FormNo.3364-930RevA

High-TorqueTrencherHead

CompactUtilityLoaders

ModelNo.22473—SerialNo.310000001andUp

ModelNo.22474—SerialNo.310000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

ThisproductcomplieswithallrelevantEuropean

G008933

1

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

DANGER

Theremaybeburiedpower,gas,and/ortelephone

linesintheworkarea.Shockorexplosionmay

occurifyoudigintothem.

Havethepropertyorworkareamarkedforburied

linesanddonotdiginmarkedareas.Contactyour

localmarkingserviceorutilitycompanytohavethe

propertymarked(forexample,intheUnitedStates,

call811forthenationwidemarkingservice).

Figure1

1.Modelandserialnumberlocation

Introduction

Thetrencherheadsareattachmentsdesignedforuseon

Torocompactutilityloaderswithavarietyofbooms

andchainstodigtrenchesinsoiltofacilitatetheburying

ofcablingandpiping.Theyarenotintendedforusein

cuttinghardmaterialssuchaswoodorconcrete.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .T oro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Figure1

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualalsouses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2010—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contents

Introduction.................................................................2

Safety...........................................................................3

StabilityRatings....................................................4

SafetyandInstructionalDecals.............................5

Setup............................................................................6

1InstallingtheBoomandDigging

Chain...............................................................6

2InstallingtheSafetyBar......................................6

3InstallingtheSpoilsAuger..................................7

4CheckingtheBearingCaseLubeLevel................7

ProductOverview........................................................8

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Specications.......................................................8

Attachments/Accessories.....................................8

Operation.....................................................................9

DiggingaTrench..................................................9

OffsettingtheTrencher........................................9

TransportingtheTrencheronaTrailer................10

OperatingTips...................................................10

Maintenance...............................................................11

RecommendedMaintenanceSchedule(s)................11

GreasingtheTrencher........................................11

ServicingtheBearingCaseLube.........................11

AdjustingDiggingChainTension.......................12

FlippingaWornBoom.......................................12

ReplacingtheDiggingTeeth...............................13

ReplacingtheDriveSprocket..............................13

Storage.......................................................................14

Troubleshooting.........................................................15

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructionsand

thoseinthetractionunit

payattentiontothesafetyalertsymbol,which

means

safetyinstruction.Failuretocomplywiththe

instructionmayresultinpersonalinjuryordeath.

Caution

,

W ar ning

Operator’ s Man ual

,or

Danger

—personal

DANGER

Theremaybeburiedpower,gas,and/ortelephone

linesintheworkarea.Shockorexplosionmay

occurifyoudigintothem.

Havethepropertyorworkareamarkedforburied

linesanddonotdiginmarkedareas.Contactyour

localmarkingserviceorutilitycompanytohavethe

propertymarked(forexample,intheUnitedStates,

call811forthenationwidemarkingservice).

.Always

DANGER

Themovingteethandaugerwillseverelycuthands,

feet,orotherbodyparts.

•Keephands,feet,andanyotherpartofyour

bodyorclothingawayfrommovingteeth,auger,

orotherparts.

•Beforeadjusting,cleaning,repairing,or

inspectingthetrencher,lowerthetrencherto

theground,stoptheengine,waitforallmoving

partstostop,andremovethekey.

WARNING

Whentheengineisoff,attachmentsintheraised

positioncangraduallylower.Someonenearbymay

bepinnedorinjuredbytheattachmentasitlowers.

Alwayslowertheattachmentlifteachtimeyoushut

offthetractionunit.

WARNING

Whengoingupordownhill,themachinecould

overturniftheheavyendistowardthedownhill

side.Someonemaybepinnedorseriouslyinjured

bythemachineifitoverturns.

Operateupanddownslopeswiththeheavyendof

themachineuphill.Anattachedtrencherwillmake

thefrontendheavy.

3

WARNING

StabilityRatings

Ifyoudonotfullyseattheattachmentlocking

pinsintheattachmentmountplateholes,the

attachmentcouldfalloffofthetractionunitseverely

injuringtheoperatororbystanders.

•Ensurethatyoufullyseattheattachment

lockingpinsthroughtheholesintheattachment

mountplatebeforeliftingtheattachment.

•Ensurethattheattachmentmountplateisfreeof

anydirtordebristhatmayhindertheconnection

ofthetractionunittotheattachment.

•Refertoyourtractionunit

fordetailedinformationonsafelyconnectingan

attachmenttoyourtractionunit.

Operator’ s Man ual

WARNING

Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

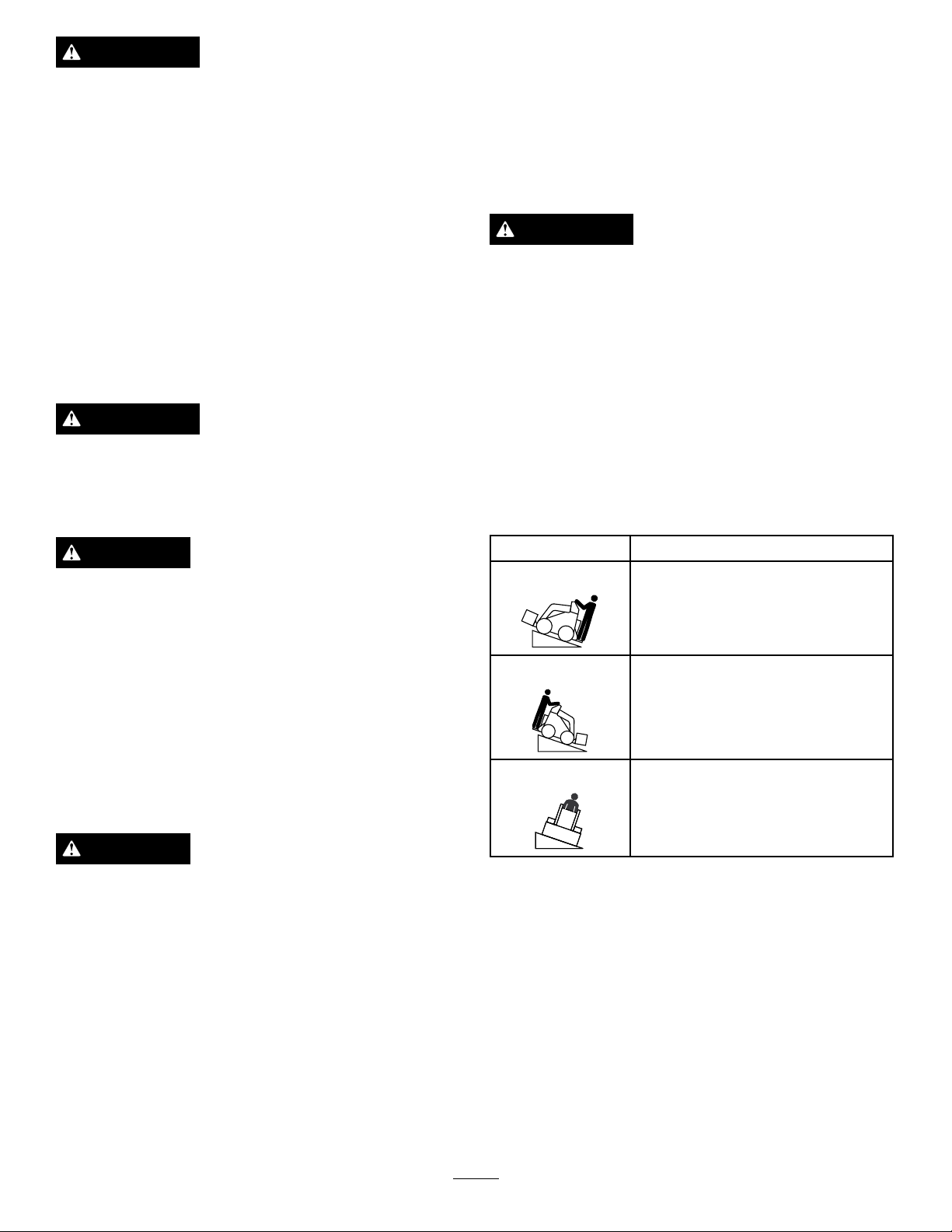

Todeterminethedegreeofslopeyoucantraversewith

thetrencherinstalledonatractionunit,ndthestability

ratingforthehillpositionyouwanttotravelinthe

appropriatetablebelow,thenndthedegreeofslope

forthesameratingandhillpositionintheStabilityData

sectionofthetractionunitOperator’sManual.

WARNING

Exceedingthemaximumrecommendedslope

cancausethetractionunittotip,crushingyouor

bystanders.

Donotdrivethetractionunitonaslopesteeper

thanthemaximumrecommendedslope,as

determinedinthefollowingtablesandthetraction

Operator’ s Man ual

unit

Important:Ifyouhaveatractionunitotherthana

TXcompactutilityloader,usethecounterweighton

thetractionunitwhenusingthetrencher.Failureto

usethecounterweightwillcausethetractionunitto

becomeunstable.

.

CAUTION

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjectedinto

theskinmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththisformofinjury

organgrenemayresult.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks,

neveruseyourhands.

CAUTION

Hydrauliccouplers,hydrauliclines/valves,and

hydraulicuidmaybehotandcanburnyouifyou

touchthem.

•Weargloveswhenoperatingthehydraulic

couplers.

OrientationStabilityRating

FrontUphill

C

RearUphill

D

SideUphill

C

•Allowthetractionunittocoolbeforetouching

hydrauliccomponents.

•Donottouchhydraulicuidspills.

4

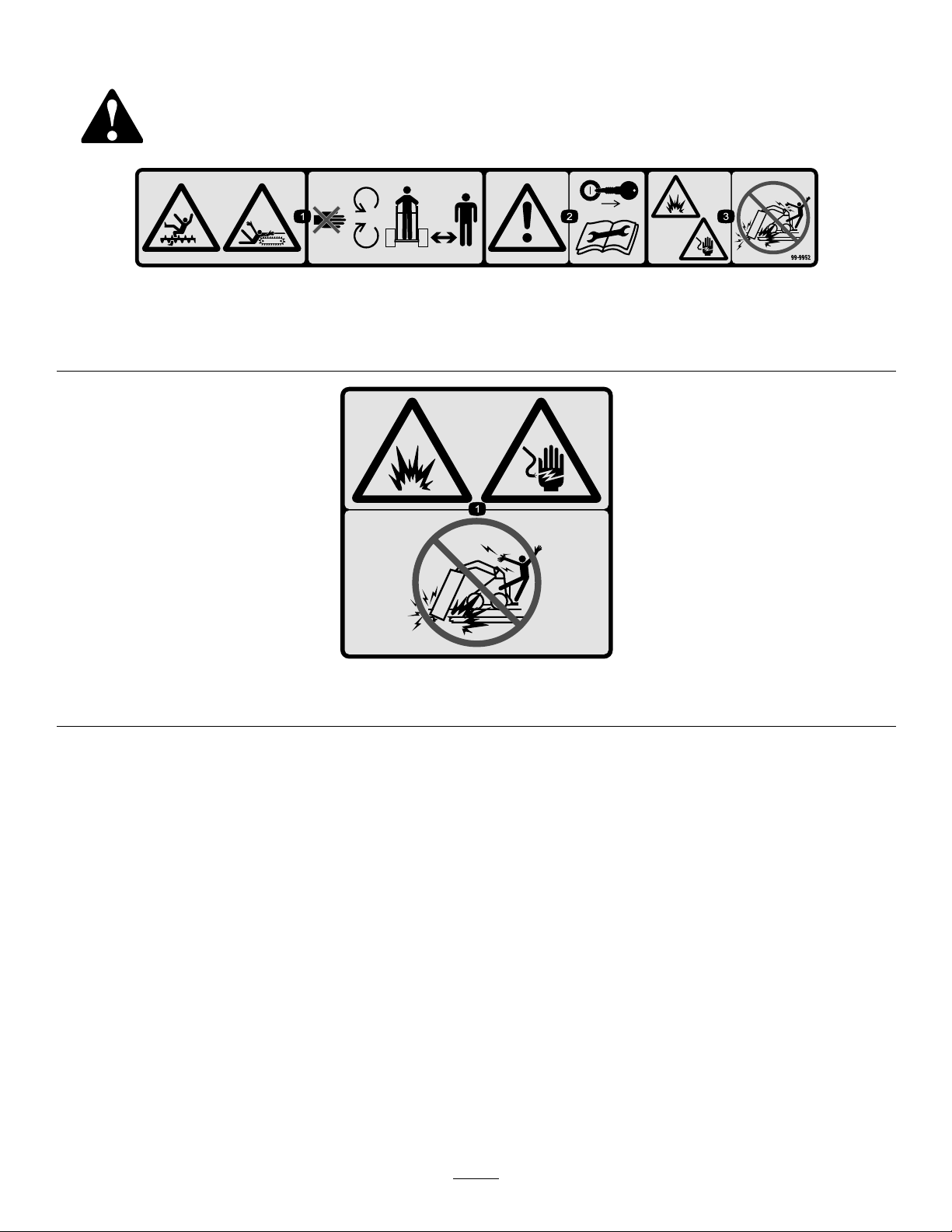

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

99-9952

1.Cuttinghazard,chainandauger—stayawayfrommovingpartsandkeepbystandersawayfromthemachine.

2.Warning—stoptheengineandremovethekeybeforepreformingandmaintenanceorrepairs.

3.Explosionand/orelectricshockhazard—donotdiginareaswithburiedgasorpowerlines.

99-9953

1.Explosionand/orelectricshockhazard—donotdiginareaswithburiedgasorpowerlines.

5

Setup

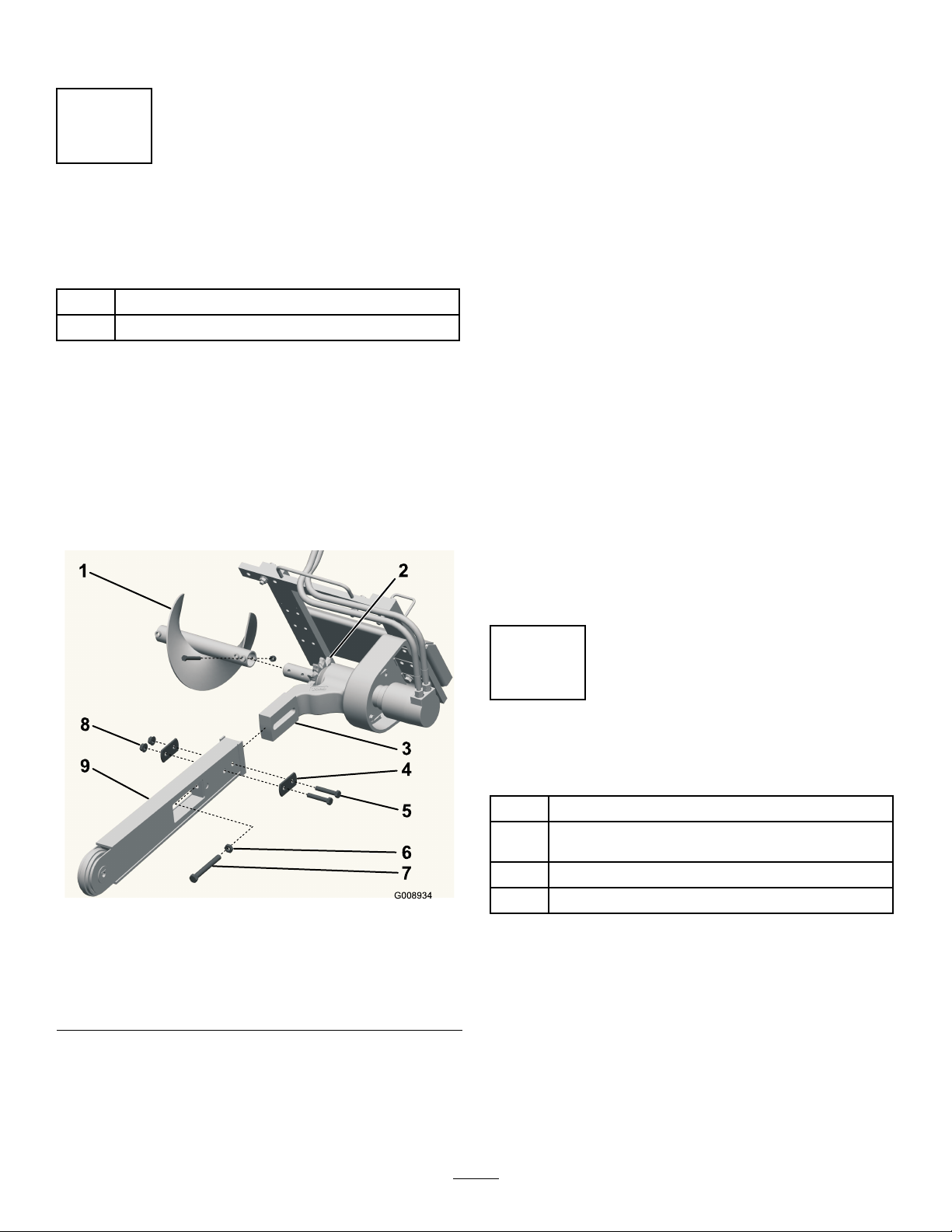

G008934

1

2

3

4

5

6

7

8

9

1

7.Installthe2bolts,nuts,anddoublewashersremoved

previouslythroughtheboomandarm,butdonot

tightenthem.

8.Ifthechainisnotconnected,connectthelinksby

pressingorhammeringtheclevispinsuppliedwith

thechainthroughthelinks.

InstallingtheBoomand

DiggingChain

Partsneededforthisprocedure:

1

Boomassembly(soldseparately)

1

Chainassembly(soldseparately)

Procedure

1.Raisethetrencherabout6inches(15cm)offofthe

ground.

2.Stoptheengineandremovethekey.

3.Removetheboltandnutsecuringthespoilsauger

andremovetheauger(

nutforfutureuse.

Figure3).Savetheboltand

Important:T oavoidbendingthechainlinks,

placeblocksunderandbetweenthelinkswhen

hammeringtheclevispinthrough.

9.Securetheclevispinwiththecotterpinsupplied

withthechain.

10.Loopthediggingchainovertheaugerdriveshaftand

ontothedrivesprocket,ensuringthatthedigging

teethpointforwardontheupperspan.

11.Settheupperspanofthechainintoplaceonthe

trencherboom,thenwrapthechainaroundthe

rollerattheendoftheboom.

12.Threadtheadjustmentboltintotheboomandturn

itinuntilthereis1-1/2to2-1/2inches(3.8to6.3

cm)ofslackinthechainonthebottomspan.

13.Threadthejamnutdowntheadjustingboltand

tightenitsecurelyagainsttheboom.

14.Torquethe2boltsandnutssecuringtheboomto

135to165ft-lb(183to223N-m).

1.Spoilsauger

2.Drivesprocket7.Adjustingbolt

3.Armonthedrivehead8.Nuts

4.Doublewasher9.Boom

5.Bolts

4.Removethe2bolts,nuts,anddoublewashersfrom

thesidesoftheboom(Figure3).

5.Loosentheadjustingboltandjamnut(Figure3).

6.Slidetheboomoverthearmonthedrivehead.

Figure3

6.Jamnut

2

InstallingtheSafetyBar

Partsneededforthisprocedure:

1

Safetybar

Safetybarextension(withboomsover2ft(61cm)

1

only)

2

Bolts(withboomsover2ft(61cm)only)

2

Procedure

1.Removethe3bolts,washers,andangenutsfrom

Locknuts(withboomsover2ft(61cm)only)

theupperleftcornerofthetrencherframe(Figure4).

6

123

4

G008935

Figure4

1

2

3

4

5

1.Safetybar

2.Washers4.Flangenuts

2.Usingthefastenersremovedpreviously ,installthe

trenchersafetybarasillustratedinFigure4.

3.Torquetheboltsandnutsto190to230ft-lb(257to

311N-m).

3.Bolts

•6inch(15cm)chainconguration

Usingtheholefarthestfromtheaugerbladein

theendoftheaugerwithtwoholes,connectthe

augertotheinnerholeontheshaft.

•8inch(20cm)chainconguration

Usingtheendoftheaugerwithonehole,

connecttheaugertotheinnerholeontheshaft.

•12inch(25or30cm)chainconguration

Usingtheendoftheaugerwithonehole,

connecttheaugertotheouterholeontheshaft.

4.Ifyouhaveaboomover2ft(61cm),securethe

safetybarextension(suppliedwiththeboom)over

theendofthesafetybarandsecureitusingthe2

boltsandlocknutssuppliedwiththeextension.

3

InstallingtheSpoilsAuger

NoPartsRequired

Procedure

Beforeoperatingthetrencher,installandpositionthe

spoilsaugertoworkcorrectlywiththediggingchain

congurationyouareusing.Failuretopositionthe

spoilsaugercorrectlymaydamagethetrencher.

1.Toinstallandpositiontheauger,usetheboltand

nutremovedfromtheaugerpreviouslytosecureit

inthecorrectholes,asdescribedinthefollowinglist:

Figure5

1.Auger

2.Connecttheseholesfora4inch(10cm)chain

3.Connecttheseholesfora6inch(15cm)chain

4.Connecttheseholesfora8inch(20cm)chain

5.Connecttheseholesfora12inch(30cm)chain

2.Torquetheboltandnutto75ft-lb(101N-m).

Note:RefertoFigure5whenperformingthis

procedure.

•4inch(10cm)chainconguration

Usingtheholeclosesttotheaugerbladeinthe

endoftheaugerwithtwoholes,connectthe

augertotheinnerholeontheshaft.

7

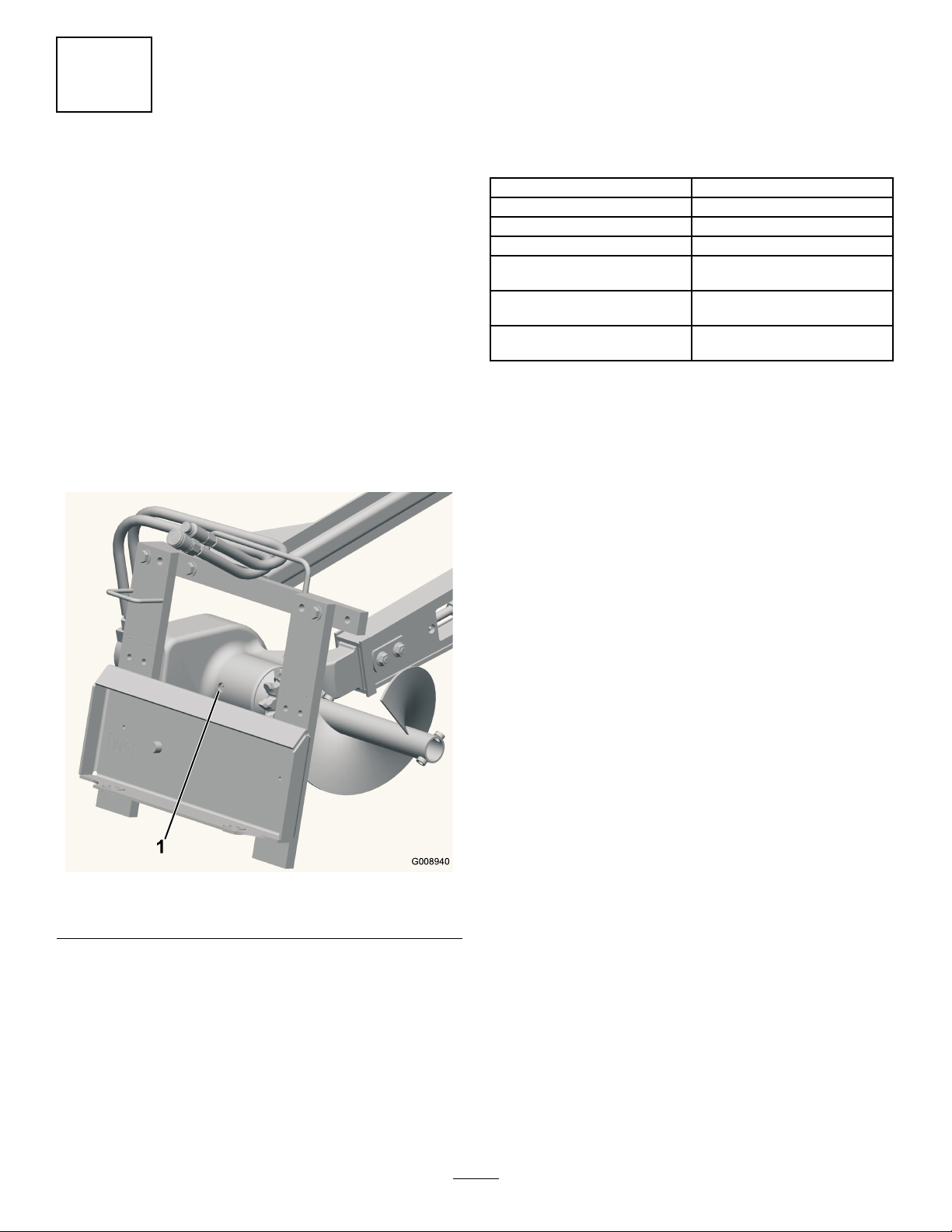

G008940

1

ProductOverview

4

CheckingtheBearingCase

LubeLevel

NoPartsRequired

Procedure

Beforeoperatingthetrencher,checktoensurethatthe

bearingcaseislledwithgearlube.

1.Lowerthetrenchertothegroundonaat,level

surfaceandtiltitsothattheboomisparallelwith

theground.

2.Stoptheengineandremovethekey.

3.Cleantheareaaroundthebearingcasellholeplug

Figure6).

(

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Width,with3ft(91cm)boom35inches(89cm)

Length,with3ft(91cm)boom65inches(165cm)

Height,with3ft(91cm)boom24inches(61cm)

Weight,with3ft(91cm)boom390lb(177Kg)

Maximumtrenchdepth,2ft(61

cm)boom

Maximumtrenchdepth,3ft(91

cm)boom

Maximumtrenchdepth,4ft

(122cm)boom

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

24inches(61cm)ata65

degreeboomangle

36inches(91cm)ata65

degreeboomangle

48inches(122cm)ata65

degreeboomangle

Figure6

1.Bearingcasellholeplug

4.Removetheplugfromthebearingcasellhole

(Figure6).

5.Lookinthehole,thelevelshouldbeuptothe

bottomofthehole;ifnotaddgearlubeuntilit

comesoutofthehole.

6.Replacetheplugandtorqueitto15to17ft-lb(20

to23N-m).

8

Operation

G008937

1

2

3

RefertoyourtractionunitOperator’ sManualformore

informationoninstallingandremovingattachments

onyourtractionunit.

Important:Alwaysusethetractionunittoliftand

movetheattachment.

DiggingaTrench

1.Ifyourtractionunithasaspeedselector,setitto

theslow(turtleposition),thenstarttheengine.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremovedwithin

afewhoursbyadoctorfamiliarwiththisform

ofinjuryorgangrenemayresult.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulic

leaks,neveruseyourhands.

2.Pulltheauxiliaryhydraulicslevertotheoperator

griptoengagethetrencher.

3.Slowlylowerthetrenchertothegroundsothatthe

boomandchainareparalleltotheground.

4.Begininsertingthenoseoftheboomandchain

intothegroundbyslowlyraisingthetrencherafew

inchesoffthegroundwhiletiltingthenosedown

intothegroundgradually.

5.Oncethetrencherboomisinthegroundata45to

60degreeangle,slowlylowerthetrencheruntilthe

spoilsaugerisjustabovetheground.

6.Ensurethatallpartsofthetrencherarefunctioning

correctly.

7.Slowlymovethetractionunitrearwardtoextend

thetrench.

Note:Ifyoumovetoofast,thetrencherwillstall.

Ifitstalls,raiseitslightly ,slowlydriveforward,or

reversethechaindirectionmomentarily .

8.Whennished,raisethetrencherandboomoutof

thetrenchbytiltingtheattachmentrearward,then

stopthetrencherbymovingtheauxiliaryhydraulics

leverintoneutral.

OffsettingtheTrencher

Youcanmovethetrenchertotherightsideofthe

trencherframetoallowyoutotrenchclosetobuildings

andotherobstacles.

2.Removethe6boltssecuringthetrencherheadto

theframe(Figure7).

Figure7

1.Trencherhead(simplied

forillustrativepurposes)

2.Safetybar

3.Movetheframetotheleft,aligningtheholesinthe

rightsideoftheframewiththoseinthehead.

4.Attachtheheadtotheframewiththe6bolts

removedpreviously(

5.Torquetheboltsto190to230ft-lb(257to311

N-m).

6.Removethe3bolts,washers,andangenutsfrom

thesafetybarandremovethebar(

7.Removethe2shortbolts,washers,andangenuts

securingtherightsideoftheupperframeand

movethemtothecorrespondingholesontheleft

(Figure7).

3.Sidehoseguide

Figure7).

Figure7).

1.Lowerthetrenchertotheground,stoptheengine,

anddisconnectthehydrauliclinesfromthetrencher.

8.Installthesafetybaroverthetrencherchainusing

the3bolts,washers,andangenutsremoved

previously(Figure7).

9.Torqueall5boltsandnutsto190to230ft-lb(257

to311N-m).

10.Movethehosesfromthehoseguideontopofthe

9

trenchertothehoseguideontheleftside(Figure7).

TransportingtheTrencheron

aTrailer

Placethetrencheronatrailerortruckcapableof

carryingit.Securelytiethetrenchertothetraileror

truckusingtiestrapsappropriatefortheweightofthe

trencherandforhighwayuse.

OperatingTips

•Cleantheareaoftrash,branchesandrocksbefore

trenchingtopreventequipmentdamage.

•Alwaysbegintrenchingwiththeslowestground

speedpossible.Increasespeedifconditionspermit.

•Alwaysusefullthrottle(maximumenginespeed)

whentrenching.

•Alwaystrenchbackwards(i.e.,inreverse).

•Nevertransportthetrencherwiththeloaderarms

raised.Keepthearmsloweredandthetrencher

tiltedup.

•Whentrenching,thespoilsaugershouldjustclear

theoriginalgroundsurfacetoobtainmaximumsoil

removal.

•Trenchata45to60degreeangleforbestresults.

•Youwillbeabletodigatrenchfasterbycontrolling

thedepthwithperiodicadjustmentsoftheloader

arms.

•Ifyourtractionunithasaspeedselector(present

onsomewheeledtractionunits),setittotheslow

(turtleposition).

•Ifyourtractionunithasaowdivider(present

onsomewheeledtractionunits),adjustitto

approximatelythe10o’clockposition.

•Ifthetrencherbindsinthesoil,pushtheauxiliary

hydraulicsleverfullyforwardtoreversethechain

direction.Oncethechainisloose,pullthelever

rearwardagainandcontinuetrenching.

•Ifyouneedthenishedtrenchtobecleanerthan

whatispossiblewiththetrencher,youcanpurchase

acrumberfromyourdealer.Thecrumbermounts

ontothetrencherandscrapesthetrenchcleanas

yourunthetrencher.

•Toimprovethequalityoftrencheslessthan24

inches(61cm)deep,usea24inch(61cm)boom

onthetrencher.

10

Maintenance

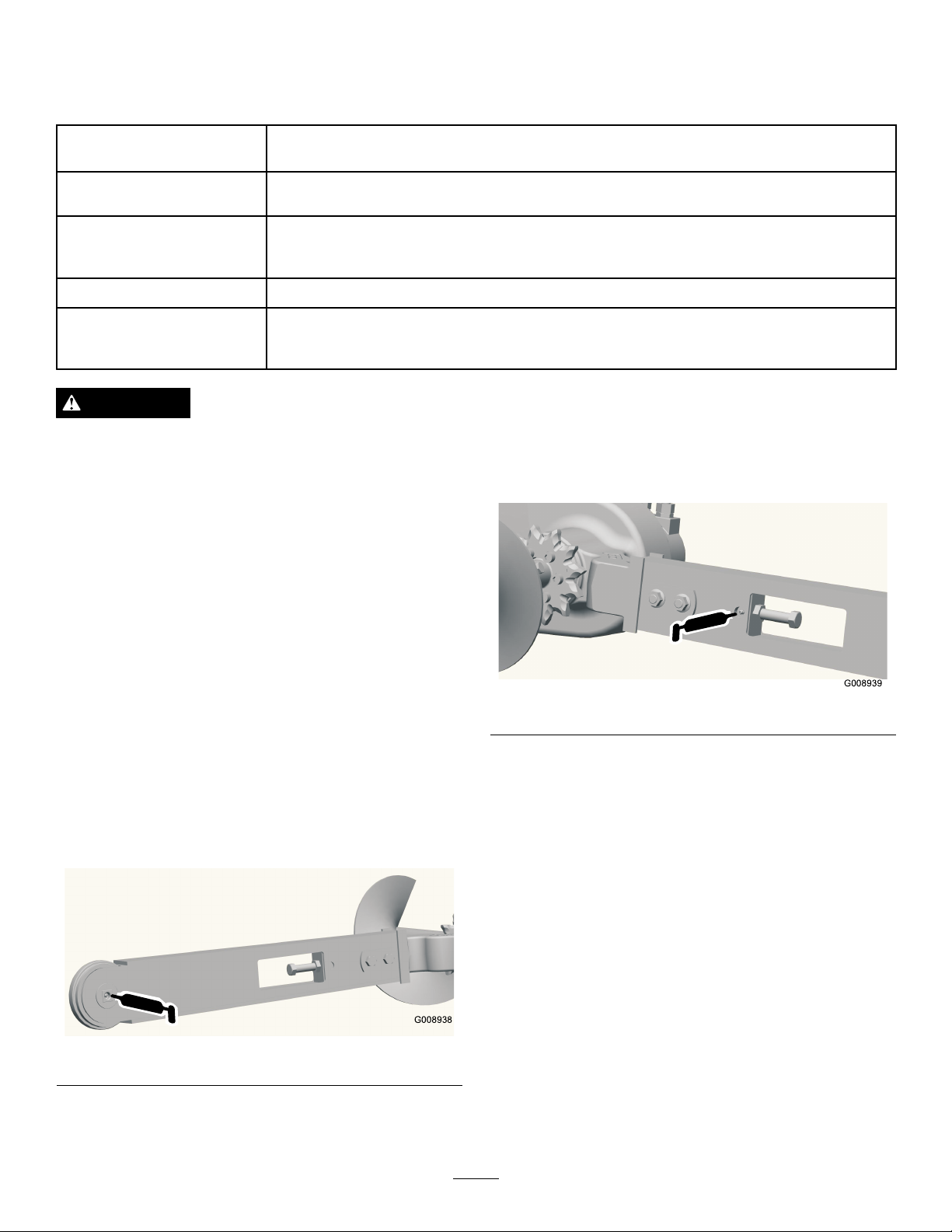

G008938

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Beforeeachuseordaily

Every25hours

Every200hours

Beforestorage

MaintenanceProcedure

•Greasethetrencher.

•Inspectthediggingteethandchainforexcessivewear .

•Checkthegearlubelevel.

•Adjustthediggingchaintension.

•Inspecttheboomforwear.

•Changethegearlube.

•Greasethetrencher.

•Checkthegearlubelevel.

•Paintchippedsurfaces.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldstarttheengine.Accidentalstartingofthe

enginecouldseriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionswitchbeforeyoudoanymaintenance.

GreasingtheTrencher

ServiceInterval:Beforeeachuseordaily

Beforestorage

Grease2ttings,asshowninFigure8andFigure9,

everydayandimmediatelyaftereverywashing.

GreaseType:General-purposegrease

1.Stoptheengineandremovethekey.

2.Cleanthegreasettingswitharag.

3.Connectagreaseguntoeachtting.

4.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings.

5.Wipeupanyexcessgrease.

Figure8

Figure9

ServicingtheBearingCase

Lube

ServiceInterval:Every25hours

Every200hours

Beforestorage

Gearlubetype:SAE90-140APIserviceGL-4orGL-5

Rellcapacity:1pint(1/2l).

CheckingtheBearingCaseLube

1.Lowerthetrenchertothegroundonaat,level

surfaceandtiltitsothattheboomisparallelwith

theground.

2.Stoptheengineandremovethekey.

3.Cleantheareaaroundthebearingcasellholeplug

(

Figure10).

11

G008940

1

Figure10

1.Bearingcasellholeplug

4.Removetheplugfromthebearingcasellhole

(Figure10).

AdjustingDiggingChain

Tension

ServiceInterval:Every25hours

Withthetrencherparalleltotheground,ensurethat

thereare1-1/2to2-1/2inches(3.8to6.3cm)between

thebottomoftheboomandthetopofthebottom

chainspan.Ifnot,adjustthechainusingthefollowing

procedure:

Important:Donotovertightenthechain.Excess

chaintensionmaydamagedrivecomponents.

1.Loosenthe2boltsandnutssecuringtheboomto

thetrencherarm(

2.Loosenthejamnutsecuringtheadjustmentbolt

Figure3).

(

3.Turntheadjustmentboltinoroutasneededto

achievethedesiredtension.

4.Tightenthejamnut.

5.Torquethe2boltsandnutssecuringtheboomto

135to165ft-lb(183to223N-m).

Figure3).

5.Lookinthehole,thelevelshouldbeuptothe

bottomofthehole;ifnotaddgearlubeuntilit

comesoutofthehole.

6.Replacetheplugandtorqueitto15to17ft-lb(20

to23N-m).

ChangingtheGearLube

1.Cleantheareaaroundthebearingcasellholeplug

(Figure10).

2.Removetheplugfromthebearingcasellhole

(Figure10).

3.Liftthetrencheruntiltheboomisvertical,draining

thelubethroughthellholeandintoapan.

4.Returnthetrenchertotheground.

5.Fillthebearingcasewithgearlubeuntilitcomes

outofthellhole.

6.Replacetheplugandtorqueitto15to17ft-lb(20

to23N-m).

FlippingaWornBoom

ServiceInterval:Every25hours

Inspectthebottomoftheboomforwear,ifitisworn,

completethefollowing:

Note:Ifyouhavealreadyippedtheboomonce,

replacetheboomwhenbothsidesareworn.

1.Removethe2boltsandnutssecuringtheboomto

thetrencherarm(Figure3).

2.Loosenthejamnutontheadjustingboltinthe

boom(

3.Loosentheadjustingboltuntilyoucanremovethe

chainfromtheboom(Figure3).

4.Removethechainfromthedrivesprocket.

5.Removetheboom,ipitoversothebottom

becomesthetop(orifyouhavealreadyippedit

once,replaceit),andinstalltheboomagain.

6.Replacethenuts,bolts,andwasherssecuringthe

boom.

Figure3).

7.Installthechainoverthedrivesprocketandfront

roller.

8.AdjustthechaintensionasdescribedinAdjusting

theDiggingChainTension.

12

ReplacingtheDiggingTeeth

G008941

123

ServiceInterval:Beforeeachuseordaily

Duetothehighamountofwearplacedonthedigging

teeth,youwillneedtoreplacethemperiodically.

Toreplaceasingletooth,removetheboltssecuringthe

toothtoremoveit,theninstallanewtoothinthesame

position.Torquetheboltssecuringtheteethto27to33

ft-lb(37to45N-m).

ReplacingtheDriveSprocket

Overtime,thedrivesprocketwillwear,especiallywhen

usedinsandyorclaysoils.Whenthishappens,the

diggingchainwillbegintoslip.Ifthechainslips,replace

thedrivesprocket,asfollows:

1.Raisethetrencherafewinchesabovetheground.

2.Stoptheengineandremovethekey.

3.Removethespoilsauger(Fig.8).

Important:Thearrowonthesprocketface

shouldbevisiblefromtherightsideofthe

trencherandshouldpointinaclockwise

direction;ifnot,turnthesprocketaround.

12.Threadthe6boltsintothesprocketngertight(Fig.

8).

13.Slowlybegintighteningtheboltsprogressingaround

thesprocketuntilallboltsaretorquedto95to115

ft-lb(129to155N-m).

Important:Tighteneachboltonlyhalfway

rst,workingyourwayaroundthesixbolts,

thenreturntoeachboltinturnandtorquethem

tothespecicationsgiveninstep13.

14.Loopthechainovertheaugerdriveshaftandonto

thedrivesprocket,ensuringthattheteethpoint

forwardontheupperspan.

15.Settheupperspanofthechainintoplaceonthe

trencherboom,thenwrapthechainaroundthe

rollerattheendoftheboom.

16.Threadtheadjustmentboltintotheboomandturn

itinuntilthereis1-1/2to2-1/2inches(3.8to6.3

cm)ofslackinthechainonthebottomspan.

Figure11

1.Spoilsauger

2.Drivesprocket

3.Bolts

4.Loosenthe2boltsandnutssecuringtheboomto

thetrencherarm(Fig.2).

5.Loosenthejamnutontheadjustingboltinthe

boom(Fig.2).

6.Loosentheadjustingboltuntilyoucanremovethe

chainfromtheboom(Fig.2).

7.Removethechainfromthedrivesprocket.

8.Removethe6boltssecuringthedrivesprocket(Fig.

8).

17.Threadthejamnutdowntheadjustingboltand

tightenitsecurelyagainsttheboom.

18.Torquethe2boltsandnutssecuringtheboomto

135to165ft-lb(183to223N-m).

19.Installthespoilsauger;refertoInstallingtheSpoils

Auger.

9.Removeanddiscardthedrivesprocket(Fig.8).

10.Cleanthesprocketmountingsurfaceonthetrencher.

11.Slidethenewsprocketontotheshaftasillustrated

inFigure8.

13

Storage

1.Beforelongtermstorage,brushthedirtfromthe

attachment.

2.Checktheconditionofthediggingchain.Adjustand

lubricatethechain.Replaceanywornordamaged

teeth.

3.Checkandtightenallbolts,nuts,andscrews.Repair

orreplaceanypartthatisdamagedorworn.

4.Ensurethatallhydrauliccouplersareconnected

togethertopreventcontaminationofthehydraulic

system.

5.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDealer.

6.Storethetrencherinaclean,drygarageorstorage

area.Coverthetrenchertoprotectitandkeepit

clean.

14

Troubleshooting

Problem

Thechaindoesnotturn.

Thetrencherdoesnotdigfastenough.

PossibleCauseCorrectiveAction

1.Ahydrauliccouplerisnotcompletely

connected.

2.Ahydrauliccouplerisdamaged.

3.Thereisanobstructioninahydraulic

hose

4.Anauxiliaryvalveonthetractionunit

isnotopening.

5.Theboomendbearingfailed.

6.Thediggingchainistootight.6.Adjustthediggingchain.

7.Thereissandbuildupintoothrootof

thedrivesprocket.

8.Hydraulicmotororchaindrivefailure8.ContactyourAuthorizedService

1.Wornteeth1.Replaceanywornteeth.

2.Wrongsettingonowdividerand

speedlever(applicablewheeledunits

only)

3.Thereisarestrictioninaquickcoupler

orhose.

4.Thehydraulicsystemistoohot.

5.Thereliefvalveissetbelow

specications.

1.Checkandtightenallcouplers.

2.Check/replacecouplers

3.Findandremovetheobstruction.

4.Repairthevalve.

5.Replacethebearing.

7.Raisethetrencherandrunthechain

backwards,thenreducethechain

tension.

Dealer.

2.Settheowdividertothe10:00

positionandthespeedlevertothe

turtleposition.

3.Checkthehosesandcouplersand

repairanyproblemsfound.

4.Shutdownandallowthesystemtocool.

5.ContactyourAuthorizedService

Dealer.

Thechainturnsinthewrongdirection

Thebearingcaselubeiscontaminated.

1.Theauxiliaryvalveleverisinthewrong

position.

2.Thehydraulichosesarereversed.2.Disconnecthosesandswitchpositions.

1.Thellplugisleaking.1.Lookformoisturearoundthellplug.

2.O-ringfailureonthemotor.2.ContactyourAuthorizedService

3.Sealfailure.3.ContactyourAuthorizedService

1.Movetheauxiliaryvalvelevertothe

rearwardposition.

Ifpresent,changetheoil,andreplace

theplugandtheplugo-ring.

Dealer.

Dealer.

15

ToroCompactUtilityEquipmentWarranty

AOne-YearLimitedWarranty

CUEProducts

ConditionsandProductsCovered

TheToro®Companyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCompactUtility

Equipment(“Product”)tobefreefromdefectsinmaterialsorworkmanship.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

Loaders,TrenchersandAttachments1yearor1000operating

hours,whicheveroccursrst

KohlerEngines3years

AllotherEngines2years

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.ContactanyAuthorizedT oroCompactUtilityEquipment(CUE)

ServiceDealertoarrangeserviceattheirdealership.T olocatea

dealerconvenienttoyou,accessourwebsiteatwww.T oro.com.

YoumayalsocallourT oroCustomerCareDepartmenttollfree

at888-865-5676(U.S.customers)or888-865-5691(Canadian

customers).

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.

3.IfforanyreasonyouaredissatisedwiththeServiceDealer’s

analysisorwiththeassistanceprovided,contactusat:

LCBCustomerCareDepartment

ToroW arrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFree:888-865-5676(U.S.customers)

TollFree:888-865-5691(Canadacustomers)

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutine

maintenance,whetherperformedbyadealerorbyyou,isatyourexpense.

Partsscheduledforreplacementasrequiredmaintenance(“Maintenance

Parts”),arewarrantedfortheperiodoftimeuptothescheduled

replacementtimeforthatpart.Failuretoperformrequiredmaintenance

andadjustmentscanbegroundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thisexpresswarranty

doesnotcoverthefollowing:

•Productfailureswhichresultfromtheuseofnon-Tororeplacement

parts,orfrominstallationanduseofadd-on,modied,orunapproved

accessories

•Productfailureswhichresultfromfailuretoperformrequired

maintenanceand/oradjustments

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligentorrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,during

normalProductoperationinclude,butarenotlimitedto,diggingteeth,

tines,sparkplugs,tires,tracks,lters,chains,etc.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,or

chemicals,etc.

•Normal“wearandtear”items.Normal“wearandtear”includes,butis

notlimitedto,wornpaintedsurfaces,scratcheddecalsorwindows,

etc.

•Anycomponentcoveredbyaseparatemanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

RepairbyanAuthorizedT oroCompactUtilityEquipment(CUE)Service

Dealerisyoursoleremedyunderthiswarranty.

NeitherTheToro®CompanynorToroWarrantyCompanyisliable

forindirect,incidentalorconsequentialdamagesinconnectionwith

theuseoftheToroProductscoveredbythiswarranty,including

anycostorexpenseofprovidingsubstituteequipmentorservice

duringreasonableperiodsofmalfunctionornon-usepending

completionofrepairsunderthiswarranty.Allimpliedwarranties

ofmerchantabilityandtnessforusearelimitedtotheduration

ofthisexpresswarranty .Somestatesdonotallowexclusionsof

incidentalorconsequentialdamages,orlimitationsonhowlong

animpliedwarrantylasts,sotheaboveexclusionsandlimitations

maynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

ExceptfortheenginewarrantycoverageandtheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.The

EmissionsControlSystemonyourProductmaybecoveredbyaseparate

warrantymeetingrequirementsestablishedbytheU.S.Environmental

ProtectionAgency(EPA)ortheCaliforniaAirResourcesBoard(CARB).

ThehourlimitationssetforthabovedonotapplytotheEmissions

ControlSystemWarranty .RefertotheCaliforniaEmissionControl

WarrantyStatementsuppliedwithyourProductorcontainedintheengine

manufacturer’sdocumentationfordetails.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor’sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheToroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany .

374-0261RevA

Loading...

Loading...