Page 1

EATON 751, 781 HYDROSATIC TRANSAXLE

Table Of Contents – Page 1 of 1

751, 851, 771, AND 781 HYDROSTATIC T RANSAX LE

TRANSAXLES 751, 851

TRANSAXLE WITH CHARGE PUMP

781 SERIES HYDROSTATIC TRANSAXLE

AXLE HOUSING DISASSEMBLY

MOTOR ROTOR DISASSEMBLY

TRANSAXLE WITH CHARGE PUMP

PUMP AND MOTOR ROTOR INSPECTION

TRANSAXLE WITH CHARGE PUMP

TRANSAXLE WITH DUMP VALVE

TRANSAXLE REASSE MB L Y

TRANSAXLE WITH DUMP VALVE

TRANSAXLE WITH CHARGE PUMP

TRANSAXLE WITH CHARGE PUMP

COVER REASSEMBLY

TRANSAXLE WITH CHARGE PUMP

AXLE HOUSING REASSEMBLY

781 SERIES TRANSAXLE

TRANSAXLE WITH CHARGE PUMP AND SPI N- ON FILT ER

FLUID RECOMMENDATIONS

TRANSAXLE PART S LISTS

FAULT-LOGIC TROUBLE SHOOTING

DIAGRAM ACTION STEP COMMENTS

Page 2

NO.

7-416

Eaton

Hydraulics

Division

t

751 851 771

and

781

Hydrostatic Transaxle

Page 3

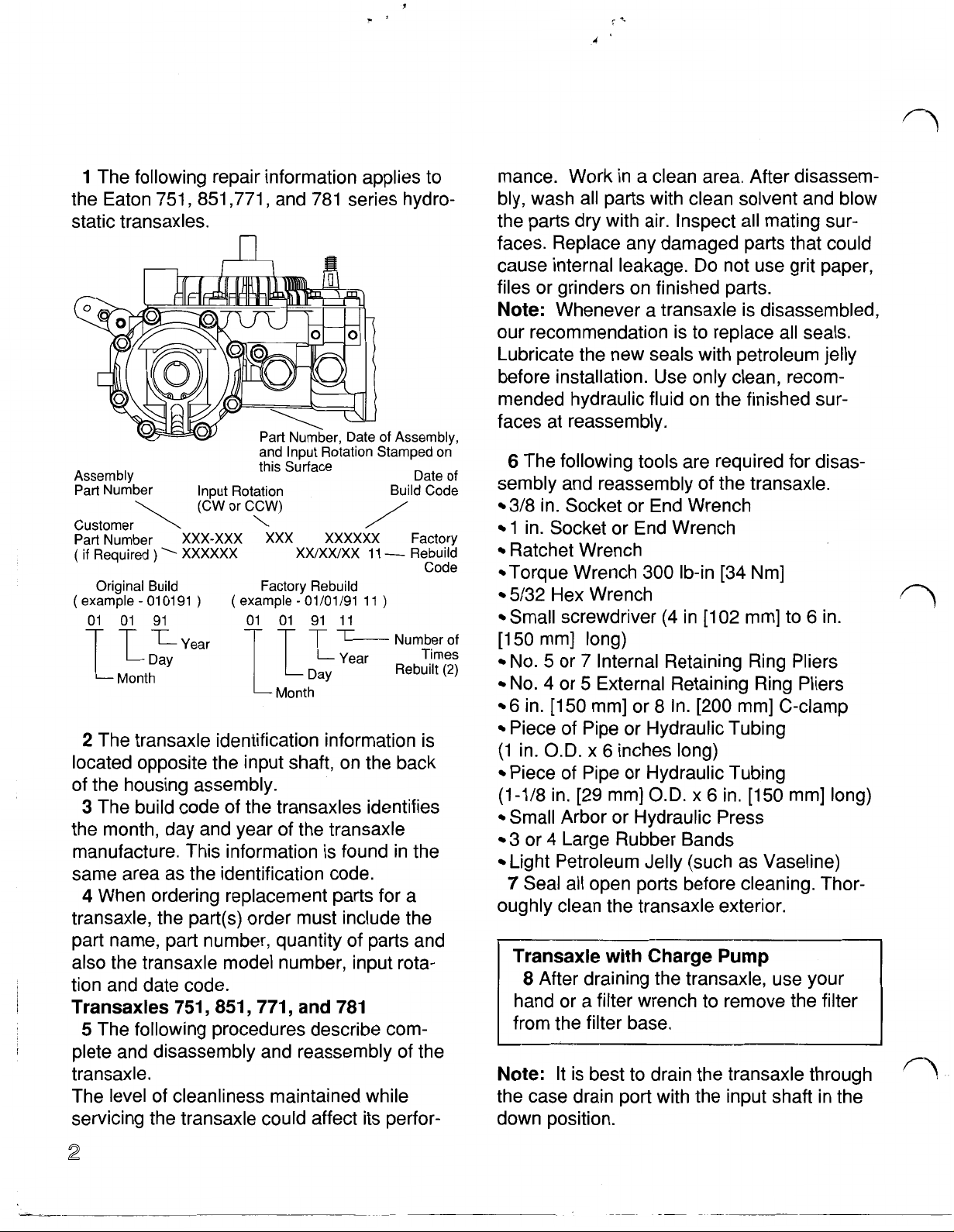

1

The following repair information applies to

the Eaton

751,851,771,

and

781

series hydro-

static transaxles.

Date

of

and Input Rotation Stamped on

Assembly Date

Part Number Input Rotation Build Code

\

Customer

Part Number

(

if

Required

Original Build Factory Rebuild

example

01 01 91 01 01 91 11

2

The transaxle identification information is

010191

Month Day

(CW or CCW)

)

)

Year Number

this Surface

\

(

example

XXXXXX Factory

01/01/91 11

Month

Assembly,

11

)

Rebuilt

Rebuild

Code

Times

located opposite the input shaft, on the back

of the housing assembly.

3

The build code of the transaxles identifies

the month, day and year of the transaxle

manufacture. This information is found in the

same area as the identification code.

4

When ordering replacement parts for a

transaxle, the part(s) order must include the

part name, part number, quantity of parts and

also the transaxle model number, input rotation and date code.

Transaxles 751,851,771, and 781

5

The following procedures describe complete and disassembly and reassembly of the

transaxle.

The level of cleanliness maintained while

servicing the transaxle could affect its perfor-

of

of

(2)

mance. Work in a clean area. After disassembly, wash all parts with clean solvent and blow

the parts dry with air. Inspect all mating surfaces. Replace any damaged parts that could

cause internal leakage.

Do

not use grit paper,

files or grinders on finished parts.

Note:

Whenever a transaxle is disassembled,

our recommendation is to replace all seals.

Lubricate the new seals with petroleum jelly

before installation. Use only clean, recommended hydraulic fluid on the finished surfaces at reassembly.

6

The following tools are required for disas-

sembly and reassembly of the transaxle.

3/8

in. Socket or End Wrench

1

in. Socket or End Wrench

Ratchet Wrench

Torque Wrench

5/32

Hex Wrench

Small screwdriver

[150

N-m) long)

300

(4

Ib-in

in

[102

[34

N-m)

N-m) to 6 in.

No. 5 or 7 Internal Retaining Ring Pliers

No.

4

or 5 External Retaining Ring Pliers

6

in.

[150

N-m) or 8 In.

[200

mm C-clamp

Piece of Pipe or Hydraulic Tubing

(1

in.

O.D.

x 6 inches long)

Piece of Pipe or Hydraulic Tubing

(1-1/8

in.

[29

mm] O.D.

x

6

in.

[150

mm] long)

Small Arbor or Hydraulic Press

3

or 4 Large Rubber Bands

Light Petroleum Jelly (such as Vaseline)

7

Seal all open ports before cleaning. Thor-

oughly clean the transaxle exterior.

8

After draining the transaxle, use your

hand or a filter wrench to remove the filter

from the filter base.

Note:

It is best to drain the transaxle through

the case drain port with the input shaft in the

down position.

2

Page 4

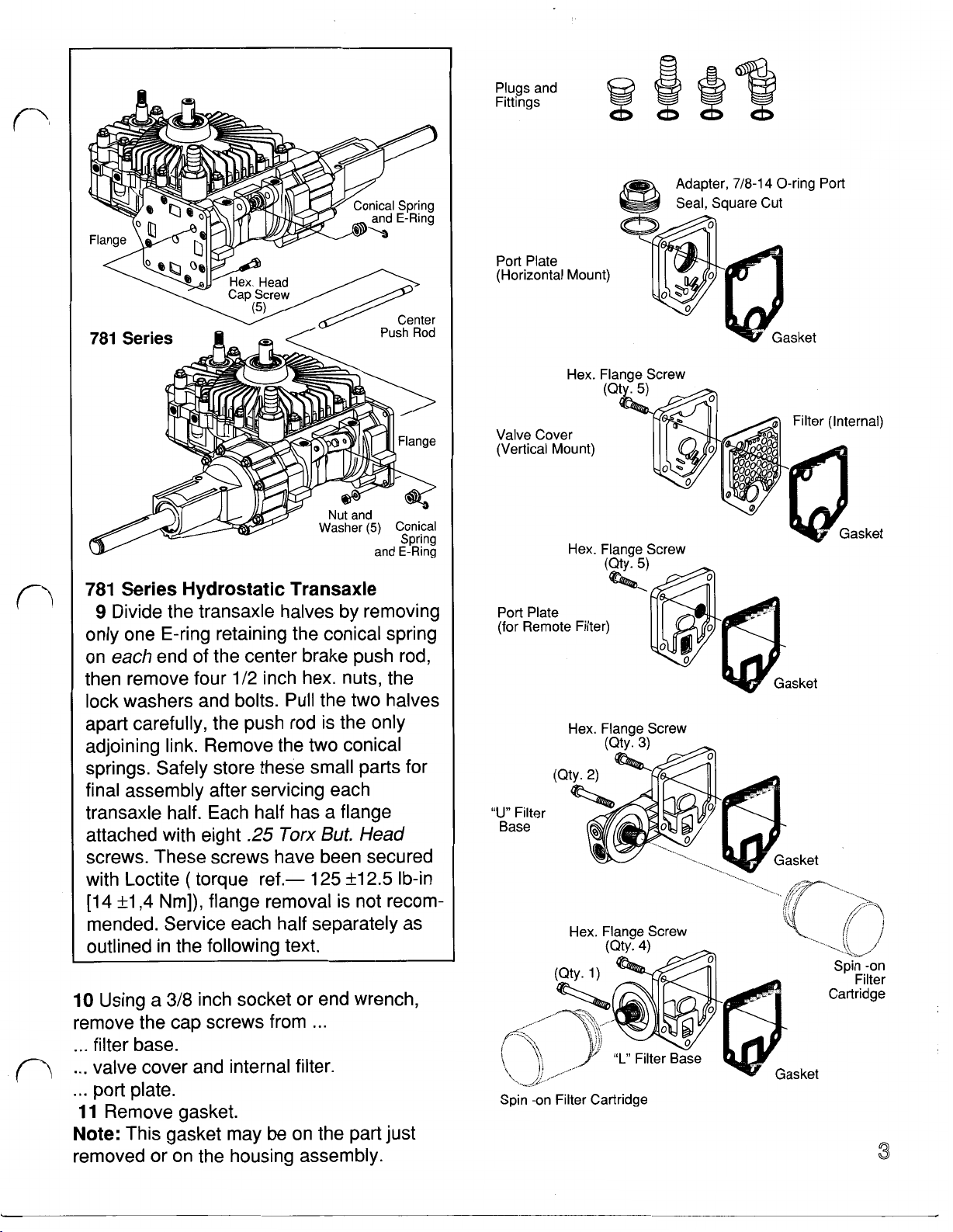

Plugs and

Fittings

781

Series Hydrostatic Transaxle

9

Divide the transaxle halves by removing

only one E-ring retaining the conical spring

on

each

end of the center brake push rod,

then remove four

1/2

inch hex. nuts, the

lock washers and bolts. Pull the two halves

apart carefully, the push rod is the only

adjoining link. Remove the two conical

springs. Safely store these small parts for

final assembly after servicing each

transaxle half. Each half has a flange

attached with eight

.25

Torx

But.

Head

screws. These screws have been secured

with Loctite ( torque ref.-

[14 +1,4

Nm]), flange removal is not recom-

125 f12.5

Ib-in

mended. Service each half separately as

outlined in the following text.

Port Plate

(Horizontal

Valve Cover

(Vertical Mount)

Port Plate

(for Remote Filter)

“U”

Filter

Base

Mount)

Hex.

Hex. Flange Screw

Hex. Flange Screw

Adapter,718-14O-ring

Seal, Square Cut

Flange Screw

(Q

(Qty.

5)

Port

Filter (Internal)

asket

10

Using a

3/8

inch socket or end wrench,

remove the cap screws from

filter base.

valve cover and internal filter.

port plate.

11

Remove gasket.

Note:

This gasket may be on the part just

removed or on the housing assembly.

Spin -on Filter Cartridge

3

Page 5

Clean

Bench C-Clamp

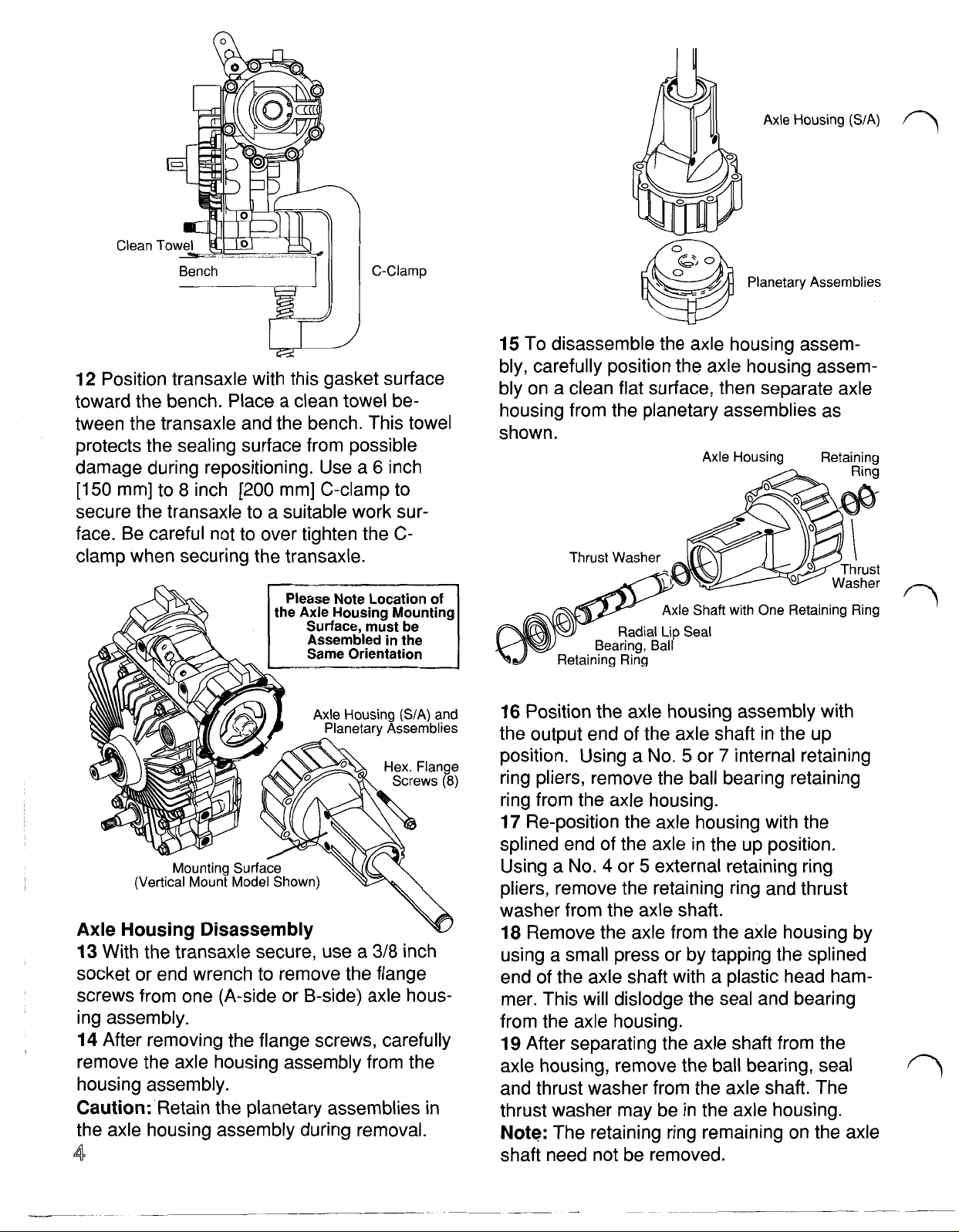

12

Position transaxle with this gasket surface

toward the bench. Place a clean towel between the transaxle and the bench. This towel

protects the sealing surface from possible

damage during repositioning. Use a 6 inch

[I50

mm] to 8 inch

[200

mm] C-clamp to

secure the transaxle to a suitable work surface. Be careful not to over tighten the

C-

clamp when securing the transaxle.

15

To disassemble the axle housing assembly, carefully position the axle housing assembly on a clean flat surface, then separate axle

housing from the planetary assemblies as

shown.

Axle Housing Retaining

Axle

Shaft

with One Retaining Ring

Axle

Housing Disassembly

13

With the transaxle secure, use a

3/8

inch

socket or end wrench to remove the flange

screws from one (A-side or B-side) axle housing assembly.

14

After removing the flange screws, carefully

remove the axle housing assembly from the

housing assembly.

Caution:

Retain the planetary assemblies in

the axle housing assembly during removal.

4

16

Position the axle housing assembly with

the output end of the axle shaft in the up

position. Using a

No.

5

or 7 internal retaining

ring pliers, remove the ball bearing retaining

ring from the axle housing.

17

Re-position the axle housing with the

splined end of the axle in the up position.

Using a

No.

4

or 5 external retaining ring

pliers, remove the retaining ring and thrust

washer from the axle shaft.

18

Remove the axle from the axle housing by

using a small press or by tapping the splined

end of the axle shaft with a plastic head hammer. This will dislodge the seal and bearing

from the axle housing.

19

After separating the axle shaft from the

axle housing, remove the ball bearing, seal

and thrust washer from the axle shaft. The

thrust washer may be in the axle housing.

Note:

The retaining ring remaining on the axle

shaft need not be removed.

Page 6

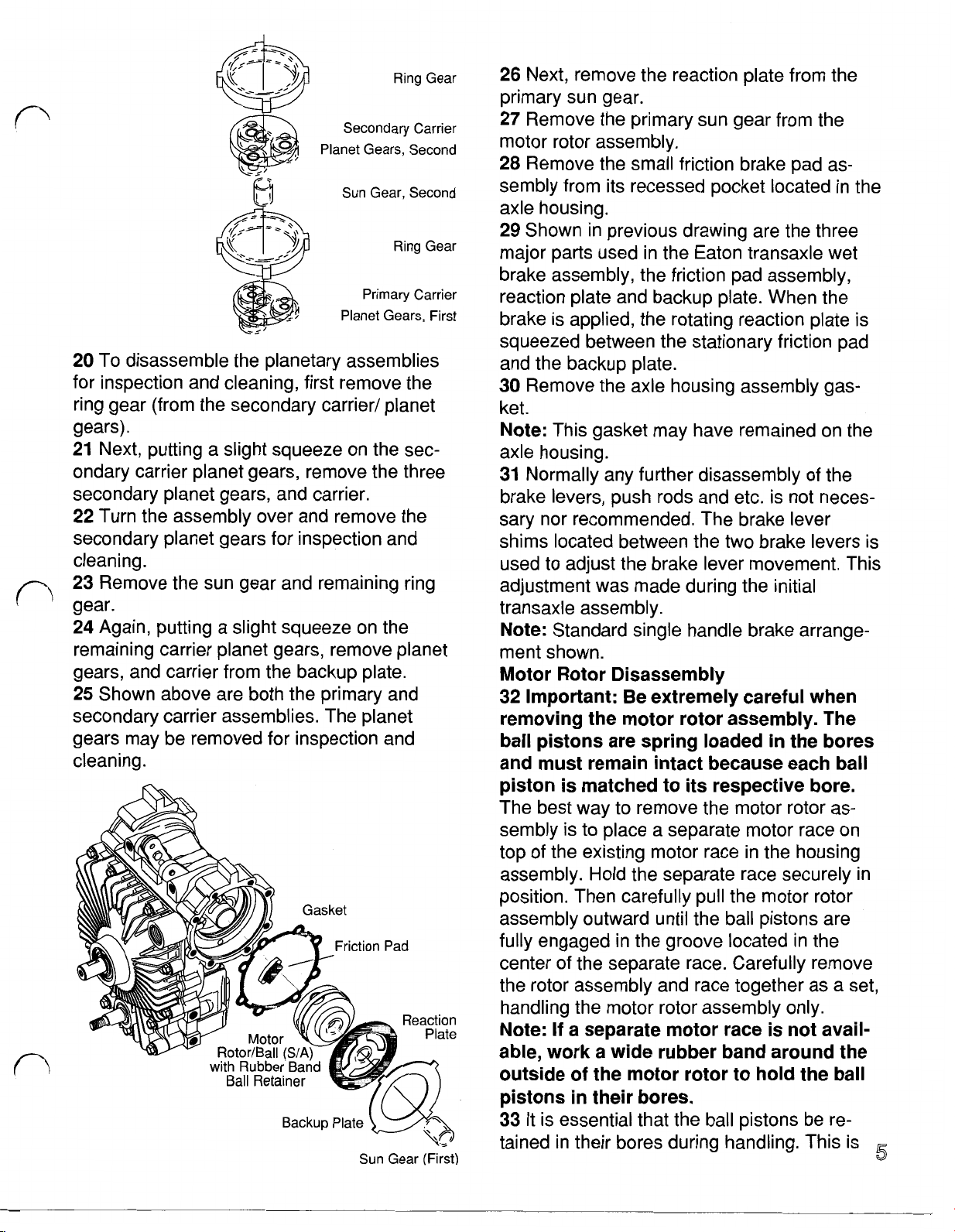

Ring Gear

Sun

Gear, Second

Ring Gear

Primary Carrier

Planet Gears, First

20

To disassemble the planetary assemblies

for inspection and cleaning, first remove the

ring gear (from the secondary carrier/ planet

gears).

21

Next, putting a slight squeeze on the secondary carrier planet gears, remove the three

secondary planet gears, and carrier.

22

Turn the assembly over and remove the

secondary planet gears for inspection and

cleaning.

23

Remove the sun gear and remaining ring

gear.

24

Again, putting a slight squeeze on the

remaining carrier planet gears, remove planet

gears, and carrier from the backup plate.

25

Shown above are both the primary and

secondary carrier assemblies. The planet

gears may be removed for inspection and

cleaning.

Backup Plate

Sun Gear (First)

26

Next, remove the reaction plate from the

primary sun gear.

27

Remove the primary sun gear from the

motor rotor assembly.

28

Remove the small friction brake pad assembly from its recessed pocket located in the

axle housing.

29

Shown in previous drawing are the three

major parts used in the Eaton transaxle wet

brake assembly, the friction pad assembly,

reaction plate and backup plate. When the

brake is applied, the rotating reaction plate is

squeezed between the stationary friction pad

and the backup plate.

30

Remove the axle housing assembly gas-

ket.

Note:

This gasket may have remained on the

axle housing.

31

Normally any further disassembly of the

brake levers, push rods and etc. is not necessary nor recommended. The brake lever

shims located between the two brake levers is

used to adjust the brake lever movement. This

adjustment was made during the initial

transaxle assembly.

Note:

Standard single handle brake arrange-

ment shown.

Motor Rotor Disassembly

32 Important: Be extremely careful when

removing the motor rotor assembly. The

ball pistons are spring loaded in the bores

and must remain intact because each ball

piston is matched to its respective bore.

The best way to remove the motor rotor assembly is to place a separate motor race on

top of the existing motor race in the housing

assembly. Hold the separate race securely in

position. Then carefully pull the motor rotor

assembly outward until the ball pistons are

fully engaged in the groove located in the

center of the separate race. Carefully remove

the rotor assembly and race together as a set,

handling the motor rotor assembly only.

Note:

If

a separate motor race is not available, work a wide rubber band around the

outside of the motor rotor to hold the ball

pistons in their bores.

33

It is essential that the ball pistons be re-

tained in their bores during handling. This is

Page 7

especially true for the motor rotor(s) as the

motor ball pistons are spring loaded in the

bores.

Note:

assembly,

The remaining transaxle axle housing

if

applicable, can be serviced at this

time (ref. steps 12-34)

Control Shaft Seal

\

\

Gasket

34

Reposition the housing assembly. Using a

Retaining Ring

Input Shaft

(S/A)

3/8 inch socket or end wrench, remove the

self tap screws from the cover assembly.

Note: One self tap screw is located in the

case drain port.

35

With all self tap screws removed (1 3),

carefully separate and remove the cover from

the housing assembly.

36

Turn the cover assembly over and remove

the two buttons.

Note:

These two buttons may have dropped

out into the housing assembly during removal

of the cover.

37

Turn the cover assembly back over and

using a

No.

5

or 7 internal retaining ring pliers,

remove the input shaft retaining ring.

38

Reposition and support the cover allowing

room for shaft removal. With the input shaft in

the down position, use a plastic head hammer

or press to remove the input shaft assembly

from the cover.

39

No

further disassembly of the shaft and

bearing assembly is required as they are

serviced as an assembly.

40

Using a screwdriver or similar tool, drive

the input shaft seal from the cover.

41

To remove the control shaft seal, reposition

the cover. Using a small screwdriver or similar

6

tool, pry the control shaft seal from the cover.

42

Remove the cover gasket from the hous-

ing.

Note:

The gasket may have remained on the

cover.

43

Remove the drive from the pump rotor

assembly.

Drive

Pump Rotor/Ball

(S/A)

Control Shaft and Band Retainer

Insert

with Rubber

Transaxle with Charge Pump

Remove the charge pressure relief

44

valve spring from the housing.

45

Using a pencil magnet or similar tool,

remove the charge pressure relief ball

from its seat in the housing.

46

Remove the control shaft and insert from

the housing and cam ring assembly.

47

Remove the cam ring insert from the con-

trol shaft.

48

Remove the cam ring assembly from the

housing.

49

Carefully remove the pump rotor assembly

from the housing, making sure the ball pistons

are not dislodged from their bores.

Important: It is essential that the pump

rotor assembly remain intact during handling as each ball piston is matched to its

respective bore.

50

Install a wide rubber band around the

pump rotor to retain the ball pistons in their

bores.

Page 8

Motor Rotor/Ball

(SA)

Pump Rotor/Ball

(SA)

Pump and Motor Rotor Inspection

Disassemble and Inspect the rotor assem-

51

bly

in the following manner. Remove the

piston balls from the rotor, one at a time,

working clockwise from the letter stamped in

the rotor face. Place the piston balls in a

prepared container (use a container such as

an egg carton or ice cube tray to hold the

balls).

Note:

The balls must be replaced in the same

bores from which they were removed because

they are all select fit.

Check for broken or collapsed springs in the

motor rotor. When broken or collapsed springs

are found with no other irregularities, the

springs may be replaced individually without

replacing the complete motor rotor assembly.

Inspect the piston balls. They must be smooth

and completely free of any irregularities.

Inspect the rotor bores, rotor bushing and

pintle journals for irregularities or excessive

clearance. The ball piston to rotor bore clearance is select fit electronically from

[,005

mm] to

.0006

inch

[,015

.0002

mm]. When

inch

irregularities are noted, replace the complete

rotor assembly. Install the ball pistons in their

matching bores. Hold them in place with a

rubber band or separate race.

Socket Head Cap Screw

Charge Pump Plate

(4)

use a

5/32

hex key to remove the cap

screws from the charge pump plate.

53

Remove the charge pump plate from

the housing.

54

Remove the charge pump gerotor

from the housing.

55

The pump and motor journals and cam ring

dowel cannot be removed once they have

been installed in the housing.

Note:

any irregularities.

Inspect the pump and motor journals for

If

any are found, the housing

must be replaced.

56

In most cases, we do not recommend

removal of the dampening pistons for inspection or cleaning. Normal flushing should be all

that is required for cleaning.

Dump

Valve

Fitting

Nut

and

O-ring

Transaxle with Dump Valve

57

To remove the dump valve assembly,

first use a 1 inch socket or end wrench to

remove the dump valve nut from the

housing.

58

Remove the O-ring from the dump

valve nut.

59

After removing the dump valve nut,

remove the dump valve bracket and

spring from the housing by sliding them

over and lifting upward.

60

Remove the spring from the dump

valve bracket.

61

Remove the O-ring from the dump

valve bracket.

Transaxle with Charge Pump

52

To inspect the charge pump assembly,

62

We do not recommend removal of the

check valve assemblies

for

inspection or

cleaning. Once again, normal flushing should

be all that is required to clean the check

valves.

a

Page 9

Transaxle Reassembly

63

Before reassembling the transaxle, clean

all parts and assemblies with clean solvent

and blow them dry with compressed air. Inspect and replace

all

scratched or damaged

parts. Replace all gaskets, seals and seal

rings. Lubricate all seals with petroleum jelly

(Vaseline) for retention during assembly.

Freely lubricate all bearings and finished part

surfaces with clean hydraulic fluid to provide

lubrication at start-up.

Dump Valve

Fitting Nut

and O-ring

Socket Head Cap Screw

Charge

(4)

Transaxle with Dump Valve

64

To reassemble the dump valve, first

lubricate and install the O-ring in the groove

located in the dump valve bracket.

65

Install the spring on the dump valve

bracket. It should be installed with the right

angle bend of the spring pointing inward,

as shown here.

66

Install the spring and dump valve

bracket in the housing.

67

The spring is properly positioned when

the longest leg points toward the check

valve assembly.

68

Lubricate and install the O-ring around

the dump valve nut.

69

Install the nut over the dump valve

bracket, into the housing.

Note:

Make sure you do not damage the

dump valve O-ring during installation.

70

Using a 1 inch socket or end wrench,

torque the dump valve nut to

150

Ib-in

[I7

Nm].

\

Designed Input Gerotor

Rotation Stamped Ring and Star Rotation Stamped

into Housing-CW into Housing-CCW

Designed Input

Transaxle with Charge Pump

Install the gerotor on the housing.

71

Note:

The gerotor ring and star have been

marked with a dot on each, the ring and

star can be placed with these marks up or

down but both marks should be on the

same side.

72

For easier assembly, rotate the

gerotor outer ring to fully engage with the

inner star. The fully engaged side of the

gerotor should point towards the designed

input rotation (CW or CCW as noted on

the housing).

Note:

The designed input rotation is

stamped on the back side of the housing

and also next to the gerotor on the inside.

73

Freely lubricate the gerotor with clean

hydraulic fluid to provide lubrication at

start-up.

74

The charge pump plate has a small

arrow cast into the outer face of the plate.

Page 10

At assembly, this arrow must face toward

the input rotation designated in the hous-

ing.

Note:

High pressure charge pumpgerotor and plate is a matched set and is

not sold separately. Class gerotor and

plate are not a matched set.

75

Aligning the rotation arrow with the

input rotation, install the pump plate over

the gerotor.

76

Install the four cap screws in the pump

plate finger tight.

77

The bottom side of the pump rotor

assembly incorporates five drive pins. At

assembly, these pins must be engaged

with the inner star of the charge pump

gerotor.

78

Lubricate and install the pump rotor

assembly on the pump journal, engaging

the drive pins with the inner star of the

gerotor.

79

Rotate the pump rotor assembly

several times to center the pump plate on

the gerotor.

While continuing to rotate the pump rotor

assembly, alternately tighten the charge

pump plate cap screws to

49

Ib-in

[6

Nm].

80

Remove the rubber band from the pump

rotor assembly. Install the cam ring assembly

in the housing with the flush side of the cam

ring facing outward.

81

Install the cam ring insert on the control

shaft pivot dowel.

82

Install the control shaft assembly, first

aligning the cam ring insert with the cam ring

assembly and then with the housing.

Transaxle with Charge Pump

Drop the charge pressure relief valve

83

ball in its bore.

84

Install the charge pressure relief valve

spring in its bore.

85

Install the drive in the pump rotor assem-

bly.

86

Install the cover gasket on the housing

assembly.

Control Shaft Seal Retaining Ring

\

Input Shaft

(S/A)

Drive

(S/A)

Control Shaft and Insert Band Retainer

Transaxle

with

Charge

Spring

Ball

with Rubber

A

Button

(2)

Cover Reassembly

Lubricate and install the control shaft oil

87

seal with the seal

lip

pointing inward. Press or

drive the seal into the seal counterbore.

88

Lubricate and install the input shaft seal

with the seal lip pointing inward. Press or drive

the seal into the counterbore.

89

Press or drive the input shaft assembly into

the cover.

90

Install the input shaft assembly retaining

ring, making sure it is firmly seated in the

retaining ring groove.

91

To help retain the buttons during assembly,

apply a small amount of petroleum jelly to

them. Install the buttons in the holes located

in the cover assembly.

9

Page 11

Self Tap

Screw

92

Install the cover assembly

by

carefully

aligning it with the control shaft, cam ring pivot

dowel and pump rotor drive.

Transaxle with Charge Pump

Caution:

During installation of the cover

assembly, be careful not to dislodge the

charge pressure relief valve from its bore.

Note:

Two axle housing flange screws may be

used to help retain the cover, gasket and

housing

93

in

position during assembly.

After engaging the control shaft and pivot

dowel in the cover assembly, carefully rotate

the input shaft to engage the pump rotor drive.

When all mating parts are aligned and engaged, the cover assembly should fall into

position on the housing assembly.

Torque

Twice in

Sequence

125

Ib-in

[I4

Nm]

94

With the cover assembly in the proper

position, remove the two alignment flange

screws (if used) and install the self tap screws

(13), and alternately tighten to 125 Ib-in

[14

Nm]. Torque each screw a second time to

compensate for gasket compression set.

Axle Housing Retaining

Thrust Washer

Axle Shaft with One Retalnlng Ring

Radial Lip Seal

Bearing, Ball

Axle Housing Reassembly (one axle hous-

ing or two, use the same procedure for

each).

95

Lubricate and install the thrust washer in

the axle housing.

96

Lubricate and install the axle shaft into the

axle housing.

97

Reposition the axle housing with the

output end of axle pointing downward. Install

the inner thrust washer and axle shaft retain-

ing ring.

Important:

The round-cornered side or die-

rolled side of the retaining ring must point

toward the axle housing.

98

Reposition the axle housing with the output

end pointing upward. Protecting the lip of the

axle seal from the retaining ring groove and

keyway, lubricate and install the seal with the

lip

pointing inward towards the axle housing.

99

Using a piece of pipe or hydraulic tubing

(1.5 inch [38mm]

O.D.

x 6 inch [150mm] long),

press the seal into the counterbore.

100

Again, using a piece of pipe or hydraulic

tubing (1.125 inch [29mm] O.D.

x 6 inch

[150mm] long), press the ball bearing over the

axle shaft and into the axle housing.

101

Using a pair of

No.

5

or 7 internal retaining ring pliers, install the ball bearing retaining

ring in the axle housing.

102

Lubricate and assemble the three planetary gears on the secondary carrier assembly.

10

Page 12

Gasket

Reaction Plate-

When they are all in alignment, the ring gear

will fall into place.

n

Motor Rotor Motor Rotor

16:l Ratio

18T Sun Gear, First

23:l

15T Sun Gear, First

Ratio

Friction Material Must Be

Toward Backup Plate

Planet Gears

Toward Axle Shaft

Carrier(First)-

Planet Gears

I

18T Sun Gear, Second

Output Shaft

107

Shown here are the first and second sun

gears for

108

secondary Planetary assembly.

109

16:l

and

23:l

Install the sun gear (second) into the

Lubricate and assemble the three plan-

15T Sun Gear, Second

Output Shaft

Gear ratios.

etary gears on the primary carrier assembly.

110

Aligning the splines, install the primary

/-

carrier assembly on the sun gear (second).

111

Install the next ring gear into the axle

housing. Install by again aligning the ears on

the outside

of

the ring gear with the notches in

the housing assembly.

Note:

Rotate the primary carrier assembly and

the ring gear will fall into position.

112

Install the primary sun gear (first) into the

primary planetary assembly.

113

Lubricate and install the backup plate in

Axle Shaft

103

Aligning the splines, install the secondary

carrier assembly on the splined end of the

axle shaft located in the housing assembly.

104

Please note that one side of each ring

gear has a bevel on one side. This bevel side

of the ring gear must be toward the output end

of the axle shaft.

105

Install one of the two ring gears into the

axle housing. Install by aligning the ears on

the outside of the ring gear with the notches in

the housing assembly.

106

Rotate the secondary carrier assembly

the axle housing assembly. Install by aligning

the ears with the notches in the axle housing.

114

Aligning the splines, install the reaction

plate on the primary sun gear

(friction

material must be toward backup plate).

115

Aligning the screw holes and notches,

install the axle housing gasket on the axle

housing assembly.

116

Reposition and clamp the housing as-

sembly to the bench as in step

12.

Install the

motor rotor assembly.

117

Install the friction brake pad into its re-

cess located in the housing assembly.

118

Carefully retain the planetary assemblies

in position, install the axle housing assembly

planet gears to align with the ring gear teeth.

11

Page 13

on the housing assembly.

119

Install the axle housing flange screws and

torque to 125 Ib-in [14Nm].

Transaxle with Charge Pump and Spin-

on

Filter

Lubricate the filter seal, install filter,

124

hand tight

(3/4

to 1 full turn after gasket/

base contact).

125

Fill transaxle with an approved hydraulic

fluid ( 781 Series-both halves must be filled

separately). The transaxle is now ready for

test and installation.

I

Motor RotorlBall

(S/A)

with Rubber

Ball Retainer

Band

Remove Rubber Band Ball Retainer

just before ball pistons enter race groove

120

Reposition the transaxle and install the

gasket and (one of the following)

filter base.

internal filter and valve cover (position metal

side of filter toward housing and gasket).

...port

121

plate.

Aligning the screw holes, install 5 flange

screws.

122

Cross torque screws to 125 Ib-in [14mm].

781 Series Transaxle

After servicing both transaxle halves,

123

the two halves, center push rod, conical

springs (2), bolts, washers and nuts (4

each ) can be installed. Torque the bolt

and nut to 16±1.6 Ib-ft [22±2 Nm]. Replace E-ring retaining the conical spring

at each end of center push rod.

Fluid Recommendations

Premium hydraulic oil having a viscosity

equivalent to SAE 2Ow-20, SAE

30

or SAE

40.

The fluid should be chemically stable, incor-

porating rust and oxidation inhibitors.

A reputable supplier can help you make the

best selection of hydraulic fluid for use in your

Eaton transaxle.

Note:

If the natural color of the fluid has

become black or milky, it is possible that an

overheating or water contamination problem

exists.

Transaxle Parts Lists

Hydrostatic Transaxle Series 751

Hydrostatic Transaxle Series 851 No. 6-426

Hydrostatic Transaxle Series 771-A

Hydrostatic Transaxle Series 771-B

Hydrostatic Transaxle Series 781 No. 6-429

No.

No.

No.

6-425

6-427

6-428

Page 14

Fault-Logic

Trouble Shooting

This Fault Logic Troubleshooting Guide is designed as a

diagnostic aid in locating possible transaxle problems by

the user.

To use this Fault-Logic Troubleshooting Guide, simply

match the transaxle symptoms with the problem statements and follow the action steps shown in the box

diagrams. This will give the user unnecessary machine

down time.

Following the Fault-Logic diagrams are diagram action

comments to further help explain the action steps shown

in the diagrams.

Where applicable, the comment number of the state-

ments appear in the action block of the diagrams.

System Jerky when Starting

Input Drive Control Linkage

Defective Defective Defective Ok

Repair Repair

Transaxle Linkage

Repair

Replace

Brake/Drive Interlock

(

if

used

Defective

Repair

)

Page 15

System Operating Hot

Oil Level

or Expansion Tank

in

Reservoir Cooling Ok

LOW Defe'ctive

Fill to

Proper

Level

Transaxle Ok Brake/Drive Linkage

Repair

Defective Defective

Repair

Replace

Inspect

Transaxle

Cooling Fins

Plugged

I

Clean

Dump Valve

(

if used

Defective

Repair

(

if Interlock used

Repair

)

)

OK

System will not Hold or Free Wheels on Incline

Dump Valve Brake/Drive Interlock

(

if used

Defective Defective Defective Ok

Replace Replace Replace

)

Linkage

(

if used

)

Repair or

Replace

Transaxle Hubs

Transaxle

Input Drive

Inspect

Wheel

Defective

Repair

14

Page 16

Loss

of

Power or System

(Will not operate in either direction)

Oil Level in Reservoir

Check

or Expansion Tank

Fill to

Proper

Level

Transaxle

Ok

inspect Wheel Ok

Defe'ctive Defective

Repair

Brake/Drive Interlock External Linkage Inspect Control

Defective Defective Defective

Repair

Replace

Repair

Repair

Ok

Dump Valve

(

if

used

Defective

Repair

Repair

)

Ok

n

Diagram Action Step Comments

1

Check oil Level in Reservoir or Expansion Tank

for:

A

Consult own/operators manual for the proper

type fluid and level dealer for warranty consideration

2

Inspect Filter for:

A

Plugged or clogged filter element (see

Transaxle Repair Information for filter location)

3

Inspect External Control Linkage

A

Misadjusted or disconnected

B Worn, binding, bent or broken

4

Inspect Transaxle Cooling Fan for:

A

Sheared or missing drive screws

B Broken or missing fan blades

5

Inspect Transaxle Cooling Fins for:

A

Plugged

6

Inspect Transaxle Input Drive

A

Drive belt worn, loose or broken

B Drive pulley key sheared or missing

7

Inspect Dump Valve for:

A

Misadjusted or disconnected

B Drive pulley key sheared or missing

or

clogged cover cooling fins

for:

for:

10

Repair or Replace Transaxle

A

When Transaxle

B

All

non warranty repairs should be preformed

by trained personnel

is

under warranty return

to

8

Inspect Brake/Drive Interlock Linkage for:

A

Misadjusted

B Worn, binding, bent or broken

9

Inspect Wheel Hubs for:

A

Drive key worn, sheared or missing

or

disconnected

Page 17

Eaton Corporation

Eaton G.m.b.H.

Hydraulics Division

Hydraulics Division

15151 Highway 5, Eden Prairie,

100

410 D-5620 Velbert 1 West Germany 49-2051-2070

Printed

in

U.S.A.

MN

55344 Telephone

(612)

937-9800

FORM

October,

NO.

7-416

1991

Loading...

Loading...