Page 1

FormNo.3360-491RevA

21inHeavy-DutyRearBagger

LawnMower

ModelNo.22178—SerialNo.260004001andUp

Registeratwww.T oro.com.OriginalInstructions(EN)

Page 2

Warning

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Theenclosed

Engine Owner’ s Man ual

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCalifornia

EmissionControlRegulationofemissionsystems,

maintenance,andwarranty.Replacementsmaybe

orderedthroughtheenginemanufacturer.

issupplied

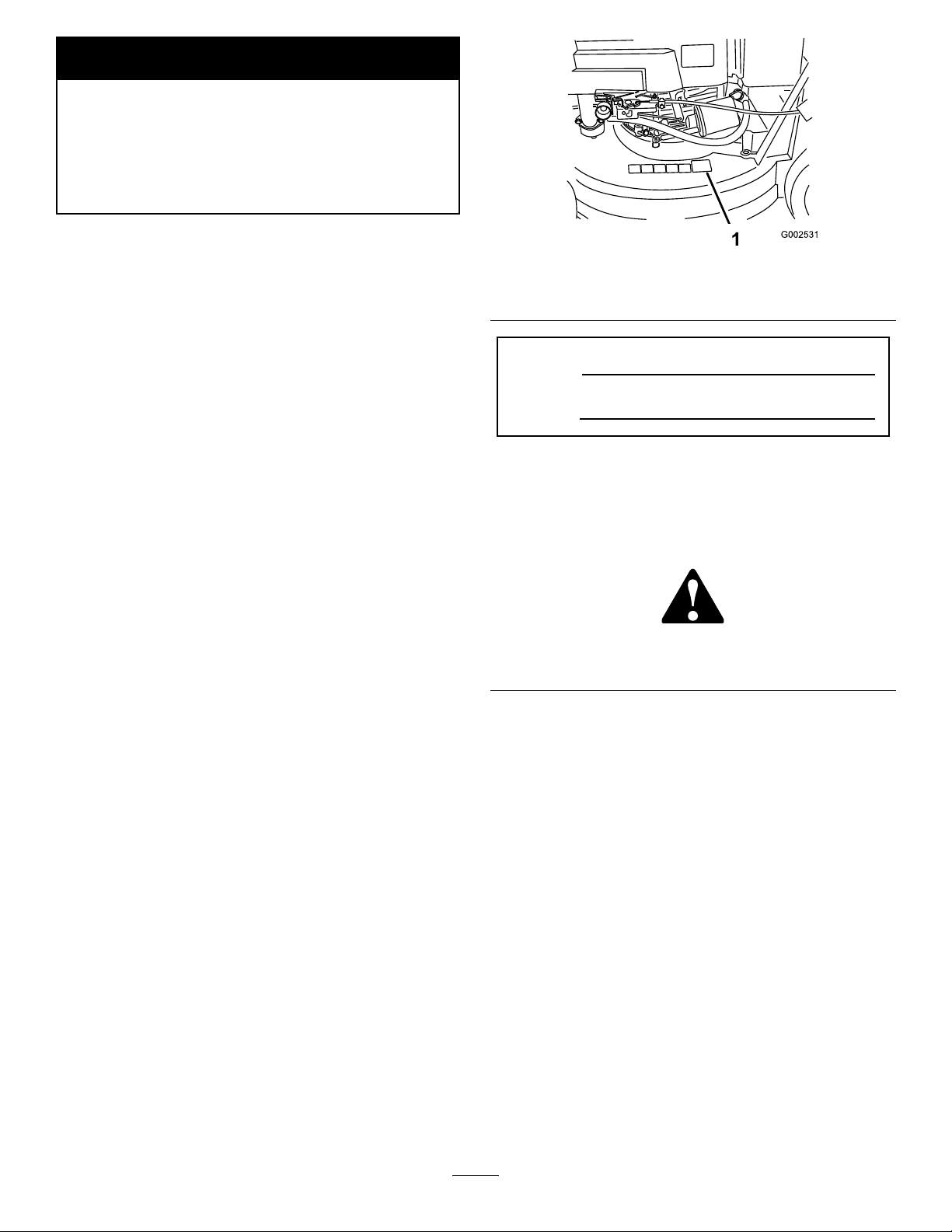

Figure1

1.Modelandserialnumberplate

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2008—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety

Introduction.................................................................2

Safety...........................................................................3

GeneralLawnMowerSafety.................................3

SafetyandInstructionalDecals.............................5

Setup............................................................................6

1InstallingtheHandle..........................................6

2InstallingtheFuelTankandtheFuel

Line..................................................................6

3FillingtheCrankcasewithOil.............................7

ProductOverview........................................................8

Controls...............................................................8

Operation.....................................................................9

CheckingtheEngineOilLevel..............................9

FillingtheFuelTankwithGasoline.......................9

StartingtheEngine.............................................11

StoppingtheEngine...........................................11

OperatingtheBlade............................................12

OperatingtheTractionDrive..............................12

CheckingtheBladeBrakeClutch........................13

AdjustingtheCuttingHeight..............................13

UsingtheGrassBag...........................................13

OperatingTips...................................................14

Maintenance...............................................................16

RecommendedMaintenanceSchedule(s)................16

Lubrication.............................................................16

LubricatingthePivotArms.................................16

LubricatingtheGearCase...................................17

EngineMaintenance...............................................17

ServicingtheAirFilter........................................17

ChangingtheEngineOil....................................18

ChangingtheOilFilter.......................................18

ServicingtheSparkPlug.....................................19

FuelSystemMaintenance.......................................20

EmptyingtheFuelTankandCleaningthe

FuelFilter.......................................................20

DriveSystemMaintenance.....................................20

AdjustingtheSelf-propelDrive...........................20

ServicingtheWheels..........................................20

ControlsSystemMaintenance.................................21

AdjustingtheBladeBrakeCable.........................21

BladeMaintenance.................................................23

MaintainingtheCuttingBlade.............................23

Cleaning.................................................................24

CleaningundertheMowerHousing....................24

CleaningtheBladeBrakeClutchShield...............25

Storage.......................................................................26

PreparingtheFuelSystem...................................26

PreparingtheEngine..........................................26

GeneralInformation..........................................26

RemovingtheLawnMowerfromStorage............26

Troubleshooting.........................................................27

ThislawnmowermeetsorexceedstheCPSC

bladesafetyrequirementsforwalk-behindrotary

lawnmowersandtheB71.4specicationsofthe

AmericanNationalStandardsInstituteineffectat

thetimeofproduction.

Improperlyusingormaintainingthislawnmower

canresultininjury.T oreducethepotentialfor

injury,complywiththesesafetyinstructions.

Torodesignedandtestedthislawnmowerfortooffer

reasonablysafeservice;however,failuretocomply

withthefollowinginstructionsmayresultin

personalinjury.

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Toensuremaximumsafety,bestperformance,and

togainknowledgeoftheproduct,itisessentialthat

youandanyotheroperatorofthelawnmowerread

andunderstandthecontentsofthismanualbefore

theengineiseverstarted.Payparticularattention

tothesafetyalertsymbol(Figure2)whichmeans

Caution,Warning,orDanger—“personalsafety

instruction.”Readandunderstandtheinstruction

becauseithastodowithsafety.Failuretocomply

withtheinstructionmayresultinpersonalinjury.

GeneralLawnMowerSafety

Thislawnmoweriscapableofamputatinghandsand

feetandofthrowingobjects.Failuretoobservethe

followingsafetyinstructionscouldresultinserious

injuryordeath.

ThefollowinginstructionsarefromtheANSI/OPEI

B71.4-2004standard.

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readEnglishitistheowner’ sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

3

Page 4

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmayrestrict

theageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtothemselves,other

people,orproperty.

includingemptyingthecatcheroruncloggingthe

chute.

•Stopequipmentandinspectbladeafterstriking

objectsorifanabnormalvibrationoccurs.Make

necessaryrepairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunits.

Preparation

•Onlyuseaccessoriesandattachmentsapprovedby

themanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glasses,andearprotection.Longhair,looseclothing

orjewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeused

andremoveallobjectssuchasrocks,toysandwire

whichcanbethrownbythemachine.

•Useextracarewhenhandlinggasolineandother

fuels.Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovegascaporaddfuelwithengine

running.Allowenginetocoolbeforerefueling.

Donotsmoke.

–Neverrefuelordrainthemachineindoors.

•Checkthatoperator’spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholes

andhiddenhazards.

•Onlystartenginefromtheoperator’sposition.

•Besureofyourfooting,especiallywhenbacking

up.Walk,don’trun.Neveroperateonwetgrass.

Reducedfootingcouldcauseslipping.

•Slowdownanduseextracareonhillsides.Besure

totravelsidetosideonhillsides.Turfconditions

canaffectthemachine’ sstability.Usecautionwhile

operatingneardrop-offs.

•Donotoperatethelawnmowerwithouteitherthe

grasscatcherortheguardinplace.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

•Keeppetsandbystandersaway.

•Slowdownandusecautionwhencrossingroadsand

sidewalks.Stopbladeifyouarenotmowing.

•Beawareofthemowerdischargedirectionanddo

notpointitatanyone.

•Donotoperatethemowerundertheinuenceof

alcoholordrugs.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

MaintenanceandStorage

•Stopengineanddisconnectsparkplugwire.Wait

forallmovementtostopbeforeadjusting,cleaning

orrepairing.

•Cleangrassanddebrisfromcuttingunit,drive,

mufer,andenginetohelppreventres.Cleanup

oilorfuelspillage.

•Letenginecoolbeforestoringanddonotstorenear

ame.

•Shutofffuelwhilestoringortransporting.Donot

storefuelnearamesordrainindoors.

•Neverallowuntrainedpersonneltoservicemachine.

•Removesparkplugwirebeforemakinganyrepairs.

•Usecarewhencheckingblade.Wrapthebladeor

weargloves,andusecautionwhenservicingthem.

Onlyreplaceblade.Neverstraightenorweldit.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Stoponlevelgroundandshutoffenginebefore

leavingtheoperator’spositionforanyreason

4

Page 5

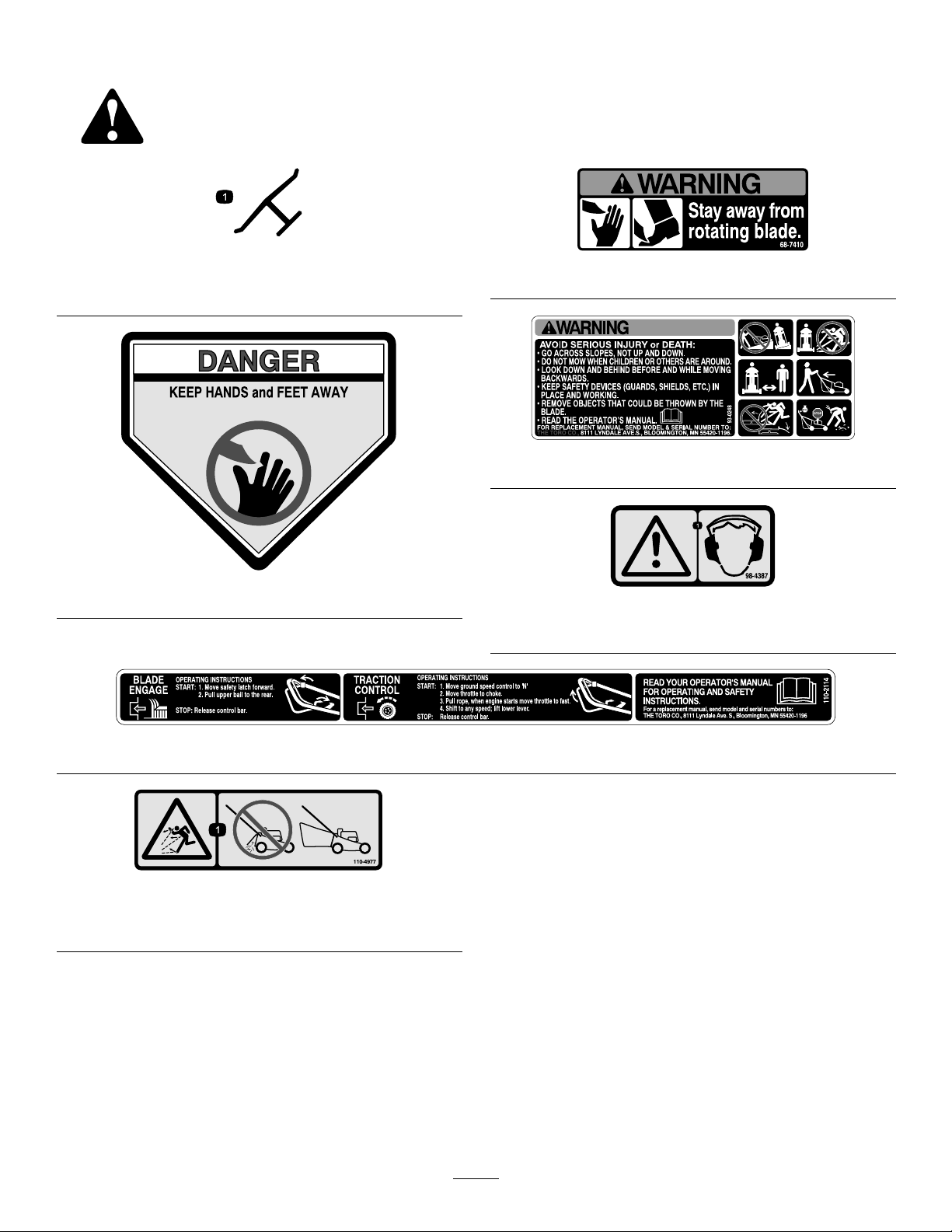

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

Manufacturer’sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

43-8480

68-7410

93-0248

98-4387

1.Warning—wearhearingprotection.

110-4977

1.Thrownobjecthazard—donotoperatethemowerwithouta

baginplace.

110-2114

5

Page 6

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Handle1

Bolt(5/16x7/8inch)

Bolt(5/16x1-1/2inches)

1

2

3

Washer4

Locknut(5/16inch)

Cabletie

Self-tappingscrew

Fueltank1

Nopartsrequired

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1

InstallingtheHandle

Qty.

Use

2

2

4

3

2

–

Installthehandle.

Installthefueltankandfuelline.

Fillthecrankcasewithoil.

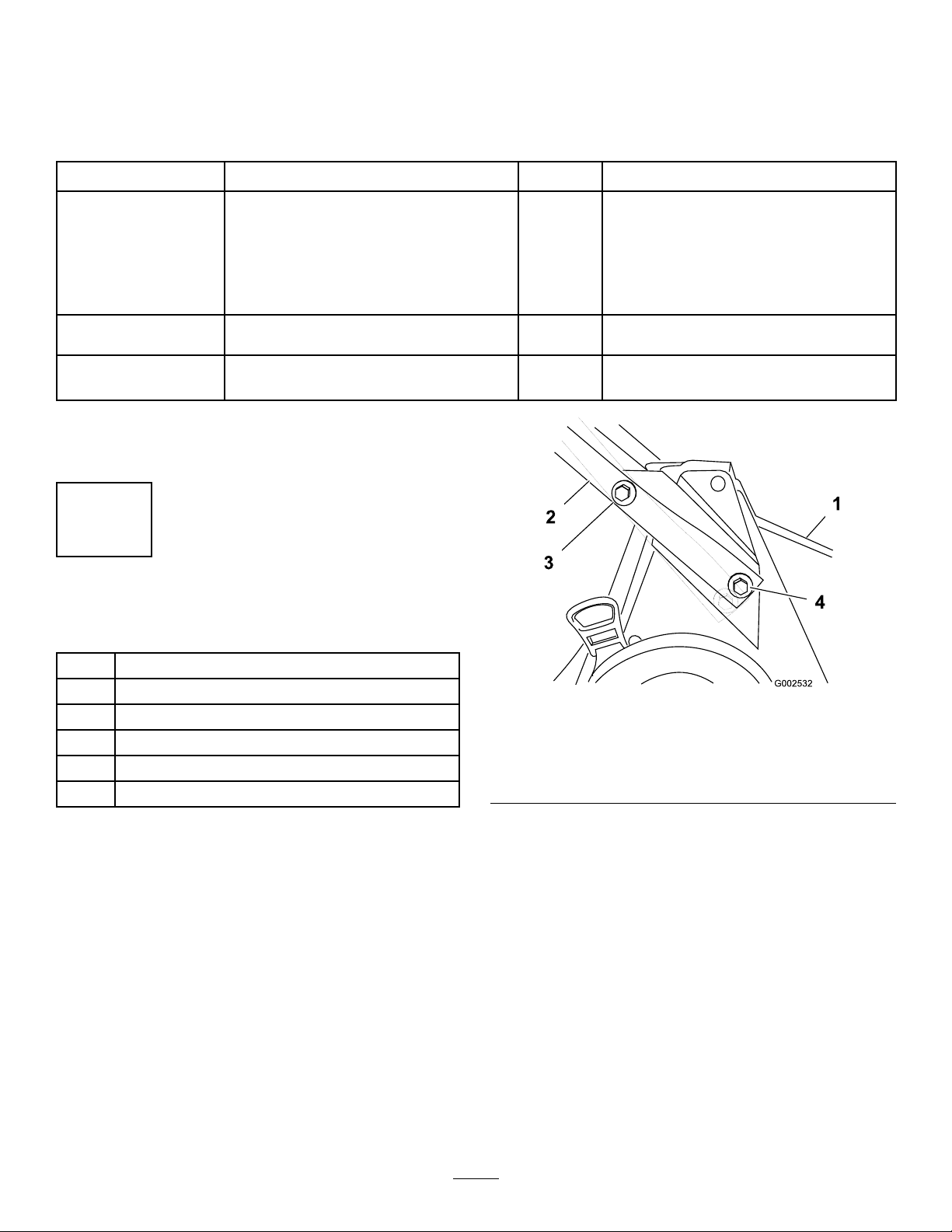

Partsneededforthisprocedure:

1Handle

2

Bolt(5/16x7/8inch)

2

Bolt(5/16x1-1/2inches)

4Washer

4

Locknut(5/16inch)

3

Cabletie

Procedure

1.Mountthehandletothemowerhousingwith2bolts

(5/16x7/8inch),2bolts(5/16x1-1/2inches),4

washers,and4locknuts(Figure3).

Figure3

1.Housing

2.Handle

3.Bolt(5/16x1-1/2inches),

washer,andlocknut

4.Bolt(5/16x7/8inch),

washer,andlocknut

Note:Installthewasherswiththecupsidefacing

thehandle.

Note:Youcanadjustthehandleheightformore

comfortableoperation.Securingthelowerhandle

endintheupperholelowersthehandle;securingthe

lowerhandleendinthelowerholeraisesthehandle.

2.Usethecabletiesprovidedtosecurethecontrol

cablestothehandle.

6

Page 7

2

G002527

1

2

3

4

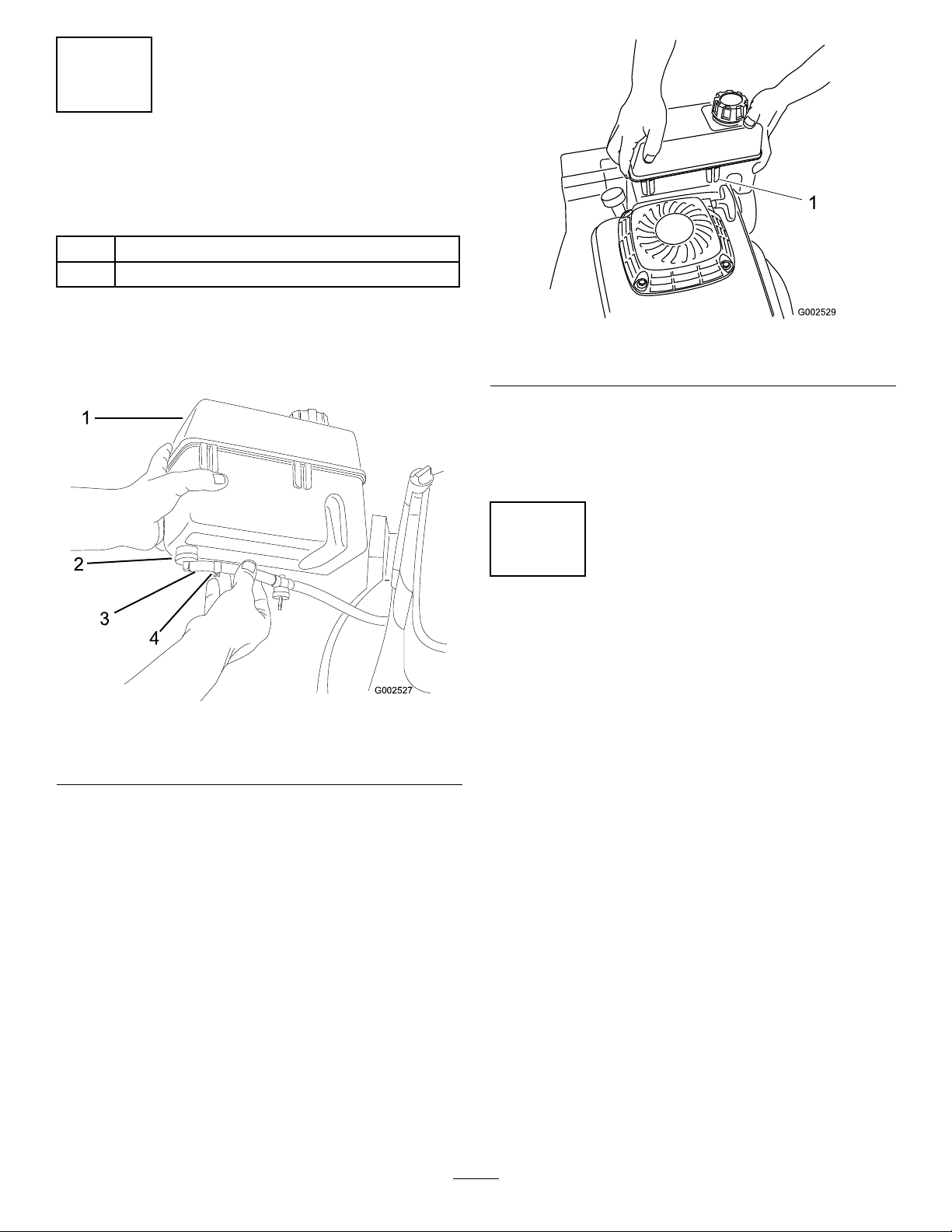

InstallingtheFuelTankand

theFuelLine

Partsneededforthisprocedure:

2

Self-tappingscrew

1Fueltank

Procedure

1.Slidetheendofthefuellineontotheelbowtting

(Figure4).

Figure4

1.Fueltank3.Fuelline

2.Elbowtting

2.Securethefuellineinplacewiththefuellineclamp

(Figure4).

4.Fuellineclamp

Figure5

1.Plasticclip(2)

4.Securethebottomofthefueltanktothefueltank

bracketbyinstallingtheself-tappingscrewsfromthe

bottom.Torquethescrewsto40to50in-lb(4.5

to5.6N-m).Donotovertightenthescrews.

3

FillingtheCrankcasewithOil

NoPartsRequired

Procedure

Theenginecrankcaseisshippedwithoutoil.Youmust

llitwithapproximately29oz.(0.85l)ofoilbefore

startingtheengine.RefertoCheckingtheEngineOil

Levelforoilspecicationsandinstructions.

3.Slidetheplasticclipsonthefrontofthefueltank

ontothefueltankmount(Figure5).

7

Page 8

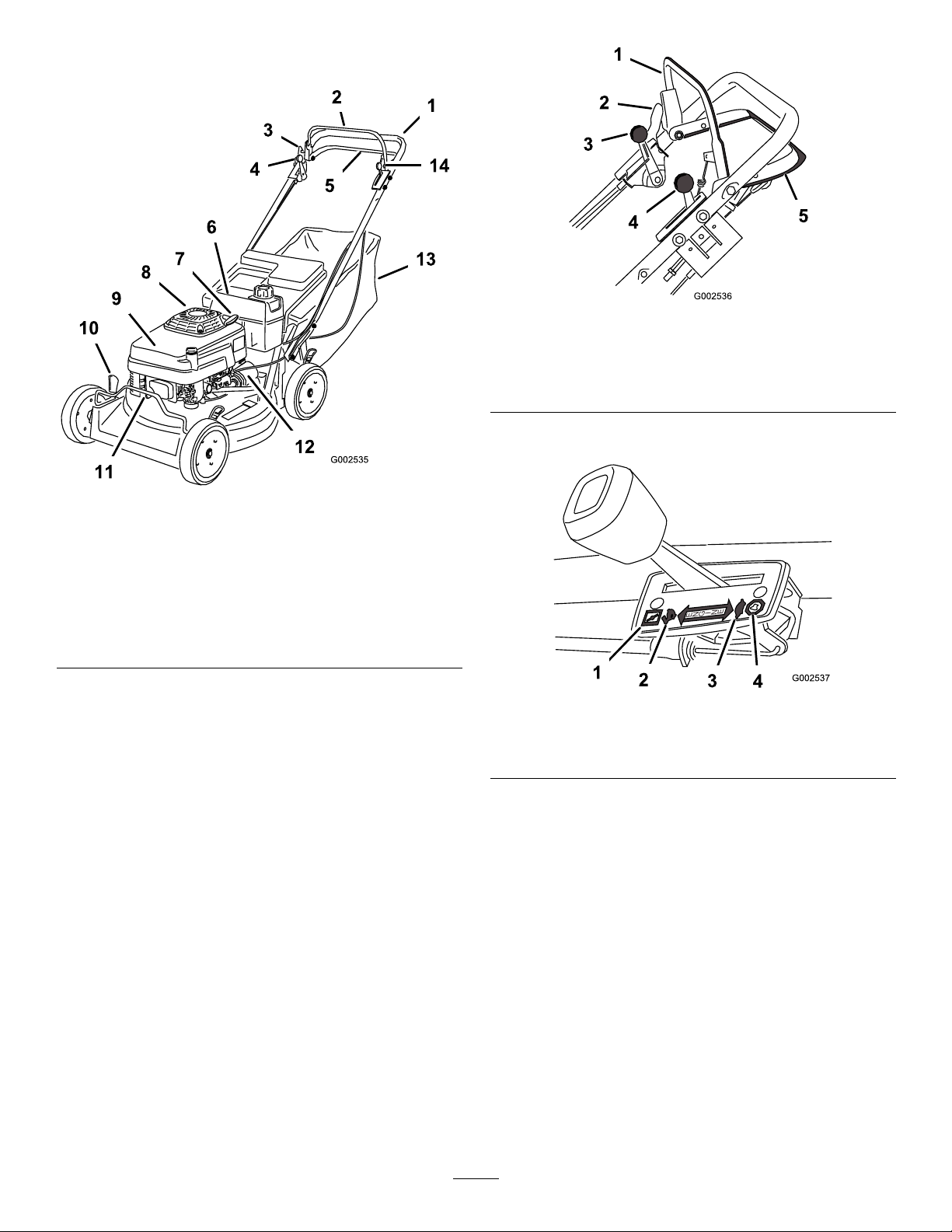

ProductOverview

Figure6

1.Handle

2.Bladecontrolbar

3.Controlbarlock10.Cuttingheightlever

4.Groundspeedcontrol

lever

5.Tractioncontrolbar

6.Fueltank

7.Starterhandle

8.Oilll/dipstick(notshown)

9.Airlter

11.Sparkplug

12.Oillter

13.Grassbag

14.Throttlecontrollever

Figure7

1.Bladecontrolbar4.Throttlecontrollever

2.Controlbarlock

3.Groundspeedcontrol

lever

5.Tractioncontrolbar

Thethrottlesettingsareshownin(Figure8).

Controls

Thebladecontrolbar,controlbarlock,groundspeed

controllever,throttlecontrollever,andtractioncontrol

barareontheupperhandleasshownin(Figure7).

Figure8

1.Choke3.Slow

2.Fast

4.Stop

8

Page 9

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Note:Whenthecrankcaseisempty,pourabout3/4

ofthecrankcasecapacityofoilinthecrankcase,then

followtheprocedureinthissection.

1.Movethelawnmowertoalevelsurface.

Eachtimebeforeyoumow ,makesurethatthe

self-propeldriveandthebladecontrolbaroperate

properly.Whenyoureleasethebladecontrolbar,the

bladeshouldstop.Ifitdoesnot,contactanAuthorized

ServiceDealer.

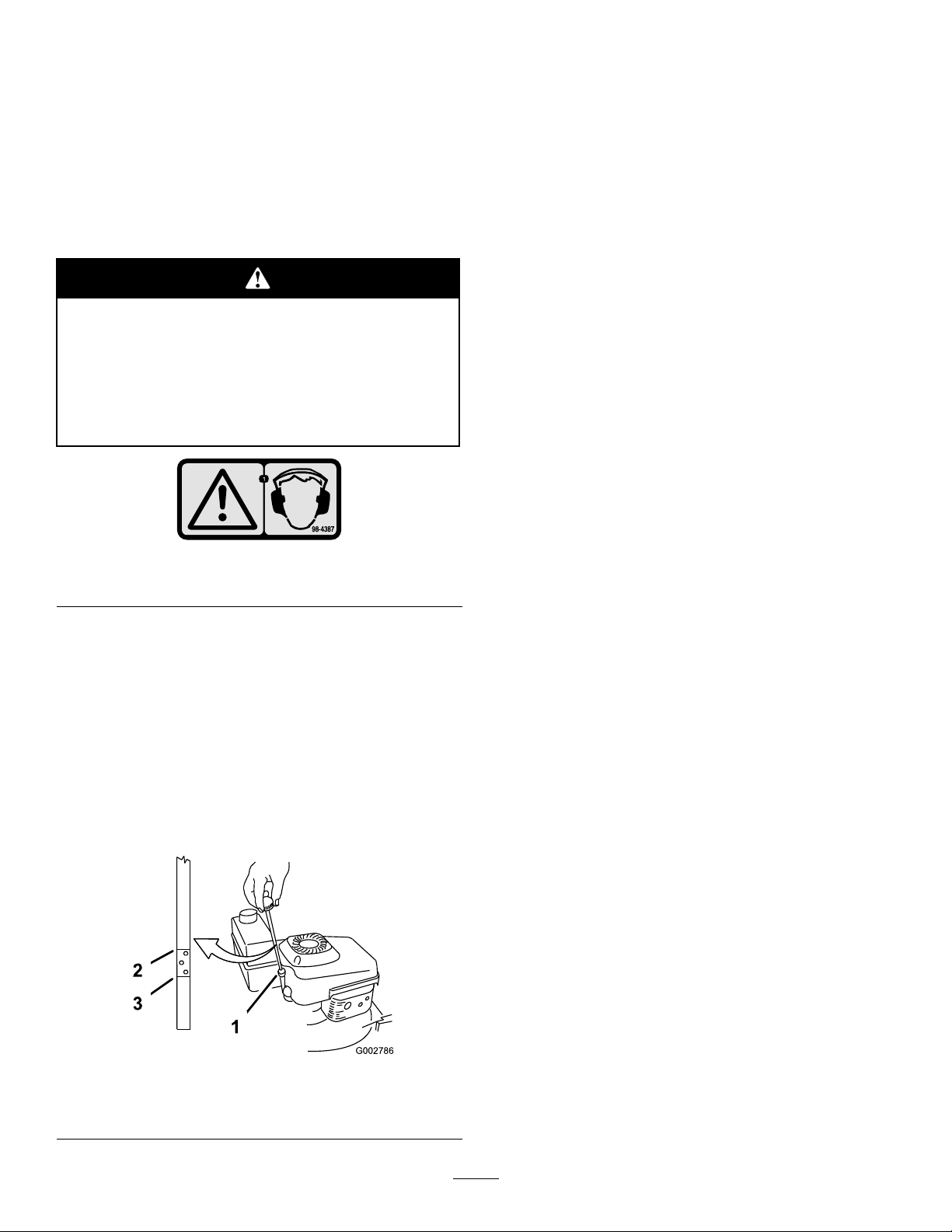

Thismachineproducessoundlevelsinexcess

of85dBAattheoperator’searandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

Figure9

1.Warning—wearhearingprotection.

2.Cleanaroundthedipstick(Figure10).

3.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout.

4.Wipethedipstickcleanwithacleancloth.

5.Insertthedipstickintothellerneck,butdonot

screwitin.

6.Removethedipstickandreadtheoillevelonthe

dipstick(Figure10).

7.IftheoillevelreadingisbelowtheAddmarkon

thedipstick,slowlypouronlyenoughoilintothe

llerholetoraisetheoilleveltotheFullmarkon

thedipstick.

Important:Donotoverllthecrankcasewith

oilandruntheengine;enginedamagewill

result.Draintheexcessoiluntiltheoillevelon

thedipstickreadsFull.

8.Insertthedipstickintothellerneckandrotatethe

capclockwiseuntilitistight.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Initially,llthecrankcasewith29ounces(0.85liters)

ofoil.Useonlyhigh-qualitySAE30orSAE10W30

weightdetergentoilthathastheAmericanPetroleum

Institute(API)serviceclassicationSF ,SG,SH,orSJ.

Beforeeachuse,ensurethattheoillevelisbetweenthe

AddandFullmarksonthedipstick(Figure10).

Figure10

1.Dipstick3.Add

2.Full

FillingtheFuelTankwith

Gasoline

Forbestresults,useclean,fresh,lead-freegasolinewith

anoctaneratingof87orhigher.T oensurefreshness,

purchaseonlythequantityofgasolinethatyouexpectto

usein30days.Usingunleadedgasolineresultsinfewer

combustiondepositsandlongerenginelife.Youmay

useleadedgasolineifunleadedgasolineisnotavailable.

Important:Donotaddoiltothegasoline.

Important:Donotusemethanol,gasoline

containingmethanol,gasoholcontainingmore

than10%ethanol,premiumgasoline,orwhitegas.

Usingthesefuelscandamagetheengine’sfuel

system.

Important:Donotusegasolinethathasbeen

storedsincethelastmowingseasonorlonger.

9

Page 10

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

Whenfueling,undercertaincircumstances,a

staticchargecandevelop,ignitingthegasoline.

Areorexplosionfromgasolinecanburnyou

andothersanddamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

andwhentheengineiscold.Wipeupany

gasolinethatspills.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1/4

to1/2inch(6to13mm)belowthebottomof

thellerneck.Thisemptyspaceinthetank

allowsthegasolinetoexpand.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwherea

sparkmayignitethegasolinefumes.

•Storegasolineinanapprovedfuelcontainer

andkeepitoutofthereachofchildren.

•Neverbuymorethana30-daysupplyof

gasoline.

•Alwaysplacegasolinecontainersonthe

groundandawayfromyourvehiclebefore

lling.

•Donotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowtheloss

ofanystaticcharge.

•Whenpractical,removegasoline-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

round.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,notfromagasoline

dispensernozzle.

•Ifyoumustuseagasolinedispensernozzle,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

Useafuelstabilizer/conditionerregularlyduring

operationandstorage.Astabilizer/conditionercleans

theengineduringoperationandpreventsgum-like

varnishdepositsfromformingintheengineduring

periodsofstorage.

Important:Donotusefueladditivesotherthan

afuelstabilizer/conditioner.Donotusefuel

stabilizerswithanalcoholbasesuchasethanol,

methanol,orisopropanol.

1.Cleanaroundthefueltankcap(Figure11).

10

Page 11

1.Oilll/dipstick

2.Fueltankcap

StartingtheEngine

1.Connectthewiretothesparkplug(Figure12).

Figure12

1.Spark-plugwire

2.Openthefuelvalve(Figure13)

Figure11

3.Aircleaner

2.Removethecapfromthetank.

3.Fillthefueltankwithunleadedgasolinetowithin

1/4to1/2inch(6to13mm)fromthetopofthe

tank.Donotllintothellerneck.

Important:Donotllthetankmorethan1/4

inch(6mm)fromthetopofthetankbecause

thegasolinemusthaveroomtoexpand.

4.Installthefueltankcapandwipeupanyspilled

gasoline.

Figure13

1.Fuelvalve

3.MovethethrottlecontrollevertotheChoke

position(Figure8).

4.MovethegroundspeedcontrollevertotheNeutral

(N)position.

5.Pullthestarterhandlelightlyuntilyoufeel

resistance,thenpullitsharply.

6.Regulatethethrottleandthegroundspeedcontrol

asdesiredwhentheenginestarts.

Note:Iftheenginefailstostartafter3pulls,repeat

steps3through6.

StoppingtheEngine

1.MovethethrottlecontroltotheStopposition.

2.Disconnectthewirefromthesparkplugifyoudo

notusethelawnmowerorleaveitunattended.

11

Page 12

OperatingtheBlade

OperatingtheTractionDrive

EngagingtheBlade

Whenyoustartyourengine,thebladedoesnotturn.

Youmustengagethebladetomow .

1.Pushthecontrolbarlockforward(Figure14).

Figure14

EngagingtheTractionDrive

1.Releasethetractioncontrolbar(Figure16).

Figure16

2.Movethegroundspeedcontrollevertothedesired

gearposition.

2.Pullthebladecontrolbartothehandleandhold

it(Figure15).

Figure15

DisengagingtheBlade

3.Squeezethetractioncontrolbaragainstthehandle

(Figure17).

Figure17

DisengagingtheTractionDrive

Releasethebladecontrolbar.

Important:Whenyoureleasethebladecontrol

bar,thebladeshouldstopwithin3seconds.Ifit

doesnotstopproperly,stopusingyourmower

immediatelyandcontactanAuthorizedService

Dealer.

Releasethetractioncontrolbar.

12

Page 13

CheckingtheBladeBrake

Clutch

Checkthebladecontrolbarbeforeeachusetoensure

thatthebladebrakeclutchsystemisoperatingproperly.

1.Installtheemptygrassbagonthedischargetunnel.

2.Starttheengine.

3.Pullthebladecontrolbartothenormalblade

engagedposition.Thebagshouldbegintoinate,

indicatingthatthebladeisengagedandrotating.

4.Releasethebladecontrolbar.Ifthebagdoesnot

immediatelydeate,itindicatesthattheblade

isstillrotating.Thebladebrakeclutchmaybe

deteriorating,and,ifignored,couldresultinan

unsafeoperatingcondition.Havethelawnmower

inspectedandservicedbyanAuthorizedService

Dealer.

Ifthebladebrakeclutchsystemisinoperative,

thebladewillcontinuetorotatewhenyou

releasethebladecontrolbail.Contactwith

bladecouldoccur,causingseriousinjury.

•Checkthebladebrakeclutchoperation

beforeeachuse.

Adjustingthecuttingheightleverscouldbring

yourhandsintocontactwithamovingblade

andresultinseriousinjury.

•Stoptheengineandwaitforallmovement

tostopbeforeadjustingthecuttingheight.

•Donotputyourngersunderthehousing

whenadjustingthecuttingheight.

1.Pullthewheelheightadjustmentlevertowardthe

wheel(Figure18)andmoveittothedesiredsetting.

Figure18

1.Wheelheightadjustmentlever

•Neveruseamowerequippedwithablade

brakeclutchthathasaninoperativesafety

system.

•TakeyourmowertoanAuthorizedService

Dealerforrepairifthesafetysystemfailsto

operateproperly.

AdjustingtheCuttingHeight

Eachwheelisadjustedindividuallywithawheelheight

adjustmentlever.Cuttingheightsare1-1/4inches(32

mm),1-3/4inches(44mm),2-1/4inches(57mm),

2-3/4inches(70mm),3-1/4inches(83mm),and

3-3/4inches(95mm).

2.Releasethewheelheightadjustmentleverandseat

itsecurelyinthenotch.

3.Adjustallthewheelstothesamecuttingheight

setting.

UsingtheGrassBag

InstallingtheGrassBag

1.Waitforallmovingpartstostop.

2.Raiseandholdupthereardoor(Figure19).

13

Page 14

MowingwiththeGrassBag

Aworngrassbagcouldallowsmallstones

andothersimilardebristobethrowninthe

operator’sorbystander’sdirectionandresultin

seriouspersonalinjuryordeathtotheoperator

orbystanders.

Checkthegrassbagfrequently.Ifitis

damaged,installanewTororeplacementbag.

Figure19

1.Reardoor

3.Installthebagonthebagmountingposts

(Figure20).

Figure20

1.Bagmountingposts

OperatingTips

GeneralTips

•Maintainasharpbladethroughoutthecutting

season.Periodicallyledownnicksontheblade.

•Replacethebladewhennecessarywithanoriginal

Tororeplacementblade.

•Mowonlydrygrassorleaves.Wetgrassandleaves

tendtoclumpontheyardandcancausethemower

toplugortheenginetostall.

Wetgrassorleavescancauseseriousinjuryif

youslipandcontacttheblade.

Mowonlyindryconditions.

•Cleanunderthemowerhousingaftereachmowing.

SeeCleaningundertheMowerHousing.

4.Lowerthereardoor.

RemovingtheGrassBag

Toremovethebag,reversethestepsabove.

Themowercanthrowgrassclippingsandother

objectsthroughanopendischargetunnel.

Objectsthrownwithenoughforcecouldcause

seriouspersonalinjuryordeathtotheoperator

orbystander.

Donotoperatethemowerwithoutagrassbag

installed.

•Keeptheengineingoodrunningcondition.

•Settheenginespeedtothefastestpositionforthe

bestcuttingresults.

14

Page 15

•Forlightleafcoverage,setallthewheelsatthesame

cuttingheightsetting.

Operatingamowerwithitsenginerunningat

aspeedgreaterthanthefactorysettingcan

causethemowertothrowapartofthebladeor

engineintotheoperator’sorbystander’sarea

andresultinseriouspersonalinjuryordeath.

–Donotchangetheenginespeedsetting.

–Ifyoususpecttheenginespeedisfaster

thannormal,contactanAuthorizedService

Dealer.

•Cleantheairlterfrequently.Mulchingstirsup

moreclippingsanddustwhichclogstheairlter

andreducesengineperformance.

CuttingGrass

•Grassgrowsatdifferentratesatdifferenttimesof

theyear.Inthesummerheat,itisbesttocutgrass

atthe2-1/4inch(57mm),2-3/4inch(70mm),or

3-1/4inch(83mm)cuttingheightsettings.Cut

onlyaboutathirdofthegrassbladeatatime.Do

notcutbelowthe2-1/4inch(57mm)settingunless

thegrassissparseoritislatefallwhengrassgrowth

beginstoslowdown.

•Whencuttinggrassover6inches(15cm)tall,rst

mowatthehighestcuttingheightsettingandwalk

slower;thenmowagainatalowersettingforthe

bestlawnappearance.Ifthegrassistoolongand

theleavesclumpontopofthelawn,themowermay

plugandcausetheenginetostall.

•Alternatethemowingdirection.Thishelpsdisperse

theclippingsoverthelawnforevenfertilization.

•Iftherearemorethan5inches(12.7cm)ofleaves

onthelawn,setthefrontcuttingheight1or2

notcheshigherthantherearcuttingheight.This

makesiteasiertofeedtheleavesunderthemower

housing.

•Slowdownyourmowingspeedifthemowerdoes

notcuttheleavesnelyenough.

•Ifyoumowoveroakleaves,youcanaddlimeto

thegrassinthespringtoreducetheacidityofthe

oakleaves.

Ifthenishedlawnappearanceisunsatisfactory,try

oneormoreofthefollowing:

•Sharpentheblade.

•Walkataslowerpacewhilemowing.

•Raisethecuttingheightonyourmower.

•Cutthegrassmorefrequently .

•Overlapcuttingswathsinsteadofcuttingafull

swathwitheachpass.

•Setthecuttingheightonthefrontwheelsonenotch

lowerthantherearwheels.Forexample,setthe

frontwheelsat2-1/4inches(57mm)andtherear

wheelsat2-3/4inches(70mm).

CuttingLeaves

•Aftercuttingthelawn,ensurethathalfofthelawn

showsthroughthecutleafcover.Youmayneedto

makemorethanonepassovertheleaves.

15

Page 16

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

Every300hours

Yearly

Important:Refertoyour

MaintenanceProcedure

•Changetheengineoil.

•Checktheengineoillevel.

•Inspectthemowerbladesforwearordamage.

•Cleanunderthemowerhousing.

•Cleanthefoampre-cleaner(morefrequentlyindustyconditions).

•Lubricatethepivotarms.

•Changetheengineoil(moreoftenindustyconditions).

•Cleanthebladebrakeclutchshield.

•Lubricatethegearcase.

•Changetheoillter.

•Checkthesparkplug.

•Replacethepaperairlter(morefrequentlyindustyconditions).

•Emptythefueltankandcleanthefuellter.

Engine Operator’ s Man ual

foradditionalmaintenanceprocedures.

Ifyouleavethewireonthesparkplug,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Disconnectthewirefromthesparkplugbeforeyoudoanymaintenance.Setthewireasidesothatit

doesnotaccidentlycontactthesparkplug.

Lubrication

LubricatingthePivotArms

ServiceInterval:Every50hours

1.Movetherearwheelcuttingheightleverstothe

centersetting.

2.Wipethegreasettingswithacleanrag(Figure21).

3.Installagreasegunontothettingandgentlyapply2

or3pumpsof#2multi-purposelithium-basegrease.

Important:Excessivegreasepressuremay

damagetheseals.

Figure21

16

Page 17

LubricatingtheGearCase

ServiceInterval:Every100hours

1.Removethegrassbag.

2.Installagreasegunontothettingthroughthebelt

coveropening(Figure22).

Figure22

EngineMaintenance

ServicingtheAirFilter

ServiceInterval:Every25hours—Cleanthefoam

pre-cleaner(morefrequentlyindusty

conditions).

Every300hours—Replacethepaper

airlter(morefrequentlyindusty

conditions).

Important:Donotoperatetheenginewithoutthe

airlterassembly;extremeenginedamagewill

occur.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug(Figure12).

3.Removethescrewthatsecurestheaircleanercover

(Figure23).

3.Gentlyapplyoneto2pumpsof#2multi-purpose

lithium-basegrease.

4.Installthegrassbag.

Figure23

1.Screw3.Paperairlter

2.Cover

4.Removethecoverandcleanitthoroughly(Figure23).

5.Removeandinspectthepaperairlter(Figure24),

anddiscarditifitisexcessivelydirty.

17

Figure24

1.Paperairlter

Important:Donottrytocleanapaperlter.

2.Foampre-cleaner

Page 18

6.Removethefoampre-cleanerandwashitwitha

milddetergentandwater,thenblotitdry.

7.Saturatethepre-cleanerwithoil,thensqueezeit(do

nottwist)toremovetheexcessoil.

8.Installthefoampre-cleaner.

9.Installthepaperairlter.

Note:Installanewpaperairlterifyoudiscarded

theoldone.

10.Installthecoverandsecureitwiththescrew.

ChangingtheOilFilter

ServiceInterval:Every100hours

ChangingtheEngineOil

ServiceInterval:Aftertherst8hours

Every50hours

OilCapacity

Withoillter29ounces(0.85liters)

Withoutoillter22ounces(0.65liters)

1.Runtheenginetowarmtheengineoil.

Note:W armoilowsbetterandcarriesmore

contaminants.

Oilmaybehotafterenginehasbeenrun,and

contactwithhotoilcancauseseverepersonal

injury.

Avoidcontactingthehotengineoilwhenyou

drainit.

2.Stoptheengineandwaitforallmovingpartstostop.

3.Disconnectthewirefromthesparkplug(Figure12).

4.Placeasuitabledrainpanundertherightsideof

themower.

Figure25

1.Oillter

2.Fuelline

1.Runtheenginetowarmtheoil.

Oilmaybehotaftertheenginehasbeenrun,

andcontactwithhotoilcancausesevere

personalinjury.

Avoidcontactingthehotengineoilwhenyou

drainit.

2.Stoptheengineandwaitforallmovingpartstostop.

3.Disconnectthewirefromthesparkplug(Figure12).

4.Draintheengineoil;refertoChangingtheEngine

Oil.

5.Placearagundertheoilltertocatchanyoilthat

mayleakoutasyouremovethelter(Figure25).

6.Removetheoillter.

7.Useyourngertocoatthegasketonthenewlter

withoil(Figure26).

5.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout.

6.Tipthemowerontoitsrightsidetodraintheoil

intothedrainpan.

Note:Youcanalsoremovetheoilfromthe

crankcaseusinganoilextractor.

7.Returnthemowertoitsoperatingposition.

8.Insertthedipstickintothellerneckandrotatethe

capclockwiseuntilitistight.

9.Recycletheusedoilaccordingtolocalcodes.

10.FillthecrankcasetotheFulllineonthedipstickwith

freshoil.RefertotheFillingtheCrankcasewithOil.

11.Wipeupanyspilledoil.

18

Page 19

Figure27

Figure26

1.Gasket

1.Centerelectrodeinsulator

2.Sideelectrode

3.Airgap(nottoscale)

8.Installthenewlterandhandtightenit2/3turn

only.

9.FillthecrankcasetotheFulllineonthedipstickwith

freshoil.RefertoFillingtheCrankcasewithOil.

10.Connectthewiretothesparkplug.

11.Runtheengineforabout3minutes.

12.Stoptheengine,waitforallmovingpartstostop,

andcheckforoilleakagearoundthelter.

13.Addoiltocompensatefortheoilintheoillter.

RefertoCheckingtheEngineOilLevel.

14.Recycletheusedoillteraccordingtolocalcodes.

ServicingtheSparkPlug

ServiceInterval:Every100hours

UseanNGKBPR5ESsparkplugorequivalent.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug(Figure12).

6.Installthesparkplugandthegasketseal.

7.Torquetheplugto17ft-lb(23N⋅m).

8.Connectthewiretothesparkplug.

3.Cleanaroundthesparkplug.

4.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,or

dirtysparkplug.Donotcleantheelectrodes

becausegritenteringthecylindercandamage

theengine.

5.Setthegapontheplugto0.030inch(0.76mm)

(Figure27).

19

Page 20

FuelSystem

DriveSystem

Maintenance

EmptyingtheFuelTankand

CleaningtheFuelFilter

ServiceInterval:Yearly

Thefuellter(screen)elementislocatedinsidethefuel

tank.

1.Stoptheengineandwaitforittocooldown.

Note:Draingasolinefromacoldengineonly .

2.Disconnectthewirefromthesparkplug.

3.Disconnectthefuellinebylooseningthetubeclamp

atthecarburetor.

4.Openthefuelvalve.

5.Drainthegasolinecompletelyfromthetankandfuel

lineintoanapprovedfuelcontainer.

6.Removethefueltankfromthemower.

Maintenance

AdjustingtheSelf-propelDrive

Ifthemowerdoesnotself-propelorhasatendencyto

creepforwardwhenthecontrolbarismorethan1-1/2

inches(3.8cm)fromthehandle,adjusttheself-propel

drive.

1.Loosenthenutthatsecurestheturnbuckle

(Figure28).

7.Pourasmallamountoffuelinthefueltank,move

thefuelaroundinthetank,andpouritoutintoan

approvedfuelcontainer.

8.Installthefueltankandfuelline;refertoInstalling

theFuelTankandtheFuelLine.

Figure28

1.Turnbuckle

2.Nut

2.Turntheturnbuckleuntilyouremovetheslackin

theexposedcable(Figure28).

3.Tightenthenut.

Note:Tochecktheadjustment,slowlypullthe

mowerbackwardwhileyougraduallymovethe

controlbartowardthehandle.Theadjustmentis

correctwhentherearwheelsstopturningandthe

topofthecontrolbarisabout1-1/2inches(3.8cm)

fromthehandle.

3.Cable

4.1-1/2inches(3.8cm)

ServicingtheWheels

RemovingtheWheels

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug(Figure12).

3.Removethebolt,thewheelspacer,andthelocknut

mountingthewheeltothepivotarm(Figure29).

20

Page 21

ControlsSystem

Maintenance

AdjustingtheBladeBrake

Cable

Figure29

1.Locknuts

2.Wheelspacer7.Lug

3.Bearing/hubassembly8.Bearing(2)

4.Bearingspacer9.Bolt

5.Wheelhalf

4.Separatethewheelhalvesfromthetirebyremoving

4boltsand4locknuts(Figure29).

Note:Ifyouremovethebearingsfromthe

bearing/hubassembly,removethembypressingon

thebearingspacer(Figure29).

6.Plasticcover(rearwheels

only)

AssemblingtheWheels

1.Positionthetireontoonewheelhalf,aligningthe

lugsoneach(Figure29).

2.Placethebearing/hubassemblyintothecenterhole

ofthewheelhalf.Ensurethatthelegsofthehubare

positionedovertheangeofthehole(Figure29).

Wheneveryouinstallanewbladebrakecableorreplace

thebladebrakeassembly,adjustthespringtensionon

thebladebrakecable.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug(Figure12).

3.Removethefueltankfromthetankbracket.

Note:Youdonotneedtodisconnectthefuelline

fromthefueltank.

4.Resetthecableadjusteronthehandlesothat1/4

inch(6mm)ofthethreadsshow ,thentightenthe

nut(Figure30).

3.Placetheotherwheelhalfontothebearing/hub

assembly,aligningthewheelandthetirelugsandthe

mountingholes(Figure29).

4.Using2fullythreadedscrewsorbolts(1/4-20x1.50

inch)andnon-lockingnuts,looselysecurethewheel

halvestogether.Mountthescrewsorboltsinthe

opposingholes(Figure29).

5.Checkthealignmentofallpartsandtightenthe

screws,alternatingfromsidetosideforauniformt,

untilthewheelhalvesaredrawntogether(Figure29).

6.Installthe2boltsand2locknutspreviouslyremoved

intheremainingholesinthewheelhalvesand

tighten.Removethe2longscrewsorboltsand

replacethemwith2boltsand2locknuts(Figure29).

7.Installthewheeltothepivotarmwiththebolts,

aspacer,andalocknut.Ensurethatthespaceris

positionedbetweenthewheelhubandthepivotarm

(Figure29).

Figure30

1.Cableadjuster3.1/4inch(6mm)ofthreads

2.Nut

5.Loosenthecableclampscrewuntilthebrakecable

conduitslides(Figure31).

21

Page 22

Figure31

1.Spring3.Cableclampscrew

2.Brakecableconduit

6.Holdthebladecontrolbarsothattheoutsideofthe

baris5-1/2inches(14cm)fromtheoutsideofthe

handle,andpullthecabletotheremovetheslack,

butdonotputtensiononthespring(Figure32).

toadjustthecableadjustertoachievethisvalue

(Figure30).

Donotovertightenthebladebrakecable.

Overtighteningthebladebrakecablecould

preventthebladebrakefromcontactingthe

brakedrumwhenyoureleasethecontrolbar.

Ifthebladebrakedoesnotcontactthebrake

drum,thebladewillnotstoprotating,which

couldcauseseriouspersonalinjury.

•Eachtimeyouadjustthebrakecable,ensure

thatthebrakestopsthebladein3seconds

orless.

•Ifthebladedoesnotstoprotatingin3

secondsorless,bringthemowertoan

AuthorizedServiceDealerforinspection

andrepair.

Figure32

1.5-1/2inches(14cm)

2.Handle

3.Bladecontrolbar

7.Torquethecableclampscrewto100to120in-lb(11

to14N-m)tolocktheadjustmentinplace.

8.Measurethelengthofthespringbothbeforeand

afterengagingthebladecontrolbar.Thedifference

betweenthese2lengthsisthespringstretch.

Note:Thespringstretchmustbebetween0.290

and0.310inches(7.4to7.9mm).Youmayneed

22

Page 23

BladeMaintenance

MaintainingtheCuttingBlade

Alwaysmowwithasharpblade.Asharpbladecuts

cleanlyandwithouttearingorshreddingthegrassblades.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug(Figure12).

3.Drainthegasolinefromthefueltank;referto

EmptyingtheFuelTankandCleaningtheFuelFilter.

4.Tipthemowerontoitsrightside(Figure33).

Figure33

1.Blade3.Anti-scalpcup

2.Bladenuts

InspectingtheBlade

Figure34

1.Sail

2.Flatpartoftheblade4.Slotformed

3.Wear

Note:Forthebestperformance,installanewblade

beforethecuttingseasonbegins.Duringtheyear,le

downanysmallnickstomaintainthecuttingedge.

Awornordamagedbladecanbreak,anda

pieceofthebladecouldbethrownintothe

operator’sorbystander’sarea,resultingin

seriouspersonalinjuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

RemovingtheBlade

Grasptheendofthebladeusingaragorathickly

paddedglove.Removethebladenuts,theanti-scalpcup,

andtheblade(Figure33).

ServiceInterval:Beforeeachuseordaily

Carefullyexaminethebladeforsharpnessandwear,

especiallywheretheatandthecurvedpartsmeet

(Figure34A).Becausesandandabrasivematerialcan

wearawaythemetalthatconnectstheatandcurved

partsoftheblade,checkthebladebeforeusingthe

mower.Ifyounoticeaslotorwear(Figure34Band

Figure34C),replacetheblade;refertoRemovingthe

Blade.

SharpeningtheBlade

Filethetopsideofthebladetomaintainitsoriginal

cuttingangle(Figure35A)andinnercuttingedgeradius

(Figure35B).Thebladewillremainbalancedifyou

removethesameamountofmaterialfrombothcutting

edges.

Figure35

1.Sharpenatthisangleonly .

23

2.Maintaintheoriginalradius

here.

Page 24

BalancingtheBlade

1.Checkthebalanceofthebladebyplacingthecenter

holeofthebladeoveranailorscrewdrivershank

clampedhorizontallyinavise(Figure36).

Figure36

Note:Youcanalsocheckthebalanceusinga

commerciallymanufacturedbladebalancer.

2.Ifeitherendofthebladerotatesdownward,lethat

end(notthecuttingedgeortheendnearthecutting

edge).Thebladeisproperlybalancedwhenneither

enddrops.

InstallingtheBlade

Cleaning

CleaningundertheMower

Housing

Toensurethebestperformance,keeptheundersideof

themowerhousingclean.

WashingMethod

ServiceInterval:Beforeeachuseordaily

1.Positionthemoweronaatconcreteorasphalt

surfacenearagardenhose.

2.Starttheengine.

3.Holdtherunninggardenhoseathandleleveland

directthewatertoowonthegroundjustinfront

oftherightrearwheel(Figure37).

1.Installasharp,balancedToroblade,theanti-scalp

cup,andthebladenuts.Thesailoftheblademust

pointtowardthetopofthemowerhousingfor

properinstallation.Torquethebladenutsto23to

27ft-lb(32to37N-m).

2.Returnthemowertoitsoperatingposition.

3.Connectthewiretothesparkplug.

Figure37

1.Rightrearwheel

Note:Thebladewillsplashintothepathofthe

blade,cleaningouttheclippings.

4.Stoptheengineandwaitforallmovingpartstostop.

5.Turnoffthewater.

6.Startthemowerandletitrunforafewminutes

todryoutthemoistureonthemowerandits

components.

ScrapingMethod

Ifwashingdoesnotremovealldebrisfromunderthe

mower,scrapeitclean.

1.Disconnectthewirefromthesparkplug(Figure12).

2.Drainthefuelfromthefueltank.RefertoEmptying

theFuelTankandCleaningtheFuelFilter.

24

Page 25

Tippingthemowermaycausethefueltoleak

fromthecarburetororthefueltank.Gasoline

isextremelyammable,highlyexplosive,and,

undercertainconditions,cancausepersonal

injuryorpropertydamage.

Avoidfuelspillsbyrunningtheenginedryor

byremovingthegasolinewithahandpump;

neversiphon.

3.Tipthemowerontoitsrightside.

4.Removethedirtandgrassclippingswithahardwood

scraper.Avoidburrsandsharpedges.

5.Returnthemowertoitsoperatingposition.

6.Fillthefueltank.

7.Connectthewiretothesparkplug.

CleaningtheBladeBrake

ClutchShield

Figure38

1.Screws(4)

7.Removetheshieldandbrushorblowallthedebris

fromundertheshieldandaroundthebladebrake

clutchsystem.

8.Installtheshieldusingthe4screwsthatyou

previouslyremoved.

2.Bladebrakeclutchshield

ServiceInterval:Every50hours

Cleaninsidethebladebrakeclutchshieldwhenyou

changetheengineoilorwhenyousharpentheblade,

becauseyouneedtoremovethebladeinorderto

removetheshield.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug(Figure12).

3.Drainthegasolinefromthefueltank;referto

EmptyingtheFuelTankandCleaningtheFuelFilter.

4.Tipthemoweronitsrightside.

Tippingthemowermaycausethefueltoleak

fromthecarburetororthefueltank.Gasoline

isextremelyammable,highlyexplosive,and,

undercertainconditions,cancausepersonal

injuryorpropertydamage.

Avoidfuelspillsbyemptyingthefueltankas

directed;neversiphon.

9.Installtheblade,theanti-scalpcup,andthe2blade

nuts.

10.Returnthemowertoitsoperatingposition.

11.Connectthewiretothesparkplug.

5.Remove2bladenuts,theanti-scalpcup,andthe

blade(Figure33).

6.Removethe4screwsthatholdtheshieldinplace

(Figure38)..

25

Page 26

Storage

2.Cleananydirtandchafffromthecylinder,cylinder

headns,andblowerhousing.

Topreparethemowerforoff-seasonstorage,perform

therecommendedmaintenanceprocedures.Referto

Maintenance.

Storethemowerinacool,clean,dryplace.Coverthe

mowertokeepitcleanandprotected.

PreparingtheFuelSystem

Gasolinecanvaporizeifyoustoreitoverlong

periodsoftimeandexplodeifitcomesinto

contactwithanopename.

•Donotstoregasolineoverlongperiodsof

time.

•Donotstorethemowerwithgasolineinthe

fueltankorthecarburetorinanenclosure

withanopename.(Forexample,afurnace

orawaterheaterpilotlight.)

•Allowtheenginetocoolbeforestoringitin

anyenclosure.

3.Removegrassclippings,dirt,andgrimefromthe

externalpartsoftheengine,theshrouding,andthe

topofthemowerhousing.

4.Checktheconditionoftheblade.Referto

MaintainingtheCuttingBlade.

5.Cleanthebladebrakeclutchshield;refertoCleaning

theBladeBrakeClutchShield.

6.Servicetheairlter;refertoServicingtheAirFilter.

7.Lubricatethepivotarms;refertoLubricatingthe

PivotArms.

8.Tightenallnuts,bolts,andscrews.

9.Touchupallrustedorchippedpaintsurfaceswith

paintavailablefromanAuthorizedServiceDealer.

RemovingtheLawnMower

fromStorage

1.Checkandtightenallfasteners.

2.Removethesparkplugandspintheenginerapidly

usingthestartertoblowexcessoilfromthecylinder.

Emptythefueltankwhenmowingthelasttimebefore

storingthemower.

1.Runthemoweruntiltheenginestopsfromrunning

outoffuel.

2.Primetheengineandstartitagain.

3.Allowtheenginetorununtilitstops.Whenyoucan

nolongerstarttheengine,itissufcientlydry.

PreparingtheEngine

1.Whiletheengineisstillwarm,changetheoilfrom

thecrankcase.RefertoChangingtheEngineOil.

2.Removethesparkplug.

3.Usinganoilcan,addaboutonetablespoonofoilto

thecrankcasethroughthesparkplughole.

4.Slowlyrotatetheengineseveraltimes,usingthe

starterrope,todistributetheoil.

5.Installthesparkplugbutdonotconnectthewireto

thesparkplug.

3.Cleanthesparkplugorreplaceitifitiscracked,

broken,oriftheelectrodesareworn.

4.Installthesparkplugandtorqueitto17ft-lb(23

N-m).

5.Performanyneededmaintenanceprocedures;refer

toMaintenance.

6.Fillthefuelinthefueltankwithfreshgasoline.

7.Checktheengineoillevel.

8.Connectthewiretothesparkplug.

GeneralInformation

1.Cleanthemowerhousing.RefertoCleaningunder

theMowerHousing.

26

Page 27

Troubleshooting

Problem

Enginedoesnotstart

Enginestartshardorlosespower

Enginerunsrough

PossibleCauseCorrectiveAction

1.Thefueltankisemptyorthefuel

systemcontainsstalefuel.

2.ThethrottleleverisnotintheChoke

position.

3.Thewireisnotconnectedtothespark

plug.

4.Thesparkplugispitted,fouled,orthe

gapisincorrect.

1.Thefueltankcontainsstalefuel.1.Drainandllthefueltankwithfresh

2.Thefuelcapventholeisplugged.2.Cleanthefuelcapventholeorreplace

3.Theairlterelementisdirtyandis

restrictingtheairow.

4.Theundersideofthemowerhousing

containsclippingsanddebris.

5.Thesparkplugispitted,fouled,orthe

gapisincorrect.

6.Theengineoillevelislowortheoilis

dirty.

1.Thewireisnotconnectedtothespark

plug.

2.Thesparkplugispitted,fouled,orthe

gapisincorrect.

3.ThethrottleleverisnotintheFast

position.

4.Theairlterelementisdirtyandis

restrictingtheairow.

1.Drainand/orllthefueltankwith

freshgasoline.Iftheproblempersists,

contactanAuthorizedServiceDealer.

2.MovethethrottlelevertotheChoke

position.

3.Connectthewiretothesparkplug.

4.Checkthesparkplugandadjustthe

gapifnecessary.Replacethespark

plugifitispitted,fouled,orcracked.

gasoline.

thefuelcap.

3.Cleantheairlterpre-cleanerand/or

replacethepaperairlter.

4.Cleanunderthemowerhousing.

5.Checkthesparkplugandadjustthe

gapifnecessary.Replacethespark

plugifitispitted,fouled,orcracked.

6.Checktheengineoil.Changetheoilif

itisdirtyoraddoilifitislow .

1.Connectthewiretothesparkplug.

2.Checkthesparkplugandadjustthe

gapifnecessary.Replacethespark

plugifitispitted,fouled,orcracked.

3.MovethethrottlelevertotheFast

position.

4.Cleantheairlterpre-cleanerand/or

replacethepaperairlter.

Lawnmowerorenginevibrates

excessively

Unevencuttingpattern

Mowerdoesnotself-propel

1.Thebladeisbentorisoutofbalance.1.Balancetheblade.Ifthebladeisbent,

2.Theblademountingnutsareloose.2.Tightentheblademountingnuts.

3.Theundersideofthemowerhousing

containsclippingsanddebris.

4.Theenginemountingboltsareloose.4.Tightentheenginemountingbolts.

1.All4wheelsarenotatthesameheight.1.Placeall4wheelsatthesameheight.

2.Thebladeisdull.

3.Y ouaremowinginthesamepattern

repeatedly.

4.Theundersideofthemowerhousing

containsclippingsanddebris.

1.Theself-propeldrivecableisoutof

adjustmentorisdamaged.

2.Thereisdebrisunderthebeltcover.

replaceit.

3.Cleanunderthemowerhousing.

2.Sharpenandbalancetheblade.

3.Changethemowingpattern.

4.Cleanunderthemowerhousing.

1.Adjusttheself-propeldrivecable.

Replacethecableifnecessary .

2.Cleanthedebrisfromunderthebelt

cover.

27

Page 28

Notes:

28

Page 29

Notes:

29

Page 30

Notes:

30

Page 31

Evaporative Emission Control Warranty Statement

California Evaporative Emission Control Warranty Statement

Your Warranty Rights and Obligations

Introduction

The California Air Resources Board and The Toro® Company are pleased to explain the evaporative emission control system’s warranty on your 2007 model

year equipment. In California, new equipment that use small off-road engines must be designed, built, and equipped to meet the State’s stringent anti-smog

standards. The Toro® Company must warrant the evaporative emission control system on your equipment for two years provided there has been no abuse,

neglect or improper maintenance of your equipment.

Your evaporative emission control system may include parts such as: fuel lines, fuel line ttings, and clamps.

Manufacturer’s Warranty Coverage:

This evaporative emission control system is warranted for two years. If any evaporative emission-related part on your equipment is defective, the part will be

repaired or replaced by The Toro® Company.

Owner’s Warranty Responsibilities:

• As the equipment owner, you are responsible for performance of the required maintenance listed in your Operator’s Manual. The Toro® Company recommends

that you retain all receipts covering maintenance on your equipment, but The Toro® Company cannot deny warranty solely for the lack of receipts.

• As the equipment owner, you should however be aware that The Toro® Company may deny you warranty coverage if your emission warranty parts have failed

due to abuse, neglect, or improper maintenance or unapproved modications.

• You are responsible for presenting your equipment to an Authorized Service Dealer as soon as the problem exists. The warranty repairs should be completed

in a reasonable amount of time, not to exceed 30 days. If you have a question regarding your warranty coverage, you should contact The Toro® Company at

1-952–948–4027 or call us toll free at the number listed in your Toro Warranty statement.

Defects Warranty Requirements:

1. The warranty period begins on the date the engine or equipment is delivered to an ultimate purchaser.

2. General Evaporative Emissions Warranty Coverage. The emission warranty parts must be warranted to the ultimate purchaser and any subsequent owner that

the evaporative emission control system when installed was:

A. Designed, built, and equipped so as to conform with all applicable regulations; and

B. Free from defects in materials and workmanship that causes the failure of a warranted part for a period of two years.

3. The warranty on evaporative emissions-related parts will be interpreted as follows:

A. Any warranted part that is not scheduled for replacement as required maintenance in the written instructions must be warranted for the warranty period

of two years. If any such part fails during the period of warranty coverage, it must be repaired or replaced by The Toro® Company. Any such part

repaired or replaced under the warranty must be warranted for a time not less than the remaining warranty period.

B. Any warranted part that is scheduled only for regular inspection in the written instructions must be warranted for the warranty period of two years. A

statement in such written instructions to the effect of “repair or replace as necessary” will not reduce the period of warranty coverage. Any such part

repaired or replaced under warranty must be warranted for a time not less than the remaining warranty period.

C. Any warranted part that is scheduled for replacement as required maintenance in the written instructions must be warranted for the period of time

prior to the rst scheduled replacement point for that part. If the part fails prior to the rst scheduled replacement, the part must be repaired or

replaced by The Toro® Company. Any such part repaired or replaced under warranty must be warranted for a time not less than the remainder of

the period prior to the rst scheduled replacement point for the part.

D. Repair or replacement of any warranted part under the warranty provisions of this article must be performed at no charge to the owner at an Authorized

Service Dealer.

E. Notwithstanding the provisions of subsection (D) above, warranty services or repairs must be provided at an Authorized Service Dealer.

F. The owner must not be charged for diagnostic labor that leads to the determination that a warranted part is in fact defective, provided that such

diagnostic work is performed at an Authorized Service Dealer.

G. Throughout the evaporative emission control system’s two year warranty period, The Toro® Company must maintain a supply of warranted parts

sufcient to meet the expected demand for such parts.

H. Manufacturer approved replacement parts must be used in the performance of any warranty maintenance or repairs and must be provided without

charge to the owner. Such use will not reduce the warranty obligations of The Toro® Company.

I. The use of any add-on or modied parts will be grounds for disallowing a warranty claim made in accordance with this article. The Toro® Company will

not be liable under this Article to warrant failures of warranted parts caused by the use of an add-on or modied part.

J. The Toro® Company shall provide any documents that describe the warranty procedures or policies within ve working days of request by the Air

Resources Board.

The following lists includes the parts covered under this warranty:

• Fuel Lines

• Fuel Line Fittings

• Clamps

Emission Warranty Parts List:

374-0092 Rev B

Page 32

Toro 21”

Commercial

Walk Power

Mower

A Two-Year Full Warranty (Limited Warranty for Commercial Use)

The Toro Total Coverage Guarantee

Conditions and Products Covered

The Toro® Company and its afliate, Toro Warranty Company, pursuant to an agreement between them, jointly promise to repair any

Toro Product, when used for residential purposes*, if defective in materials or workmanship or if it stops functioning due to the failure

of a component. The following time periods apply from the date of original purchase:

Products

All Products and attachments 2-year full warranty

This warranty covers the cost of parts and labor, but you must pay transportation costs. This warranty applies to all Toro Commercial

Duty Walk Power Mowers and their attachments.

Warranty Period

Limited Warranty for Commercial Use

Toro Products used for commercial, institutional, or rental use are warranted against defects in materials or workmanship for the

following time periods from the original date of purchase:

Products

Engine

All Products and attachments 1-year limited warranty

Components failing due to normal wear are not covered by this warranty.

Warranty Period

2-year limited warranty

Items and Conditions Not Covered

There is no other express warranty except for special emission system coverage on some products. This express warranty does not

cover the following:

• Cost of regular maintenance service or parts, such as lters, fuel, lubricants, oil changes, air lter, blade sharpening/worn blade on

mowers, paddles/scrapers/skids on snowthrowers, cable/linkage adjustments, or brake and clutch adjustments

• Any product or part which has been altered or misused and requires replacement or repair due to accidents or lack of proper

maintenance

• Repairs necessary due to improper battery care, electrical supply irregularities, or failure to use fresh fuel (less than one month old),

or failure to properly prepare the unit prior to any period of non-use over one month

• Operational misuse, neglect, or accidents

• Repairs or attempted repairs by anyone other than an Authorized Toro Service Dealer.

• Pickup and delivery charges

All repairs covered by this warranty must be performed by an Authorized Toro Service Dealer using Toro approved replacement parts.

Owner Responsibilities

You must maintain your Toro Product by following the maintenance procedures described in the Operator’s Manual. Such routine

maintenance, whether performed by a dealer or by you, is at your expense.

Instructions for Obtaining Warranty Service

If you think that your Toro Product contains a defect in materials or workmanship, follow this procedure:

1. Contact any Toro Authorized Service Dealer to arrange service at their dealership. To locate a dealer convenient to you, refer

to the Yellow Pages of your telephone directory (look under "Lawn Mowers" or “Snow Removal”) or access our website at

www.Toro.com . U.S. Customers may also call the number listed in item #3 to use our 24-hour Toro dealer locator system.

2. Bring the product and your proof of purchase (sales receipt) to the Service Dealer. The dealer will diagnose the problem and

determine if it is to be covered under warranty.

If for any reason you are dissatised with the Service Dealer’s analysis or with the assistance provided, contact us at:

Customer Care Department — Consumer, Toro Warranty Company, 8111 Lyndale Avenue South, Bloomington, MN 55420-1196; or

call us toll free at 1-888-865-5676 (U.S. Customers) or 1-888-865-5691 (Canada customers).

General Conditions

All repairs covered by these warranties must be performed by an Authorized Toro Service Dealer using Toro approved replacement parts.

Neither The Toro® Company nor Toro Warranty Company is liable for indirect, incidental, or consequential damages in connection with

the use of the Toro Products covered by these warranties, including any cost or expense of providing substitute equipment or service

during reasonable periods of malfunction or non-use pending completion of repairs under these warranties.

Some states do not allow exclusions of incidental or consequential damages, so the above exclusions and limitations may not apply

to you.

This warranty gives you specic legal rights, and you may also have other rights which vary from state to state.

Countries Other than the United States or Canada

Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor

(Dealer) to obtain guarantee policies for your country, province, or state. If for any reason you are dissatised with your Distributor’s

service or have difculty obtaining guarantee information, contact the Toro importer. If all other remedies fail, you may contact us

at Toro Warranty Company.

* Residential purposes means use of the product on the same lot as your home. Use at more than one location is considered commercial

use, and the commercial use warranty would apply.

374-0083 Rev A

Loading...

Loading...