Page 1

Form No. 3323–284

Over–the–Tire Tracks

Model 22457 and 22431

IMPORTANT:

all pr

ecautions listed ther

Loose

DESCRIPTION QTY. USE

Pivot

pin

Hex set–screw

Wheel spacers

Lug nuts (20 provided with the wheel spacers

and 20 on the traction unit)

Over–the–tire track assembly

Bolt

Locknut

Befor

Parts

e using this pr

e.

oduct, r

ead the safety section in your traction unit operator’s manual, and follow

2

2

4

40

2

4

4

Install on loader arm hydraulic cylinders

Install on wheels

Install on traction unit

Installation

Instructions

Installation

IMPORTANT:

the Sitework Systems or turf tread tir

over any other type of tir

machine.

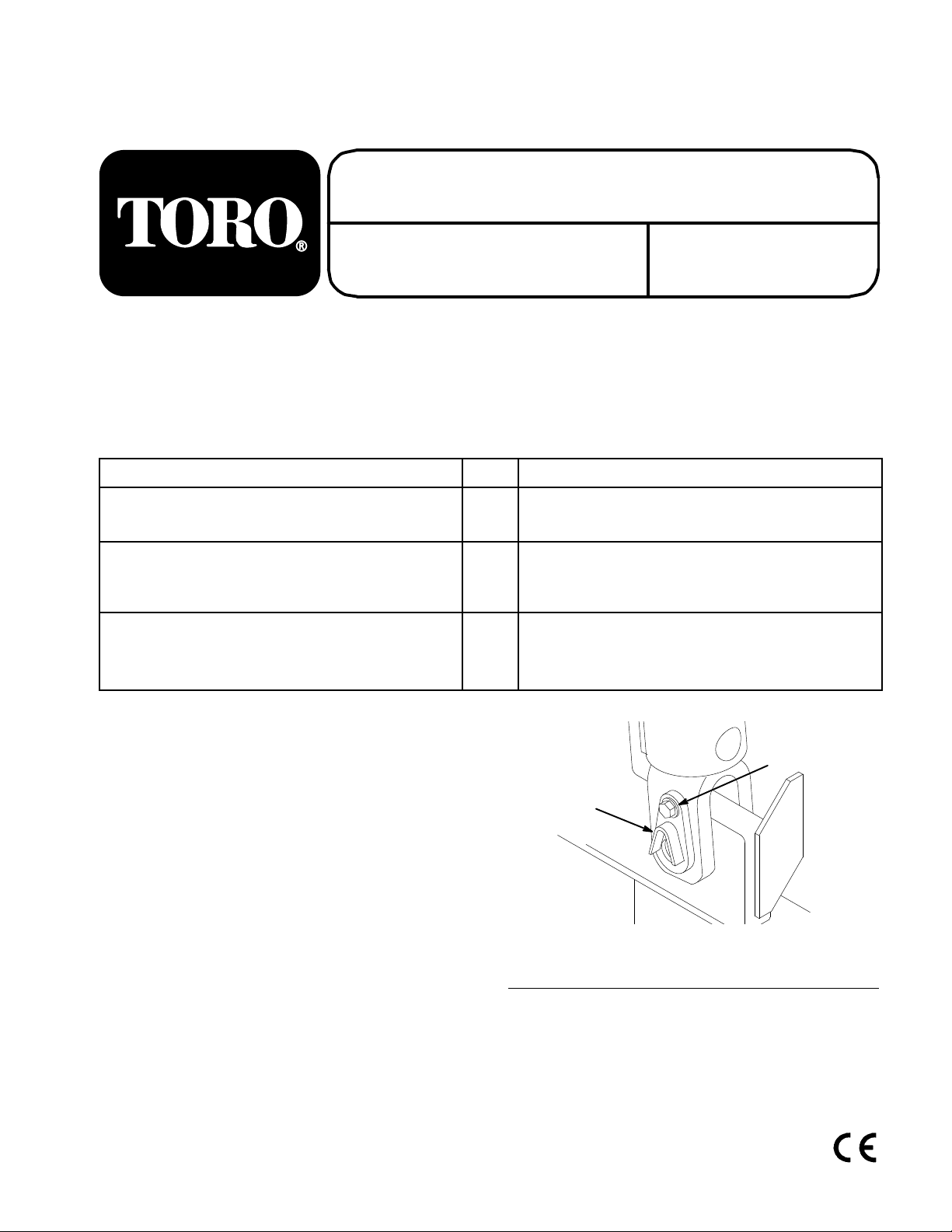

Installing Pivot Pins

Model

22457 Only

1.

Lower the loader arms as low as possible.

2. T

urn the traction unit of

Remove the existing pivot pin from the bottom of a

3.

loader arm hydraulic cylinder (Fig. 1). Retain the bolt

for later use.

The T

8111 Lyndale Ave. South

Bloomington, MN 55420–1196

The tracks must only be installed over

es. Installation

oro Company

e may r

– 1999

esult in damage to the

f and remove the key

.

1

1. Pivot

4. Remove

pin

the grease fitting from the center of the pivot

pin and discard the pin.

Figure

2

m–3933

1

2. Bolt

All Rights Reserved

Printed in the USA

Page 2

Installation Instructions

5.

Install the new pivot pin using the bolt removed in step

3 (Fig. 2).

3

4

1

2

3

1. Pivot

2. Bolt

pin

6. Thread

Figure

the grease fitting removed from the old pivot

2

Hex set–screw

3.

pin into the opening in the face of the new pivot pin.

7.

Connect a grease gun to the fitting. Pump grease into

the fitting until grease begins to ooze out of the

bearing.

ipe up any excess grease.

8. W

9.

Remove the grease fitting and replace it with the hex

set-screw (Fig. 2).

10.

Repeat steps 3 through 9 for the other loader arm

hydraulic cylinder

Store the grease fittings for future use (refer to

11.

.

Greasing Pivot Pins, page 3).

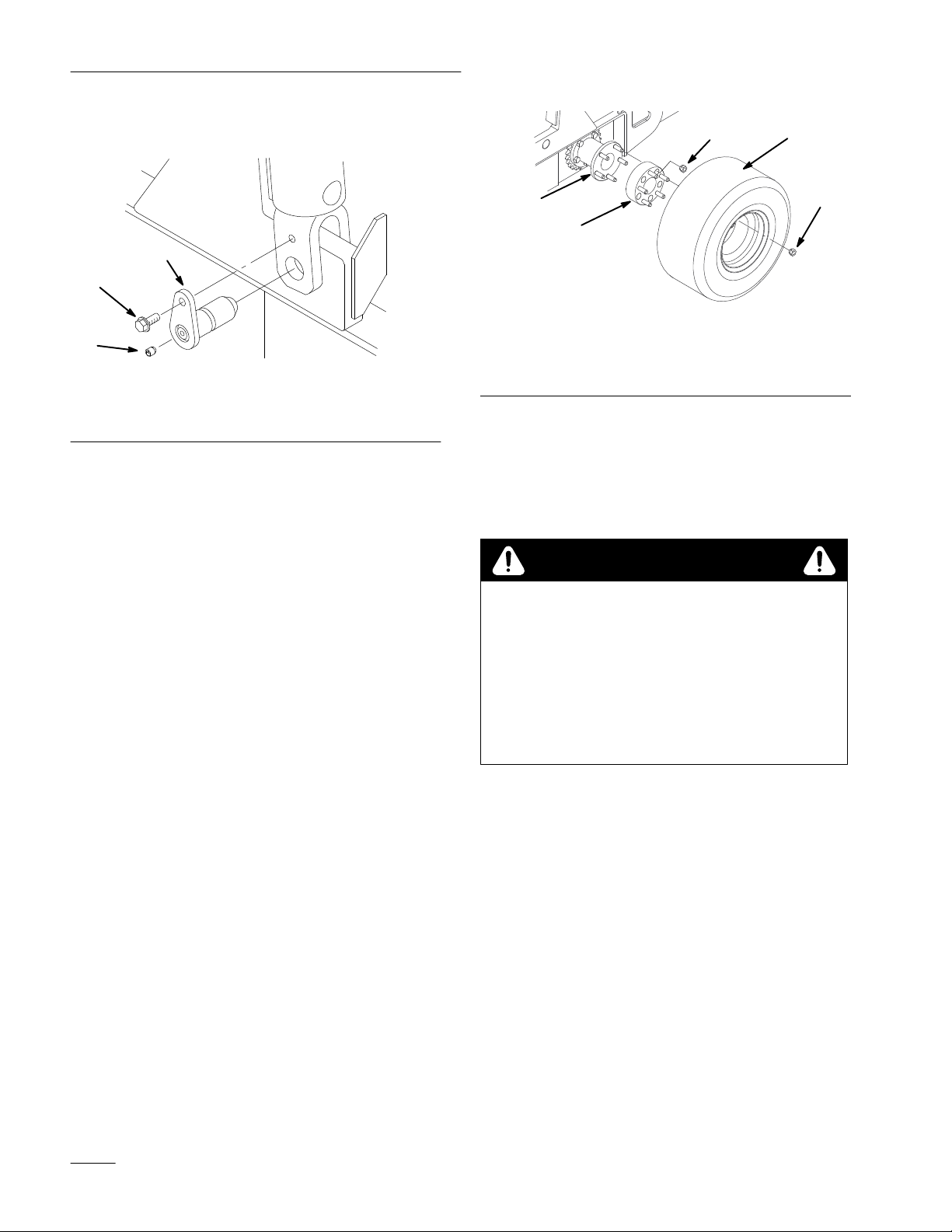

Installing Wheel Spacers

1. Put

the traction unit up on blocks and remove the

wheels.

Slide the wheel spacers onto the studs on the wheel

2.

hub and secure them with lug nuts

(Fig. 3). T

3.

Install the wheels on the studs on the wheel spacers

and secure them with lug nuts (Fig. 3). T

nuts to 55 ft-lbs (75 N·m).

orque the lug nuts to 55 in–lbs (75 N·cm).

orque the lug

m–3935

2

1

Figure

1. Wheel

2.

4. Return

5.

spacer

Wheel hub

the traction unit to the ground.

After the first 8 hours of operation, torque the lug nuts

3

3.

Lug nut

4. Wheel

again to 55 ft-lbs (75 N·m).

Installing the Tracks

CAUTION

POTENTIAL

•

Some ar

moving parts that can pinch.

WHA

T CAN HAPPEN

• Y

ou could be cut or pinched while handling the

tracks.

HOW T

• W

ear leather gloves while handling the tracks.

1.

Lay one track on a level surface.

2.

Drive the traction unit onto the track until both wheels

on one side are centered in the track.

3.

Pull the front and rear of the track up and over the tires

and secure them with a ratchet and straps (Fig. 4).

4.

Connect the track by installing (2) bolts and (2)

locknuts through the connector links on both sides of

the track (Fig. 4).

HAZARD

eas of the tracks have sharp edges and

O AVOID THE HAZARD

3

m–3900

2

Page 3

Installation Instructions

5

2

4

3

Figure

1. Track

2. Bolt

3. Locknut

5. Remove

6.

Repeat steps 1 through 4 for the other side of the

the ratchet and straps.

4

4. Connector

5.

Rachet and straps

link

traction unit.

7.

Drive the traction unit for a few minutes to loosen the

tracks.

Lay a long, straight bar across the top of each track.

8.

There should be 1 to 3 in. (25 to 76 cm) of slack in the

top span of the track below the bar (Fig. 5).

1

m–3899

Remove the bolts and nuts from the connector links

2.

and lay the track flat.

3.

Drive slowly of

4.

Place the bolts and nuts in the holes in the connector

f of the track.

for storage.

5.

Repeat steps 1 through 4 for the other track.

Operating Tips

WARNING

POTENTIAL

•

The moving tracks can pinch hands or feet.

WHA

T CAN HAPPEN

•

Injury or amputation could r

HOW T

•

Keep clear of the tracks during operation.

A

void operating on asphalt or concrete surfaces as damage

may occur to the surface, as well as excessive wear on the

tracks.

HAZARD

esult.

O AVOID THE HAZARD

Maintenance

1

Figure

1. 1

to 3 in. (25 to 76 cm)

9. If

there is too much or too little slack in the track,

5

adjust the track tension; refer to Adjusting T

ension, page 4.

T

Removing the Tracks

1. Stop

the traction unit so that one set of the bolted

connector links on a track is in the middle of the top

span.

rack

m–3898

Greasing Pivot Pins

Model

22457 Only

Grease the pivot pins on the hydraulic cylinders as

instructed in the traction unit Operator’s Manual. T

grease the pivot pins installed with the tracks, complete

the following procedure:

1.

Lower the loader arms as far as possible.

2. T

urn the traction unit of

Clean the face of each pivot pin with a rag.

3.

4.

Remove the hex set–screws from the center of the

f and remove the key

pivot pins.

5.

Thread the grease fittings removed from the old pivot

pins during installation into the openings vacated by

the set–screws.

6.

Connect a grease gun to each fitting. Pump grease

into the fittings until it begins to ooze out of the

bearings.

ipe up any excess grease.

7. W

8.

Remove the grease fittings and replace them with the

hex set–screws.

o

.

3

Page 4

Installation Instructions

Adjusting Track Tension

Check

the tension of the tracks every 25 operating hours

by laying a long, straight bar across the top of each track.

There should be 1 to 3 in. (25 to 76 cm) of slack in the top

span of the track below the bar (Fig. 5). If the track needs

adjustment, complete the following procedure:

Note:

When you adjust the traction drive chain (if you

traction unit has traction drive chains), the track may also

need to be adjusted.

1.

Park the traction unit so that one set of the bolted

connector links is in the middle of the top span.

2.

Remove the bolts from the connector and reconnect

them through the inner holes of the track section to

tighten the track (Fig. 6).

Note: T

o loosen the track you can move a connector

installed in an inner hole to the outer hole.

2

4

3

1. Track

2. Bolt

3. Check

Figure

the track tension and repeat steps 1 and 2 for

6

3. Locknut

4. Connector

link

one of the other adjustable track sections if additional

tensioning is required.

m–3899

1

Storage

1.

Before long term storage, wash the tracks with mild

deter

gent and water to remove dirt and grime.

2.

Check the condition of the tracks and tighten all bolts

and nuts. Repair or replace any part that is damaged or

worn.

Store the tracks in a clean, dry garage or storage area.

3.

Cover them to protect them and keep them clean.

4

Loading...

Loading...