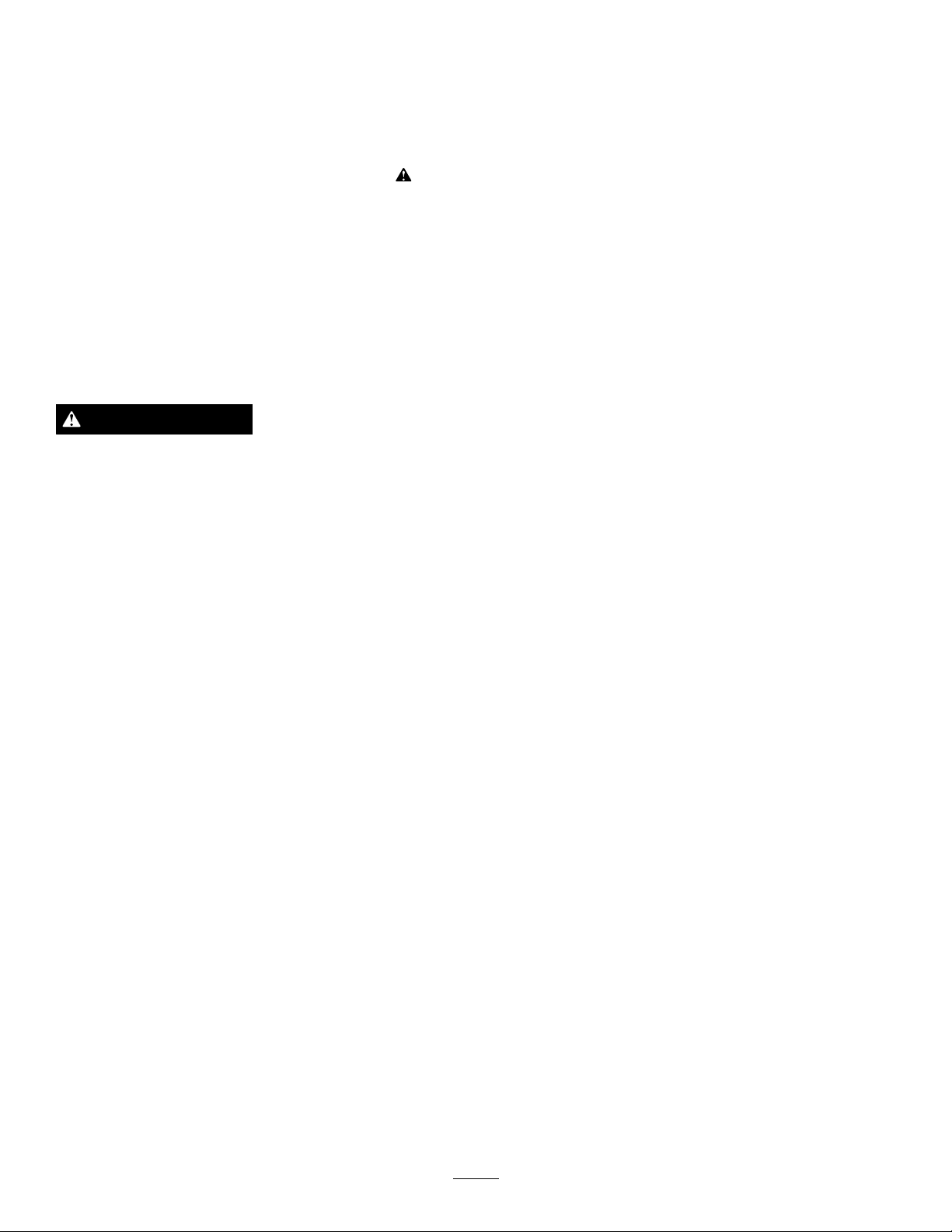

HandleReleaseKnob

Thehandleonthismachinehasthecapabilitytobe

foldeddownforeasiertransport.Unscrewthehandle

releaseknobfromthemachine(Figure4).

6

Page 7

g014871

1

1.HandleReleaseKnob

g014870

g014874

2

1

g014872

Figure4

Foldthehandledowntowardthemachineandscrewthe

handlebackontothemachine(Figure5).

Figure5

ThrottleLeverandSafetyBail

Thethrottlelevercontrolsenginespeed.Withthelever

down,inthedisengagedposition,theenginerunsat

idle.Thisisalsothestartingposition.Whenthethrottle

leverissqueezedtheenginespeedincreasesandthe

centrifugalclutchengagesandthecuttingwheelrotates.

Thesafetybailcontrolstheenginerunning.Holdthe

safetybailagainstthehandletodeactivatetheenginekill

switchsotheenginewillstart.Releasingthebailstops

theengine.

Figure6

1.Throttlelever

2.Safetybail

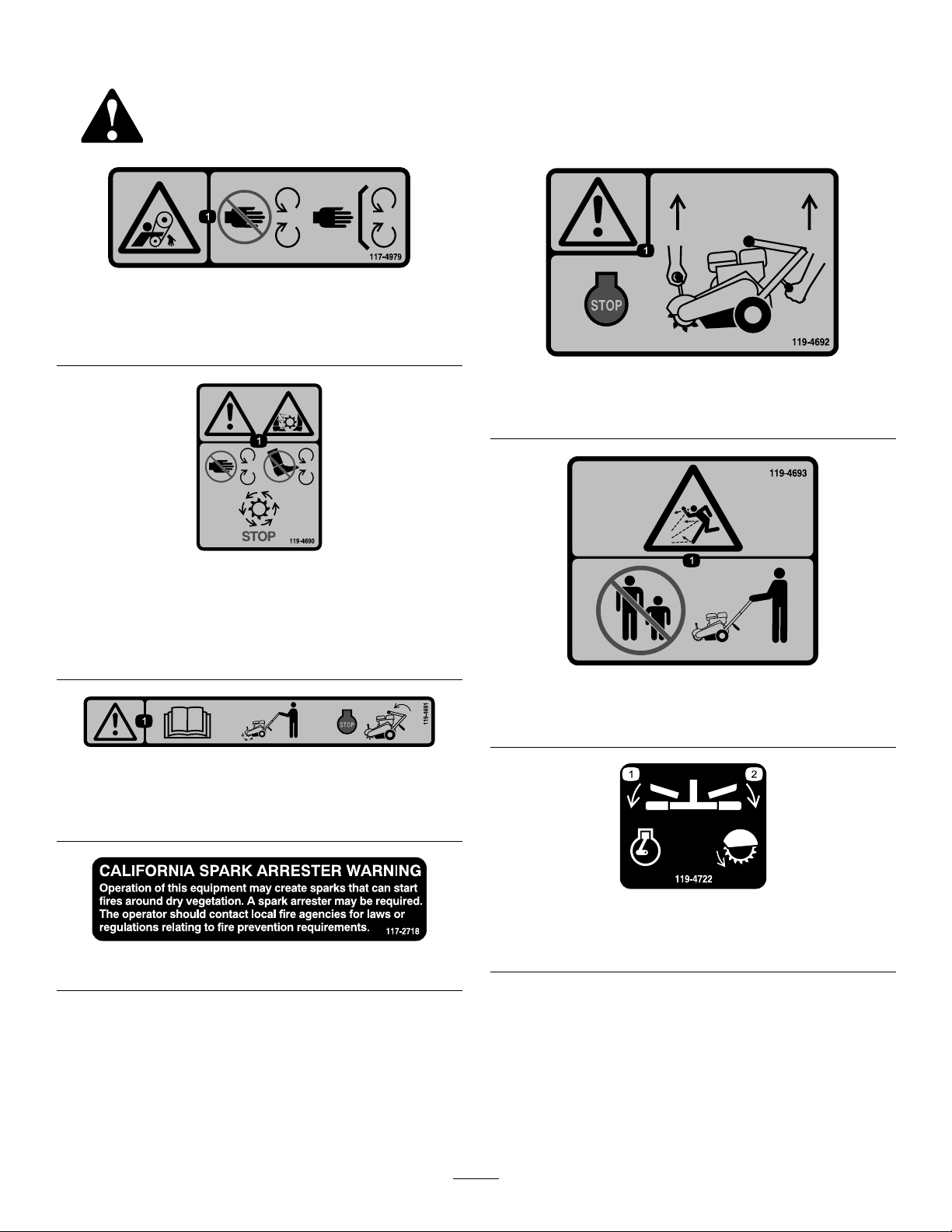

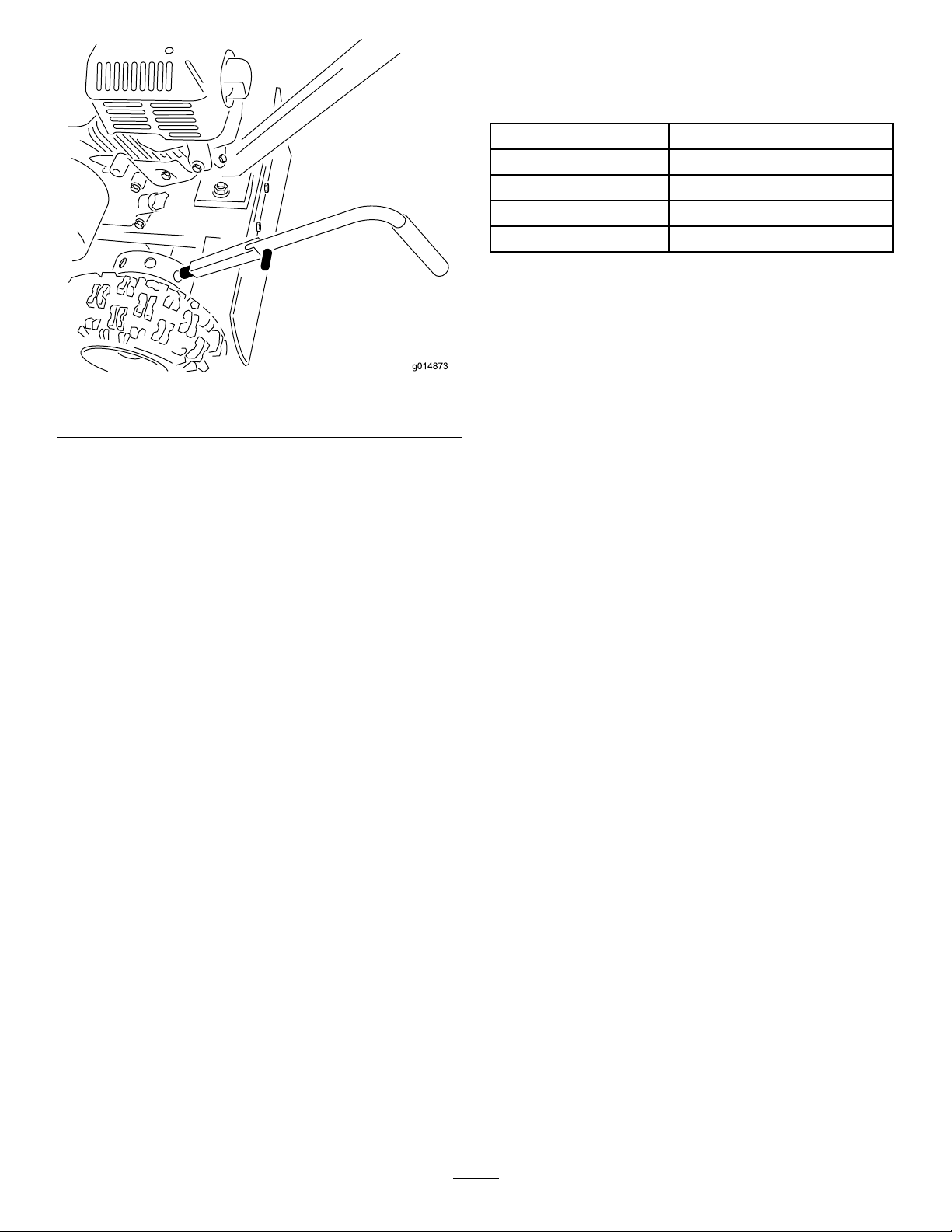

ParkingBrake

Theparkingbrakeholdstheleftwheelfromturning

tosecurethemachineandforeasymovementofthe

machinefromsidetosidewhengrindingthestump.

Figure7

1.Engagedbrake

7

Page 8

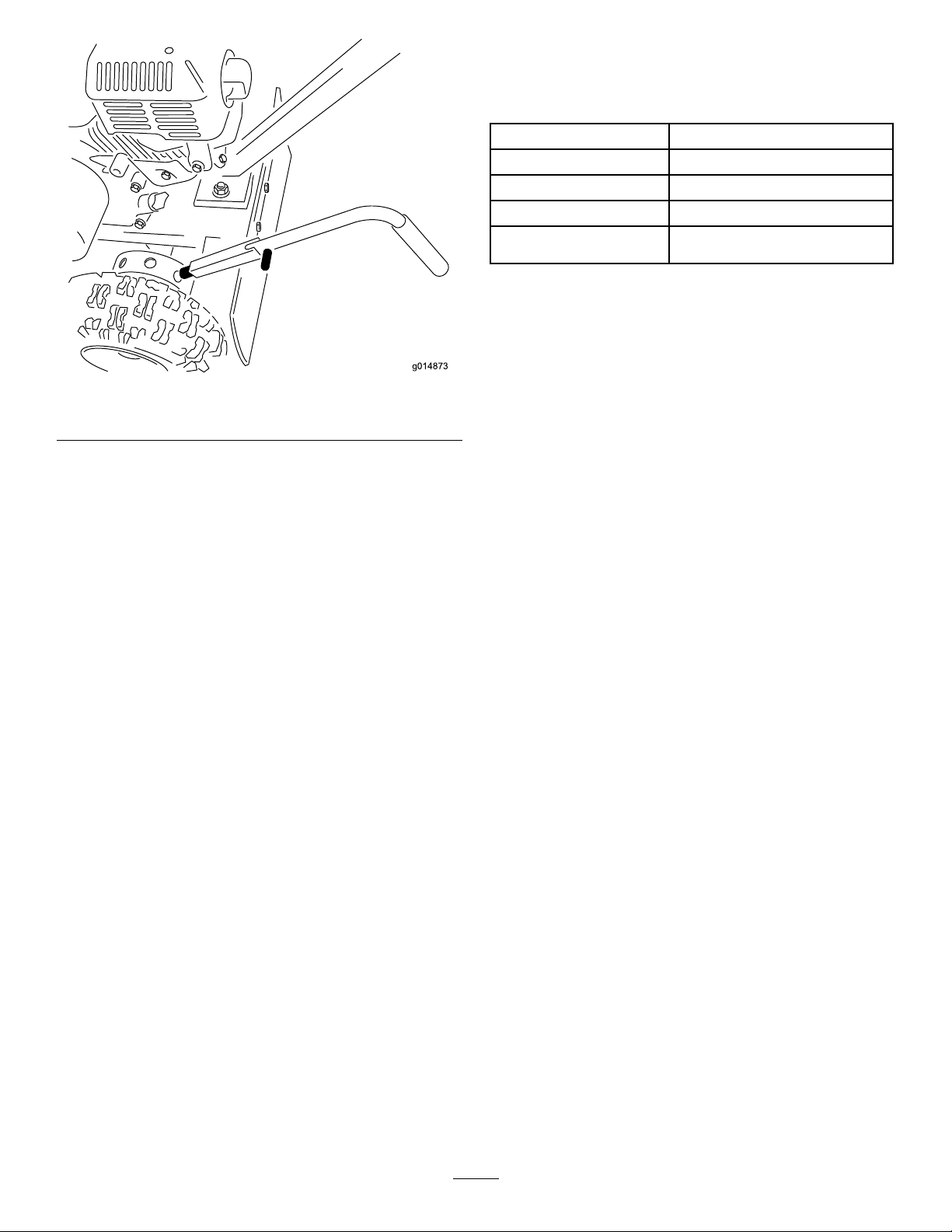

g014873

1.DisengagedBrake

Figure8

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

CuttingDepthApprox12inches(30.48cm)

Length

Width

Height

Weight

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

50inches(127cm)

22inches(56cm)

42inches(107cm)

103lbs(47Kg)

8

Page 9

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Important:Beforeoperating,checkthefueland

oillevel,andremovedebrisfromthemachine.

Also,ensurethattheareaisclearofpeopleand

debris.Youshouldalsoknowandhavemarkedthe

locationsofallutilitylines.

BeforeyouStart

•Digawaytheearthandremoveanystonesnear

thetreestumpthatmayinterferewithyourwork.

Checkthatthegroundisfreeofforeignobjects,

suchaselectricalcables,barbedwire,etc.

•Cutortrimthestumpusingapowersaw.

•Reviewallthemachine’ssafetydecals.

•Useahard-hat,hearing,andeyeprotection.A

meshvisoralonedoesnotprovidesufcienteye

protection;supplementwithprotectiveglasses.

•Ensurethatyouarefamiliarwithsafetyregulations

andshutdownproceduresdescribedinthe

Operator’sManual.

•Ensurethatallguardsareinplaceandingood

condition.

•Ensurethatthebladesandcuttersareinplaceand

ingoodcondition.

•Ensurethattheworkarea,cutter,andstumpin

particulararefreefrommetallicobjectssuchas

wire,nails,etc.thatcouldbethrownoutandinjure

personsinthevicinityanddamagetheequipment.

•Ensurethateveryone,includingchildrenand

animals,maintainadistanceofatleast50feet(15

m)fromthemachine.Debriscanbethrownout

andinjurepeopleandanimals.

AddingFuel

Useunleadedgasoline(87pumpoctaneminimum).

Leaded,regulargasolinemaybeusedifunleadedisnot

available.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1/4to

1/2inch(6to13mm)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystem

inplaceandinproperworkingcondition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmayinsulate

thecontainerandslowthelossofanystatic

charge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerandrefuel

theequipmentwithitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

Important:Donotusemethanol,gasoline

containingmethanol,orgasoholcontainingmore

9

Page 10

than10%ethanolbecausethefuelsystemcouldbe

damaged.Donotmixoilwithgasoline.

UsingStabilizer/Conditioner

Important:Thisspaceinthetankallows

gasolinetoexpand.Donotllthefueltank

completelyfull.

5.Installthefueltankcapsecurely.

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysor

less.Forlongerstorageitisrecommendedthatthe

fueltankbedrained.

•Cleanstheenginewhileitruns.

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting.

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditioner

tothegas.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.Tominimizethe

chanceofvarnishdepositsinthefuelsystem,usefuel

stabilizeratalltimes.

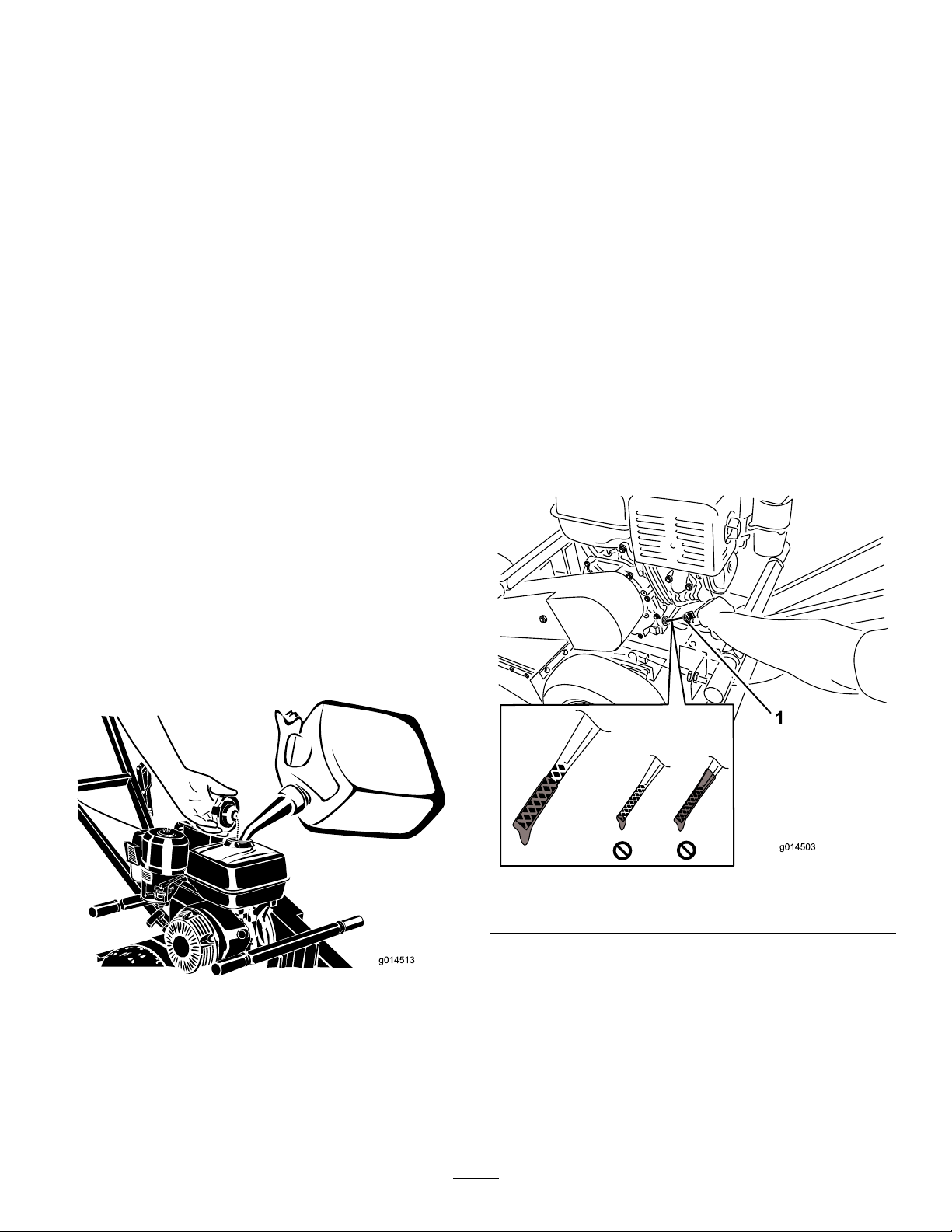

FillingtheFuelTank

1.Parkthemachineonalevelsurface,lowerthe

grinder,andstoptheengine.

6.Wipeupanygasolinethatmayhavespilled.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

1.Tiltthemachinesotheengineislevel,andstop

theengine.

2.Allowtheenginetocool.

3.Cleanaroundtheoildipstick.

4.Removethedipstickandwipetheendclean.

5.Slidethedipstickfullyintothedipsticktubewithout

threadingitintothellerneck.

6.Pullthedipstickoutandlookattheend.The

oilshouldbetothetopoftheupperlimitrange

(Figure10).

2.Allowtheenginetocool.

3.Cleanaroundthefueltankcapandremoveit

(Figure9).

Figure9

viewmayvarydependingonmodel

1.Fueltankcap

Figure10

1.Oildipstick

Important:Runningtheenginewithlowoil

levelcancauseenginedamage.Thistypeof

damageisnotcoveredbywarranty.

Theengineisequippedwithanoilalertsystem

thatwillautomaticallystoptheenginebefore

theoillevelfallsbelowthesafelimit.

4.Addunleadedgasolinetothefueltank,untilthe

levelis1/4to1/2inchbelowthebottomofthe

llerneck.

7.Iftheoillevelislow,slowlypouronlyenoughoil

intothecrankcasetoraisetheleveltotheupper

limit.

10

Page 11

Important:Donotoverllthecrankcasewith

oilbecausetheenginemaybedamaged.

8.Replacethedipstick.

StartingandStoppingthe

DANGER

Themachinewillcutandamputatehandsandfeet.

•Stayintheoperator’spositionwhilethe

machineisrunningandkeepawayfromthe

cuttingwheel.

Engine

StartingtheEngine

1.MovethefuelvalvetotheOpenposition,allthe

waytotheright.

2.MovethechokeleverlefttotheOnpositionifyou

arestartingacoldengine.

Note:Awarmorhotenginemaynotrequire

choking.

3.Holdthesafetybailagainstthehandleandpushthe

handledownenoughtoraisethecuttingwheeloff

theground.

4.Pullthestarterhandlelightlyuntilyoufeel

resistance,thenpullthehandlebriskly.Returnthe

starterhandlegently.

5.Aftertheenginestarts,graduallymovethechoke

leverbacktotheOffposition.Iftheenginestallsor

hesitates,movethechokebacktoOnagainuntilthe

enginewarmsup.ThenmoveittotheOffposition.

6.Holdthethrottleleveragainstthehandletorotate

thecuttingwheel.

StoppingtheEngine

1.Releaseyourhandfromthethrottlelever.

Note:Iftheenginehasbeenworkinghardoris

hot,letitrunforaminutebeforereleasingthe

safetybail.Thishelpstocooltheenginebefore

stopping.Inanemergency,theenginemaybe

stoppedimmediately.

•Keepallbystandersasafedistancefromthe

machine.

•Stopthemachineimmediatelyifanypeopleor

animalsentertheworkarea.

WARNING

Grindingastumpwillthrowwoodchips,soil,and

otherdebrisintotheairwhichcouldinjureyouor

bystanders.

•Alwaysweareyeprotectionwhenusingthe

machine.

•Keepallbystandersasafedistancefromthe

machine.

WARNING

Alwayswearhearingprotectionwhenusingthe

machine.

1.Releasethethrottlesothatitisindisengaged

position.

2.Starttheengine;referto

StartingtheEngine(page11).

3.Allowenginetowarmupatidlefortwominutes.

4.Pushthehandledownenoughtoraisethecutting

wheelofftheground.

5.Holdthethrottleagainstthehandlesothatitisin

engagedposition,thiswillengagethecentrifugal

clutchandthecuttingwheelrotates.

2.Releasethesafetybailtostoptheengine.

3.MovethefuelvalvetotheClosedposition,allthe

waytotheleft.

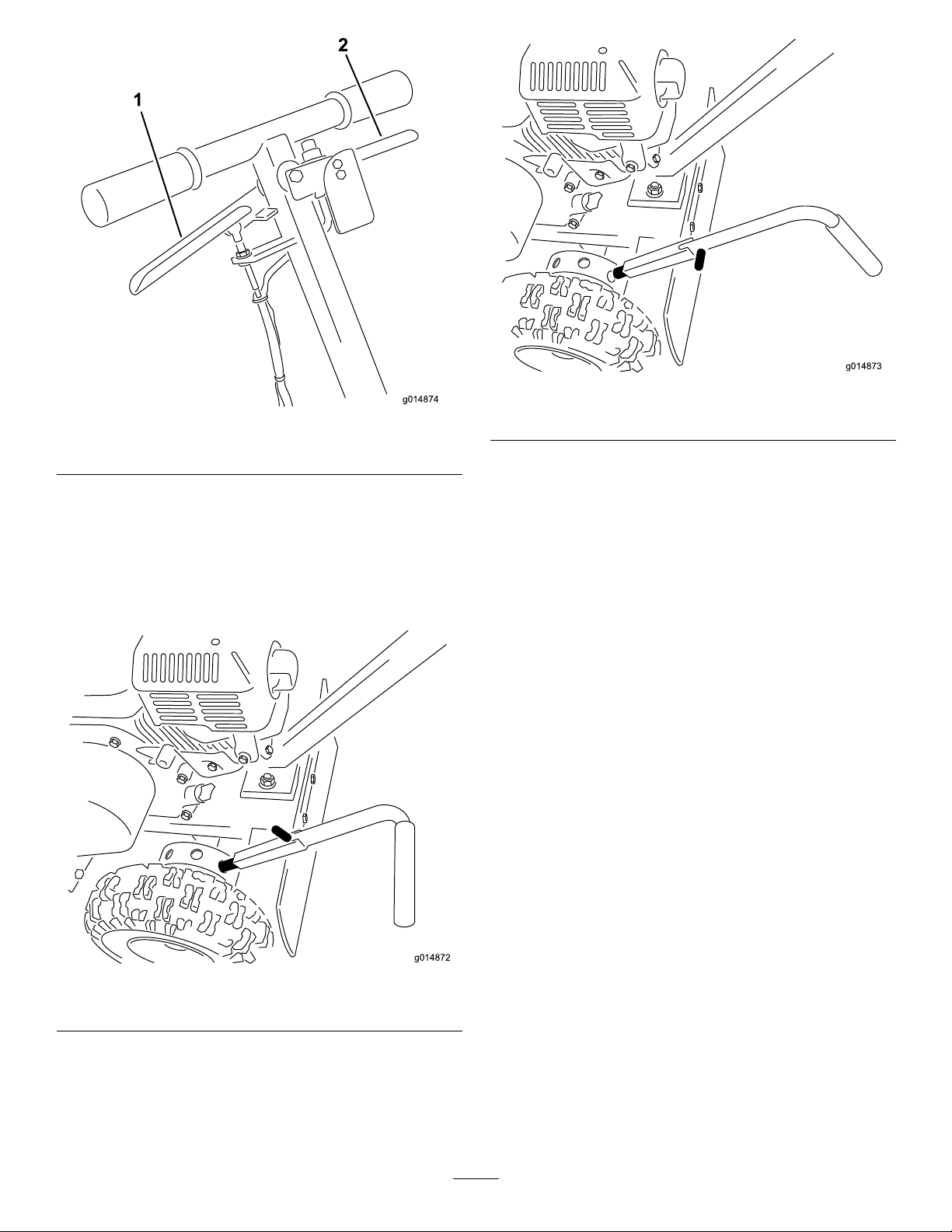

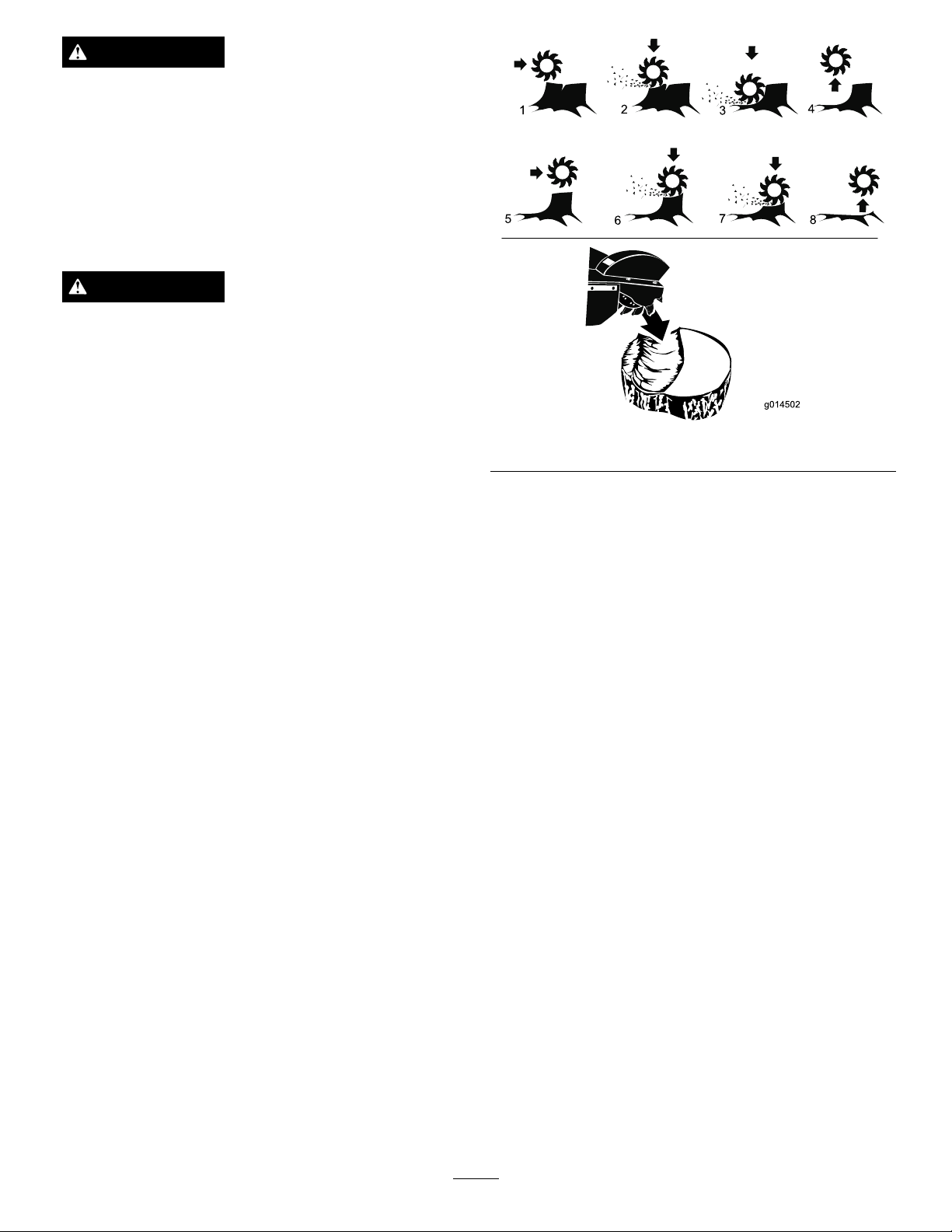

GrindingaStump

Placethemachineintopositionwiththecuttingwheel

nearthefront-topedgeofthestump.

6.Movethemachinetothefrontofthestumpandset

theparkingbrake.

7.Swingthecuttingwheeltooneside,thenlowerit

approximately1/2inchto1inchintothefront-top

cornerofthestump.Swingthecuttingwheelback

andforth,loweringthecuttingwheelapproximately

1/2inchto1inchbeforeeachsweep,untilyouhave

removedthefrontportionofthestumptoground

Figure11).

level(

11

Page 12

g014502

1

2

3

4

5

6

8

7

Figure11

8.Raisethecuttingwheeluntilcenterofcuttingwheel

isjustabovetopofthestump.

Note:DoNotletthefrontoftheunittouchthe

grounduntilyouaresurethecuttingwheelhas

stoppedturning.

DANGER

Arotatingcuttingwheelisverydangerousand

cancutandamputatehandsandfeet.

Stayattheoperatingpositionandbesurethat

thecuttingwheelhascometoacompletestop

beforedoinganythingelse.

9.Withthecuttingwheelofftooneside,releasethe

parkingbrakeandadvancethemachineforward,

resettheparkingbrake.

10.Continuesweepingandcuttingwheelleftandright

acrossstump,advancingthemachinebeforeeach

sweep,cutting1/2inchto1inchdepthofcutwith

eachsweep.

11.Continuecuttinguntilthetoplevelofstumpisall

removed,makingsurenottocutstumpdeeperthan

groundlevelduringthisrststage.

12.Releasethethrottlesothatitisindisengaged

position,pushthehandledownenoughtoraisethe

cuttingwheelofftheground.Waittensecondsfor

thecuttingwheeltostoprotatingthenreleasethe

brakeandpullthemachineawayfromthestump.

13.Pullthemachineawayfromthestumpandrakethe

chipsawayfromthestump.

14.Movethemachinetothefrontofthestumpandset

theparkingbrake.

15.Holdthethrottleagainstthehandlesothatitisin

engagedposition,thiswillengagethecentrifugal

clutchandthecuttingwheelrotates.

16.Continuecuttinguntilbyrepeatingstep10again

andagainuntilthelevelofstumpisdeeperthan

groundlevelasdesired.

17.Stopthemachine;referto

StoppingtheEngine(page11).

12

Page 13

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Important:Themachinemaybetippedbackward

oronitssidetofacilitateaccessforcleaningor

service,butnolongerthan2minutes.Ifthe

machineisheldinthispositionfortoolong,the

enginecanbedamagedbygasolinedraininginto

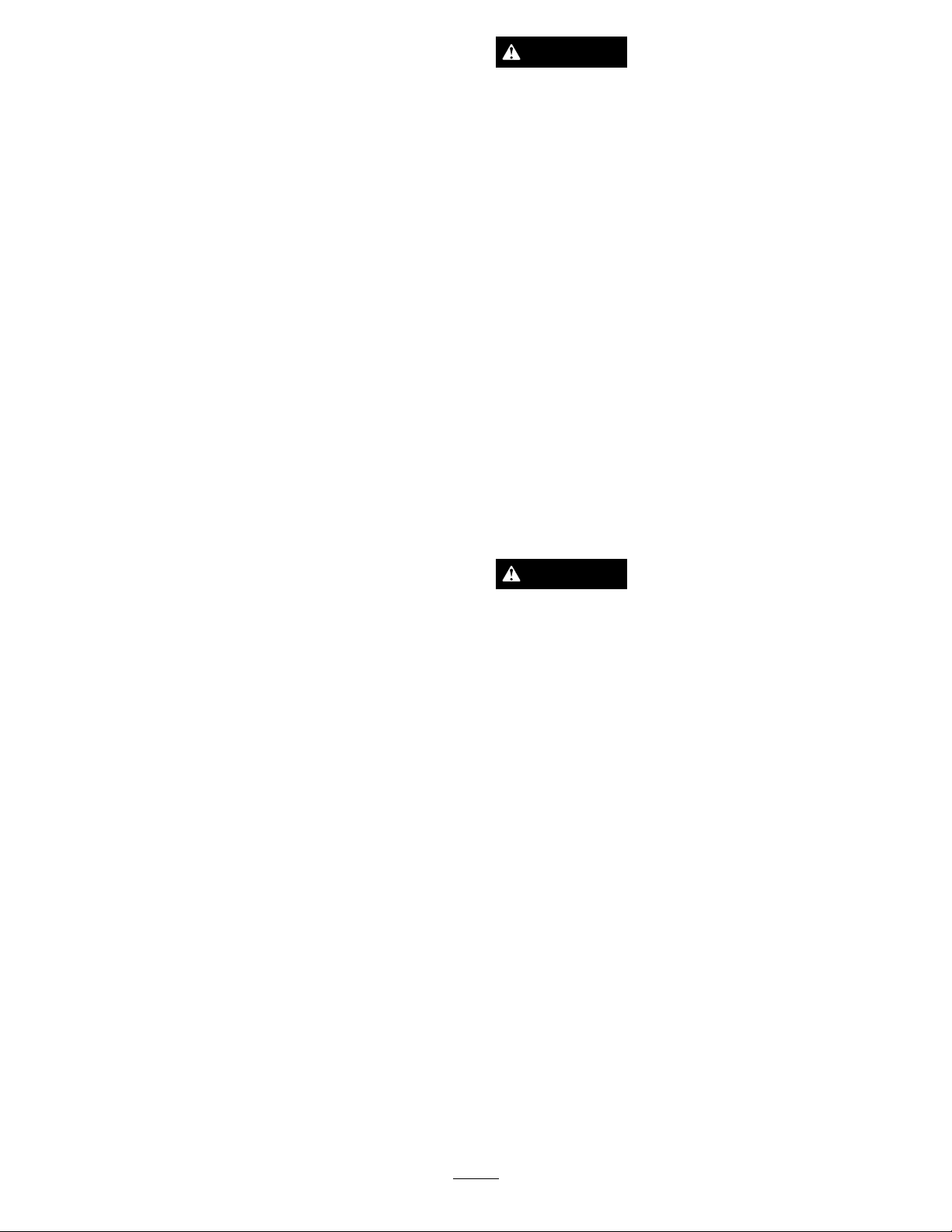

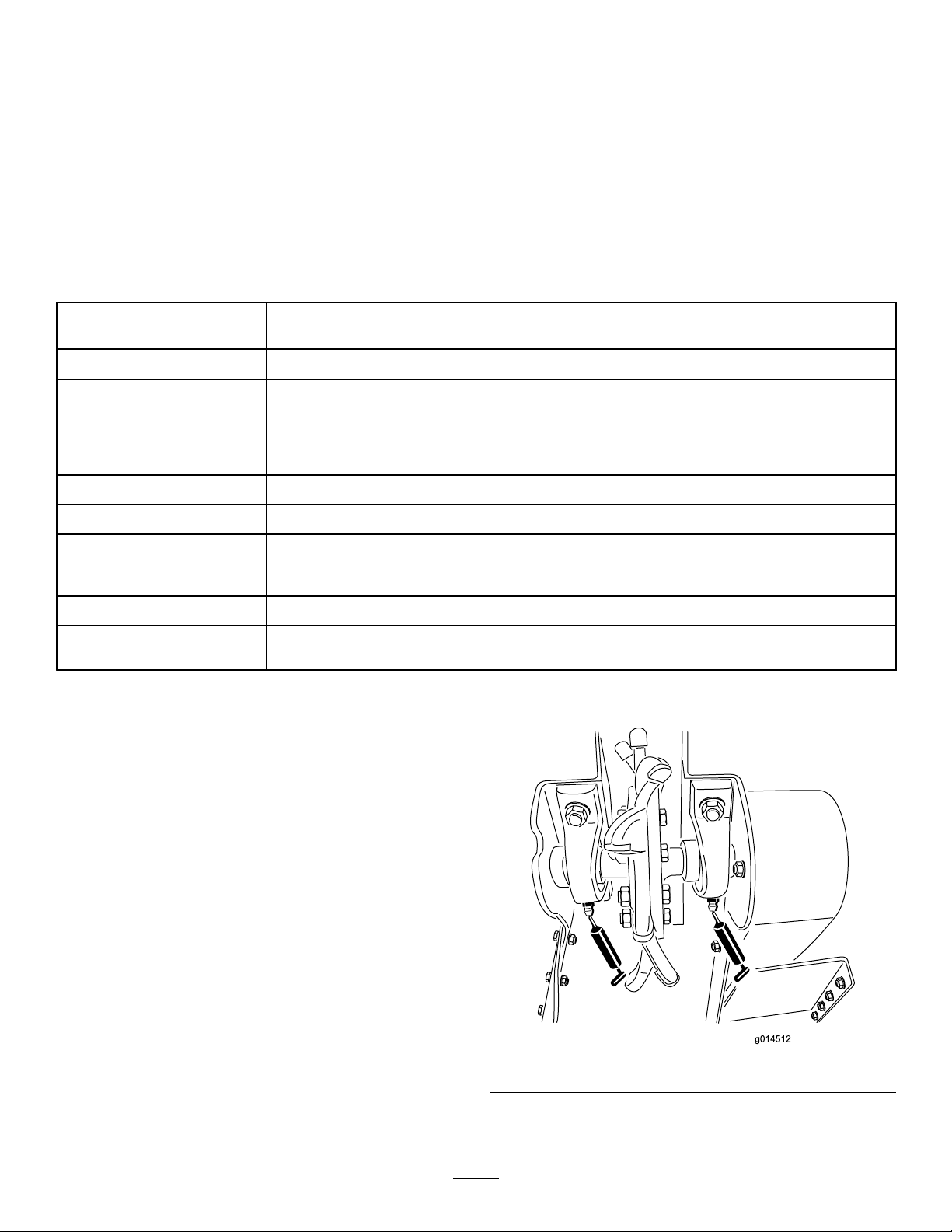

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst25hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

MaintenanceProcedure

•Changetheoil.

•Checktheengineoillevel.

•Greasethemachine.

•Checktheairlter.

•Checkthecuttingwheelblades.

•Removedebrisfromthemachine.

•Checkthedrivebelttension.

•Servicetheairlter.

•Changetheoil.

•Cleanthesedimentcup.

•Checkthesparkplugs.

thecrankcase.Shouldthishappen,performan

extraoilchangeontheengine.Thenturnthe

engineoverafewrevolutionswiththestarterhandle

beforestartingtheengineagain.

Every200hours

Yearlyorbeforestorage

Important:Refertoyour

•Replacetheairlter.

•Changetheoil.

•Cleanthesedimentcup.

Engine Operator’ s Man ual

Lubrication

GreasingtheMachine

ServiceInterval:Beforeeachuseordaily

GreaseType:General-purposegrease.

1.Cleanthegreasettingswitharag.

2.Connectagreaseguntoeachtting.

3.Lubricatetwottings,oneoneachcuttingwheel

bearing.

foradditionalmaintenanceprocedures.

Figure12

13

Page 14

4.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings(approximately3pumps).

EngineMaintenance

5.Wipeupanyexcessgrease.

Important:Pumpgreaseinslowlyandcarefully

topreventdamagetothebearingseals.

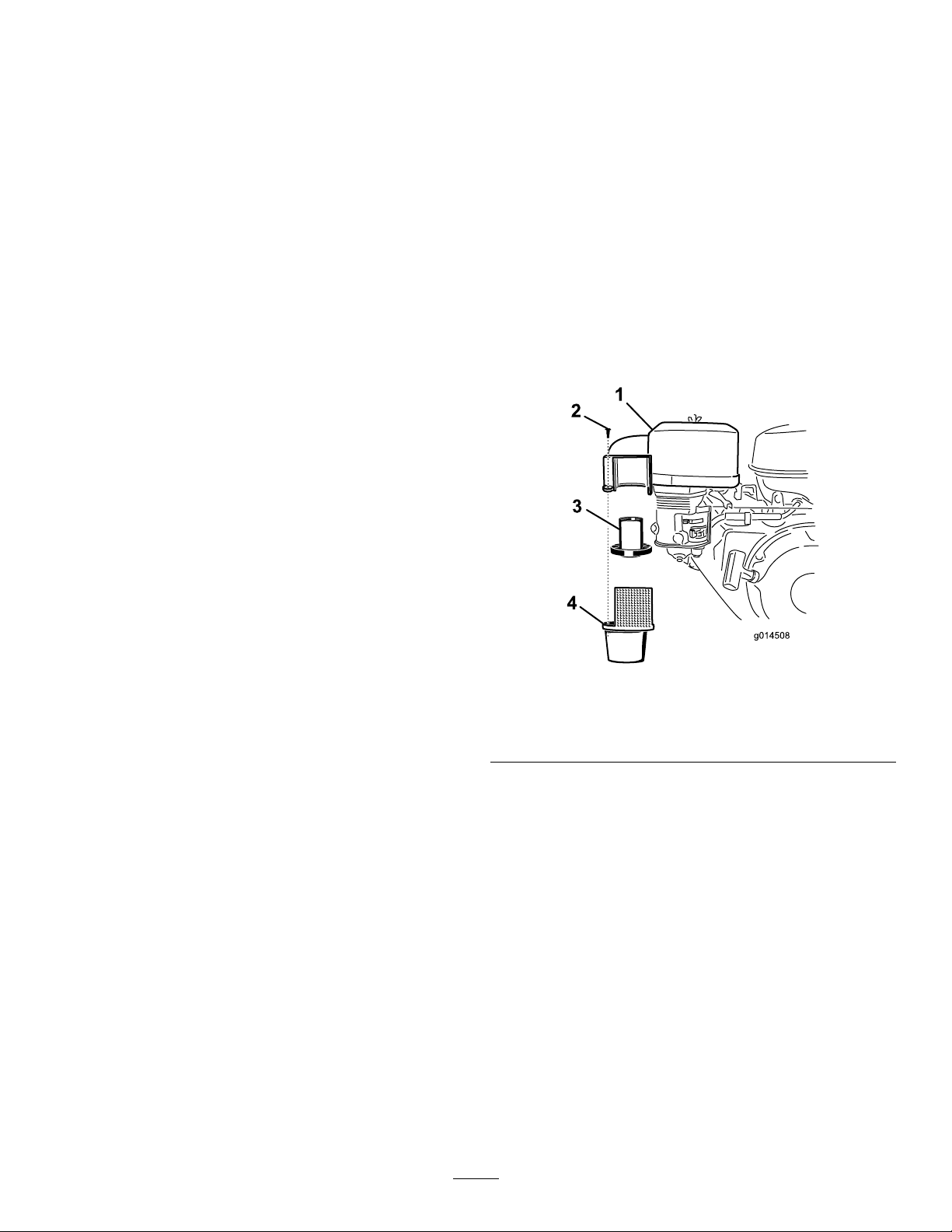

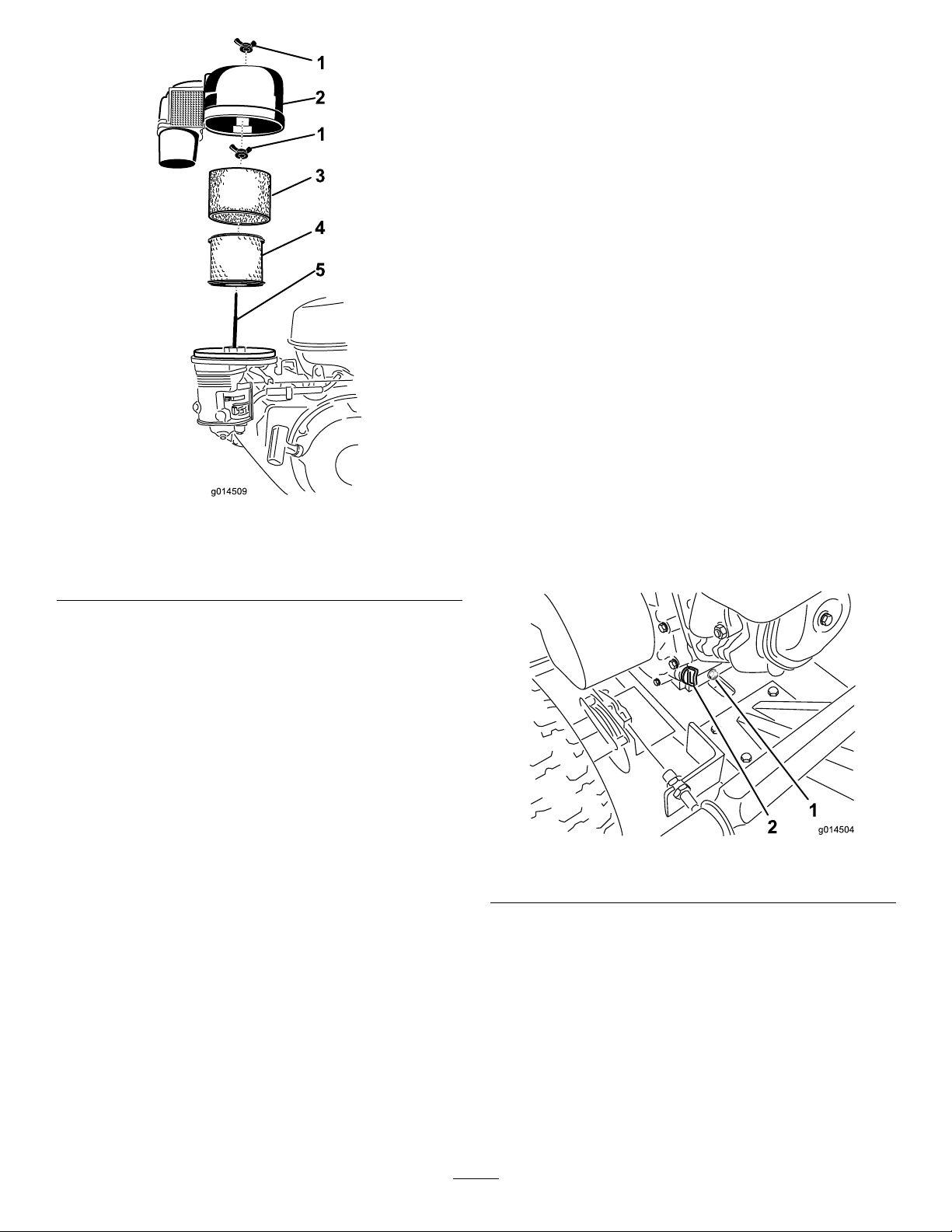

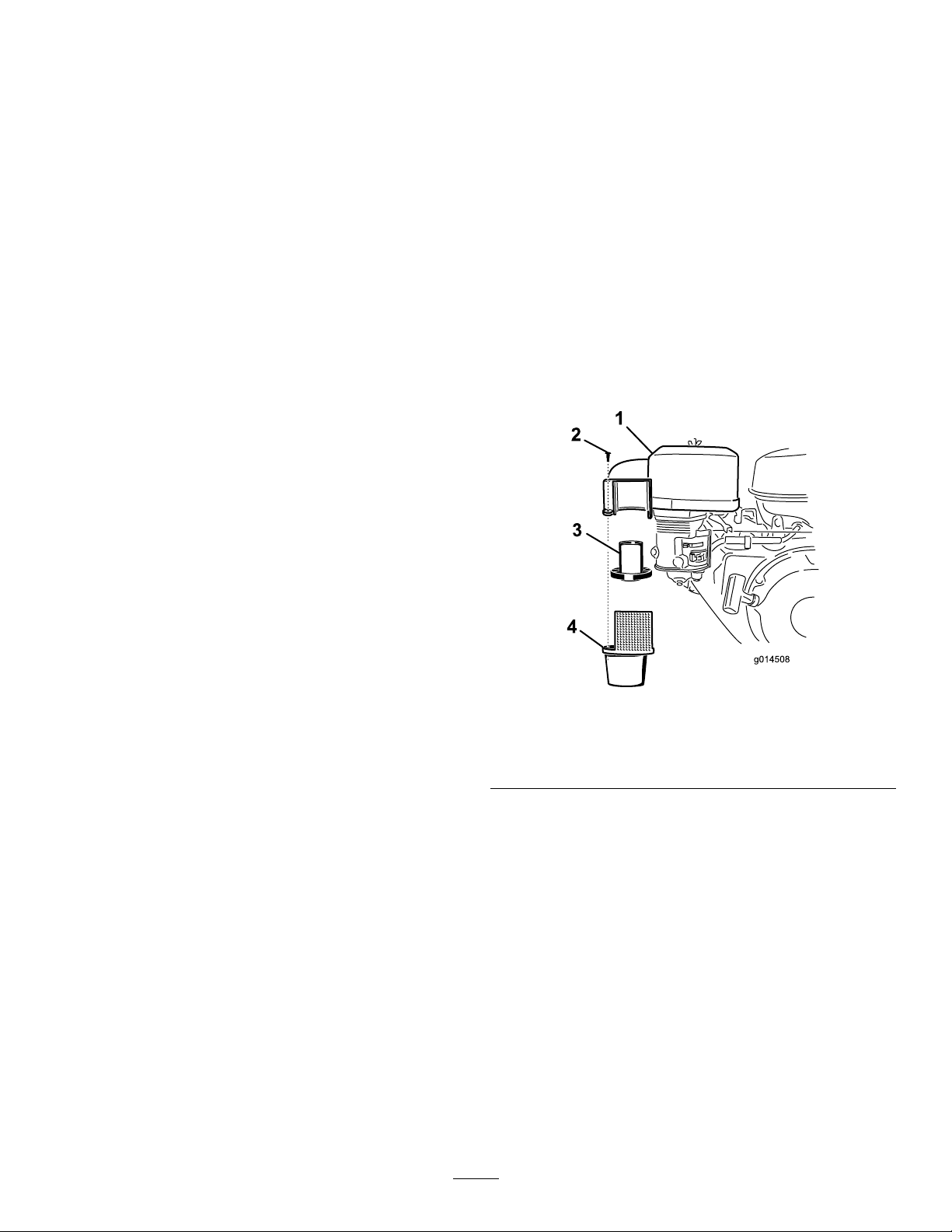

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily

Thecycloneairltercollectsthelargestcontaminant

particles,whichcollectinthecontainer.Whenyoucan

seealayerofdirtatthebottomofthecontainer,clean

thecyclonehousing,airchannels,andairintakescreen.

ServicingtheCycloneAirFilter

ServiceInterval:Every50hours

1.Removethe3screwsholdingthecyclonehousing.

2.Removethehousingwiththeairintakescreenand

removetheairchannels.

Figure13

1.Cyclonehousing

2.Screw4.Cyclonehousingwithair

Note:Theairchannelsmayremainintheupper

portionorfollowalongwiththehousingwhen

removed.

3.Cleanthecomponents.Usewater,detergentanda

brush.Drycarefully.

4.Placetheairchannelsinthecyclonehousing.

5.Insertcyclonehousingintopositionandmakesure

ittsintheupperportion.Donotuseforce;alignit

inplacebeforettingthescrews.

3.Airchannels

intakescreen

ReplacingtheAirFilter

ServiceInterval:Every200hours

Iftheengineislowonpower,producesblacksmokeor

runsunevenly,theairltermaybeclogged.

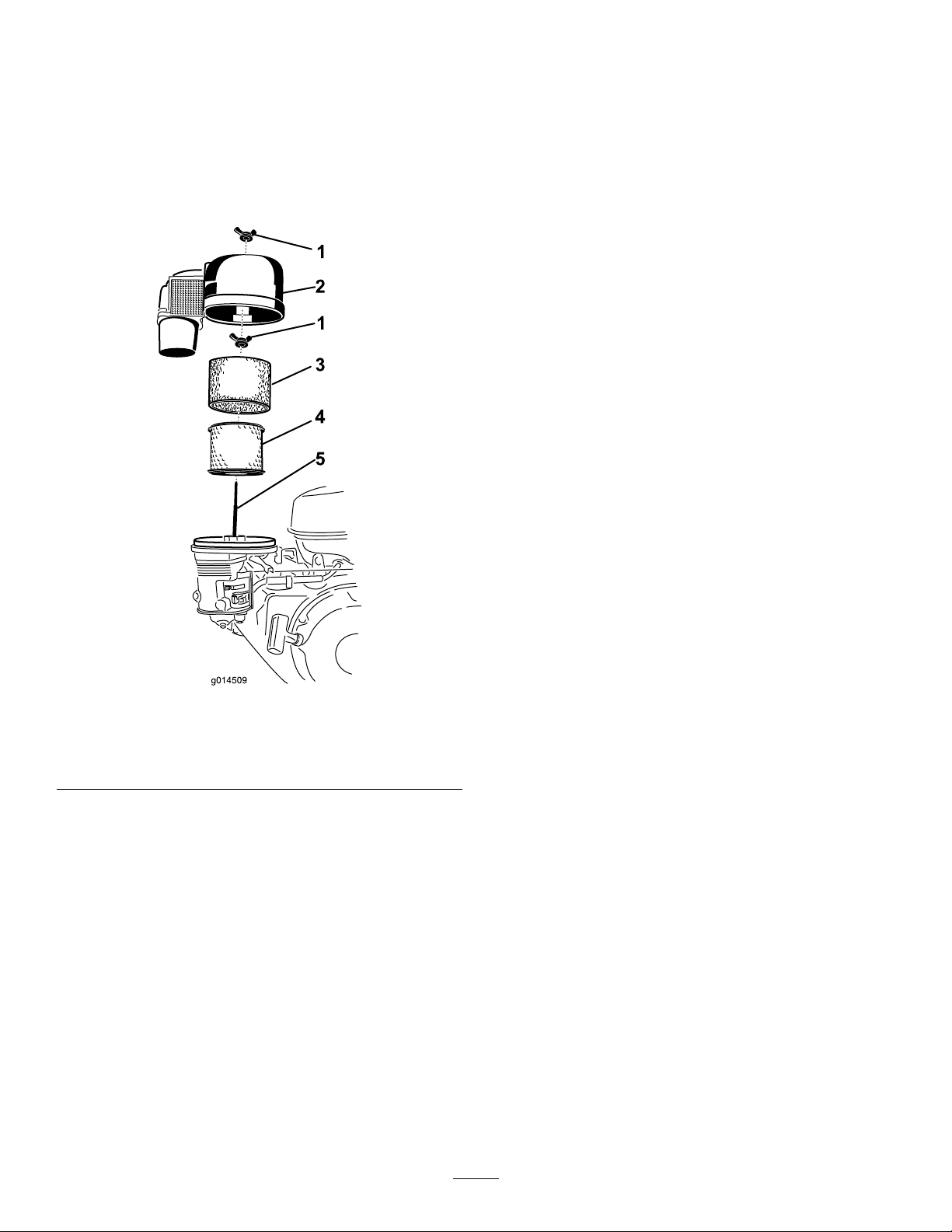

1.Removethewingnutandliftoffthecyclonelter

withtheairltercowling(

Figure14).

14

Page 15

Figure14

g014504

1

2

1.Wingnut

2.Cycloneairlter5.Stud

3.Foampre-lter

4.Airlter

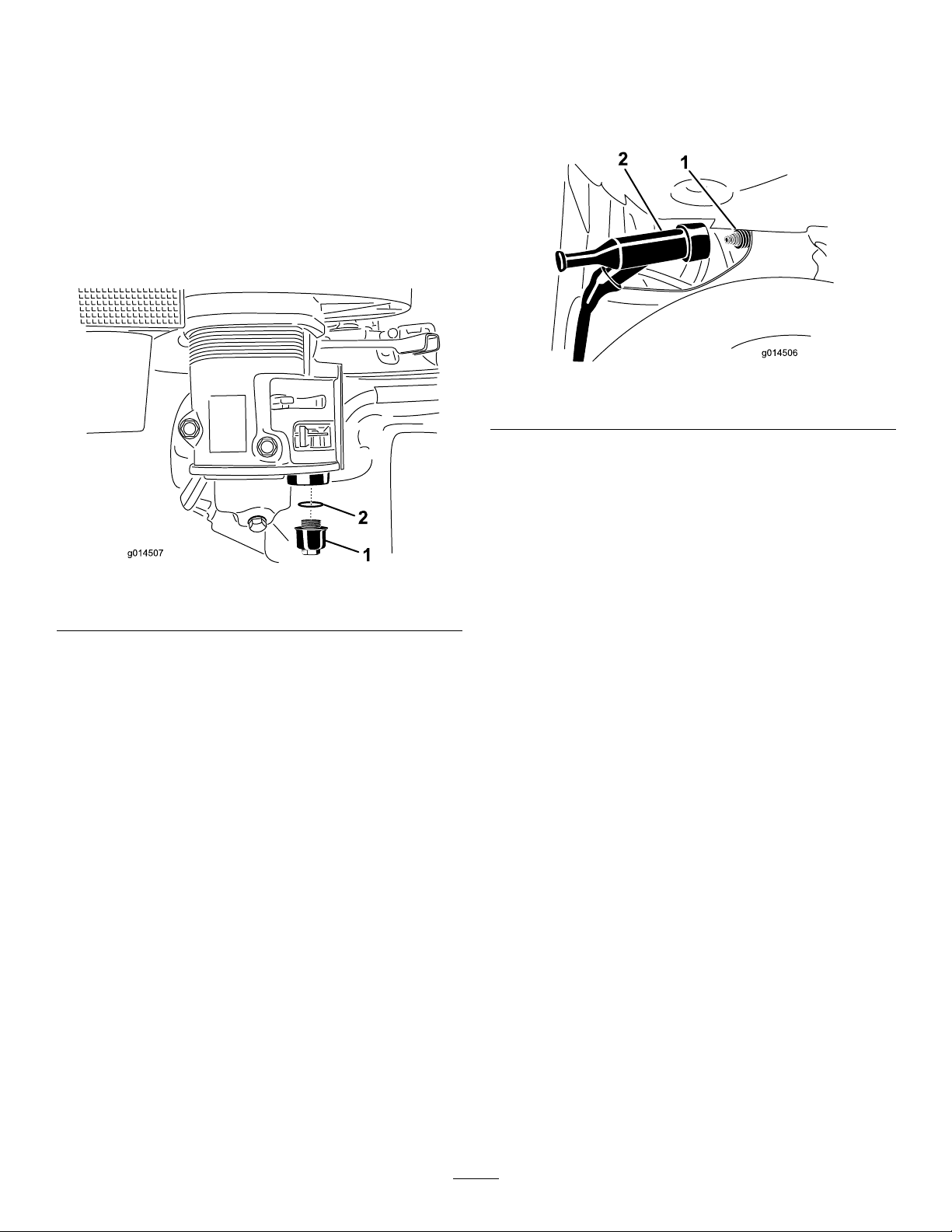

ServicingtheEngineOil

Note:Changetheoilmorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy.

OilType:DetergentoilwithanAPIserviceofSJor

higher.

CrankcaseCapacity:.63qt(.6liters)

Viscosity:SAE10W-30isrecommendedforgeneral

use.

ChangingtheEngineOil

ServiceInterval:Aftertherst25hours

Every100hours

Yearlyorbeforestorage

1.Starttheengineandletitrunveminutes.This

warmstheoilsoitdrainsbetter.

2.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoensurethattheoil

drainscompletely.

3.Settheparkingbrakeandstoptheengine.

4.Placeapanundertheoildrainhole.

5.Removethedrainpluganddraintheoilthroughthe

holeslotintheframe(

Figure15).

2.Removethefoampre-lterandcleanitasfollows

A.Washthepre-lterusingamilddetergentand

water.

B.Squeezeitdrywithacleancloth.

C.Soakitwithnewengineoil.

D.Gentlywindthelterinanabsorbentclothand

squeezeoutexcessoil.

3.Removethewingnutontopoftheairlterand

removethepaperlter.

4.Tapthepaperlteragainstaxedsurfacetoremove

dust.Ifthepaperlterisstilldirtyordamaged,

replaceit.Thepaperltershouldbereplacedevery

200hours.

Important:Donotusecompressedairtoblow

outthepaperelement,thiscandamageit.

5.Mountthepaperlterintheairlterhousingand

secureitwiththewingnut.

6.Positionthefoampre-lteroverthepaperlter.

7.Installthecyclonelterwiththeairltercoverand

secureitwiththewingnut.

Figure15

1.Oildrainhole2.Oilllcap

6.Whentheoilhasdrainedcompletely,installtheplug

andwipeupanyspilledoil.

Note:Disposeoftheusedoilatacertiedrecycling

center.

7.Removetheoilllcapandslowlypourapproximately

80percentofthespeciedamountofoilintothe

engine(Figure15).

8.Slowlyaddadditionaloiltobringtheoilleveltothe

upperlimitmarkonthedipstick.Referto(page).

9.Installtheoilllcap.

15

Page 16

CleaningtheSedimentCup

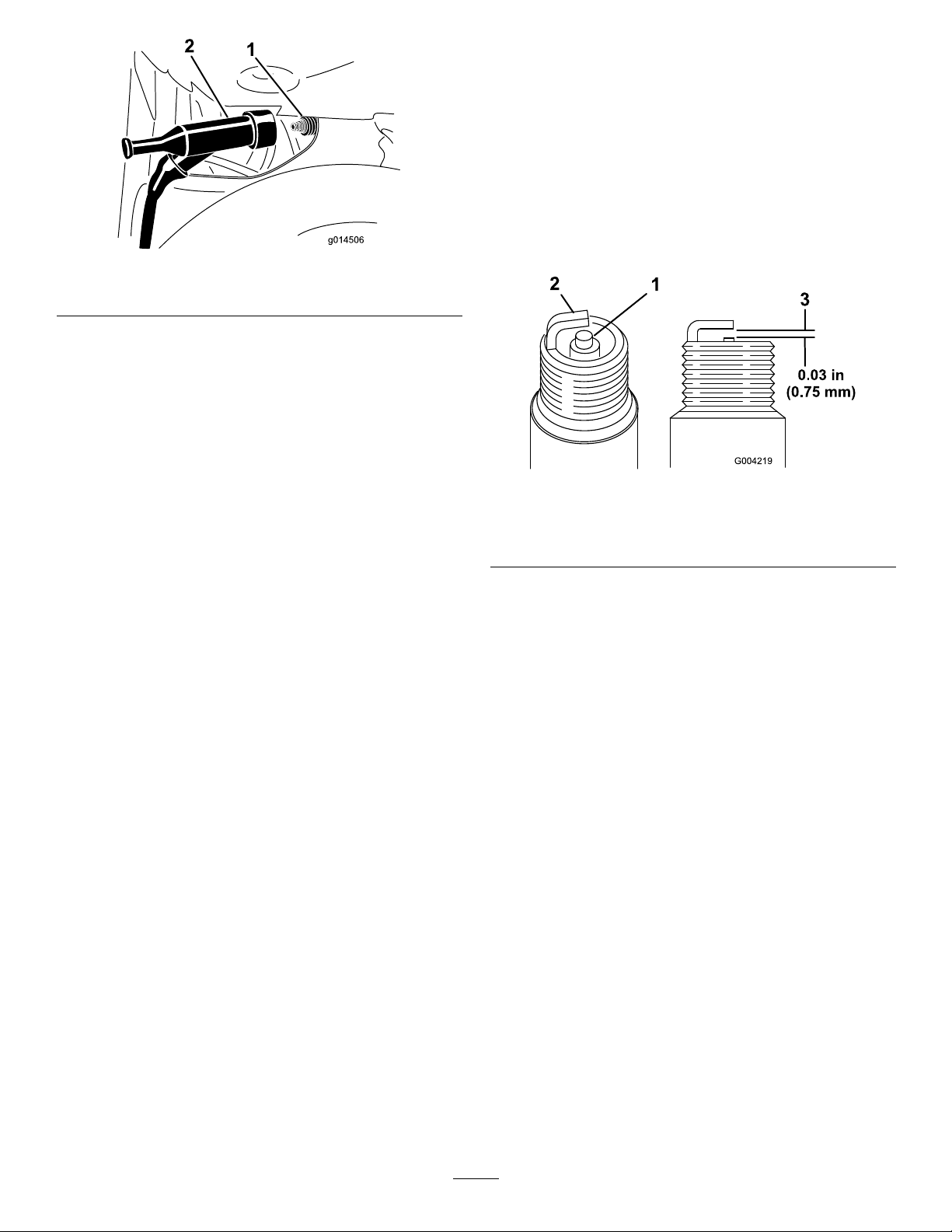

RemovingtheSparkPlug

ServiceInterval:Every100hours

Yearlyorbeforestorage

Underneaththefuelvalveisasedimentcuptocatch

dirtinthefuel.

1.MovethefuelvalvetotheOffposition,alltheway

totheleft.

2.Unscrewthesedimentcup.Makesurenotto

misplacetheo-ring(

Figure16).

1.Lowerthegrinderandstopthemachine;Referto

StoppingtheEngine(page11).

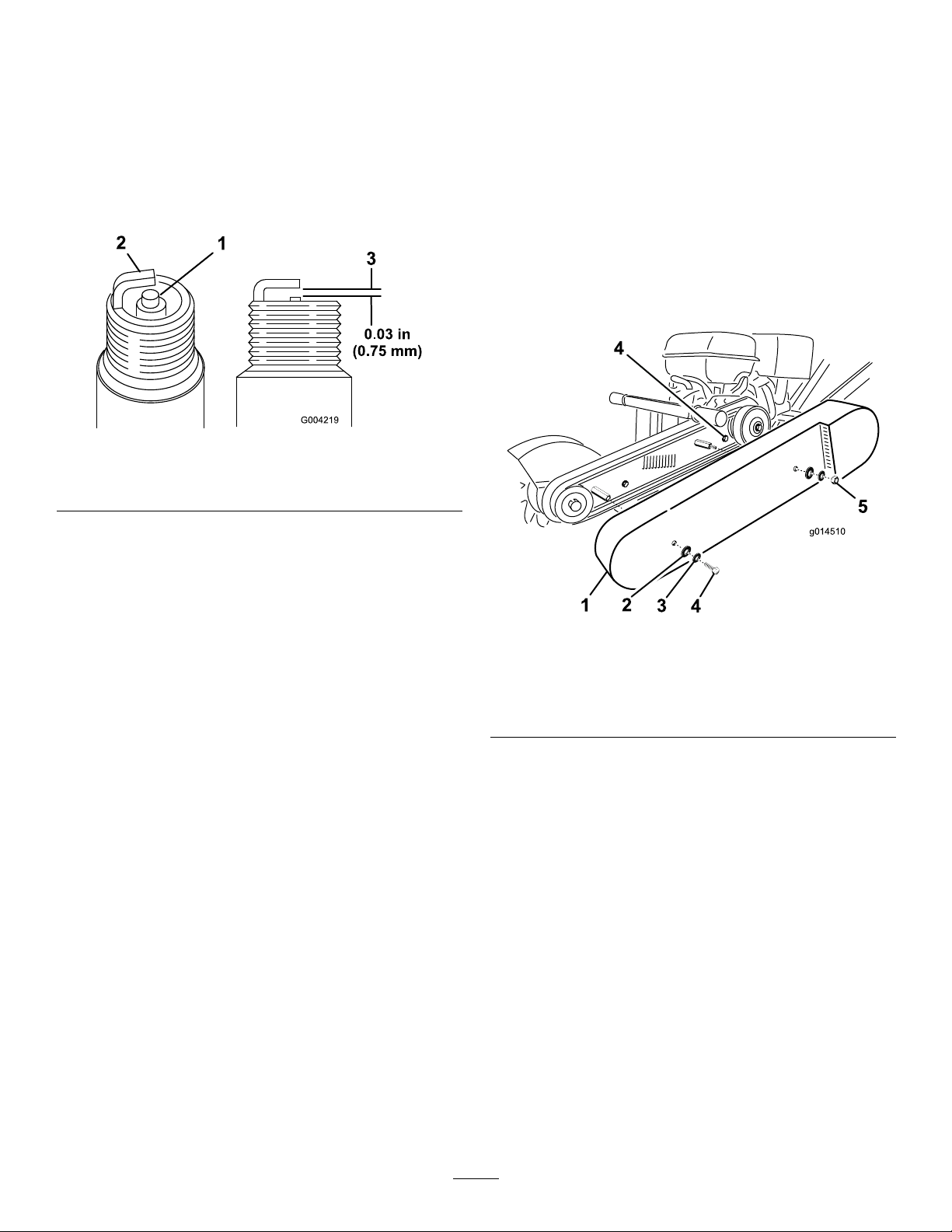

2.Pullthewireoffofthesparkplug(Figure17).

Figure17

1.Sparkplug

2.Wire

3.Cleanaroundthesparkplug.

4.Removethesparkplugandthemetalwasher.

Figure16

1.Sedimentcup2.O-Ring

3.Cleanthereservoirandtheo-ringusingacleaning

solventanddrycarefully.

Note:Makesurenottomisplacetheo-ring.

4.Puttheo-ringinplaceinthegrooveofthecupand

replacethesedimentcup.

5.TurnthefuelvalvetotheOnposition,alltheway

totheright,andcheckforleaks.Ifitleaks,replace

theo-ring.

ServicingtheSparkPlug

ServiceInterval:Every100hours—Checkthespark

plugs.

Ensurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplug.

Useasparkplugwrenchforremovingandinstallingthe

sparkplugandagappingtool/feelergaugetocheckand

adjusttheairgap.Installanewsparkplugifnecessary.

Type:BPR6ES(NKG)orequivalent

AirGap:0.28–0.031inch(0.70-0.80mm)

16

Page 17

CheckingtheSparkPlug

g014510

1

2

3

4

5

4

1.Lookatthecenterofthesparkplug(Figure18).

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeansthattheaircleanerisdirty.

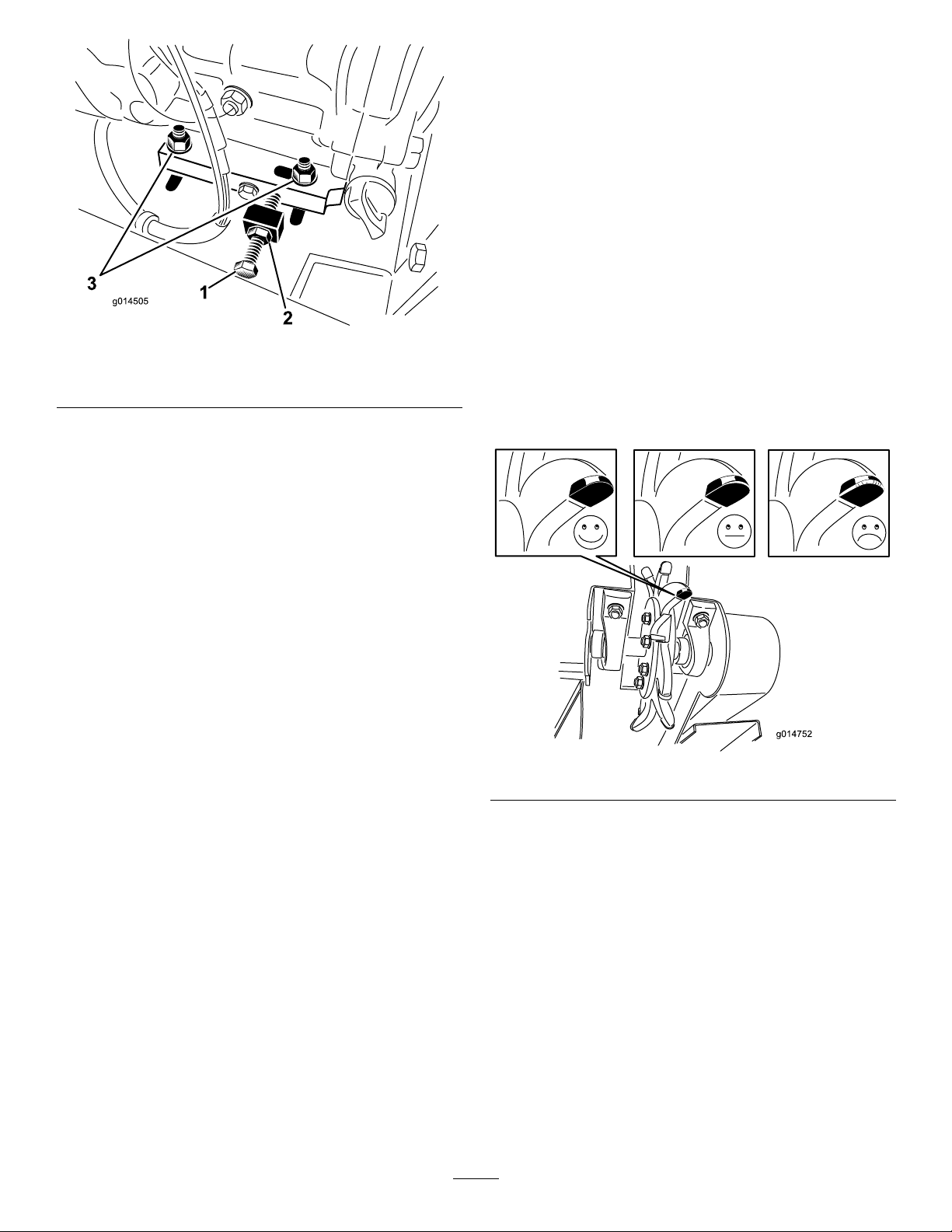

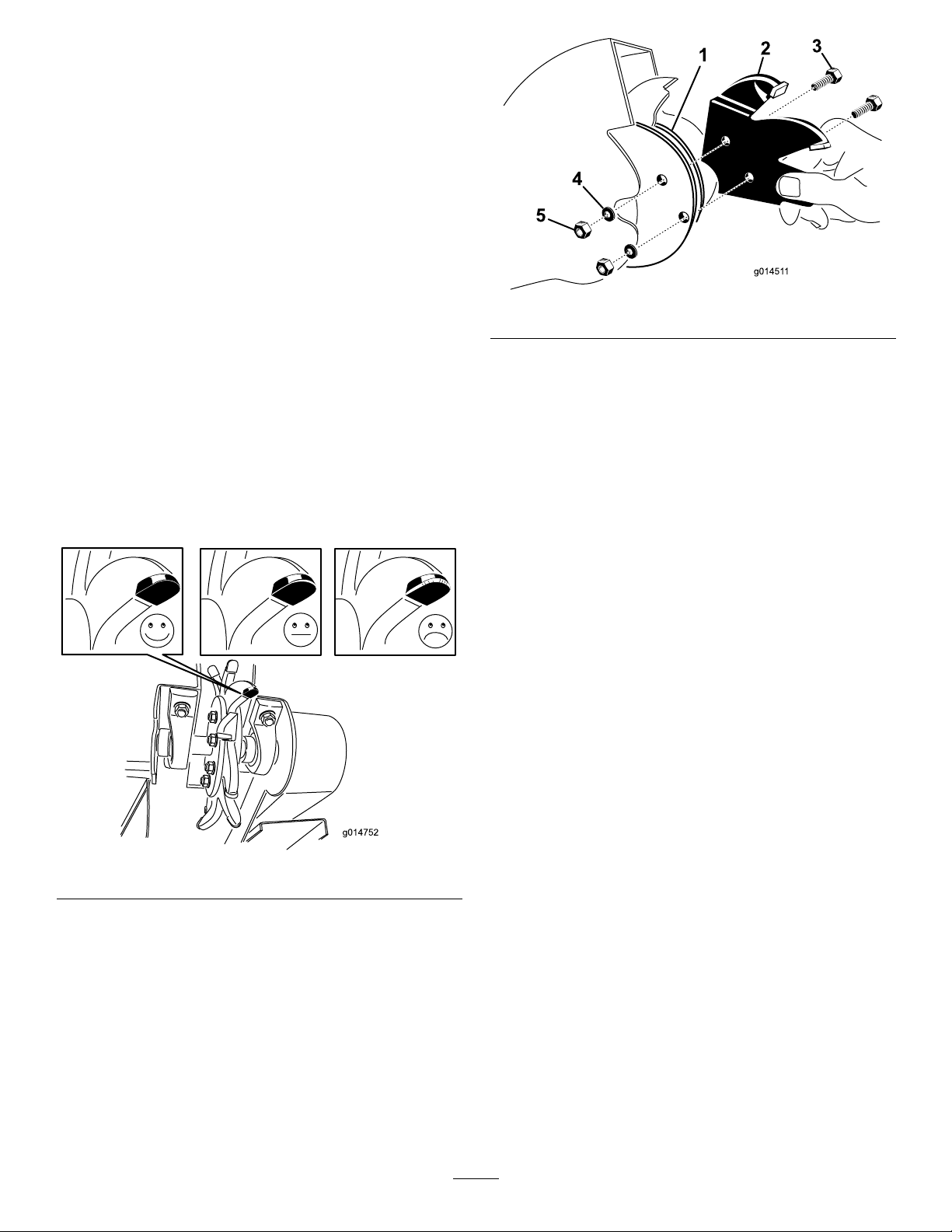

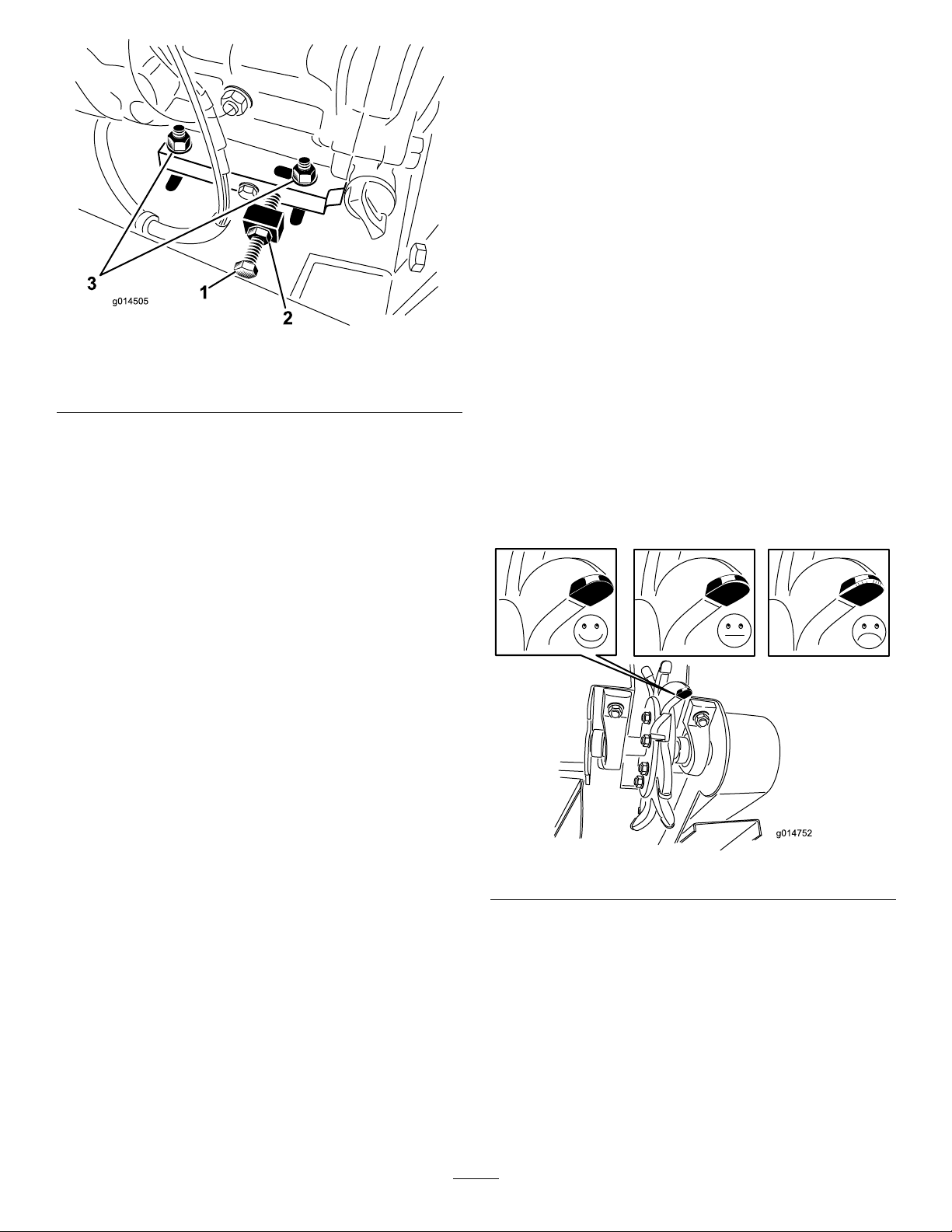

BeltMaintenance

CheckingtheDriveBelt

Tension

Important:NeverCleanthesparkplug.Always

replacethesparkplugwhenithasablack

coating,wornelectrodes,anoilylm,orcracks.

Figure18

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

2.Checkthegapbetweenthecenterandsideelectrodes

(Figure18).Bendthesideelectrode(Figure18)if

thegapisnotcorrect.

ServiceInterval:Every25hours

Note:Replacethebeltifitshowsanysignsofwear,

cracks,ordamage.

1.Shutofftheengineandwaitforallrotatingparts

tostop.

2.Removebeltguardretainingscrews(

Figure19).

InstallingtheSparkPlug

1.Threadthesparkplugintothesparkplughole.

2.Tightenthesparkplugto20ft-lb(27N-m).

3.Pushthewireontothesparkplug.

Figure19

viewmayvarydependingonmodel

1.Beltguard4.Bolt

2.Lockwasher5.Nut

3.Washer

3.Tocheckbelttension,gentlysqueezethebeltspans

together.Youshouldbeabletopushthebeltdown

about1/4–3/8inch(6–10mm)fromtheoriginal

position.

Important:Toextendthebeltlife,propertension

mustbemaintained.Aloosebeltwillcause

excessivecuttingwheelslippageandearlybelt

failure.Abeltthatistootightcancausebearing

andshaftfailure,andrapidbeltwear.

AdjustingtheDriveBelt

1.Removethebeltguard.

2.Loosenthe4enginemountingbolts,andjamnuts

holdingtheadjustmentbolt(Figure20).

17

Page 18

Figure20

1.Bolt3.Enginemountbolt

2.JamNut

3.Turnsquareheadadjustingboltontheframe

clockwisetotightenthebelt,counterclockwiseto

loosenthebelt

Important:Important:Makesuretotighten

alltheengineboltsafterproperbeltadjustment

isachieved.

GrinderMaintenance

CheckingtheCuttingWheel

Blades

ServiceInterval:Beforeeachuseordaily

Amongthemostcriticalelementsofthemachineisthe

cuttingwheelblades.Theyarealsothemostsubjectto

damageandwear.Inthecourseofgrindingstumps

theynotonlymakecontactwiththewood,buttheyalso

encounternumerousabrasivesandobjects,suchasdirt,

stones,andoccasionallyalargerockorburiedscrap.

Thewearandlossofcuttingteethcansignicantly

impairtheefciencyandperformanceofthemachine.

Therefore,itisimportanttomakefrequentchecksof

theconditionofallofthecuttingteethandreplaceany

damagedorwornbladesections(

Figure21).

4.Installthebeltguardandsecurewithpreviously

removedhardware.

Figure21

ReplacingtheCuttingWheel

Blades

1.Cleanalldirtfromthecuttingwheelandmounting

anges.

2.Removethetwoboltsthatholdeachcuttingblade

section.Usecarenottoletasectiondropandchip

whentheybecomeloose(

Figure22).

18

Page 19

Cleaning

RemovingDebrisfromthe

Machine

Regularcleaningandwashingwillincreasethelifespan

ofthemachine.Cleanthemachinedirectlyafteruse,

beforethedirthardens.

Checkbeforecleaningthatthefueltankcapisproperly

inplacetoavoidgettingwaterinthetank.

Figure22

3.Checkeachsectionforcracks.Replaceablade

sectionifitiscrackedorhasmissingorwornteeth.

Note:Whenreplacingcuttingwheelbladesections,

makesurebladesectionisplacedincorrect

alignmentwithbladerotation.

4.Insertthebladesectionbetweentheblademounting

anges(

lockwashers,andnuts.

5.Torquethefastenersto27–33ft-lb(37–45N-m).

Figure22),andsecurethemwith2bolts,

Usecarewhenusingahigh-pressuresprayerbecauseit

candamagewarningdecals,instructionsigns,andthe

engine

Important:Lubricatethecuttingwheelblade

bearingsaftercleaning.

19

Page 20

Storage

17.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDealer.

Forstorageover30days,preparetheunitasfollows:

1.Removedirtandgrimefromtheexternalpartsof

theentireunit,especiallytheengine.Cleandirt

andsawdustchipsfromtheoutsideoftheengine

cylinderheadnsandblowerhousing.

Important:Youcanwashtheunitwithmild

detergentandwater.

2.Addapetroleumbasedstabilizer/conditionerto

fuelinthetank.Followmixinginstructionsfrom

stabilizermanufacturer.(1oz.perUSgallon).Do

notuseanalcoholbasedstabilizer(ethanolor

methanol).

Note:Fuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasolineandusedatalltimes.

Important:Donotstorestabilizer/conditioned

gasolineover90days.

3.Runtheenginetodistributeconditionedfuel

throughthefuelsystem(5minutes).

4.Stoptheengine,allowittocool,anddrainthefuel

tankusingapumptypesiphon.Disposeoffuel

properly;recycleasperlocalcodes.

18.Storetheunitinaclean,drygarageorstoragearea.

19.Covertheunittoprotectitandkeepitclean.

5.Starttheengineandrunituntilitstops.

6.Choketheengine.

7.Startandruntheengineuntilitwillnotstartagain.

8.Cleanthesedimentcup;referto

CleaningtheSedimentCup(page16).

9.Servicetheaircleaner;referto

ServicingtheCycloneAirFilter(page14)

and,ReplacingtheAirFilter(page14).

10.Changetheenginecrankcaseoil;referto(page).

11.Removethesparkplugandcheckthecondition;

referto(page).

12.Withthesparkplugremovedfromtheengine,pour

twotablespoonsofengineoilintothesparkplug

hole.

13.Pullthestarterslowlytocranktheengineand

distributetheoilinsidethecylinder.

14.Installthesparkplug,butdonotinstallthewireon

thesparkplug.

15.Greasethecutterwheelbearings;referto

GreasingtheMachine(page13).

16.Checkandtightenallbolts,nuts,andscrews.Repair

orreplaceanypartthatisdamaged.

20

Page 21

Troubleshooting

Problem

Theenginewillnotstart.

Theenginerunsrough.

Thebeltslipsorcomesoffthepulleys1.Thebelttensionisinsufcient.

Thecuttingwheeldoesnotrotate.

Thecuttingwheelcontinuestorotate.

1.TheengineswitchisintheOffposition.1.Holdthesafetybailagainstthehandle.

2.Thefuelshutoffvalveisclosed.2.Openthefuelvalve.

3.Thechokeisopen.

4.Thefueltankisempty.4.Filltankwithfreshfuel.

5.Thesparkplugwireislooseor

disconnected.

1.Thechokeislefton.1.Openthechoke.

2.Theairlterisclogged.2.Cleanorreplacetheairlter.

3.Thefuellineisclogged.3.Cleanthesedimentcup.

4.Thereiswaterorcontaminantsinthe

fuel.

5.Thesparkplugsarewornorhave

buildupontheelectrodes.

1.Theenginespeedisinsufcientto

activatethecentrifugalclutch.

2.Thebelttensionisinsufcient.

3.Theclutchshoesareworn.3.Replacetheclutch.

1.Theenginespeedisexcessive.1.MovethethrottletotheDisengaged

2.Thebeltisoffofthepulleysorbroken.

3.Clutchspringsareweakorbroken.

PossibleCauseCorrectiveAction

3.Closethechokewhenstartingacold

engine.

5.Checktheelectrodegapandcleanor

replacethesparkplug.

4.Drainandllthetankwithfreshfuel.

5.Checkelectrodegapandcleanor

replacethesparkplug.

1.Adjustthebelttension.Reducethe

cuttingdepth.

1.MovethethrottletotheEngaged

position.

2.Adjustthebelttension.

position.

2.Replacethedrivebelt.

3.Replacetheclutch.

21

Page 22

Notes:

22

Page 23

Notes:

23

Page 24

ToroCompactUtilityEquipmentWarranty

AOne-YearLimitedWarranty

CUEProducts

ConditionsandProductsCovered

TheToro®Companyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCompactUtility

Equipment(“Product”)tobefreefromdefectsinmaterialsorworkmanship.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

Loaders,Trenchers,StumpGrinders,

Chippers,LogSplittersandAttachments

KohlerEngines3years

AllotherEngines2years

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

1yearor1000operating

hours,whicheveroccursrst

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.ContactanyAuthorizedToroCompactUtilityEquipment(CUE)

ServiceDealertoarrangeserviceattheirdealership.Tolocatea

dealerconvenienttoyou,accessourwebsiteatwww.Toro.com.

YoumayalsocallourT oroCustomerCareDepartmenttollfree

at888-865-5676(U.S.customers)or888-865-5691(Canadian

customers).

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.

3.IfforanyreasonyouaredissatisedwiththeServiceDealer’s

analysisorwiththeassistanceprovided,contactusat:

LCBCustomerCareDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFree:888-865-5676(U.S.customers)

TollFree:888-865-5691(Canadacustomers)

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutine

maintenance,whetherperformedbyadealerorbyyou,isatyourexpense.

Partsscheduledforreplacementasrequiredmaintenance(“Maintenance

Parts”),arewarrantedfortheperiodoftimeuptothescheduled

replacementtimeforthatpart.Failuretoperformrequiredmaintenance

andadjustmentscanbegroundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thisexpresswarranty

doesnotcoverthefollowing:

•Productfailureswhichresultfromtheuseofnon-Tororeplacement

parts,orfrominstallationanduseofadd-on,modied,orunapproved

accessories

•Productfailureswhichresultfromfailuretoperformrequired

maintenanceand/oradjustments

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligentorrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,during

normalProductoperationinclude,butarenotlimitedto,teeth,tines,

blades,sparkplugs,tires,tracks,lters,chains,etc.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,or

chemicals,etc.

•Normal“wearandtear”items.Normal“wearandtear”includes,butis

notlimitedto,wornpaintedsurfaces,scratcheddecalsorwindows,

etc.

•Anycomponentcoveredbyaseparatemanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

RepairbyanAuthorizedT oroCompactUtilityEquipment(CUE)Service

Dealerisyoursoleremedyunderthiswarranty.

NeitherTheToro®CompanynorToroWarrantyCompanyisliable

forindirect,incidentalorconsequentialdamagesinconnectionwith

theuseoftheToroProductscoveredbythiswarranty,including

anycostorexpenseofprovidingsubstituteequipmentorservice

duringreasonableperiodsofmalfunctionornon-usepending

completionofrepairsunderthiswarranty.Allimpliedwarranties

ofmerchantabilityandtnessforusearelimitedtotheduration

ofthisexpresswarranty.Somestatesdonotallowexclusionsof

incidentalorconsequentialdamages,orlimitationsonhowlong

animpliedwarrantylasts,sotheaboveexclusionsandlimitations

maynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

ExceptfortheenginewarrantycoverageandtheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.The

EmissionsControlSystemonyourProductmaybecoveredbyaseparate

warrantymeetingrequirementsestablishedbytheU.S.Environmental

ProtectionAgency(EPA)ortheCaliforniaAirResourcesBoard(CARB).

ThehourlimitationssetforthabovedonotapplytotheEmissions

ControlSystemWarranty .RefertotheCaliforniaEmissionControl

WarrantyStatementsuppliedwithyourProductorcontainedintheengine

manufacturer’sdocumentationfordetails.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirToroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor’sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheToroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany.

374-0261RevB

Page 25

ADVERTENCIA

Introducción

CALIFORNIA

AdvertenciadelaPropuesta65

Losgasesdeescapedeesteproductocontienen

productosquímicosqueelEstadodeCalifornia

sabequecausancáncer,defectoscongénitos

uotrospeligrosparalareproducción.

PELIGRO

Puedehabertendidoseléctricos,degasy/o

telefónicosenterradosenlazonadetrabajo.Si

seperforan,puedencausardescargaseléctricaso

explosiones.

Marquelasáreasdelazonadetrabajoque

contienentendidosenterrados,ynoexcaveen

laszonasmarcadas.Póngaseencontactoconsu

serviciodemarcadolocaloconsucompañíade

electricidad/agua,etc.,paraquemarquenlanca

(porejemplo,enlosEstadosUnidos,llameal811

paracontactarconelserviciodemarcadonacional).

Estesistemadeencendidoporchispacumplelanorma

canadienseICES-002.

Estamáquinaestádiseñadaparadesbastaryeliminar

toconesdeárbolesyraícessuperciales.Noestá

diseñadaparacortarrocasuotrosmaterialesqueno

seanlamaderaylatierraquehayalrededordeuntocón.

Leaestemanualdetenidamenteparaaprenderautilizar

ymantenercorrectamentesuproducto,yparaevitar

lesionesydañosalproducto.Ustedeselresponsablede

utilizarelproductodeformacorrectaysegura.

UstedpuedeponerseencontactodirectamenteconToro

enwww.Toro.comsideseainformaciónsobreproductos

yaccesorios,osinecesitalocalizarundistribuidoro

registrarsuproducto.

Cuandonecesiteasistenciatécnica,piezasgenuinasToro

oinformaciónadicional,póngaseencontactoconun

ServicioTécnicoAutorizadooconAsistenciaalCliente

Toro,ytengaamanolosnúmerosdemodeloyseriede

suproducto.

Figura1indicalaubicacióndelosnúmeros

demodeloyserieenelproducto.Escribalosnúmeros

enelespacioprovisto.

Puestoqueenalgunaszonasexistennormaslocales,

estatalesofederalesquerequierenelusodeun

parachispasenelmotordeestamáquina,estádisponible

unparachispascomoopción.Siusteddeseaadquirirun

parachispas,póngaseencontactoconsuDistribuidor

AutorizadoToro.

LosparachispasTorogenuinosestánhomologados

porelUSDAForestryService(ServicioForestaldel

DepartamentodeAgriculturadeEE.UU .).

Importante:Elusoolaoperacióndelmotoren

cualquierterrenoforestal,demonteocubiertode

hierbaconelmotorobstruidoosinsilenciadorcon

parachispasmantenidoenbuenascondicionesde

funcionamiento,equipadoymantenidoparala

prevencióndeincendios,constituyeunainfracción

delalegislacióndeCalifornia(CaliforniaPublic

ResourceCodeSection4442).Otrosestadosozonas

federalespuedentenerunalegislaciónsimilar.

Man ual del pr opietario del motor

El

adjunto

ofreceinformaciónsobrelasnormasdelaU.S.

EnvironmentalProtectionAgency(EPA)ydela

CaliforniaEmissionControlRegulationsobre

sistemasdeemisiones,mantenimientoygarantía.

Puedesolicitarseunmanualnuevoalfabricante

delmotor.

©2010—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Póngaseencontactoconnosotrosenwww.Toro.com.

2

Reservadostodoslosderechos

ImpresoenEE.UU.

Page 26

g014868

1

Figura1

1.Placaconlosnúmerosdemodeloydeserie

Nºdemodelo

Nºdeserie

Estemanualidenticapeligrospotencialesycontiene

mensajesdeseguridadidenticadosporelsímbolode

alertadeseguridad(Figura2),queseñalaunpeligroque

puedecausarlesionesgravesolamuertesiustedno

siguelasprecaucionesrecomendadas.

Controles.............................................................7

Especicaciones...................................................9

Accesorios............................................................9

Operación....................................................................9

Antesdeempezar.................................................9

Cómoañadircombustible.....................................9

Vericacióndelniveldeaceitedelmotor.............11

Arranqueyparadadelmotor...............................11

Cómodesbastaruntocón...................................12

Mantenimiento...........................................................14

Calendariorecomendadodemantenimiento............14

Lubricación............................................................14

Engrasadodelamáquina....................................14

Mantenimientodelmotor.......................................15

Mantenimientodellimpiadordeaire...................15

Mantenimientodelaceitedemotor.....................16

Mantenimientodelabujía...................................17

Mantenimientodelascorreas..................................19

Comprobacióndelatensióndelacorreade

transmisión....................................................19

Ajustedelacorreadetransmisión.......................19

Mantenimientodeldesbastador..............................20

Comprobacióndelascuchillasdelaruedade

corte...............................................................20

Sustitucióndelascuchillasdelaruedade

corte...............................................................20

Limpieza................................................................21

Cómolimpiarlamáquina....................................21

Almacenamiento........................................................21

..........................................................................21

Solucióndeproblemas...............................................23

Figura2

1.Símbolodealertadeseguridad

Estemanualutiliza2palabrasmáspararesaltar

información.Importantellamalaatenciónsobre

informaciónmecánicaespecial,yNotaresalta

informacióngeneralquemereceunaatenciónespecial.

Contenido

Introducción................................................................2

Seguridad.....................................................................4

Prácticasdeoperaciónsegura................................4

Pegatinasdeseguridadeinstrucciones...................6

Elproducto..................................................................7

3

Page 27

Seguridad

Elusoomantenimientoindebidoporpartedel

operadoroelpropietariopuedecausarlesiones.

Parareducirelpeligrodelesiones,cumplaestas

instruccionesdeseguridadypresteatención

siemprealsímbolodealertadeseguridad,

quesignica:

instrucciónrelativaalaseguridadpersonal.El

incumplimientodeestasinstruccionespuededar

lugaralesionespersonaleseinclusolamuerte.

Cuidado

,

Adv er tencia

o

P elig r o

seguridadyprotecciónauditiva.Elpelolargoylas

prendasojoyassueltaspuedenenredarseenpiezas

enmovimiento.

•Inspeccioneeláreadondesevaautilizarelequipoy

retiretodoslosobjetos,comoporejemplopiedras,

juguetesyalambres,quepuedanserarrojadospor

lamáquina.

–

•Extremelasprecaucionescuandomanejegasolinay

otroscombustibles.Soninamablesysusvapores

sonexplosivos.

–Utilicesolamenteunrecipientehomologado.

Prácticasdeoperaciónsegura

Esteproductoescapazdeamputarmanosypies.Siga

siempretodaslasinstruccionesdeseguridadconeln

deevitarlesionescorporalesgraveseinclusolamuerte.

ADVERTENCIA

Losgasesdeescapedelmotorcontienenmonóxido

decarbono,queesunvenenoinodoroquepuede

matarle.

Nohagafuncionarelmotordentrodeunedicioo

enunlugarcerrado.

Formación

•LeaelManualdeloperadoryotrosmaterialesde

formación.Sielolosoperadoresomecánicos

nosabenleerelespañol,esresponsabilidaddel

propietarioexplicarlesestematerial.

•Familiaríceseconlaoperaciónseguradelequipo,los

controlesdeloperadorylasseñalesdeseguridad.

•Todoslosoperadoresymecánicosdebenrecibiruna

formaciónadecuada.Elpropietarioesresponsable

deproporcionarformaciónalosusuarios.

•Nodejenuncaqueelequiposeautilizadoo

mantenidoporniñosoporpersonasquenohayan

recibidolaformaciónadecuadaalrespecto.La

normativalocalpuedeimponerlímitessobrelaedad

deloperador.

•Elpropietario/usuariopuedeprevenir,yes

responsablede,losaccidentesolesionessufridospor

élmismo,oporotraspersonasobienes.

Preparación

•Evalúeelterrenoparadeterminarlosaccesoriosy

aperosnecesariospararealizareltrabajodemanera

correctaysegura.Utilicesolamentelosaccesoriosy

aperoshomologadosporelfabricante.

•Lleveropaadecuada,incluyendocasco,pantalla

facial,gafasdeseguridad,pantalónlargo,calzadode

–Nuncaretireeltapóndecombustibleniañada

combustibleconelmotorenmarcha.Dejeque

seenfríeelmotorantesderepostarcombustible.

Nofume.

–Noañadanidrenenuncaelcombustibledentro

deunedicio.

•Compruebequeloscontrolesdepresenciadel

operador,losinterruptoresdeseguridadylos

protectoresdeseguridadestáninstaladosyque

funcionancorrectamente.Noutilicelamáquinasi

nofuncionancorrectamente.

•Compruebequelaruedadecortehadejadodegirar

alreducirlavelocidad.

Operación

•Nohagafuncionarnuncaelmotorenunlugar

cerrado.

•Utiliceelequipoúnicamenteconbuenaluz,

alejándosedeagujerosypeligrosocultos.

•Asegúresedequetodaslastransmisionesestánen

puntomuertoantesdearrancarelmotor.Arranque

elmotorsólodesdelaposicióndeloperador.

•Noutiliceelequiponuncasinoestáncolocados

rmementelosprotectoresdeseguridad.Asegúrese

dequetodoslosinterruptoresdeseguridadestán

conectados,correctamenteajustadosyquefuncionan

correctamente.

•Nocambielosajustesdelreguladordelmotorni

hagafuncionarelmotoraunavelocidadexcesiva.

•Pareenunterrenollano,bajeeldesbastadorypare

elmotorantesdeabandonarelpuestodeloperador

porcualquierrazón.

•Mantengalasmanosylospiesalejadosdelarueda

ylosdientesdeldesbastadorcuandoestánen

movimiento.

•Mirehaciaatrásyhaciaabajoantesdeponermarcha

atrásparaasegurarsedequeelcaminoestádespejado.

4

Page 28

•Mantengaalejadasaotraspersonasyaanimales

domésticos.

•Noalmaceneelcombustiblecercadeunallama,yno

lodrenedentrodeunedicio.

•Noutilicelamáquinabajolainuenciadealcohol

odrogas.

•Tengacuidadoalcargarodescargarlamáquina

en/desdeunremolqueouncamión.

•Asegúresedequenohayotraspersonasenlazona

antesdeponerenmarchalamáquina.Parela

máquinasialguienentraenlazona.

•Nodejenuncadesatendidalamáquinasiestáen

marcha.Siemprepareelmotorycompruebequelas

ruedasdecortehandejadodegirar.

•Nuncamuevabruscamenteloscontroles;utilice

movimientossuavesycontinuos.

•Vigileeltrácocuandoestécercadeunacalleo

carreteraocuandocruceuna.

•Notoquepiezasquepuedenestarcalientesdespués

deestarenfuncionamiento.Dejequeseenfríenantes

derealizarcualquieroperacióndemantenimiento,

ajusteorevisión.

•Asegúresedeutilizarlamáquinaenzonasenlasque

nohayaobstáculospróximosaloperador.Sino

semantieneaunadistanciaapropiadadeárboles,

paredes,murosyotrasbarreras,puededarlugar

alesionesdurantelaoperacióndelamáquinaen

marchaatrás,sieloperadornoestáatentoaloquele

rodea.Sóloutilicelaunidadenáreasenlasquehay

sucienteespacioparaqueeloperadormaniobreel

productoconseguridad.

•Antesdedesbastar,hagaqueseseñalecualquier

conducciónsubterránea(gas,agua,etc.)delazonay

nodesbasteenlaszonasmarcadas.

•Localicelaszonaspeligrosasseñaladasenlamáquina,

ymantengaalejadoslospiesylasmanosdeestas

zonas.

•Losrayospuedencausargraveslesionesoincluso

lamuerte.Sisevenrelámpagosorayos,oseoyen

truenosenlazona,noutilicelamáquina;busqueun

lugardonderesguardarse.

Mantenimientoyalmacenamiento

•Pareelmotor.Dejequesedetengatodomovimiento

antesdeajustar,limpiaroreparar.

•Limpiecualquierresiduodeldesbastador,las

transmisiones,lossilenciadoresyelmotorpara

ayudaraprevenirincendios.Limpiecualquieraceite

ocombustiblederramado.

•Espereaqueseenfríeelmotorantesdeguardarel

cortacésped,ynologuardecercadeunallama.

•Aparquelamáquinaenunasupercienivelada.No

permitajamásquelamáquinasearevisadaoreparada

porpersonalnodebidamenteformado.

•Alivieconcuidadolatensióndeaquellos

componentesquetenganenergíaalmacenada.

•Retireelcabledelabujíaantesdeefectuarreparación

alguna.

•Mantengalasmanosylospiesalejadosdelaspiezas

enmovimiento.Siesposible,nohagaajustes

mientraselmotorestáfuncionando.

•Mantengatodaslaspiezasenbuenascondicionesde

funcionamiento,ytodoslosherrajesbienapretados.

Sustituyacualquierpegatinadesgastadaodeteriorada.

•Mantengaapretadoslospernosylastuercas.

Mantengaelequipoenbuenascondicionesde

funcionamiento.

•Nomanipulenuncalosdispositivosdeseguridad.

•Mantengalamáquinalibredeacumulacionesde

hierba,hojasyotrosresiduos.Limpiecualquier

aceiteocombustiblederramado.Dejequeseenfríe

lamáquinaantesdealmacenarla.

•Extremelasprecaucionescuandomanejegasolinay

otroscombustibles.Soninamablesysusvapores

sonexplosivos.

–Utilicesolamenteunrecipientehomologado

–Noretirenuncaeltapóndecombustibleniañada

combustibleconelmotorenmarcha.Dejeque

seenfríeelmotorantesderepostarcombustible.

Nofume.

–Norepostenuncalamáquinaenunrecinto

cerrado.

–Noguardenuncalamaquinaounrecipiente

decombustibledentrodeunediciocercade

unallamadesnuda,porejemplo,cercadeun

calentadordeaguaounacaldera.

–Nollenenuncaunrecipienteconelrecipiente

dentrodeunvehículo,maletero,lacajadeuna

camionetaniningunaotrasuperciequenosea

elsuelo.

–Mantengalaboquilladelrecipienteencontacto

coneldepósitoduranteelrepostaje.

•Pareeinspeccioneelequiposigolpeaunobjeto.

Hagacualquierreparaciónnecesariaantesdevolver

aarrancar.

•UtilicesolamentepiezasderepuestogenuinasToro

paraasegurarquesemantenganlosnivelesdecalidad

originales.

5

Page 29

Pegatinasdeseguridadeinstrucciones

Laspegatinasdeseguridadeinstruccionesestánalavistadeloperadoryestánubicadascercade

cualquierzonadepeligropotencial.Sustituyacualquierpegatinaqueestédañadaoquefalte.

117–4979

1.Peligrodeenredamiento,correa–noseacerquealas

piezasenmovimiento;mantengacolocadostodoslos

protectores.

119-4692

1.Advertencia—pareelmotor;utiliceambosagarraderos

paralevantareldesbastador.

119-4690

1.Advertencia:peligrodecorte/desmembramiento,cuchilla

deldesbastador—mantengalasmanosylospiesalejados

detodaslaspiezasenmovimiento;mantengacolocados

todoslosprotectores;espereaquesedetengantodaslas

piezasenmovimiento.

119-4691

1.Advertencia—leaelManualdeloperador;espereaquese

detengalacuchilladeldesbastador,pareelmotorypliegue

elmanillar.

117–2718

119-4693

1.Peligrodeobjetosarrojados—mantengaaotraspersonas

aunadistanciaprudencialdelamáquina.

119-4722

1.Motor—marcha

2.Cuchilladeldesbastador—engranar

6

Page 30

Elproducto

g014869

3

9

1

2

4

5

6

7

8

10

11

12

13

g014871

1

g014870

Figura4

1.Pomodedesbloqueodelmanillar

Pliegueelmanillarhacialamáquinayvuelvaaenroscar

elpomoenlamáquina(Figura5).

Figura3

1.Manillar8.Arrancador

2.Palancadelacelerador9.Ruedadecorte

3.Pomodedesbloqueodel

manillar

4.Filtrodeaire

5.Tazadesedimentos12.Tapóndecombustible

6.Válvuladecombustible13.Barradeseguridad

7.Estárter

10.Elevación

11.Cubiertadelacorrea

Figura5

Controles

Antesdeponerenmarchaelmotorytrabajarconla

máquina,familiarícesecontodosloscontroles(Figura3

yFigura6).

Pomodedesbloqueodelmanillar

Elmanillardeestamáquinapuedeplegarseparafacilitar

eltransporte.Desenrosqueelpomodedesbloqueodel

manillardelamáquina(Figura4).

Palancadelaceleradorybarrade

seguridad

Lapalancadelaceleradorcontrolalavelocidaddel

motor.Conlapalancahaciaabajo,enlaposiciónde

Desengranado,elmotorfuncionaavelocidadderalentí.

Éstaestambiénlaposicióndearranque.Alapretarla

palancadelacelerador,lavelocidaddelmotoraumenta,

seengranaelembraguecentrífugoylaruedadecorte

gira.

Labarradeseguridadcontrolaelfuncionamientodel

motor.Sujetelabarradeseguridadcontraelmanillar

paradesactivarelinterruptordeparadadelmotory

poderarrancarelmotor.Siustedsueltalabarra,el

motorsepara.

7

Page 31

g014874

2

1

Figura6

g014872

g014873

1.Palancadelacelerador2.Barradeseguridad

Frenodeestacionamiento

Elfrenodeestacionamientoimpidequegirelarueda

izquierdaparainmovilizarlamáquina,yfacilitael

desplazamientodelamáquinadeunladoaotromientras

sedesbastaeltocón.

Figura8

1.Frenoquitado

Figura7

1.Frenopuesto

8

Page 32

Especicaciones

Nota:Especicacionesydiseñosujetosamodicación

sinprevioaviso.

Profundidaddecorte

Longitud

Anchura

Altura

Peso

Aproximadamente12pulgadas

127cm(50pulgadas)

56cm(22pulgadas)

107cm(42pulgadas)

103libras(47kg)

(30,48cm)

Operación

Nota:Losladosderechoeizquierdodelamáquinase

determinandesdelaposiciónnormaldeloperador.

Importante:Antesdeluso,compruebeelnivel

degasolinaydeaceite,yretirecualquierresiduo

delamáquina.Asegúresetambiéndequeno

hayotraspersonasoresiduosenlazona.Usted

tambiéndebeconoceryhaberseñaladolaposición

decualquierconducciónsubterránea.

Accesorios

Estádisponibleunaseleccióndeaccesorios

homologadosporToroquesepuedenutilizarconla

máquinaandepotenciaryaumentarsusprestaciones.

PóngaseencontactoconsuDistribuidorAutorizado

Toroovisitewww.Toro.comparaobtenerunalistade

todoslosaccesorioshomologados.

Antesdeempezar

•Excavelatierrayretirecualquierpiedradelas

proximidadesdeltocónquepuedainterferircon

sutrabajo.Compruebequeelterrenoestálibre

deobjetosextraños,talescomocableseléctricos,

alambredeespinas,etc.

•Taleorecorteeltocónusandounasierramecánica.

•Revisetodaslaspegatinasdeseguridaddela

máquina.

•Utiliceuncasco,yprotecciónauditivayocular.

Unapantallademallaporsísolanoproporciona

protecciónocularsuciente;utilicegafasprotectoras

también.

•Asegúresedequeestáfamiliarizadoconlasnormas

deseguridadylosprocedimientosdeparada

descritosenelManualdeloperador.

•Asegúresedequetodoslosprotectoresestán

colocadosyenbuenestadodefuncionamiento.

•Compruebequelascuchillasylosdientesde

corteestáncolocadosyenbuenascondicionesde

funcionamiento.

•Asegúresedequelazonadetrabajo,elcortadoryel

tocónenparticularestánlibresdeobjetosmetálicos,

comoporejemploalambresoclavos,etc.,que

podríanserarrojadosylesionaracualquierpersona

queestécerca,odañarelequipo.

•Asegúresedequenohaynadie,incluyendoniñosy

animales,enunradiodealmenos50pies(15m)de

lamáquina.Lamáquinapuedearrojarresiduosque

podríanlesionaraotraspersonasyanimales.

Cómoañadircombustible

Utilicegasolinasinplomo(87octanosmínimo)Se

puedeutilizargasolinanormalconplomosinohubiera

gasolinasinplomodisponible.

9

Page 33

PELIGRO

PELIGRO

Enciertascondicioneslagasolinaes

extremadamenteinamableyaltamenteexplosiva.

Unincendioounaexplosiónprovocadosporla

gasolinapuedecausarlequemadurasaustedya

otraspersonasasícomodañosmateriales.

•Lleneeldepósitodecombustibleenelexterior,

enunazonaabiertayconelmotorfrío.Limpie

lagasolinaderramada.

•Nollenenuncaeldepósitodecombustible

dentrodeunremolquecerrado.

•Nollenecompletamenteeldepósitode

combustible.Añadagasolinaaldepósitode

combustiblehastaqueelnivelestéentre6y13

mm(1/4-1/2pulg.)pordebajodelextremo

inferiordelcuellodellenado.Esteespacio

vacíoeneldepósitopermitiráladilataciónde

lagasolina.

•Nofumenuncamientrasmanejagasolinay

manténgasealejadodellamasdesnudasode

lugaresdondeunachispapudierainamarlos

vaporesdegasolina.

•Almacenelagasolinaenunrecipiente

homologadoymanténgalafueradelalcancede

losniños.Nocomprenuncagasolinaparamás

de30díasdeconsumonormal.

•Noutilicelamáquinaamenosqueesté

instaladounsistemacompletodeescapeen

buenascondicionesdefuncionamiento.

Endeterminadascondicionesduranteelrepostaje,

puedetenerlugarunadescargadeelectricidad

estática,produciendounachispaquepuede

prenderlosvaporesdelagasolina.Unincendioo

unaexplosiónprovocadosporlagasolinapuede

causarlequemadurasaustedyaotraspersonasasí

comodañosmateriales.

•Coloquesiemprelosrecipientesdegasolinaen

elsuelo,lejosdelvehículoqueestárepostando.

•Nollenelosrecipientesdegasolinadentro

deunvehículo,camiónoremolqueyaque

lasalfombrasolosrevestimientosdeplástico

delinteriordelosremolquespodríanaislar

elrecipienteyretrasarlapérdidadelacarga

estática.

•Cuandoseaposible,retireelequipoarepostar

delcamiónoremolqueyreposteconlasruedas

delequiposobreelsuelo.

•Siestonoesposible,reposteelequiposobre

elcamiónoremolquedesdeunrecipiente

portátil,envezdeusarunsurtidordegasolina.

•Siesimprescindibleelusodeunsurtidor,

mantengalaboquillaencontactoconelborde

deldepósitodecombustibleolaaberturadel

recipienteentodomomentohastaquetermine

derepostar.

Importante:Nousemetanol,gasolinaque

contengametanologasoholconmásdel10%

etanolporquesepodríanproducirdañosenel

sistemadecombustibledelmotor.Nomezcle

aceiteconlagasolina.

Usodelestabilizador/acondicionador

Useunestabilizador/acondicionadorenlamáquina

paraconseguirlosbeneciossiguientes:

•Mantienelagasolinafrescaduranteunperíodo

dealmacenamientode90díasomenos.Paraun

almacenamientomáslargo,serecomiendadrenarel

depósitodecombustible.

•Limpiaelmotorduranteelfuncionamiento;.

•Eliminalaacumulacióndedepósitospegajosos,con

aspectodebarniz,delsistemadecombustible,que

puedendicultarelarranque.

Importante:Noutiliceaditivosdecombustible

quecontenganmetanoloetanol.

Agreguelacantidadadecuadadeestabilizador/acondicionadoralagasolina.

10

Page 34

Nota:Unestabilizador/acondicionadorde

combustibleesmásecazcuandosemezclacon

gasolinafresca.Parareduciralmínimolosdepósitosde

barnizenelsistemadecombustible,utilicesiempreun

estabilizadordecombustible.

Cómollenareldepósitode

combustible

1.Aparquelamáquinaenunasupercienivelada,baje

eldesbastadorypareelmotor.

2.Dejequeelmotorseenfríe.

3.Limpiealrededordeltapóndeldepósitode

combustibleyretireeltapón(

Figura9).

3.Limpiealrededordelavarilladeaceite.

4.Retirelavarilladeaceiteylimpieelextremo.

5.Introduzcalavarillaafondoeneltubodelavarilla

sinenroscarlaenelcuellodellenado.

6.Retirelavarillayobserveelextremo.Elaceitedebe

llegarallímitesuperior(

Figura10).

Figura9

losdetallespuedenvariardependiendodelmodelo

1.Tapóndeldepósitodecombustible

4.Añadagasolinasinplomoaldepósitode

combustiblehastaqueelnivelestéentre(1/4y1/2

pulgada)pordebajodelextremoinferiordelcuello

dellenado.

Importante:Esteespaciovacíopermitirá

ladilatacióndelagasolina.Nollene

completamenteeldepósitodecombustible.

5.Coloqueeltapóndeldepósitodecombustible

rmemente.

6.Limpielagasolinaderramada.

Vericacióndelniveldeaceite

delmotor

Figura10

1.Varilladeaceite

Importante:Siseponeenmarchaelmotor

conunnivelbajodeaceite,puededañarseel

motor.Estetipodedañonoestácubiertopor

lagarantía.

Elmotorincorporaunsistemadealertade

aceitequeparaelmotorantesdequeelnivel

deaceitedesciendapordebajodellímitede

seguridad.

7.Sielniveldeaceiteesbajo,viertalentamenteenel

cártersólolacantidaddeaceitesucienteparaque

elnivelllegueallímitesuperior.

Importante:Nolleneexcesivamenteelcárter

deaceiteyaquepodríadañarelmotor.

8.Vuelvaacolocarlavarilla.

Arranqueyparadadelmotor

Intervalodemantenimiento:Cadavezqueseutilice

odiariamente

1.Inclinelamáquinademaneraqueelmotoresté

nivelado,ypareelmotor.

2.Dejequeelmotorseenfríe.

Cómoarrancarelmotor

1.Muevalaválvuladecombustiblealaposiciónde

Abierto,totalmentehacialaderecha.

2.Muevalapalancadelestárterhacialaizquierdaala

posicióndeActivadosielmotorestáfrío.

11

Page 35

Nota:Sielmotorestácaliente,puedenoser

necesariousarelestárter.

3.Sujetelabarradeseguridadcontraelmanillar,y

empujeelmanillarhaciaabajoparalevantarlarueda

decortedelsuelo.

4.Tiredelarrancadorsuavementehastaquenote

resistencia,luegotireconfuerza.Dejequeel

arrancadorvuelvalentamenteasuposicióninicial.

5.Cuandoelmotorarranque,muevalapalancadel

estárterpocoapocoalaposicióndeDesactivado.

Sielmotorsecalaofuncionadeformairregular,

muevaelestárterdenuevoaActivadohastaqueel

motorsecaliente.Luegomuévaloalaposiciónde

Desconectado.

6.Sujetelapalancadelaceleradorcontraelmanillar

parahacergirarlaruedadecorte.

Cómopararelmotor

1.Quitelamanodelapalancadelacelerador.

ADVERTENCIA

Aldesbastaruntocón,lamáquinalanzavirutas

demadera,tierrayotrosresiduosalaire,y

éstospodríancausarlelesionesaustedoaotras

personas.

•Utilicesiempreprotecciónocularmientras

utilizalamáquina.

•Mantengaaotraspersonasaunadistancia

prudencialdelamáquina.

ADVERTENCIA

Llevesiempreprotecciónauditivamientrasutiliza

lamáquina.

1.Suelteelaceleradorydéjeloenposiciónde

desengranado.

2.Arranqueelmotor;consulte

Cómoarrancarelmotor(página11).

Nota:Sielmotorhaestadotrabajandoduro

oestámuycaliente,déjelofuncionardurante

unminutoantesdesoltarlabarradeseguridad.

Estoayudaaenfriarelmotorantesdepararlo.

Enunaemergencia,sepuedepararelmotor

inmediatamente.

2.Sueltelabarradeseguridadparapararelmotor.

3.Muevalaválvuladecombustiblealaposiciónde

Cerrado,totalmentehacialaizquierda.

Cómodesbastaruntocón

Pongalamáquinaenposiciónconlaruedadecorte

cercadelbordedelanterosuperiordeltocón.

PELIGRO

Lamáquinapuedecortaryamputarlasmanosy

lospies.

•Permanezcaenelpuestodeloperadorcuando

lamáquinaestáenmarcha,ynoseacerquea

laruedadecorte.

3.Dejequeelmotorsecalienteavelocidadderalentí

durantedosminutos.

4.Empujeelmanillarhaciaabajolosucientepara

levantarlaruedadecortedelsuelo.

5.Sujeteelaceleradorcontraelmanillarenlaposición

deEngranado;deestamaneraseengranael

embraguecentrífugoylaruedadecortegira.

6.Muevalamáquinaalapartedelanteradeltocóny

pongaelfrenodeestacionamiento.

7.Muevalaruedadecorteaunlado,luegobájela

aproximadamente1/2pulgada–1pulgadasobre

laesquinasuperiordelanteradeltocón.Muevala

ruedadecortehaciaunladoyotro,bajandola

ruedade1/2pulgadaa1pulgadaaproximadamente

antesdecadapasada,hastaquehayaeliminadola

partedelanteradeltocónhastaelniveldelsuelo

Figura11).

(

•Mantengaaotraspersonasaunadistancia

prudencialdelamáquina.

•Parelamáquinainmediatamentesientranotras

personasoanimalesenlazonadetrabajo.

12

Page 36

g014502

1

2

3

4

5

6

8

7

Figura11

8.Elevelaruedadecortehastaqueelcentrodela

ruedaestéjustoporencimadelapartesuperiordel

tocón.

16.Sigacortando,repitiendoelpaso10unayotravez

hastaqueeltocónestéalniveldeseadopordebajo

delniveldelsuelo.

17.Parelamáquina;consulte

Cómopararelmotor(página12).

Nota:Nodejequelapartedelanteradelamáquina

toqueelsuelohastaqueestésegurodequelarueda

decortehadejadodegirar.

PELIGRO

Unaruedadecorteenrotaciónesmuy

peligrosaypuedecortaryamputarlasmanos

ylospies.

Permanezcaenelpuestodeloperadory

asegúresedequelaruedadecorteseha

detenidocompletamenteantesdehacernada

más.

9.Conlaruedadecortedesplazadaaunlado,

quiteelfrenodeestacionamientoydesplacela

máquinahaciaadelante;luegopongaelfrenode

estacionamiento.

10.Continúepasandolaruedadecortedeunladoa

otroporlacaradeltocón,moviendolamáquina

haciaadelanteantesdecadapasada,ycortando

hastaunaprofundidadde1/2"a1"encadapasada.

11.Sigacortandohastaeliminarporcompletolaparte

superiordeltocón,asegurándosedenocortarpor

debajodelniveldelsueloenestaprimerafase.

12.Suelteelaceleradorydéjeloenlaposiciónde

desengranado,yempujeelmanillarhaciaabajolo

sucienteparalevantarlaruedadecortedelsuelo.

Esperediezsegundosparaquelaruedadecorte

dejedegirar,luegoquiteelfrenoyretirelamáquina

deltocón.

13.Retirelamáquinadeltocónyrastrillelasvirutasde

alrededordeltocón.

14.Muevalamáquinaalapartedelanteradeltocóny

pongaelfrenodeestacionamiento.

15.Sujeteelaceleradorcontraelmanillarenlaposición

deEngranado;deestamaneraseengranael

embraguecentrífugoylaruedadecortegira.

13

Page 37

Mantenimiento

Nota:Losladosderechoeizquierdodelamáquinasedeterminandesdelaposiciónnormaldeloperador.

Importante:Lamáquinapuedeserinclinadahacia

atrásohaciaunladoparafacilitarlalimpiezayel

mantenimiento,perodurantenomásde2minutos.

Silamáquinasemantienedemasiadotiempoen

estaposición,elmotorpuedeserdañadosiseltra

Calendariorecomendadodemantenimiento

Intervalodemanteni-

mientoyservicio

Despuésdelasprimeras

25horas

Cadavezqueseutilice

odiariamente

Cada25horas

Cada50horas

Cada100horas

Procedimientodemantenimiento

•Cambieelaceite.

•Compruebeelniveldeaceitedelmotor.

•Engraselamáquina.

•Compruebeelltrodeaire.

•Compruebelascuchillasdelaruedadecorte.

•Eliminecualquierresiduodelamáquina.

•Compruebelatensióndelacorreadetransmisión.

•Reviseelltrodeaire.

•Cambieelaceite.

•Limpielatazadesedimentos.

•Compruebelasbujías.

gasolinaenelcárter.Siestoocurre,realiceun

cambioadicionaldelaceitedelmotor.Luegohaga

girarelmotorunascuantasrevolucionesconel

arrancadorantesdearrancarelmotordenuevo.

Cada200horas

Cadaañooantesdel

almacenamiento

Importante:Consulteenel

•Cambieelltrodeaire.

•Cambieelaceite.

•Limpielatazadesedimentos.

Man ual del operador del motor

Lubricación

Engrasadodelamáquina

Intervalodemantenimiento:Cadavezqueseutilice

odiariamente

Tipodegrasa:Grasadepropósitogeneral.

1.Limpieconuntrapolospuntosdeengrase.

2.Conecteunapistoladeengrasarencadapuntode

engrase.

3.Lubriqueendospuntos,unoencadacojinetedela

ruedadecorte.

procedimientosadicionalesdemantenimiento.

Figura12

14

Page 38

4.Bombeegrasahastaqueempiecearezumargrasade

loscojinetes(3aplicacionesaproximadamente)

Mantenimientodelmotor

5.Limpiecualquierexcesodegrasa.

Importante:Bombeelagrasalentamentey

concuidado,paraevitardañarlasjuntasdelos

cojinetes.

Mantenimientodellimpiador

deaire

Intervalodemantenimiento:Cadavezqueseutilice

odiariamente

Elltrodeaireciclónicorecogelaspartículas

contaminantesmásgrandes,quesedepositanenel

recipiente.Cuandoveaunacapadesuciedadenelfondo

delrecipiente,limpielacarcasadelciclón,losconductos

deaireylarejilladeentradadeaire.

Mantenimientodelltrodeaire

ciclónico

Intervalodemantenimiento:Cada50horas

1.Retirelostrestornillosquesujetanlacarcasadel

ltrociclónico.

2.Retirelacarcasaconlarejilladeentradadeairey

retirelosconductosdeaire.

Figura13

1.Carcasadelltrociclónico3.Conductosdeaire.

2.Tornillo

Nota:Losconductosdeairepuedenpermaneceren

lapartesuperiororetirarsejuntoconlacarcasa.

3.Limpieloscomponentes.Utiliceagua,detergentey

uncepillo.Séquelosconcuidado.

4.Coloquelosconductosdeaireenlacarcasadel

ciclón.

5.Introduzcalacarcasadelciclónyasegúresedeque

encajacorrectamenteenlapartesuperior.Nola

fuerce;alinéelabienantesdecolocarlostornillos.

15

4.Carcasadelltrociclónico

conrejilladeentradade

aire

Page 39

Cambiodelltrodeaire

Intervalodemantenimiento:Cada200horas

Sielmotortienepocapotencia,producehumonegroo

funcionadeformairregular,elltrodeairepuedeestar

atascado.