Page 1

Stump Grinder

for Compact Utility Loaders

Model No. 22429—210000001 and Up

Form No. 3353-843 Rev A

Operator’s Manual

Original Instructions (EN)Register your product at www.Toro.com

Page 2

Contents

Page

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Decals 4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stability Ratings 5. . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembling the Operator Shield 6. . . . . . . . . . . . .

Installing the Chip Guard 8. . . . . . . . . . . . . . . . . . .

Operation 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Grinding Stumps 9. . . . . . . . . . . . . . . . . . . . . . . . .

Grinding Roots 9. . . . . . . . . . . . . . . . . . . . . . . . . . .

Tips for Grinding 10. . . . . . . . . . . . . . . . . . . . . . . . .

Transporting the Stump Grinder on a Trailer 10. . .

Maintenance 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Maintenance Schedule 10. . . . . . . .

Greasing the Stump Grinder 11. . . . . . . . . . . . . . . .

Replacing the Teeth 11. . . . . . . . . . . . . . . . . . . . . . .

Storage 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

Thank you for purchasing a Toro product.

All of us at Toro want you to be completely satisfied with

your new product, so feel free to contact your local

Authorized Service Dealer for help with service, genuine

replacement parts, or other information you may require.

Whenever you contact your Authorized Service Dealer or

the factory, always know the model and serial numbers of

your product. These numbers will help the Service Dealer

or Service Representative provide exact information about

your specific product. You will find the model and serial

number plate at the location shown in Figure 1.

1

For your convenience, write the product model and serial

numbers in the space below.

Model No:

Serial No.

Read this manual carefully to learn how to operate and

maintain your product correctly. Reading this manual will

help you and others avoid personal injury and damage to

the product. Although we design, produce and market

safe, state-of-the-art products, you are responsible for

using the product properly and safely. You are also

responsible for training persons, who you allow to use the

product, about safe operation.

The warning system in this manual identifies potential

hazards and has special safety messages that help you and

others avoid personal injury, even death. Danger,

Warning, and Caution are signal words used to identify

the level of hazard. However, regardless of the hazard, be

extremely careful.

Danger signals an extreme hazard that will cause serious

injury or death if the recommended precautions are not

followed.

Warning signals a hazard that may cause serious injury or

death if the recommended precautions are not followed.

Caution signals a hazard that may cause minor or

moderate injury if the recommended precautions are not

followed.

Two other words are also used to highlight information.

Important calls attention to special mechanical

information, and Note emphasizes general information

worthy of special attention.

Safety

Improper use or maintenance by the operator or owner

can result in injury. To reduce the potential for injury,

comply with these safety instructions and always pay

attention to the safety alert symbol, which means

CAUTION, WARNING, or DANGER—“personal

safety instruction.” Failure to comply with the

instruction may result in personal injury or death.

Figure 1

1. Model and serial number plate

W 2005 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Contact us at www.Toro.com

All Rights Reserved

2

Printed in the USA

Page 3

Danger

Warning

The stump grinder is solely designed and tested

for use grinding stumps less than 36 in. (91 cm)

tall. Any other uses may cause a hazardous

situation resulting in injury or death to you or

bystanders.

Only use the stump grinder for grinding stumps

less than 36 in. (91 m) tall.

Danger

If you grind roots around buried power, gas,

and/or telephone lines, you may cut them causing

shock or explosion.

Have the property or work area marked for

buried lines and do not grind roots in marked

areas.

Danger

The moving teeth will severely cut hands, feet, or

other body parts.

• Keep hands, feet, and any other parts of your

body or clothing away from moving teeth.

• Before adjusting, cleaning, repairing, or

inspecting the stump grinder, lower it to the

ground, stop the engine, wait for all moving

parts to stop, and remove the ignition key.

During operation, debris will fly in all directions

and can cause injury to eyes and other exposed

body parts.

• Never operate the stump grinder without the

shield installed on the traction unit and the chip

guard on the grinder.

• Wear personal protective gear during

operation.

• Keep all bystanders at least 30 feet (9 m) away

from the work area.

Warning

If you do not fully seat the quick attach pins

through the attachment mount plate, the

attachment could fall off of the traction unit,

crushing you or bystanders.

• Ensure that your quick attach pins are fully

seated in the attachment mounting plate.

• Ensure that the attachment mounting plate is

free of any dirt or debris that may hinder the

connection of the traction unit to the

attachment.

• Refer to your traction unit Operator’s Manual

for detailed information on safely connecting an

attachment to your traction unit.

Warning

Warning

The loader arms may lower when in the raised

position after stopping the engine, crushing

anyone under them.

Lower the loader arms before stopping the engine.

Hydraulic fluid escaping under pressure can

penetrate skin and cause injury. Fluid injected

into the skin must be surgically removed within a

few hours by a doctor familiar with this form of

injury or gangrene may result.

• Keep your body and hands away from pin hole

leaks or nozzles that eject high pressure

hydraulic fluid.

• Use cardboard or paper to find hydraulic leaks,

never use your hands.

3

Page 4

Caution

Hydraulic couplers, hydraulic lines/valves, and

hydraulic fluid may be hot. If you contact hot

components you may be burned.

• Wear gloves when operating the hydraulic

couplers.

• Allow the traction unit to cool before touching

hydraulic components.

• Do not touch hydraulic fluid spills.

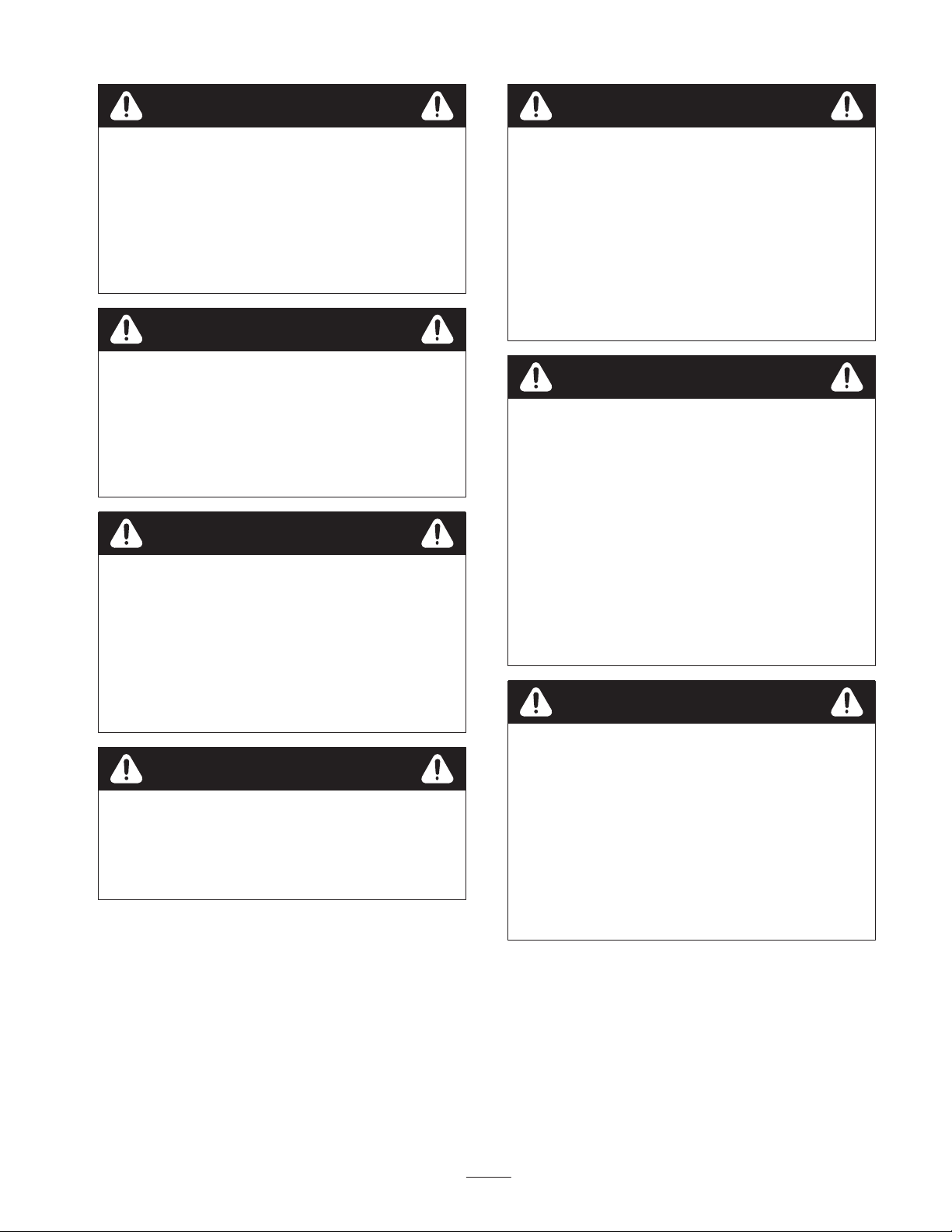

Safety Decals

Safety decals and instructions are easily visible to the operator and are located near any

area of potential danger. Replace any decal that is damaged or lost.

100-4708

1. Thrown object hazard—keep bystanders away

93-9854

1. Warning—read the Operator’s Manual before operating

93-7321

1. Cutting hazard, foot and hand—keep away from moving parts

104-5850

1. Thrown object hazard—do not operate without the chip guard

properly installed

4

Page 5

Specifications

Width with chip guard 44 in. (112 cm)

Width without chip guard 26 in. (66 cm)

Length 20 in. (51 cm)

Height 31 in. (79 cm)

Weight 265 lb. (120 kg)

Stability Ratings

To determine the degree of slope you can traverse with the

stump grinder installed on a traction unit, find the stability

rating for the hill position you want to travel in the

following table, then find the degree of slope for the same

rating and hill position in the Stability Data section of the

traction unit Operator’s Manual.

Orientation Stability Rating

Wheel speed 2000 RPM

Tooth tip speed 148 ft./s (45 m/s)

Number of teeth 12

Wheel diameter without

teeth

Wheel diameter with teeth 17 in. (43 cm)

Maximum height 36 in. (91 cm)

Maximum depth below grade 21 in. (53 cm)

Wheel index 0 or 30 degrees

Chip guard vertical

adjustment

Wheel stopping time Less than 5 seconds

13.4 in. (34 cm)

6 in. (15 cm)

Front Uphill

D

Rear Uphill

C

Side Uphill

C

Warning

If you exceed the maximum slope, the traction

unit could tip, possibly crushing you or

bystanders.

Do not drive the traction unit on a slope steeper

than the maximum recommended slope.

Important If you have a traction unit other than the

TX compact utility loader, do not use the rear

counterweight with the stump grinder. If you use the

counterweight, the traction unit will be less stable in the

front and side uphill positions.

5

Page 6

Installation

Refer to your traction unit Operator’s Manual for complete instructions on installing attachments onto the traction unit and

connecting hydraulic hoses.

Loose Parts

DESCRIPTION QTY. USE

Shield bracket, right

Shield bracket, left

Self-tapping screw, 5/16 x 3/4 in. (200/300

series traction units use only two screws)

Shield support

Shield

Skirt

Bolt, 1/4 x 1-1/2 in.

Washer

Locknut, 1/4 in.

TX bracket mounting template

Stump grinder

Chip guard

Guard pin

Hairpin cotter

Assembling the Operator

Shield

1

1

4

2

1

1

6

6

6

1

1

1

1

1

Assemble the operator shield

Install the chip guard

1

Installing the Shield Bracket on a 200 or

300 Series Traction Unit

1. Insert the tab on the shield bracket into the lift point

hole on the traction unit, with the hole in the bracket

aligning with the small hole in the traction unit frame

(Fig. 2).

Note: There is a right and left bracket. Ensure that

you install the correct bracket on each side. The tab

should be in the lift point hole and the bracket should

be on the outside of the frame (Fig. 2).

2

3

Figure 2

1. Shield bracket

2. Lift point hole

2. Secure the bracket to the frame with a self-tapping

screw (Fig. 2).

3. Repeat steps 1 and 2 for the other side of the traction

unit.

6

3. Tab

4. Self-tapping screw

4

m–5267

Page 7

Installing the Shield Bracket on a TX

Traction Unit

1. Measure in from the edges of the frame as illustrated

in Figure 3 and mark the locations of the holes for

mounting the shield bracket.

Note: If the holes exist, skip to step 3.

1.8 in.

(4.57 cm)

1

0.56 in.

(1.42 cm)

1.8 in.

(4.57 cm)

2

3

m–5277

Figure 4

1. Shield bracket 2. Self-tapping screw

4. Secure the bracket to the frame with 2 self-tapping

screws as illustrated in Figure 4.

5. Repeat steps 1 through 4 for the other side of the

traction unit.

Assembling the Shield

1

Figure 3

1. Mounting holes

2. Drill a hole (5/16 in. dia.) through the frame at each

marked location.

3. Align the tab on the shield bracket with the front edge

of the frame with the bracket inside of the loader arm

pocket (Fig. 4).

Note: There is a right and left bracket. Ensure that

you install the correct bracket on each side. The tab

should be over the frame edge and the bracket should

be inside the loader arm pocket with the 2 smaller

holes in the bracket lined up with the holes you drilled

in the frame (Fig. 4).

1. Slide the shield supports into the pockets in the shield

brackets on the traction unit (Fig. 5).

2. Assemble the shield and flexible skirt to the shield

supports as illustrated in Figure 5, using 6 bolts (1/4 x

1-1/2 in.), washers, and locknuts (1/4 in.).

Note: The skirt should drape over the engine or hood.

7

Page 8

3

7

5

6

5

3

4

4

1

m–5266

Figure 5

1. Shield support

2. Shield bracket

3. Shield

4. Skirt

5. Bolt, 1/4 x 1-1/2 in.

6. Washer

7. Locknut, 1/4 in.

Note: Install or remove the shield as needed by sliding it

into the brackets or pulling it out of the brackets. Do not

remove the brackets from the traction unit. You can

remove the shield easily by flexing it in the center as you

pull it out of the brackets.

Installing the Chip Guard

The stump grinder has 4 sets of mounting holes for

positioning the chip guard (Fig. 6). Move the guard up

(upper holes) when you are grinding close to the ground

and down (lower holes) when you are chipping tall

stumps. Install the chip guard as follows:

1. Position the mounting tube on the guard between two

holes on the grinder (Fig. 6).

2

m–5265

1

2

Figure 6

1. Mounting holes

2. Chip guard

3. Mounting tube

4. Guard pin

5. Hairpin cotter

2. Slide the guard pin through the holes in the grinder

and the mounting tube (Fig. 6).

3. Secure the pin with a hairpin cotter (Fig. 6).

Operation

Warning

During operation, debris will fly in all directions

and can cause injury to eyes and other exposed

body parts.

• Never operate the stump grinder without the

shield installed on the traction unit and the chip

guard on the grinder.

• Wear personal protective gear during

operation.

• Keep all bystanders at least 30 feet (9 m) away

from the work area.

Important Always use the traction unit to lift and

move the attachment.

8

Page 9

Grinding Stumps

1. If your traction unit has a speed selector, set it to the

slow (turtle position).

2. Start the engine.

3. Pull the auxiliary hydraulics lever to the operator grip

to engage the stump grinder.

4. Position the grinder on the left side and behind the

stump (Fig. 7).

5. Swing the grinder toward you using the attachment tilt

lever, grinding at a depth of 1/4 to 2 in. (0.5 to 5 cm),

depending on the hardness of the wood (Fig. 7).

Note: If you take too deep of a cut, the grinder will stall.

If it stalls, raise it slightly and try again.

6. Swing the grinder back out (Fig. 7), lower it 1/4 to 2

in. (0.5 to 5 cm) and repeat steps 4 through 6 until you

have ground down a few inches.

7. Raise the loader arms to the original height.

8. Move the grinder to the right (Fig. 7).

9. Repeat steps 4 through 8 until you reach the right side

of the stump.

m–5275

Figure 7

10. Return the grinder to the left side of the stump, lower

it, and repeat steps 3 through 10 until you have ground

the stump into the ground.

Note: To contain the chips, you may need to stop the

grinder and move the chip guard up as you move the

grinder down.

11. When finished, stop the grinder by moving the

auxiliary hydraulics lever into neutral.

Grinding Roots

1. Stop the grinder and hang it vertically from the loader

arms a few inches off of the ground.

2. Stop the engine and remove the key.

9

Page 10

3. Loosen the large bolt on the top of the grinder (Fig. 8).

2

1

11. When finished, stop the grinder by moving the

auxiliary hydraulics lever into neutral.

12. Loosen the large bolt on the top of the grinder (Fig. 8).

13. Remove the front bolt and nut securing the grinder

(Fig. 8).

14. Swing the grinder 30 degrees counter-clockwise

(Fig. 8).

15. Torque the large bolt on top of the grinder to 300 ft.-lb.

(406 N⋅m) (Fig. 8)

16. Install the bolt and nut in the front hole and torque

them to 75 ft.-lb. (101 N⋅m) (Fig. 8).

Tips for Grinding

• Always use full throttle (maximum engine speed).

m–5273

Figure 8

1. Large bolt—loosen 2. Front bolt—remove

4. Remove the front bolt and nut securing the grinder

(Fig. 8).

5. Swing the grinder 30 degrees clockwise (Fig. 8).

6. Torque the large bolt on top of the grinder to 300 ft.-lb.

(406 N⋅m) (Fig. 8)

7. Install the bolt and nut in the front hole and torque

them to 75 ft.-lb. (101 N⋅m) (Fig. 8).

8. Start the traction unit and start the grinder.

9. Lower the grinder into the root.

10. Move the grinder along the length of the root by

moving the traction unit over the root.

Maintenance

• Never transport the stump grinder with the loader arms

raised. Keep the arms lowered and the grinder tilted

up.

• On 200 and 300 series traction units set the speed

selector to the slow (turtle position) and the flow

divider to approximately the 10 o’clock position.

Transporting the Stump

Grinder on a Trailer

• Place the stump grinder on a trailer or truck capable of

carrying it.

• Securely tie the grinder to the trailer or truck using tie

straps appropriate for the weight of the grinder and for

highway use.

• Remove the operator’s shield from the traction unit

before transporting the traction unit or the shield may

be damaged in transport.

Recommended Maintenance Schedule

Maintenance Service

Interval

8 hours

Storage Service

Maintenance Procedure

• Grease all fittings.

• Check the teeth and replace any that are worn or damaged.

• Ensure that the disk stops within 5 seconds of releasing the auxiliary hydraulics

lever. If not, contact your Authorized Toro Dealer for brake service.

• Grease all fittings.

• Paint chipped surfaces

10

Page 11

Caution

If you leave the key in the ignition switch, someone could accidently start the engine and

seriously injure you or other bystanders.

Remove the key from the ignition and disconnect the wire from the spark plug before you do

any maintenance. Set the wire aside so that it does not accidentally contact the spark plug.

Greasing the Stump Grinder

Grease all pivot joints every 8 operating hours and

immediately after every washing.

Grease Type: General-purpose grease.

1. Clean the grease fittings with a rag.

2. Connect a grease gun to each fitting

(Fig 9).

m–5276

Figure 9

3. Pump grease into the fittings until grease begins to

ooze out of the bearings (approximately 3 pumps).

4. Wipe up any excess grease.

3. Manually rotate the grinding wheel until you can

access the teeth you want to replace (Fig. 10).

3

1

4

2

Figure 10

1. Straight teeth

2. Curved teeth

3. Bolt

4. Disk

m–5274

Replacing the Teeth

Due to the high amount of wear placed on the teeth, you

will need to replace them periodically. There are two

types of teeth, curved and straight. The teeth are mounted

on the wheel in pairs, alternating between curved and

straight. Each pair contains a right and a left version of

the tooth. Always replace the teeth in pairs (2 curved or 2

straight together). Always replace teeth with the same

type of tooth (curved or straight).

In each pair, one tooth has two counter sunk holes through

it; the other has two threaded holes. Mount the teeth

facing the same direction as the teeth you removed.

To replace a pair of teeth, complete the following

procedure:

1. Disconnect the stump grinder from the traction unit.

2. Connect the stump grinder hydraulic connectors

together.

4. Remove the two bolts securing the teeth and discard

the teeth (Fig. 10).

5. Install the new teeth on the disc in the same location

and orientation as the teeth you removed using the

existing mounting bolts (Fig. 10).

Note: The location on the disk for curved teeth is

marked by an indent ground into the disk between the

tooth mounting holes. Straight tooth locations do not

have this indent.

6. Torque the bolts securing the teeth to 240 ft.-lb.

(325 N⋅m).

Storage

1. Before long term storage, brush the dirt from the

attachment. Do not wash it, because washing will

cause rust.

2. Check the condition of the teeth. Replace any worn or

damaged teeth.

11

Page 12

3. Grease all fittings.

gpgg

g

4. Check and tighten all bolts, nuts, and screws. Repair or

replace any part that is damaged or worn.

6. Paint all scratched or bare metal surfaces. Paint is

available from your Authorized Service Dealer.

7. Store the grinder in a clean, dry garage or storage area.

5. Ensure that all hydraulic couplers are connected

together to prevent contamination of the hydraulic

system.

Troubleshooting

Problem Possible Causes Corrective Action

Cutting disk stops during cutting.

Cutting disk does not turn.

1. Too deep of a cut 1. Raise the loader arms 1/2 in.

2. Teeth worn, damaged, or

broken.

1. Hydraulic coupler not

completely connected

2. Damaged hydraulic coupler 2. Check/replace couplers

3. A hydraulic hose is kinked,

pinched, or obstructed

4. Auxiliary valve on the traction

unit is not opening.

5. Hydraulic motor failure 5. Contact Authorized Service

8. Cover the grinder to protect it and keep it clean.

2. Replace any worn, damaged,

or broken teeth.

1. Check and tighten all couplers.

3. Find and remove the kink,

pinch, or obstruction.

4. Repair the valve.

Dealer.

Does not cut fast enough.

Cutting disk turns in the wrong

direction

1. Worn teeth 1. Replace any worn teeth.

2. Wrong setting on flow divider

and speed lever

3. Quick coupler or hose

restriction

4. Hydraulic system too hot 4. Shutdown and allow the

5. Relief valve set below

specifications

1. Auxiliary valve lever in wrong

position

2. Hydraulic hoses reversed 2. Disconnect hoses and switch

2. Set the flow divider to the 10:00

position and the speed lever to

the turtle position.

3. Check hoses and couplers and

repair any problems found.

system to cool.

5. Contact Authorized Service

Dealer.

1. Move auxiliary valve lever to

the rearward position.

connectors.

12

Loading...

Loading...