Page 1

FORM NO. 3319–569GB

ProLine 53cm Recycler II

Walk-behind Power Mower

Model No. 22157 — 8900001 & Up

Operator’s Manual

Page 2

Figures

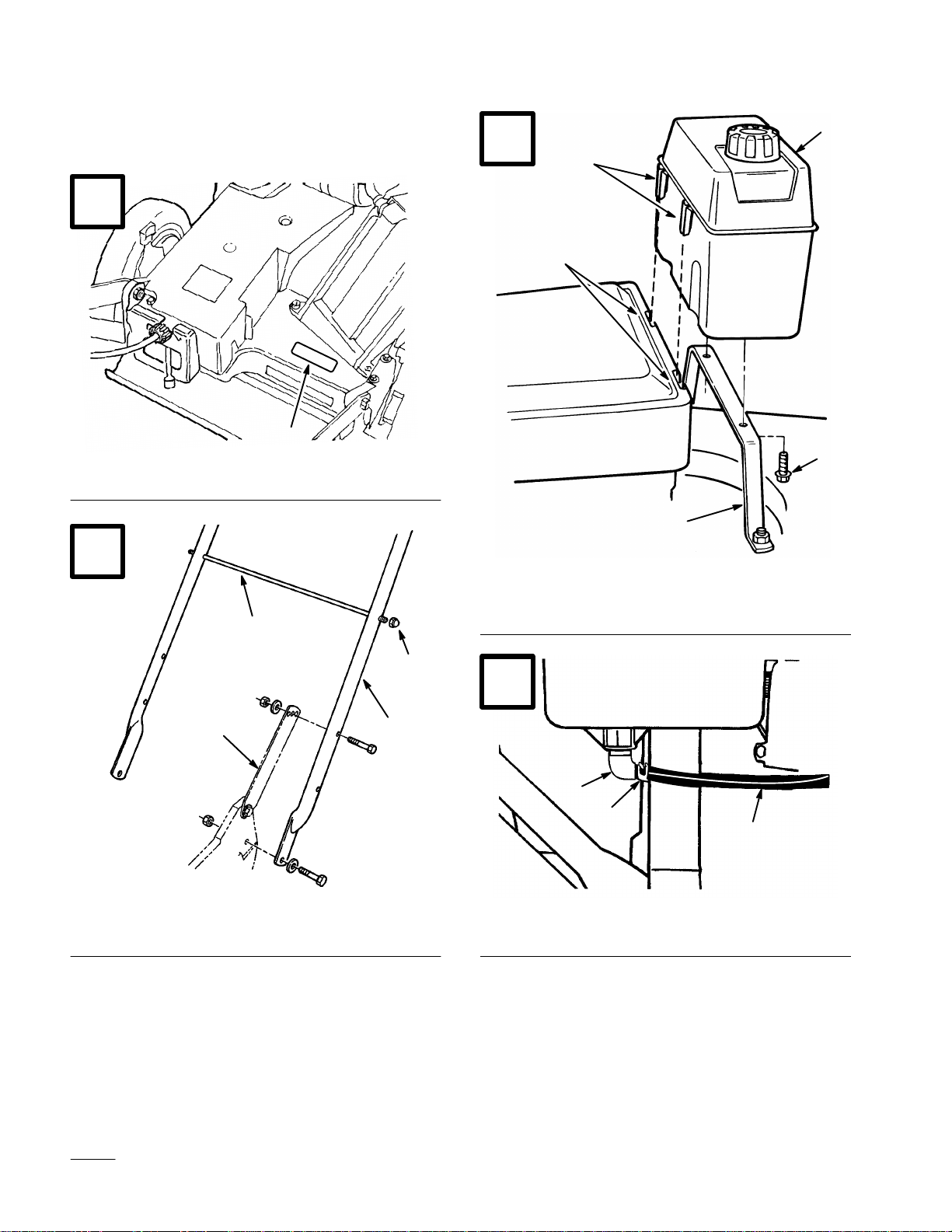

1

4

3

3

2

1. Model and serial number decal

2

1

1. Handle latch

2. Bag support rod

1

2

3. Cap locknut

4. Handle

224

1

1. Tank bracket

2. Slots

3. Plastic clips

3

4. Gas tank

5. Self-tapping screw

5

530

4

4

3

534

1. Fuel line clamp

2. Fuel line

1

3. Elbow fitting

2

2045

EThe Toro Company – 1998

i

All Rights Reserved

Printed in USA

Page 3

Figures

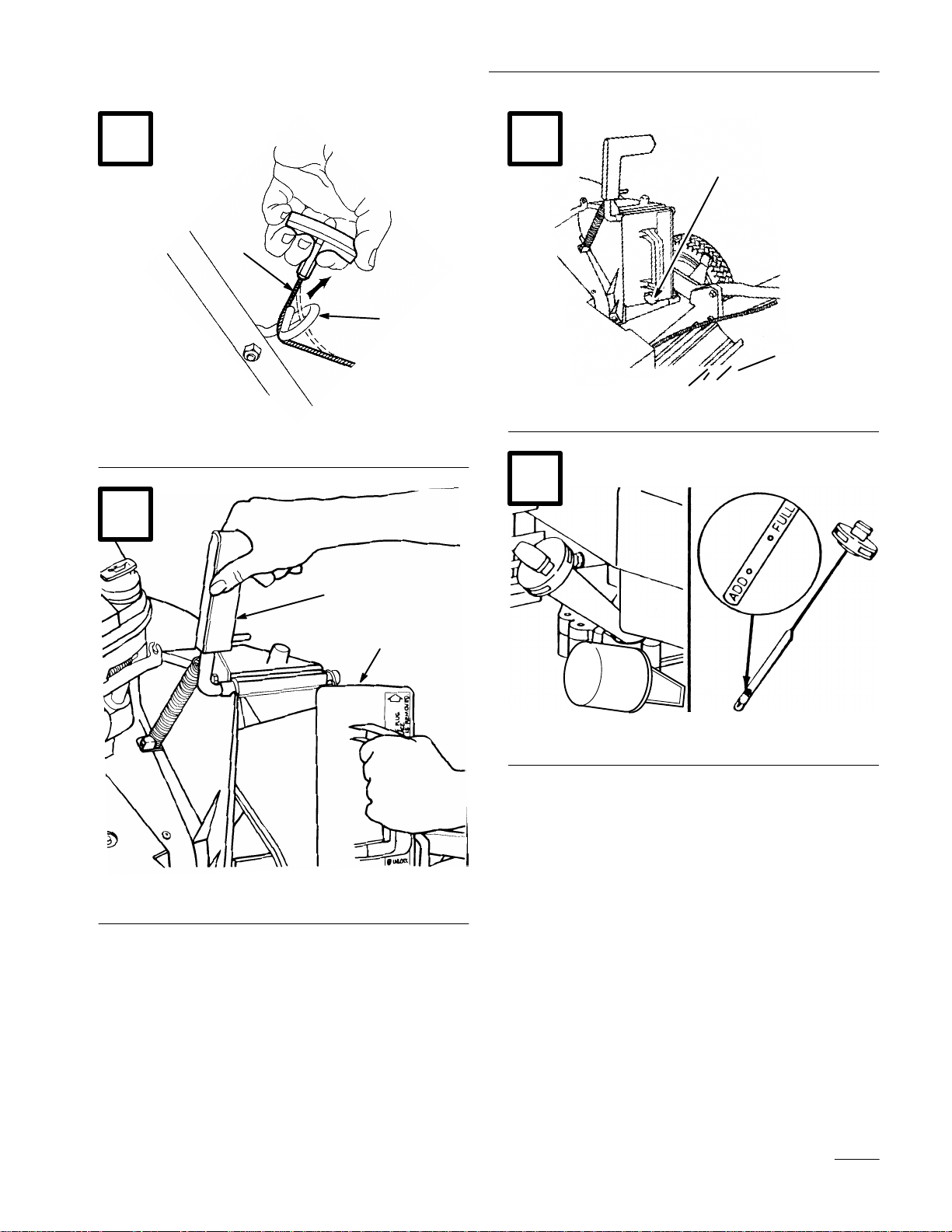

5

2

1. Rope guide 2. Starter rope

6

1

7

1

1

m–210

1. Spring clip

m–275

8

2

m–262

1. Discharge door handle 2. Plug rotated clockwise

2

1

m–3845

1. Oil fill tube 2. Dipstick

ii

Page 4

Figures

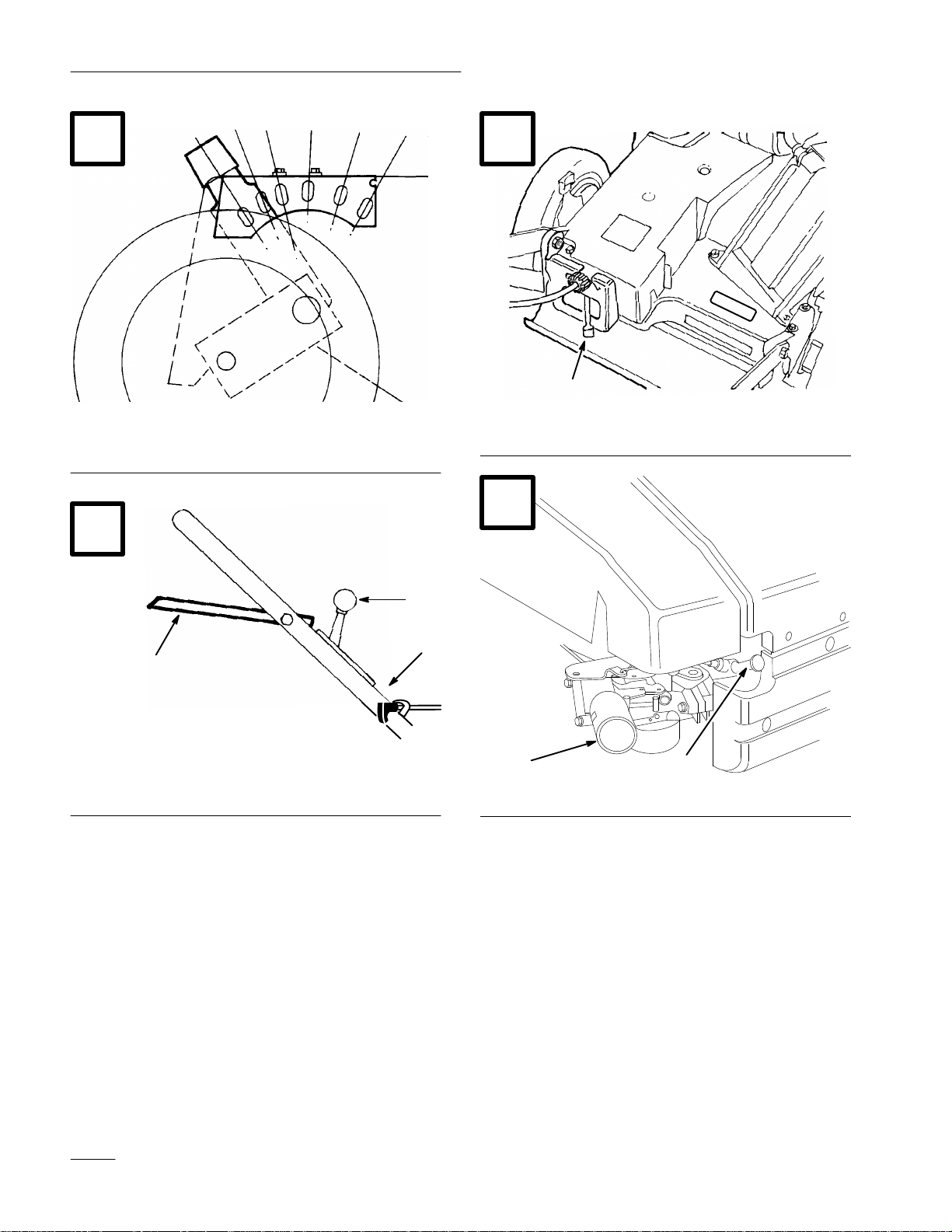

9

10

#4!4#4!4

#4!4

11

976

1. Ground speed control

1

224

12

1

1. Blade/self-propelled

control bar

2. Throttle

3. Fingertip starter

2

3

1992

1 2

1. Primer 2. Spark plug wire

m–3662

iii

Page 5

Figures

13

14

15

1

m-3769

1. Pin locked in bag notch

2

1

16

m–260

1. Bag frame on retaining

post

2. Pin engaged in catch

1

3

3. Handle fully forward.

Discharge door closed.

m–261

225

1. Height-of-cut adjuster

iv

Page 6

Figures

17

3

1. Knob

2. Cover

18

1

4

3. Foam pre–cleaner

4. Paper cartridge

1

2

m–3664

19

1. Oil fill tube 2. Oil filter

1

20

m–3848

2

1

1. .020 in. (.5 mm)

v

m-3862

110

1. Gasket

Page 7

Figures

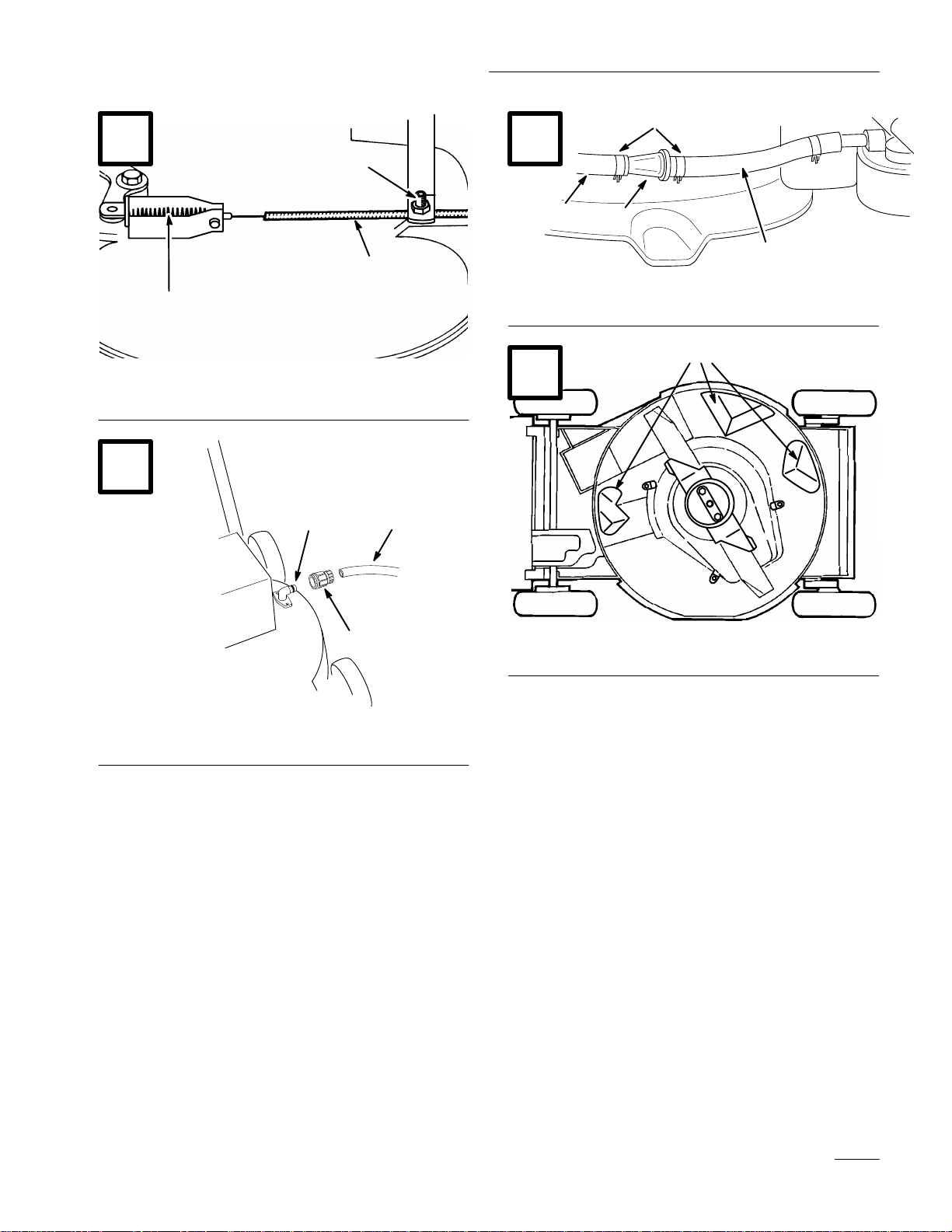

21

1. Cable clamp screw

2. Governor control lever

22

23

3. Throttle cable

4. Casing

m-3638

1. One inch

1

m–1992

4

3

24

1. Control knob

2

1

228

1. Blade

2. Blade nuts

3. Anti-scalp cup

4. Accelerator

1

796

vi

Page 8

Figures

25

1. Sail

2. Flat part of blade

3

4

3. Wear

4. Slot formed

27

1

2

1

1

1

232

270

1. Grease fitting

1

28

26

1

1. Sharpen at this angle only

153

2

1. Grease fitting 2. Belt cover

224

vii

Page 9

29

Figures

1

31

2

1

1. Spring

2. Cable clamp screw

30

3

3. Cable conduit

1

2

2

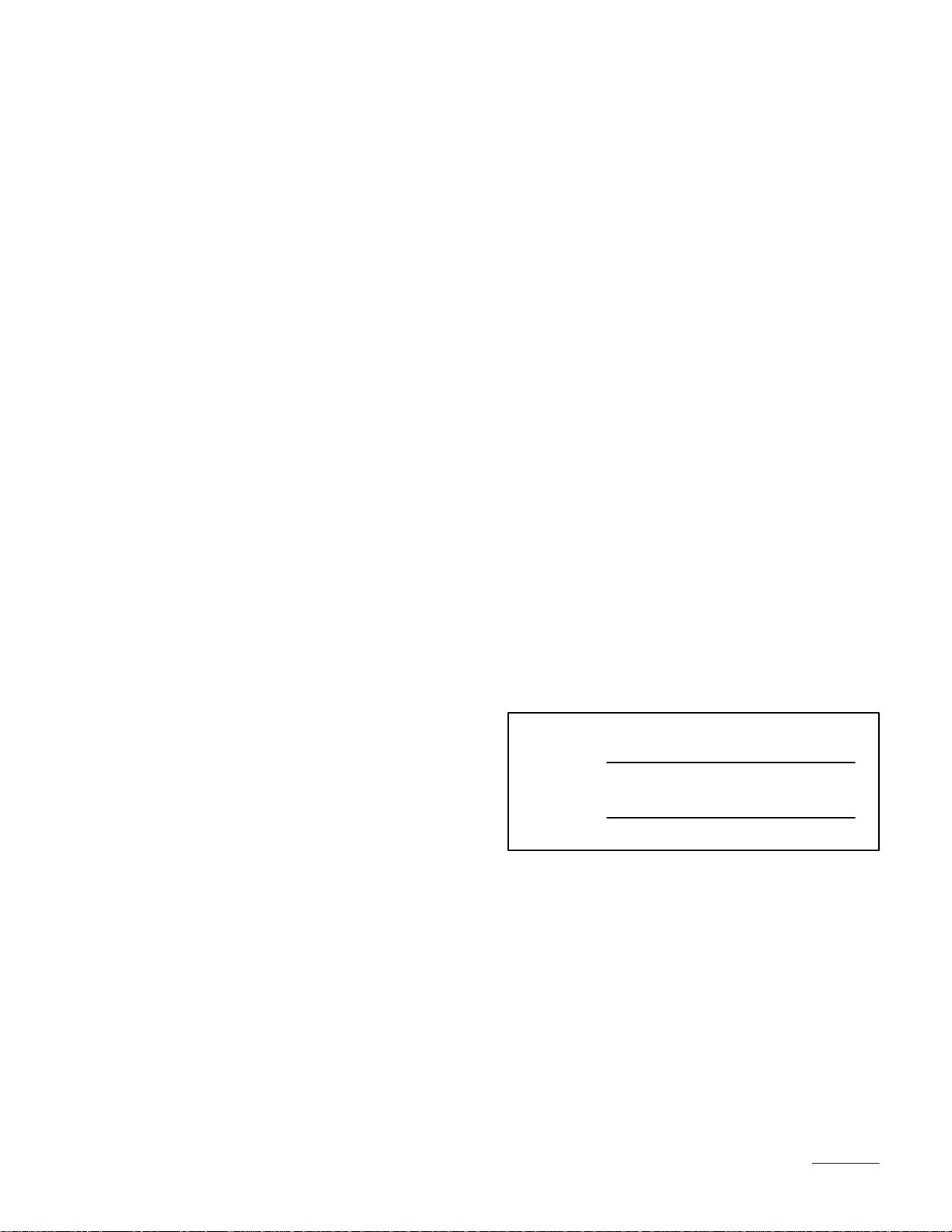

1. Hose clamp

2. Fuel line

278

3

2

3. Filter

m–3844

32

3

796

1. Kicker plates

1. Washout fitting

2. Quick disconnect coupling

m-2858

3. Hose

viii

Page 10

Figures

3

2

33

1

1. BBC shield

2. Tabs and nuts

3. Tab and bolt

34

12 3 45

35

20471

1. Side discharge chute

796

1

67 5 7 8 9

1. Locknuts

2. Wheel spacer

3. Bearing/hub assembly

4. Bearing spacer

5. Wheel half

6. Plastic cover (rear wheels

only)

7. Lug

8. Bearing (2)

9. Capscrew

ix

296

Page 11

Contents

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Training 2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 2. . . . . . . . . . . . . . . . . . . . . . . . .

Operation 2. . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance And Storage 3. . . . . . . . . . . . .

Sound Pressure Level 4. . . . . . . . . . . . . . . . .

Sound Power Level 4. . . . . . . . . . . . . . . . . .

Vibration Level 4. . . . . . . . . . . . . . . . . . . . .

Symbol Glossary 5. . . . . . . . . . . . . . . . . . . .

Assembly 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handle 8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gas Tank 8. . . . . . . . . . . . . . . . . . . . . . . . . .

Discharge Tunnel Plug 8. . . . . . . . . . . . . . . .

Before Starting 8. . . . . . . . . . . . . . . . . . . . . . . . . .

Fill Crankcase With Oil 8. . . . . . . . . . . . . . .

Fill Fuel Tank With Gasoline 9. . . . . . . . . . .

Recycling Tips 10. . . . . . . . . . . . . . . . . . . . . . . . . .

General Tips 10. . . . . . . . . . . . . . . . . . . . . . . .

Operation 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Tips 11. . . . . . . . . . . . . . . . . . . . . .

Controls 11. . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting, Stopping, And Self–propelling 11. .

Using Discharge Tunnel Plug 11. . . . . . . . . .

Using Grass Bag 12. . . . . . . . . . . . . . . . . . . . .

Adjusting Height-of-cut 13. . . . . . . . . . . . . . .

Maintenance 13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Servicing Air Cleaner 13. . . . . . . . . . . . . . . .

Replacing Spark Plug 14. . . . . . . . . . . . . . . . .

Draining Gasoline 14. . . . . . . . . . . . . . . . . . .

Changing Crankcase Oil 14. . . . . . . . . . . . . .

Replacing Oil Filter 14. . . . . . . . . . . . . . . . . .

Adjusting Throttle 15. . . . . . . . . . . . . . . . . . .

Cleaning Cooling System 15. . . . . . . . . . . . . .

Adjusting Wheel Drive 15. . . . . . . . . . . . . . .

Inspecting/Removing/Sharpening Blade 15. .

Lubrication 16. . . . . . . . . . . . . . . . . . . . . . . . .

Lubricating Gear Case 16. . . . . . . . . . . . . . . .

Page

Adjusting Blade Brake Cable 16. . . . . . . . . . .

Cleaning Mower 17. . . . . . . . . . . . . . . . . . . . .

Cleaning Blade Brake Clutch Shield 18. . . . .

Servicing Wheels 18. . . . . . . . . . . . . . . . . . . .

Fuel Filter 19. . . . . . . . . . . . . . . . . . . . . . . . . .

Storage 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

Thank you for purchasing a Toro product.

All of us at Toro want you to be completely satisfied

with your new product, so feel free to contact your

local Authorized Service Dealer for help with service,

genuine Toro parts, or other information you may

require.

Whenever you contact your Authorized Service

Dealer or the factory, always know the model and

serial numbers of your product. These numbers will

help the Service Dealer or Service Representative

provide exact information about your specific

product. You will find the model and serial number

decal located in a unique place on the product

(Fig. 1).

For your convenience, write the product model and

serial numbers in the space below.

Model No:

Serial No.

Read this manual carefully to learn how to operate

and maintain your product correctly. Reading this

manual will help you and others avoid personal injury

and damage to the product. Although Toro designs,

produces and markets safe, state-of-the-art products,

you are responsible for using the product properly

and safely. You are also responsible for training

persons who you allow to use the product about safe

operation.

The Toro warning system in this manual identifies

potential hazards and has special safety messages that

help you and others avoid personal injury, even death.

GB–1

Page 12

DANGER, WARNING and CAUTION are signal

words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

DANGER signals an extreme hazard that will cause

serious injury or death if the recommended

precautions are not followed.

WARNING signals a hazard that may cause serious

injury or death if the recommended precautions are

not followed.

CAUTION signals a hazard that may cause minor or

moderate injury if the recommended precautions are

not followed.

Preparation

1. While mowing, always wear substantial

footwear and long trousers. Do not operate the

equipment when barefoot or wearing open

sandals.

2. Always wear safety glasses or eye shields during

operation to protect eyes from foreign objects

that may be thrown from the machine. Keep

face, hands, and feet away from the mower

housing and cutter blade when the engine is

running. Stay behind the handle until the engine

stops.

3. Thoroughly inspect the area where the

equipment is to be used and remove all objects

which may be thrown by the machine.

Two other words are also used to highlight

information. “Important” calls attention to special

mechanical information and “Note” emphasizes

general information worthy of special attention.

The left and right side of the machine is determined

by standing behind the handle in the normal

operator’s position.

Safety

Training

1. Read the instructions carefully. Be familiar with

the controls and the proper use of the equipment.

2. Never allow children or people unfamiliar with

these instructions to use the lawnmower. Local

regulations may restrict the age of the operator.

3. Never mow while people, especially children, or

pets are nearby.

4. WARNING – Petrol is highly flammable.

• Store fuel in containers specifically designed for

this purpose.

• Refuel outdoors only and do not smoke while

refuelling.

• Add fuel before starting the engine. Never

remove the cap of the fuel tank or add petrol

while the engine is running or when the engine is

hot.

• If petrol is spilled, do not attempt to start the

engine but move the machine away from the are

of spillage and avoid creating any source of

ignition until petrol vapors have dissipated.

• Replace all fuel tanks and container caps

securely.

5. Replace faulty silencers.

6. Before using, always visually inspect to see that

the blades, blade bolts and cutter assembly are

not worn or damaged. Replace worn or damaged

blades and bolts in sets to preserve balance.

7. On multi-bladed machines, take care as rotating

one blade can cause other blades to rotate.

Operation

4. Keep in mind that the operator or user is

responsible for accidents or hazards occurring to

other people or their property.

GB–2

1. Do not operate the engine in a confined space

where dangerous carbon monoxide fumes can

collect.

Page 13

2. Mow only in daylight or in good artificial light.

3. Avoid operating the equipment in wet grass,

where feasible.

4. Always be sure of your footing on slopes.

17. Do not put hands or feet near or under rotating

parts. Keep clear of the discharge opening at all

times.

18. Never pick up or carry a lawnmower while the

engine is running.

5. Walk, never run.

6. For wheeled rotary machines, mow across the

face of slopes, never up and down.

7. Exercise extreme caution when changing

direction on slopes.

8. Do not mow excessively steep slopes.

9. Use extreme caution when reversing or pulling

the lawnmower towards you.

10. Stop the blade(s) if the lawnmower has to be

tilted for transportation when crossing surfaces

other than grass, and when transporting the

lawnmower to and from the area to be mowed.

11. Never operate the lawnmower with defective

guards or shields, or without safety devices for

example deflectors and/or grass catchers in

place.

19. Stop the engine and disconnect the spark plug

wire.

• before clearing blockages or unclogging chute;

• before checking, cleaning or working on the

lawnmower;

• after striking a foreign object. Inspect the

lawnmower for damage and make repairs before

restarting and operating the lawnmower;

• if lawnmower starts to vibrate abnormally (check

immediately).

20. Stop the engine

• whenever you leave the lawnmower;

• before refuelling.

21. Reduce the throttle setting during engine shut

down and, if the engine is provided with a

shut-off valve, turn the fuel off at the conclusion

of mowing.

12. Do not change the engine governor settings or

overspeed the engine.

13. Disengage all blade and drive clutches before

starting the engine.

14. Start the engine or switch on the motor carefully

according to instructions and with feet well away

from the blade(s).

15. Do not tilt the lawnmower when starting the

engine or switching on the motor, except if the

lawnmower has to be tilted for starting. In this

case, do not tilt it more than absolutely necessary

and lift only the part which is away from the

operator.

16. Do not start the engine when standing in front of

the discharge chute.

22. Go slow when using a trailing seat.

Maintenance And Storage

1. Keep all nuts, bolts and screws tight to be sure

the equipment is in safe working condition.

2. Never store the equipment with petrol in the tank

inside a building where fumes may reach an

open flame or spark.

3. Allow the engine to cool before storing in any

enclosure.

4. To reduce the fire hazard, keep the engine,

silencer, battery compartment and petrol storage

area free of grass, leaves, or excessive grease.

5. Check the grass catcher frequently for wear or

deterioration.

GB–3

Page 14

6. Replace worn or damaged parts for safety.

Sound Power Level

7. If the fuel tank has to be drained, this should be

done outdoors.

Sound Pressure Level

This unit has an equivalent continuous A-weighted

sound pressure at the operator ear of: 85 dB(A), based

on measurements of identical machines per ANSI

B71.5-1984 procedures.

This unit has a sound power level of: 100 dB(A)/1

pW, based on measurements of identical machines per

Directive 84/538/EEC and amendments.

Vibration Level

This unit has a maximum hand-arm vibration level of

4.20 m/s@, based on measurement of identical

machines per ISO 5349 procedures.

GB–4

Page 15

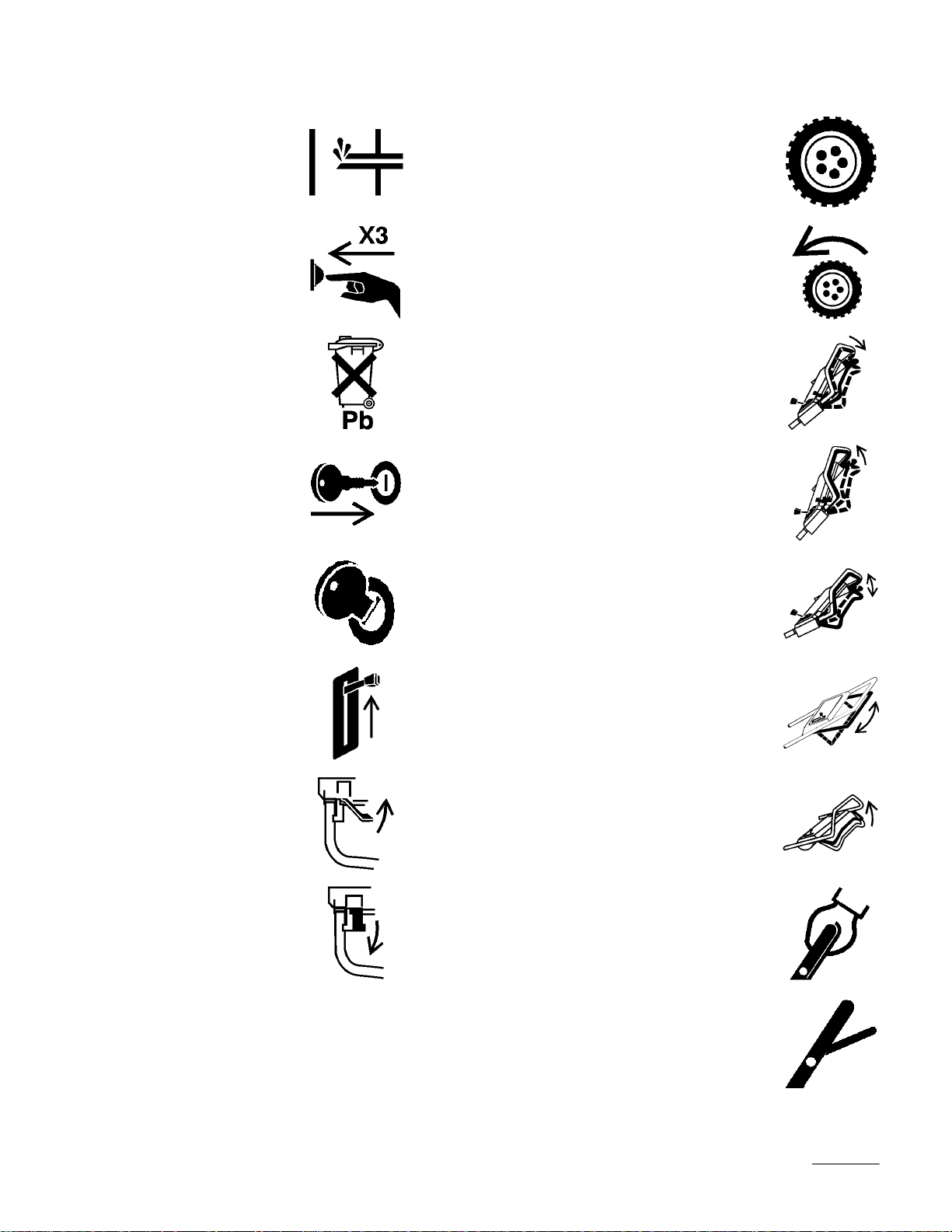

Symbol Glossary

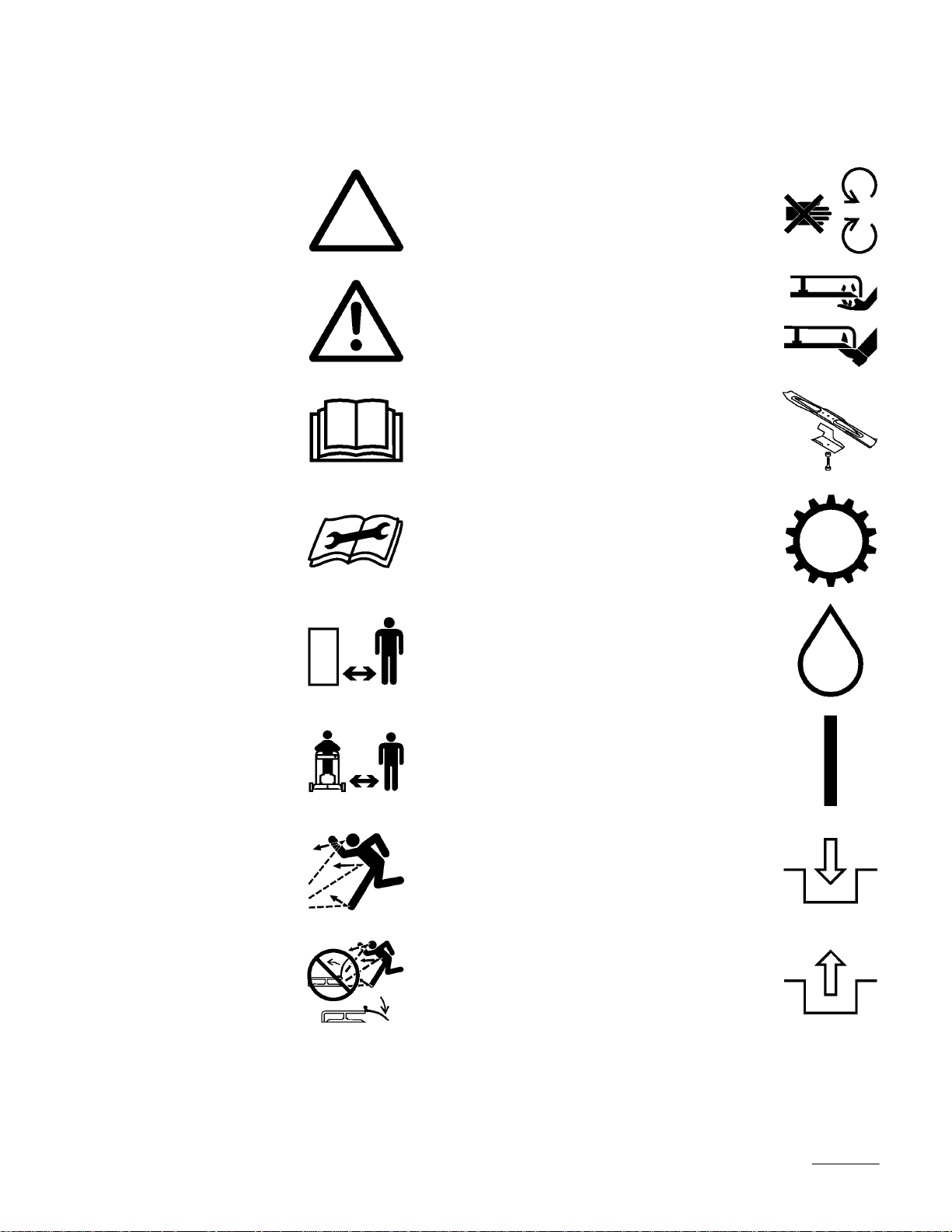

Safety alert triangle —

symbol within triangle

indicates a hazard.

Safety alert symbol

Read operator’s

manual.

Consult technical

manual for proper

service procedures.

Do not open or

remove safety shields

while engine is

running.

Rotating blade can cut

off toes or fingers.

Stay clear of mower

blade as long as

engine is running.

To avoid blade failure

when mulching, use

blade stiffener when

mower is equipped

with mulching plug.

Transmission

Stay a safe distance

from the machine.

Stay a safe distance

from the mower.

Throw or flying

objects — Whole body

exposure

Thrown or flying

objects — Rotary

side-mounted mower.

Keep deflector shield

in place.

Oil

On/Run

Engage

Disengage

GB–5

Page 16

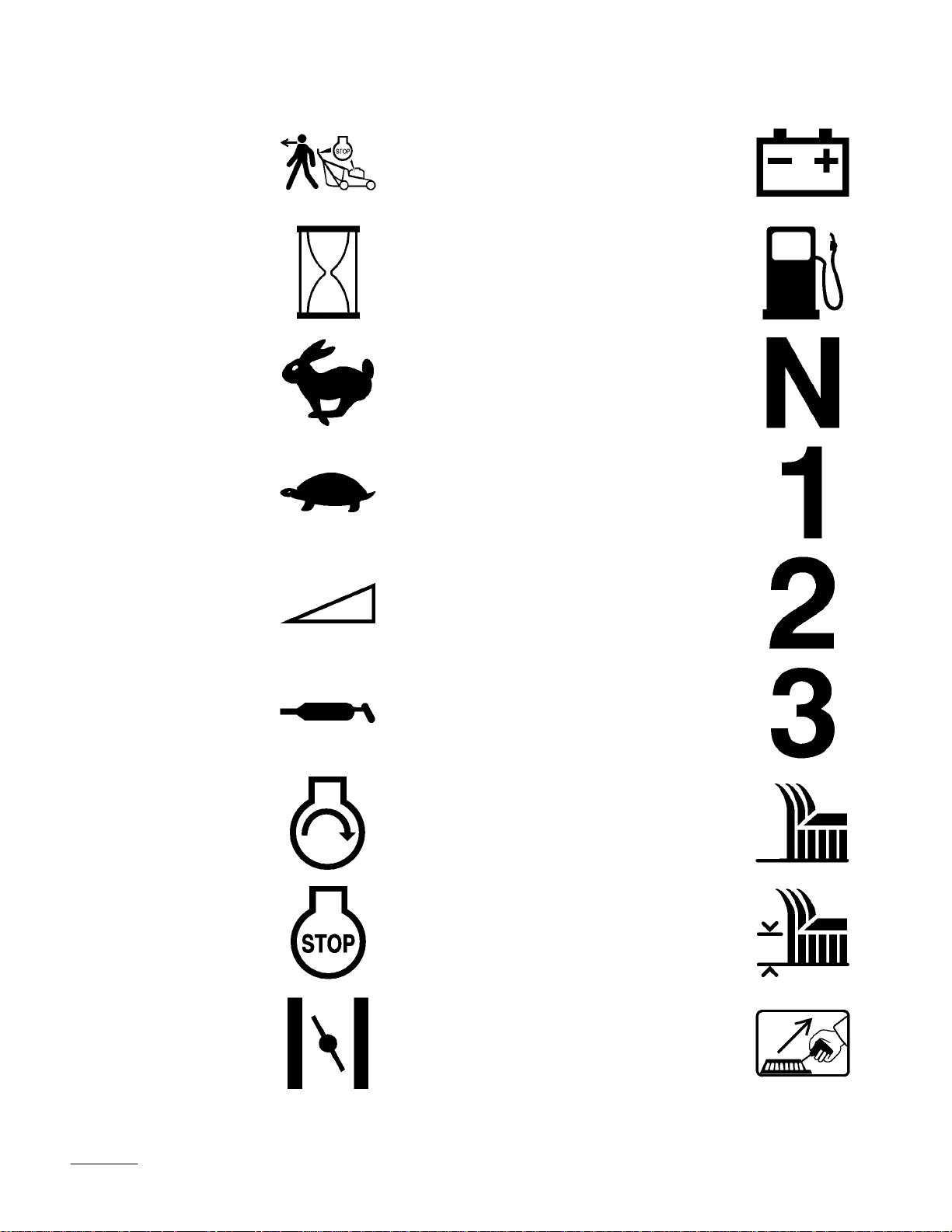

Stop engine before

leaving operator

position.

Battery charging

condition

Hourmeter/elapsed

operating hours

Fast Neutral

Slow First gear

Decreasing/Increasing Second gear

Grease lubrication

point

Fuel

Third gear

Engine start

Engine stop

Choke Pull rope.

Cutting element —

basic symbol

Cutting element —

height adjustment

GB–6

Page 17

Primer (start aid) Wheel

Push primer three

times.

Properly dispose of

batteries.

Insert key in ignition

switch.

Turn key in ignition

switch.

Move control.

Wheel traction

Lower control bar.

Raise control bar.

Raise/lower control

bar.

Raise/lower control

bar.

Move control forward. Raise control bar.

Move control

rearward.

Raise control bar.

Lower control bar.

GB–7

Page 18

Assembly

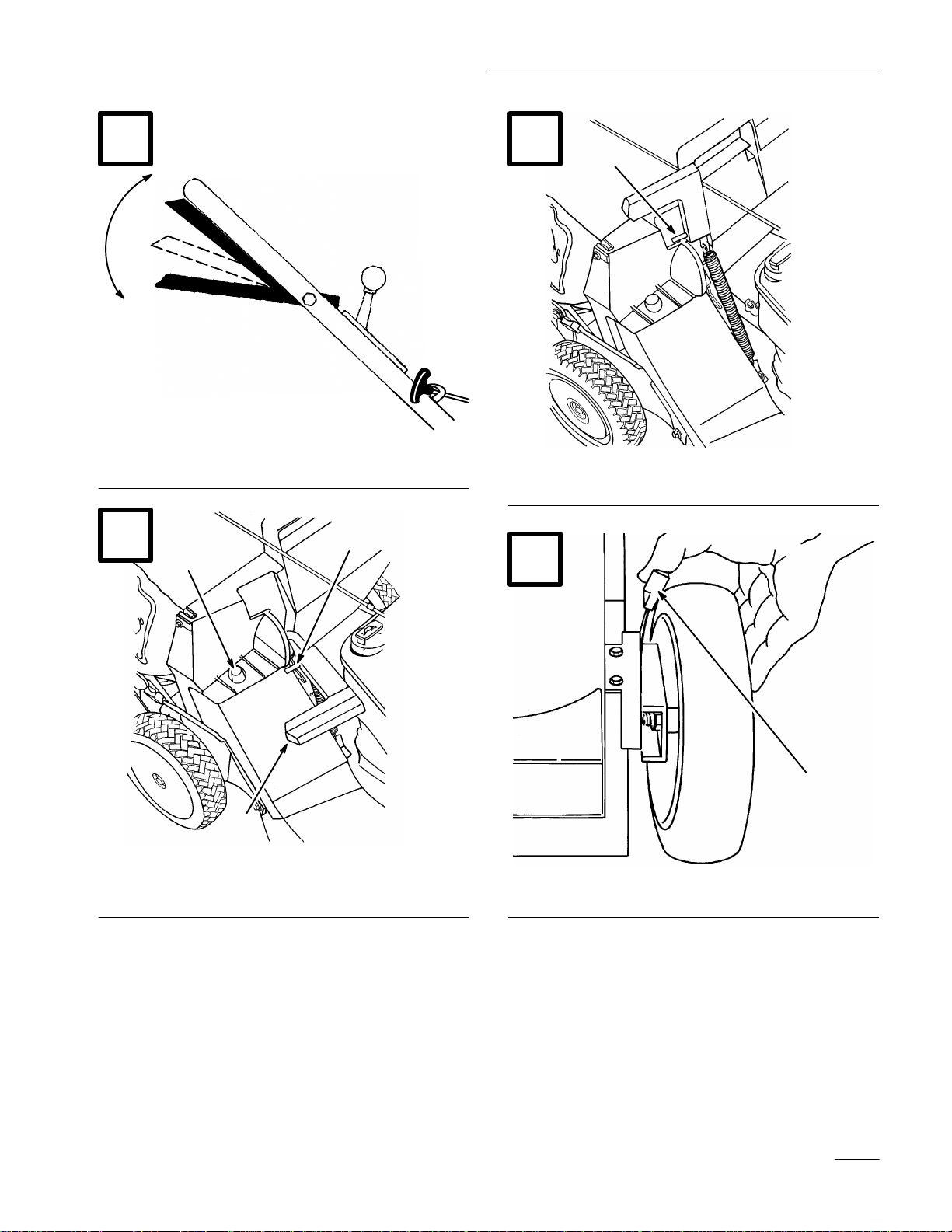

Handle

1. Mount handle to outside of mower housing,

using bottom hole, with (2) 5/16–18 x 1–1/4” lg.

capscrews, washers, and thin nylon insert

locknuts (Fig. 2).

2. Secure handle latches to handle with (2) 5/16–18

x 1–1/2” lg. capscrews, washers and nylon insert

locknuts (Fig. 2).

Note: Handle height is adjustable for

operator comfort. Stand behind mower

handle to gauge height. To adjust

handle height, reposition capscrews

and locknuts securing handle latches to

handle into other mounting holes in

latches.

Discharge Tunnel Plug

1. Open the discharge door by pulling forward on

the handle and moving it rearwards (Fig. 6).

Hold the discharge door handle to prevent the

spring–loaded door from closing while inserting

the plug.

2. Since the plug is slightly wider than the

discharge tunnel opening, rotate the plug

clockwise slightly while inserting it (Fig. 6).

Make sure the arrow on the plug decal is

pointing upwards.

3. Push the plug all the way in until the spring clip

on the bottom of the plug clicks into place,

locking the plug securely into the discharge

tunnel (Fig. 6). Release discharge door handle to

lock top of plug.

Before Starting

3. Slide bag support rod thru top mounting holes in

handle and secure each end with a cap locknut

(Fig. 2).

4. Use a cable tie to secure the control cables to left

handle below the bag support rod.

5. Pull starter rope through rope guide on handle

(Fig. 5).

Gas Tank

1. Start self–tapping screws into bottom of gas tank

and then remove screws.

2. Hook plastic clips on front of gas tank into slots

on rear of engine (Fig. 3).

3. Secure gas tank to tank base with (2)

self–tapping screws (Fig. 3). Do not overtighten

screws.

4. Remove red cap from end of fuel line and from

end of elbow fitting on gas tank. Slide end of

fuel line onto elbow fitting (Fig. 4). Secure fuel

line in place with fuel line clamp.

Fill Crankcase With Oil

Fill crankcase with SAE 30 or 10W30 oil until oil

level reaches FULL mark on dipstick as shown in

(Fig. 8). The maximum crankcase capacity is 26

ounces (0.77 liters) of oil with the oil filter installed

and 22 ounces (0.65 liters) without the oil filter

installed. Use any high quality detergent oil having

the American Petroleum Institute (API) “service

classification” — SF, SG, SH or SJ.

Before each use, ensure oil level is between ADD and

FULL marks on dipstick (Fig. 8). Add oil if level is

low.

1. Position mower on level surface and clean

around oil dipstick.

2. Remove dipstick by rotating cap

counterclockwise 1/4 turn.

3. Wipe dipstick and insert it into filler neck.

Rotate cap clockwise 1/4 turn. Then remove

dipstick and check level of oil (Fig. 8). If level is

low, add only enough oil to raise level to FULL

mark on dipstick. DO NOT FILL ABOVE

FULL MARK BECAUSE ENGINE COULD

BE DAMAGED WHEN STARTED. POUR

OIL SLOWLY.

GB–8

Page 19

4. Insert dipstick into filler neck and rotate cap

clockwise 1/4 turn to lock.

Note: Check oil level each time mower is

used or after every 5 operating hours.

Initially, change oil after the first 5

hours of operation; thereafter, change

oil after every 50 hours of operation.

More frequent oil changes are required

in dusty or dirty conditions.

Fill Fuel Tank With Gasoline

POTENTIAL HAZARD

• In certain conditions gasoline is extremely

flammable and highly explosive.

WHAT CAN HAPPEN

• A fire or explosion from gasoline can burn

you, others, and cause property damage.

HOW TO AVOID THE HAZARD

• Use a funnel and fill the fuel tank outdoors,

in an open area, when the engine is cold.

Wipe up any gasoline that spills.

• Do not fill the fuel tank completely full.

Add gasoline to the fuel tank until the level

is 1/4” to 1/2” (6 mm to 13 mm) below the

bottom of the filler neck. This empty space

in the tank allows gasoline to expand.

• Never smoke when handling gasoline, and

stay away from an open flame or where

gasoline fumes may be ignited by a spark.

• Store gasoline in an approved container

and keep it out of the reach of children.

• Never buy more than a 30-day supply of

gasoline.

This engine is certified to operate on unleaded

gasoline. Toro strongly recommends the use of fresh,

clean, UNLEADED regular grade gasoline with an

octane rating of 85 or higher in Toro gasoline

powered products. Unleaded gasoline burns cleaner,

extends engine life, and promotes good starting by

reducing the build-up of combustion chamber

deposits. In countries other than U.S.A., leaded

gasoline may be used if it is commercially available

and unleaded is unavailable.

IMPORTANT: Do not mix oil with the gasoline.

Do not use gasoline that has been stored in an

approved container from one season to the next.

Toro also recommends that Toro

Stabilizer/Conditioner be used regularly in all Toro

gasoline powered products during operation and

storage seasons. Toro Stabilizer/Conditioner cleans

the engine during operation and prevents gum–like

varnish deposits from forming in the engine during

periods of storage.

IMPORTANT: Some fuels, called oxygenated or

reformulated gasolines, are gasolines blended with

alcohols or ethers. Excessive amounts of these

blends can damage the fuel system or cause

performance problems. Never use methanol

gasoline containing methanol, gasohol containing

more than 10% ethanol or white gas because

engine fuel system damage could result. If any

undesirable operating symptoms occur, use

gasoline with a lower percentage of alcohol or

ether.

Do not use fuel additives other than those

manufactured for fuel stabilization during storage

such as Toro’s Stabilizer/Conditioner or a similar

product. Toro’s Stabilizer/Conditioner is a

petroleum distillate based conditioner/stabilizer.

Toro does not recommend stabilizers with an

alcohol base such as ethanol, methanol or

isopropyl. Additives should not be used to try to

enhance the power or performance of machine.

1. Clean around fuel tank cap and remove cap from

tank. Using unleaded gasoline, add fuel to 1/4”

to 1/2” (6 to 13 mm) from top of tank, not into

the filler neck. Do not fill the tank full.

2. Reinstall fuel tank cap and wipe up any spilled

gasoline.

3. Connect spark plug wire (if disconnected)

(Fig. 12).

,

GB–9

Page 20

Recycling Tips

General Tips

!/3 of the grass blade should be cut off. Cutting

below the 1-#/4” setting is not recommended

unless grass is sparse or it is late fall when grass

growth begins to slow down.

Follow these instructions whether cutting grass or

leaves for the best cutting results and lawn

appearance:

• Maintain a sharp blade

season. Periodically file down nicks on blade.

• Only mow dry grass or leaves. Wet grass and

leaves tend to clump on yard and may cause

mower to plug or engine to stall. They also may

be slippery to walk on and could cause you to

slip and fall.

POTENTIAL HAZARD

throughout the cutting

• Wet grass or leaves can cause you to slip

and contact blade.

WHAT CAN HAPPEN

• Blade contact can seriously injure you.

HOW TO AVOID THE HAZARD

• Mow only in dry conditions.

• Set engine speed to fastest position. Maximum

horsepower provides best cutting results.

• When cutting grass over six inches tall, you may

want to first mow using the highest height-of-cut

setting and a slower walking speed; then mow

again at a lower setting for best lawn appearance.

If grass is too long and leaves clumps on top of

lawn, mower may plug and cause engine to stall.

• Alternate mowing direction. This helps disperse

clippings over lawn for even fertilization.

If the finished cut lawn appearance is unsatisfactory,

try one or more of the following:

• Sharpen the blade.

• Walk at a slower pace while mowing.

• Raise the height-of-cut setting on your mower.

• Cut grass more frequently.

• Overlap cutting swaths instead of cutting a full

swath with each pass.

• Mow across the marginal areas a second time.

• Set height-of-cut on front wheels one notch

lower than rear wheels. (example: set front

wheels at 1-#/4” setting and rear wheels at 2-!/4”

setting)

• Clean clippings or leaves from underside of

mower deck after each mowing.

• Keep engine in good running condition. Cutting

and recutting requires more horsepower.

• Clean air filter more frequently. Cutting and

recutting stirs up more clippings and dust which

clogs the air filter and reduces engine

performance.

Cutting Grass

• Grass grows at different rates at different times

of the year. In the heat of the summer, it is

generally best to cut grass at the 1-#/4”, 2-!/4” or

2-#/4” height-of-cut settings (Fig. 9). Only about

GB–10

Cutting Leaves

• When cutting is complete, always be sure that

50% of the lawn shows through the cut leaf

cover. This may require one or more passes over

the leaves.

• For light leaf coverage, position all wheels at the

same height-of-cut setting.

• If there are more than five inches of leaves on

lawn, set the front wheels one or two notches

higher than the rear wheels. This makes it easier

to feed leaves under mower deck.

• Walk at a slower mowing speed if leaves are not

being cut up finely enough to be hidden down in

the grass.

Page 21

• If you cut up a lot of oak leaves, you might want

to add lime to your grass in the spring. Lime

reduces the acidity of oak leaves.

Operation

Operating Tips

1. CHECK OIL LEVEL—Maintain oil level

between ADD and FULL marks as shown on

dipstick (Fig. 8).

2. BEFORE EACH MOWING—Be sure blade

brake, self–propelled drive, and control bar

function properly. When control bar is released,

blade and self–propelled drive are designed to

stop. If controls are not functioning properly, do

not use mower until controls are repaired.

3. SHARP BLADE—Begin each cutting season

with a sharp blade. Periodically file down nicks.

Controls

Throttle control, blade/self–propelled control bar and

fingertip starter are on upper handle (Fig. 10). Ground

speed control is located at rear of belt cover (Fig. 11).

Note: Do not use primer to restart a warm

engine after a short shutdown.

However, cool weather may require

priming to be repeated.

5. Pull recoil starter out until positive engagement

results; then pull vigorously to start the engine.

Allow the engine to warm-up. During warm-up,

the equipment can be operated. Regulate throttle

as desired when engine starts. Move ground

speed control to desired setting.

6. BLADE AND TRACTION OPERATION

(Fig. 13)—When control bar is in position “A”,

slide control bar to right and raise to position

“B” to engage blade. Squeeze control bar against

handle to position “C” to drive. To disengage

traction drive but keep blade engaged, gradually

release control bar to position “B”. To

self–propel with blade disengaged, simply

squeeze control bar against handle to position

“C”, without sliding control bar to right.

7. STOPPING—To stop engine, release control bar

and move throttle control to

off spark plug if mower will be unattended or

not used.

(OFF). Pull wire

Using Discharge Tunnel Plug

Starting, Stopping, And

Self–propelling

Note: The engine requires a warm-up period

of one minute to several minutes,

depending on the temperature.

1. Push spark plug wire onto spark plug (Fig. 12).

2. Move throttle control to

3. Move ground speed control to

4. Push primer three (3) times (Fig. 12). Wait

about two (2) seconds between each push.

(FAST) position.

(NEUTRAL).

1. Make sure engine is off. Open the discharge door

by pulling forward on the handle and moving it

rearwards (Fig. 6). Hold the discharge door

handle to prevent the spring–loaded door from

closing while inserting the plug.

2. Since the plug is slightly wider than the

discharge tunnel opening, you must rotate the

plug clockwise slightly while inserting it

(Fig. 6). Make sure the arrow on the plug decal

is pointing upwards.

3. Push the plug all the way in until the spring clip

on the bottom of the plug clicks into place,

locking the plug securely into the discharge

tunnel (Fig. 7). Release the discharge door

handle to lock the top of the plug.

GB–11

Page 22

4. To remove the plug, move the discharge door

handle rearwards while at the same time lift up

the spring clip on the bottom of the plug. When

the plug is unlocked, pull it out of the discharge

tunnel.

Note: When grass is thick and lush, clippings

may collect on and around the

discharge tunnel plug. This may make

plug removal difficult. Clean plug

thoroughly after each use. Refer to

Cleaning Mower, page 17.

Using Grass Bag

Occasionally you may wish to use the grass bag for

bagging extra long grass, lush grass or leaves.

1. Stop engine and wait for all moving parts to

stop.

4. Pull discharge door handle forward until pin

clears catch and move handle rearward until pin

locks in bag notch (Fig. 15). Discharge door in

mower housing is now open.

POTENTIAL HAZARD

• A worn grass bag could allow small stones

and other similar debris to be thrown in

operator’s or bystander’s direction.

WHAT CAN HAPPEN

• Thrown objects can cause serious personal

injury or death to operator or bystanders.

HOW TO AVOID THE HAZARD

• Check the grass bag frequently. If it is

damaged, install a new genuine TORO

replacement bag.

2. Ensure discharge door handle is fully forward

and pin is engaged in catch (Fig. 14).

3. INSTALLING BAG—Slide hole in bag frame

onto retaining post on discharge tunnel (Fig. 14).

Set rear of bag frame onto lower handle.

POTENTIAL HAZARD

• Grass clippings and other objects can be

thrown from an open discharge tunnel.

WHAT CAN HAPPEN

• Objects thrown with enough force could

cause serious personal injury or death to

operator or bystander.

HOW TO AVOID THE HAZARD

• Never open door on discharge tunnel when

engine is running unless the grass bag,

optional side discharge attachment or

discharge tunnel plug is securely installed.

POTENTIAL HAZARD

• Thrown objects may result if discharge

door does not close completely.

WHAT CAN HAPPEN

• Thrown objects can cause serious

personal injury or death.

HOW TO AVOID THE HAZARD

• If discharge door cannot be closed because

grass clippings clog discharge area, stop

engine and gently move discharge door

handle back and forth until door can be

closed completely. If door still cannot be

closed, remove obstruction with a stick, not

your hand.

5. EMPTYING BAG—Stop engine and wait for all

moving parts to stop. Raise discharge door

handle and move it forward to engage the

locking pin with the catch (Fig. 14). Grasp

handles at front and rear of bag and lift bag off

mower. Gradually tip bag forward to empty

clippings.

GB–12

Page 23

6. To reinstall bag, repeat steps 3-4.

Adjusting Height-of-cut

The height-of-cut is adjustable from approximately

#/4 to 3-!/4 inches (19 mm to 83 mm), in !/2 inch

(12.7 mm) increments (Fig. 9). Moving height-of-cut

adjuster forward raises height-of-cut.

1. Stop the engine and wait for all moving parts to

stop. Pull wire off spark plug (Fig. 12).

Maintenance

POTENTIAL HAZARD

• When wire is on spark plug, someone could

accidentally start the engine.

WHAT CAN HAPPEN

• Accidental starting of engine could

seriously injure you or other bystanders.

HOW TO AVOID THE HAZARD

• Pull wire off spark plug before you do any

maintenance. Also push wire aside so it

does not accidentally contact spark plug.

Servicing Air Cleaner

2. For easier adjustment, lift housing up so wheel is

off ground. Do not place hands under deck to

lift housing. Squeeze adjusting lever toward

wheel (Fig. 16) and move it to the desired

setting. Assure pin on adjusting lever engages

notch in mower housing wear plate. Adjust all

wheels to the same setting.

POTENTIAL HAZARD

• Adjusting height-of-cut levers could bring

hands into contact with moving blade.

WHAT CAN HAPPEN

• Contact with blade could cause serious

personal injury.

HOW TO AVOID THE HAZARD

• Stop engine and wait for all moving parts

to stop before changing height-of-cut.

• Do not put fingers under housing to lift

mower when adjusting height-of-cut levers.

Normally, clean air cleaner pre-cleaner after every 25

operating hours or every season. Clean the paper

cartridge after every 100 hours or every season. More

frequent cleaning is required when mower is operated

in dusty or dirty conditions. Replace air cleaner parts,

if very dirty.

IMPORTANT: Do not operate engine without

air filter elements; extreme engine wear or

damage will occur.

Note: Tipping mower on wrong side to

service underside of mower may cause

damage to air filters.

1. Stop engine and pull wire off spark plug

(Fig. 12).

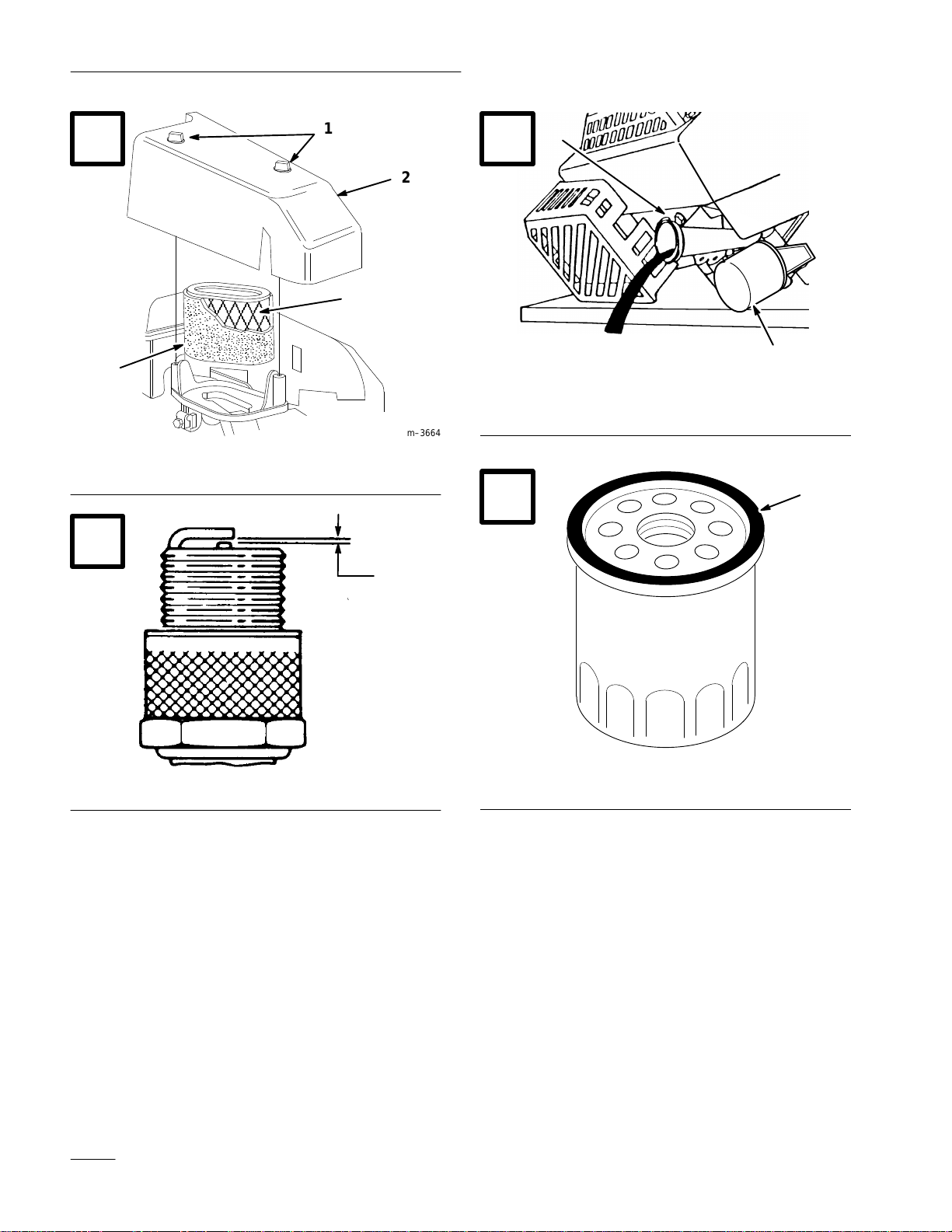

2. Remove two (2) knobs securing air cleaner cover

to engine (Fig. 17).

3. Lift cover off. Clean cover thoroughly.

4. Carefully remove pre-cleaner. If pre-cleaner is

dirty, carefully wash it in a solution of liquid

soap and warm water. Rinse in clear water.

Allow to dry thoroughly before using.

5. If paper cartridge is dirty, clean the paper filter

by tapping it gently on a flat surface. If very

dirty, replace cartridge.

GB–13

Page 24

IMPORTANT: Do not oil pre–cleaner or

paper cartridge. Do not use pressurized air to

clean paper cartridge.

6. Reinstall pre-cleaner over paper cartridge.

Reinstall air cleaner cover and tighten securely

in place with two (2) knobs.

Changing Crankcase Oil

Change oil after the first 5 operating hours and then

after every 50 hours or every season. Change oil

while engine is warm.

Note: Change oil every 25 hours when

operating under heavy load or in high

temperatures.

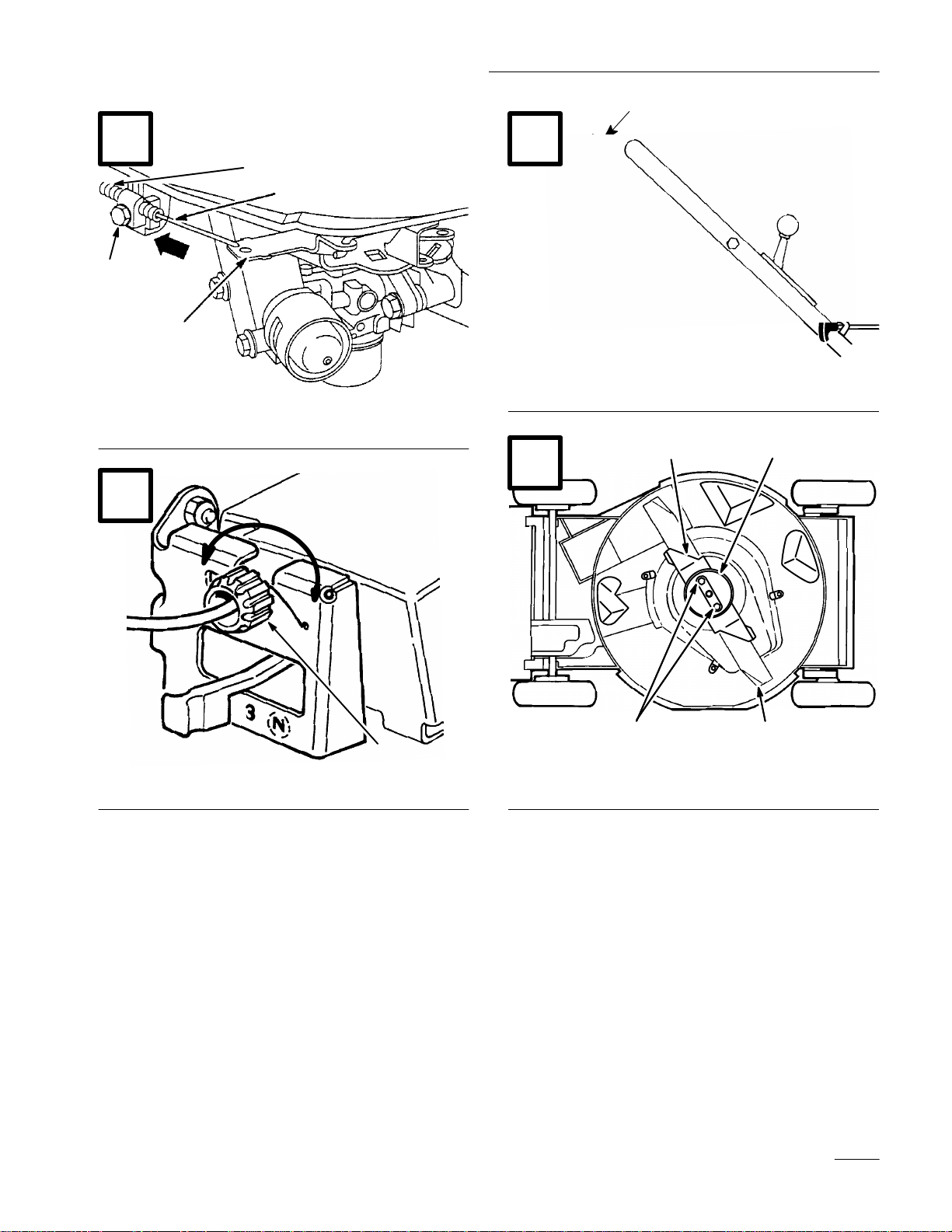

Replacing Spark Plug

Remove plug after every 25 operating hours and

check its condition. Replace spark plug every 100

operating hours or every season. Use a Champion

RC12YC spark plug or equivalent.

1. Stop engine and wait for all moving parts to

stop. Pull wire off spark plug (Fig. 12).

2. Clean around spark plug and remove plug from

cylinder head.

IMPORTANT: Replace a cracked, fouled, or

dirty spark plug. Do not sand blast, scrape, or

clean electrodes because engine damage could

result from grit entering cylinder.

3. Set air gap at 0.020” (0.5 mm) (Fig. 18). Install

correctly gapped spark plug and gasket seal.

Tighten plug firmly to 14 ft–lb (19 Nm).

1. Stop engine and wait for all moving parts to

stop. Pull wire off spark plug (Fig. 12).

2. Remove grass bag. Drain gasoline from fuel

tank: refer to Draining Gasoline, page 14.

3. Remove dipstick from oil fill tube and place a

drain pan next to left side of mower.

4. Tip mower on its left side, allowing oil to drain

into drain pan (Fig. 19).

5. When oil is drained, return mower to upright

position and add fresh oil to engine. Refer to Fill

Crankcase With Oil, page 8.

Replacing Oil Filter

Replace the oil filter (Fig. 19) after every 100

operating hours or yearly, whichever occurs first.

1. Drain gasoline from fuel tank; refer to Draining

Gasoline, page 14.

Draining Gasoline

1. Stop engine and wait for engine to cool. Pull

wire off spark plug (Fig. 12).

Note: Drain gasoline from a cold engine

only.

2. Remove cap from fuel tank and use pump–type

syphon to drain fuel into clean gas can.

Note: This is the only procedure

recommended for draining fuel.

GB–14

2. Drain oil. Refer to Changing Crankcase Oil,

page 14.

3. Place a rag under oil filter to catch any oil that

may leak out as filter is removed.

4. Remove oil filter and discard it.

5. Using your finger, coat the gasket on the new

filter with oil (Fig. 20).

6. Install the new filter and hand tighten it 2/3 turn

only.

7. Check the filter for any oil leaks.

8. Properly discard the oily rag.

Page 25

Adjusting Throttle

Throttle control adjustment may be required if engine

does not start. Whenever a new throttle control cable

is installed, throttle must be adjusted.

3. CHECK ADJUSTMENT—Slowly pull mower

backward while control bar is gradually moved

toward handle. Adjustment is correct when rear

wheels stop turning and control bar is about 1

inch from handle (Fig. 23).

1. Stop engine and wait for all moving parts to

stop. Pull wire off spark plug (Fig. 12).

2. Loosen cable clamp screw until throttle cable

slides (Fig. 21).

3. Move governor control lever, throttle cable and

casing in direction of arrow as far as possible

(Fig. 21).

4. Move throttle control to

5. Tighten cable clamp screw to lock adjustment in

place.

(FAST position).

Cleaning Cooling System

After every 100 operating hours, clean dirt and chaff

from cylinder, cylinder head fins and from around

carburetor and linkage. Also remove debris from air

intake slots on recoil housing. This will ensure proper

cooling and optimum engine performance.

Adjusting Wheel Drive

Inspecting/Removing/

Sharpening Blade

Always mow with a sharp blade. A sharp blade cuts

cleanly and without tearing or shredding the grass

blades like a dull blade.

1. Stop engine and wait for all moving parts to

stop. Pull wire off spark plug (Fig. 12).

2. Drain gasoline from fuel tank; refer to Draining

Gasoline, page 14.

3. Tip mower on its left side (Fig. 24).

POTENTIAL HAZARD

• Someone could accidentally start the

engine.

WHAT CAN HAPPEN

• Accidental starting of engine could cause

serious injury to operator or bystanders.

HOW TO AVOID THE HAZARD

• Do not attempt to inspect, remove or

replace blade without first removing the

spark plug wire from spark plug and

fastening it away from accidental contact

with spark plug.

If mower does not self–propel or self–propels when

control bar is more than 1–1/2 inches from the

handle, adjust wheel drive control knob on rear of

gear box.

1. Close door in mower housing and remove grass

bag.

2. ADJUSTMENT (Fig. 22)—Rotate control knob

clockwise 1/2 turn if mower does not

self–propel. If mower creeps forward, rotate

knob 1/2 turn counterclockwise to loosen belt.

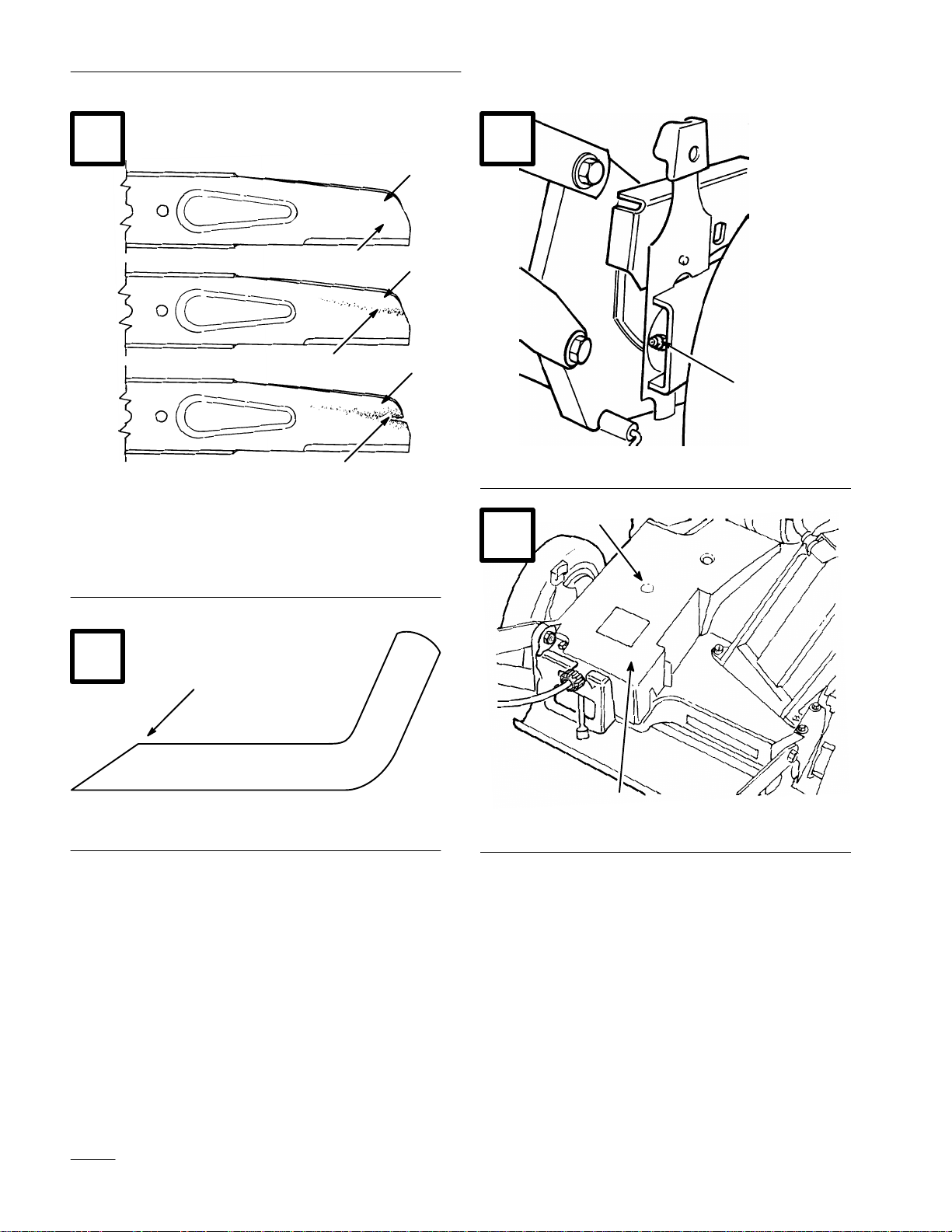

4. INSPECTING BLADE—Carefully examine

blade for sharpness and wear, especially where

flat and curved parts meet (Fig. 25A). Since sand

and abrasive material can wear away the metal

that connects the flat and curved parts of the

blade, check blade before using the mower. If a

slot or wear is noticed, (Fig. 25B & C), replace

blade. Refer to step 5.

Note: For best performance, install new blade

before cutting season begins. During

the year, file down small nicks to

maintain the cutting edge.

GB–15

Page 26

POTENTIAL HAZARD

• A worn or damaged blade could break and

a piece of blade could be thrown into

operator’s or bystander’s area.

POTENTIAL HAZARD

• Operating mower without accelerator in

place could cause blade to flex, bend or

break.

WHAT CAN HAPPEN

• A thrown piece of blade could cause serious

personal injury or death to operator or

bystanders.

HOW TO AVOID THE HAZARD

• Inspect blade periodically for wear or

damage.

• Replace a worn or damaged blade.

5. REMOVING BLADE—Grasp end of blade

using a rag or thickly padded glove. Remove

blade nuts, anti–scalp cup, accelerator, and blade

(Fig. 24).

6. SHARPENING BLADE—Using a file, sharpen

top side of blade and maintain original cutting

angle (Fig. 26). The blade will remain balanced

if same amount of material is removed from both

cutting edges.

WHAT CAN HAPPEN

• A broken blade could cause serious injury

or death to operator or bystanders.

HOW TO AVOID THE HAZARD

• Do not operate mower without accelerator.

Lubrication

After every 25 operating hours or when season ends,

pivot arms must be lubricated.

1. Move rear wheel height–of–cut levers to center

setting. Wipe grease fittings with clean rag

(Fig. 27). Install grease gun onto fitting and

gently apply 2 or 3 pumps of #2 Multi–Purpose

Lithium Base Grease. Excessive grease pressure

may damage seals.

Lubricating Gear Case

After every 100 operating hours, grease the gear case

with #2 Multi–Purpose Lithium Base Grease.

IMPORTANT: Check balance of blade by

putting it on a blade balancer. An inexpensive

balancer can be purchased at a hardware

store. A balanced blade stays in a horizontal

position and an unbalanced blade settles to

the heavy side. If blade is not balanced, file

more metal off cutting edge on heavy end of

blade.

7. Reinstall sharp, balanced blade, blade

accelerator, anti–scalp cup, and blade nuts. Sail

part of blade must point toward top of mower

housing to assure correct installation. Tighten

blade nuts to 15–27 ft–lbs (20–37 Nm).

GB–16

1. Remove bag.

2. Install grease gun onto fitting thru belt cover

opening (Fig. 28). Gently apply 1–2 pumps of

grease.

3. Reinstall bag.

Adjusting Blade Brake Cable

Whenever a new blade brake cable assembly is

installed or the blade brake belt is replaced, the blade

brake cable should be adjusted.

1. Stop engine and wait for all moving parts to

stop. Pull wire off spark plug (Fig. 12).

Page 27

2. Loosen cable clamp screw until brake cable

conduit slides (Fig. 29). Pull cable to remove

slack, but do not put tension on spring. Tighten

screw to lock adjustment in place.

POTENTIAL HAZARD

• Do not over–tighten blade brake cable.

Over–tightening could cause blade brake to

be pulled off brake drum. If brake does not

contact drum, blade will not stop rotating

when control bar is released.

WHAT CAN HAPPEN

• A rotating blade could cause serious

personal injury.

HOW TO AVOID THE HAZARD

• Check the blade brake mechanism each

time brake cable is adjusted to ensure

brake is stopping blade in 3 seconds or less.

• If blade does not stop rotating in 3 seconds

or less, bring unit to your local Authorized

Toro Service Dealer for inspection and

repair.

POTENTIAL HAZARD

• Grass clippings and other objects can be

thrown from an open discharge tunnel.

WHAT CAN HAPPEN

• Thrown objects can cause serious injury or

kill operator or bystanders.

HOW TO AVOID THE HAZARD

• Never start or operate the mower unless

one of the following is true:

1. The discharge tunnel plug is locked

securely in discharge tunnel.

2. The grass bag is locked in place.

3. The optional side discharge chute is

locked in place.

4. The discharge tunnel door is locked

in place.

Underside of Mower Housing

Keep underside of mower housing clean. Be

especially careful to keep kickers free of debris

(Fig. 32).

Cleaning Mower

Plug

To ensure best performance, the discharge tunnel plug

must be cleaned after each use. When grass is thick

and lush, clippings may collect on and around the

plug; this may make plug removal difficult. After

each use, remove plug from discharge tunnel and

clean off all debris.

Discharge Tunnel

Always be sure that discharge tunnel door closes

securely when handle is released. If debris prevents

discharge door from closing securely, clean inside of

discharge tunnel and door thoroughly.

Washing Method

1. Position mower on a flat surface near a garden

hose.

2. Attach a quick disconnect coupling (sold

separately) to the end of the garden hose. Attach

coupling to mower washout fitting and turn

water on high (Fig. 30).

3. Start the engine.

4. Let mower run for two minutes.

5. Stop the engine.

6. Turn the water off and remove coupling from the

washout fitting.

7. Restart mower and let it run for one minute to

dry out moisture on the mower and its

components.

GB–17

Page 28

8. If underside of mower deck has excessive grass

build-up or packing, reconnect the hose to the

washout fitting, turn the water on high and run

the mower for two minutes. Stop the mower and

turn off the water. Let the mower soak for 30

minutes. Then turn the water on high again and

run the mower for another two minutes.

1. Stop engine and wait for all moving parts to

stop. Pull wire off spark plug (Fig. 12).

2. Drain gasoline from fuel tank; refer to Draining

Gasoline, page 14.

3. Tip mower on its left side.

Scraping Method

If washing does not remove all debris from under

deck, tip mower and scrape it clean.

1. Pull wire off spark plug (Fig. 12).

2. Drain gasoline from fuel tank: refer to Draining

Gasoline, page 14.

3. Tip mower on its left side (Fig. 32).

4. Remove dirt and grass clippings with a

hardwood scraper. Avoid burrs and sharp edges.

5. Turn mower upright.

6. Refill gas tank.

7. Reconnect spark plug wire.

Belt Cover

Keep area under belt cover free of debris.

1. Remove bolts securing belt cover (Fig. 28) to

mower housing. Lift off cover and brush out all

debris from belt area. Reinstall belt cover.

4. Remove (2) blade nuts, anti–scalp cup,

accelerator, and blade (Fig. 24).

5. Loosen tabs securing BBC shield to deck by

loosening nuts or bolts on tabs (Fig. 33). Rotate

tabs 180_ to move them out of the way.

6. Remove BBC shield and brush or blow all debris

from under shield and around BBC system.

7. Reinstall BBC shield. Rotate tabs 180_ back into

position. Tighten nuts or bolts on tabs to secure

BBC shield to deck.

8. Reinstall blade, accelerator, anti–scalp cup, and

(2) blade nuts.

9. Turn mower upright.

10. Reinstall spark plug wire on spark plug.

Servicing Wheels (Fig. 34)

Removal

1. Stop engine and wait for all moving parts to

stop. Pull wire off spark plug (Fig. 12).

2. Remove capscrew, wheel spacer, and locknut

mounting wheel to pivot arm.

Cleaning Blade Brake Clutch

Shield

The BBC (Blade Brake Clutch) shield should be

cleaned periodically during the mowing season and at

the end of each mowing season to ensure best

performance and to prevents parts degradation. It is

convenient to clean the BBC shield at the same time

the blade is being sharpened because the blade needs

to be removed in order to remove the BBC shield.

GB–18

3. Separate wheel halves from tire by removing (4)

capscrews and locknuts.

Note: If bearings are to be removed from

bearing/hub assembly, remove by

pressing on bearing spacer.

Assembly

1. Position tire onto (1) wheel half, aligning lugs

on each.

Page 29

2. Place bearing/hub assembly into center hole of

wheel half. Make sure legs of hub are positioned

over flange of hole.

3. Place other wheel half onto bearing/hub

assembly aligning wheel and tire lugs and

mounting holes.

4. Using (2) 1/4—20 x 1.50” lg. fully threaded

screws or bolts and non–locking nuts, loosely

secure wheel halves together. Mount screws or

bolts in opposing holes.

Storage

1. For long term storage, either drain gasoline from

fuel tank or add a fuel stabilizer to the gasoline.

To drain gasoline, refer to Draining Gasoline,

page 14. After fuel is drained, start engine and

let it idle until all fuel is consumed and engine

stops. Repeat the starting procedure two more

times to ensure all gas is removed from the

engine. If gasoline is not drained, gum–like

varnish deposits will form and cause poor engine

operation, even starting problems.

5. Check alignment of all parts and tighten screws,

alternating from side to side for a uniform fit,

until wheel halves are drawn together.

6. Install (2) capscrews and locknuts, previously

removed, in remaining holes in wheel halves and

tighten. Remove (2) long screws or bolts and

replace with (2) capscrews and locknuts.

7. Reinstall wheel to pivot arm with capscrews,

spacer, and locknut. Make sure spacer is

positioned between wheel hub and pivot arm.

Fuel Filter

Replacing the Fuel Filter

Replace the fuel filter after every 100 operating hours

or yearly, whichever occurs first. The best time to

replace the fuel filter (Fig. 31) is when the fuel tank is

empty. Never install a dirty filter if it is removed from

the fuel line.

1. Squeeze the ends of the hose clamps together

and slide them away from the filter (Fig. 31).

Note: If engine is operating on oxygenated or

reformulated gasoline (gasoline

blended with an alcohol or an ether),

remove all fuel from tank and run

engine until it stops from lack of fuel

before storing.

Fuel can be left in gas tank only if a fuel

additive, such as Toro’s Stabilizer/Conditioner, is

added to gasoline and run through engine before

storing. Toro’s Stabilizer/Conditioner is a

petroleum distillate based conditioner/stabilizer.

Toro does not recommend stabilizers with an

alcohol base, such as ethanol, methanol or

isopropyl. Use fuel additive in recommended

quantities as specified on container.

Under normal conditions, fuel additives remain

effective in fuel for 6–8 months.

2. Drain oil: refer to Changing Crankcase Oil,

page 14. After oil is drained, do not fill

crankcase with oil until the following steps

(3–11) are completed.

3. Remove spark plug and pour 2 tablespoons of

SAE 30 oil into hole in cylinder. Pull starter rope

slowly to coat inside of cylinder. Install spark

plug and tighten to 14 ft–lb (19 Nm). DO NOT

REINSTALL WIRE ON SPARK PLUG.

2. Remove the filter from the fuel lines.

3. Install a new filter and move the hose clamps

close to the filter.

4. Clean mower housing: refer to Cleaning Mower,

page 17.

5. Clean BBC shield: refer to Cleaning Blade

Brake Clutch Shield, page 18.

GB–19

Page 30

6. Clean dirt and chaff from cylinder, cylinder head

fins, and blower housing. Also remove grass

clippings, dirt, and grime from external parts of

the engine, shrouding, and top of mower

housing.

13. Store mower in a clean, dry place, out of the

reach of children. Cover mower to keep it clean

and protected.

7. Check condition of blade: refer to

Inspecting/Removing/Sharpening Blade,

page 15.

8. Tighten all nuts, bolts, and screws.

9. Clean air cleaner: refer to Servicing Air Cleaner,

page 13.

10. Lubricate the pivot arms: refer to Lubrication,

page 16.

11. Touch up all rusted or chipped paint surfaces.

Toro Re–Kote paint is available from an

Authorized TORO Service Dealer.

12. Fill crankcase with oil: refer to Fill Crankcase

With Oil, page 8.

Accessories

For special conditions, the following accessories may

be purchased at your local Authorized Toro Service

Dealer.

1. Side Discharge Kit, Model No. 59113—Installs

in seconds. Rear mounted in place of the grass

bag or discharge tunnel plug. Disperses clippings

while trimming on both sides (Fig. 35).

2. Spark Arrestor and Screw (Part No.

94–1681)—If a spark arrestor is required

because of local, state, or federal regulations, it

may be purchased at your local Authorized

TORO Service Dealer. Clean screen after every

75 hours of operation. If mower is operated on

any California forest, brush, or grass covered

land without a properly operating spark arrestor,

the operator is violating state law, Section 4442

Public Resources Code.

GB–20

Loading...

Loading...