Page 1

FormNo.3386-286RevA

G025787

SGR-6StumpGrinder

ModelNo.22600—SerialNo.314000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3386-286*A

Page 2

WARNING

G025788

Introduction

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

DANGER

Theremaybeburiedpower,gas,and/ortelephone

linesintheworkarea.Shockorexplosionmay

occurifyoudigintothem.

Havethepropertyorworkareamarkedforburied

linesanddonotdiginmarkedareas.Contactyour

localmarkingserviceorutilitycompanytohavethe

propertymarked(forexample,intheUnitedStates,

call811forthenationwidemarkingservice).

ThissparkignitionsystemcomplieswithCanadianICES-002.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

Thismachineisdesignedtogrindandremovetreestumps

andsurfaceroots.Itisnotintendedtocutrockoranyother

materialotherthanwoodandthesoilaroundastump.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1illustratesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Theenclosed

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Engine Owner's Man ual

issuppliedfor

Figure1

1.Modelandserialnumberplate

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Safety

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Introduction..................................................................2

Safety...........................................................................3

SafeOperatingPractices...........................................3

SafetyandInstructionalDecals.................................5

ProductOverview..........................................................6

Controls................................................................6

Specications.........................................................7

Attachments/Accessories.........................................7

Operation.....................................................................8

BeforeStarting........................................................8

AddingFuel............................................................8

CheckingtheEngine-OilLevel..................................9

StartingandStoppingtheEngine..............................10

GrindingaStump...................................................10

Maintenance.................................................................12

RecommendedMaintenanceSchedule(s)......................12

EngineMaintenance..................................................12

ServicingtheAirCleaner.........................................12

ServicingtheEngineOil..........................................13

ServicingtheSparkPlug..........................................14

BeltMaintenance......................................................15

CheckingtheDriveBeltTension...............................15

AdjustingtheDriveBelt..........................................15

GrinderMaintenance..................................................16

ReplacingtheTeeth................................................16

Cleaning...................................................................17

RemovingDebrisfromtheMachine..........................17

Storage........................................................................17

StoringtheMachine................................................17

Troubleshooting...........................................................18

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafetyalertsymbol,which

means:

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

Caution

,

W ar ning

,or

Danger

—personalsafety

SafeOperatingPractices

Thisproductiscapableofamputatinghandsandfeet.Always

followallsafetyinstructionstoavoidseriousinjuryordeath.

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)can’treadEnglish,itisthe

owner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

peopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludinghardhat,faceshield,

safetyglasses,longpants,safetyshoes,andhearing

protection.Longhair,looseclothingorjewelrymayget

tangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toys,andwirewhichcan

bethrownbythemachine.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer

–Neverremovethegascaporaddfuelwiththeengine

running.Allowtheenginetocoolbeforerefueling.

Donotsmoke.

3

Page 4

–Neverrefuelordrainthemachineindoors.

•Checkthattheoperatorpresencecontrols,safetyswitches,

andshieldsareattachedandfunctioningproperly.Donot

operateunlesstheyarefunctioningproperly.

•Checkthatthecuttingwheelhasstoppedrotatingwhen

youreducethethrottle.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralbeforestartingtheengine.

Onlystarttheenginefromtheoperator'sposition.

•Neveroperatewiththeguardsnotsecurelyinplace.Be

sureallinterlocksareattached,adjustedproperly ,and

functioningproperly.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelground,lowerthegrinder,andshutoff

theenginebeforeleavingtheoperator'spositionforany

reason.

•Keephandsandfeetawayfromthemovinggrinderwheel

andteeth.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Keeppetsandbystandersaway .

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Ensurethattheareaisclearofotherpeoplebefore

operatingthemachine.Stopthemachineifanyoneenters

thearea.

•Neverleavearunningmachineunattended.Alwaysstop

theengineandverifythecuttingwheelshasstopped

rotating.

•Neverjerkthecontrols;useasteadymotion.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservice.

•Ensurethatyouoperatethemachineinareaswhere

therearenoobstaclesincloseproximitytotheoperator.

Failuretomaintainadequatedistancefromtrees,walls,

andotherbarriersmayresultininjuryasthemachine

backsupduringoperationiftheoperatorisnotattentive

tothesurroundings.Onlyoperatetheunitinareaswhere

thereissufcientclearancefortheoperatortosafely

maneuvertheproduct.

•Beforegrinding,havetheareamarkedforunderground

utilities,anddonotgrindinmarkedareas.

•Locatethepinchpointareasmarkedonthemachineand

keephandsandfeetawayfromtheseareas.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

MaintenanceandStorage

•Stoptheengine.Waitforallmovementtostopbefore

adjusting,cleaning,orrepairing.

•Cleandebrisfromthegrinder,drives,mufers,andengine

tohelppreventres.Cleanupoilorfuelspillage.

•Lettheenginecoolbeforestoringanddonotstorenear

ame.

•Donotstorefuelnearamesordrainindoors.

•Parkthemachineonlevelground.Neverallowuntrained

personneltoservicethemachine.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Removethesparkplugwirebeforemakinganyrepairs.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Keepnutsandboltstight.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.

•Keepthemachinefreeofgrass,leaves,orotherdebris

build-up.Cleanupoilorfuelspillage.Allowthemachine

tocoolbeforestoring.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethegascaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

–Neverrefuelthemachineindoors.

–Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Neverllacontainerwhileitisinsideavehicle,trunk,

pick-upbed,oranysurfaceotherthantheground.

–Keepcontainernozzleincontactwiththetankduring

lling.

•Stopandinspecttheequipmentifyoustrikeanobject.

Makeanynecessaryrepairsbeforerestarting.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

4

Page 5

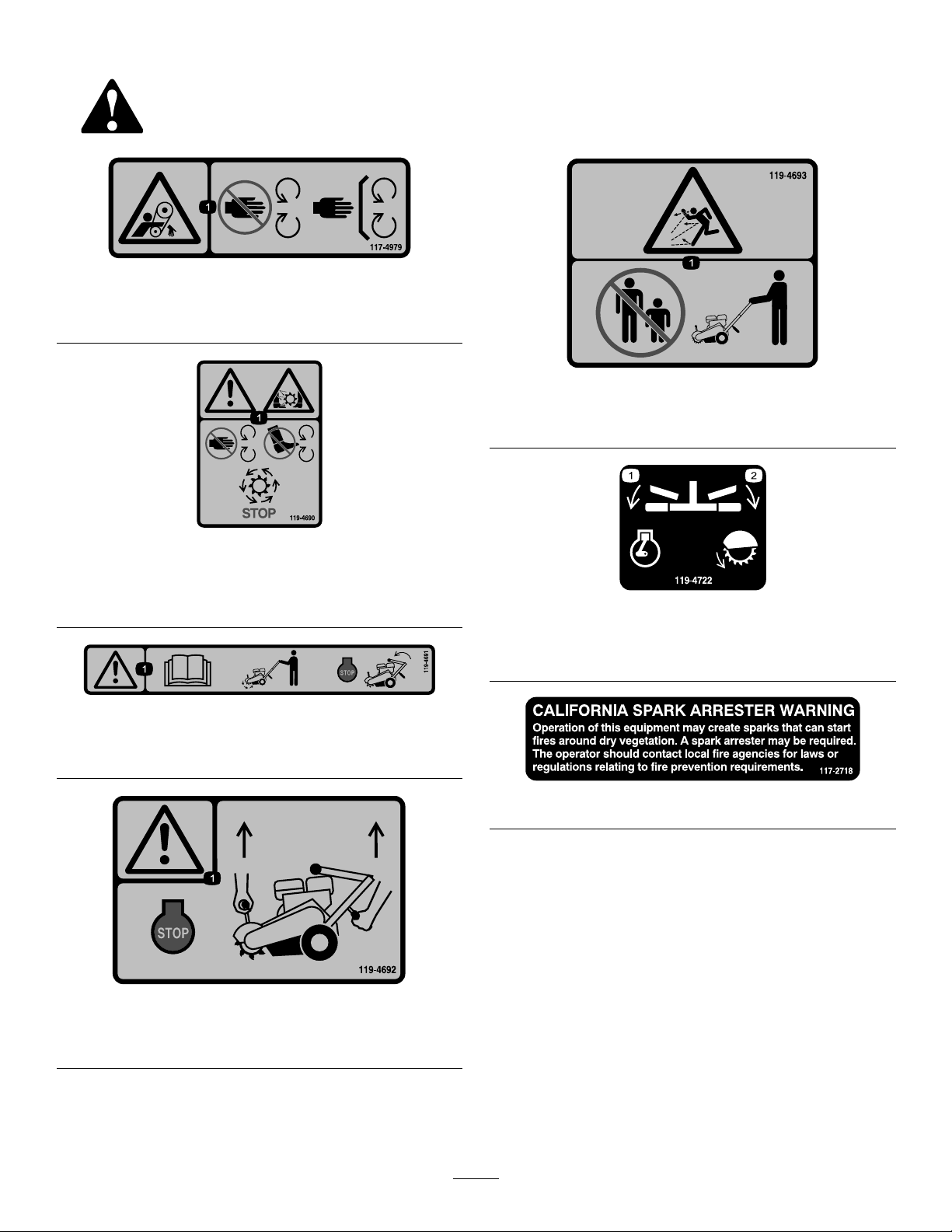

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

117–4979

1.Entanglementhazard,belt—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

119-4693

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

119-4690

1.Warning;cutting/dismembermenthazard,grinding

blade—keephandsandfeetawayfromallmovingparts,

keepallshieldsinplace;waitforallmovingpartstostop.

119-4691

1.Warning—readtheOperator'sManual;waitforgrinder

bladetostop,stoptheengineandfoldthehandle.

119-4722

1.Engine—run

2.Grinderblade—engage

117-2718

119-4692

1.Warning—stoptheengine;usebothhandholdstoliftthe

grinder.

5

Page 6

ProductOverview

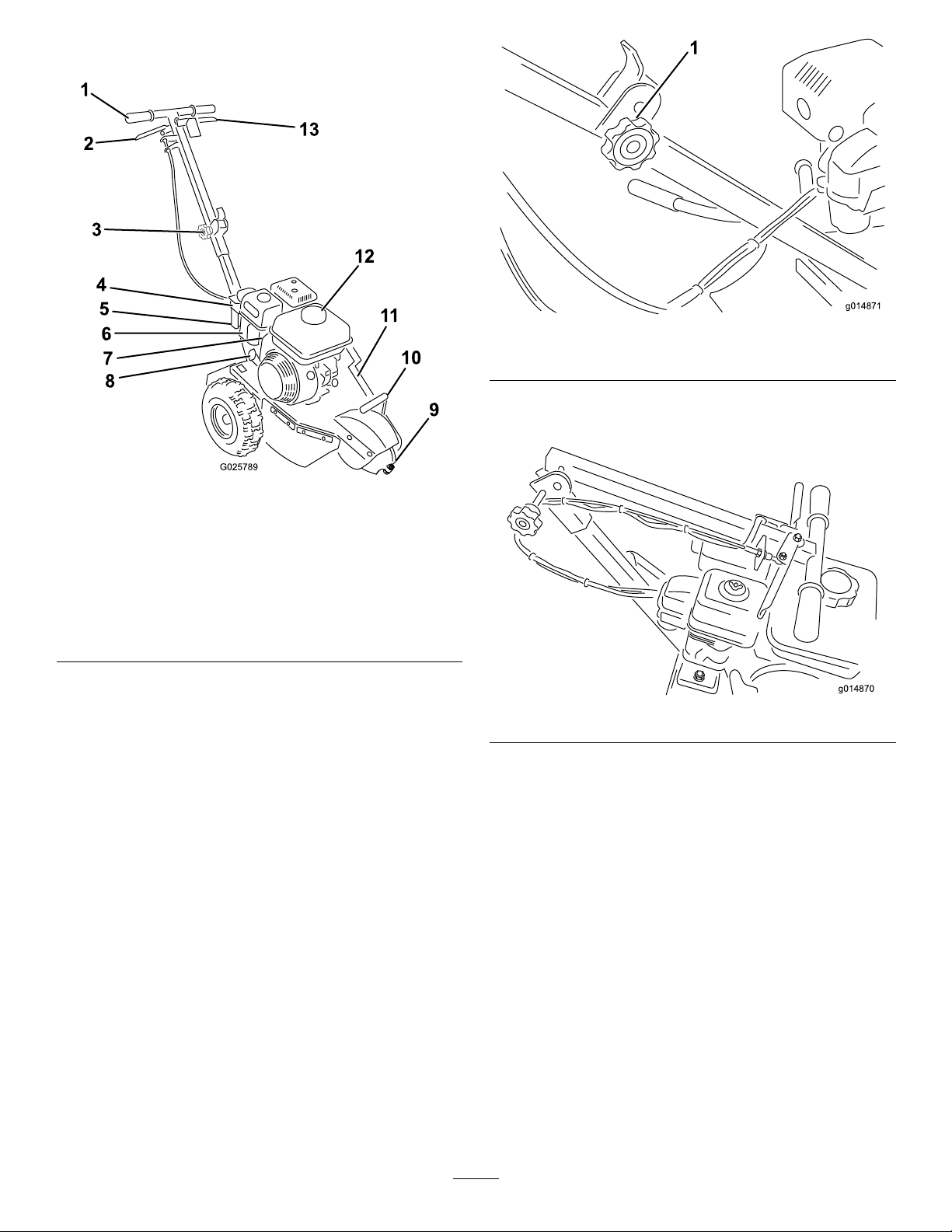

G025789

1

2

3

4

5

6

7

8

9

10

11

12

13

g014871

1

g014870

Figure4

1.Handle-releaseknob

Foldthehandledowntowardthemachineandscrewthe

knobbackontothehandle(Figure5).

Figure3

1.Handle

2.Throttlelever

3.Handle-releaseknob

4.Airlter

5.Sedimentcup

6.Fuelvalve

7.Choke

Controls

8.Starter

9.Cuttingwheel

10.Lift

11.Beltcover

12.Fuelcap

13.Safetybail

Figure5

Becomefamiliarwithallthecontrols(Figure3andFigure6)

beforeyoustarttheengineandoperatethemachine.

ThrottleLeverandSafetyBail

Handle-Release-Knob

Thehandleonthismachinehasthecapabilitytobefolded

downforeasiertransport.Unscrewthehandlereleaseknob

fromthemachine(Figure4).

Thethrottlelevercontrolstheenginespeed.Withthelever

released,inthedisengagedposition,theenginerunsatidle.

Thisisalsothestartingposition.Whenyoupulltheleverto

thehandle,theenginespeedincreases,thecentrifugalclutch

engages,andthecuttingwheelrotates.

Thesafetybailcontrolstheengine.Holdthesafetybail

againstthehandletodeactivatetheenginekillswitchsothat

theenginewillstart.Releasethesafetybailtostoptheengine.

6

Page 7

g014874

2

1

g014872

g014873

Figure8

Figure6

1.Throttlelever

2.Safetybail

ParkingBrake

Theparkingbrake(Figure6andFigure7)holdstheleftwheel

fromturningtosecurethemachineandforeasymovement

ofthemachinefromsidetosidewhengrindingastump.

1.Disengagedbrake

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

CuttingDepth30cm(12inches)

Length

Width

Height

Weight

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

127cm(50inches)

56cm(22inches)

107cm(42inches)

47kg(103lb)

1.Engagedbrake

Figure7

7

Page 8

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Important:Beforeoperating,checkthefuelandoil

level,andremovedebrisfromthemachine.Also,ensure

thattheareaisclearofpeopleanddebris.Y oushould

alsoknowandhavemarkedthelocationsofallutility

lines.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

BeforeStarting

•Digawaytheearthandremoveanystonesnearthetree

stumpthatmayinterferewithyourwork.Checkthatthe

groundisfreeofforeignobjects,suchaselectricalcables,

barbedwire,etc.

•Cutortrimthestumpusingapowersaw.

•Reviewallthesafetydecalsonthemachine.

•Useahard-hat,hearing,andeyeprotection.Amesh

visoralonedoesnotprovidesufcienteyeprotection;

supplementwithprotectiveglasses.

•Ensurethatyouarefamiliarwithsafetyregulationsand

shutdownproceduresdescribedinthismanual.

•Ensurethatallguardsareinplaceandingoodcondition.

•Ensurethatthebladesandcuttersareinplaceandin

goodcondition.

•Ensurethattheworkarea,cutter,andstumpinparticular

arefreefrommetallicobjectssuchaswire,nails,etc.that

couldbethrownoutandinjurepersonsinthevicinity

anddamagetheequipment.

•Ensurethateveryone,includingchildrenandanimals,

maintainadistanceofatleast50feet(15m)fromthe

machine.Debriscanbethrownoutandinjurepeople

andanimals.

AddingFuel

Useunleadedgasoline(87pumpoctaneminimum).Leaded,

regulargasolinemaybeusedifunleadedisnotavailable.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1/4to

1/2inch(6to13mm)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

Important:Donotusemethanol,gasolinecontaining

methanol,orgasoholcontainingmorethan10%ethanol

8

Page 9

becausethefuelsystemcouldbedamaged.Donotmix

oilwithgasoline.

6.Wipeupanygasolinethatmayhavespilled.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

•Cleanstheenginewhileitruns.

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting.

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionertothe

gas.

Note:Afuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshgasoline.Tominimizethechanceofvarnish

depositsinthefuelsystem,usefuelstabilizeratalltimes.

FillingtheFuelTank

1.Parkthemachineonalevelsurface,lowerthegrinder,

andstoptheengine.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

1.Tiltthemachinesotheengineislevel,andstopthe

engine.

2.Allowtheenginetocool.

3.Cleanaroundtheoildipstick.

4.Removethedipstickandwipetheendclean.

5.Slidethedipstickfullyintothedipsticktubewithout

threadingitintothellerneck.

6.Pullthedipstickoutandlookattheend;theoilshould

betothetopoftheupperlimitrange(Figure10).

2.Allowtheenginetocool.

3.Cleanaroundthefueltankcapandremoveit(Figure9).

Figure9

Viewmayvarydependingonmodel

1.Fuel-tankcap

4.Addunleadedgasolinetothefueltank,untilthelevelis

6mmto13mm(1/4to1/2inch)belowthebottomof

thellerneck.

Important:Thisspaceinthetankallowsgasoline

toexpand.Donotllthefueltankcompletelyfull.

Figure10

1.Oildipstick

Important:Runningtheenginewithlowoillevel

cancauseenginedamage.Thistypeofdamageis

notcoveredbywarranty.

Theengineisequippedwithanoilalertsystem

thatwillautomaticallystoptheenginebeforethe

oillevelfallsbelowthesafelimit.

7.Iftheoillevelislow,slowlypouronlyenoughoilinto

thecrankcasetoraisetheleveltotheupperlimit.

Important:Donotoverllthecrankcasewithoil

becausetheenginemaybedamaged.

8.Replacethedipstick.

5.Installthefueltankcapsecurely.

9

Page 10

StartingandStoppingthe

GrindingaStump

Engine

StartingtheEngine

1.MovethefuelvalvetotheOpenposition,alltheway

totheright(Figure11).

Figure11

1.Choke3.Starter

2.Fuelvalve

2.MovethechokeleverlefttotheOnpositionifyou

arestartingacoldengine.

Note:Awarmorhotenginemaynotrequirechoking.

3.Holdthesafetybailagainstthehandleandpushthe

handledownenoughtoraisethecuttingwheeloffthe

ground.

4.Pullthestarterhandlelightlyuntilyoufeelresistance,

thenpullthehandlebriskly .Returnthestarterhandle

gently(Figure11).

5.Aftertheenginestarts,graduallymovethechokelever

backtotheOffposition.

DANGER

Themachinewillcutandamputatehandsandfeet.

•Stayintheoperator'spositionwhilethemachine

isrunningandkeepawayfromthecutting

wheel.

•Keepallbystandersasafedistancefromthe

machine.Stopthemachineimmediatelyifany

peopleoranimalsentertheworkarea.

•Neverleavearunningmachineunattended.

Alwaysstoptheengineandverifythecutting

wheelhasstoppedrotating.

WARNING

Grindingastumpwillthrowwoodchips,soil,and

otherdebrisintotheairwhichcouldinjureyouor

bystanders.

•Alwaysweareyeprotectionandahardhatwhen

usingthemachine.Ameshvisoralonedoesnot

providesufcienteyeprotection;supplement

withprotectiveglasses.

•Ensurethateveryone,includingchildrenand

animals,maintainadistanceofatleast15m(50

feet)fromthemachine.

1.SetthrottletotheDisengageposition,starttheengine,

andallowthemachinetowarmupfor2minutes.

2.Pushthehandledownenoughtoraisethecutting

wheelofftheground(Figure12).

Note:Iftheenginestallsorhesitates,movethechoke

backtoOnagainuntiltheenginewarmsup.Then

moveittotheOffposition.

6.Holdthethrottleleveragainstthehandletospinthe

cuttingwheel.

StoppingtheEngine

1.Releaseyourhandfromthethrottlelever.

Note:Iftheenginehasbeenworkinghardorishot,

letitrunforaminutebeforereleasingthesafetybail.

Thishelpstocooltheenginebeforestopping.Inan

emergency,theenginemaybestoppedimmediately .

2.Releasethesafetybailtostoptheengine.

3.MovethefuelvalvetotheClosedposition,alltheway

totheleft.

10

Page 11

2

G025887

1

Figure12

1.Pivotpoint2.Pivotpointwhenthe

parkingbrakeisengaged.

Figure13

6.Raisethecuttingwheel,releasetheparkingbrake,

andmovethemachineforwardafewinches.Setthe

parkingbrake.

3.Movethemachinetothefrontofthestumpandset

theparkingbrake.

4.MovethrottleuptotheEngageposition.Thecutting

wheelwillbeginrotating.

5.Swingthecuttingwheeltooneside(Figure12),then

loweritapproximately13mmto25mm(1/2inchto

1inch)intothefront-topcornerofthestump.Swing

thecuttingwheelbackandforth,loweringthecutting

wheelapproximately13mmto25mm(1/2inchto1

inch)beforeeachsweep,untilyouhaveremovedthe

frontportionofthestumptogroundlevel(Athrough

DinFigure13).

7.Repeatsteps5and6untilyouhavecompletely

removedthestump(EthroughHinFigure13).

8.MovethrottletotheDisengageposition,pushthe

handledownenoughtoraisethecuttingwheeloffthe

ground.W aitforthecuttingwheeltostoprotating

thenreleasetheparkingbrakeandpullthemachine

awayfromthestump.

Note:Donotletthefrontofthemachinetouchthe

grounduntilyouaresurethecuttingwheelhasstopped

turning.

9.Stopthemachine;refertoStoppingtheEngine(page

10).

11

Page 12

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Important:Themachinemaybetippedbackwardoronitssidetofacilitateaccessforcleaningorservice,butno

longerthan2minutes.Ifthemachineisheldinthispositionfortoolong,theenginecanbedamagedbygasoline

drainingintothecrankcase.Shouldthishappen,performanextraoilchangeontheengine.Thenturntheengine

overafewrevolutionswiththestarterhandlebeforestartingtheengineagain.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst25hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

Every200hours

Yearlyorbeforestorage

Important:Refertoyour

EngineMaintenance

MaintenanceProcedure

•Changetheoil.

•Checktheengine-oillevel.

•Checktheairlter.

•Checktheconditionoftheteethandrotateorreplaceanythatarewornordamaged.

•Removedebrisfromthemachine.

•Checkthedrivebelttension.

•Servicetheairlter.

•Changetheoil.

•Cleanthesedimentcup.

•Checkthesparkplugs.

•Replacetheairlter.

•Changetheoil.

•Cleanthesedimentcup.

Engine Owner's Man ual

foradditionalmaintenanceprocedures.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily

Thecycloneairltercollectsthelargestcontaminantparticles,

whichcollectinthecontainer.Whenyoucanseealayerof

dirtatthebottomofthecontainer,cleanthecyclonehousing,

airchannels,andairintakescreen.

ServicingtheCycloneAirFilter

ServiceInterval:Every50hours

1.Removethe3screwsholdingthecyclonehousing.

2.Removethehousingwiththeairintakescreenand

removetheairchannels.

Figure14

1.Cyclonehousing

2.Screw4.Cyclonehousingwithair

Note:Theairchannelsmayremainintheupper

portionorfollowalongwiththehousingwhen

removed.

3.Cleanthecomponentswithwater,detergent,anda

brushthendrythecomponentscarefully..

3.Airchannels

intakescreen

12

Page 13

4.Placetheairchannelsinthecyclonehousing.

g014504

1

2

5.Insertcyclonehousingintopositionandmakesureit

tsintheupperportion.

Note:Donotuseforce;alignitinplacebeforetting

thescrews.

ReplacingtheAirFilter

ServiceInterval:Every200hours

Iftheengineislowonpower,producesblacksmokeorruns

unevenly,theairltermaybeclogged.

1.Removethewingnutandliftoffthecyclonelterwith

theair-ltercowling(Figure15).

4.Tapthepaperlteragainstaxedsurfacetoremove

dust.Ifthepaperlterisstilldirtyordamaged,replace

it.

Important:Donotusecompressedairtoblow

outthepaperelement,thiscandamageit.

5.Mountthepaperlterintheairlterhousingand

secureitwiththewingnut.

6.Positionthefoampre-lteroverthepaperlter.

7.Installthecyclonelterwiththeairltercoverand

secureitwiththewingnut.

ServicingtheEngineOil

Note:Changetheoilmorefrequentlywhentheoperating

conditionsareextremelydustyorsandy.

OilType:DetergentoilwithanAPIserviceofSJorhigher.

CrankcaseCapacity:0.6L(0.63qt)

Viscosity:SAE10W -30isrecommendedforgeneraluse.

ChangingtheEngineOil

Figure15

1.Wingnut

2.Cycloneairlter5.Stud

3.Foampre-lter

4.Airlter

2.Removethefoampre-lterandcleanitasfollows

ServiceInterval:Aftertherst25hours

Every100hours

Yearlyorbeforestorage

1.Starttheengineandletitrun5minutes.Thiswarms

theoilsoitdrainsbetter.

2.Parkthemachinesothatthedrainsideisslightlylower

thantheoppositesidetoensurethattheoildrains

completely.

3.Settheparkingbrakeandstoptheengine.

4.Placeapanundertheoildrainhole.

5.Removethedrainpluganddraintheoilthroughthe

holeslotintheframe(Figure16).

A.Washthepre-lterusingamilddetergentand

water.

B.Squeezeitdrywithacleancloth.

C.Soakitwithnewengineoil.

D.Gentlywindthelterinanabsorbentclothand

squeezeoutexcessoil.

3.Removethewingnutontopoftheairlterand

removethepaperlter.

Figure16

1.Oildrainhole2.Oilllcap

6.Whentheoilhasdrainedcompletely,installtheplug

andwipeupanyspilledoil.

13

Page 14

Note:Disposeoftheusedoilatacertiedrecycling

center.

7.Removetheoilllcapandslowlypourapproximately

80percentofthespeciedamountofoilintothe

engine(Figure16).

8.Slowlyaddadditionaloiltobringtheoilleveltothe

upperlimitmarkonthedipstick.RefertoCheckingthe

Engine-OilLevel(page9).

9.Installtheoilllcap.

CleaningtheSedimentCup

ServiceInterval:Every100hours

Yearlyorbeforestorage

Underneaththefuelvalveisasedimentcuptocatchdirtin

thefuel.

1.MovethefuelvalvetotheOffposition,alltheway

totheleft.

2.Unscrewthesedimentcup.Makesurenottomisplace

theO-ring(Figure17).

gappingtool/feelergaugetocheckandadjusttheairgap.

Installanewsparkplugifnecessary.

Type:BPR6ES(NKG)orequivalent

AirGap:0.70-0.80mm(0.28–0.031inch)

RemovingtheSparkPlug

1.Lowerthegrinderandstopthemachine;Referto

StoppingtheEngine(page10).

2.Pullthewireoffthesparkplug(Figure18).

Figure18

Figure17

1.Sedimentcup2.O-ring

3.CleanthereservoirandtheO-ringusingacleaning

solventanddrycarefully.

Note:MakesurenottomisplacetheO-ring.

4.PuttheO-ringinplaceinthegrooveofthecupand

replacethesedimentcup.

5.TurnthefuelvalvetotheOnposition,allthewayto

theright,andcheckforleaks.

1.Sparkplug

3.Cleanaroundthesparkplug.

4.Removethesparkplugandthemetalwasher.

2.Wire

CheckingtheSparkPlug

1.Lookatthecenterofthesparkplug(Figure19).Ifyou

seelightbrownorgrayontheinsulator,theengineis

operatingproperly .Ablackcoatingontheinsulator

usuallymeansthattheaircleanerisdirty.

Important:Donotcleanthesparkplug.Always

replacethesparkplugwhenithasablackcoating,

wornelectrodes,anoilylm,orcracks.

Note:Ifitleaks,replacetheO-ring.

ServicingtheSparkPlug

ServiceInterval:Every100hours—Checkthesparkplugs.

Ensurethattheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingthesparkplug.Useasparkplug

wrenchforremovingandinstallingthesparkpluganda

Figure19

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

2.Checkthegapbetweenthecenterandsideelectrodes

(Figure19).Bendthesideelectrode(Figure19)ifthe

gapisnotcorrect.

14

Page 15

InstallingtheSparkPlug

g014510

1

2

3

4

5

4

1.Threadthesparkplugintothesparkplughole.

BeltMaintenance

2.Tightenthesparkplugto20ft-lb(27N-m).

3.Pushthewireontothesparkplug.

CheckingtheDriveBelt Tension

ServiceInterval:Every25hours

Note:Replacethebeltifitshowsanysignsofwear,cracks,

ordamage.

1.Shutofftheengineandwaitforallrotatingpartsto

stop.

2.Removebeltguardretainingscrews(Figure20).

Figure20

Yourmodelmayvary

1.Beltguard4.Bolt

2.Lockwasher5.Nut

3.Washer

3.Tocheckbelttension,gentlysqueezethebeltspans

together.Youshouldbeabletopushthebeltdown

about6–10mm(1/4–3/8inch)fromtheoriginal

position.

Important:T oextendthebeltlife,propertensionmust

bemaintained.Aloosebeltwillcauseexcessivecutting

wheelslippageandearlybeltfailure.Abeltthatistoo

tightcancausebearingandshaftfailure,andrapidbelt

wear.

AdjustingtheDriveBelt

1.Removethebeltguard.

2.Loosenthe4enginemountingbolts,andjamnuts

holdingtheadjustmentbolt(Figure21).

15

Page 16

Figure21

1.Bolt3.Enginemountbolt

2.JamNut

3.Turnsquareheadadjustingboltontheframeclockwise

totightenthebelt,counterclockwisetoloosenthebelt

Important:Important:Makesuretotighten

allengineboltsafterproperbeltadjustmentis

achieved.

GrinderMaintenance

ReplacingtheTeeth

ServiceInterval:Beforeeachuseordaily—Checkthe

conditionoftheteethandrotateor

replaceanythatarewornordamaged.

Duetothehighamountofwearplacedontheteeth,youwill

needtorotateandreplacethemperiodically.

4.Installthebeltguardandsecurewithpreviously

removedhardware.

Figure22

1.Nut3.Toothholder

2.Spacer

Eachtoothisindexedwith3positionssoyoucanrotate

ittwice,exposinganewsharpedgebeforereplacingthe

tooth.Torotateatooth,loosenthenutsecuringthetooth

(Figure22).Pushthetoothforwardandrotateit1/3ofa

turn,bringinganunusededgetotheoutside.Torquethenut

securingthetoothto37to45N-m(27to33ft-lb).

Toreplaceatooth,removethenutsecuringthetooth,then

installanewtoothandnutinthesameposition(Figure22).

Thespacergoesbetweentheholderandthenut.Torquethe

nutsecuringthetoothto37to45N-m(27to33ft-lb).

Note:Ensurethatthenarrowendofthespacerisinstalled

towardtheholder.

4.Tooth

16

Page 17

Cleaning

Storage

RemovingDebrisfromthe Machine

Regularcleaningandwashingwillincreasethelifespanof

themachine.Cleanthemachinedirectlyafteruse,beforethe

dirthardens.

Checkbeforecleaningthatthefueltankcapisproperlyin

placetoavoidgettingwaterinthetank.

Usecarewhenusingahigh-pressuresprayerbecauseitcan

damagewarningdecals,instructionsigns,andtheengine

Important:Lubricatethecuttingwheelbladebearings

aftercleaning.

StoringtheMachine

Forstorageover30days,preparetheunitasfollows:

1.Removedirtandgrimefromtheexternalpartsof

theentireunit,especiallytheengine.Cleandirtand

sawdustchipsfromtheoutsideoftheenginecylinder

headnsandblowerhousing.

Important:Y oucanwashtheunitwithmild

detergentandwater.

2.Addapetroleumbasedstabilizer/conditionertofuel

inthetank.Followmixinginstructionsfromstabilizer

manufacturer.(1ozperUSgallon).Donotusean

alcoholbasedstabilizer(ethanolormethanol).

Note:Fuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasolineandusedatalltimes.

Important:Donotstorestabilizer/conditioned

gasolineover90days.

3.Runtheenginetodistributeconditionedfuelthrough

thefuelsystem(5minutes).

4.Stoptheengine,allowittocool,anddrainthefueltank

usingapumptypesiphon.Disposeoffuelproperly;

recycleasperlocalcodes.

5.Starttheengineandrunituntilitstops.

6.Choketheengine.

7.Startandruntheengineuntilitwillnotstartagain.

8.Cleanthesedimentcup;refertoCleaningtheSediment

Cup(page14).

9.Servicetheaircleaner;refertoServicingtheAir

Cleaner(page12).

10.Changetheenginecrankcaseoil;refertoChangingthe

EngineOil(page13).

11.Removethesparkplugandcheckthecondition;refer

toServicingtheSparkPlug(page14).

12.Withthesparkplugremovedfromtheengine,pour

twotablespoonsofengineoilintothesparkplughole.

13.Pullthestarterslowlytocranktheengineanddistribute

theoilinsidethecylinder.

14.Installthesparkplug,butdonotinstallthewireon

thesparkplug.

15.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamaged.

16.Paintallscratchedorbaremetalsurfaceswithpaint

availablefromyourAuthorizedServiceDealer.

17.Storetheunitinaclean,drygarageorstoragearea.

18.Covertheunittoprotectitandkeepitclean.

17

Page 18

Troubleshooting

Problem

Theenginewillnotstart.

Theenginerunsrough.

Thebeltslipsorcomesoffthepulleys.1.Thebelttensionisinsufcient.

Thecuttingwheeldoesnotrotate.

Thecuttingwheelcontinuestorotate.

1.TheengineswitchisintheOffposition.1.Holdthesafetybailagainstthehandle.

2.Thefuelshutoffvalveisclosed.2.Openthefuelvalve.

3.Thechokeisopen.

4.Thefueltankisempty .4.Filltankwithfreshfuel.

5.Thesparkplugwireislooseor

disconnected.

1.Thechokeislefton.1.Openthechoke.

2.Theairlterisclogged.2.Cleanorreplacetheairlter.

3.Thefuellineisclogged.3.Cleanthesedimentcup.

4.Thereiswaterorcontaminantsinthe

fuel.

5.Thesparkplugsarewornorhave

buildupontheelectrodes.

1.Theenginespeedisinsufcientto

activatethecentrifugalclutch.

2.Thebelttensionisinsufcient.

3.Theclutchshoesareworn.3.Replacetheclutch.

1.Theenginespeedisexcessive.1.MovethethrottletotheDisengaged

2.Thebeltisoffofthepulleysorbroken.

3.Clutchspringsareweakorbroken.

PossibleCauseCorrectiveAction

3.Closethechokewhenstartingacold

engine.

5.Checktheelectrodegapandcleanor

replacethesparkplug.

4.Drainandllthetankwithfreshfuel.

5.Checktheelectrodegapandcleanor

replacethesparkplug.

1.Adjustthebelttension.Reducethe

cuttingdepth.

1.MovethethrottletotheEngaged

position.

2.Adjustthebelttension.

position.

2.Replacethedrivebelt.

3.Replacetheclutch.

18

Page 19

Notes:

19

Page 20

ToroCompactUtilityEquipmentWarranty

AOne-Y earLimitedWarranty

CompactUtilityEquipment

(CUE)Products

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,T oroWarrantyCompany,pursuantto

anagreementbetweenthem,jointlywarrantyourToroCompactUtility

Equipment(“Product”)tobefreefromdefectsinmaterialsorworkmanship.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

ProSneak

CompactUtilityLoaders,

Trenchers,StumpGrinders,

andAttachments

KohlerEngines3years

AllotherEngines2years

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

*

SomeenginesusedonToroProductsarewarrantedbytheenginemanufacturer .

1yearor1000operatinghours,

whicheveroccursrst

*

*

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.ContactanyAuthorizedT oroCompactUtilityEquipment(CUE)

ServiceDealertoarrangeserviceattheirdealership.T olocatea

dealerconvenienttoyou,accessourwebsiteatwww .Toro.com.You

mayalsocallourToroCustomerCareDepartmenttollfreeatthe

numberbelow.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.

3.IfforanyreasonyouaredissatisedwiththeServiceDealer’s

analysisorwiththeassistanceprovided,contactusat:

SWSCustomerCareDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFree:888-384-9940

OwnerResponsibilities

YoumustmaintainyourToroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutinemaintenance,

whetherperformedbyadealerorbyyou,isatyourexpense.Parts

scheduledforreplacementasrequiredmaintenance(“MaintenanceParts”),

arewarrantedfortheperiodoftimeuptothescheduledreplacementtime

forthatpart.Failuretoperformrequiredmaintenanceandadjustmentscan

begroundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarrantyperiod

aredefectsinmaterialsorworkmanship.Thisexpresswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,modied,orunapproved

accessories

•Productfailureswhichresultfromfailuretoperformrequired

maintenanceand/oradjustments

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligentorrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

productoperationinclude,butarenotlimitedto,belts,wipers,spark

plugs,tires,lters,gaskets,wearplates,seals,O-rings,drivechains,

clutches.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,or

chemicals,etc.

•Normal“wearandtear”items.Normal“wearandtear”includes,butis

notlimitedto,wornpaintedsurfaces,scratcheddecals,etc.

•Repairsnecessaryduetofailuretofollowrecommendedfuel

procedure(consultOperator'sManualformoredetails)

–Removingcontaminantsfromthefuelsystemisnotcovered

–Useofoldfuel(morethanonemonthold)orfuelwhichcontains

morethan10%ethanolormorethat15%MTBE

–Failuretodrainthefuelsystempriortoanyperiodofnon-use

overonemonth

•Anycomponentcoveredbyaseparatemanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

RepairbyanAuthorizedT oroCompactUtilityEquipment(CUE)Service

Dealerisyoursoleremedyunderthiswarranty .

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletionof

repairsunderthiswarranty .Allimpliedwarrantiesofmerchantability

andtnessforusearelimitedtothedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sothe

aboveexclusionsandlimitationsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

ExceptfortheenginewarrantycoverageandtheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .The

EmissionsControlSystemonyourProductmaybecoveredbyaseparate

warrantymeetingrequirementsestablishedbytheU.S.Environmental

ProtectionAgency(EPA)ortheCaliforniaAirResourcesBoard(CARB).

ThehourlimitationssetforthabovedonotapplytotheEmissions

ControlSystemWarranty.RefertotheCaliforniaEmissionControl

WarrantyStatementsuppliedwithyourProductorcontainedintheengine

manufacturer’sdocumentationfordetails.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsoutsidetheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtainguarantee

policiesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguarantee

information,contacttheT oroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oro

Dealer.

374-0261RevE

Loading...

Loading...