Page 1

Form No. 3323-269

Vibratory

Plow

Sitework Systems Attachment

Model No. 22437—990001 & Up

Operator’s Manual

English (CE)

Page 2

Contents

Page

Introduction 2.

Safety 2

V

ibration Level3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Decals3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 4

Stability Ratings4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5

Loose Parts5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Plow on the T

Assembling the Plow5. . . . . . . . . . . . . . . . . . . . . . .

Removing the Plow from the Traction Unit5. . . . . .

Operation 6

Plowing 6

T

ransporting the Plow7. . . . . . . . . . . . . . . . . . . . . .

Gaging Plow Depth8. . . . . . . . . . . . . . . . . . . . . . . .

T

ips for Plowing8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 9

Service Interval Chart9. . . . . . . . . . . . . . . . . . . . . .

Greasing 9

Lubrication 10

Storage 11

Troubleshooting 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

raction Unit5. . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

W

e want you to be completely satisfied with your new

product, so feel free to contact your local Authorized

Service Dealer for help with service, genuine replacement

parts, or other information you may require.

Whenever you contact your Authorized Service Dealer or

the factory

your product. These numbers will help the Service Dealer

or Service Representative provide exact information about

your specific product. Y

number on a plate located on the attachment receiver

plate.

, always know the model and serial numbers of

ou will find the model and serial

For your convenience, write the product model and serial

numbers in the space below

Model No:

Serial No.

The

warning system in this manual identifies potential

hazards and has special safety messages that help you and

others avoid personal injury

W

ARNING and CAUTION are signal words used to

identify the level of hazard. However

hazard, be extremely careful.

DANGER

serious injury or death if the recommended precautions

are not followed.

WARNING

or death if the recommended precautions are not followed.

CAUTION

moderate injury if the recommended precautions are not

followed.

wo other words are also used to highlight information.

T

“Important” calls attention to special mechanical

information and “Note” emphasizes general information

worthy of special attention.

The left and right side of the machine is determined by

standing in the normal operator’s position.

signals an extreme hazard that will cause

signals a hazard that may cause serious injury

signals a hazard that may cause minor or

.

, even death. DANGER,

, regardless of the

Safety

Impr

oper use or maintenance by the operator or owner

can r

esult in injury

comply with the safety instructions in the traction unit

operator’

safety alert

W

ARNING, or DANGER—“personal safety

instruction.” Failur

may r

s manual and always pay attention to the

esult in personal injury or death.

. T

o r

educe the potential for injury

symbol, which means CAUTION,

e to comply with the instruction

,

The Toro Company – 1999

8111 Lyndale Ave. South

Bloomington, MN 55420–1196

2

All Rights Reserved

Printed in the USA

Page 3

DANGER

WARNING

POTENTIAL HAZARD

• Ther

WHA

•

HOW T

•

e may be buried power

telephone lines in the ar

T CAN HAPPEN

Shock or explosion may occur

O AVOID THE HAZARD

Have the pr

for buried lines and do not plow in marked

areas.

operty or ar

, gas, and/or

ea being plowed.

.

ea to be plowed marked

DANGER

POTENTIAL HAZARD

•

Contact with moving plow may cause injury

WHA

T CAN HAPPEN

•

The moving plow can cut hands, feet, or other

body parts.

HOW T

•

• Befor

O AVOID THE HAZARD

Keep your hands, feet, and any other part of

your body or clothing away fr

e adjusting, cleaning, repairing, and

inspecting the plow

the engine, r

moving parts to stop.

, lower it to the ground, stop

emove the key

om moving parts.

, and wait for all

POTENTIAL HAZARD

•

When the plow is out of the gr

could be injur

The traction unit could be overturned by the

•

inertia of the swinging plow

WHA

T CAN HAPPEN

• Y

ou or bystanders could be crushed by the

traction unit or plow

HOW T

•

•

•

.

O AVOID THE HAZARD

Keep the plow low at all times.

Use caution when turning and do not turn

quickly.

Keep all bystanders at least 6 ft. (2 meters)

away while operating.

Vibration

This

unit has a maximum hand-arm vibration level of

7 m/s2 and

based on measurements of identical machines per EN

1033 and EN 1032.

Safety

1

Decals

ed by the swinging plow

.

Level

whole body vibration level of 0.2 m/s

2

ound, bystanders

.

3

.

2

4

WARNING

POTENTIAL HAZARD

•

When the engine is off, attachments in the

raised position can gradually lower

WHA

T CAN HAPPEN

•

Someone nearby may be pinned or injur

the attachment as it lowers.

HOW T

•

O AVOID THE HAZARD

Always lower the attachment lift each time you

shut off the traction unit.

.

ed by

5

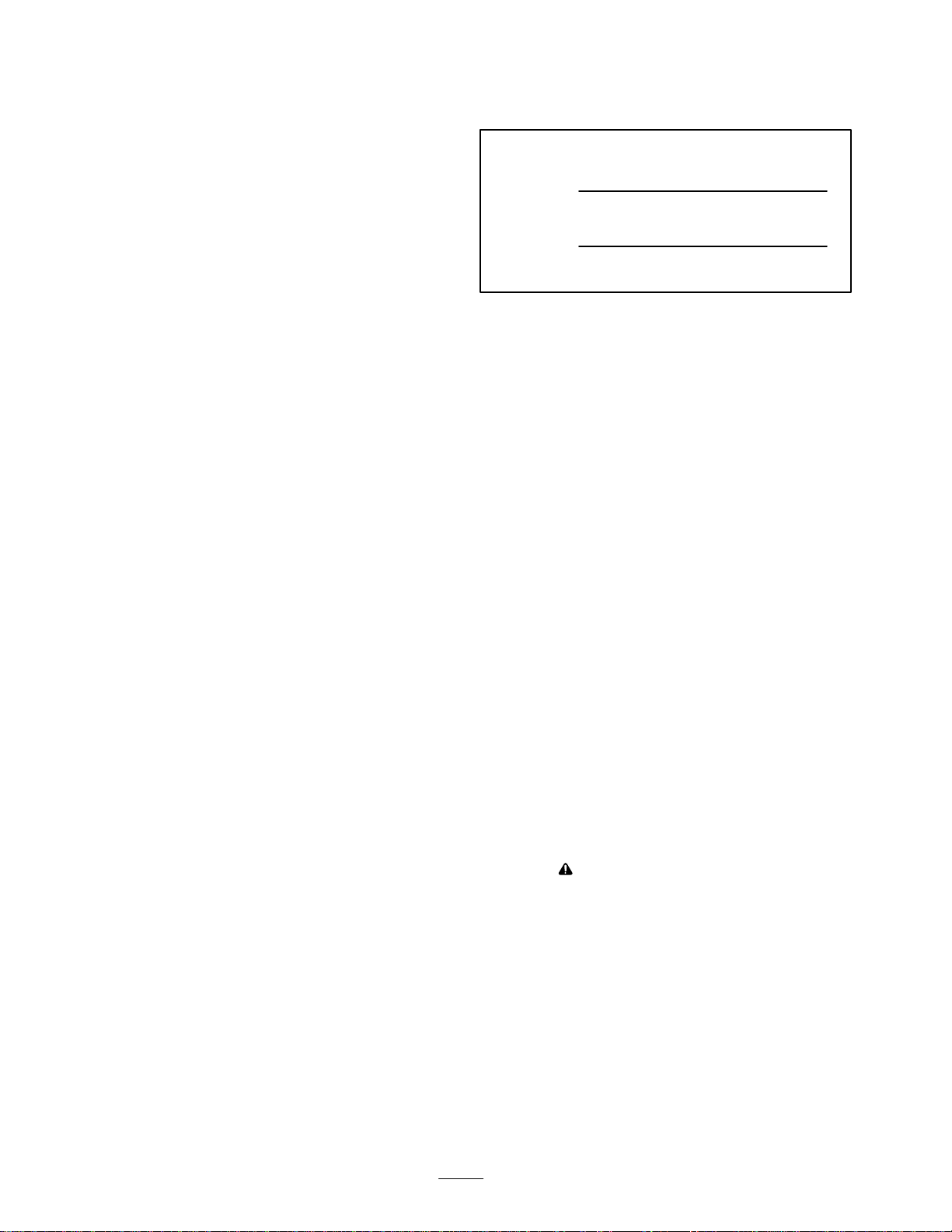

# 100–4649

1. Explosion

2.

Shock hazard

3. Pinching/crushing

hazard—hand

hazard

6

Figure 1

#

100–4650

4. Pinching/crushing

hazard—foot

Do not dig in areas with

5.

underground utility lines

6.

Keep bystanders away

6

3

Page 4

Specifications

Note:

Specifications and design are subject to change

without notice.

Width 29

Length

Height

W

eight (without blade)

Hydraulic motor

displacement

Plow cycles

inches (73.6 cm)

35 inches (89 cm)

24 inches (60 cm)

400 lbs (181.5 Kg)

1.27 in3/rev (20.8 cc)

1,528 VPM

WARNING

POTENTIAL HAZARD

•

Exceeding the maximum r

can cause the traction unit to tip.

WHA

T CAN HAPPEN

•

If the traction unit tips, you or bystanders could

be crushed.

HOW T

•

O AVOID THE HAZARD

Do not drive the traction unit on a slope steeper

than the maximum r

determined in the pr

traction unit operator’s manual.

ecommended slope

ecommended slope, as

evious table and the

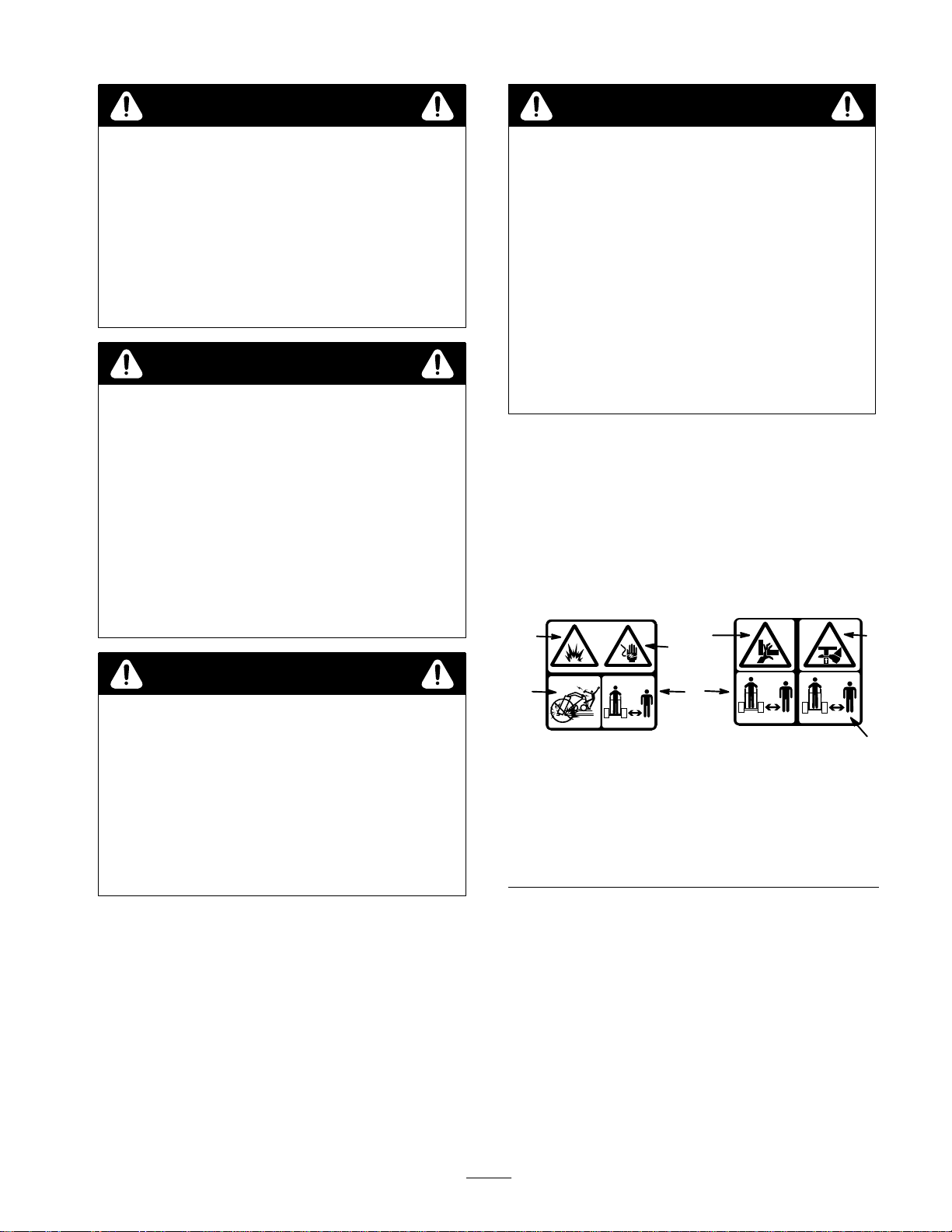

Stability

To

determine the maximum degree of slope you can

traverse with the plow installed on a traction unit, find the

stability rating for the hill orientation you want to travel in

the table below

rating and orientation in the Stability Data section of the

traction unit operator’s manual.

Orientation

Front Uphill

Ratings

, then find the degree of slope for the same

Stability Rating

C

Rear Uphill

D

Side Uphill

C

IMPORTANT:

operator’

on the platform while using the plow, or the traction

unit will become unstable.

If your traction unit has a r

s platform, the counterweight must be used

ear

4

Page 5

Installation

Loose

DESCRIPTION QTY. USE

Vibratory

Blade

Coulter

Installing

T

raction Unit

Refer

instructions on installing attachments onto the traction

unit and connecting hydraulic hoses.

Assembling

Installing the Blade

1. Raise

and install the cylinder locks.

2.

Stop the engine and remove the key

Parts

plow

the Plow on the

to your traction unit operator’s manual for complete

the Plow

the plow about 36 in. (1 m) of

f of the ground

.

1

1

1

Assemble the plow

Figure

1. Coulter

2. Completely

3.

4.

pin screw

remove the coulter pin screw

coulter pin (Fig. 4).

Put the coulter into the coulter bracket (Fig. 4).

Slide the coulter pin through the bracket and coulter

and secure it with the coulter pin screw and washer

(Fig. 4).

3

1

m–4154

, washer

, and

Remove the two click pins from the clevis pins in the

3.

blade bracket, then remove the clevis pins (Fig. 2).

4.

Slide the blade into the blade bracket and secure it at

the desired depth (a change in mounting holes will

change the depth by 3 in. (7.6 cm)), using the clevis

pins and click pins removed previously (Fig. 2).

1

3

1. Click

2.

Clevis pin

Figure

pin

2

3. Blade

Installing the Coulter

1. Back

out the coulter pin screw about 0.5 in. (1.3 cm),

then strike it several times with a hammer to loosen

the pin (Fig. 3).

2

m–4155

1

2

Figure

1. Coulter

2. Coulter

3.

5. Torque

Removing

T

raction Unit

Refer

instructions on removing attachments from the traction

unit and disconnecting hydraulic hoses.

1. W

pin

Coulter bracket

the screw to 45 ft. lbs (61 N

the Plow from the

to your traction unit operator’s manual for complete

ith the plow raised above the ground, stop the

engine.

3

4

5

4

4. Washer

5.

Coulter pin screw

⋅m).

m–4144

5

Page 6

2.

Remove the lower click pin and clevis pin securing the

blade to the plow (to completely remove the blade,

remove both the upper and lower click and clevis pins)

(Fig. 2).

3.

Swing the blade up and secure it as illustrated in

Figure 5.

CAUTION

POTENTIAL HAZARD

•

When you swing the blade up, you could dr

it.

WHA

T CAN HAPPEN

•

The blade could swing down a sever

you.

HOW T

•

O AVOID THE HAZARD

Always hold the blade secur

ely when moving it

and wear work boots.

4. T

ilt the plow forward and lower it to the ground or

trailer

, with the stand and coulter supporting the

weight of the plow (Fig. 5).

ely injur

op

Operation

Note:

Always use the traction unit to lift and move the

attachment.

Plowing

1.

Move the lynch pins to the outside holes on the spring

rods to allow the plow to move from side to side

(Fig. 6).

e

1. Outer

2. L

hole

ynch pin (in inner hole)

Figure

6

3.

Spring rod

1

3

2

m–4146

1

Figure

1. Stand 2. Coulter

5. Stop

the engine and remove the plow as directed in

5

your traction unit operator’s manual.

m–4337

CAUTION

POTENTIAL

•

When you r

fr

ee to swing.

WHA

2

T CAN HAPPEN

•

The plow could swing into you or a bystander

or cause the traction unit to become unstable.

HOW T

•

Hold the plow in the neutral position when

moving the lynch pins.

2.

Thread the tapered end of the tubing bullet into the

end of the tubing to be installed, ensuring that you

achieve a tight bond (Fig. 7).

1. Tubing

HAZARD

emove the lynch pin, the plow is

O AVOID THE HAZARD

1

2

Figure

bullet

7

2. Tubing

,

m–4153

6

Page 7

WARNING

CAUTION

POTENTIAL

•

The thr

•

If you ar

be frayed.

WHA

T CAN HAPPEN

•

The threads could cut you or others.

•

The wir

wounds.

HOW T

•

Keep away fr

only by the facetted end above the thr

Replace a frayed basket grip.

•

• W

ear leather gloves when handling either the

bullet or a basket grip.

3.

If your traction unit has a speed selector

slow (turtle) position.

4.

Start the engine.

5. T

ilt the attachment plate completely back so that the

top of the plow is parallel to the ground

(Fig. 9)

6.

Lower the plow so that it is resting on the ground.

HAZARD

eads on the bullet ar

e using a basket grip, the wir

es on a basket grip can cause punctur

O AVOID THE HAZARD

om the thr

e sharp.

eads, holding the bullet

, move it to the

es could

eads.

POTENTIAL HAZARD

•

When plowing on a hill, the plow can swing

down hill when raised out of the soil.

WHA

T CAN HAPPEN

•

Due to the weight of the plow

fast, the force could tip the traction unit

e

injuring you or others.

HOW T

•

10.

11.

12.

13.

Transporting

O AVOID THE HAZARD

When plowing on a hill, raise the plow out of

the gr

ound slowly

bullet is still in the soil.

Raise the plow out of the ground far enough to pull the

bullet out of the soil.

Move the traction unit rearward to pull out a working

length of pipe, then move forward slightly to create

some slack in the line.

Stop the engine.

Remove the tubing from the tubing bullet.

, letting it swing while the

the Plow

, if it swings too

IMPORTANT

the gr

ound befor

lever

. Failur

the traction unit, possibly resulting in damage.

Note:

If you dig a hole to lower the blade into before

starting, it will reduce the risk of bending the blade.

7.

Pull the auxiliary hydraulics lever to the operator grip

to engage the plow

Slowly lower the plow into the ground to the desired

8.

depth, while moving the traction unit backward.

IMPORTANT

gr

ound during operation, r

hydraulics lever to stop the plow befor

ough the surface. If you will continue plowing after

thr

br

eaking the surface, r

tubing.

When finished, release the auxiliary hydraulics lever

9.

to stop the plow

: Always ensur

e engaging the auxiliary hydraulics

e to do so will cause excessive vibration of

.

: If you need to raise the bullet out of the

.

e that the plow is on or in

elease the auxiliary

e br

eaking

etighten the bullet into the

1. Move

the lynch pins to the inside holes on the spring

rods to prevent side to side movement (Fig. 6).

CAUTION

POTENTIAL HAZARD

• Failur

WHA

•

HOW T

•

2.

Raise the loader arms just enough to ensure that the

blade clears the ground.

IMPORTANT

fully raised.

e to secur

side to side and unbalance the plow

T CAN HAPPEN

Due to the weight of the plow

fast, the force could tip the traction unit

injuring you or others.

O AVOID THE HAZARD

Always secur

the inner holes of the spring r

transporting the plow

e the plow will allow it to swing

.

, if it swings too

e the plow with the lynch pins in

ods befor

.

: Never transport the plow with the arms

e

7

Page 8

Gaging

Normally,

by the blade; however

Plow Depth

you will be plowing at the maximum depth set

, the plow is also equipped with a

gage to allow you to lift the plow and determine how high

above maximum depth you are plowing.

The gage is located on the the left side of the plow facing

the traction unit. A rod assembly runs from the gage to

the ground. When the plow is lifted, the indicator on the

gage moves down. Marks on the gage show the number

of inches lower or higher than the maximum depth that

you are plowing. The gage reads from +2 to –3 inches

(+5 to –7.6 cm), with zero being the maximum depth on

bare ground and –3 being 3 inches (7.6 cm) above

maximum depth. Figures 8 and 9 illustrate the gage.

When

plowing bare ground, maximum depth is indicated

on the gage as the zero mark. Y

ou can plow down to the

+1 mark, but in this case you will be contacting the

ground with the coulter axle. Plowing any lower may

damage the coulter

.

When plowing grass covered ground, the gage will read

about an inch lower than the actual depth because of the

grass. In this case, lower the plow to the desired coulter

depth and note the reading on the gage.

If you are transporting the plow or are plowing extremely

rough terrain, you can lock the gage at the +2 position to

keep it from being damaged. T

o lock the gage, manually

raise it to the +2 position and move the locking lever to

the left.

1

1. Depth

gage

2

Figure

8

2.

Gage locking lever

Tips

for Plowing

2

• When

plowing long runs it is advisable to install two

hairpin cotters through the spring and quick attach pins

on the mount plate (Fig. 10). This will ensure that the

vibration of the plow will not cause the pins to come

loose.

If your quick attach pins do not have holes in them

Note:

for the hairpin cotters, contact your dealer to obtain new

quick attach pins.

m–4145

1

Figure

1. Hairpin

• To

cotters

reduce wear on the traction unit drive chain (if your

10

m–4056

model has one), tighten the chain so there is only 2 in.

(5 cm) of slack on the upper span (refer to your

traction unit Operator’s Manual for instructions).

1. Gage

rod assembly

Figure

1

9

2.

Parallel to the ground

m–4336

•

Clean the area of trash, branches and rocks before

plowing to prevent equipment damage.

•

Always begin plowing with the slowest ground speed

possible. Increase speed if conditions permit.

•

Always use full throttle (maximum engine speed)

when plowing.

•

Always plow backwards (i.e., in reverse).

•

If your traction unit has a speed selector and a flow

divider

, move the speed selector to slow (turtle) and

the flow divider to the 10 o’clock position.

8

Page 9

• A

void sharp turns when plowing to increase

productivity and minimize ground disturbance.

•

If your traction unit has tires and you have the

agricultural or Sitework Systems tires installed on the

traction unit, remove the tires and move the right side

Maintenance

tires to the left and the left side tires to the right. This

will ensure that the tire tread points to the rear to give

you the most traction when using the vibratory plow

.

Service

Service

Grease pivot pin fittings

Gear lube oil—check level

Gear lube oil—change

Chipped surfaces—paint

Interval Chart

Operation

POTENTIAL

•

If you leave the key in the ignition switch, someone could start the engine.

WHA

T CAN HAPPEN

•

Accidental starting of the engine could seriously injur

HOW T

•

O AVOID THE HAZARD

Remove the key fr

Greasing

HAZARD

om the ignition switch befor

Each

Use5Hours25Hours

X X

X

CAUTION

e you or other bystanders.

e you do any maintenance.

Fitting Locations

200

Hours

X

Storage

Service

X

Notes

Service Interval/Specification

Grease

6 fittings, as shown in Figures 1

every 8 operating hours. Grease all fittings immediately

after every washing.

Grease Type: General-purpose grease.

1 through 14,

m–4146

Figure 11

9

Page 10

Lubrication

Service Interval/Specification

Check

the gear lubrication oil level in the gear case every

25 operating hours and change it every 200 operating

hours or once a year, whichever occurs first.

Gear lube type: SAE 90–140 API service GL–4 or GL–5

Figure 12

Figure 13

m–4150

m–4148

Refill capacity: 3 pints.

Checking Gear Lube

1. Position

and lower the attachment lift so that the plow is on the

ground.

Stop the engine and remove the key

2.

Check the clear glass gage on the side of the gear case

3.

(Fig. 15). The gear lube should be at the level of the

red dot in the center of the gage.

4.

If the gear lube level is low

(Fig. 15) and fill the case with gear lube until it is

level with the red dot in the gage.

the traction unit and plow on a level surface

.

, remove the fill plug

3

1

Figure 14

How to Grease

1. Lower

2.

3.

4.

5. W

the plow/loader arms, stop the engine, and

remove the key

.

Clean the grease fittings with a rag.

Connect a grease gun to the fittings.

Pump grease into the fittings until grease begins to

ooze out of the bearings.

ipe up any excess grease.

m–4151

1. Glass

2.

5. Replace

gage

Drain plug

the fill plug.

Changing Gear Lube

1. Position

2.

3.

4.

10

and lower the attachment lift so that the plow is on the

ground.

Stop the engine and remove the key

Prepare an appropriate container to catch the used oil

under the plow

Remove the drain plug (Fig. 15), allowing the oil to

spill out into the container

the traction unit and plow on a level surface

.

Figure

.

15

3.

2

Fill plug

m–4147

.

Page 11

5.

When finished, replace the drain plug, ensuring that it

is tight.

6.

Remove the fill plug (Fig. 15) and fill the case with

gear lube until it is level with the red dot in the gage.

7.

Replace the fill plug.

Storage

1.

Before long term storage, wash the attachment with

mild deter

2.

Grease the plow

gent and water to remove dirt and grime.

.

Troubleshooting

Check gear case lubrication.

3.

4.

Check and tighten all bolts, nuts, and screws. Repair or

replace any part that is damaged or worn.

5.

Ensure that all hydraulic couplers are connected

together to prevent contamination of the hydraulic

system.

Paint all scratched or bare metal surfaces. Paint is

6.

available from your Authorized Service Dealer

Store the attachment in a clean, dry garage or storage

7.

area. Cover it to protect it and keep it clean.

.

PROBLEM POSSIBLE

The plow does not operate.

CAUSES

1.

Hydraulic coupler not

completely connected

2.

Defective hydraulic coupler

3.

An obstruction in a hydraulic

hose

4.

Auxiliary valve on the traction

unit is not opening.

CORRECTIVE ACTION

1.

Check and tighten all couplers.

2.

Check couplers and replace

any that are defective.

3.

Find and remove the

obstruction.

4.

Repair the valve.

11

Page 12

Loading...

Loading...