Page 1

COMMERCIAL REAR WHEEL DRIVE REBUILD GUIDE

Table of Contents – Page 1 of 1

PREFACE

HOW TO USE THIS PUBLICATION

COMMERCIAL INPUT SHAFT

1983-1989

COMMERCIAL SHIFTER MECHANISM

1983-1985

SERVICE TIP:

1986-1989

SERVICE TIP:

COMMERCIAL INTERMEDIATE SHAFT

1983-1985

1986-1989

COMMERCIAL SUSPENSION SYSTEM

MINOR REBUILD** 1983

SERVICE TIP:

MAJOR REBUILD** 1983

SERVICE TIPS:

MINOR REBUILD** 1984-1985

SERVICE TIPS:

MAJOR REBUILD** 1984-1985

SERVICE TIPS:

MINOR REBUILD** 1986

SERVICE TIP:

MAJOR REBUILD** 1986

SERVICE TIPS:

MINOR REBUILD** 1987

SERVICE TIP:

MAJOR REBUILD** 1987

SERVICE TIP:

MINOR REBUILD** 1988-1989

SERVICE TIP:

MAJOR REBUILD** 1988-1989

SERVICE TIP:

Page 2

Page 3

PREFACE

The rear drive system on Toro Commercial Rear Drive Walk Power Mowers has

been improved almost yearly since

very durable, high quality mower, servicing can be difficult because of the many

improvements and parts cross-references.

The purpose of this guide is to aid in servicing the rear drive system on 1983

through 1989 Toro Commercial Rear Drive Mowers. We’re hopeful that

1. Inform you of the most effective way to rebuild the Toro

Commercial Rear Drive System.

2.

Reduce time spent paging from cross reference to cross reference

in the parts catalog.

3. Help reduce your parts stock by indicating obsolete parts.

This document supercedes Commercial Rotaries Service Bulletins 13 and 16

regarding rebuilding the rear drive system. However, use of the rebuild kits

referenced in Service Bulletin number 17 is still highly recommended whenever

output shaft replacement becomes necessary.

If

you have comments or questions regarding this guide, please

contact us at:

its

introduction in 1983. While the result is a

it

will:

feel

free to

The Toro Company

Consumer Service Department

81 11 Lyndale Avenue South

Minneapolis,

phone: 612-888-8801

MN,

USA 55420

Page 4

Table

of

Contents

How

to Use

Input

Shifter Mechanism

Intermediate Shaft

Suspension System

This

Publication Page

Shaft

(1983-1989)

(1983-1985)

(1986-1989)

(1983-1985)

(1986-1989)

Minor Rebuild(1983)

Major Rebuild(1983)

Minor Rebuild(1984-1985)

Major Rebuild(1984-1985)

.............................................................................

.............................................................................

.............................................................................

............................................................................

............................................................................

..............................................................

......................................................................

......................................................................

...............................................................

...............................................................

2

3

4

5

6

7

8

9

10

11

Minor

Rebuild(1986)

Major Rebuild(1986)

Minor Rebuild (1987)

Major Rebuild(1987)

Minor Rebuild(1988-1989)

Majaor Rebuild(1989-1989)

.....................................................................

.....................................................................

.....................................................................

......................................................................

...............................................................

..............................................................

12

13

14

15

16

17

1

...

....

...

....

.....

.

..........

........

...

Page 5

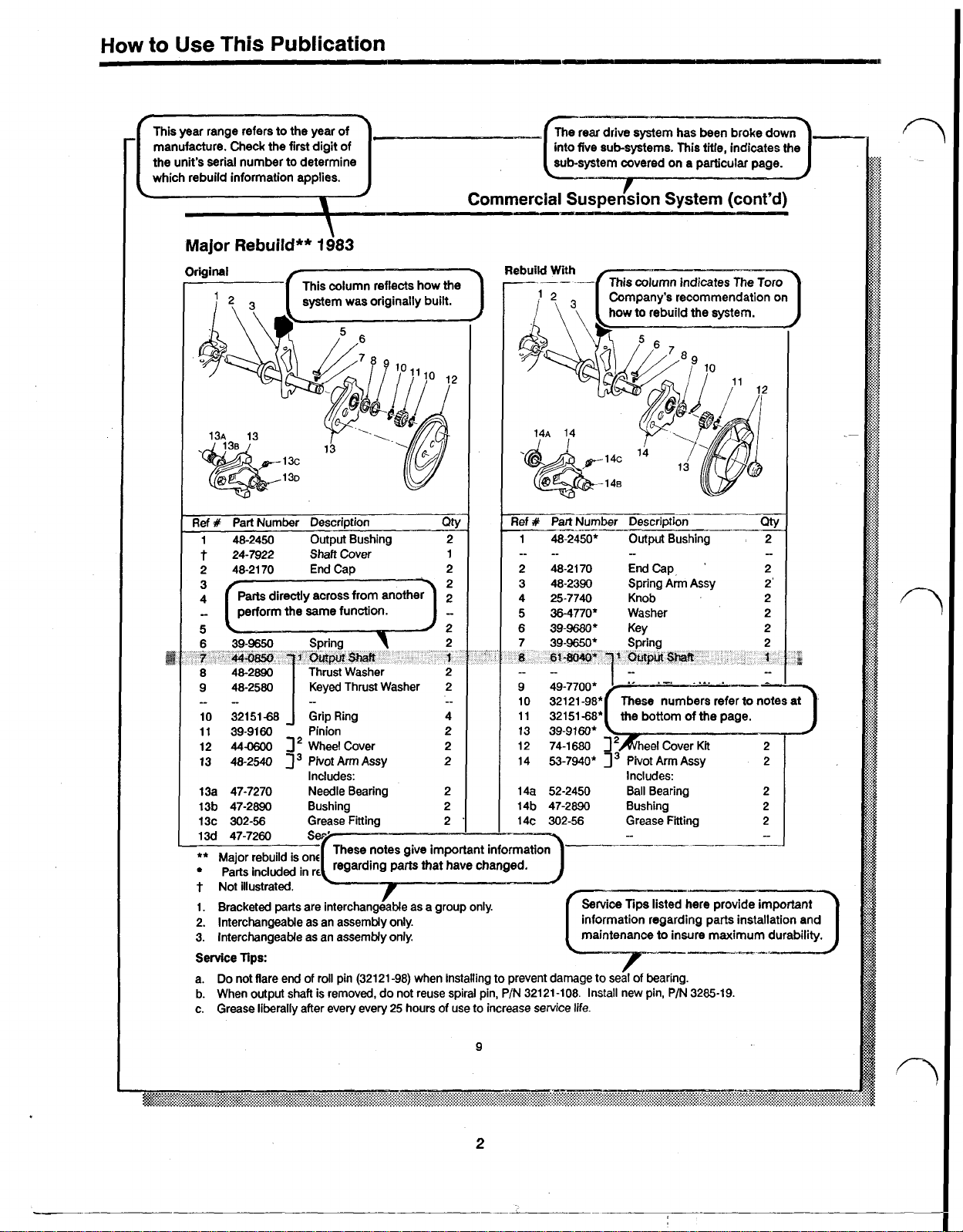

How

to

Use

This

Publication

Major

Original

-

-

Rebuild**

1983

Rebuild With

Ref X Part

1

__

2 48-2170 End Cap.

3 48-2390 Spring Arm Assy 2'

4 25-7740 Knob 2

5

6

7 39-9650* Spring 2

__

~-

Number

48-2450' Output Bushing

__

36-4770*

39-9680*

-

Company's recommendation on

how

to

rebuild the system.

~-

Description

___

__

'

Washer 2

Key 2

Qty.

I

2

-

2

f

h

I

10

32121-98*( These numbers refer to

11 bottom of

11 39-9160

44-0600

12

13 48-2540

13a 47-7270 Needle Bearing

13b 47-2890 Bushing

13C 302-56 Grease Fitting

13d

-

47-7260

**

Major rebuild is one

parts

included

t

Not

illustrated.

1. Bracketed parts are interchangeable as a group only.

2. Interchangeable as an assembly only. information regarding parts installation and

3. Interchangeable as an assembly only. maintenance to insure maximum durability.

Service

lips:

a.

Do

not flare end

b. When output shaft is removed, do not reuse spiral pin, P/N 32121-108. Install new pin,

c. Grease liberally after every every 25 hours of use

Pinion

]

Wheel Cover

3

Pivot Arm Assy

Includes:

These

notes give important information

in

rc

regarding parts that have changed.

I

\

of

roll pin (32121 -98) when installing

13 39-9160*

12 74-1680

14 53-7940*

14a 52-2450 Ball Bearing 2

14b 47-2890 Bushing 2

14C 302-56 Grease Fitting 2

7

3'

heel Cover

]

pivot Arm Assy

Includes:

_-

~~___

---7--------~-~-

to

prevent damage to seal

to

increase service life.

9

of

bearing.

P/N

the

page.

Kt

--

3285-19.

2

I

J

Page 6

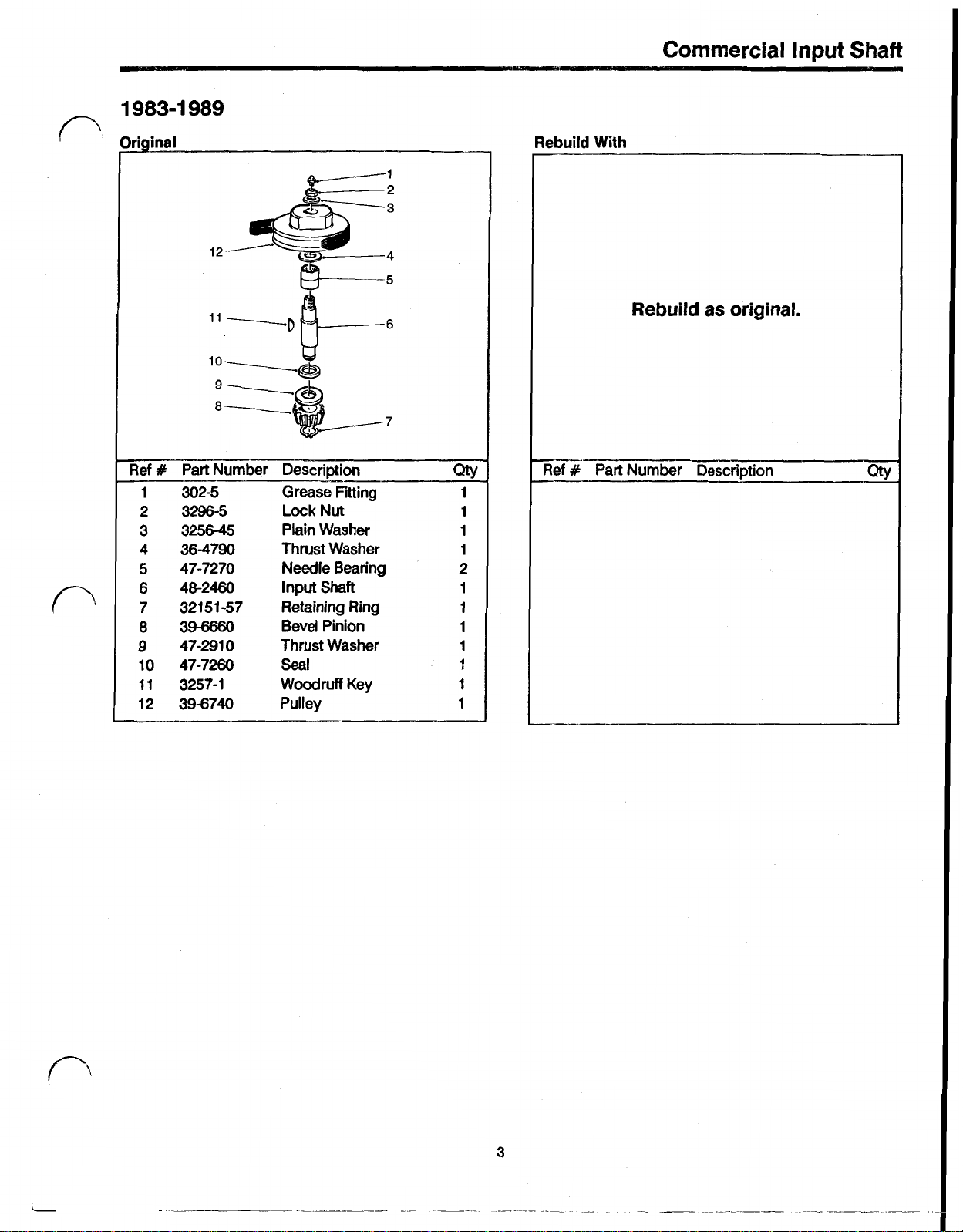

1983-1989

Commercial

Input

Shaft

Original

12

4 36-4790 Thrust Washer

5

47-7270

6 48-2460 Input

Needle

Bearing

Shaft

2

6

1

2

1

Rebuild

With

Rebuild as original.

8 39-6660 Bevel Pinion

9 47-2910

10

47-7260

Thrust Washer

Seal

1

1

1

3

Page 7

Commercial Shifter Mechanism

1983-1 985

Original

Ref

#

Part Number Description

2 48-2560

3256-14

3 3290-134

4 29-9520

5

29-9690

6 42-4740 38

7 364710

8 29-9271

9

46-3560

10

39-7830

11

39-6730

12

29-9330

13 39-6720

14 29-9340

15

36-4780

16

17 3296-2

18

29-9560

19 32121-99

]

]

Shift Lever Cover

Machine Screw

Shift Yoke

Plain Washer

Tooth Gear

Gear Spacer

Tooth Gear

42

52

Tooth Gear

Key Retainer

Sleeve Body

Shift

Key

Sleeve

Shift Collar

Plain Washer

Spiral Pin

Locknut

Shift Lever

Roll

Pin

16

1

Qty.

1

1

1

1

1

1

2

1

1

1

1

2

1

1

1

1

1

1

1

Rebuild

Ref

#

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

With

Part Number Description

55-8040

329O-134

29-9520

29-9690

42-4740 38

36-4770

29-9271 42

463560

55-8020

55-8010

29-9330

39-6720

29-9340

36-4780

3285-19

3296-2

29-9560

321 21 -99

1

Shift Lever Cover

Machine Screw

Shift Yoke

Plaln Washer

Tooth Gear

Gear

Tooth Gear

52

Tooth Gear

Key Retainer

]

Gear Sleeve

Shift Key

Sleeve

Shift Collar

Plain Washer

Groove

Locknut

Shift Lever

Roll Pin

15

Spacer

Fin

Qty.

1

1

1

1

1

3

1

1

1

1

2

1

1

1

1

1

1

1

1.

Bracketed parts are interchangeable as a group only.

2.

Bracketed parts are interchangeable

3.

Directly interchangeable.

Service

a.

Use

Tip

one or

two

spacers, part number

as

a group only.

36-4770,

as required

4

to

reduce side play.

Page 8

1986-1 989

Commercial Shifter Mechanism (cont'd)

Original

Ref # Part Number Description

1 3256-14

2 55-8040 Shift Lever Cover 1

3 3290-134 Machine Screw 1

4 29-9520 Shift Yoke 1

5

29-9690 Plain Washer 1

6 42-4740 38 Tooth Gear 1

7 36-4770 Gear Spacer 3

8 29-9271 42 Tooth Gear 1

9 46-3560 52 Tooth Gear 1

10 55-8020 Key Retainer 1

11

55-8010 Gear Sleeve -1

12 29-9330 Shift Key 2

13 39-6720 Sleeve

14 29-9340

15 36-4780

16 3285-19 Groove Pin 1

17 3296-2

18 29-9560

19 32121-99

Service

lip:

Shift Collar 1

Plain Washer 1

Locknut 1

Shift Lever .1

Roll

Pin 1

&

.

'87) 1

--

Qty

1

Rebuild

Ref # Part Number Description

---

With

Rebuild

as original

a. Use one or

two

spacers,

part

number 36-4770, as required to reduce side play.

5

Page 9

Commercial Intermediate Shaft

1983-1 985

Original

1

Ref # Part Number Description

252-1 03

36-4790

39-7841

48-2520

39-6670

463540

46-3550

39-6650

Closed Bearing

Thrust Washer

Square Key

]

Intermediate Shaft

Bevel Gear

12

Tooth Gear

14

Tooth Gear

18

Tooth Gear

Rebuild

Ref # Part Number Description

With

1

1 252-103

2 36-4790

4 53-7950

39-7843

5 39-6670

6 463540

7 463550

8 39-6650

Closed Bearing

Thrust Washer

1

Square Key

Intermediate Shaft

Bevel Gear

12

14

18

Qty.

2

4

1

1

1

Tooth Gear

Tooth Gear

Tooth Gear

1

1

1

1.

Bracketed

parts

are interchangeable as a group only.

6

Page 10

1986-1 989

Commercial Intermediate

Shaft

Original

Ref

#

1

2

3

4

5

6

7

8

1

Part Number

252-1

03

36-4790

39-7843

53-7950

39-6670

46-3540

46-3550

39-6650

Description

Closed

Thrust Washer

Square Key

Intermediate Shaft

Bevel Gear

12 Tooth Gear

14 Tooth Gear

18 Tooth Gear

Bearing

Qty.

2

4

1

1

1

1

1

1

Rebuild

With

Rebuild

as

original

7

Page 11

Commercial

Suspension

System

Minor

Original

Ref

#

1

2

3

4

5

6

7

8

9

10

11

1

la

11b

1

1C

11d

Rebuild**

Part Number Description

48-2 1 70

48-2390 Spring Arm Assy

25-7740

39-9680

39-9650

48-2890

48-2580

32151-68 Grip

39-91

60

44-0600 Wheel Cover

48-2540 Pivot Arm Assy

47-7270

47-2890

302-56

47-7260

1983

End

Cap

Knob Arm

Key

Spring

Thrust Washer

Keyed Thrust Washer

Ring

Pinion

Includes:

Needle Bearing

Bushing

Grease Fitting

Seal

Rebuild

0

Ref # Part Number Description

2

2

2

2

2

2

2

4

2

2

2

2

2

2

2

With

1

48-21 70

2 48-2390

3 25-7740

4

39-9680

5

39-9650

6

48-2890 Thrust Washer

7 48-2580

8

32151-68 Grip Ring

9 39-9160 Pinion

10

74-1680

1

1

53-7940

1

1

a

52-2450 Ball Bearing

11b

47-2890

1

1c

302-56

End Cap 2

Spring Arm Assy 2

Knob 2

Key 2

Spring 2

Keyed Thrust Washer 2

1

Wheel Cover

2

Pivot Arm

Includes:

Bushing 2

Grease Fitting 2

--

Kit

Assy.

Qty.

2

4

2

2

2

2

e

**

Minor rebuild is one where output shaft

1.

Interchangeable as an assembly only.

2. Interchangeable as an assembly only.

Service

a. Grease liberally after every

Tip:

25

hours of use to increase service life.

does

not

require replacement.

8

Page 12

Commercial

Suspension System (cont’d)

Major

Original

Rebuild**

2 48-21 70

3 48-2390

4 25-7740

6 39-9650

8 48-2890 Thrust Washer

11 39-9160

12

444600

13 48-2540 Pivot Arm Assy

13a

47-7270 Needle Bearing

1983

Keyed Thrust Washer 2

]

Wheel Cover

Rebuild

I

Ref

#

1 48-2450* Output Bushing 2

2 48-2170 End Cap 2

3 48-2390 Spring Arm Assy 2

4 25-7740 Knob 2

5

6 39-9680* Key 2

7 39-9650* Spring 2

8

9 49-7700* Keyed Thrust Washer

10 32121-98*

11 32151-68* Grip Ring 2

13 39-9160* Pinion 2

12 74-1 680

14 53-7940* Pivot Arm Assy 2

14a

52-2450 Ball Bearing 2

14b 47-2890 Bushing 2

14~ 302-56

With

Part Number Description

-- --

36-4770* Washer 2

61-8040*

____--

1

Output

Shaft

--

Roll

Pin 2

I

]

Wheel Cover

Includes:

Grease Fitting 2

--

Kit

Qty.

1

2

2

**

Major rebuild is one where output shaft requires replacement.

*

Parts included in rebuild part number 13-3449

t

Not illustrated.

1. Bracketed parts are interchangeable as a group only.

2. Interchangeable as an assembly only.

3. Interchangeable as an assembly only.

Service

a.

b. When output shaft

c. Grease liberally after every every 25 hours of use to increase service life.

Tips:

Do

not flare end

of

roll pin (32121-98) when installing to prevent damage to seal

is

removed,

do

not reuse spiral pin, P/N 32121-108. Install new pin, P/N 3285-19.

9

of

bearing.

Page 13

Commercial Suspension System (cont'd)

Minor Rebuild** 1984-1 985

Original

2

Ref # Part Number Description

1

48-2170

2 49-8810

3

25-7740

4 39-9680

5

39-9650

53-7850

6 36-4770

7 48-2890

8 48-2580

9 32151-68

10 39-9160

11

44-0600

12 48-2540

12a 47-7270

12b 47-2890

12~ 302-56

12d 47-7260

,End Cap

1

Spring Arm Assy

Knob Arm

Key

Spring

Spring

Washer

Thrust Washer

Keyed Thrust Washer

Grip Ring

Pinion

Wheel Cover

3

Pivot Arm Assy

Includes:

Needle Bearing

Bushing

Grease Fitting

Seal

(1

(1985) 2

Qty.

2

2

2

2

984) 2

2

2

2

4

2

2

2

2

2

2

2

Rebuild

Ref # Part Number Description-

With

12

1

48-21 70

2

66-7561

25-7740

3

4

39-9680

5

39-9650

6

36-4770

7

48-2890

8

48-2580

9

321 51 -68

10

39-91 60

11

74-1680

53-7940

12

12a

52-2450

12b

47-2890

12c

302-56

End Cap

Spring Arm Assy

Knob

Key

Spring

Washer

Thrust Washer

Keyed Thrust Washer

Grip Ring

Pinion

Wheel Cover

3

Pivot Arm Assy

Includes:

Ball Bearing

Bushing

Grease Fitting

Kit

Qty.

2

2

2

2

2

2

2

2

4

2

2

2

2

2

2

**

A

minor rebuild is one in which the output shaft

1.

Directly interchangeable.

2.

Interchangeable as an assembly only

3.

Interchangeable as an assembly only.

Service

a. Spring arm

b. Grease liberally after every

Tips:

66-7561

all four at once.

will change height of cut slightly when compared with

25

hours of use to increase service life.

does

10

not

require replacement.

49-8810.

When retrofitting, update

Page 14

Commercial

Suspension

System

(cont’d)

Major

Original Rebuild

Ref

8 44-0850 Output Shaft 2

9 48-2890 Thrust Washer 2

12 44-0600 Wheel Cover 2 12 74-1680 Wheel Cover

13 39-9160 Pinion 2 13 39-9160* Pinion 2

14 48-2540 Pivot Arm Assy 2 14 53-7940* Pivot Arm Assy 2

14a 47-7270 Needle Bearing 2

14b 47-2890 Bushing 2

14d 47-7260 Seal 2

Rebuild**

Part Number Description

1

48-2450

24-7922 Shaft Cover

2 48-2170

3 49-8810

4 25-7740 Knob Arm 2 4

5

36-4770 Washer 2

6

39-9680 Key 2

53-7850 Spring (1985) 2

10 48-2580 Keyed Thrust Washer 2

11 32151-68 Grip Ring 4

1984-1 985

Output Bushing 2

End

Cap

’

Spring Arm Assy 2

Includes: Includes:

at;:

2

2

I\

14A

--

Ref # Part Number Description

1 48-2450* Output Bushing

2 48-21 70 End

3 66-7561 Spring Arm Assy 2

5

6 39-9680* Key 2

7

8 61-8040*

9 49-7700* Keyed Thrust Washer 2

10 32121-98* Roll Pin 2

11 32151-68* Grip Ring 2

14a 52-2450 Ball Bearing 2

14b 47-2890 Bushing 2

14~ 302-56 Grease Fitting 2 14C 302-56 Grease Fitting 2

With

3

14

.

25-7740

36-4770* Washer 2

39-9650* Spring 2 7 39-9650 Spring (1984) 2

2

Cap

Knob 2

Output Shaft

Kit

Qty

2

2

1

2

**

A

major rebuild is one which requires replacement of the output

*

Parts included in rebuild

Not illustrated.

1. Directly Interchangeable.

2. Bracketed parts interchangeable

3. Interchangeable

4.

Interchangeable as an assembly only.

Service

a. See Service Tips at the

Tips:

as

kit

part number 13-3449.

an assembly only.

bottom

as

a group only.

of

page 13.

shaft.

11

Page 15

Commercial Suspension System (cont’d)

Minor Rebuild**

Original

Ref # Part Number Description

1

48-21 70

2

49-8810

3

25-7740

4 39-9680

5

39-9650

6

36-4770

7 48-2580

8

3215181

9

39-9160

10

44-0600

11

53-7940

1

1

a

52-2450

llb 47-2890

1

IC

302-56

1986

End Cap

Spring Arm Assy

Knob Arm

Key

Spring

Washer

Keyed Thrust Washer

Snap Ring

Pinion

Wheel Cover

Pivot Arm Assy

Includes:

Ball Bearing

Bushing

Grease Fitting

1

Qty.

2

2

2

2

2

2

2

4

2

2

2

2

2

2

Rebuild

Ref # Part Number Description

With

1

48-21 70

2 66-7561

3

25-7740

4 39-9680

5

39-9650

6

36-4770

7 48-2500

8

3215181

9

.39-9160

10 74-1680

11 53-7940

1 1

a

52-2450

11

b

47-2890

1

IC

302-56

End Cap

Spring Arm Assy

Knob

Key

Spring

Washer

Keyed Thrust Washer

Snap Ring

Pinion

Wheel Cover

Pivot Arm Assy

Includes:

Ball Bearing

Bushing

Grease Fitting

Kit

Qty.

2

2

2

2

2

2

2

4

2

2

2

2

2

2

**

A minor rebuild is one that does

1.

Directly interchangeable.

2.

Directly interchangeable.

Service

a. Spring arm

b.

Tip:

66-7561

all four at once.

Grease liberally after every

will change height of cut slightly when compared with

25

not

hours

include replacement of the output shaft.

of

use

to

increase service

12

life.

49-8810.

When retrofitting, update

Page 16

Commercial Suspension System (cont'd)

Major Rebuild**

Original

.

Ref

#

Part

Number

1

48-2450

24-7922

t

48-2 1 70

2

49-88

1

51

0

-61

60

1

3

3

3

4

5

6

7

8

9

10

11

12

13

13a

13b

13c

25-7740

36-4770

39-9680

39-9650

44-0850

48-2580

321

44-0600

39-91

53-7940

52-2450

47-2890

302-56

1986

Description

Output Bushing

Shaft Cover

End Cap

Spring Arm Assy

Knob Arm

Washer

Key

Spring

Output Shaft

Keyed Thrust Washer

Snap Ring

Wheel Cover

Pinion

Pivot Arm Assy

Includes:

Ball Bearing

Bushing

Grease Fitting

Qty.

2

1

2

2

2

2

2

2

1

2

4

2

2

2

2

2

2

Rebuild

14A

Ref

1

2

3

4

5

6

7

8

9

10

11

12

13

14

14a

14b

1

4c

With

3

14

Part Number Description

48-2450* Output Bushing 2

48-21 70 End Cap

66-7561 Spring Arm Assy

25-7740 Knob

36-4770*

39-9680*

39-9650*

61-8040*

49-7700*

321 21 -98*

32151-68*

74-1

680

39-91

60*

53-7940* Pivot Arm Assy

52-2450

47-2890

302-56

Washer

Key

Spring

Output Shaft

Keyed Thrust Washer

Roll

Pin

Grip Ring

1

Wheel Cover

Pinion

Includes:

Ball Bearing

Bushing

Grease Fitting

Kit

Qty

2

2

2

2

2

2

1

2

2

2

2

2

2

2

2

2

A

major rebuild is one which requires replacement of the output shaft.

*

Parts included in rebuild

Not illustrated

1.

Directly interchangeable.

2. Bracketed

3. Directly interchangeable.

Service

a. Do not flare end

b.

When output shaft

c. Spring arm 66-7561 will change height

all four at once.

d.

Grease liberally after every

lips:

parts

interchangeable as a group only.

of

kit

part number 13-3449.

roll

pin (32121-98) when installing to prevent damage to seal of bearing.

is

removed,

25

do

not reusue spiral pin, P/N 32121-108. Install new pin, P/N 3285-19.

hours

of

of

cut slightly when compared with 49-881

use to increase service life.

13

0.

When retrofitting, update

!

Page 17

Commercial Suspension System (cont'd)

Minor Rebuild**

Original

13B

Ref

#

Part Number Description

1 3215136 Retaining Ring

2 36-4770 Thrust Washer 2

3 48-21 70 End Cap 2

4 61-8081

5 25-7740

6 39-9680

7 39-9650

8 32121-98

9 49-7700 Keyed Thrust Washer 2

10 39-9160 Pinion 2

11 32151-68 Grip Ring 2

12

444600

13 61 -8200 Pivot Arm Assy 2

13a 61-8050

13b 47-2890

13~ 302-55

**

A

minor rebuild is one in which the output shaft does

1

1987

Qt

Spring Arm Assy 2

Knob Arm 2

Key 2

Spring 2

Roll

Pin 2

Wheel Cover 2

Includes:

Ball Bearing 2

Bushing 2

Grease Fitting 2

Rebuild With

1

12-

12c

\

12B

Ref # Part Number Description

2

1

32151-36

2

364770

48-21 70 End Cap

3

4

66-7561

25-7740 Knob

5

39-9680 Key

6

7

39-9650 Spring

8

49-7700 Keyed Thrust Washer

9

10

11

12

60

39-91

32151 -68 Grip Ring

74-1680

66-7350

Retaining Ring

Thrust Washer

Spring Arm Assy

I

Pinion

Wheel Cover

Pivot Arm Assy

_I~-

Qty.

2

2

2

2

2

2

2

6

2

2

Kit

2

2

f--

1

Includes:

12a

52-2450

12b

47-2890

12c

I

not

30265 Grease Fitting

require replacement.

Ball Bearing

Bushing

2

2

2

1. Directly interchangeable.

2. Directly interchangeable.

3. Interchangeable as as assembly only.

Service

Tip:

a. Grease liberally after 25 hours of use to increase service life.

,

14

Page 18

Commercial Suspension System (cont'd)

Major Rebuild**

Ref # Part Number Description

48-2450

1

2

32151-36

36-4770

3

48-2 1 70

4

5

61 -8081

25-7740 Knob Arm 2

6

7

39-9680

39-9650 Spring 2

8

61-8040 output shaft

9

32121-98 Roll Pin 2

10

49-7700 Keyed Thrust Washer 2

11

32151-68 Grip Ring 2

12

44-0600

13

14

39-91

60

61 -8200 Pivot Arm Assy 2

15

-8050

61

15a

47-2890

15b

302-56

15c

1987

Output

Retaining Ring 2

Thrust Washer 2

End

Spring Arm Assy 2

Key

1

Wheel Cover 2

Pinion 2

Includes:

Ball Bearing 2

Bushing 2

Grease Fitting 2

158

aty

Bushing 2

Cap 2

2

1

Ref

--

Part Number

#

1

48-2450*

2

32151-36

3 36-4770 Thrust Washer 2

4 48-21 70

5

66-7561 Spring Arm Assy 2

6 25-7740 Knob 2

7 39-9680* Key 2

8 39-9650* Spring 2

9 66-7330* Output Shaft

10 49-7700* Keyed Thrust Washer 2

11 32151

12 623830* Special Washer 2

13 74-1680

14 39-9160* Pinion 2

15 66-7350* Pivot Arm Assy 2

15a

15b

15C

-68*

52-2450 Ball Bearing 2

47-2890 Bushing

302-55 Grease Fitting 2

Description

Output Bushing 2

Retaining Ring 2

End

Cap 2

I

Grip Ring 4

1

Wheel

Includes:

Cover 2

Qty.

1

2

**

A

major

rebuild is one in which the output shaft requires replacement.

Parts included

1. Directly interchangeable.

2. Bracketed parts are interchangeable as a group only.

3. Directly interchangeable.

4. Interchangeable as an assembly only.

Service

a. Grease liberally after every 25 hours of use to increase service life.

Tip:

in

rebuild

Kit

part number 13-3439.

15

Page 19

Commercial Suspension (cont’d)

Minor

Original

Ref

#

1

2

3

4

5

6

7

8

9

10

11

12

13

13a

13b

13c

Rebuild**

1988-1 989

13B

Part Number Description

-36

32151

36-4770

48-21 70

66-7561

25-7740

39-9680

39-9650

49-7700

321 51 -68

62-3830

39-91

60

44-0600

66-7350

Retaining Ring

Thrust Washer 2

End

Cap 2

Spring Arm Assy

Knob 2

Key 2

Spring 2

Keyed Thrust Washer 2

Grip Ring 4

Special Washer 2

Pinion 2

Wheel Cover 2

Pivot Arm Assy 2

Includes:

52-2450

47-2890

302-55

Ball Bearing 2

Bushing

Grease Fitting 2

Qty.

2

2

2

Rebuild With

-.-

Ref# Part Number Description

1

2

3

4

5

6

7

8

9

10

11

12

13

32151-36

36-4770

48-21 70

66-7561

25-7740

39-9680

39-9650

49-7700

321 51 -68

62-3830

60

39-91

74-1680

66-7350

Retaining Ring

Thrust Washer

End Cap

Spring Arm Assy

Knob

Key

Spring

Keyed Thrust Washer

Grip Ring

Special Washer

Pinion

Wheel Cover

Pivot Arm Assy

Includes:

13a

13b

13c

52-2450

47-2890

302-55

__I--~-

Ball Bearing

Bushing

Grease Fitting

Kit

Qty.

2

2

2

2

2

2

2

2

4

2

2

1

2

2

2

2

**

A

minor rebuild is one in which

the

output shaft does

not

require replacement.

1. Directly interchangeable.

Service

Tip:

a. Grease liberally after every 25 hours of use to increase service life.

16

Page 20

Commercial

Suspension

(cont’d)

Ref

#

Part Number Description

1 48-2450 Output Bushing

2 321 51

3

36-4770

4 48-21 70

5

66-7561

6 25-7740

7 39-9680

8

39-9650 Spring 2

9 66-7330

10 62-3830

11 32151-68 Grip Ring

12

49-7700

13 44-0600

14 39-9160

15 66-7350

15a 52-2450

15b

47-2890 Bushing 2

15c

302-55

15B

-36

Retaining Ring 2

Thrust Washer 2

End

Cap 2

Spring Arm Assy 2

Knob 2

Key 2

output

Keyed Thrust Washer 2

Special

1

Wheel Cover 2

Pinion 2

Pivot Arm

Includes:

Ball Bearing 2

Grease Fitting 2

Shaft 1

Thrust Washer 2

Assy

2

4

2

Rebuild

Ref

With

158

#

Part Number Description

1 48-2450* Output Bushing

2

32151-36 Retaining Ring 2

3

36-4770 Thrust Washer 2

4 48-2170

5

66-7561

6 25-7740

7 39-9680*

8

39-9650* Spring

9 66-7330* Output Shaft 1

10 62-3830*

11

32151-68* Grip Ring 4

12 49-7700*

13 74-1680

14 39-9160* Pinion 2

15 66-7350*

15a 52-2450

15b

47-2890 Bushing

15c 302-55 Grease Fitting 2

.-

End

Cap 2

Spring Arm Assy 2

Knob 2

Key 2

Keyed Thrust Washer 2

Special Thrust Washer 2

Wheel

Cover

Pivot

Arm

Includes:

Ball Bearing 2

Kit

Assy.

Qty.

2

2

1

2

2

.-

**

A

major

rebuild is one

*

Parts included

1. Directly interchangeable.

Service

a. Grease liberally after every 25 hours

Tip:

in

rebuild

in

which

kit

the

part

number 13-3439.

output shaft requires replacement.

of

use to increase service life.

17

Loading...

Loading...