Page 1

Broom

Sitework Systems Attachment

Model No. 22415—990001 & Up

Form No. 3323-263

Operator’s Manual

English (CE)

Page 2

Contents

Page

Introduction 2.

Safety 2

Safety Decals3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 3

Stability Ratings4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5

Loose Parts5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembling the Broom5. . . . . . . . . . . . . . . . . . . . . .

Greasing the Broom6. . . . . . . . . . . . . . . . . . . . . . . .

Checking Castor T

Installing the Broom on the T

Connecting the Hydraulic Hoses8. . . . . . . . . . . . . .

Removing the Broom from the Traction Unit8. . . .

Adjusting the Downward Pressure of the Broom8.

Operation 9

T

ips for Sweeping9. . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 10

Service Interval Chart10. . . . . . . . . . . . . . . . . . . . . .

Greasing and Lubrication10. . . . . . . . . . . . . . . . . . . .

Changing Brushes12. . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Castor Fork Bushings12. . . . . . . . . . .

Servicing a Castor Wheel13. . . . . . . . . . . . . . . . . . . .

Storage 13

Troubleshooting 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ire Pressure6. . . . . . . . . . . . . . . .

raction Unit6. . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model No:

Serial No.

The

warning system in this manual identifies potential

hazards and has special safety messages that help you and

others avoid personal injury

W

ARNING and CAUTION are signal words used to

identify the level of hazard. However

hazard, be extremely careful.

DANGER

serious injury or death if the recommended precautions

are not followed.

WARNING

or death if the recommended precautions are not followed.

CAUTION

moderate injury if the recommended precautions are not

followed.

wo other words are also used to highlight information.

T

“Important” calls attention to special mechanical

information and “Note” emphasizes general information

worthy of special attention.

The left and right side of the machine is determined by

standing in the normal operator’s position.

signals an extreme hazard that will cause

signals a hazard that may cause serious injury

signals a hazard that may cause minor or

, even death. DANGER,

, regardless of the

Safety

Introduction

W

e want you to be completely satisfied with your new

product, so feel free to contact your local Authorized

Service Dealer for help with service, genuine replacement

parts, or other information you may require.

Whenever you contact your Authorized Service Dealer or

the factory

your product. These numbers will help the Service Dealer

or Service Representative provide exact information about

your specific product. Y

number on a plate located on the product. For your

convenience, write the product model and serial numbers

in the space below

, always know the model and serial numbers of

ou will find the model and serial

.

Impr

oper use or maintenance by the operator or owner

can r

esult in injury

comply with the safety instructions in the traction unit

operator’

safety alert

W

ARNING, or DANGER—“personal safety

instruction.” Failur

may r

s manual and always pay attention to the

esult in personal injury or death.

. T

o r

educe the potential for injury

symbol, which means CAUTION,

e to comply with the instruction

,

The Toro Company – 1999

8111 Lyndale Ave. South

Bloomington, MN 55420–1196

2

All Rights Reserved

Printed in the USA

Page 3

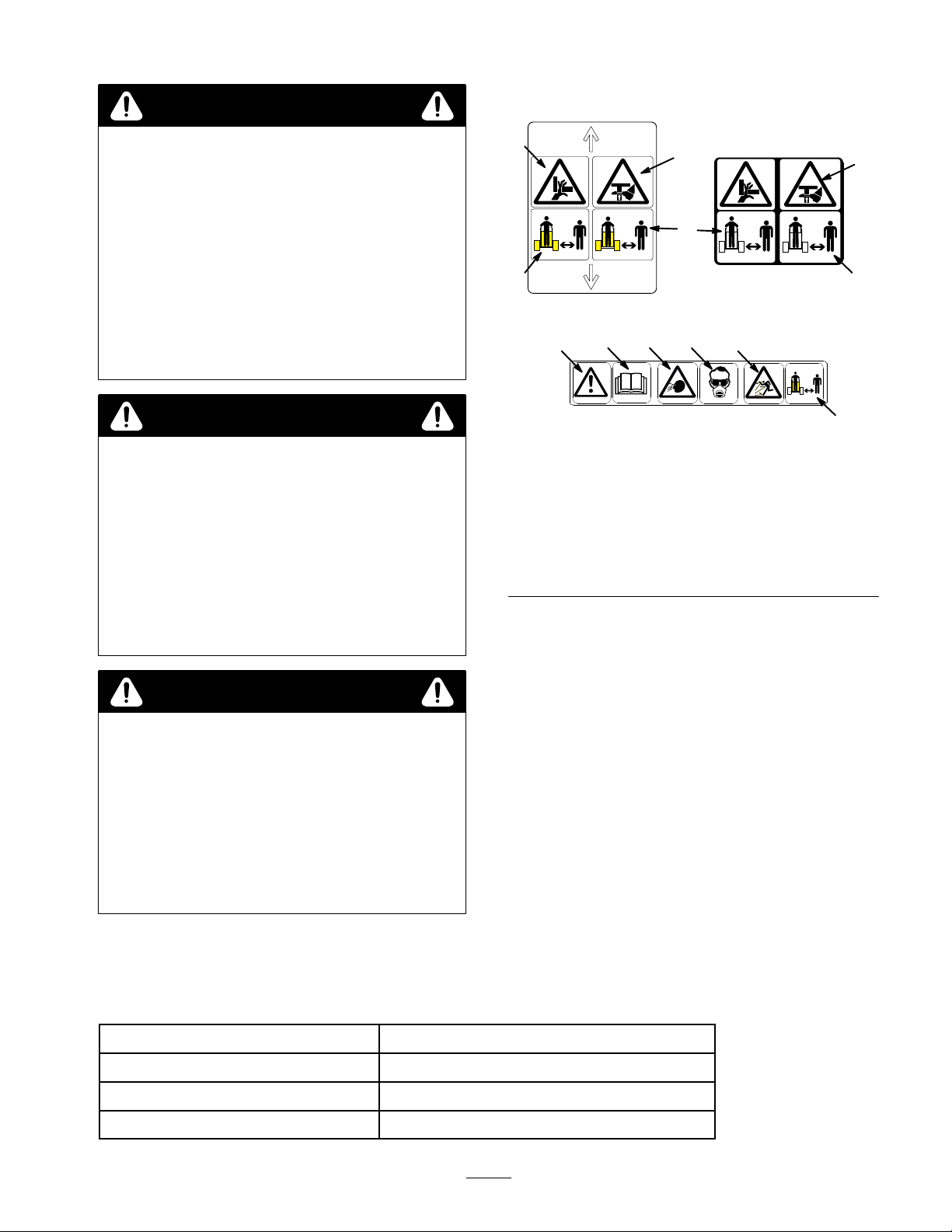

WARNING

Safety

Decals

POTENTIAL HAZARD

•

Contact with r

WHA

T CAN HAPPEN

•

Rotating bristles can injur

body parts.

HOW T

•

• Befor

O AVOID THE HAZARD

Keep your hands, feet, and any other part of

your body or clothing away fr

parts.

e adjusting, cleaning, repairing and

inspecting the br

gr

ound and stop the engine. Remove the key

otating bristles may cause injury

e hands, feet or other

om r

otating

oom, lower the br

oom to the

WARNING

POTENTIAL HAZARD

•

Small stones, dirt clumps, or other debris may

be thr

own during sweeping.

WHA

T CAN HAPPEN

•

Serious injury may r

HOW T

•

•

O AVOID THE HAZARD

Keep childr

area.

Always wear safety glasses or goggles when

operating the br

en and bystanders out of the work

esult.

oom.

1

.

3

# 100–4652

5 6 7

.

4

1. Pinching/crushing

hazard—hand

2. Pinching/crushing

hazard—foot

3. Keep

4.

5.

bystanders away

Safety alert symbol

Read operator’s manual

2

3

8

# 100–4654

Figure 1

6.

7. W

8.

#

100–4650

Thrown object

hazard—face

ear eye and breathing

protection

Thrown object

hazard—whole body

2

3

3

WARNING

POTENTIAL HAZARD

•

When the engine is off, attachments in the

raised position can gradually lower

WHA

T CAN HAPPEN

•

Someone nearby may be pinned or injur

the attachment as it lowers.

HOW T

•

O AVOID THE HAZARD

Always lower the attachment lift each time you

shut off the traction unit.

.

ed by

Specifications

Note:

Specifications and design are subject to change without notice.

Width 53

Length

Height

Weight

inches (135 cm)

40 inches (102 cm)

50 inches (127 cm)

476 lbs (216 Kg)

3

Page 4

Maximum swing angle

Sweeping width

with no swing rotation

With 25 degree swing rotation

Broom diameter 24 inches (51 cm)

25 degrees

48 inches (122 cm)

42 inches (106.6 cm)

Number of brushes

Brush material

Brush rotation speed

Hydraulic drive

Castor wheels

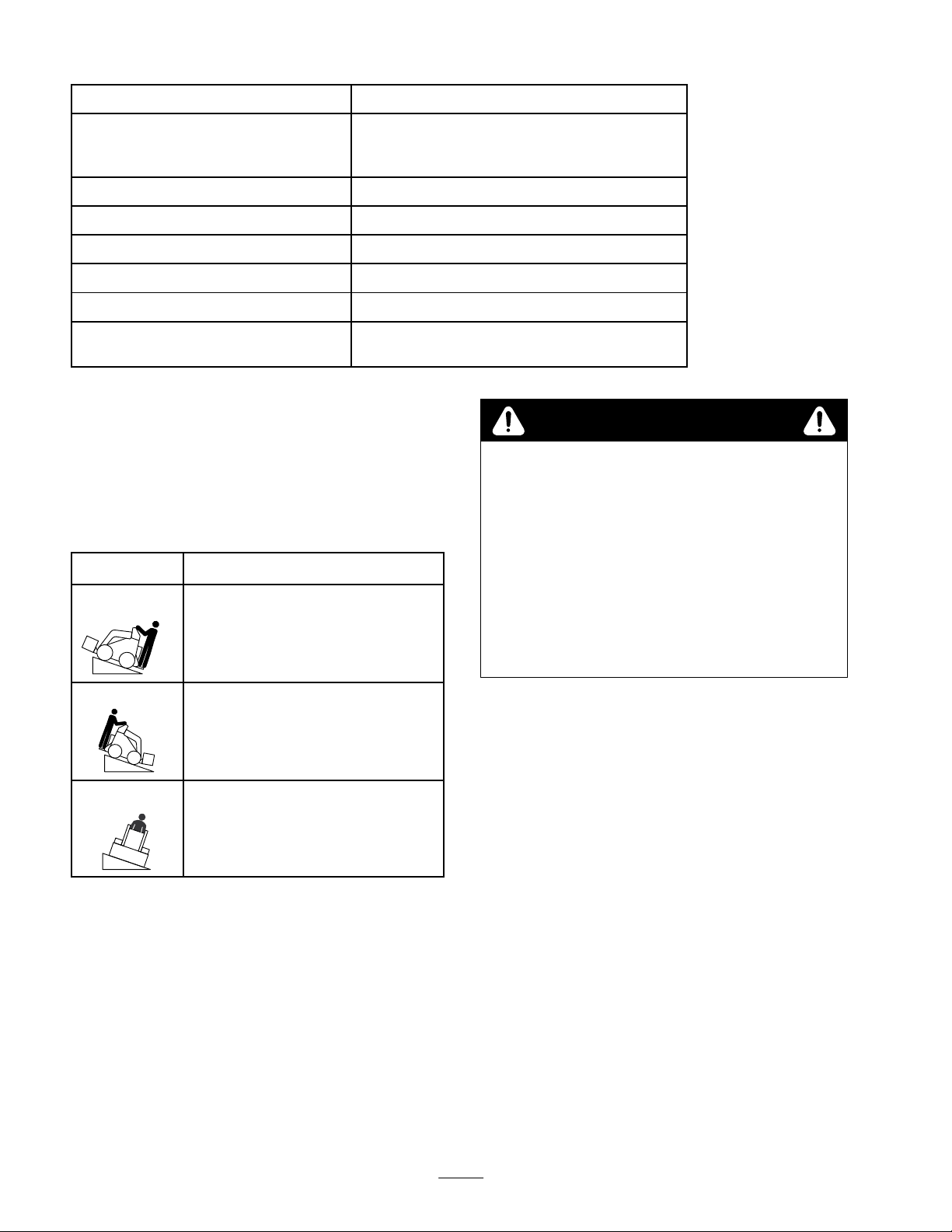

Stability

To

determine the degree of slope you can traverse with the

broom installed on a traction unit, find the stability rating

for the hill position you want to travel in the table below

then find the degree of slope for the same rating and hill

position in the Stability Data section of the traction unit

operator’

Orientation

Front Uphill

Ratings

s manual.

Stability Rating

27

Polypropylene and/or steel

150 rpm

Direct drive, 1

T

wo 8.5 in. (21.5 cm) x 3.5 in. (8.9) pneumatic

tires

C

1.9 cu. in. (195 cc) geroler motor

,

POTENTIAL HAZARD

•

Exceeding the maximum r

can cause the traction unit to tip.

WHA

T CAN HAPPEN

•

If the traction unit tips, you or bystanders could

be crushed.

HOW T

•

O AVOID THE HAZARD

Do not drive the traction unit on a slope steeper

than the maximum r

determined in the pr

traction unit operator’s manual.

WARNING

ecommended slope

ecommended slope, as

evious table and the

Rear Uphill

C

Side Uphill

C

Note:

On traction units with a rear operator platform, the

broom is rated for use without the counterweight. If you

use the counterweight with the broom, the traction unit

will be less stable in the front and side uphill positions.

4

Page 5

Installation

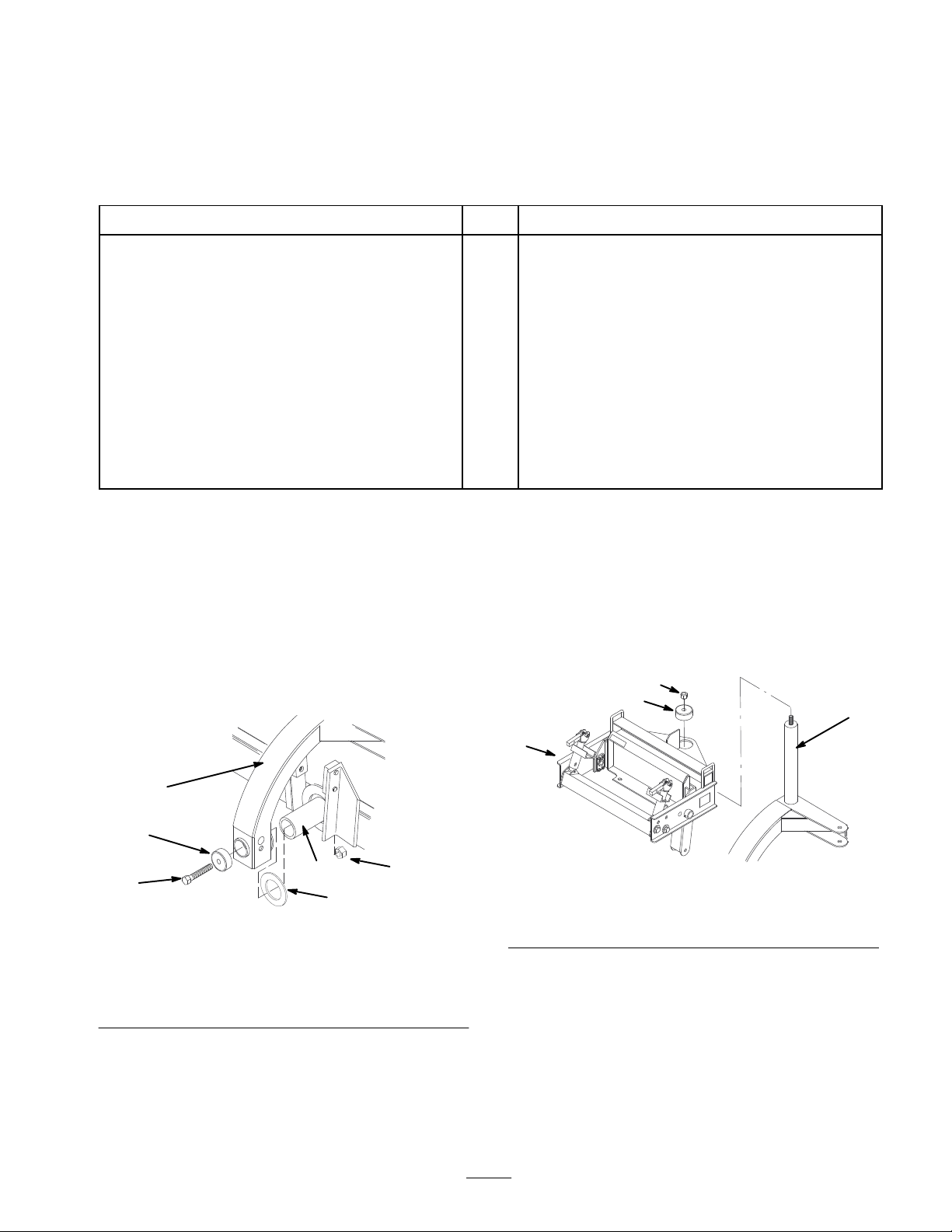

Loose

Note:

Parts

Use the chart below to identify parts for assembly

DESCRIPTION

Pivot frame

Broom head

Attachment frame

Swing arm

Bolt, 3/4 in. (1.9 cm) x 10 1/2 in. (26.7 cm)

Nut, 3/4 in. (1.9 cm)

Thrust washer, large

Pivot cap

Bolt, 3/4 in. (1.9 cm) x 4 in. (10 cm)

Spacer

Assembling

1. Slide

the thrust washer and the pivot frame onto the

the Broom

shaft on the back of the broom head (Fig. 2)

2.

Secure the pivot frame with a pivot cap, 3/4 in.

(1.9 cm) x 10 1/2 in. (26.7 cm) bolt, and 3/4 in.

(1.9 cm) nut (Fig. 2).

Note:

Ensure that the pivot frame rotates around the shaft.

If it cannot, the bolt and nut are too tight.

.

QTY. USE

1

1

1

1

1

Assemble broom

4

1

2

2

4

3. Lubricate

the shaft on the top of the pivot frame

(Fig. 3) with a corrosion resistant, calcium-sulphonate

based grease.

4.

Slide the attachment frame onto the shaft on the top of

the pivot frame (Fig. 3).

5.

Secure the attachment frame with a pivot cap and

3/4 in. (1.9 cm) nut (Fig. 3).

4

3

2

3

5

1. Pivot

2. Shaft

3.

Pivot cap

4.

Thrust washer

1

frame

Figure

2

4

2

5.

Bolt, 3/4 in. (1.9 cm) x

10 1/2 in. (26.7 cm)

6.

Nut, 3/4 in. (1.9 cm)

1

6

m–4176

m–4175

Figure

1. Assembly

2. Shaft

6. Torque

7.

Connect the swing arm to the swing bracket on the

frame

the nut to 265 ft·lbs (359 Nm).

3

Pivot cap

3.

4.

Nut, 3/4 in. (1.9 cm)

pivot frame with two spacers, a 3/4 in. (1.9 cm) x 4 in.

(10 cm) bolt, and a 3/4 in. (1.9 cm) nut (Fig. 4).

T

orque to 265 ft·lbs (359 Nm).

5

Page 6

8.

Route the hydraulic hoses through the ring on the back

of the pivot frame (Fig. 4)

6

5

2

5

4

m–4077

Installing

T

raction Unit

the Broom on the

3

IMPORTANT:

machine, make sur

1

or debris.

1.

Position the broom on a level surface with enough

Befor

e connecting any attachments to

e mount plates ar

e fr

ee of any dirt

space behind it to accommodate the traction unit.

2.

Start the engine.

3. T

ilt the attachment mount plate forward.

4.

Lift the loader arms so the mount plate is above the

rear beam on the broom.

5.

Drive forward, positioning the mount plate into the

upper lip of the receiver plate (Fig. 6).

1. Swing

2.

3.

9. Thread

bracket

Swing arm

Bolt, 3/4 in. (1.9 cm) x

4 in. (10 cm)

the clamp levers into the clamp bases until

Figure

4

4.

Nut, 3/4 in. (1.9 cm)

5. Spacer

6. Ring

they are approximately 1/4 in. (0.6 cm) from the

rubber springs (Fig. 5)

3

2

1. Clamp

2.

Rubber spring

Figure

lever

5

3.

1/4 in. (0.6 cm)

1

2

m–4055

1

1. Mount

6. Tilt

plate

the mount plate back until the receiver plate

Figure

6

2.

Receiver plate

contacts the mount plate

7.

Engage the attachment lock pins (Fig. 7).

1

m–4079

Greasing

Before

using the broom for the first time, grease all of the

the Broom

fittings and the loader arm clamps; refer to Greasing and

Lubrication, page 10.

Checking

Before

using the broom, ensure that the castor tires are

Castor T

ire Pressure

filled to 50 psi (344.75 kPa).

Figure

1. Attachment

8. Raise

9.

Remove the front legs/clamp levers (Fig. 8).

lock pins (shown in engaged position)

the broom about 6 in. (15 cm) of

6

m–4056

7

f the ground.

Page 7

Figure

1. Front

10.Install

leg/clamp lever

the clamp levers on the loader arm clamps and

secure them with latch pins (Fig. 9).

8

WARNING

POTENTIAL HAZARD

•

The loader arm clamps ar

can pr

opel the clamp levers up and forward at

gr

eat speeds when r

WHA

T CAN HAPPEN

•

The clamp lever could strike you or a

1

bystander causing sever

HOW T

• Ensur

O AVOID THE HAZARD

e that you do not stand in the path of the

clamp lever and that all bystanders ar

the ar

m–4139

12.

Swing the loader arm clamps over the loader arms and

ea.

secure them by pulling the clamp levers down and

back (Fig. 10).

Note:

Ensure that the rubber spring is compressed

approximately 1/4 in. (0.6 cm) when the clamp is secured.

3

4

1

2

e spring loaded and

eleased.

e injury

.

e clear of

1

3

1. Loader

2.

Clamp lever

11. If

necessary

Figure

arm clamp

, release the loader arm clamps by

9

3.

Latch pin

swinging the clamp levers up and over the clamps.

m–4130

1. Loader

2.

Loader arm

arm clamp

Figure

10

3.

Clamp lever

4.

Rubber spring

2

m–4131

7

Page 8

Connecting

the Hydraulic

Hoses

WARNING

POTENTIAL

•

Hydraulic fluid escaping under pr

penetrate skin and cause injury

WHA

T CAN HAPPEN

•

Fluid accidentally injected into the skin must be

surgically r

doctor familiar with this form of injury or

gangr

HOW T

•

Keep body and hands away from pin hole leaks

or nozzles that eject high pr

fluid.

Use cardboard or paper to find hydraulic leaks,

•

never use your hands.

1.

Stop the engine.

2.

Move the auxiliary hydraulic lever forward, backward,

and back to neutral position to relieve hydraulic

pressure at the hydraulic couplers.

IMPORTANT

cleaned fr

connections.

Remove protective covers from hydraulic couplers on

3.

the traction unit. Connect covers together to prevent

contamination during operation.

4.

Slide collar back on hydraulic coupler and connect

attachment couplers to machine couplers.

5.

Confirm that connection is secure by pulling on hoses.

HAZARD

essur

.

emoved within a few hours by a

ene may r

O AVOID THE HAZARD

om hydraulic connections befor

: Ensur

esult.

e that all for

essur

e hydraulic

eign matter is

e can

e making

4.

Swing the clamp levers up to release the loader arm

clamps.

WARNING

POTENTIAL HAZARD

•

The loader arm clamps ar

can pr

opel the fr

gr

eat speeds when r

WHA

T CAN HAPPEN

•

The fr

ont leg could strike you or a by stander

causing sever

HOW T

• Ensur

5.

6.

7.

8.

9.

10.

O AVOID THE HAZARD

e that you do not stand in the path of the

fr

ont leg and that all bystanders ar

area.

Swing the clamps of

Remove the front legs/clamp levers from the loader

arms.

Raise the broom about 6 in. (15 cm) of

and install the front legs in front of the broom.

Lower the broom to the ground.

Disengage the attachment lock pins by turning them to

the outside.

Start the engine, tilt the mount plate forward and back

the traction unit away from the drive head.

Adjusting

ont legs up and forward at

e injury

f of the loader arms.

the Downward

e spring loaded and

eleased.

.

e clear of the

f of the ground,

Pressure of the Broom

Improper

to 95% (depending on the incorrect amount of pressure).

downward pressure can decrease broom life up

Removing

T

raction Unit

1. Start

2.

3.

IMPORTANT

pr

storage.

the engine and lower the broom to the ground or

onto a trailer

Slide collar back on hydraulic couplers and disconnect

them.

Install protective covers onto the hydraulic couplers on

the traction unit.

event hydraulic system contamination during

the Broom from the

.

: Connect attachment hoses together to

A broom sweeps with the tips of its bristles. When too

much down pressure is applied, the broom is no longer

using it’

the bristles. This limits the flicking action of the bristles

and limits it’

T

broom on the ground, rotating at normal operating speed

with traction unit remaining stationary

broom. Measure the width of swept area (Fig. 1

properly adjusted broom will have a sweeping path width

of 2 to 4 inches (5 to 10 cm).

8

s tips; the broom is now working with the sides of

s sweeping ef

o check for correct downward pressure, operate the

fectiveness.

. Stop and raise the

1). A

Page 9

5

2

m–4135

1

Figure 11

1. 2

to 4 inches (5 to 10 cm)

Adjust

castor height for proper broom ground pressure.

The castor wheel height is adjustable from 4 to 7 inches

(10 to 18 cm) in 1/2 inch (1.2 cm) increments by adding

or removing an equal amount of spacers from each castor

wheel.

Start the engine and raise the broom.

1.

2.

Stop the engine.

3.

Remove the cap securing the castor spindle to the

frame bracket (Fig. 12).

4.

Move desired amount of spacers to the top or bottom

of the bracket (Fig. 12). Ensure that the spacers are

equal on both castor wheels and that a thrust washer is

positioned on each side of the frame bracket.

5.

Install the cap and lower the broom (Fig. 12).

4

3

2

1

1. Castor

2. Spacers

3.

Thrust washer

Figure

spindle

12

4.

Frame bracket

5. Cap

Operation

Note:

Always use the traction unit to lift and move the

attachment.

3

o operate the broom, pull the auxiliary hydraulics lever

T

to the operator grip and hold it there.

Tips

• If

•

•

for Sweeping

ground speed is too fast, debris will pile up in front

of the broom, causing it to bulldoze instead of sweep.

This can damage the broom.

More pressure will not give a better sweep, but it will

wear out the broom faster

A level broom lasts longer

.

.

9

Page 10

•

When sweeping, try to keep the flange on the top of

the pivot pin level with the gage plate

(Fig. 13). This will allow you adequate room for

movement if you run over bumps or low areas.

1

1. Pivot

Figure

pin

13

2.

Maintenance

Service

Service

Main pivot shaft–lubricate

Grease fittings

Interval Chart

Operation

2

m–4132

Gage plate

Each

Use8Hours

X X

X X

200

Hours

Storage

Service

Notes

Change brushes

Replace castor fork bushings

Replace castor wheel bearings

Chipped surfaces–paint

POTENTIAL

•

If you leave the key in the ignition switch, someone could start the engine.

WHA

•

Accidental starting of the engine could seriously injur

HOW T

•

Remove the key fr

Greasing

T CAN HAPPEN

and Lubrication

HAZARD

O AVOID THE HAZARD

om the ignition switch befor

Service Interval/Specification

Grease

one fitting on the broom pivot shaft (Fig. 14) with

a corrosion resistant, calcium-sulphonate based grease

before each use. Grease 8 other fittings, located on each

As required

X

When the castor wheel is

wobbly.

X

CAUTION

e you or other bystanders.

e you do any maintenance.

castor shaft (Fig. 15, only one side shown), on the right of

the the axle (Fig. 16), on the motor/axle linkage (Fig. 17),

on the right and left arms (Fig. 18, only one side shown),

and on the loader arm clamps (Fig. 9, only one side

shown), every 8 operating hours. Grease all fittings

immediately after every washing.

10

Page 11

Grease T

ype: corrosion resistant, calcium-sulphonate

based grease (pivot shaft only) and general-purpose grease

(all other fittings).

1

Fitting Locations

Figure

14

m–4132

1. Knuckle

Figure 17

joint inside the broom axle

Figure

18

m–4180

m–4133

m–4130

Figure 15

Figure 16

m–4134

Figure 19

How to Grease

1. Lower

2.

3.

4.

5. W

the broom/loader arms and stop the engine.

Remove the key

.

Clean the grease fittings with a rag.

Connect a grease gun to the fittings.

Pump grease into the fittings until grease begins to

ooze out of the bearings.

ipe up any excess grease.

11

Page 12

Changing

The

axle of the broom holds 27 removable brushes. In

Summer

, install all polypropylene brushes. In the W

Brushes

alternate polypropylene and steel brushes to aid in

removing hard packed snow and ice.

1.

Remove the two bolts securing the side guard plate

and remove the plate (Fig. 20).

2.

Remove the two bolts securing the hydraulic motor

housing (Fig. 20)

3

inter,

7.

Slide a new brush onto the axle assembly so the

alignment pins of the brush ride over

the bottom

of the axle assembly (Fig. 22).

8.

Rotate the next brush 180_ from side to side and top to

bottom and slide it onto the axle assembly so the

alignment pins of the brush ride over

top

bar of axle

assembly (Fig. 22).

1

5

bar

1

2

3

1. Side

guard plate

2. Hydraulic

housing

3. Carefully

Figure

motor and motor

remove the hydraulic motor and motor

20

3. Remove

housing with the axle attached.

4.

Loosen the two bolts securing the axle locking collar

(Fig. 21).

1

m–4136

2

m–4138

Figure

1. Axle

2. Axle

plate

3.

Bolt (3)

9. Repeat

10.

.

11.

12.

steps 7 and 8 until all brushes are installed.

Replace the axle plate and secure it with the bolts and

washers removed in step 5.

Secure the axle locking collar

Slide the hydraulic motor and motor housing into

22

4. W

asher (3)

5. Brushes

.

4 3

position and secure it with the bolts removed in step 2.

13.

Install the side guard and secure it with the bolts

removed in step 1.

m–4137

1. Axle

locking collar

5. Remove

Figure

the three bolts and washers securing the axle

21

2. Loosen

plate on the axle and remove the plate

(Fig. 22)

6.

Slide the brushes of

f of the axle assembly

(Fig. 22).

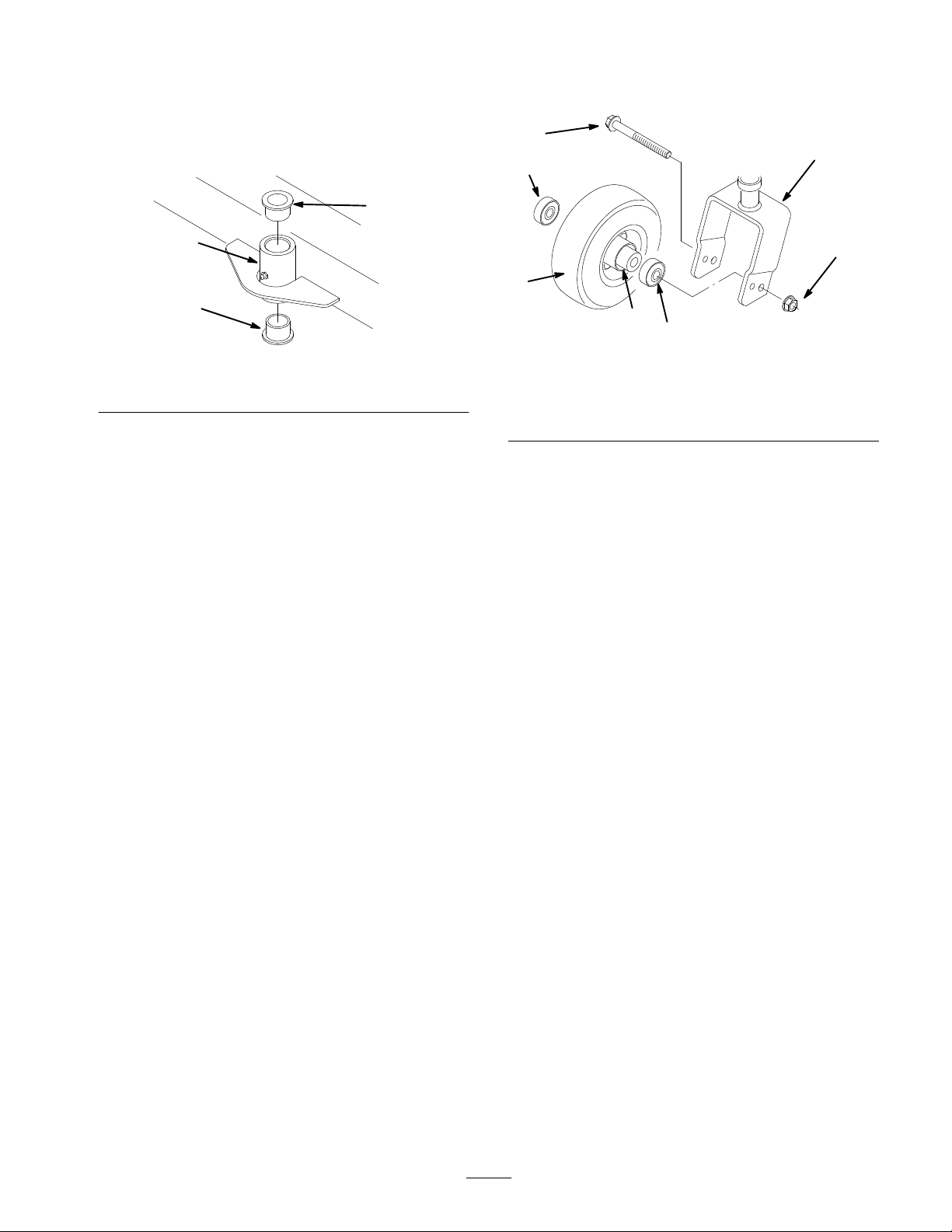

Replacing

the Castor Fork

Bushings

After

2

12

many hours of operation, the bushings pressed into

the top and bottom of the frame bracket will wear

. To

check the bushings, move the castor fork fore and aft and

from side to side. If the castor spindle is loose in the

bushings, the bushings are worn and must be replaced.

1.

Start the engine and raise the broom to highest

possible position.

2.

Install the cylinder locks then stop the engine.

3.

Remove the cap and thrust washers from top of castor

spindle.

Page 13

4.

Pull the castor spindle out of the bracket, allowing the

thrust washers to remain on the bottom of the spindle.

6.

Remove the other outer bearing (Fig. 24).

5.

Using a pin punch, drive the bushings out of the

bracket (Fig. 23).

2

1

2

Figure

1. Frame

6. Clean

7.

bracket

inside of the bracket to remove any dirt.

Apply grease to the inside and outside of the new

23

2. Bushing

bushings.

Using a hammer and a flat plate, drive the bushings

8.

into the bracket (Fig. 23)

9.

Inspect the castor shaft for wear and replace it if

necessary.

Install the castor spindle into the bracket, place the

10.

thrust washers onto the spindle, and secure it with the

cap.

3

5

2

6

5

Figure

1. Castor

2.

3. Capscrew

7. Check

8.

9.

10.

fork

Castor wheel

the bearings, spacer

for wear

. Replace any defective parts.

Push an outer bearing into the wheel hub.

Slide the bearing spacer into the wheel hub.

Push other bearing into the open side of the wheel hub

24

4. Locknut

5.

Outer bearing

6.

Bearing spacer

, and inside of wheel hub

to captivate the spacer inside.

11.

Install castor wheel assembly in the castor fork and

secure it in place with a capscrew and locknut.

1

4

Servicing

When

a castor wheel becomes wobbly, it usually indicates

a Castor Wheel

that the wheel bearings are worn. Perform this procedure

to fix a wobbly castor wheel.

1.

Start the engine and raise the broom to highest

possible position.

2.

Install the cylinder locks then stop the engine.

3.

Remove locknut and capscrew that secure the castor

wheel assembly in the castor fork

(Fig. 24).

4.

Remove the castor wheel from the fork (Fig. 24).

5.

Remove the outer bearing from wheel hub and allow

the bearing spacer to fall out (Fig. 24).

Storage

1.

Before long term storage wash the attachment with

mild deter

2.

Check the condition of the brushes and replace if

necessary.

Apply grease to all grease fittings.

3.

4.

Check and tighten all bolts, nuts, and screws. Repair or

replace any part that are damaged or worn.

5.

Paint all scratched or bare metal surfaces. Paint is

available from your Authorized Service Dealer

Store the broom in a clean, dry garage or storage area.

6.

Cover it to protect it and keep it clean.

gent and water to remove dirt and grimee.

.

13

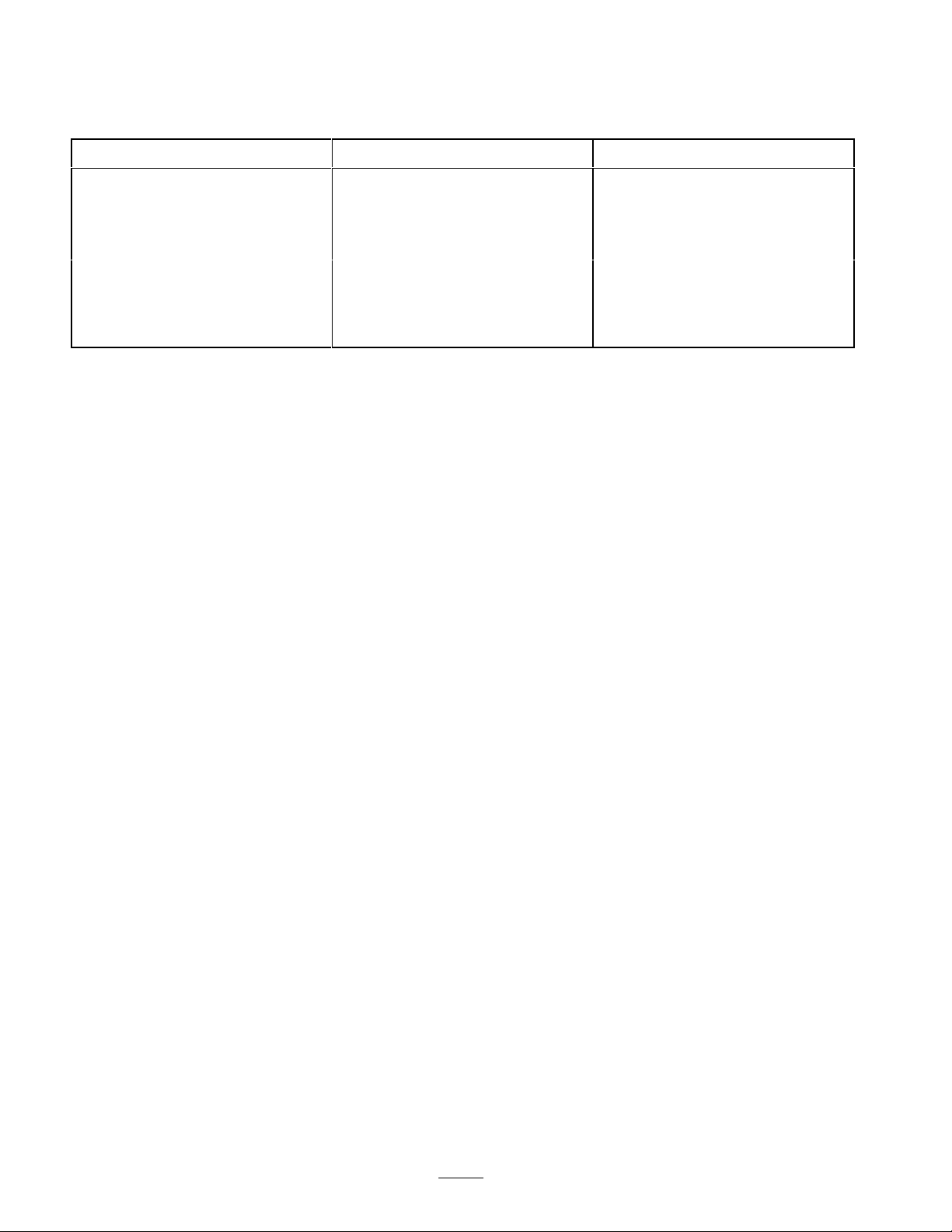

Page 14

Troubleshooting

PROBLEM POSSIBLE

Broom does not rotate.

CAUSES

1.

Hydraulic coupler not

completely connected

2.

Defective hydraulic coupler

3.

An obstruction in a hydraulic

hose

4.

Auxiliary valve on the traction

unit is not opening.

CORRECTIVE ACTION

1.

Check and tighten all couplers.

2.

Check couplers and replace

any that are defective.

3.

Find and remove the

obstruction.

4.

Repair the valve.

14

Page 15

Page 16

Loading...

Loading...