FormNo.3429-971RevB

Pick-UpBroom

TXL2000ToolCarrier

ModelNo.22543—SerialNo.318000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3429-971*B

WARNING

CALIFORNIA

Proposition65Warning

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

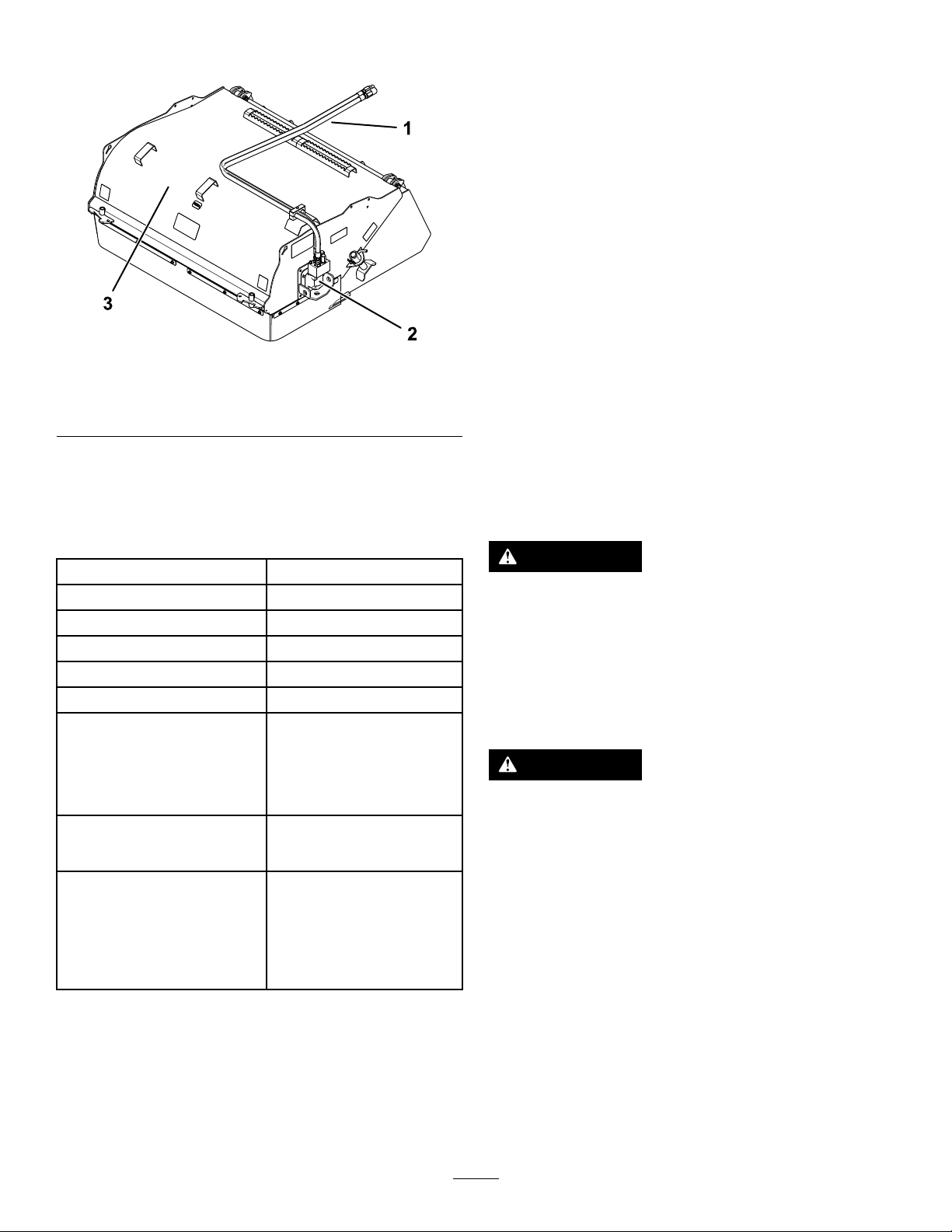

g268001

Figure1

Introduction

ThebroomattachmentisdesignedforuseonaToro

toolcarrier.Itisintendedtosweepwalkwaysand

drivewaysofdirtorsnow.Usingthisproductfor

purposesotherthanitsintendedusecouldprove

dangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Y ouareresponsiblefor

operatingtheproductproperlyandsafely .

Visitwww.Toro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

©2019—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Safety.......................................................................3

GeneralSafety...................................................3

SlopeSafety.......................................................3

BroomSafety......................................................4

MaintenanceandStorageSafety........................4

SafetyandInstructionalDecals..........................5

ProductOverview.....................................................6

Specications....................................................6

Operation..................................................................6

InstallingandRemovingtheAttachment.............6

UsingtheBroom.................................................7

CheckingtheSweepingPath..............................7

AdjustingtheSweepingPath..............................7

DumpingtheBroomBucket................................8

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

ClearingaCloggedBroom..................................8

TransportPosition..............................................8

OperatingTips...................................................9

Maintenance...........................................................10

GreasingtheBroom..........................................10

ReplacingtheBrushes......................................10

CheckingtheHydraulicLines............................11

Storage...................................................................12

Troubleshooting......................................................13

Safety

GeneralSafety

Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.

•Donottransportanattachmentwiththe

armsraisedorextended;alwaystransportthe

attachmentclosetotheground,withtheloader

armsretracted;refertoTransportPosition(page

8).

•ReadandunderstandthecontentofthisOperator’s

Manualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Neverallowchildrenoruntrainedpeopleto

operatethemachine.

•Keepyourhandsandfeetawayfromthemoving

componentsandattachments.

•Donotoperatethemachinewithouttheguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepbystandersandpetsasafedistanceaway

fromthemachine.

•Stopthemachine,shutofftheengine,andremove

thekeybeforeservicing,fueling,orunclogging

themachine.

Improperlyusingormaintainingthismachinecan

resultininjury.T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthisOperator’sManual.

,which

SlopeSafety

•Operatethemachineupanddownslopeswith

theheavyendofthemachineuphill.Weight

distributionchangeswithattachments.This

attachmentmakesthefrontofmachinetheheavy

end.

•Keeptheattachmentintheloweredposition

withtheloaderarmsretractedwhenonslopes.

Raisingtheattachmentorextendingtheloader

armsonaslopeaffectsthestabilityofthemachine.

•Slopesareamajorfactorrelatedtolossofcontrol

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Operatingthemachineonany

slopeoruneventerrainrequiresextracaution.

3

•Establishyourownproceduresandrulesfor

operatingonslopes.Theseproceduresmust

includesurveyingthesitetodeterminewhich

slopesaresafeformachineoperation.Always

usecommonsenseandgoodjudgmentwhen

performingthissurvey.

•Slowdownanduseextracareonhillsides.Ground

conditionscanaffectthestabilityofthemachine.

•Avoidstartingorstoppingonaslope.Ifthe

machinelosestraction,proceedslowly,straight

downtheslope.

•Avoidturningonslopes.Ifyoumustturn,turn

slowlyandkeeptheheavyendofthemachine

uphill.

•Neveroperatethemachineathightransport

speedsonslipperysurfaces.Usecarewhen

reversing.

•Donotoperatethemachinenearglassenclosures,

automobiles,windowwells,dropoffs,etc.without

properadjustmentofthedischargeangle.Keep

childrenandpetsaway.

•Donotoverloadthemachinecapacityby

attemptingtoclearsnow,dirt,orthatchattoofast

ofarate.

•Afterstrikingaforeignobject,shutofftheengine,

removethekey,thoroughlyinspecttheattachment

foranydamage,andrepairthedamagebefore

startingandoperatingtheattachment.

•Keepallmovementsonslopesslowandgradual.

Donotmakesuddenchangesinspeedor

direction.

•Ifyoufeeluneasyoperatingthemachineona

slope,donotdoit.

•Watchforholes,ruts,orbumps,asuneventerrain

couldoverturnthemachine.T allgrasscanhide

obstacles.

•Usecautionwhenoperatingonwetsurfaces.

Reducedtractioncouldcausesliding.

•Evaluatetheareatoensurethatthegroundis

stableenoughtosupportthemachine.

•Usecautionwhenoperatingthemachinenearthe

following:

–Drop-offs

–Ditches

–Embankments

–Bodiesofwater

Themachinecouldsuddenlyrolloverifatrack

goesovertheedgeortheedgecavesin.Maintain

asafedistancebetweenthemachineandany

hazard.

•Alwayslowertheattachmenteachtimeyoushut

offthemachineorleavetheoperatingposition.

MaintenanceandStorage

Safety

•Checkfastenersatfrequentintervalsforproper

tightnesstoensurethattheequipmentisinsafe

operatingcondition.

•RefertotheOperator’sManualforimportant

detailsifyoustoretheattachmentforanextended

periodoftime

•Maintainorreplacesafetyandinstructionlabels,

asnecessary.

•Donotremoveoraddattachmentsonaslope.

•Donotparkthemachineonahillsideorslope.

BroomSafety

•Wearappropriateclothingincludingeyeprotection,

longpants,substantialslip-resistantfootwear,and

hearingprotection;alsoweararespiratorordust

maskindustyconditions.Tiebacklonghairand

donotwearlooseclothingorloosejewelry .

•Sharpobjectscanbecomeentangledinthe

bristles.Wearprotectiveglovesandusecaution

whencleaningoutthebroomofforeignobjects;do

notuseyourbarehands.

4

SafetyandInstructional

Decals

Safetydecalsandinstructionsare

easilyvisibletotheoperatorandare

locatednearanyareaofpotential

danger.Replaceanydecalthatis

damagedormissing.

131-0711

1.Crushinghazard—keepawayfrompinchpointsand

actuatingparts.

133-8061

Decal139-2835isforthePick-UpBroomwiththe

WaterKitandGutterBrushinstalled.

decal131-0711

decal133-8061

125-6107

1.Crushinghazardofhandandfoot—keephandsandfeet

away.

125-6128

1.Highpressureuidhazard,injectionintothebody—read

theOperator’sManualbeforeperformingmaintenance.

decal125-6107

decal139-2835

139-2835

1.Tippinghazard—readtheTXL2000Operator’sManualfor

loadlimits;themaximumloadis523kg(1,155lb);donot

raiseorextendtheattachment.

Decal139-2840isforthePick-UpBroomwithoutkits.

decal125-6128

decal139-2840

139-2840

1.Tippinghazard—readtheTXL2000Operator’sManualfor

loadlimits;themaximumloadis623kg(1,375lb);donot

raiseorextendtheattachment.

5

ProductOverview

Operation

InstallingandRemoving

theAttachment

RefertotheOperator’sManualforthetractionunitfor

theinstallationandremovalprocedure.

Important:Beforeinstallingtheattachment,

positionthemachineonalevelsurface,ensure

thatthemountplatesarefreeofanydirtordebris,

andensurethatthepinsrotatefreely .Ifthepins

donotrotatefreely,greasethem.

Figure3

1.Hydraulichoses3.Hood

2.Motor

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Sweepingwidth152cm(60inches)

OverallWidth173cm(68inches)

Depth

Height

Numberofbrushes

Weight(Broomonly)449kg(990lb)

Loadratingcapacity

(Broomonly)

Loaderarmsretracted

Loaderarmsextended

Weight(Broomwithgutter

brushandwaterkitwithfull

tank)

Loadratingcapacity

(Broomwithgutterbrushand

waterkitwithfulltank)

Loaderarmsretracted

Loaderarmsextended

1.PerSAEJ1197

1

1

157cm(62inches)

79cm(31inches)

29

624kg(1,375lb)

279kg(614lb)

669kg(1,474lb)

526kg(1,160lb)

191kg(420lb)

g271714

Note:Alwaysusethetractionunittoliftandmove

theattachment.

Note:T ochecktherotationofthebroom,raisethe

broomoffthegroundandengagethehydraulics

usingthedetentpositiononthetractionunit.The

broomshouldsweepawayfromthemachineorrotate

clockwisewhenviewedfromtheleftside.Ifitsweeps

towardthemachineorrotatescounterclockwisewhen

viewedfromtheleftside,switchthecouplersonthe

hydraulichoses.

WARNING

Ifyoudonotfullyseatthequick-attach

pinsthroughtheattachmentmountplate,

theattachmentcouldfalloffthemachine,

crushingyouorbystanders.

Ensurethatthequick-attachpinsarefully

seatedintheattachmentmountplate.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliarwith

thisformofinjury;otherwise,gangrenemay

result.

•Ensurethatallhydraulic-uidhoses

andlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretothehydraulic

system.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks;neveruseyourhands.

6

CAUTION

Hydrauliccouplers,hydrauliclines/valves,

andhydraulicuidmaybehot.Ifyoucontact

hotcomponents,youmaybeburned.

•Weargloveswhendisconnectingthe

hydrauliccouplers.

•Allowthemachinetocoolbeforetouching

hydrauliccomponents.

•Donottouchhydraulicuidspills.

UsingtheBroom

Usethedetent(oat)positionasyouoperatethe

broom.Usetheauxiliaryhydrauliccontrolstooperate

thebroom.

Note:Thebroomshouldsweepdebrisawayfromthe

machine,overthebrushes,andintothebucket(i.e.,

rotateclockwisewhenviewedontheleftsideofthe

machine).Ifthebroomsweepstowardthemachine,

switchthecouplersonthehydraulichoses.

Important:Donotquicklychangerotation

directionwithoutwaitingforthebroomtostop;

otherwise,youmaydamagedrivecomponents

orthemotor.

CheckingtheSweeping

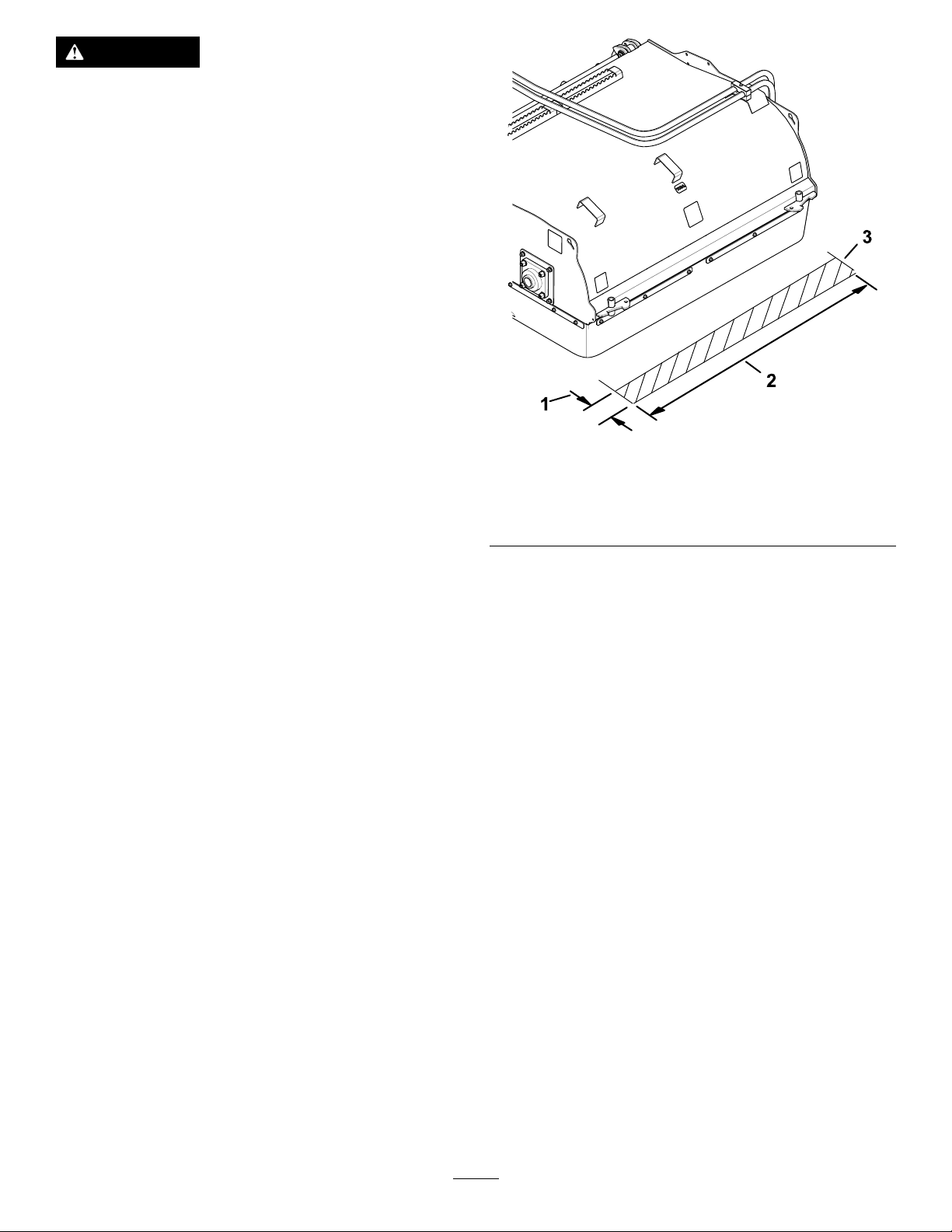

Figure4

1.51to102mm(2to4

inches)maximumwidth

2.Lengthofbroom

7.Ifthewidthoftheareasweptisincorrect,

proceedtoAdjustingtheSweepingPath(page

7).

3.Sweptarea

g267356

Path

Abroomsweepswiththetipsofitsbristles.Whenyou

applytoomuchdownwardpressure,thebroomno

longerusesitstips;thebroomisnowworkingwiththe

sidesofthebristles.Thislimitstheickingactionof

thebristlesandsweepingeffectiveness,decreasing

theservicelifeofthebroom.

1.Drivethemachinetoaat,dustyorsnowyarea

andstopthemachine.

2.Raisethebroom,engageit,slowlylowerittothe

groundtosweepawaysomesnowordebrisfor

about10seconds,andthenraiseit.

3.Backthemachineawayfromtheareaswept.

4.Disengagethebroomandshutoffthemachine

andremovethekey.

5.Waitforallmovingpartstostopbeforeleaving

theoperatingposition.

6.Makesurethattheareasweptequalsthelength

ofthebroomandamaximumwidthof51to102

mm(2to4inches)asshownFigure4.

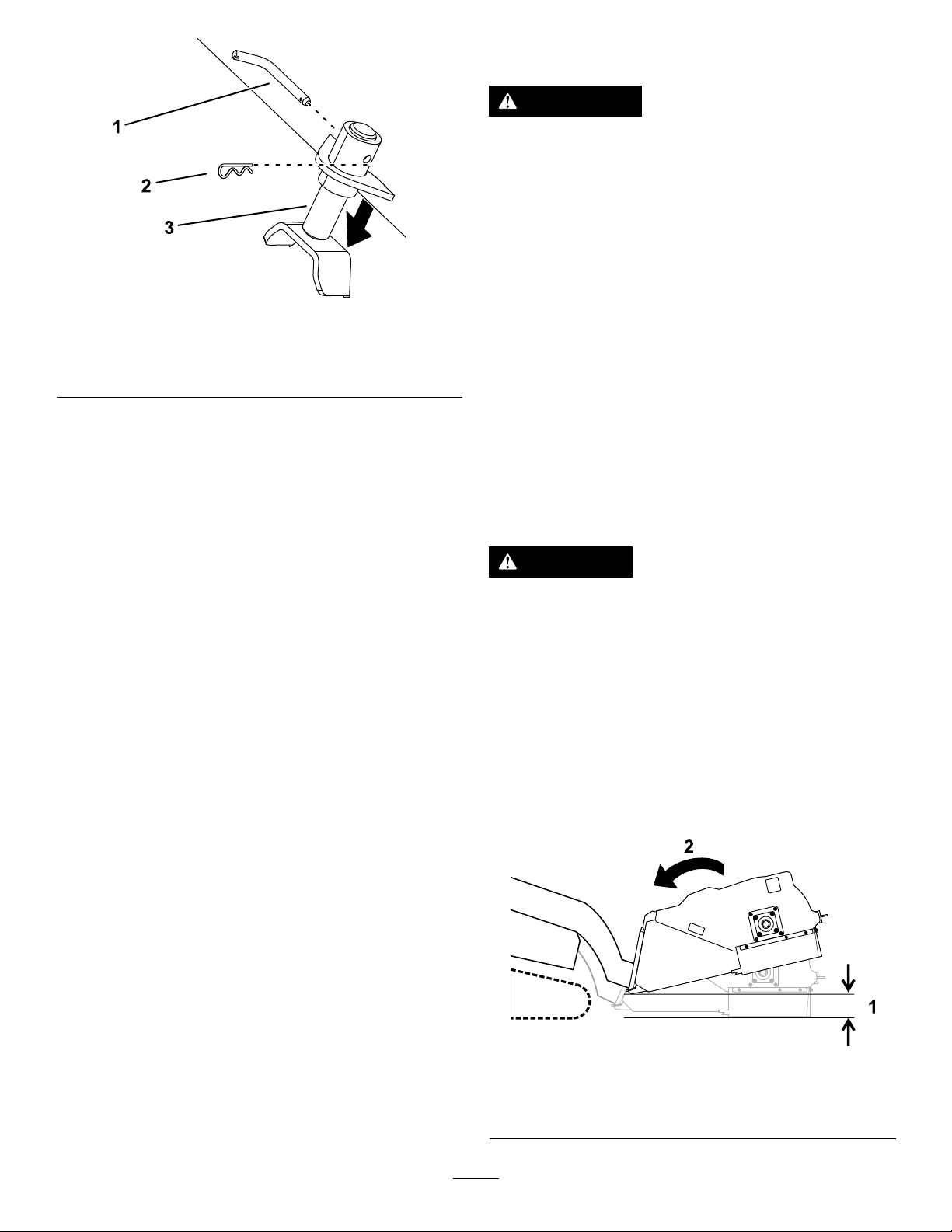

AdjustingtheSweeping

Path

1.Parkthemachineonalevelsurfaceand

disengagetheauxiliaryhydraulics.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Propupthefrontofthebroom.

4.Removethehairpincotterandpinandlower

thehooddowntheshafttothenextlowerhole

(Figure5).

7

Figure5

1.Pin

2.Hairpincotter

5.Installthepinandhairpincotter.

6.Repeatsteps4and5fortheothersideofthe

broom.

3.Adjustmentshaft

Note:Ensuretoadjustbothsidesevenlyto

ensurethebristlesacrossthebroomwear

evenly.

ClearingaCloggedBroom

WARNING

Therotatingbroomcouldcauseserious

injury.

Shutoffthemachineandallowallrotating

partstostopbeforecleaningthebroom.

1.Stayintheoperatingpositionandreleasethe

tractioncontrol.

2.Whileengagingthebroom,raisethebroom

g268495

abovetheground.

Ifyoucannotunclogthebroombyliftingitintotheair,

clearthebroomasfollows:

1.Parkthemachineonalevelsurfaceand

disengagetheauxiliaryhydraulics.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Whilewearingthickly-paddedgloves,use

cautiontomanuallyclearforeignobjectsoutof

thebroom.

7.Checkthesweepingpathagain;referto

CheckingtheSweepingPath(page7).

DumpingtheBroomBucket

1.Movethebroomtothedumpinglocation.

2.Raisetheloaderarmsandtiltthebroomforward.

3.Startthebroomsothatitrotatesclockwisewhen

viewedfromtheleftside.

4.Whenthebucketisempty,stopthebroom,tilt

thebroomrearward,andlowertheloaderarms.

CAUTION

Sharpobjectscanbecomeentangledinthe

bristlesandcancausepersonalinjury.

Wearglovesandusecautionwhencleaning

foreignobjectsoutofthebroom;neveruse

yourbarehands.

TransportPosition

Whentransportinganattachment,keepthe

attachmentasclosetothegroundaspossible,no

morethan15cm(6inches)abovetheground,and

keeptheloaderarmsretracted.Tiltitrearward.

1.Nomorethan15cm(6

inches)abovetheground

8

g267349

Figure6

2.Tilttheattachment

rearward.

OperatingTips

•Ifthegroundspeedistoofast,debriswillpileupin

frontofthebroom,causingittobulldozeinsteadof

sweep.Thiscandamagethebroom.

•Reducegroundspeedonroughterraintominimize

bouncingthebroom.

•Morepressuredoesnotgiveabettersweep,but

itwillwearoutthebroomfaster.

•Alevelbroomlastslonger.

•Sweepwiththewindtoavoiddebrisblowingback

intotheoperator.

•Whendrivingforward,sweepwiththebroom

movingintheforwarddirectionsothatmaterial

sweepsoverthebristlesanintothebucket.

•Whendrivinginreverse,sweepwiththebroom

movinginthereversedirectionsothatmaterial

sweepsdirectlyintothebucket.

9

Maintenance

GreasingtheBroom

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurfaceand

disengagetheauxiliaryhydraulics.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Greasethettingsonthe2hingesandthe

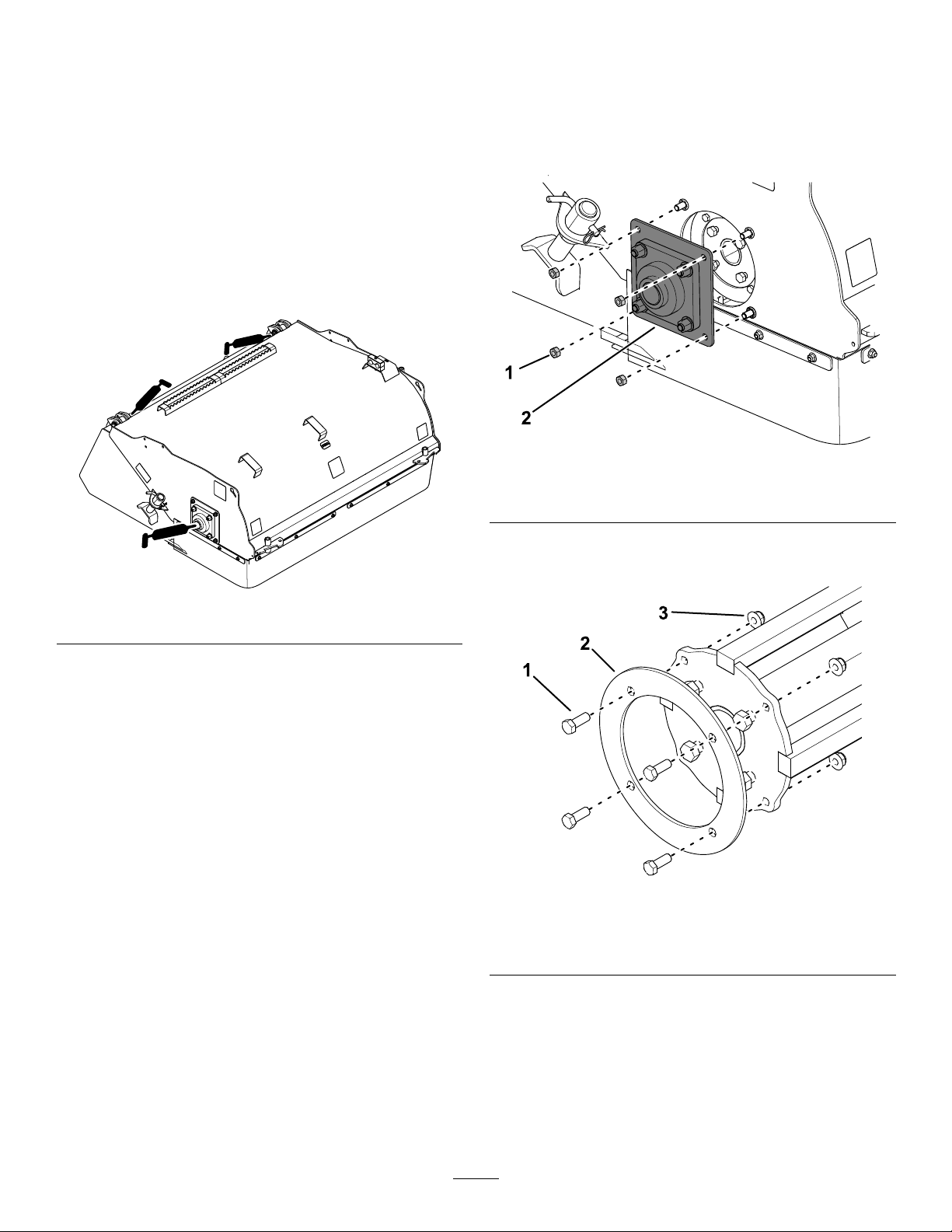

bearing(Figure7).

5.Ontherightsideofthemachine,removethe4

nuts(1/2inch)securingthebearingmountplate

andremovethebearingmountplate(Figure8).

Note:Thebroomcoreshouldbefreefromthe

hood.Pushthebroomcoretowardthemotor

endtoallowittodropfromthehood.

g271673

Figure8

Figure7

ReplacingtheBrushes

ServiceInterval:Beforeeachuseordaily—Check

thebrushesforwearandremove

anydebris.

RemovingtheBrushes

Replacethebrusheswhentheoutsidediameterof

thebrushesis33cm(13inches,orhalftheoriginal

diameter).

Note:Replaceallbristlesatthesametime;

otherwise,amixofoldandnewbristlesreduces

performance.

1.Nut(1/2inch)

6.Removethe4bolts,4nuts,andtheretaining

plate(Figure9).

g268538

1.Bolt—3/8x1inch(4)3.Nut—3/8inch(4)

2.Retainingplate

2.Bearingmountplate

g271675

Figure9

1.Parkthemachineonalevelsurfaceand

disengagetheauxiliaryhydraulics.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethehosesfromthehoseclamp.

4.Removethe4nutssecuringthemotorassembly

andremovetheassembly .

7.Slidethebrushesoffthebroom.

10

InstallingtheBrushes

1.Inspectthebroomcorefordamageorexcessive

wear.Replaceitifitisdamaged.

2.Standthebroomcoreonend.Startingwith

apolypropylenebrush,installnewbrushes,

ensuringtheprongsstraddletherodsofthecore

(Figure10).Alternatebetweenpolypropylene

andwirebrushes,witheachconsecutivebrush

180°apart.

Note:Thelastbrushinstalledshouldbea

polypropylenebrush.

g271172

Figure11

Figure10

1.Prongs3.Polypropylenebrush

2.Rod4.Wirebrush

3.Installtheretainingplate(Figure9).

4.Laythecoreontheground.

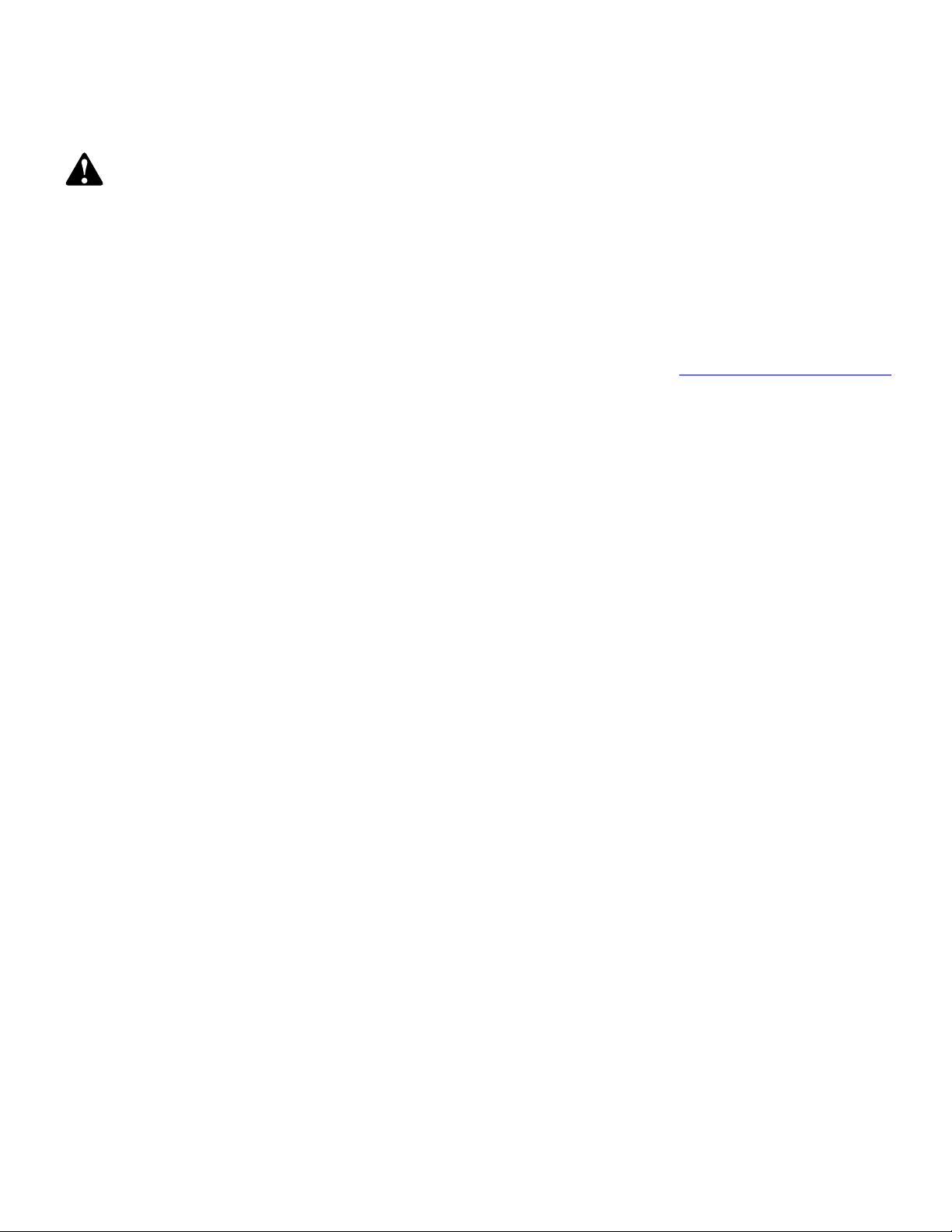

1.Bolt(3/8x3-1/2inches)

2.Washer5.Motor

3.Driveadapter

9.Securethedriveadapterusingthebolt(3/8x

3-1/2inches)andwasher(Figure1 1).

10.Installthemotorassemblyusingthe4bolts

removedpreviously.

11.Installthehosesintheclamp.

4.Motorsplines

CheckingtheHydraulic

Lines

ServiceInterval:Beforeeachuseordaily

g271173

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliarwith

thisformofinjury;otherwise,gangrenemay

result.

Important:Donotmovethecoreusingthe

brushes.

5.Lowerthehoodoverthecore.

Note:Y oumayneedtopushthebroomcore

towardthemotorendtobypassthesideofthe

hoodwheninstallingit.

6.Installthebearingmountplate(Figure8).

7.Installthemountplateandsecureitwiththe

nuts.

8.Removethebolt(3/8x3-1/2inches)andwasher

securingthedriveadaptertothehydraulicmotor

andapplyathinlayerofgreasetothesplinesof

themotor(Figure11).

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks;neveruseyourhands.

11

Storage

1.Beforelong-termstorage,washtheattachment

withmilddetergentandwatertoremovedirtand

grime.

2.Paintallscratchedorbaremetalsurfaces.

Note:PaintisavailablefromyourAuthorized

ServiceDealer.

3.Storetheattachmentinaclean,drygarageor

storagearea.Coverittoprotectitandkeepit

clean.

Important:Donotstorethebroomwith

weightonthebrushes.

12

Troubleshooting

Problem

Thebroomdoesnotcleanthesurface.

Thebroomwearsoutprematurely .1.Y ouareusingtheincorrectbroom

1.Thebroomheightisincorrect.1.Adjustthebroomheight.

2.Y ouarecleaningtoomuchdebrisat

atime.

1.Thebroomisclogged.1.Unclogthebroom. Thebroomdoesnotrotate.

2.Theauxiliaryhydraulicsarenot

engaged.

height.

PossibleCauseCorrectiveAction

2.Slowdownandclearsmallerareasof

debris.

2.Engagetheauxiliaryhydraulics.

1.Adjustthebroomheight.

13

Notes:

Notes:

CaliforniaProposition65WarningInformation

Whatisthiswarning?

Youmayseeaproductforsalethathasawarninglabellikethefollowing:

WARNING:CancerandReproductiveHarm—www.p65Warnings.ca.gov.

WhatisProp65?

Prop65appliestoanycompanyoperatinginCalifornia,sellingproductsinCalifornia,ormanufacturingproductsthatmaybesoldinorbroughtinto

California.ItmandatesthattheGovernorofCaliforniamaintainandpublishalistofchemicalsknowntocausecancer,birthdefects,and/orother

reproductiveharm.Thelist,whichisupdatedannually,includeshundredsofchemicalsfoundinmanyeverydayitems.ThepurposeofProp65isto

informthepublicaboutexposuretothesechemicals.

Prop65doesnotbanthesaleofproductscontainingthesechemicalsbutinsteadrequireswarningsonanyproduct,productpackaging,orliteraturewith

theproduct.Moreover,aProp65warningdoesnotmeanthataproductisinviolationofanyproductsafetystandardsorrequirements.Infact,the

CaliforniagovernmenthasclariedthataProp65warning“isnotthesameasaregulatorydecisionthataproductis‘safe’or‘unsafe.’”Manyofthese

chemicalshavebeenusedineverydayproductsforyearswithoutdocumentedharm.Formoreinformation,gotohttps://oag.ca.gov/prop65/faqs-view-all

AProp65warningmeansthatacompanyhaseither(1)evaluatedtheexposureandhasconcludedthatitexceedsthe“nosignicantrisklevel”;or(2)

haschosentoprovideawarningbasedonitsunderstandingaboutthepresenceofalistedchemicalwithoutattemptingtoevaluatetheexposure.

Doesthislawapplyeverywhere?

Prop65warningsarerequiredunderCalifornialawonly.ThesewarningsareseenthroughoutCaliforniainawiderangeofsettings,includingbutnot

limitedtorestaurants,grocerystores,hotels,schools,andhospitals,andonawidevarietyofproducts.Additionally ,someonlineandmailorder

retailersprovideProp65warningsontheirwebsitesorincatalogs.

.

HowdotheCaliforniawarningscomparetofederallimits?

Prop65standardsareoftenmorestringentthanfederalandinternationalstandards.TherearevarioussubstancesthatrequireaProp65warning

atlevelsthatarefarlowerthanfederalactionlimits.Forexample,theProp65standardforwarningsforleadis0.5μg/day,whichiswellbelow

thefederalandinternationalstandards.

Whydon’tallsimilarproductscarrythewarning?

•ProductssoldinCaliforniarequireProp65labellingwhilesimilarproductssoldelsewheredonot.

•AcompanyinvolvedinaProp65lawsuitreachingasettlementmayberequiredtouseProp65warningsforitsproducts,butothercompanies

makingsimilarproductsmayhavenosuchrequirement.

•TheenforcementofProp65isinconsistent.

•CompaniesmayelectnottoprovidewarningsbecausetheyconcludethattheyarenotrequiredtodosounderProp65;alackofwarningsfora

productdoesnotmeanthattheproductisfreeoflistedchemicalsatsimilarlevels.

WhydoesToroincludethiswarning?

Torohaschosentoprovideconsumerswithasmuchinformationaspossiblesothattheycanmakeinformeddecisionsabouttheproductstheybuyand

use.T oroprovideswarningsincertaincasesbasedonitsknowledgeofthepresenceofoneormorelistedchemicalswithoutevaluatingthelevelof

exposure,asnotallthelistedchemicalsprovideexposurelimitrequirements.WhiletheexposurefromT oroproductsmaybenegligibleorwellwithinthe

“nosignicantrisk”range,outofanabundanceofcaution,T orohaselectedtoprovidetheProp65warnings.Moreover ,ifTorodoesnotprovidethese

warnings,itcouldbesuedbytheStateofCaliforniaorbyprivatepartiesseekingtoenforceProp65andsubjecttosubstantialpenalties.

RevA

Loading...

Loading...