FormNo.3395-258RevB

StumpGrinder

CompactUtilityLoaders

ModelNo.22429—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3395-258*B

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Useofthisproductmaycauseexposureto

chemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orother

reproductiveharm.

ThisproductcomplieswithallrelevantEuropeandirectives.

Fordetails,pleaseseetheDeclarationofIncorporation(DOI)

atthebackofthispublication.

Introduction

ThismachineisdesignedforuseonTorocompactutility

loaderstogrindandremovetreestumpsandsurfaceroots.It

isnotintendedtocutrockoranyothermaterialotherthan

woodandthesoilaroundastump.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

g013652

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

g000502

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Contents

Safety

Safety...........................................................................3

StabilityRatings.......................................................5

SafetyandInstructionalDecals.................................5

Setup............................................................................6

1AssemblingtheOperatorShield..............................6

2InstallingtheChipGuard.......................................8

ProductOverview..........................................................8

Specications.........................................................8

Attachments/Accessories.........................................8

Operation.....................................................................9

GrindingStumps.....................................................9

GrindingRoots......................................................10

TransportingtheStumpGrinderonaTrailer..............10

OperatingTips......................................................10

Maintenance.................................................................11

RecommendedMaintenanceSchedule(s)......................11

GreasingtheMachine.............................................11

ReplacingtheTeeth................................................12

Storage........................................................................12

Troubleshooting...........................................................13

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandthoseinthe

tractionunit

thesafetyalertsymbol,whichmeans

or

Danger

complywiththeinstructionmayresultinpersonalinjury

ordeath.

Operator's Man ual

—personalsafetyinstruction.Failureto

.Alwayspayattentionto

Caution

,

W ar ning

DANGER

Theremaybeburiedpower,gas,and/ortelephone

linesintheworkarea.Shockorexplosionmay

occurifyoudigintothem.

Havethepropertyorworkareamarkedforburied

linesanddonotdiginmarkedareas.Contactyour

localmarkingserviceorutilitycompanytohavethe

propertymarked(forexample,intheUnitedStates,

call811forthenationwidemarkingservice).

DANGER

,

Thestumpgrinderissolelydesignedandtestedfor

usegrindingstumpslessthan91cm(36inch)tall.

Anyotherusesmaycauseahazardoussituation

resultingininjuryordeathtoyouorbystanders.

Onlyusethestumpgrinderforgrindingstumps

lessthan91cm(36inch)tall.

WARNING

Whentheengineisoff,attachmentsintheraised

positioncangraduallylower.Someonenearbymay

bepinnedorinjuredbytheattachmentasitlowers.

Alwayslowertheattachmentlifteachtimeyoushut

offthetractionunit.

WARNING

Duringoperation,debriswillyinalldirections

andcancauseinjurytoeyesandotherexposed

bodyparts.

•Neveroperatethestumpgrinderwithoutthe

shieldinstalledonthetractionunitandthechip

guardonthegrinder.

•Wearpersonalprotectivegearduringoperation.

•Keepallbystandersatleast9m(30feet)away

fromtheworkarea.

3

WARNING

CAUTION

Whengoingupordownhill,themachinecould

overturniftheheavyendistowardthedownhill

side.Someonemaybepinnedorseriouslyinjured

bythemachineifitoverturns.

Operateupanddownslopeswiththeheavyendof

themachineuphill.Thisattachmentwillmakethe

frontendheavy.

WARNING

Ifyoudonotfullyseattheattachmentlocking

pinsintheattachmentmountplateholes,the

attachmentcouldfalloffofthetractionunitseverely

injuringtheoperatororbystanders.

•Ensurethatyoufullyseattheattachment

lockingpinsthroughtheholesintheattachment

mountplatebeforeliftingtheattachment.

•Ensurethattheattachmentmountplateisfreeof

anydirtordebristhatmayhindertheconnection

ofthetractionunittotheattachment.

Hydrauliccouplers,hydrauliclines/valves,and

hydraulicuidmaybehotandcanburnyouifyou

touchthem.

•Weargloveswhenoperatingthehydraulic

couplers.

•Allowthetractionunittocoolbeforetouching

hydrauliccomponents.

•Donottouchhydraulicuidspills.

•Refertoyourtractionunit

fordetailedinformationonsafelyconnectingan

attachmenttoyourtractionunit.

Operator’ s Man ual

WARNING

Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

CAUTION

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjectedinto

theskinmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththisformofinjury

organgrenemayresult.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks,

neveruseyourhands.

4

StabilityRatings

Todeterminethedegreeofslopeyoucantraversewith

thestumpgrinderinstalledonatractionunit,ndthe

stabilityratingforthehillpositionyouwanttotravelinthe

appropriatetablebelow ,thenndthedegreeofslopeforthe

sameratingandhillpositionintheStabilityDatasectionof

thetractionunitOperator’ sManual.

WARNING

Exceedingthemaximumrecommendedslope

cancausethetractionunittotip,crushingyouor

bystanders.

Donotdrivethetractionunitonaslopesteeper

thanthemaximumrecommendedslope,as

determinedinthefollowingtablesandthetraction

Operator's Man ual

unit

Important:IfyouhaveatractionunitotherthanaTX

compactutilityloader,donotusethecounterweight

.

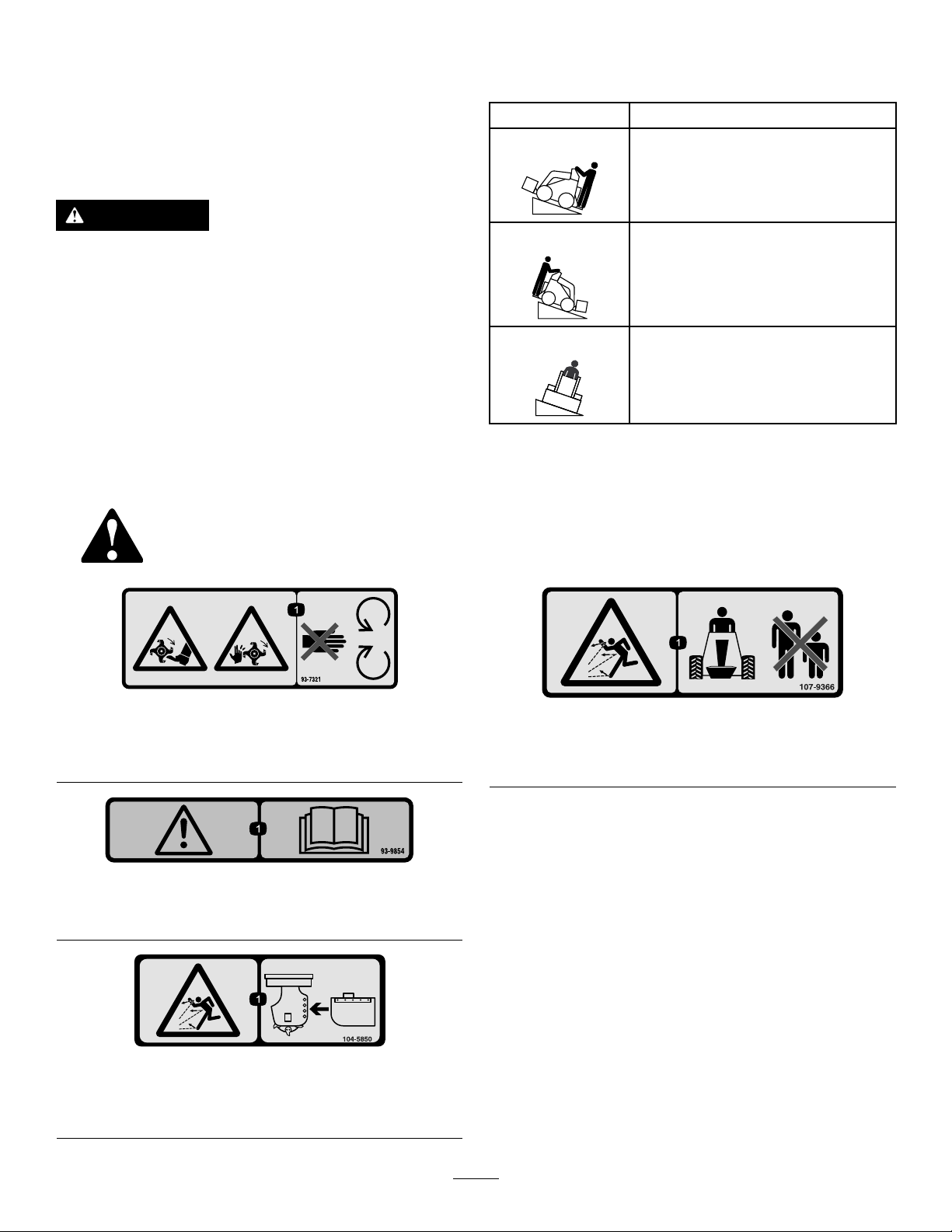

SafetyandInstructionalDecals

onthetractionunitwhenusingthestumpgrinder.If

youusethecounterweight,thetractionunitwillbeless

stableinthefrontandsideuphillpositions.

OrientationStabilityRating

FrontUphill

D

RearUphill

C

SideUphill

C

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93-7321

1.Cutting/dismembermenthazardofhandsandfeet,rotating

knives/blades—stayawayfrommovingparts.

93-9854

1.Warning—readtheOperator’sManual.

decal93-7321

107-9366

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

decal93-9854

decal107-9366

104-5850

1.Thrownobjecthazard—donotoperatewithoutthechip

guardproperlyinstalled.

decal104-5850

5

Setup

g013653

1

2

3

4

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

1

AssemblingtheOperator Shield

Rightshieldbracket1

Leftshieldbracket

Self-tappingscrew(5/16x3/4inch)

Shieldsupport

Shield

Bolt(1/4x1-1/2inch)

Washer6

Locknut(1/4inch)

TXbracketmountingtemplate1

Chipguard

Guardpin

Hairpincotter1

Qty.

Use

1

4

2

1

6

6

1

1

Assembletheoperatorshield.

Installthechipguard.

Partsneededforthisprocedure:

1Rightshieldbracket

1

Leftshieldbracket

4

Self-tappingscrew(5/16x3/4inch)

2

Shieldsupport

1

Shield

6

Bolt(1/4x1-1/2inch)

6Washer

6

Locknut(1/4inch)

1TXbracketmountingtemplate

InstallingtheShieldBracketona200

or300SeriesTractionUnit

1.Insertthetabontheshieldbracketintotheliftpoint

holeonthetractionunit,withtheholeinthebracket

aligningwiththesmallholeinthetractionunitframe

(Figure3).

Note:Thereisarightandleftbracket.Ensurethat

youinstallthecorrectbracketoneachside.Thetab

shouldbeintheliftpointholeandthebracketshould

beontheoutsideoftheframe(Figure3).

Figure3

1.Shieldbracket

2.Lift-pointhole4.Self-tappingscrew

2.Securethebrackettotheframewithaself-tapping

screw(Figure3).

3.Repeatsteps1and2fortheothersideofthetraction

unit.

3.Tab

InstallingtheShieldBracketonaTX

TractionUnit

1.Measureinfromtheedgesoftheframeasillustrated

inFigure4andmarkthelocationsoftheholesfor

mountingtheshieldbracket.

Note:Iftheholesexist,skiptostep3.

g013653

6

g013654

0.56 inch

(1.42 cm)

1.8 inch

(4.57 cm)

1.8 inch

(4.57 cm)

1

g013655

1

2

Figure5

g013656

1

2

3

4

5

6

7

1.Self-tappingscrew2.Shieldbracket

4.Securethebrackettotheframewith2self-tapping

screwsasillustratedinFigure5.

5.Repeatsteps1through4fortheothersideofthe

tractionunit.

AssemblingtheShield

g013655

g013654

Figure4

1.Mountingholes

bracketsonthetractionunit(Figure6).

2.Drillahole(5/16inchdiameter)throughtheframe

ateachmarkedlocation.

3.Alignthetabontheshieldbracketwiththefrontedge

oftheframewiththebracketinsideoftheloaderarm

pocket(Figure5).

1.Slidetheshieldsupportsintothepocketsintheshield

Note:Thereisarightandleftbracket.Ensurethat

youinstallthecorrectbracketoneachside.Thetab

shouldbeovertheframeedgeandthebracketshould

beinsidetheloaderarmpocketwiththe2smaller

holesinthebracketlinedupwiththeholesyoudrilled

intheframe(Figure5).

g013656

Figure6

1.Locknut

2.Washer

3.Shield7.Shieldbracket

4.Bolt

5.Skirt

6.Shieldsupport

7

2.Assembletheshieldandexibleskirttotheshield

g013657

1

2

3

4

5

supportsasillustratedinFigure6,using6bolts(1/4x

1-1/2inch),washers,andlocknuts(1/4inch).

Note:Theskirtshoulddrapeovertheengineorhood.

2

InstallingtheChipGuard

Partsneededforthisprocedure:

1

Chipguard

1

Guardpin

1Hairpincotter

ProductOverview

Procedure

Thestumpgrinderhas4setsofmountingholesfor

positioningthechipguard(Figure7).Movetheguardup

(upperholes)whenyouaregrindingclosetothegroundand

down(lowerholes)whenyouarechippingtallstumps.Install

thechipguardasfollows:

1.Positionthemountingtubeontheguardbetween2

holesonthegrinder(Figure7).

Figure7

1.Guardpin

2.Mountingholes5.Hairpincotter

3.Chipguard

4.Mountingtube

g013651

Figure8

1.Chipguard4.Stumpgrindinghead

2.Mountingplate5.Teeth

3.Pivotbolt

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Width,withchipguard

Width,withoutchipguard

Length

Height

Weight

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

g013657

attachmentsandaccessories.

112cm(44inches)

66cm(26inches)

51cm(20inches)

79cm(31inches)

120Kg(265lb)

2.Slidetheguardpinthroughtheholesinthegrinder

andthemountingtube(Figure7).

3.Securethepinwithahairpincotter(Figure7).

8

Operation

WARNING

Duringoperation,debriswillyinalldirections

andcancauseinjurytoeyesandotherexposed

bodyparts.

•Neveroperatethestumpgrinderwithoutthe

shieldinstalledonthetractionunitandthechip

guardonthegrinder.

•Wearpersonalprotectivegearduringoperation.

•Keepallbystandersatleast30feet(9m)away

fromtheworkarea.

RefertoyourtractionunitOperator’sManualformore

informationoninstallingandremovingattachmentsonyour

tractionunit.

Important:Alwaysusethetractionunittoliftandmove

theattachment.

GrindingStumps

5.Swingthegrindertowardyouusingtheattachment

tiltlever,grindingatadepthof0.5to5cm(1/4to

2inches),dependingonthehardnessofthewood

(Figure9).

Note:Ifyoutaketoodeepofacut,thegrinderwill

stall.Ifitstalls,raiseitslightlyandtryagain.

6.Swingthegrinderbackout(Figure9),lowerit0.5to5

cm(1/4to2inches)andrepeatsteps4through6until

youhavegrounddownafewinches.

7.Raisetheloaderarmstotheoriginalheight.

8.Movethegrindertotheright(Figure9).

9.Repeatsteps4through8untilyoureachtherightside

ofthestump.

10.Returnthegrindertotheleftsideofthestump,lower

it,andrepeatsteps3through10untilyouhaveground

thestumpintotheground.

Note:Tocontainthechips,youmayneedtostopthe

grinderandmovethechipguardupasyoumovethe

grinderdown.

11.Whennished,stopthegrinderbymovingtheauxiliary

hydraulicsleverintoneutral.

1.Ifyourtractionunithasaspeedselector,setittothe

Slow(turtle)position.

2.Starttheengine.

3.Pulltheauxiliaryhydraulicslevertotheoperatorgrip

toengagethestumpgrinder.

4.Positionthegrinderontheleftsideandbehindthe

stump(Figure9).

Figure9

g013658

9

GrindingRoots

1.Stopthegrinderandhangitverticallyfromtheloader

armsafewcentimeters(inches)offtheground.

2.Stoptheengineandremovethekey.

3.Loosenthelargeboltonthetopofthegrinder(Figure

10).

TransportingtheStump GrinderonaTrailer

Placetheattachmentonatrailerortruckcapableofcarrying

it.Securelytieittothetrailerortruckusingtiestraps

appropriatefortheweightoftheattachmentandforhighway

use.

Important:Removetheoperator'sshieldbefore

transportingthetractionunittoavoiddamagetothe

shieldofthetractionunit.

OperatingTips

•Alwaysusefullthrottle(maximumenginespeed).

•Nevertransporttheattachmentwiththeloaderarms

raised.Keepthearmsloweredandtheattachmenttilted

up.

•Ifyourtractionunithasaspeedselector(presentonsome

wheeledtractionunits),setittotheslow(turtleposition).

•Ifyourtractionunithasaowdivider(presentonsome

wheeledtractionunits),adjustittoapproximatelythe10

o’clockposition.

Figure10

1.Largebolt—loosen2.Frontbolt—remove

4.Removethefrontboltandnutsecuringthegrinder

(Figure10).

5.Swingthegrinder30degreesclockwise(Figure10).

6.Torquethelargeboltontopofthegrinderto406N-m

(300ft-lb)(Figure10)

7.Installtheboltandnutinthefrontholeandtorque

themto101N-m(75ft-lb)(Figure10).

8.Startthetractionunitandstartthegrinder.

9.Lowerthegrinderintotheroot.

10.Movethegrinderalongthelengthoftherootby

movingthetractionunitovertheroot.

11.Whennished,stopthegrinderbymovingtheauxiliary

hydraulicsleverintoneutral.

12.Loosenthelargeboltonthetopofthegrinder(Figure

10).

13.Removethefrontboltandnutsecuringthegrinder

(Figure10).

14.Swingthegrinder30degreescounter-clockwise(Figure

10).

15.Torquethelargeboltontopofthegrinderto406N-m

(300ft-lb)(Figure10).

16.Installtheboltandnutinthefrontholeandtorque

themto101N-m(75ft-lb)(Figure10).

g013659

10

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Beforeeachuseordaily

Beforestorage

MaintenanceProcedure

•Greasethemachine.

•Checktheconditionoftheteethandrotateorreplaceanythatarewornordamaged.

•Greasethemachine.

•Paintchippedsurfaces.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldstarttheengine.Accidentalstartingofthe

enginecouldseriouslyinjureyouorbystanders.

Removethekeyfromtheignitionswitchbeforeyoudoanymaintenance.

GreasingtheMachine

ServiceInterval:Beforeeachuseordaily

Beforestorage

Grease2ttings,asshowninFigure11,everydayand

immediatelyaftereverywashing.

Figure11

GreaseType:General-purposegrease

1.Stoptheengineandremovethekey.

2.Cleanthegreasettingswitharag.

3.Connectagreaseguntoeachtting.

4.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings.

5.Wipeupanyexcessgrease.

g013660

11

ReplacingtheTeeth

ServiceInterval:Beforeeachuseordaily—Checkthe

conditionoftheteethandrotateor

replaceanythatarewornordamaged.

Duetothehighamountofwearplacedontheteeth,youwill

needtorotateandreplacethemperiodically.

Eachtoothisindexedwiththreepositionssoyoucanrotate

ittwice,exposinganewsharpedgebeforereplacingthe

tooth.Torotateatooth,loosenthenutsecuringthetooth

(Figure12).Pushthetoothforwardandrotateitonethird

ofaturn,bringinganunusededgetotheoutside.Torquethe

nutsecuringthetoothto37to45N-m(27to33ft-lb).

Storage

1.Beforelongtermstorage,brushthedirtfromthe

attachment.

2.Checktheconditionoftheteeth.Turnorreplaceany

wornordamagedteeth.

3.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamagedorworn.

4.Ensurethatallhydrauliccouplersareconnected

togethertopreventcontaminationofthehydraulic

system.

5.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDealer.

6.Storetheattachmentinaclean,drygarageorstorage

area.Coverittoprotectitandkeepitclean.

Figure12

(Yourgrinder'sappearancemayvaryfromthatshownin

theillustration)

1.Nut3.Tooth

2.Toothholder

Toreplaceatooth,removethenutsecuringthetoothto

removeit,theninstallanewtoothandnutinthesame

position(Figure12).Torquethenutsecuringthetoothto

37to45N-m(27to33ft-lb).

g013417

12

Troubleshooting

Problem

Cuttingdiskstopsduringcutting.

Thecuttingdiskdoesnotturn.

Thegrinderdoesnotcutfastenough.

PossibleCauseCorrectiveAction

1.Toodeepofacut.1.Raisetheloaderarms13mm(1/2

2.Teethworn,damaged,orbroken.2.Rotateorreplaceanyworn,damaged,

1.Ahydrauliccouplerisnotcompletely

connected.

2.Ahydrauliccouplerisdamaged.

3.Thereisanobstructioninahydraulic

hose.

4.Anauxiliaryvalveonthetractionunit

isnotopening.

5.Hydraulicmotororchaindrivefailure.5.ContactyourAuthorizedService

1.Wornteeth.1.Rotateorreplaceanywornteeth.

2.Wrongsettingonowdividerand

speedlever(applicablewheeledunits

only).

3.Thereisarestrictioninaquickcoupler

orhose.

4.Thehydraulicsystemistoohot.

5.Thereliefvalveissetbelow

specications.

inch).

orbrokenteeth.

1.Checkandtightenallcouplers.

2.Check/replacecouplers.

3.Findandremovetheobstruction.

4.Repairthevalve.

Dealer.

2.Settheowdividertothe10:00

positionandthespeedlevertothe

turtleposition.

3.Checkthehosesandcouplersand

repairanyproblemsfound.

4.Shutdownandallowthesystemto

cool.

5.ContactyourAuthorizedService

Dealer.

Thecuttingdiskturnsinthewrong

direction

1.Theauxiliaryvalveleverisinthewrong

position.

2.Thehydraulichosesarereversed.2.Disconnecthosesandswitchpositions.

1.Movetheauxiliaryvalvelevertothe

rearwardposition.

13

DeclarationofIncorporation

TheT oroCompany,8111LyndaleAvenueSouth,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.

22429315000001andUp

SerialNo.

ProductDescriptionInvoiceDescription

StumpGrinder

STUMPGRINDER

ATT ACHMENTCE

GeneralDescription

StumpGrinder2006/42/EC

Directive

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedToromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:EUTechnicalContact:

MarcelDutrieux

ManagerEuropeanProductIntegrity

ToroEuropeNV

Nijverheidsstraat5

2260Oevel

JoeHagerBelgium

Sr.EngineeringManager

811 1LyndaleAve.South

Bloomington,MN55420,USA

February4,2015

Tel.+3216386659

InternationalDistributorList

Distributor:

AgrolancKft

BalamaPrimaEngineeringEquip.HongKong85221552163

B-RayCorporation

CascoSalesCompany

CeresS.A.CostaRica

CSSCTurfEquipment(pvt)Ltd.SriLanka

CyrilJohnston&Co.

CyrilJohnston&Co.RepublicofIreland

EquiverMexico525553995444ParklandProductsLtd.NewZealand6433493760

FemcoS.A.Guatemala

ForGarderOU

G.Y .K.CompanyLtd.

GeomechanikiofAthensGreece

GolfinternationalTurizm

GuandongGoldenStarChina

HakoGroundandGardenSweden

HakoGroundandGarden

HayterLimited(U.K.)

HydroturfInt.CoDubai

HydroturfEgyptLLC

IrrimacPortugal351212388260ToroEuropeNVBelgium3214562960

IrrigationProductsInt'lPvtLtd.India0091442449

JeanHeybroekb.v.Netherlands31306394611VictusEmakPoland48618238369

Country:

Hungary3627539640

Korea82325512076

PuertoRico7877888383

NorthernIreland442890813121

Estonia3723846060

Japan81726325861

Turkey902163365993Riversa

Norway4722907760

UnitedKingdom441279723444

UnitedArabEmirates97143479479T-MarktLogisticsLtd.Hungary3626525500

Egypt2025194308ToroAustraliaAustralia61395807355

PhoneNumber:Distributor:

5062391138

94112746100

442890813121

5024423277

30109350054

862087651338

4635100000

4387

Country:

MaquiverS.A.Colombia

MaruyamaMfg.Co.Inc.

Mountelda.s.CzechRepublic

Mountelda.s.Slovakia

MunditolS.A.

NormaGarden

OslingerTurfEquipmentSA

OyHakoGroundandGarden

Ab

Perfetto

PratoverdeSRL.

Prochaska&Cie

RTCohen2004Ltd.

LelyTurfcare

SolvertS.A.S.

SpyprosStavrinidesLimitedCyprus

SurgeSystemsIndiaLimited

ValtechMorocco21253766

Japan81332522285

Argentina54114821

Russia749541 16120

Ecuador59342396970

Finland35898700733

Poland48618208416

Italy390499128

Austria4312785100

Israel97298617979

Spain

Denmark4566109200

France331308177

India911292299901

Phone

Number:

5712364079

420255704

220

420255704

220

9999

128

34952837500

00

35722434131

3636

EuropeanPrivacyNotice

TheInformationToroCollects

ToroWarrantyCompany(T oro)respectsyourprivacy.Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalT orocompanyordealer.

TheT orowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIV ACYNOTICE.

TheWayT oroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.ToromayshareyourinformationwithT oro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany.Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw .

Toro'sCommitmenttoSecurityofYourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailatlegal@toro.com.

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalToroDealer.

374-0269RevH

TheToroUndergroundWarranty

ALimitedWarranty

Underground

Equipment

ConditionsandProductsCovered

TheToroCompanyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourToroUnderground

Equipment(“Product”)tobefreefromdefectsinmaterialsorworkmanship.

Whereawarrantableconditionexists,wewillrepairtheProduct

atnocosttoyouincludingdiagnostics,labor,andparts.

ThefollowingwarrantyappliesfromthedatetheProductisdeliveredtothe

originalretailpurchaserorrentalowner.

ProductsWarrantyPeriod

EnginePoweredUnits&FluidMixers

AllSerializedAttachments

RockHammer6months

Engines

1yearor1000operatinghours,

whicheveroccursrst

1year

Throughenginemanufacturers:

2yearsor2000operatinghours,

whicheveroccursrst

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheUndergroundDealerfromwhomyou

purchasedtheProductassoonasyoubelieveawarrantablecondition

exists.IfyouneedhelplocatingaUndergroundDealer ,orifyouhave

questionsregardingyourwarrantyrightsorresponsibilities,youmay

contactusat:

ToroCustomerCare

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFreeat855-493-0088(U.S.Customers)

1-952-948-4318(InternationalCustomers)

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto:brakes,lters,lights,

bulbs,belts,tracksortires,diggingteeth,diggingbooms,digging,

drive,ortrackchains,trackpads,drivesprockets,idlers,rollers,

blades,cuttingedges,orothergroundengagingcomponents.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear ,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecals,etc.

•Haulingexpenses,traveltime,mileage,orovertimeassociatedwith

transportingproducttotheauthorizedT orodealer.

Parts

Partsscheduledforreplacementasrequiredmaintenanceinthe

Operator’sManual,arewarrantedfortheperiodoftimeuptothescheduled

replacementtimeforthatpart.Partsreplacedunderthiswarrantyare

coveredforthedurationoftheoriginalproductwarrantyandbecomethe

propertyofT oro.T orowillmakethenaldecisionwhethertorepairany

existingpartorassemblyorreplaceit.Toromayuseremanufacturedparts

forwarrantyrepairs.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroUndergroundDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourUndergroundDealer’sserviceorhavedifculty

obtainingguaranteeinformation,contacttheToroimporter.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oro

Dealer.

374-0292RevB

Loading...

Loading...