Page 1

LawnStriperKit

ModelNo.20601

FormNo.3368-615RevA

OperatorManual

Safety

•Readalloftheinstructionsinthismanualpriorto

usingthelawnstriperattachment.

•Thelawnstriperattachestoandfollowsbehindyour

lawnmowerduringnormalgrass-cuttingoperations,

andshouldnotaffecttheoperatingcharacteristicsof

yourmower.Carefullyfollowallofyourlawnmower

manufacturer’soperatinginstructionsandwarnings

whenusingthelawnstriperattachment.

•Thelawnstriperattachmentshouldnot

interferewithnormalmoweroperations,such

ascutting/mulching/bagging.Ifthereisany

interferenceimmediatelyshutoffmower,then

inspectthelawnstriperattachmentinstallation,make

anyadjustmentsneededtocorrecttheproblem,and

reassessoperationstoverifythattheinterferencehas

beenresolved.

•Thelawnstriperattachmentisdesignedtoworkwith

mostwalk-behind,self-propelled,andpush-type

lawnmowers.Donotusewithanyothertypeof

mower.

•Thelawnstriperattachmentmustbeproperly

installed,attached,andadjustedinordertowork

alongwithyourparticularlawnmower.

•Ifthelawnstriperattachmentshouldinterfere

withyourabilitytomowaroundobstructions,

walkways,orothertightlyconstrainedareas,shutoff

themower,removetherollerassembly,andthen

mowaroundtheobstructedareawithouttheroller

assemblyattached.

CAUTION

Donotassemble,disassemble,attach,inspect,or

adjustthelawnstriperattachmentwhilethemower

isrunning.

Shutoffthemowerbeforeperforminganyofthese

actions.

CAUTION

Donotplaceclampsystemoveranytypeofexisting

wires/cablesthatmaybepresentonlawnmower

handlebars.

©2011—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

Page 2

Installation

5

6

4

3

2

1

7

G015775

1

G015781

1

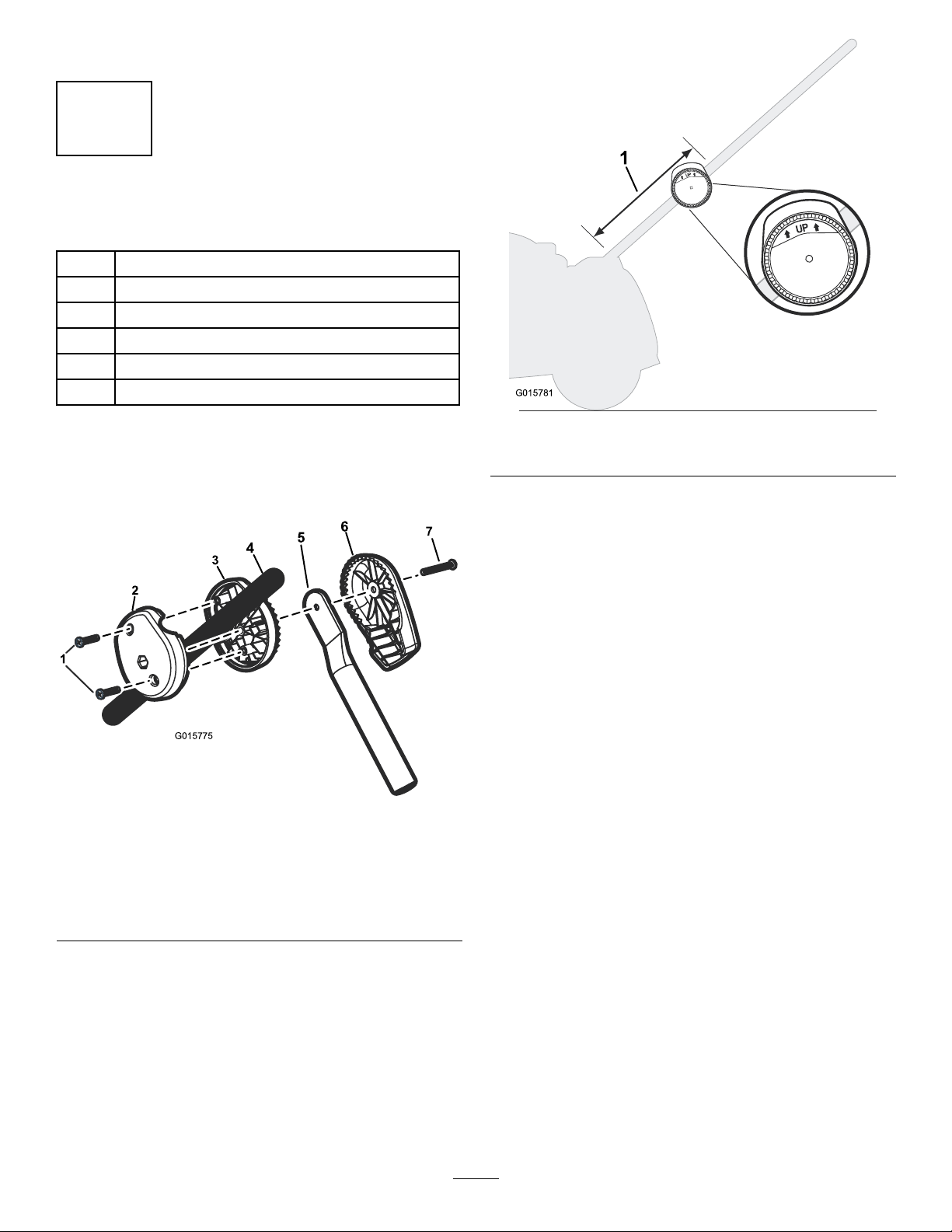

InstallingtheClamps

Partsneededforthisprocedure:

4Phillipsscrew

2Panheadscrew

2Innerclamp

2

Outerclamp

2Verticaltube

2Angleadjuster

Procedure

1.Withinthelowerthirdofthehandlebar,placethe

innerclampontheinsideofhandlebar(Figure1).

Figure2

1.Lowerthirdofmowerhandlebar

3.Settheverticaltubeintotheangleadjuster.Make

surethatthetopportionoftheverticaltuberestsat

ontheinnerportionoftheangleadjuster(

Figure1).

Figure1

Right-handhandlebarshown

1.Phillipsscrew5.Verticaltube

2.Innerclamp6.Angleadjuster

7.Panheadscrew

3.Outerclamp

4.Mowerhandlebar

2.Placeouterclampontheoutsideofhandlebar,with

thewordUpfacingupward(Figure2),andconnect

thetwoclampstothehandlebarusing2phillips

screws(

Figure1).

4.Usethepanheadscrewtoattachtheverticaltube

andangleadjustertotheclampassemblyasshown

Figure1.

in

Important:Donotfullytightenpanheadscrew,

asangleadjustmentswillbemadelater.

5.Repeatthisprocessfortheoppositehandlebar.

Important:Donotfullytightenphillipsscrews

asheightadjustmentswillbemadelater.

2

Page 3

2

3

4

2

1

5

G015780

6

1

2

G015776

3

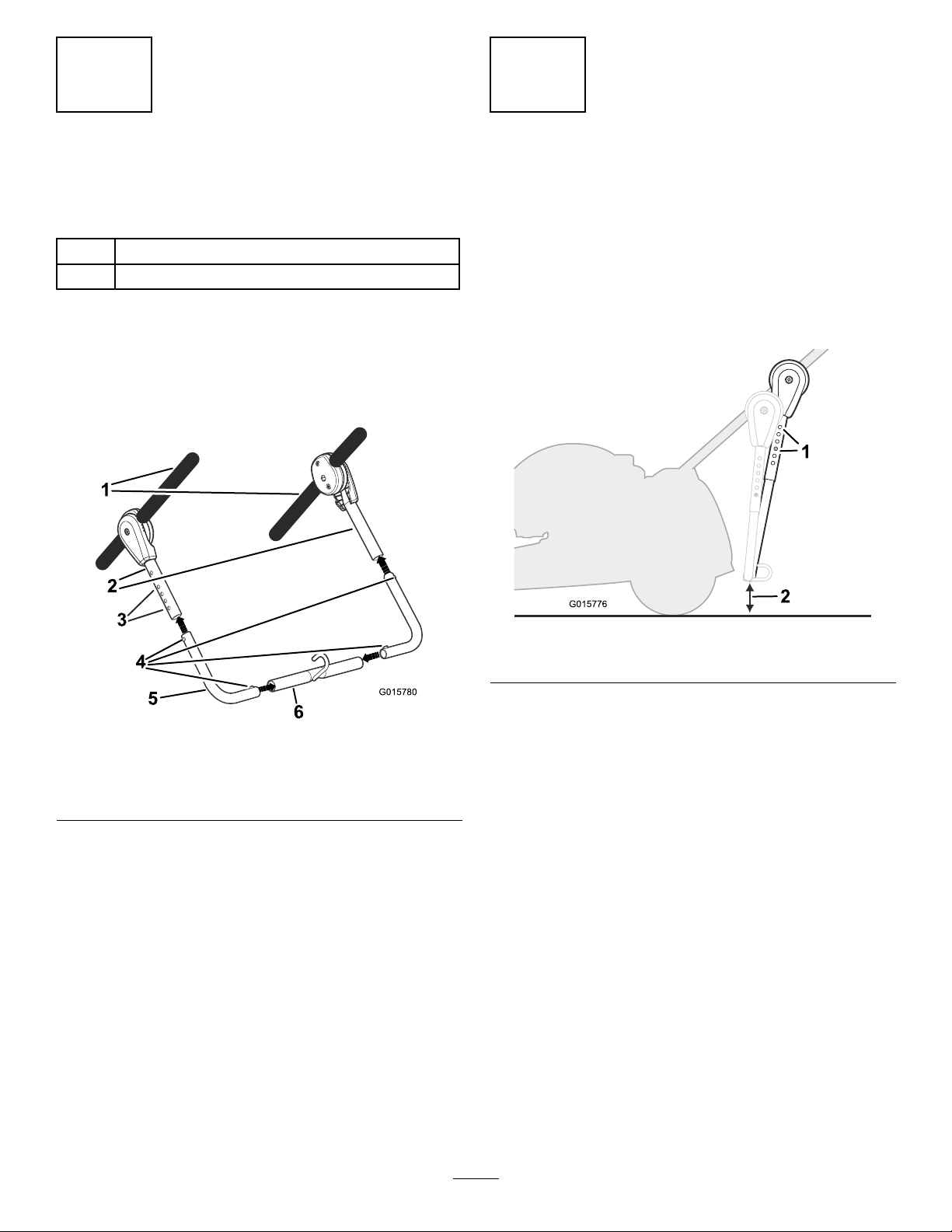

AssemblingtheHitchTube

andCornerTubes

Partsneededforthisprocedure:

2

Cornertube

1Hitchtube

Procedure

1.Attachcornertubestothehitchtubebypressing

downonthevalcopinsandlockingthemintoplace

inthevalcoholes(

Figure3).

AdjustingAngleandHeight

NoPartsRequired

Procedure

1.Angletheassemblyasclosetothemoweraspossible

bymovingtheclampsupordownonthemower

handlebarswithouthittingthemowerorimpeding

themowerbaggingsystem(

Figure4).

Figure4

1.Valcohole

2.Fullytightenthe2panheadscrewsand4phillips

Figure3

1.Lawnmowerhandlebars4.Valcopins

2.Verticaltubes

3.Valcoholes6.Hitchtube

2.Attachthecornertubestotheverticaltubesby

pressingdownonthevalcopinsandlockingthem

intoplaceinthevalcoholes(

Note:Whensettingwidthandheightofthe

assembly,makesurethevalcopinsoneachsideare

inmatchingholesontheoppositeside.

5.Cornertube

Figure3).

screws.

3.Settheheightoftheassemblyusingthevalcopinson

eitherside,makingsuretheassemblyisaminimum

of3-1/2inchesofftheground.

2.Minimumof3-1/2inches

3

Page 4

4

3

2

1

G015779

1

2

G015777

FillingandAttachingRoller

Assembly

Partsneededforthisprocedure:

1Rollerplug

1Rollerassembly

Procedure

1.Filltherollerassemblywithapproximately16to20

lbs.ofsand.

Figure6

1.Hitchtube2.Rollerassembly

4.Verifythattherollerassemblydoesnotinterfere

withanypartofthemower,includingotherkitsor

safetyfeatures.

Figure5

1.Rollerplug3.Rollerassembly

2.Pourdrysandintohere

2.Sealtherollerassemblywithrollerplug(Figure5).

Important:Makesuretherollerplugisfully

tightened.Failuretodosowillresultinroller

plugimpedingtheroller’sabilitytoturn.

3.Attachthesand-lledrollerassemblyontohitchtube

hookasshownin

Figure6.

4

Page 5

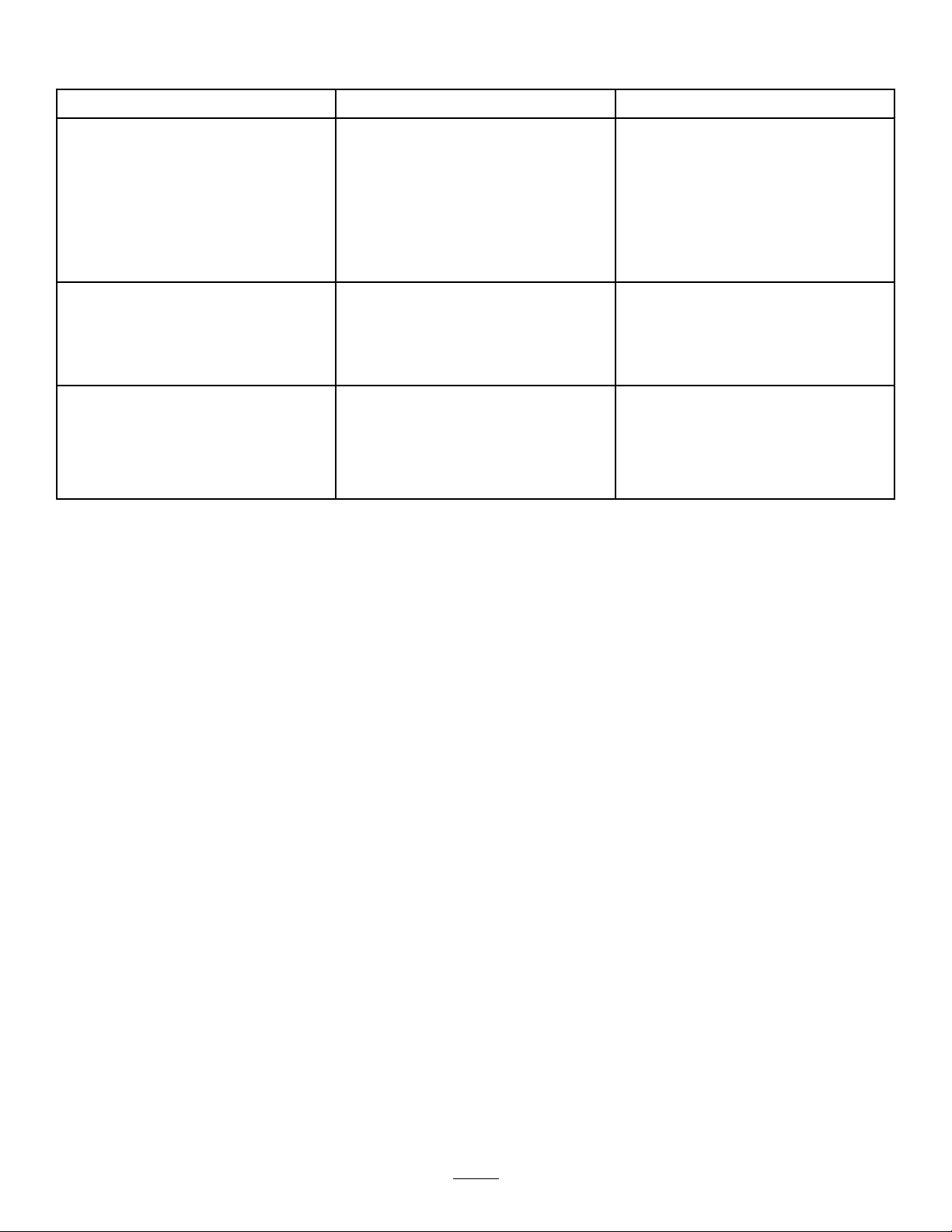

Troubleshooting

Problem

Rollerdoesnotturn.

Patterningeffectdoesnotshow.

U-Barassemblyishittingtheground.

PossibleCauseCorrectiveAction

1.Debrisstuckinrollerassembly

2.Rollerplugisnotfullytightened.2.Checktoseethatrollerplugisush

3.Rollerassemblyisnotlled.3.Makesuretherollerassemblyislled

1.Lawnstriperisnotattachedcorrectly

2.Grassiscuttooshort.2.Waitforgrasstogrowbeforecutting

3.Lackofpropersunlight.3.Partial/fullsunlightisoptimal.

1.Assemblyisnotatproperheight.

2.Heightisdifferentoneithersideof

assembly.

1.Turnoffmowerandverify/removeany

debris(bark,twigs,stones)thatare

obstructingtheroller.

withendcap,andtightenrollerplug

fully.

withapproximately16to20lbs.of

DRYsand.

1.RefertoOwner’sManualforproper

installation.

withthelawnstriperattached.

1.Turnoffthemower,andsetassembly

toproperheightandangleasoutlined

inOwner’sManual.

2.Makesurethatheightisthesame

onbothsidesasoutlinedinOwner’s

Manual.

5

Page 6

Kitderayadodelcésped

Nºdemodelo20601

FormNo.3368-615RevA

OperatorManual

Seguridad

•Leatodaslasinstruccionesdeestemanualantesde

utilizarelrodillodecésped.

•ElrodillodecéspeddeToroseacoplaasu

cortacéspedyesarrastradodetrásdurantelasiega

normal,peronodebeafectaralascaracterísticasde

operacióndesucortacésped.Sigacuidadosamente

todaslasinstruccionesdeusoyadvertenciasdel

fabricantedesucortacéspedmientrasutilizael

rodillodecésped.

•Elrodillodecéspednodebeinterferirconlas

operacionesdesieganormales,talescomolasiega,el

mulchingoelensacado.Sihayalgunainterferencia

pareinmediatamenteelmotordelcortacésped,

luegocompruebelainstalacióndelrodillodecésped,

hagalosajustesnecesariosparacorregirelproblema,

yhagaunaspruebasparavericarquelainterferencia

haquedadoresuelta.

•Elrodillodecéspedestádiseñadoparafuncionar

conlamayoríadeloscortacéspedesdirigidos,

autopropulsados,ymanuales.Noloutilicecon

otrostiposdecortacésped.

•Elrodillodecéspeddebeserinstalado,acopladoy

ajustadocorrectamenteparaquefuncioneconsu

modelodecortacésped.

•Sielrodillodecéspedinterereconsucapacidad

parasegaralrededordeobstáculos,caminos,uotros

lugaresestrechos,pareelmotordelcortacésped,

retireelconjuntodelrodilloyluegosieguealrededor

delazonaproblemáticasinteneracopladoel

conjuntodelrodillo.

CUIDADO

Nomonte,desmonte,acople,inspeccioneoajuste

elrodillodecéspedconelmotordelcortacésped

enmarcha.

Pareelmotordelcortacéspedantesderealizar

cualquieradeestasactividades.

CUIDADO

Nocoloqueelmecanismodejaciónsobre

cualquiertipodecablequehubieraenelmanillar

delcortacésped.

©2011—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registresuproductoenwww.T oro.com.

Traduccióndeloriginal(ES)

ImpresoenEE.UU.

Reservadostodoslosderechos

Page 7

Instalación

5

6

4

3

2

1

7

G015775

1

G015781

1

Instalacióndelmecanismode

apriete

Piezasnecesariasenestepaso:

4TornilloPhillips

2Tornillodecabezaredonda

2Piezainteriordelaabrazadera

2Tubovertical

2Ajustadordeángulo

Procedimiento

1.Coloquelapiezainteriordelaabrazaderaenel

interiordeltercioinferiordelmanillar(Figura1).

Figura2

1.Tercioinferiordelmanillardelcortacésped

3.Coloqueeltuboverticalenelajustadordeángulo.

Asegúresedequelapartesuperiordeltubovertical

estáplanasobrelaporcióninteriordelajustadorde

ángulo(Figura1).

Figura1

Manillarderechoilustrado

1.TornilloPhillips5.Tubovertical

2.Piezainteriordela

abrazadera

3.Piezaexteriordela

abrazadera

4.Manillardelcortacésped

2.Coloquelapiezaexteriordelaabrazaderaenel

exteriordelmanillar,conlapalabraUphaciaarriba

Figura2),yconectelasdospiezasdelaabrazadera

(

6.Ajustadordeángulo

7.Tornillodecabeza

redonda

almanillarcondostornillosPhillips(Figura1).

4.Utiliceeltornillodecabezaredondaparaacoplarel

tuboverticalyelajustadordeánguloalaabrazadera,

segúnsemuestraen

Figura1.

Importante:Noaprietetotalmenteeltornillo

decabezaredonda,porquemásadelanteserá

necesarioajustarelángulo.

5.Repitaesteprocedimientoenelotromanillar.

Importante:Noaprietetotalmentelostornillos

Phillips,porquemásadelanteseránecesario

ajustarlaaltura.

2

Page 8

2

3

4

2

1

5

G015780

6

1

2

G015776

3

Montajedeltubodeenganche

ylostubosdeesquina

Piezasnecesariasenestepaso:

2Tubodeesquina

1Tubodeenganche

Procedimiento

1.Conectelostubosdeesquinaaltubodeenganche

presionandolospasadoresdeajustehaciadentroy

bloqueándolosenlosagujeros(

Figura3).

Ajustedelánguloydelaaltura

Nosenecesitanpiezas

Procedimiento

1.Ajusteelconjuntoparaqueestélomáscercaposible

delcortacésped,desplazandolasabrazaderashacia

arribaohaciaabajoenelmanillarsinquelostubos

choquencontraelcortacéspedoestorbenelsistema

deensacado(

Figura4).

Figura4

1.Agujerodeajuste

Figura3

1.Manillardelcortacésped4.Pasadoresdeajuste

2.Tubosverticales5.Tubodeesquina

3.Agujerosdeajuste6.Tubodeenganche

2.Conectelostubosdeesquinaalostubosverticales

presionandolospasadoresdeajustehaciadentroy

bloqueándolosenlosagujeros(

Nota:Alajustarlaanchuraylaalturadelsistema,

asegúresedequelospasadoresdeajusteestánenel

mismoagujeroencadalado.

Figura3).

2.Aprietedeltodolos2tornillosdecabezaredonda

ylos4tornillosPhillips.

3.Ajustelaalturadelconjuntousandolospasadoresde

ajustedecadalado,asegurándosedequeelconjunto

estáa3,5pulg.(9cm)comomínimodelsuelo.

2.Mínimode3,5pulg.(9cm)

3

Page 9

4

3

2

1

G015779

1

2

G015777

Llenadoyconexióndelrodillo

Piezasnecesariasenestepaso:

1Tapóndelrodillo

1

Conjuntodelrodillo

Procedimiento

1.Lleneelrodilloconaproximadamente16–20libras

(7,2–9kg)dearena.

Figura6

1.Tubodeenganche

4.Compruebequeelconjuntodelrodillonointerere

conningúnelementodelcortacésped,incluyendo

otroskitsyelementosdeseguridad.

2.Conjuntodelrodillo

Figura5

1.T apóndelrodillo

2.Viertaarenasecaaquí

2.Coloqueeltapónparasellarelrodillo(Figura5).

Importante:Asegúresedequeeltapóndel

rodilloestábienapretado.Sinoestábien

apretado,impediráqueelrodillogire.

3.Conecteelrodillollenodearenaalganchodeltubo

deenganche,segúnsemuestraen

3.Conjuntodelrodillo

Figura6.

4

Page 10

Solucióndeproblemas

ProblemaPosiblecausa

Elrodillonogira.

Noseaprecianlasfranjasenelcésped.

LabarraenUchocacontraelsuelo.

Accióncorrectora

1.Hayresiduosqueobstruyenelrodillo.1.Pareelmotordelcortacéspedy

2.Eltapóndelrodillonoestábien

apretado.

3.Elrodillonosehallenado.3.Asegúresedequeelrodilloseha

1.Elrodillodecéspednoestá

correctamenteconectado

2.Lahierbaestádemasiadocorta.2.Espereaquecrezcalahierba

3.Faltadeluzsolar.

1.Elconjuntonoestáalaalturacorrecta.1.Pareelmotordelcortacéspedyajuste

2.Laalturaesdiferenteencadaladodel

conjunto.

compruebelapresenciaderesiduos

(corteza,ramitas,piedras,etc.);retire

cualquierresiduodelrodillo.

2.Compruebequeeltapóndelrodillo

estáenrasadoconelextremodel

rodillo,yaprieteeltapónafondo.

llenadoconaproximadamente16–20

libras(7,2–9kg)dearenaSECA.

1.Consulteelprocedimientode

instalacióncorrectoenelManualdel

usuario.

parasegarconelrodillodecésped

acoplado.

3.Sevemejorconbuenaluzdelsol.

correctamentelaalturayelángulo,

segúnloindicadoenelManualdel

usuario.

2.Asegúresedequelaalturaeslamisma

enamboslados,segúnloindicadoen

elManualdelusuario.

5

Page 11

Kittraceur

N°demodèle20601

FormNo.3368-615RevA

OperatorManual

Sécurité

•Liseztouteslesinstructionsdecemanuelavant

d'utiliserlerouleautraceur.

•Lerouleautraceursexederrièrelatondeuse

quiletirependantlesopérationsdetonte

habituellesilnedevraitmodierlescaractéristiques

defonctionnementdelatondeuse.Observez

scrupuleusementlesinstructionsd'utilisationdu

fabricantdelatondeuseetlesmisesengardelorsque

vousutilisezlerouleautraceur.

•Lerouleautraceurnedevraitpasgênerles

opérationsnormalesdetonte,commelatonte/le

mulching/leramassage.Encasdeproblème,arrêtez

immédiatementlatondeuse,puisexaminezle

montagedurouleautraceureteffectuezlesréglages

nécessairespourremédierauproblème,etfaitesun

essaipourconrmerqueplusriennegênelebon

fonctionnementdelamachine.

•Lerouleautraceurestconçupourfonctionneravec

laplupartdestondeusesàconducteurmarchant,

autotractéesetpoussées.Nel'utilisezpassur

d'autrestypesdetondeuse.

•Lerouleautraceurdoitêtremonté,xéetréglé

correctementpourfonctionneravecvotretondeuse

spécique.

•Silerouleautraceurvousgênepourtondreautour

d'obstacles,d'alléesouautreslieuxtrèsétroits,

arrêtezlatondeuse,retirezlerouleauettondezàces

endroitssanslerouleau.

PRUDENCE

Nemontezpas,nedémontezpas,nexezpas,

n'inspectezpasetneréglezpaslerouleautraceur

pendantlefonctionnementdelatondeuse.

Arrêtezlatondeuseavantdeprocéderàl'unede

sesactions.

PRUDENCE

Neplacezpaslesbridesdeserragesuraucun

câbles/lsexistantspouvantsetrouversurle

guidondelatondeuse.

©2011—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Enregistrezvotreproduitàwww.Toro.com.Traductiondutexted'origine(FR)

ImpriméauxÉtats-Unis.

Tousdroitsréservés

Page 12

Montage

5

6

4

3

2

1

7

G015775

1

G015781

1

Montagedesbridesdeserrage

Piècesnécessairespourcette

opération:

4VisPhillips

2Boulonàtêtetronconique

2Brideintérieure

2Tubevertical

2

Dispositifderéglagedel'angle

Procédure

1.Dansletiersinférieurdugudion,placezlabride

intérieureàl'intérieurdugudion(

Figure1).

Figure2

1.Tiersinférieurduguidondetondeuse

3.Placezletubeverticaldansledispositifderéglage

del'angle.Assurez-vousquelapartiesupérieuredu

tubeverticalreposeàplatsurlapartieintérieuredu

dispositifderéglagedel'angle(

Figure1).

Figure1

Côtédroitduguidonmontré

1.VisPhillips5.Tubevertical

2.Brideintérieure

3.Brideextérieure7.Boulonàtêtetronconique

4.Guidondetondeuse

2.Placezlabrideextérieureàl'extérieurdugudion,la

6.Dispositifderéglagede

l'angle

mentionUptournéeverslehaut(Figure2),etxez

lesdeuxbridesauguidonaumoyende2visPhillips

(

Figure1).

4.Utilisezlavisàtêtetronconiquepourxerletube

verticaletledispositifderéglagedel'angleàlabride

deserragecommeillustréàla

Figure1.

Important:Neserrezpascomplètementlavisà

têtetronconiquecardesréglagesd'angleseront

effectuésultérieurement.

5.Répétezcetteprocéduredel'autrecôtéduguidon.

Important:Neserrezpascomplètementles

visPhillipscardesréglagesdehauteurseront

effectuésultérieurement.

2

Page 13

2

3

4

2

1

5

G015780

6

1

2

G015776

3

Montagedutubed'attelageet

destubesd'angle

Piècesnécessairespourcette

opération:

2Tubed'angle

1Tubed'attelage

Procédure

1.Fixezlestubesd'angleautubed'attelageenappuyant

surlesgoupillesValcoetenlesverrouillantenplace

danslestrousValco(

Figure3).

Réglagedel'angleetdela

hauteur

Aucunepiècerequise

Procédure

1.Déplacezlesbridesverslehautoulebaspour

inclinezl'ensembled'attelageetlerapprocherautant

quepossibledelatondeuse,sansheurterleplateau

decoupenigênerlesystèmederamassage(

Figure4).

Figure4

1.TrouV alco2.Minimumde9cm

2.Serrezcomplètementles2visàtêtetronconiqueet

Figure3

1.Guidondelatondeuse4.GoupillesValco

2.Tubesverticaux5.Tubed'angle

3.TrousV alco6.Tubed'attelage

2.Fixezlestubesd'angleautubesverticauxen

appuyantsurlesgoupillesValcoetenlesverrouillant

enplacedanslestrousValco(Figure3).

Remarque:Lorsduréglagedelalargeuretdela

hauteurdel'ensembled'attelage,vériezdesdeux

côtésquelesgoupillesValcosontinséréesdansles

trouscorrespondantsdel'autrecôté.

les4visPhillips.

3.Réglezlahauteurdel'ensembled'attelagedechaque

côtéàl'aidedesgoupillesValco,enveillantàcequ'il

setrouveaumoinsà9cmdusol.

3

Page 14

4

3

2

1

G015779

1

2

G015777

Remplissageetxationdu

rouleau

Piècesnécessairespourcette

opération:

1Bouchonderouleau

1Rouleau

Procédure

1.Remplissezlerouleaude7,2à9kgenvirondesable.

Figure6

1.Tubed'attelage2.Rouleau

4.Vériezquelerouleaunegêneaucunepartiedela

tondeuse,ycomprisd'autreskitséventuellement

présentsoudesdispositifsdesécurité.

Figure5

1.Bouchonderouleau3.Rouleau

2.Versezlesablesecici

2.Fermezlerouleauhermétiquementaveclebouchon

(Figure5).

Important:Vériezquelebouchonestserréà

fond.Lebouchonpourraitsinonempêcherle

rouleaudetournercorrectement.

3.Fixezlerouleauremplidesableaucrochetdutube

d'attelage,commeillustréàla

Figure6.

4

Page 15

Dépistagedesdéfauts

ProblèmeCausepossible

Lerouleaunetournepas

Lesrayuresn'apparaissentpas.

L'ensembled'attelagetouchelesol.

Mesurecorrective

1.Desdébrissontaggloméréssurle

rouleau

2.Lebouchondurouleaun'estpas

complètementserré.

3.Lerouleaun'estpasrempli.3.Remplissezlerouleaude7,2à9kg

1.Lerouleautraceurn'estpasmonté

correctement.

2.L'herbeesttropcourte.2.Attendezquel'herbepousseavant

3.Laluminositén'estpasbonne.3.Uneluminositépartielleouleplein

1.Lahauteurdel'ensembled'attelage

n'estpasréglécorrectement.

2.Lahauteurn'estpaslamêmede

chaquecôté.

1.Arrêtezlatondeuseet

recherchez/enlevezlesdébris

(écorce,brindilles,cailloux)quigênent

lerouleau.

2.Vériezquelebouchonestdeniveau

aveclechapeaud'extrémité,etserrez

lebouchonàfond.

environdesableSEC.

1.Reportez-vousauManuelde

l'utilisateurpourlaprocédure

d'installationcorrecte.

delatondreenassociationavecle

rouleautraceur.

soleildonneradesrésultatsoptimaux.

1.Arrêtezatondeuseetréglezl'ensemble

d'attelageàlahauteurcorrecte,comme

expliquédansleManueldel'utilisateur.

2.Réglezlahauteuruniformémentde

chaquecôté,commeexpliquédansle

Manueldel'utilisateur.

5

Page 16

Loading...

Loading...