FormNo.3430-923RevA

StumpGrinder

CompactToolCarrier

ModelNo.22429—SerialNo.404320000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3430-923*A

ThisproductcomplieswithallrelevantEuropean

directives.Fordetails,pleaseseetheDeclarationof

Incorporation(DOI)atthebackofthispublication.

WARNING

CALIFORNIA

Proposition65Warning

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

ThismachineisdesignedforuseonTorocompact

toolcarrierstogrindandremovetreestumpsand

surfaceroots.Itisnotintendedtocutrockoranyother

materialotherthanwoodandthesoilaroundastump.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

g245347

Figure1

1.Modelandserialnumberlocation

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Y ouareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactT orodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2019—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Contents

Safety

Safety.......................................................................3

GeneralSafety...................................................3

SlopeSafety.......................................................3

StumpGrinderSafety.........................................4

MaintenanceandStorageSafety........................4

SafetyandInstructionalDecals..........................5

Setup........................................................................6

1PreparingtheTractionUnit..............................6

2InstallingtheShieldBrackets...........................6

3AssemblingtheOperatorShield.......................9

4InstallingtheChipGuard................................10

ProductOverview....................................................11

Specications...................................................11

Operation.................................................................11

InstallingandRemovingtheAttachment............11

GrindingStumps...............................................12

GrindingRoots.................................................13

TransportPosition............................................13

TransportingtheStumpGrinderona

Trailer............................................................13

OperatingTips.................................................13

Maintenance...........................................................14

RecommendedMaintenanceSchedule(s)...........14

GreasingtheMachine.......................................14

ReplacingtheTeeth..........................................15

Storage...................................................................16

Troubleshooting......................................................17

DANGER

Theremaybeburiedutilitylinesinthework

area.Diggingintothemmaycauseashock

oranexplosion.

Havethepropertyorworkareamarkedfor

buriedlinesanddonotdiginmarkedareas.

Contactyourlocalmarkingserviceorutility

companytohavethepropertymarked(for

example,intheUS,call811orinAustralia,

call1100forthenationwidemarkingservice).

GeneralSafety

Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.

•Donottransportanattachmentwiththearms

raised.Alwaystransporttheattachmentcloseto

theground;refertoTransportPosition(page13).

•Havethepropertyorworkareamarkedforburied

linesandotherobjects,anddonotdiginmarked

areas.

•ReadandunderstandthecontentofthisOperator’s

Manualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Neverallowchildrenoruntrainedpeopleto

operatethemachine.

•Keepyourhandsandfeetawayfromthemoving

componentsandattachments.

•Donotoperatethemachinewithouttheguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepbystandersandpetsawayfromthemachine.

•Stopthemachine,shutofftheengine,andremove

thekeybeforeservicing,fueling,orunclogging

themachine.

Improperlyusingormaintainingthismachinecan

resultininjury.T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

SlopeSafety

•Operatethemachineupanddownslopeswith

theheavyendofthemachineuphill.Weight

distributionchangeswithattachments.This

3

,which

attachmentmakesthefrontofmachinetheheavy

end.

•Keeptheattachmentintheloweredposition

whenonslopes.Raisingtheattachmentona

slopeaffectsthestabilityofthemachine.

•Slopesareamajorfactorrelatedtolossofcontrol

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Operatingthemachineonany

slopeoruneventerrainrequiresextracaution.

•Establishyourownproceduresandrulesfor

operatingonslopes.Theseproceduresmust

includesurveyingthesitetodeterminewhich

slopesaresafeformachineoperation.Always

usecommonsenseandgoodjudgmentwhen

performingthissurvey.

StumpGrinderSafety

•Forwheeledmachines,donotusethe

counterweightonthetractionunitwhenusingthe

stumpgrinder.

•Neveroperatethestumpgrinderwithouttheshield

installedonthetractionunitandthechipguard

onthegrinder.

•Keepallbystandersatleast9m(30ft)awayfrom

theworkarea.

•Onlyusethestumpgrinderforgrindingstumps

lessthan91cm(36inch)tall.

MaintenanceandStorage

•Slowdownanduseextracareonhillsides.Ground

conditionscanaffectthestabilityofthemachine.

•Avoidstartingorstoppingonaslope.Ifthe

machinelosestraction,proceedslowly,straight

downtheslope.

•Avoidturningonslopes.Ifyoumustturn,turn

slowlyandkeeptheheavyendofthemachine

uphill.

•Keepallmovementsonslopesslowandgradual.

Donotmakesuddenchangesinspeedor

direction.

•Ifyoufeeluneasyoperatingthemachineona

slope,donotdoit.

•Watchforholes,ruts,orbumps,asuneventerrain

couldoverturnthemachine.T allgrasscanhide

obstacles.

•Usecautionwhenoperatingonwetsurfaces.

Reducedtractioncouldcausesliding.

•Evaluatetheareatoensurethatthegroundis

stableenoughtosupportthemachine.

•Usecautionwhenoperatingthemachinenearthe

following:

Safety

•Checkfastenersatfrequentintervalsforproper

tightnesstoensurethattheequipmentisinsafe

operatingcondition.

•RefertotheOperator’sManualforimportant

detailsifyoustoretheattachmentforanextended

periodoftime

•Maintainorreplacesafetyandinstructionlabels,

asnecessary.

–Drop-offs

–Ditches

–Embankments

–Bodiesofwater

Themachinecouldsuddenlyrolloverifatrack

goesovertheedgeortheedgecavesin.Maintain

asafedistancebetweenthemachineandany

hazard.

•Donotremoveoraddattachmentsonaslope.

•Donotparkthemachineonahillsideorslope.

4

SafetyandInstructional

Decals

Safetydecalsandinstructionsare

easilyvisibletotheoperatorandare

locatednearanyareaofpotential

danger.Replaceanydecalthatis

damagedormissing.

decal133-8061

133-8061

decal136-5814

136-5814

1.Warning—readthe

Operator'sManual.

2.Cutting/dismemberment

hazardofhands

andfeet,rotating

knives/blades—waitforall

movingpartstostop;keep

allguardsandshieldsin

place.

3.Thrownobject

hazard—keepallguards

andshieldsinplace;keep

bystandersawayfromthe

machine.

136-5817

1.Cutting/dismembermenthazardoffoot,rotating

knives/blades—waitforallmovingpartstostop;keephands

andfeetawayfrommovingparts.

decal136-5817

136-5818

1.Thrownobjecthazard—keepallguardsandshieldsin

place;keepbystandersawayfromthemachine.

decal136-5818

5

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

Nopartsrequired

Rightshieldbracket(3holes)—200/300

SeriesorTX400/500Seriesonly

Leftshieldbracket(3holes)—200/300

SeriesorTX400/500Seriesonly

Self-tappingscrew(5/16x3/4inch)

Rightshieldbracket(2holes)—TX1000

only

Leftshieldbracket(2holes)—TX1000

only

Bolt(1/4x3/4inch)—TX1000only

Locknut(1/4inch)—TX1000only

Shieldsupport(1bend)—200/300

SeriesorTX400/500Series

Shieldsupport(2bends)—TX1000only

Shield

Bolt(1/4x1-1/2inch)

Washer8

Locknut(1/4inch)

Chipguard

Guardpin

Hairpincotter1

Qty.

Use

–

1

1

4

1

1

4

4

2

2

1

8

8

1

1

Preparethetractionunit.

Installtheshieldbrackets.

Assembletheoperatorshield.

Installthechipguard.

1

PreparingtheTractionUnit

NoPartsRequired

Procedure

1.Parkthemachineonalevelsurface.

2.Lowertheloaderarms.

3.Engagetheparkingbrake(ifapplicable).

4.Shutofftheengineandremovethekey.

6

2

InstallingtheShield

3.Repeatsteps1and2fortheothersideofthe

tractionunit.

TX400or500SeriesTractionUnit

Only

Brackets

Partsneededforthisprocedure:

Rightshieldbracket(3holes)—200/300SeriesorTX

1

400/500Seriesonly

Leftshieldbracket(3holes)—200/300SeriesorTX

1

400/500Seriesonly

4

Self-tappingscrew(5/16x3/4inch)

1

Rightshieldbracket(2holes)—TX1000only

1

Leftshieldbracket(2holes)—TX1000only

4

Bolt(1/4x3/4inch)—TX1000only

4

Locknut(1/4inch)—TX1000only

200or300SeriesTractionUnit

Only

Important:Usetheshieldbracketswith3holes.

1.Insertthetabontheshieldbracketintothe

lift-pointholeonthetractionunit,withthehole

inthebracketaligningwiththesmallholeinthe

tractionunitframe(Figure3).

Important:Usetheshieldbracketswith3holes.

1.Measureinfromtheedgesoftheframeas

illustratedinFigure4andmarkthelocationsof

theholesformountingtheshieldbracket.

Note:Iftheholesexist,skiptostep3.

Note:Thereisarightandleftbracket.Ensure

thatyouinstallthecorrectbracketoneachside.

Thetabshouldbeinthelift-pointholeandthe

bracketshouldbeontheoutsideoftheframe

(Figure3).

Figure3

1.Shieldbracket

2.Lift-pointhole4.Self-tappingscrew

3.Tab

g203568

Figure4

1.4.6cm(1.8inch)3.4.6cm(1.8inch)

2.1.4cm(0.6inch)

2.Drillahole(5/16inch)throughtheframeateach

markedlocation.

3.Alignthetabontheshieldbracketwiththefront

edgeoftheframewiththebracketinsideofthe

loader-armpocket(Figure5).

g013653

Note:Thereisarightandleftbracket.Ensure

thatyouinstallthecorrectbracketoneachside.

Thetabshouldbeovertheframeedgeandthe

bracketshouldbeinsidetheloader-armpocket

withthe2smallerholesinthebracketlinedup

withtheholesyoudrilledintheframe(Figure5).

4.Mountingholes

2.Securethebrackettotheframewitha

self-tappingscrew(Figure3).

7

Figure5

1.Self-tappingscrew2.Shieldbracket

4.Securethebrackettotheframewith2

self-tappingscrewsasillustratedinFigure5.

5.Repeatsteps1through4fortheothersideof

thetractionunit.

TX1000TractionUnitOnly

Important:Usetheshieldbracketswith2holes.

3.Installtheleftshieldbracketontheleftframe

using2bolts(1/4x3/4inch)and2Locknuts(1/4

inch)asshowninFigure7.

g013655

g202825

Figure7

1.Bolts(1/4x3/4inch)3.Locknut(1/4inch)

2.Leftshieldbracket

4.Installtherightshieldbracketontherightframe

2bolts(1/4x3/4inch)and2locknuts(1/4inch),

similartoFigure7.

1.Measureinfromtheedgesoftheframeas

illustratedinFigure6andmarkthelocationsof

theholesformountingtheshieldbracket.

Note:Iftheholesexist,skiptostep3.

Figure6

g245655

1.7.0cm(2-3/4inch)

2.5.7cm(2-1/4inch)5.Referencebar

3.1.3cm(1/2inch)

4.Hole

2.Drillahole(9/32inch)throughtheframeateach

markedlocation.

8

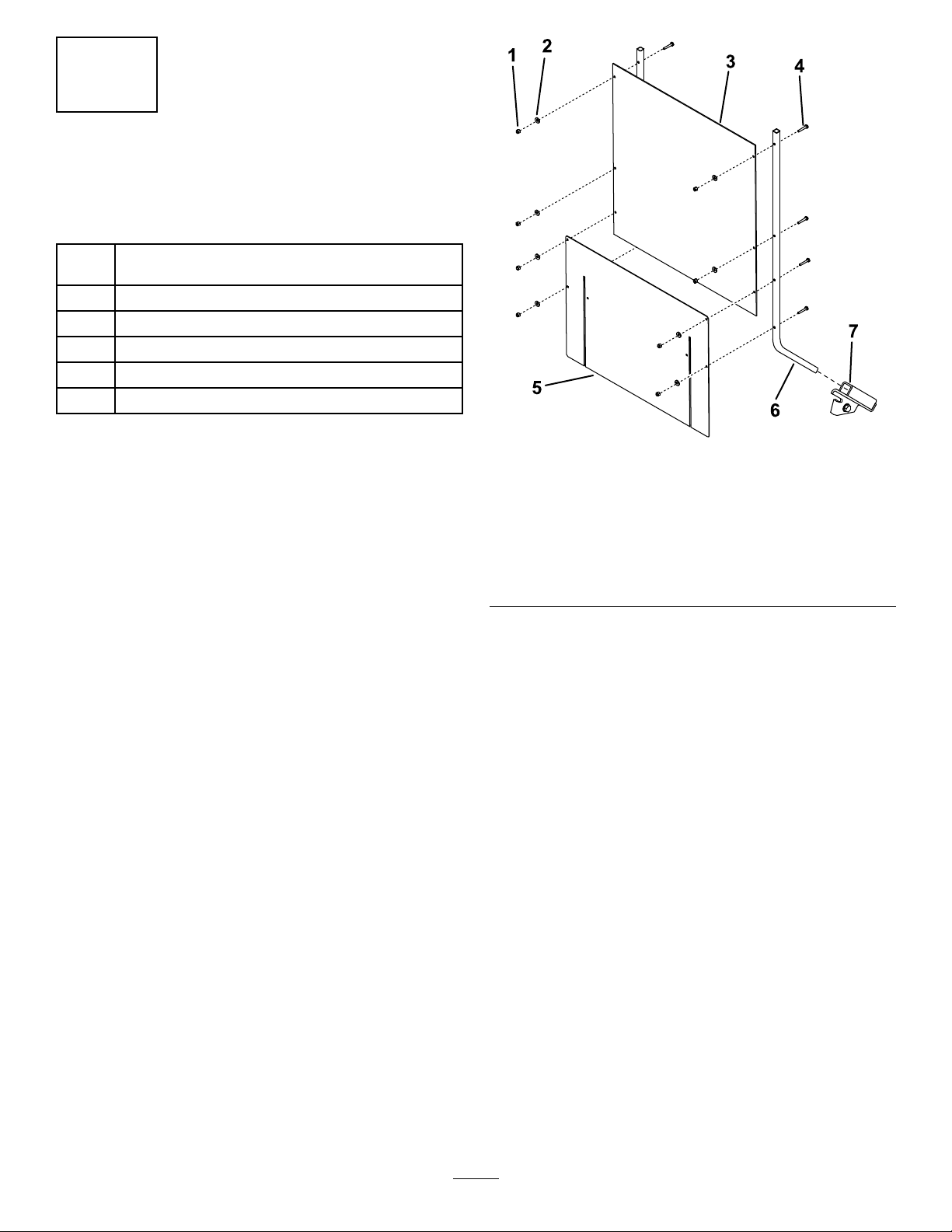

3

AssemblingtheOperator

Shield

Partsneededforthisprocedure:

Shieldsupport(1bend)—200/300SeriesorTX

2

400/500Series

2

Shieldsupport(2bends)—TX1000only

1

Shield

8

Bolt(1/4x1-1/2inch)

8Washer

8

Locknut(1/4inch)

AssemblingtheShield

Note:Usetheshieldsupportswith1bendfor

200/300seriesorTX400/500seriestractionunits.

Usetheshieldsupportswith2bendsforTX1000

tractionunits.

1.Slidetheshieldsupportsintothepocketsinthe

shieldbracketsonthetractionunit(Figure8or

Figure9).

Figure8

200/300SeriesorTX400/500SeriesTractionUnits

1.Locknut(8)

2.Washer(8)6.Shieldsupport(2)

3.Shield7.Shieldbracket(2)

4.Bolt(8)

5.Skirt

g202610

9

Figure9

TX1000TractionUnitsOnly

1.Locknut(8)

2.Washer(8)6.Shieldsupport(2)

3.Shield7.Shieldbracket(2)

4.Bolt(8)

5.Skirt

4

InstallingtheChipGuard

Partsneededforthisprocedure:

1

Chipguard

1

Guardpin

1Hairpincotter

Procedure

Thestumpgrinderhas4setsofmountingholesfor

positioningthechipguard(Figure10).Movethe

guardup(upperholes)whenyouaregrindingclose

tothegroundanddown(lowerholes)whenyouare

g202842

chippingtallstumps.Installthechipguardasfollows:

1.Positionthemountingtubeontheguard

between2holesonthegrinder(Figure10).

2.Assembletheshieldandexibleskirttothe

shieldsupportsasillustratedinFigure8or

Figure9,using8bolts(1/4x1-1/2inch),8

washers,and8locknuts(1/4inch).

Note:Theskirtshoulddrapeovertheengine

orhood.

Figure10

1.Guardpin

2.Mountingholes5.Hairpincotter

3.Chipguard

2.Slidetheguardpinthroughtheholesinthe

grinderandthemountingtube(Figure10).

3.Securethepinwithahairpincotter(Figure10).

4.Mountingtube

g202609

10

ProductOverview

Figure11

1.Chipguard4.Stumpgrindinghead

2.Mountingplate

3.Pivotbolt

5.Teeth

Operation

InstallingandRemoving

theAttachment

RefertotheOperator’sManualforthetractionunitfor

theinstallationandremovalprocedure.

Important:Beforeinstallingtheattachment,

positionthemachineonalevelsurface,ensure

thatthemountplatesarefreeofanydirtordebris,

andensurethatthepinsrotatefreely .Ifthepins

donotrotatefreely,greasethem.

Note:Alwaysusethetractionunittoliftandmove

theattachment.

WARNING

Ifyoudonotfullyseatthequick-attach

g013651

pinsthroughtheattachmentmountplate,

theattachmentcouldfalloffthemachine,

crushingyouorbystanders.

Ensurethatthequick-attachpinsarefully

seatedintheattachmentmountplate.

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Width(withchipguard)112cm(44inches)

Width(withoutchipguard)66cm(26inches)

Length

Height

Weight

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

51cm(20inches)

79cm(31inches)

120kg(265lb)

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliarwith

thisformofinjury;otherwise,gangrenemay

result.

•Ensurethatallhydraulic-uidhoses

andlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretothehydraulic

system.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks;neveruseyourhands.

11

CAUTION

Hydrauliccouplers,hydrauliclines/valves,

andhydraulicuidmaybehot.Ifyoucontact

hotcomponents,youmaybeburned.

•Weargloveswhenoperatingthehydraulic

couplers.

•Allowthemachinetocoolbeforetouching

hydrauliccomponents.

•Donottouchhydraulicuidspills.

GrindingStumps

WARNING

Duringoperation,debrisyinalldirections

andcancauseinjurytoeyesandother

exposedbodyparts.

•Neveroperatethestumpgrinderwithout

theshieldinstalledonthetractionunitand

thechipguardonthegrinder.

•Duringoperation,weareyeprotection,

hearingprotection,substantial,

slip-resistantfootwear,andlong

pants.

•Keepallbystandersatleast9m(30ft)

awayfromtheworkarea.

1.Ifyourtractionunithasaspeedselector,move

ittotheSLOWposition.

2.Starttheengine.

3.Pulltheauxiliaryhydraulicslevertotheoperator

griptoengagethestumpgrinder.

4.Positionthegrinderontheleftsideandbehind

thestump(Figure12).

g013658

Figure12

5.Swingthegrindertowardyouusingthe

attachment-tiltlever,grindingatadepthof0.5

to5cm(1/4to2inches),dependingonthe

hardnessofthewood(Figure12).

Note:Ifyoucuttoodeep,thegrinderstalls.Ifit

stalls,raiseitslightlyandtryagain.

6.Swingthegrinderbackout(Figure12),lowerit

0.5to5cm(1/4to2inches),andrepeatsteps

4through6untilyouhavegrounddownafew

inches.

7.Raisetheloaderarmstotheoriginalheight.

8.Movethegrindertotheright(Figure12).

9.Repeatsteps4through8untilyoureachthe

rightsideofthestump.

10.Returnthegrindertotheleftsideofthestump,

lowerit,andrepeatsteps3through10untilyou

havegroundthestumpintotheground.

Note:T ocontainthechips,youmayneedto

stopthegrinderandmovethechipguardupas

youmovethegrinderdown.

11.Whennished,stopthegrinderbymoving

theauxiliaryhydraulicslevertotheNEUTRAL

position.

12

GrindingRoots

1.Stopthegrinderandhangitverticallyfromthe

loaderarmsafewcentimeters(inches)offthe

ground.

2.Shutofftheengineandremovethekey.

3.Loosenthelargeboltonthetopofthegrinder

(Figure13).

15.Swingthegrinder30degreescounter-clockwise

(Figure13).

16.T orquethelargeboltontopofthegrinderto406

N∙m(300ft-lb)asshowninFigure13.

17.Installtheboltandnutinthefrontholeand

torquethemto101N∙m(75ft-lb)asshownin

Figure13.

TransportPosition

Whentransportingtheattachment,keepitasclose

tothegroundaspossible,nomorethan15cm(6

inches)abovetheground.Tiltitrearward.

Figure13

1.Largebolt—loosen2.Frontbolt—remove

4.Removethefrontboltandnutsecuringthe

grinder(Figure13).

5.Swingthegrinder30degreesclockwise(Figure

13).

6.T orquethelargeboltontopofthegrinderto406

N∙m(300ft-lb)asshowninFigure13.

7.Installtheboltandnutinthefrontholeand

torquethemto101N∙m(75ft-lb)asshownin

Figure13.

8.Startthetractionunitandstartthegrinder.

9.Lowerthegrinderintotheroot.

10.Movethegrinderalongthelengthoftherootby

movingthetractionunitovertheroot.

11.Whennished,stopthegrinderbymoving

theauxiliaryhydraulicslevertotheNEUTRAL

position.

12.Shutofftheengineandremovethekey.

13.Loosenthelargeboltonthetopofthegrinder

(Figure13).

14.Removethefrontboltandnutsecuringthe

grinder(Figure13).

g245446

Figure14

g013659

1.Nomorethan15cm(6

inches)abovetheground

2.Tilttheattachment

rearward.

TransportingtheStump

GrinderonaTrailer

Placetheattachmentonatrailerortruckcapableof

carryingit.Securelytieittothetrailerortruckusing

tiestrapsappropriatefortheweightoftheattachment

andforhighwayuse.

Important:Removetheoperator'sshieldbefore

transportingthetractionunittoavoiddamageto

theshieldofthetractionunit.

OperatingTips

•Alwaysusefullthrottle(maximumenginespeed).

•Nevertransporttheattachmentwiththeloader

armsraised.Keepthearmsloweredandthe

attachmenttiltedup.

•Ifyourtractionunithasaspeedselector(present

onsomewheeledtractionunits),setittotheSLOW

(turtle)position.

•Ifyourtractionunithasaowdivider(present

onsomewheeledtractionunits),adjustitto

approximatelythe10o’clockposition.

13

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Beforeeachuseordaily

Beforestorage

MaintenanceProcedure

•Greasethemachine.

•Checktheconditionoftheteethandrotateorreplaceanythatarewornordamaged.

•Greasethemachine.

•Paintchippedsurfaces.

GreasingtheMachine

ServiceInterval:Beforeeachuseordaily

Beforestorage

GreasethettinginFigure15.

GreaseType:General-purposegrease

1.Parkthemachineonalevelsurface,lowerthe

loaderarms,andengagetheparkingbrake(if

applicable).

2.Shutofftheengineandremovethekey.

3.Cleanthegreasettingwitharag.

4.Connectagreaseguntothetting.

5.Pumpgreaseintothettinguntilgreasebegins

tooozeoutofthebearings.

6.Wipeupanyexcessgrease.

Figure15

g203602

14

ReplacingtheTeeth

ServiceInterval:Beforeeachuseordaily—Check

theconditionoftheteethandrotate

orreplaceanythatarewornor

damaged.

Duetothehighamountofwearplacedontheteeth,

youwillneedtorotateandreplacethemperiodically .

Eachtoothisindexedwith3positionssothatyoucan

rotateittwice,exposinganewsharpedgebefore

replacingthetooth.

g246708

Figure17

(Yourgrinder'sappearancemayvaryfromthatshownin

theillustration)

Figure16

1.Sharptooth

2.Worntooth

Torotateatooth,loosenthenutsecuringthetooth

(Figure17).Pushthetoothforwardandrotateitone

thirdofaturn,bringinganunusededgetotheoutside.

Torquethenutsecuringthetoothto37to45N∙m(27

to33ft-lb).

g034325

1.Nut3.Toothholder

2.Spacer

4.Tooth

Toreplaceatooth,removethenutsecuringthetooth

toremoveit,theninstallanewtoothandnutinthe

sameposition(Figure17).T orquethenutsecuring

thetoothto37to45N∙m(27to33ft-lb).

15

Storage

1.Beforelong-termstorage,washtheattachment

withmilddetergentandwatertoremovedirtand

grime.

2.Checktheconditionoftheteeth.Turnorreplace

anywornordamagedteeth.

3.Checkandtightenallbolts,nuts,andscrews.

Repairorreplaceanydamagedorwornpart.

4.Ensurethatallhydrauliccouplersareconnected

togethertopreventcontaminationofthe

hydraulicsystem.

5.Paintallscratchedorbaremetalsurfaces.Paint

isavailablefromyourAuthorizedServiceDealer.

6.Storetheattachmentinaclean,drygarageor

storagearea.Coverittoprotectitandkeepit

clean.

16

Troubleshooting

Problem

Thecuttingdiskstopsduringcutting.

Thecuttingdiskdoesnotturnorturns

slowly.

Thegrinderdoesnotcutfastenough.

PossibleCauseCorrectiveAction

1.Y ouarecuttingtoodeep.

2.T eethareworn,damaged,orbroken.2.Rotateorreplaceanyworn,damaged,

1.Ahydrauliccouplerisnotcompletely

connected.

2.Ahydrauliccouplerisdamaged.

3.Thereisanobstructioninahydraulic

hose.

4.Anauxiliaryvalveonthetractionunit

isnotopening.

5.Thehydraulicmotorordrivehasfailed.5.ContactyourAuthorizedService

6.Thecheckvalvebrakeisreversed.6.Reversethecheckvalvedirection;

1.T eethareworn.1.Rotateorreplaceanywornteeth.

2.Thesettingiswrongontheowdivider

andspeedlever(applicablewheeled

unitsonly).

3.Thereisarestrictioninaquickcoupler

orhose.

4.Thehydraulicsystemistoohot.

5.Thereliefvalveissetbelow

specications.

1.Raisetheloaderarms13mm(1/2

inch).

orbrokenteeth.

1.Checkandtightenallcouplers.

2.Check/replacecouplers.

3.Findandremovetheobstruction.

4.Repairthevalve.

Dealer.

contactyourAuthorizedService

Dealer.

2.Settheowdividertothe10o’clock

positionandthespeedlevertothe

turtleposition.

3.Checkthehosesandcouplersand

repairanyproblemsfound.

4.Shutthesystemdownandallowitto

cool.

5.ContactyourAuthorizedService

Dealer.

Thecuttingdiskturnsinthewrong

direction.

1.Theauxiliary-valveleverisinthe

wrongposition.

2.Thehydraulichosesarereversed.2.Disconnectthehosesandswitch

1.Movetheauxiliary-valvelevertothe

rearwardposition.

positions.

17

DeclarationofIncorporation

TheT oroCompany,8111LyndaleAvenueSouth,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.

22429404320000andUp

SerialNo.

ProductDescriptionInvoiceDescription

StumpGrinder

STUMPGRINDER

ATT ACHMENTCE

GeneralDescription

StumpGrinder2006/42/EC

Directive

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedToromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:

JoeHager

Sr.EngineeringManager

811 1LyndaleAve.South

Bloomington,MN55420,USA

February18,2019

AuthorizedRepresentative:

MarcelDutrieux

ManagerEuropeanProductIntegrity

ToroEuropeNV

Nijverheidsstraat5

2260Oevel

Belgium

EuropeanPrivacyNotice

TheInformationToroCollects

ToroWarrantyCompany(T oro)respectsyourprivacy.Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalT orocompanyordealer.

TheT orowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIV ACYNOTICE.

TheWayT oroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.ToromayshareyourinformationwithT oro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany.Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw .

Toro'sCommitmenttoSecurityofYourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailatlegal@toro.com.

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalToroDealer.

374-0282RevC

CaliforniaProposition65WarningInformation

Whatisthiswarning?

Youmayseeaproductforsalethathasawarninglabellikethefollowing:

WARNING:CancerandReproductiveHarm—www.p65Warnings.ca.gov.

WhatisProp65?

Prop65appliestoanycompanyoperatinginCalifornia,sellingproductsinCalifornia,ormanufacturingproductsthatmaybesoldinorbroughtinto

California.ItmandatesthattheGovernorofCaliforniamaintainandpublishalistofchemicalsknowntocausecancer,birthdefects,and/orother

reproductiveharm.Thelist,whichisupdatedannually,includeshundredsofchemicalsfoundinmanyeverydayitems.ThepurposeofProp65isto

informthepublicaboutexposuretothesechemicals.

Prop65doesnotbanthesaleofproductscontainingthesechemicalsbutinsteadrequireswarningsonanyproduct,productpackaging,orliteraturewith

theproduct.Moreover,aProp65warningdoesnotmeanthataproductisinviolationofanyproductsafetystandardsorrequirements.Infact,the

CaliforniagovernmenthasclariedthataProp65warning“isnotthesameasaregulatorydecisionthataproductis‘safe’or‘unsafe.’”Manyofthese

chemicalshavebeenusedineverydayproductsforyearswithoutdocumentedharm.Formoreinformation,gotohttps://oag.ca.gov/prop65/faqs-view-all

AProp65warningmeansthatacompanyhaseither(1)evaluatedtheexposureandhasconcludedthatitexceedsthe“nosignicantrisklevel”;or(2)

haschosentoprovideawarningbasedonitsunderstandingaboutthepresenceofalistedchemicalwithoutattemptingtoevaluatetheexposure.

Doesthislawapplyeverywhere?

Prop65warningsarerequiredunderCalifornialawonly.ThesewarningsareseenthroughoutCaliforniainawiderangeofsettings,includingbutnot

limitedtorestaurants,grocerystores,hotels,schools,andhospitals,andonawidevarietyofproducts.Additionally ,someonlineandmailorder

retailersprovideProp65warningsontheirwebsitesorincatalogs.

.

HowdotheCaliforniawarningscomparetofederallimits?

Prop65standardsareoftenmorestringentthanfederalandinternationalstandards.TherearevarioussubstancesthatrequireaProp65warning

atlevelsthatarefarlowerthanfederalactionlimits.Forexample,theProp65standardforwarningsforleadis0.5μg/day,whichiswellbelow

thefederalandinternationalstandards.

Whydon’tallsimilarproductscarrythewarning?

•ProductssoldinCaliforniarequireProp65labellingwhilesimilarproductssoldelsewheredonot.

•AcompanyinvolvedinaProp65lawsuitreachingasettlementmayberequiredtouseProp65warningsforitsproducts,butothercompanies

makingsimilarproductsmayhavenosuchrequirement.

•TheenforcementofProp65isinconsistent.

•CompaniesmayelectnottoprovidewarningsbecausetheyconcludethattheyarenotrequiredtodosounderProp65;alackofwarningsfora

productdoesnotmeanthattheproductisfreeoflistedchemicalsatsimilarlevels.

WhydoesToroincludethiswarning?

Torohaschosentoprovideconsumerswithasmuchinformationaspossiblesothattheycanmakeinformeddecisionsabouttheproductstheybuyand

use.T oroprovideswarningsincertaincasesbasedonitsknowledgeofthepresenceofoneormorelistedchemicalswithoutevaluatingthelevelof

exposure,asnotallthelistedchemicalsprovideexposurelimitrequirements.WhiletheexposurefromT oroproductsmaybenegligibleorwellwithinthe

“nosignicantrisk”range,outofanabundanceofcaution,T orohaselectedtoprovidetheProp65warnings.Moreover ,ifTorodoesnotprovidethese

warnings,itcouldbesuedbytheStateofCaliforniaorbyprivatepartiesseekingtoenforceProp65andsubjecttosubstantialpenalties.

RevA

Loading...

Loading...