Page 1

220 Brass Series

Valves

Built for superior performance under pressure, these Toro

and stainless steel valves are rugged and reliable. The debris-resistant design is

tested and proven under the harshest conditions.

®

heavy-duty brass

Features & Benefits

Nearly Three Times the Lightning

Protection of Competitive Product with a lightning rating exceeding 20,000 volts.

Precise Pressure Control Option

Compact EZReg® dial-design technology (factory or field installed no need to

remove solenoid).

Dirty Water Resistance

120-mesh, stainless steel filter screen is constantly flushed by the flow, enabling

the use of very dirty water without clogging and valve closure failure.

External Downstream Manual Bleed

Keeps valve box dry and allows for manually setting pressure regulation.

Spike-Guard™ Solenoid

Reduces wire size requirements, allows twice as many valves to run simultaneously

on a transformer and lowers power costs.

Water Management Highlight

Dirty Water Resistance

The 120-mesh, stainless steel

filter screen is positioned on

the supply side of the water

stream. It is constantly flushed

by the flow, enabling the use

of very dirty water without

clogging. Stainless steel

construction of both the filter

screen and the valve solenoid

seat ensure long component

life in all types of water

and pressures.

Effluent

Options

Available

DC Latching

Solenoid

Option

Spike-Guard

Standard

Pressure

Regulation

Page 2

Specifications

220 Brass Series

Dimensions

• 1”(25mm): 5 ¼” H x 5” W (133 x 127mm)

• 1 ¼” (32mm): 6 ½” H x 6” W (165 x 152mm)

• 1 ½”(40mm): 6 ½” H x 6” W (165 x 152mm)

• 2” (50mm): 7 ½” H x 7” W (191 x 178mm)

• 2 ½” (65mm): 8 ¾” H x 8 ½” W (223 x 216mm)

• 3” (80mm): 8 ¾” H x 8 ½” W (223 x 216mm)

Operating Specifications

• Flow Range:

– 1”(25mm): 5 to 40 GPM (19 to 151 LPM)

– 1 ¼” (32mm): 20 to 100 GPM (75 to 378 LPM)

– 1 ½”(40mm): 20 to 130 GPM (75 to 492 LPM)

– 2” (50mm): 30 to 180 GPM (114 to 681 (LPM)

– 2 ½” (65mm): 60 to 250 GPM (227 to 946 LPM)

– 3” (80mm): 80 to 350 GPM (303 to 1324 LPM)

• Operating Pressure:

– Electric – 10 to 220 psi 1,4 to 15,2 Bar)

• Pressure regulating:

– Outlet (EZR-30): 5 to 30 psi ± 3 (0,3 to 2,1 Bar)

– Outlet (EZR-100): 5 to 100 psi ± 3 (0,3 to 7,0 Bar)

• Inlet: 10 to 220 psi (1,4 to 15,2 Bar)

• Minimum pressure differential (between inlet and outlet)

for pressure regulation: 10 psi (1,4 Bar) 2” & 3”

- 20 PSI (1,38 Bar)

• Burst pressure safety rating: 750 psi (51,7 Bar)

• Body styles:

– Globe valve – 1” (25mm), 1 ¼”(32mm), 1 ½”(40mm),

2”(50mm) female threads

– Angle valve – 2 ½”(65mm), 3”(80mm) female threads

• Spike Guard™ Solenoid: 24 VAC (50/60 Hz) Standard

– Inrush: 60 Hz: 0.12 amps

– Holding: 60 Hz: 0.1 amps

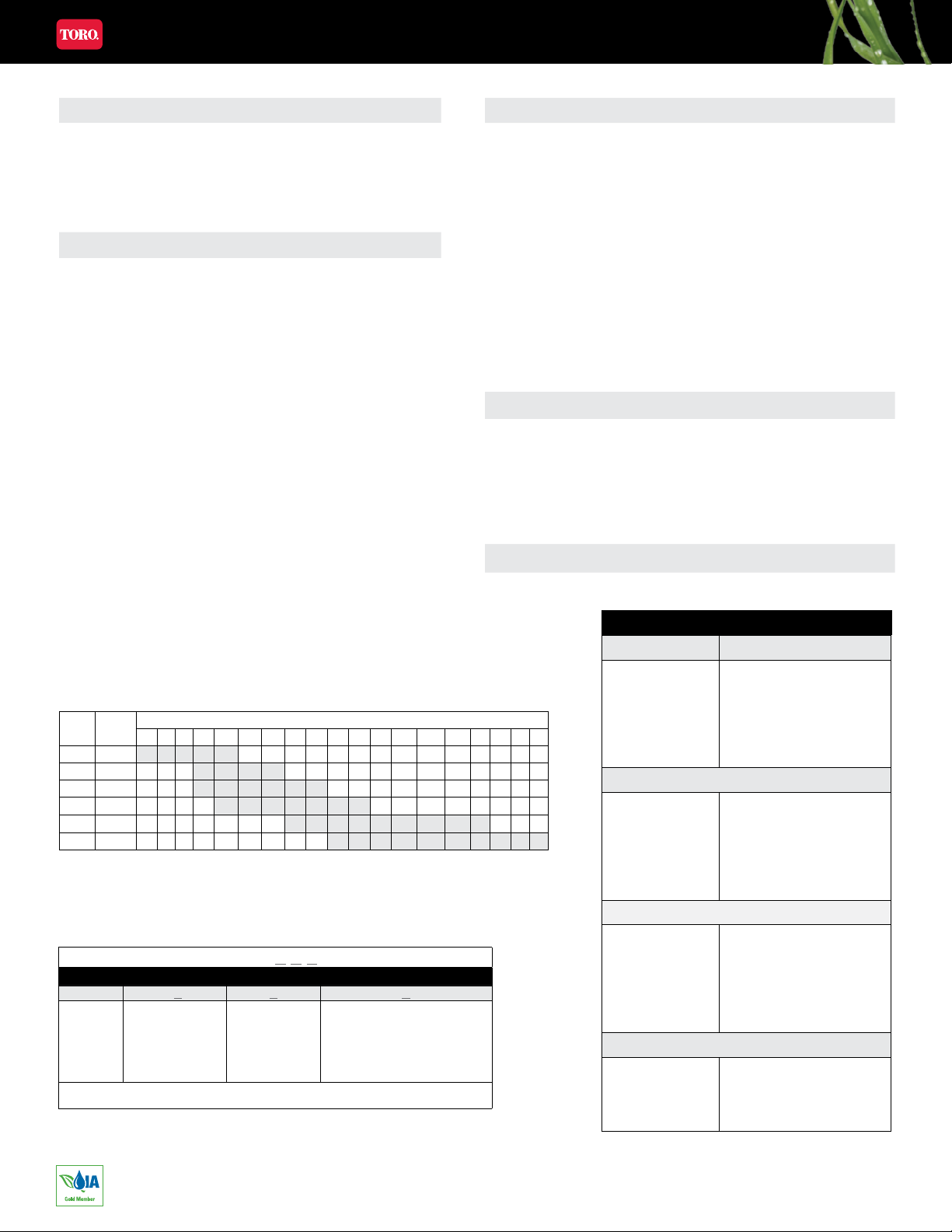

220 Brass Series Friction Loss Data

Model Type

1" Electric

11⁄4" Electric

11⁄2" Electric

2" Electric

21⁄2" Electric

3" Electric

Notes: For optimum performance when designing a system, calculate total friction loss to ensure

5 10 15 20 30 40 50 60 70 80 100 120 150 170 180 200 250 300 350

1.75 2.0 2.2 3.10 5.05 7.80

1.85 2.50 2.70 3.50 4.10 5.6

2.15 2.45 2.80 3.05 3.80 5.0 6.55

3.05 3.20 2.90 2.95 3.25 3.40 4.50 6.55 10.10 13.45 14.85

For optimum regulation performance, size regulating valves toward the higher flow ranges.

■

Flow rates are recommended not to exceed 5 psi loss.

GPM Flow

2.0 2.2 2.3 2.4 2.5 3.0 4.0 4.5 5.5

2.2 2.4 2.5 3.0 4.0 4.5 5.5 6.5 7.0 7.5

sufficient downstream pressure.

Specifying Information—220 Brass

220-2X-X-X

Model Activation Type Solenoid Size

220

220—220

Series

Brass

Valve

220 Series Brass Valve with Spike Guard solenoid, would be specified as: 220-27-04

2X X X

6—NPT, Electric

7—NPT, Pressure

regulated

(5–100)

Example: A 1" (25mm) NPT pressure-regulated,

0—Spike Guard

Solenoid

6—Less

Solenoid

9 - DC Latching

Solenoid

Note: 1", 1

4—1” (25mm)

1

5—1

⁄4”(32mm)

6—11⁄2”(40mm)

1

⁄2

" and 2" —globe configuration.

1

⁄2

" and 3"—angle configuration.

2

8—2” (50mm)

9—21⁄2”(65mm)

0—3” (80mm)

Additional features

• Diaphragm stem guide

• 316 nuclear-grade stainless-steel stem for maximum

corrosion resistance

• Pressure regulator can be installed as a service kit without

draining the main line

• Pressure regulates in electric and manual modes, serviceable

under pressure

• Forward-flow design for more precise regulation

• Standard, built-in Schrader-type valve for downstream

pressure verification

• Anti-vandal dust cap on pressure-regulating models

• No external tubing for either electric or pressure

regulating models

• Manual flow control: adjustable to zero flow

• Tough, double-beaded, fabric-reinforced rubber diaphragm

Options Available

• EZR-30 - EZReg, 5-30 psi (0,3-2,1 Bar) Regulator Module

• EZR-100 - EZReg, 5-100 psi (0,3-7,0 Bar) Regulator Module

• EFF-KIT-60 Hz - Effluent Water (Lavender) Solenoid Assembly

(24 VAC, 60 Hz) and Warning Tag

• 118-5982 - 24 VAC Solenoid Assembly, 60 Hz,

18” (45,7cm) Leads, Captive Plunger

• DCLS-P - Potted DC Latching Solenoid Assembly

Warranty

• Five years

220 Brass Series Model List

Model Description

• 220-26-04

• 220-26-05

• 220-26-06

• 220-26-08

• 220-26-09

• 220-26-00

Pressure Regulated With EZREG

• 220-27-04

• 220-27-05

• 220-27-06

• 220-27-08

• 220-27-09

• 220-27-00

1” (25mm) In-line

1 ¼” (32mm) In-line

1 ½” (40mm) In-line

2” (50mm) In-line

2 ½” (65mm) Angle

3” (80mm) Angle

®

1” (25mm) In-line

1 ¼” (32mm) In-line

1 ½” (40mm) In-line

2” (50mm) In-line

2 ½” (65mm) Angle

3” (80mm) Angle

With Latching Solenoid

• 220-26-94

• 220-26-95

• 220-26-96

• 220-26-98

• 220-26-99

• 220-26-90

1” (25mm) In-line

1 ¼” (32mm) In-line

1 ½” (40mm) In-line

2” (50mm) In-line

2 ½” (65mm) Angle

3” (80mm) Angle

Electric Valves Less Solenoid

• 220-26-64

• 220-26-66

• 220-26-68

• 220-26-60

1” (25mm) In-line

1 ½” (40mm) In-line

2” (50mm) In-line

3” (80mm) Angle

www.toro.com The Toro Company • Irrigation Division • 5825 Jasmine St. Riverside, CA • 92504 • 877-345-8676

Specifications subject to change without notice. For more information, contact your local Toro distributor.

©2014 The Toro Company. All rights reserved. P/N 14-1129-IRC

Loading...

Loading...