Page 1

FORM NO. 3321–604

Breaker

Attachment

Model No. 22441– 990001 & Up

Operator’s Manual

IMPORTANT: Read this manual carefully. It contains information about your

safety and the safety of others. Also become familiar with the controls and

their proper use before you operate the product.

Page 2

Introduction

We want you to be completely satisfied with your

new product, so feel free to contact your local

Authorized Service Dealer for help with service,

genuine replacement parts, or other information you

may require.

Whenever you contact your Authorized Service

Dealer or the factory, always know the model and

serial numbers of your product. These numbers will

help the Service Dealer or Service Representative

provide exact information about your specific

product. You will find the model and serial number

on a plate located on the breaker frame.

For your convenience, write the product model and

serial numbers in the space below.

Model No:

Serial No.

The warning system in this manual identifies

potential hazards and has special safety messages that

help you and others avoid personal injury, even death.

DANGER, WARNING and CAUTION are signal

words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

DANGER signals an extreme hazard that will cause

serious injury or death if the recommended

precautions are not followed.

WARNING signals a hazard that may cause serious

injury or death if the recommended precautions are

not followed.

CAUTION signals a hazard that may cause minor or

moderate injury if the recommended precautions are

not followed.

Two other words are also used to highlight

information. “Important” calls attention to special

mechanical information and “Note” emphasizes

general information worthy of special attention.

The left and right side of the machine is determined

by standing in the normal operator’s position.

Printed in USA

Page 3

Contents

Page

Safety 2.

Specifications 4

Installation 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety and Instruction Decals 3

. . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications: 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts 5

Installing the Breaker on the Traction Unit 5

Installing the Bit 6

Connecting the Hydraulic Hoses7. . . . . . . .

Removing the Breaker from the

Traction Unit 7

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . . .

Page

Operation 8

Maintenance 10

Troubleshooting 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Tips 8

Breaking a Vertical Surface 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Interval Chart 10

Greasing the Bit 10

Storage 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

1

Page 4

Safety

Improper use or maintenance by the operator or

owner can result in injury. To reduce the potential

for injury, comply with the safety instructions in

the traction unit operator’s manual and always

pay attention to the safety alert

means CAUTION, WARNING, or

DANGER—“personal safety instruction.” Failure

to comply with the instruction may result in

personal injury or death.

symbol, which

POTENTIAL HAZARD

• When the engine is off, attachments in the

raised position can gradually lower.

WHAT CAN HAPPEN

• Someone nearby may be pinned or injured

by the attachment as it lowers.

POTENTIAL HAZARD

• There may be buried power, gas, and/or

telephone lines in the work area.

WHAT CAN HAPPEN

• Shock or explosion may occur.

HOW TO AV

OID THE HAZARD

• Have the property or area to be broken

marked for buried lines and do not break

in marked areas.

POTENTIAL HAZARD

• Contact with moving breaker may cause

injury.

WHAT CAN HAPPEN

• Moving breaker can crush hands, feet or

other body parts.

HOW TO AV

OID THE HAZARD

• Always lower the attachment lift each time

you shut off the traction unit.

POTENTIAL HAZARD

• During operation, the breaker thr

pieces of broken material and dust.

WHAT CAN HAPPEN

ows small

• Flying debris may damage eyes.

• Inhaling the dust can damage lungs.

HOW TO AV

OID THE HAZARD

• The operator and all bystanders must wear

safety glasses, goggles, or a face shield

during operation of the breaker.

• The operator and all bystanders must wear

a face mask or other filter over mouths and

noses during operation of the breaker.

• Keep bystanders at least 25 feet away from

the beaker during operation.

HOW TO AV

OID THE HAZARD

• Keep your hands, feet, and any other part

of your body or clothing away from moving

parts.

• Before adjusting, cleaning, repairing, and

inspecting the breaker, lower it to the

ground, stop the engine, remove the key,

and wait for all moving parts to stop.

2

Page 5

POTENTIAL HAZARD

• The breaker is very loud during operation.

WHAT CAN HAPPEN

• Over time, your hearing may be impaired if

unprotected.

Safety

HOW TO AV

OID THE HAZARD

• Wear hearing protection during operation.

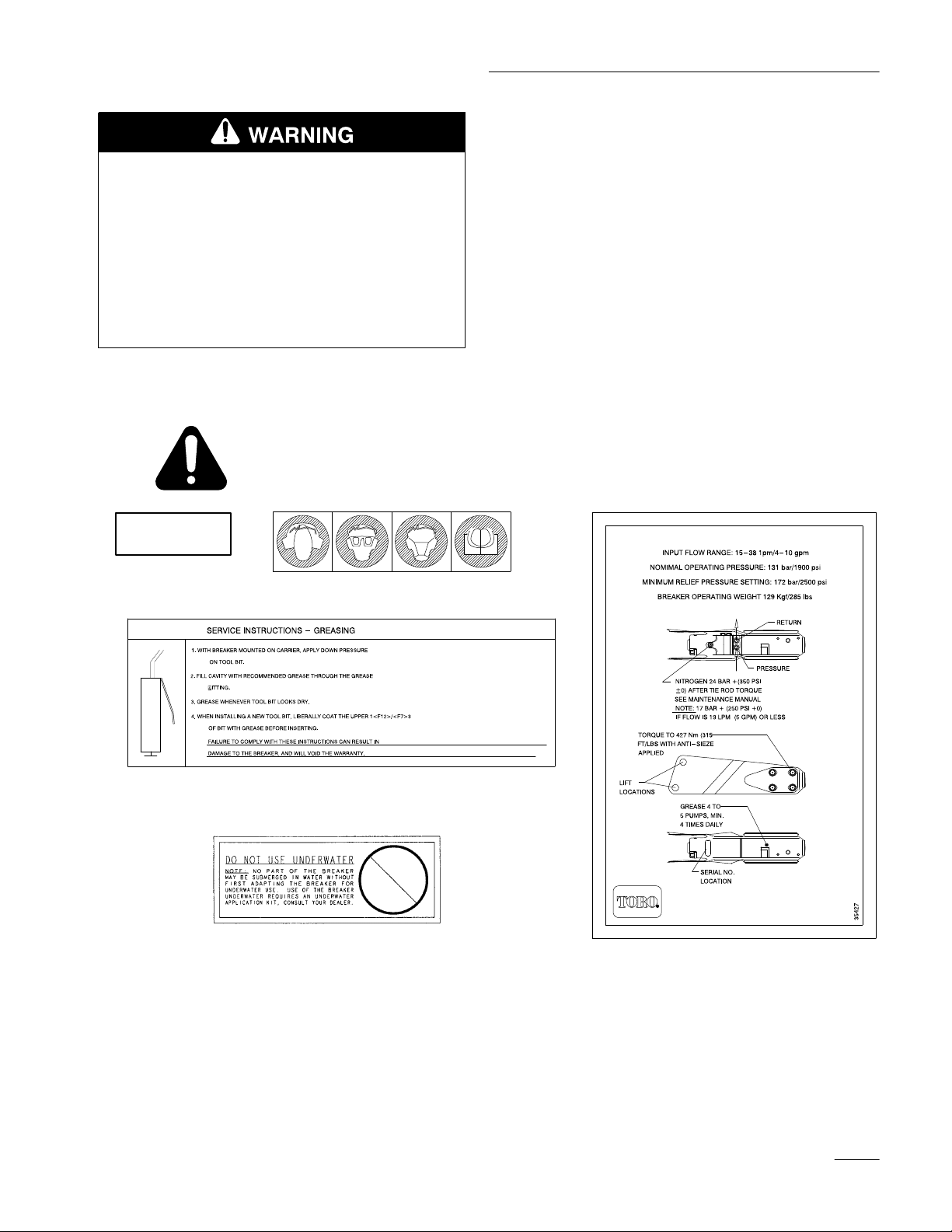

Safety

and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near

any area of potential danger. Replace any decal that is damaged or lost.

(Part No. 2771

1)

(Part No. 28886)

(Part No. 26068)

(Part No. 35487)

(Part No. 35427)

3

Page 6

Specifications

General

Overall width 24.5 inches (62 cm)

Overall length 49.0 inches (125 cm)

Overall height 13.0 inches (33 cm)

Weight (with bit) 285 lbs (129 Kg)

Bit working length 11.0 inches (27.9 cm)

Bit diameter 1.75 inches (4.4 cm)

Impact ener

Blows per minute 1200

Flow range 4 to 10 gpm (15 to 38 lpm)

Specifications:

gy class

175 ft·lbs (237 J)

4

Page 7

Installation

Loose

DESCRIPTION QTY. USE

Breaker

Bit–concrete

contact your T

Installing

T

raction Unit

Parts

breaker (other bits are available;

oro dealer for more information)

IMPORTANT: The Hydraulic Relief kit must

be installed on some traction units prior to

using the breaker or serious damage may

occur to the hydraulic system. Failure to

install the relief kit will void the warranty of

your traction unit. To determine if your

traction unit needs a Hydraulic Relief Kit,

contact your authorized Toro dealer.

the Breaker on the

IMPORTANT: Before installing the breaker,

ensure that the mount plates are free of any

dirt or debris.

1

1

Assemble the breaker

2. Move pump control lever to slow (turtle)

position.

3. Start the engine.

4. Slowly push the attachment tilt lever forward to

tilt the attachment mount plate forward.

5. Position mount plate into the upper lip of the

attachments receiver plate (Fig. 1).

2

1

1. Position the breaker on a level surface with

enough space behind it to accommodate the

traction unit.

Figure 1

1. Mount

6. Raise the loader arms while tilting back the

plate

mount plate at the same time.

IMPORTANT: The attachment should be

raised enough to clear the ground and the

mount plate tilted all the way back.

2.

Receiver plate

m–4055

5

Page 8

Installation

7. Stop the engine.

8. Engage the attachment lock pins (Fig. 2).

1

1

3

4

Figure 2

1. Attachment

Installing

lock pins (shown in engaged position)

the Bit

1. Raise the horizontal breaker so it is about 6

inches off of the ground.

2. Stop the engine and remove the key.

3. Using a hammer and punch, drive the bit

retaining pin 3/4 of the way out of the breaker

housing (Fig. 3). It will require a blow of

considerable force to drive the pin from its

seating in the breaker.

m–4056

2

m–4248

Figure 3

1. Retaining

2. Bit

pin

3. Notch

4.

Grease here

4. Remove the plastic spacer.

5. Smear grease completely over the top six inches

of the bit (Fig. 3).

6. Slide the bit into the breaker with the notch in

the bit facing the right side of the breaker

(Fig. 3).

7. Insert the bit retaining pin into the breaker and

drive it into place with a hammer (Fig. 3).

8. Grease the bit before use. For detailed

instructions on when and how to grease the bit,

refer to Greasing the Bit, page 10.

Note: To change bits, repeat the above

procedure. When changing bits the

current bit will be removed instead of

the plastic spacer

6

.

Page 9

Installation

Connecting

the Hydraulic

Hoses

1. Stop the engine.

2. Move the auxiliary hydraulics lever forward,

backward, and back to neutral to relieve pressure

at the hydraulic couplers.

IMPORTANT: Ensure that all foreign matter

is cleaned from the hydraulic connections

before making connections.

3. Remove the protective covers from the hydraulic

couplers on the traction unit. Connect the covers

together to prevent contamination during

operation.

4. Ensure that the hydraulic hoses on the breaker

are routed through the loop on the top of the

mount plate.

5. Slide the collar back on the hydraulic coupler

and connect the attachment couplers to the

machine couplers.

5. Slide the collar back on the hydraulic couplers

and disconnect them.

IMPORTANT: Connect the attachment hoses

together to prevent hydraulic system

contamination during storage.

POTENTIAL HAZARD

• Hydraulic fluid escaping under pressure

can penetrate skin and cause injury.

WHAT CAN HAPPEN

• Fluid accidentally injected into the skin

must be surgically removed within a few

hours by a doctor familiar with this form of

injury or gangrene may result.

HOW TO AV

OID THE HAZARD

• Keep body and hands away from pin hole

leaks or nozzles that eject high pressure

hydraulic fluid.

• Use cardboard or paper to find hydraulic

leaks, never use your hands.

6. Confirm that the connection is secure by pulling

on the hoses.

Removing

T

raction Unit

1. Start the engine and lower the breaker to the

ground or onto a trailer.

2. Stop the engine.

3. Disengage the attachment lock pins by turning

them to the outside.

4. Move the auxiliary hydraulics lever forward,

backward, and back to neutral to relieve pressure

at the hydraulic couplers.

the Breaker from the

6. Install the protective covers onto the hydraulic

couplers on the traction unit.

7. Start the engine, tilt the mount plate forward,

and back the traction unit away from the breaker.

7

Page 10

Operation

Operating Tips

• Always use full throttle (maximum engine

speed) when breaking.

• Use low range (turtle position) on the speed

selector for best performance and smoothest

operation.

• Adjust the flow divider valve to approximately

the 10 o’clock position.

• Place the bit within 6 to 18 inches of the edge of

the material to be broken with the breaker angled

slightly towards the edge (Fig. 4).

• When breaking, always apply downward

pressure with the loader arms until the front

wheels raise off of the ground a few inches

(Fig. 4). Maintain this pressure as the bit works

its way into the material being broken.

• Do not move the auxiliary hydraulics lever to

engage the breaker unless the bit is on the

ground and downward pressure is applied.

• Do not bind the bit in the material being cut.

Binding of the bit can cause the bit to bend or

wear out prematurely. Ensure that all force

applied to the breaker is inline with the bit, not

side to side or front to back. This will require

frequent adjustments in the positioning of the

traction unit.

• Listen to the sound of the breaker when is is

operating. The sound will be different when

there is adequate downward pressure than when

not enough pressure is being applied.

m–4249

Figure 4

• If the bit is positioned too far from the edge of

the material the energy may be absorbed by the

material without breaking it. If the material has

not cracked after 15 to 20 seconds, stop the

breaker and move the bit to a different location.

IMPORTANT: Continuous penetration in the

same location for long periods of time will

create high temperatures at the tip of the bit.

This could cause the bit to lose its temper and

mushroom under impact, destroying the bit.

• Many materials do not respond well to continued

hammering in one place. Move the the breaker

each time that it penetrates the material without

breaking it. When you move the breaker to a

new location, move it in a line parallel to the

edge of the material, about 3 inches from the

previous hole. This will score the material and if

done repeatedly, break off a large piece of the

material (Fig. 5).

8

Page 11

m–4250

Operation

1

2

1

Figure 5

IMPORTANT: Never pry with the bit.

• If you are breaking rebar reinforced concrete, use

a chisel bit in the breaker to cut through the

rebars in the concrete. The rebar can also be cut

with a torch.

IMPORTANT: Do not use the breaker in or

under water.

Breaking

a V

ertical Surface

Converting the Breaker

1. Tilt the breaker as far forward as possible and

lower it until the tip is resting on the ground.

2. Remove the click pin securing the front

mounting pin (Fig. 6).

2

Figure 6

1. Click

pin

2.

Front mounting pin

Operating Tips for Vertical Surfaces

• Position the bit on the vertical surface in the

same manner as you would position it on a

horizontal surface.

• Maintain pressure on the bit by driving the

traction unit forward into the vertical surface

while operating the breaker.

m–4251

3. Drive the front mounting pin out of the breaker

(Fig. 6).

4. Lower the loader arms until the holes in the

breaker align with the upper holes in the mount

(Fig. 6).

5. Drive the front mounting pin through the upper

holes and secure it with the click pin (Fig. 6).

9

Page 12

Maintenance

Service

Service

Grease the bit

Inspect and tighten all fasteners

Inspect the mounting pins, holes, lower bushing

(above the bit), bit retaining pin, and roll pins for

looseness or wear

Check for hydraulic leaks at all fittings and hoses.

Chipped surfaces—paint

Interval Chart

Operation

.

POTENTIAL HAZARD

• If you leave the key in the ignition switch, someone could start the engine.

WHAT CAN HAPPEN

• Accidental starting of the engine could seriously injure you or other bystanders.

Each

Use

X X

X X

X X

X X

Storage

Service

X

Notes

Grease before each use and then

every 1 to 2 operating hours

Reseat or replace as necessary

Repair leaky fittings and/or replace

leaky hoses.

.

HOW TO AV

OID THE HAZARD

• Remove the key from the ignition switch before you do any maintenance.

Greasing

the Bit

Service Interval/Specification

Grease the bit before each use and then after every 1

to 2 hours of operation. Grease it immediately after

washing.

Grease Type: General-purpose grease, certified NGLI

number 1 or 2.

How to Grease

1. Tilt the breaker so that it is vertical, then lower it

to the ground so that the bit is pushed up into the

breaker as far as possible.

IMPORTANT: Failure to push the bit up into

the breaker before greasing will allow the

grease to fill the space between the top of the

bit and the breaker piston. When you next

use the breaker, the piston will pr

grease and cause seal damage.

2. Stop the engine and remove the key.

essurize this

10

Page 13

3. Clean the grease fitting with a rag.

Maintenance

POTENTIAL HAZARD

• Hydraulic fluid escaping under pressure

can penetrate skin and cause injury.

WHAT CAN HAPPEN

• Fluid accidentally injected into the skin

must be surgically removed within a few

hours by a doctor familiar with this form of

injury or gangrene may result.

m–4152

Figure 7

4. Connect a grease gun to the fitting.

5. Pump grease into the fitting until either grease

begins to ooze out of the lower bushing and

retaining pin or it becomes difficult to pump the

grease gun.

6. Wipe up any excess grease.

Storage

1. Before long term storage, wash the machine with

mild detergent and water to remove dirt and

grime from the entire machine.

HOW TO AV

OID THE HAZARD

• Keep body and hands away from pin hole

leaks or nozzles that eject high pressure

hydraulic fluid.

• Use cardboard or paper to find hydraulic

leaks, never use your hands.

6. Ensure that all hydraulic couplers are connected

together to prevent contamination of the

hydraulic system.

7. Paint all scratched or bare metal surfaces. Paint

is available from your Authorized Service

Dealer.

8. Store the breaker in a vertical position in a

clean, dry garage or storage area. Cover it to

protect it and keep it clean.

IMPORTANT: If the breaker will be stored

for more than a month, it must be stored

vertically to avoid damaging o–rings and

seals inside the breaker.

2. Grease the bit.

3. Check and tighten all bolts, nuts, and screws.

4. Inspect all mounting pins, holes, the lower

bushing, roll pins, and the bit retaining pin.

Repair or replace any part that is damaged or

worn.

5. Inspect all hydraulic fittings and hoses for leaks.

Repair or replace any fittings or hoses that leak.

11

Page 14

Troubleshooting

PROBLEM

The breaker does not operate.

POSSIBLE CAUSES

1.

Hydraulic coupler not

completely connected

2.

Damaged hydraulic coupler

3.

An obstruction in a hydraulic

hose

4.

Auxiliary valve on the traction

unit is not opening.

5.

Low nitrogen level in the

breaker

CORRECTIVE ACTION

1.

Check and tighten all

couplers.

2.

Check couplers and replace

any that are damaged.

3.

Find and remove the

obstruction.

4.

Repair the valve.

5.

Refer to you authorized T

dealer.

oro

12

Page 15

Page 16

Loading...

Loading...