Page 1

2-CYCLE GTS 120 ENGINE SERVICE MANUAL

Table of Contents – Page 1 of 1

PREFACE

I. GENERAL INFORMATION

SAFETY INSTRUCTIONS

MAINTENANCE

MODEL AND SERIAL NUMBERS

TWO-CYCLE ENGINE THEORY AND OPERATION

CARBURETOR THEORY AND OPERATION

SPECIAL TOOLS LIST

II. MAINTENANCE

AIR CLEANER

SPARK PLUG

EXHAUST SYSTEM

DECARBONING CYLINDER HEAD

IGNITION TIMING (MODEL 47PZ2 ONLY)

IGNITION TIMING (DIAL INDICATOR)

CONTACT POINTS AND CONDENSER MODEL47PZ2 ONLY

IGNITION COIL

GOVERNOR

GOVERNOR OPERATION

FUEL TANK

CARBURETOR

STORAGE

III. TROUBLESHOOTING AND TEST PROCEDURES

PRELIMINARY TROUBLESHOOTING

ENGINE BRAKE AND IGNITION SWITCH

BBC APPLICATIONS

FUEL TANK

TESTING COMPRESSION

CRANKCASE

ENGINE TROUBLESHOOTING CHART

IV. ENGINE REMOVAL, DISASSEMBLY, ASSEMBLY AND REPAIR INSTRUCTIONS

ENGINE REMOVAL

ENGINE DISASSEMBLY AND REPAIR

RECOIL STARTER REPAIR

CARBURETOR REPAIR

ENGINE ASSEMBLY AND REPAIR

SERVICE DATA SPECIFICATIONS

Page 2

Page 3

PREFACE

This service manual was written expressly for TORO Two-Cycle Rotary Mowers.

All

units with the model number

have been taken into consideration.

The Toro Company has made every

tool for the service and maintenance of your

assure proper and effective performance, you are urged to read this manual

carefully.

of

The purpose

this manual is to provide the Service Dealer with working

guidelines of maintenance, troubleshooting, test, and overhaul procedures.

The Toro Company reserves the right to change product specifications or this

manual without notice.

47P22,47PD3,47PE4,

effort

to make this service manual a useful

TORO

Rotary Mower Engine. To

and

47PF5

engines

The Toro Company

Service

Department

COPYRIGHT ALL RIGHTS RESERVED

The

Toro

MINNEAPOLIS,

Company

MN

55420

1986

U.S.A.

i

Page 4

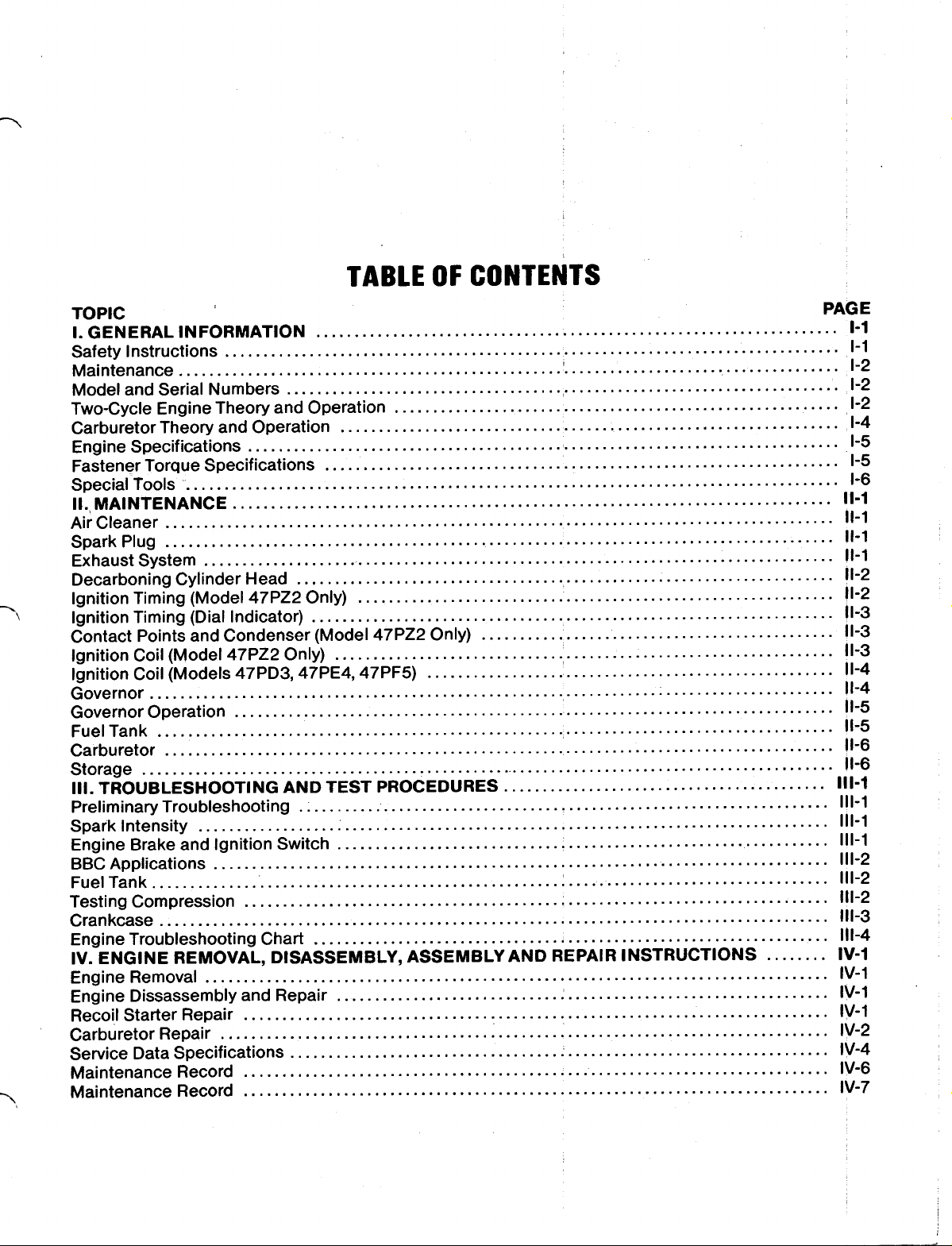

TABLE

TOPIC PAGE E

1

.

GENERAL INFORMATION

Safety Instructions

Maintenance

Model and Serial Numbers

Two-cycle Engine Theory and Operation

Carburetor Theory and Operation

Engine Specifications

Fastener Torque Specifications

Special Tools

II.>

MAINTENANCE

Air Cleaner

Spark Plug

Exhaust System

Decarboning Cylinder Head

Ignition Timing (Model 47PZ2 Only)

Ignition Timing (Dial Indicator)

Contact Points and Condenser (Model 47PZ2 Only)

Ignition Coil (Model 47P22 Only)

Ignition Coil (Models 47PD3.47PE4. 47PF5)

Governor

Governor Operation

Fuel Tank

Carburetor

Storage

111

.

TROUBLESHOOTING AND TEST PROCEDURES

Preliminary Troubleshooting

Spark Intensity

Engine Brake and Ignition Switch

BBC Applications

Fuel Tank

Testing Compression

Crankcase

Engine Troubleshooting Chart

IV

.

ENGINE REMOVAL, DISASSEMBLY, ASSEMBLY AND REPAIR INSTRUCTIONS

Engine Removal

Engine Disassembly and Repair

Recoil Starter Repair

Carburetor Repair

Service Data Specifications

Maintenance Record

Maintenance Record

.......................................................................................

.......................................................................................

..................................................................

........................................................................................

.......................................................................................

...........................................................................................

.....................................................

.......................................................................................

................................................................................

.......................................................................................

.............................................................................

......................................................................................

..............................................................................

..................................................................................

..............................................................................

..................................................................................

................................................................................

............................................................................

.................................................................................

............................................................................

...............................................................................

............................................................................

............................................................................

....................................................................

...................................

.................................................................

...................................................................

......................................................................

..............................................................

....................................................................

.................................................................

.....................................................................

................................................................

...................................................................

................................................................

......................................................................

OF

CONTENTS

.,.

...................................

..........................................................

..............................................

..................

..................................

......................

..........................................

..................................

........

1-1

1-1

1-2

1-2

1-2

1-4

1-5

1-5

1-6

11-1

11-1

11-1

11-1

11-2

11-2

11-3

11-3

11-3

11-4

11-4

11-5

11-5

11-6

11-6

111-1

111-1

111-1

111-1

111-2

111-2

111-2

111-3

111-4

1v-1

1v-1

1v-1

1v-1

1v-2

1v-4

1v-6

1v-7

Page 5

SAFETY INSTRUCTIONS

Your rotary mower at the time of its manufacture,

meets the blade safety requirements of the Consumer Product Safety Commissions Safety Standard for Walk Behind Power Lawn Mowers.

representative sample was tested and verified by

an independent laboratory for compliance with

the B71.1-1980 Specifications of the American

National Standards Institute. However, improper

use or maintenance by the operator or owner

can still result in injury. To reduce the potential

for injury follow these safety instructions.

This machine is equipped with a blade brake

which is designed to stop the blade within

seconds when the control lever is released.

Check to be sure the control and brake function

correctly before each use of the mower. Repair

any defective or damaged safety components

before operation is commenced. To further

reduce the possibility of injury, always stop the E. Wipe up any spilled gasoline.

engine before leaving the operator’s position.

This safety symbol means

WARNING

PERSONAL SAFETY INSTRUCTION

Read the instruction because

do

with safety. Failure to comply with

the instruction may result in personal

injury.

Before Operating

1.

Operate your mower only after reading the engine is running. Stay behind the handle

Operators Manual.

available by sending the complete model 12. During operation the grass defector

and serial number to: The Toro Company, plete bagging assembly must be installed on

81 11 Lyndale Avenue South, Minneapolis, the mower.

Minnesota

2.

Never allow children to operate the mower

or adults to operate mower without

proper instructions.

3. Become familiar with the controls and know

how to stop the engine quickly.

4.

Keep everyone, especially children and pets,

away from the area of operation. Remove

sticks, stones, wire and any other debris that

might be picked up and thrown by the blade.

5.

TAMPERING WITH

SAFETY DEVICE

RESULTS IN NONCONFORMANCE WITH

SAFETY STANDARD, MAY RESULT IN PER-

SONAL INJURY. Each time before operating

the mower, check for damage or abnormal

wear.

defective or damaged, repair or replace it

before operation is commenced.

55420.

If

a safety device, shield, or decal

Attn: Publications. 13. Stop the engine and wait for all moving parts

OR

or

CAUTION

it

has to

A

replacement manual is

OR

DEFEATING

COMPONENT WHICH

A

3

-

-

A

A

is

1-1

6. Wear long pants and substantial shoes.

not operate the mower while wearing

sandals, tennis shoes, sneakers or shorts.

Do not wear loose fitting clothing that could

get caught in moving parts.

If

long grass will be cut, set the height-of-cut

7.

in the highest position. After mowing, reinspect the area and remove all debris. Then

lower the height-of-cut and mow the grass

again.

8. Since gasoline is highly flammable, handle it

carefully

A. Use an approved gasoline container.

B.

Do not

hot or running.

C. Do not smoke while handling gasoline.

D.

Fill the fuel tank outdoors and up to about

one-half inch from the top of the tank, not

the filler neck.

While Operating

9. Cutting the grass with a rotary mower demands attention. Always maintain secure

footing, balance and control.

10. Cut the grass during the daytime or when

there

from side to side, but avoid slopes when the

grass is wet.

is dry for best results.

11. Keep face, hands and feet away from the

mower housing and cutter blade while the

until the engine and all moving parts stop.

to stop before removing the bag, bagging

assembly, or unclogging the discharge

chute.

the high tension wire from the spark plug to

prevent the possibility

Use a stick to remove the obstruction.

If

a solid object is hit by the blade or

14.

mower vibrates abnormally, stop the engine

immediately. Disconnect the high tension

wire from the spark plug to prevent the

possibility of accidental starting. Then check

the mower for possible damage, bent blade,

an obstruction or loose parts. Repair the

mower before using it again.

15. Stop the engine before adjusting the

height-of-cut.

If

16.

a gravel driveway, road or path must be

crossed, stop the engine

fill

the fuel tank when the engine is

is

adequate artificial light. Cut slopes

If

possible, mow when the grass

or

If

the chute must be unclogged, pull

of

accidental starting.

so

loose sand and

Do

com-

if

the

-

Page 6

rocks are not thrown.

17.

Before leaving the operator’s position behind

the handle, stop the engine and wait for all

moving parts to stop. Do not walk in front of

the mower while the engine is running. Disconnect the high tension wire from the spark

plug

if

the mower will be unattended.

18.

Do

not touch any part of the engine while it is

running or shortly after it is stopped because

the engine will be hot enough to cause a

burn.

Muffler

children and pets away.

MAINTENANCE

Before the mower is serviced or adjusted,

19.

stop the engine and remove the key from the

switch. Disconnect the high tension wire from

the spark plug to prevent the possibility of

accidental starting.

20.

To assure the mower is in safe operating

condition, keep all nuts, bolts and screws

tight. Assure the blade capscrew is tightened

to the proper torque.

21.

If

major repairs are ever needed or

tance is desired, contact an Authorized

TORO Service Dealer.

22.

If

the mower must be tipped when it is

serviced or adjusted, drain the gasoline from

the fuel tank.

23.

If

a guard, safety device or safety decal is

damaged, replace the defective part(s) be-

fore operating the mower.

24.

To reduce potential fire hazards, assure the

mower is free

leaves and accumulations of dirt.

25.

The grass bag must always be in good condition; therefore, check it before each use to

assure the bag is not torn

Always replace a defective grass bag.

26.

Allow the engine to cool before storing the

mower in any enclosure such as a garage or

storage shed.

any open flame or where gasoline fumes

may be ignited by a spark.

27.

Do not overspeed the engine by changing

the governor settings. Recommended speed

of the engine is

and accuracy, have an Authorized TORO

Service Dealer check the engine speed with

a tachometer.

28.

At the time of manufacture the mower conformed to the safety standards in effect for

is

extremely hot. Keep

of

excessive grease, grass,

or

deteriorated.

Do

not store the mower near

3000

rpm. To assure safety

if

assis-

rotary mowers. To assure optimum performance and continued safety certification of

the mower, use genuine TORO replacement

parts and accessories. Replacement parts

and accessories made by other manufacturers may result in nonconformance with

the safety standards.

MODEL AND SERIAL NUMBERS

The TORO Two-cycle Rotary Mower has two sets

of identification numbers. There is a model and

serial number to identify the engine and a model

and serial number to identify the chassis. The

engine identification numbers are stamped into

the blower housing behind the air cleaner. Model

I

47PF5 engines built for

identification numbers stamped in the blower

housing above the spark plug. Engine models

47PE4 and 47PF5 have serial numbers that start

with the number

zone start application. The number 2 indicates

BBC application and the number

commercial application.

The chassis identification numbers are located on

a decal on the back

the rear wheels.

In any correspondence concerning the mower,

supply the model and serial numbers to assure

that thecorrect information and replacement parts

are obtained. Genuine TORO replacement parts

may be ordered through your

rized Service Dealer.

TWO-CYCLE ENGINE THEORY AND

OPERATION

Theory

Two-cycle engines have special advantages

which make their use more practical in certain

applications. Two-cycle engines are lightweight

with an excellent power to weight ratio and can

be operated in any position. They are also

notably easy to maintain and service because of

their uncomplicated design.

The TORO Two-cycle Engine used on the TORO

Rotary Mowers is a third-port, loop scavenged

design. This design name describes the path of

/

the fuel

bustion chamber, and the exhausting of spent

gases.

In a loop-scavenge engine, a high pressure area

is created in the crankcase by the downward

movement of the piston. Pressurized fuel-air

mixture rushes into the combustion chamber

through the intake ports and is directed toward

the cylinder head. This fresh mixture then strikes

the cylinder head and loops down forcing burnt

gases in the combustion chamber out through

air mixture into the crankcase and com-

1, 2 or

of

1986

3. The

the mower housing, between

have the engine

number 1 indicates

local

3

indicates

TORO Autho-

a

1-2

Page 7

the exhaust ports. The third port design engine

has the carburetor mounted on the side of the

cylinder. The passage from the carburetor into

the crankcase is called the third port.

All

ports

within the engine are opened and closed by the

piston skirt as the piston moves up and down

within the cylinder.

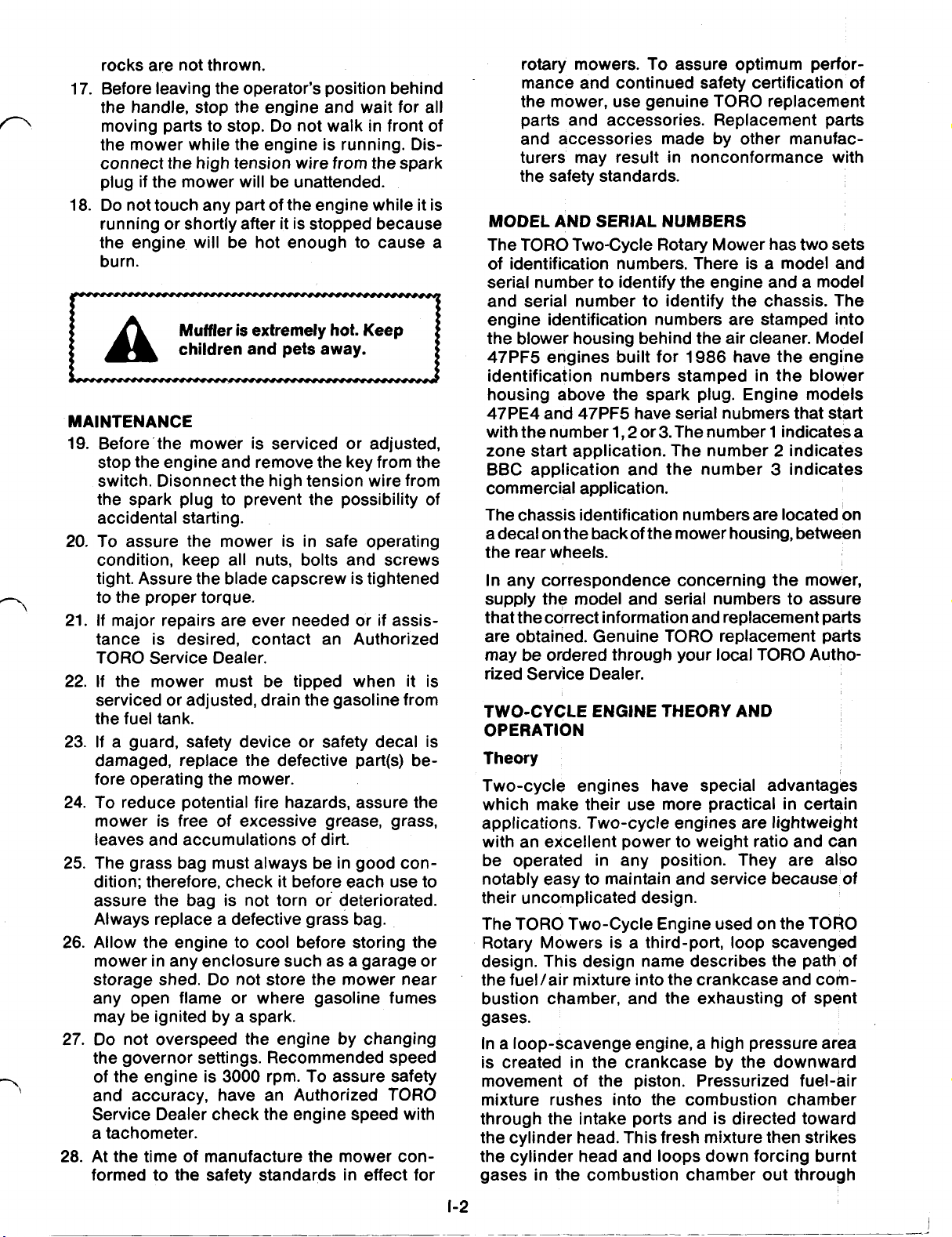

Operation

The piston closes all engine ports as it moves

toward the combustion chamber (Figure 1-1). The

moving piston creates a high pressure in the combustion chamber and a partial vacuum in the

crankcase.

Intake Ports Closed

Co

gases begin to be expelled from the combustion

chamber (Figure 1-3).

__-

Intake Ports Closed

Exhaust Port

~

Figure

--l_____m_

I

Third

Port Closed

1-3

At a point of piston travel slightly before bottom

dead center (BBDC)

the

fuel transfer ports, on the

sides of the cylinder walls, are uncovered and

the compressed fuel/air mixture in the crankcase

-is allowed to enter the combustion chamber

where they help expel the burnt gases and

charge the chamber for the following piston

stroke (Figure 1-4).

Figure 1-1

At

a point slightly before top dead center (BTDC) of

the piston travel, from the plug ignitesthe

fuel air mixture (Figure 1-2). Also, at this time, the

third port opens allowing the fresh fuel/air mixture

to rush into the crankcase to equalize the partial

vacuum.

Intake Ports Closed

\

Figure 1-2

When the fuel is ignited by the spark plug, the

expanding gases from the burning fuel in the combustion chamber force the piston down thecylinder,

closing the third-port and increasing the pressure

in the

crankcase. At

of the stroke, the exhaust port opens and the burnt

a point approaching the bottom

Intake Ports

Exhaust

Change

Open

__-__

Figure 1-4

CARBURETOR THEORY AND OPERATION

Theory

The carburetor receives fuel from the tank and

it

mixes

with air in the right proportions to

provide a highly combustible mixture to the

engine.

As the piston moves up on the compression

stroke a partial vacuum is created within the

engine crankcase, causing the greater atmospheric pressure to force air to flow through the

carburetor into the cylinder. The velocity of the

air increases as it flows through the carburetor

venturi and the air pressure is reduced at this

point to less than atmospheric pressure. The

differences of pressure in the venturi of the

1-3

Page 8

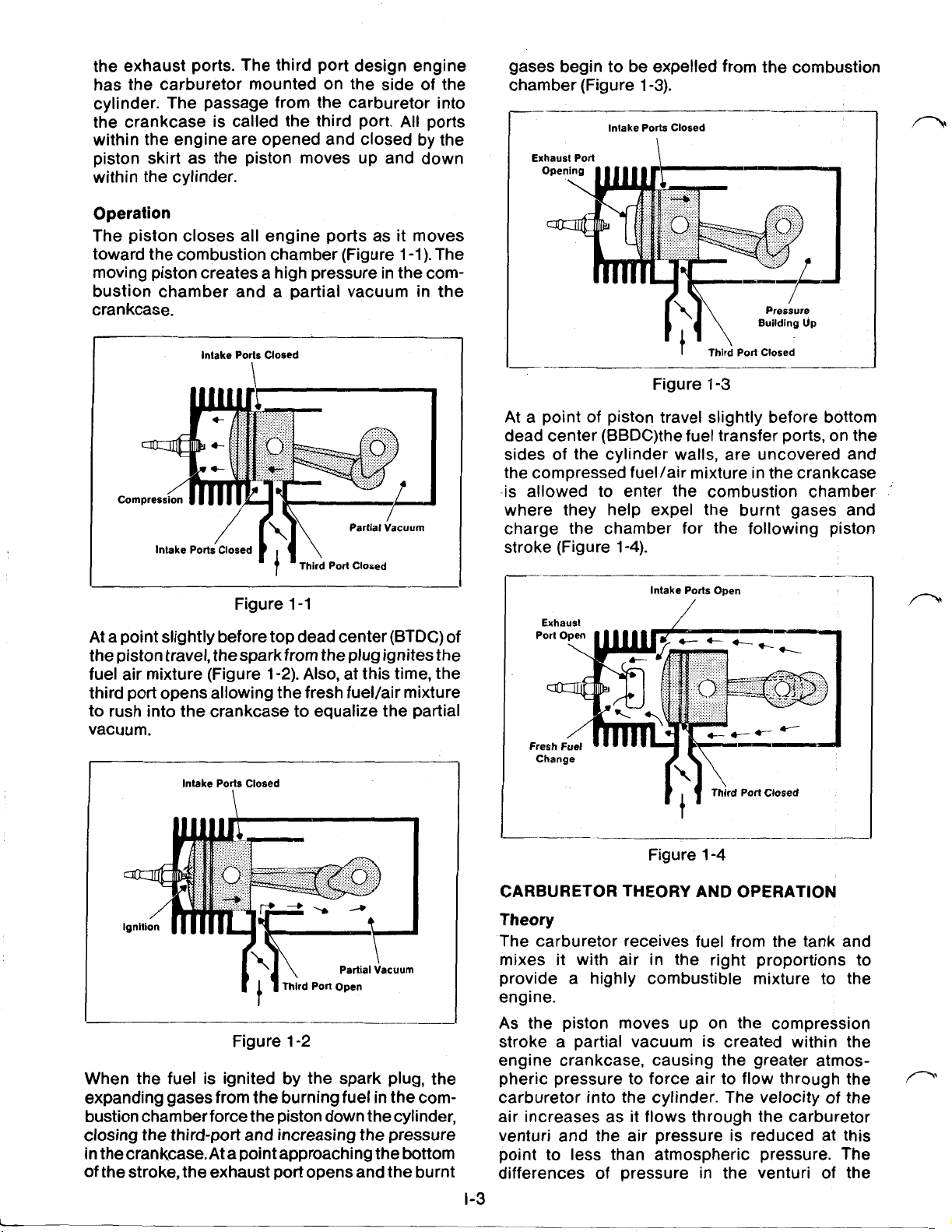

carburetor causes atmospheric pressure to push

rawfuel from the

bowl into theair

stream, where

float

it breaks up into a fine spray, or becomes atomized,

and mixes with the air stream (Figure

1-5).

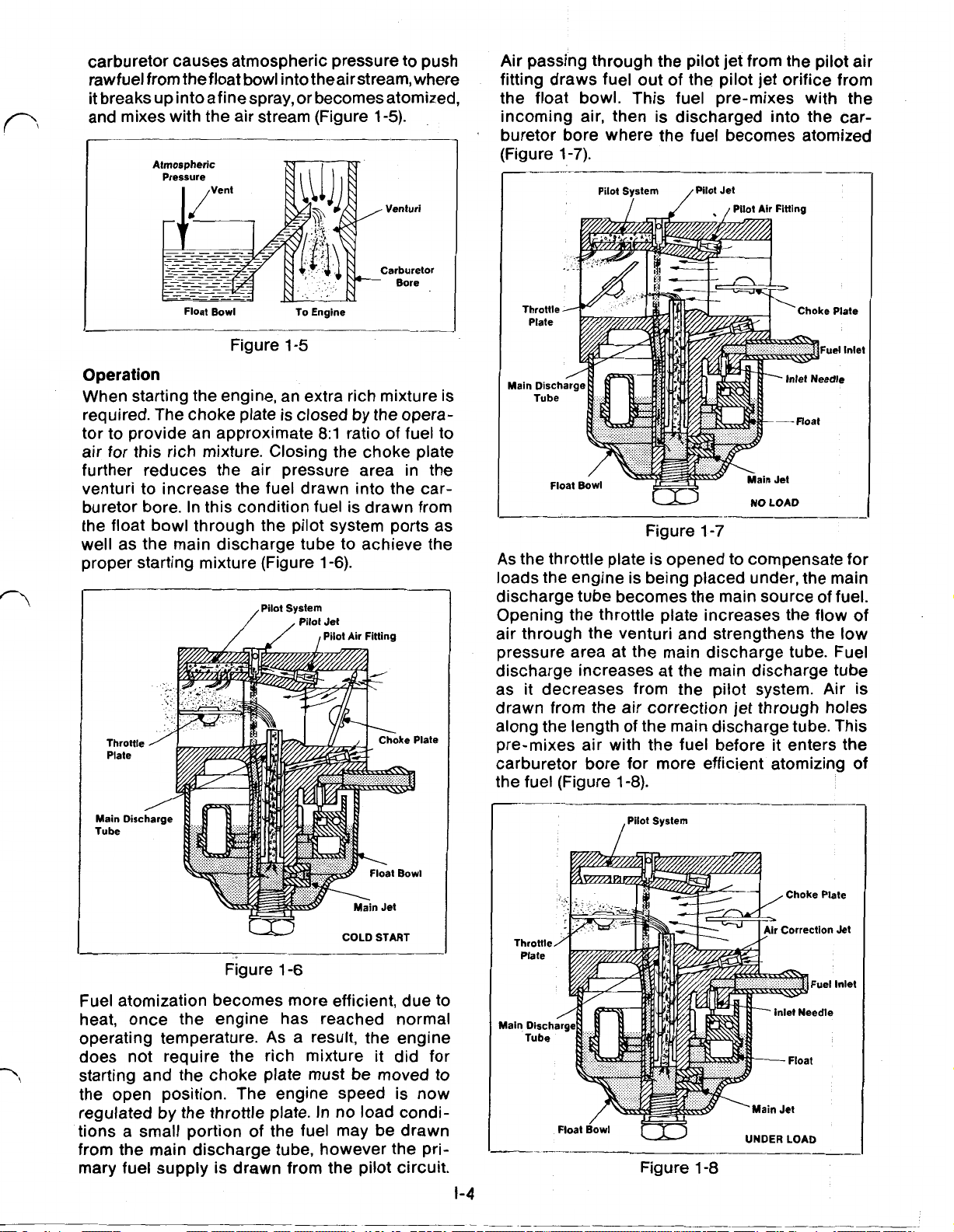

Air passing through the pilot jet from the pilot air

fitting draws fuel out of the pilot jet orifice from

the float bowl. This fuel pre-mixes with the

incoming air, then is discharged into the carburetor bore where the fuel becomes atomized

Float

Bowl

(Figure

To Engine

1-7).

Figure

1-5

Operation

When starting the engine, an extra rich mixture is

required. The choke plate is closed by the opera-

tor to provide an approximate

8:1

ratio of fuel to

air for this rich mixture. Closing the choke plate

further reduces the air pressure area in the

venturi to increase the fuel drawn into the car-

buretor bore. In this condition fuel is drawn from

the float bowl through the pilot system ports as

well as the main discharge tube to achieve the

proper starting mixture (Figure

Pilot System

1-6).

Pilot

Jet

Pilot Air Fitting

NO

LOAD

Figure

As

the throttle plate is opened to compensate for

1-7

loads the engine is being placed under, the main

discharge tube becomes the main source of fuel.

Opening the throttle plate increases the flow of

air through the venturi and strengthens the low

pressure area at the main discharge tube. Fuel

discharge increases at the main discharge tube

as

it

decreases from the pilot system. Air

is

drawn from the air correction jet through holes

along the length of the main discharge tube. This

pre-mixes air with the fuel before it enters the

carburetor bore for more efficient atomizing of

:he fuel (Figure

1-8).

COLD START

Figure

1-6

Fuel atomization becomes more efficient, due to

heat, once the engine has reached normal

operating temperature.

As

a result, the engine

does not require the rich mixture it did for

starting and the choke plate must be moved

to

the open position. The engine speed is now

regulated by the throttle plate. In no load condi-

tions a small portion of the fuel may be drawn

from the main discharge tube, however the pri-

mary fuel supply is drawn from the pilot circuit.

1-4

Float

Bowl

/pilot

System

Figure

UNDER LOAD

1-8

Page 9

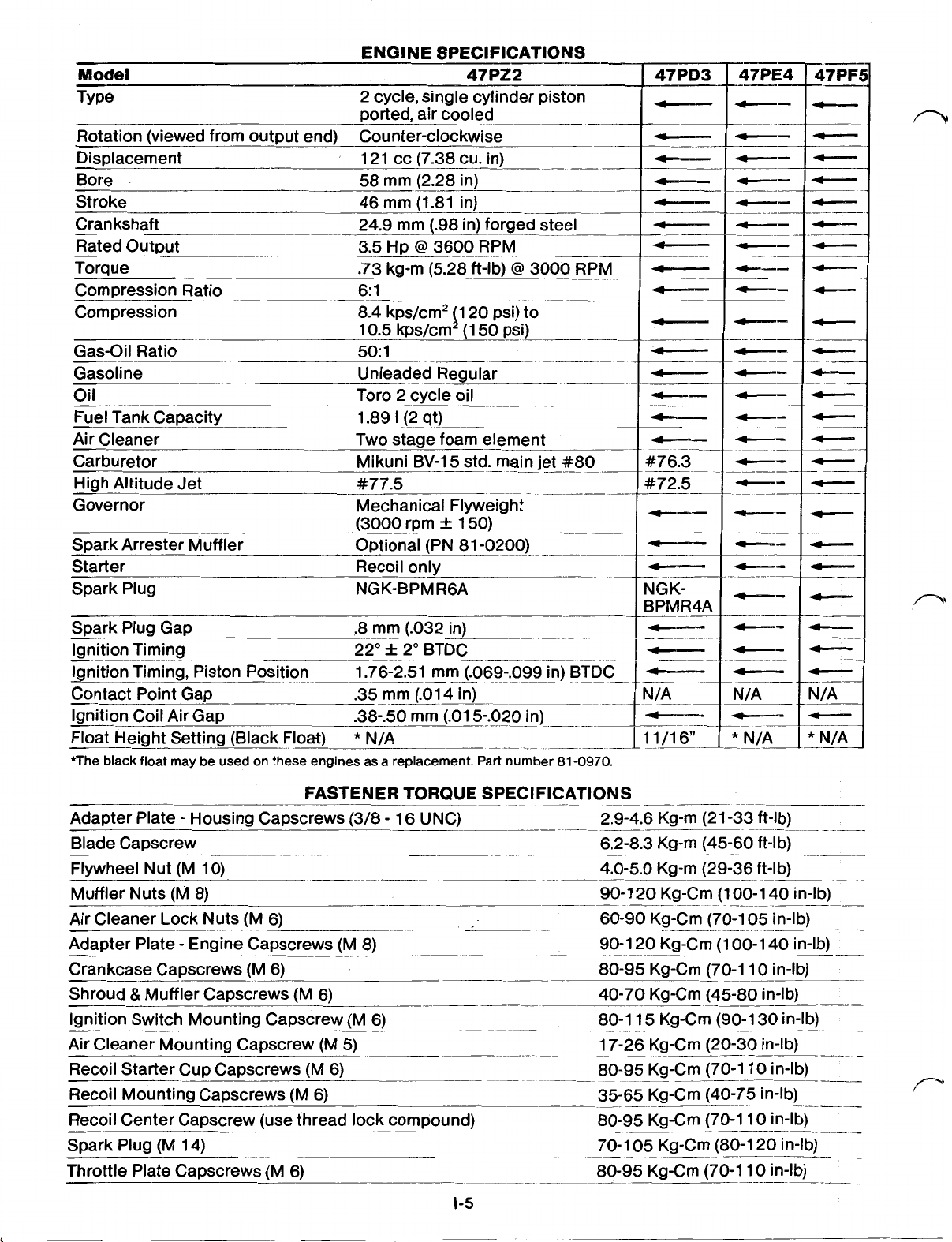

ENGINE SPECIFICATIONS

Model

~---

47P22

Type 2 cycle, single cylinder piston

ported, air cooled

Rotation (viewed from output end) Counter-clockwise

Displacement 121 cc (7.38 cu. in)

Bore 58 mm (2.28 in)

Stroke 46 mm (1.81 in)

Crankshaft 24.9 mm (.98in) forged steel

Rated Output

Torque .73 kg-m (5.28 ft-lb)

3.5

Hp @ 3600 RPM

@

3000

Compression Ratio 6: 1

Compression

Gas-Oil Ratio

8.4kps/cm2 20 psi) to

50

10.5 kps/cm (1

50:

1

psi)

Gasoline Unleaded Regular

TTO

Oil 2 cycle oil

Fuel Tank Capacity

Air Cleaner

Carburetor Mikuni

High Altitude Jet

Governor Mechanical Flyweight

-~

1.89

I

(2 qt)

Two stage foam element

BV-15std.

main jet #80

#77.5

~-

RPM

--

47PD3

#76.3

#72.5

Spark Arrester Muffler Optional (PN 81-0200)

Starter Recoil only

Spark Plug NGK-BPMR6A

~-

NGKBPMR4A

Ignition Timing 22" 2" BTDC

Ignition Timing, Piston Position 1.76-2.51mm (.069-.099in) BTDC

Contact Point Gap .35 mm (.014in)

~-

N/A

Ignition Coil Air Gap .38-.50 mm (.015-.020in)

Float Height Setting (Black Float)

*The black float may be used on these engines as a replacement. Part number

*

N/A

.

11/16"

81-0970.

*

N/A

FASTENER TORQUE SPECIFICATIONS

Adapter Plate Housing Capscrews (3/8-16UNC) 2.9-4.6 Kg-m (21

-33

ft-lb)

Blade Capscrew 6.2-8.3 Kg-m (45-60 ft-lb)

Flywheel Nut (M 10) 4.0-5.0 Kg-m (29-36 ft-lb)

Muffler Nuts (M 8)

Air Cleaner Lock Nuts (M 6)

Adapter Plate Engine Capscrews (M 8)

90-120Kg-Cm (100-140 in-lb)

60-90 Kg-Cm (70-1

05

.

in-lb)

90-120Kg-Cm (100-140in-lb)

Crankcase Capscrews (M 6) 80-95 Kg-Cm (70-1 10 in-lb)

&

Shroud

Ignition Switch Mounting Capscrew (M 6) 80-1 15 Kg-Cm (90-1

Air Cleaner Mounting Capscrew (M

Muffler Capscrews (M 6)

-..-

5)

40-70 Kg-Cm (45-80 in-lb)

30

in-lb)

17-26 Kg-Cm (20-30 in-lb)

Recoil Starter Cup Capscrews (M 6) 80-95 Kg-Cm (70-1 10 in-lb)

Recoil Mounting Capscrews (M 6) 35-65 Kg-Cm (40-75 in-lb)

Recoil Center Capscrew (use thread lock compound) 80-95 Kg-Cm (70-1 10 in-lb)

05

Spark Plug (M 14) 70-1

__-

Kg-Cm (80-1 20 in-lb)

Throttle Plate Capscrews (M 6) 80-95 Kg-Cm (70-1 10 in-lb)

.-

1-5

Page 10

SPECIAL TOOLS LIST

ITEM

1

2

3

4

5

6

7

8.

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Flywheel Puller..

Starter Cup Wrench

Timing Tester..

Spark Tester

Continuity Light

Tachometer..

Ohmmeter (Multimeter).

Feeler Gauges

Micrometer.

Spark Plug Gapping Tool

Compression Gauge..

Threebond#1104 (Loctite#515).

Loctite

Timing Dial Indicator..

Dial Indicator..

Cylinder Gauge Set..

Spark Plug Socket..

Coil Gauge

Torque Wrench (ft-lb)

Torque Wrench (in-lb).

Magnetic

Dial Indicator Stand

DESCRIPTION

..................................

................................

....................................

......................................

...................................

..

.................................

...........................

....................................

.......................................

..........................

.............................

.................

#242

(Threebond#1342).

.................

.............................

....................................

..............................

...............................

.38-.50mm

(.015-.020 in)

..............................

.............................

“V”

Blocks..

.............................

...............................

...............

PART

41-7650

45-1 390

41 -7900

41 -7890

36-4050

42-2730

505-80

505-76

NO.

Page 11

SPARK PLUG

CAUTION: To reduce poten-

tial accidents, never perform

an adjustment or maintenance procedure while the engine is running. Pull

off

the high tension wire

the spark plug

to prevent an accidental start.

Many times an inspection of the spark plug can

determine whether the engine is functioning

properly. A spark plug which is functioning

normally will show slight electrode wear with

brown

black carbon fouled plugs are caused by a rich

carburetor mixture, weak spark, or improper

gasoline to oil mixture. Excessively worn elec-

trodes or a blistered insulator indicate spark plug

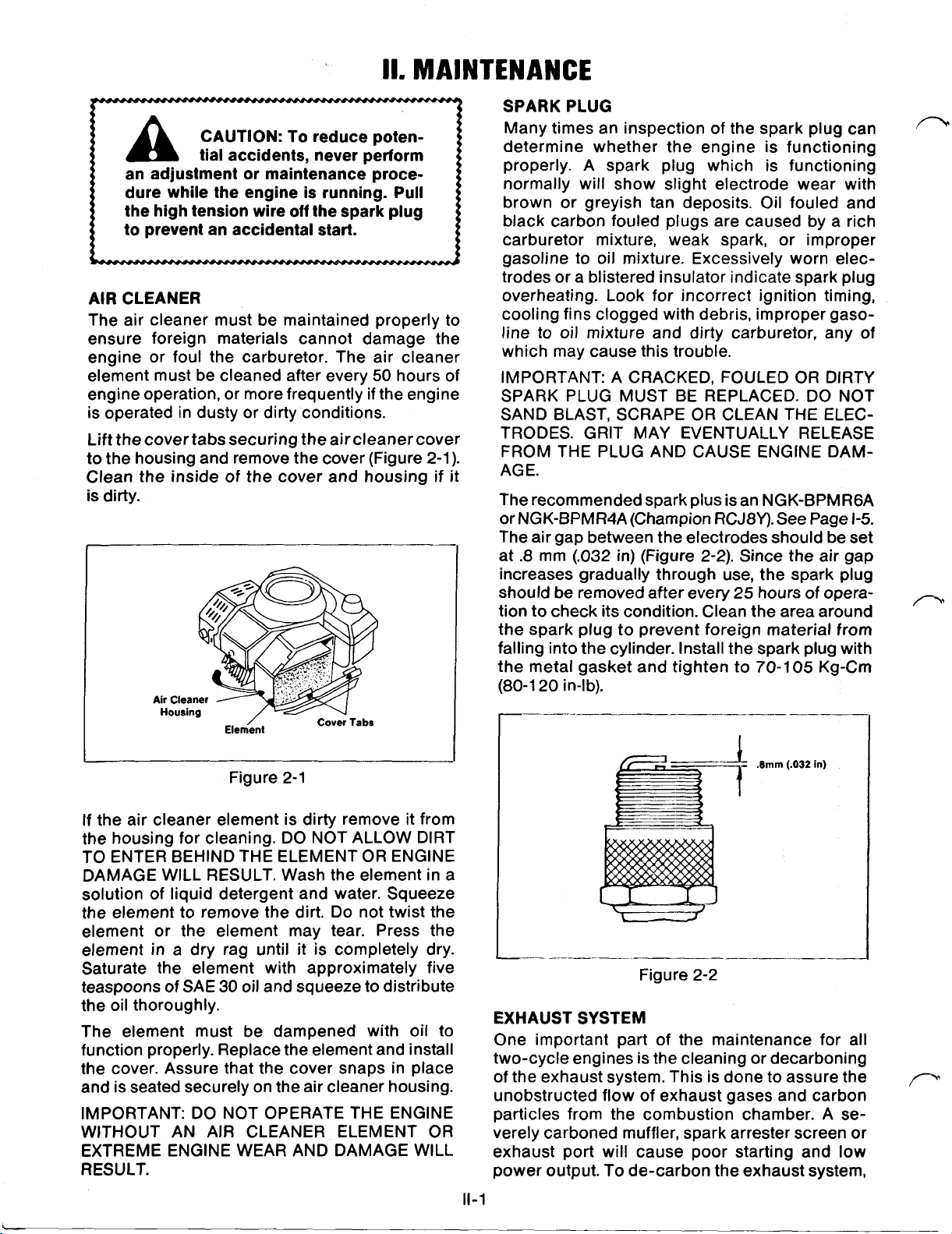

AIR

CLEANER

The air cleaner must be maintained properly to

ensure foreign materials cannot damage the

engine

element must be cleaned after every

engine operation, or more frequently

is operated in dusty

or

foul the carburetor. The air cleaner

50

hours of

if

the engine

or

dirty conditions.

Lift the cover tabs securing the air cleaner cover

to the housing and remove the cover (Figure 2-1).

Clean the inside

is

dirty.

of

the cover and housing if it

overheating. Look for incorrect ignition timing,

cooling fins clogged with debris, improper gasoline to oil mixture and dirty carburetor, any of

which may cause this trouble.

IMPORTANT:

SPARK PLUG MUST BE REPLACED. DO NOT

SAND BLAST, SCRAPE OR CLEAN

TRODES. GRIT MAY EVENTUALLY RELEASE

FROM THE PLUG AND CAUSE ENGINE DAM-

AGE.

The recommended spark plus is an NGK-BPMRGA

or

NGK-BPMR4A (Champion RCJ8Y). See Page

The air gap between the electrodes should be set

.8

at

increases gradually through use, the spark plug

should be removed after every 25 hours of operation to check its condition. Clean the area around

the spark plug to prevent foreign material from

falling into the cylinder. Install the spark plug with

the metal gasket and tighten to 70-105 Kg-Cm

(80-1 20 in-lb).

or

greyish tan deposits. Oil fouled and

A

CRACKED, FOULED

mm

(.032 in)

(Figure 2-2). Since the air gap

OR

THE

DIRTY

ELEC-

1-5.

Figure 2-1

If the air cleaner element is dirty remove it from

the housing

cleaning.

DO

NOT ALLOW DIRT

for

TO ENTER BEHIND THE ELEMENT OR ENGINE

DAMAGE WILL RESULT. Wash the element in a

solution of liquid detergent and water. Squeeze

the element to remove the dirt. Do not twist the

element or the element may tear. Press the

element in a dry rag until it is completely dry.

Saturate the element with approximately five

teaspoons of SAE

30

oil and squeeze to distribute

the oil thoroughly.

The element must be dampened with oil to

function properly. Replace the element and install

the cover. Assure that the cover snaps in place

and is seated securely on the air cleaner housing.

IMPORTANT: DO NOT OPERATE THE ENGINE

AIR

WITHOUT AN

CLEANER ELEMENT OR

EXTREME ENGINE WEAR AND DAMAGE WILL

RESULT.

(.032

EXHAUST SYSTEM

One important part of the maintenance for all

or

two-cycle engines is the cleaning

de-carboning

of the exhaust system. This is done to assure the

unobstructed flow of exhaust gases and carbon

particles from the combustion chamber.

verely carboned muffler, spark arrester screen or

exhaust port will cause poor starting and

power output. To de-carbon the exhaust system,

11-1

in)

A

se-

low

Page 12

remove the muffler from the engine by removing

the two retaining nuts and the through bolt (Figure

2-3).

Figure 2-3

the loose carbon from the muffler using com-

pressed air. Install the muffler using a new gasket

and attach it with proper fasteners tightened to

the correct torque. See page

1-5.

DECARBONING CYLINDER HEAD

If the exhaust ports and muffler show signs of excessive carbon buildup,

it

may be necessary to

de-carbon the cylinder head. To accomplish this the

entire engine must be disassembled to allow

access into the combustion chamber. (See Disassembly Instructions Page IV-1.) Remove the

carbon deposits from the piston and the cylinder

chamber using a wooden stick. TAKE CARE NOT

TO SCRATCH THE PISTON

CHAMBER AND DO NOT USE A METAL TOOL TO

REMOVE THE DEPOSITS.

OR

CYLINDER

Check the cylinder exhaust port.

If

necessary,

remove the carbon deposits from the port using

a wooden stick. Also clean the small hole next to

the exhaust port. This hole acts as a compression

relief to lessen the force required to start the

If

engine.

plugged, the recoil starter will be hard

to pull (Figure 2-4).

IMPORTANT: WHEN REMOVING CARBON DEPOSITS, ROTATE THE CRANKSHAFT TO

CLOSE THE EXHAUST PORT WITH THE PISTON. THIS WILL PREVENT LOOSE CARBON

DEPOSITS FROM FALLING INTO THE CYLIN-

DER. TAKE CARE NOT TO SCRATCH THE

PISTON AND DO NOT USE

A

METAL TOOL TO

REMOVE THE DEPOSITS.

IGNITION

To check the timing

TIMING

(MODEL

it

is necessary to remove the

47P22

ONLY)

air cleaner to view the flywheel. (See Disassembly

Instructions.) The flywheel has a group of three

raised marks on its outer edge. The center mark

corresponds to BTDC and the others represent

the tolerance of plus or minus 2O.Connect one lead

of the timing tester to the engine frame (ground).

(A

timing tester must be used. An Ohmmeter or continuity light will not indicate the position of the contact points.) Disconnect the wire at the ignition

switch under the fuel tank and connect the other

tester lead to this wire (Figure2-5).Turn theengine

crankshaft in its normal rotation, counter-clockwise

as viewed from the output end. The contact points

should open, as indicated by the timing tester, when

the pointer on thecrankcase housing points to the

Center of the

three

marks on the flywheelcasting.

If

the timing is wrong the flywheel must be removed

and the contact points re-gapped or replaced.

Models 47PD3, 47PE4 and 47PF5 use solid state

ignition systems and have their timing fixed at

BTDC.

Figure 2-4

Before installing the muffler check for cracks and

leaks. Inspect the inlet and outlet for carbon

\

buildup. Remove excessive deposits with a

scraping tool and soak the muffler in solvent to

remove wet oil deposits. Allow to air dry or dry

with compressed air. Remove the muffler heat

shield and tap the muffler body with a plastic

hammer

to

loosen the carbon deposits. Blow all

Figure

2-5

11-2

Page 13

IGNITION TIMING (DIAL INDICATOR)

The ignition timing may be more accurately

checked using a dial indicator. Remove the spark

plug wire and spark plug and insert the dial indicator into the spark plug hole. Rotate the engine

crankshaft until the dial indicator registers the piston at top dead center and “zero” the dial. Connect

one lead of a timing tester to the engine frame.

(A

timing tester must be used. An Ohmmeter or continuity light will not indicate the position of the

con-

tact points.) Disconnect the wire at the ignition

switch under the fuel tank and connect the other

tester lead to this wire (Figure 2-6). Slowly rotate

the crankshaft clockwise, as viewed from the out-

put end, until the tester signals the contact points

are opening.

(.069

in) and 2.51 mm

If

the testersignals between 1.76 mm

(.099

in) of piston travel, as

read on the dial indicator, the engine is properly

timed. If the timing is wrong the flywheel must be

removed and the contact points re-gapped.

installing new or reconditioned contact points

ensure that the wiring is routed through the channel

in the crankcase housing and under the ignition

coil. FAILURE TO ROUTE THE WIRES PROPERLY

MAY ALLOW THE WIRING TO CONTACT THE FLY-

WHEEL

the contact points to

AND

CAUSE A SHORT CIRCUIT. Adjust

.35

mm (.014 in) air gap, using

a feeler gauge, with the cam follower on the high

point of the timing cam (Figure

2-7).

Check the timing using either method previously described. It

may be necessary to readjust the contact point

gap to obtain the timing specification.

Contact Point

Assembly

Figure 2-6

CONTACT POINTS AND CONDENSER

MODEL 47P22 ONLY

The contact points and condenser do wear out

through use and their performance level is

affected by dust, moisture and corrosion. Inspection of these components requires removal of the

flywheel.

(See Disassembly Instructions.) With the flywheel

removed, inspect for wear of the cam follower

and burning or pitting of the contact points. The

surface of the contact points should have a grey,

frosted appearance

if

wearing normally.

If

the

contact points are cratered or have surface

buildup they should be cleaned or replaced. The

contacts can be cleaned with an electrical

sol-

vent and contact point sandpaper. Ensure that all

dust and dirt

is

removed after sanding. Cratering

of the points indicates the condenser may be

faulty. Verify the condition of the condenser

If

through tests with an ignition analyzer.

an

analyzer is not available the condenser must be

be

considered faulty and should

replaced. When

Condenser

Figure

Cam

I

Follower

2-7

IGNITION COIL

Whenever the flywheel is exposed the ignition

coil condition and air gap should be checked.

for

Inspect the ignition coil

a cracked casing, loose

laminations, damaged wires and over heating. The

ignition coil air gap is

.38-50

mm (.015-.020 in).

A

non-metallic flexible gauge such as shown in the

Special Tools Section should be used. To adjust,

rotate the flywheel magnets away from the ignition coil and loosen the two ignition coil retaining

capscrews. Insert the gauge between the coil

laminations and the flywheel (Figure 2-8).Tighten

the retaining capscrews to hold the adjustment.

Figure

2-8

11-3

Page 14

The ignition coil contains two separate windings

inside the coil casing (Figure 2-9). Use an Ohmmeter to check the resistance levels of each winding. To check the primary winding, disconnect the

ignition switch wire and connect the positive lead

of the Ohmmeter to the ignition coil lead. Connect

the negative lead to the engine frame (ground).

primary winding resistance is ohms

The

(Rxl

scale). To check the secondary winding, disconnect

the high tension wire at the spark plug. Connect

the positive lead of the Ohmmeter to the high tension wire. Connect the negative lead to the engine

GOVERNOR

The governor linkage is factory preset to regu-

late the engine speed at

Check the adjustment of the governor

engine is suspected of improper speed. To gain

access to the governor linkage removal of the

air cleaner is recommended. (See Disassembly

Instructions.) Before adjusting the governor,

inspect the control linkage for bent, broken and

worn parts. Loosen the governor arm clamping

bolt and use a screwdriver to spread the governor arm clamp (Figure 2-1 1).

frame (ground). The secondary coil resistance

should be 5800-7940 ohms

ignition coil must be replaced

(Rxl

000

if

the resistance

scale). The

levels are incorrect.

3000

150 RPM.

if

the

Ignition Switch Wire

Primary

Coil

ohms

Ground

High Tension Wire

\

Secondary

5800-7940

(R

x

1000

Model

47P22

Coil

ohms

scale)

Figure 2-9

The ignition coil used on models 47PD3, 47PE4,

and 47PF5 consists of the main coil, high tension

wire and ignition kill wire (See Figure 2-1

Testing of the coil may becompleted with a

0).

Graham

Lee ignition tester model number 31-SMXH. In-

structions for testing are included with the tester.

Figure 2-1 1

Adjust the governor by holding the governor

lever to the right while turning the governor shaft

to the right. Hold the adjustment and tighten the

clamp bolt (Figure 2-1 2).

High Tension

Wi

Figure 2-1

0

Figure 2-1

2

Connect the return spring to the center hole in

the governor spring bracket. The center hole

should govern the engine speed at the recom-

mended

engine speed 150

3000

RPM. The top hole will raise the

RPM

and the bottom hole will

lower the engine speed 150 RPM. Engine speed

can be verified using a tachometer such as listed

in the Special Tools Section. (See page

II

-4

1-6).

Page 15

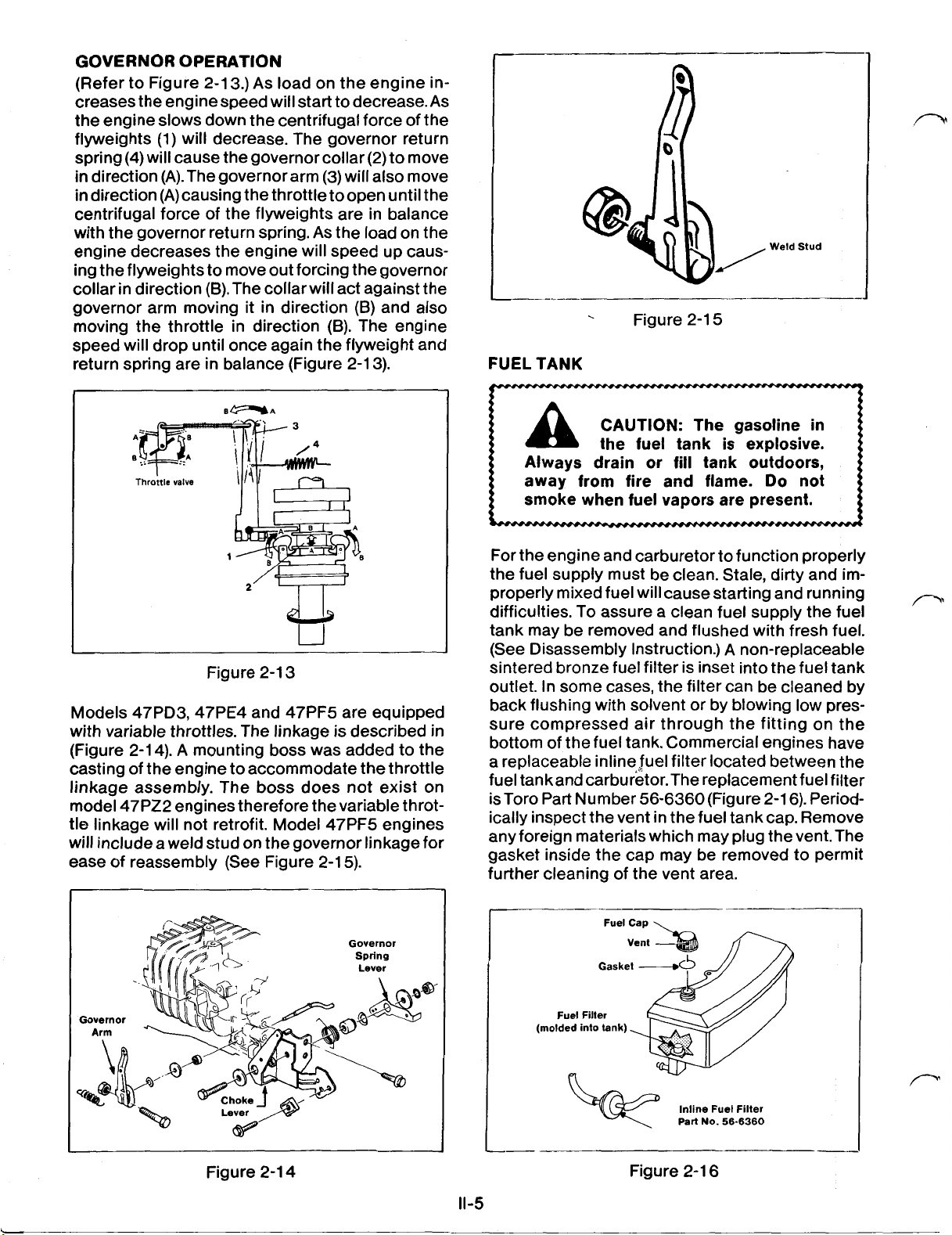

GOVERNOR

OPERATION

(Refer to Figure 2-1 3.) As load on the engine increases the enginespeed will start to

decrease. As

the engine slows down the centrifugal force of the

flyweights (1) will decrease. The governor return

spring (4) will cause the governor collar (2) to move

in direction (A).

in direction (A) causing the throttle to

centrifugal force

The

governorarm (3) will also move

open

of

the flyweights are in balance

until the

with the governor return spring. As the load on the

engine decreases the engine will speed up causing the flyweights to move out forcing the governor

collar in direction (B).

The

collar will act against the

governor arm moving it in direction (B) and also

moving the throttle in direction

(B).

The engine

speed will drop until once again the flyweight and

return spring are in balance (Figure 2-1 3).

FUEL

TANK

Figure 2-1

5

1

Figure 2-1

3

Models 47PD3,47PE4 and 47PF5 are equipped

with variable throttles. The linkage is described in

(Figure 2-1 4).

A

mounting boss was added to the

casting of the engine to accommodate the throttle

linkage assembly. The boss does not exist on

model 47PZ2 engines therefore thevariable throt-

tle linkage will not retrofit. Model 47PF5 engines

will include a weld stud on the governor linkage for

ease of reassembly (See Figure 2-1

5).

CAUTION:

!

the fuel tank is explosive.

Always drain or

away from fire and flame.

The gasoline in

fill

tank outdoors,

Do

not

smoke when fuel vapors are present.

For the engine and carburetor to function properly

the fuel supply must be clean. Stale, dirty and im-

properly mixed fuel will cause starting and running

difficulties. To assure a clean fuel supply the fuel

tank may be removed and flushed with fresh fuel.

A

(See Disassembly Instruction.)

non-replaceable

sintered bronze fuel filter is inset into the fuel tank

outlet. In some cases, the filter can be cleaned by

back flushing with solvent or by blowing low pressure compressed air through the fitting on the

bottom of the fuel tank. Commercial engines have

a replaceable inline fuel filter located between the

fuel tank

and carburetor. The

replacementfuel filter

is Toro Part Number 56-6360 (Figure 2-1 6). Periodically inspect the vent in the fuel tank cap. Remove

any foreign materials which may plug the

vent. The

gasket inside the cap may be removed to permit

further cleaning of the vent area.

Governor

Arm

Figure 2-1 4

Governor

Spring

11-5

Fuel

Fuel

Filter

(molded into lank).

Cap

Inline

Part

No.

Figure 2-1 6

Fuel Filter

56-6360

Page 16

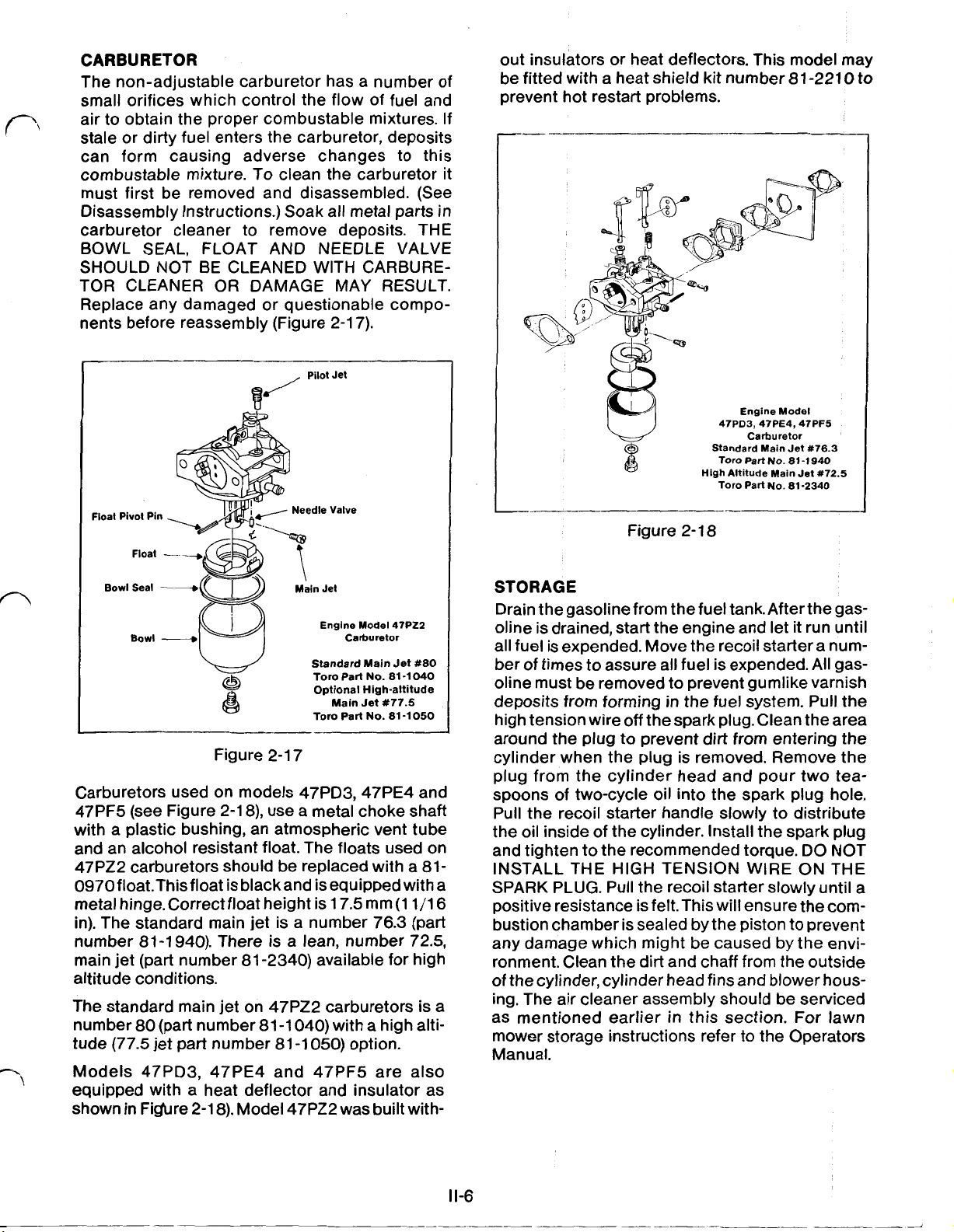

CARBURETOR

The non-adjustable carburetor has a number of

small orifices which control the flow of fuel and

air to obtain the proper combustable mixtures.

stale or dirty fuel enters the carburetor, deposits

can form causing adverse changes to this

cornbustable mixture. To clean the carburetor it

must first be removed and disassembled. (See

Disassembly Instructions.) Soak all metal parts in

carburetor cleaner to remove deposits. THE

BOWL SEAL, FLOAT

AND

NEEDLE VALVE

SHOULD NOT BE CLEANED WITH CARBURETOR CLEANER

OR

DAMAGE MAY RESULT.

Replace any damaged or questionable compo-

nents before reassembly (Figure 2-1 7).

Pilot Jet

Float Pivot Pin

Needle Valve

If

out insulators or heat deflectors. This model may

be fitted with a heat shield kit number 81 -221

0

to

prevent hot restart problems.

Engine Model

47PD3,47PE4,47PF5

Carburetor

Standard Main Jet

Toro

Part

No.

Part

No.

81-1940

81-2340

Figure

High Altitude Main Jet

Toro

2-

18

Bowl

Seal

Bowl

Engine Model 47P22

Carburetor

Standard Main Jet

Toro

Part

Main

Part

No.

Jet

No.

Optional High-altitude

Tor0

#80

81-1040

#77.5

81 -1

050

Figure 2-1 7

Carburetors used on models 47PD3,47PE4 and

47PF5 (see Figure 2-1 8), use a metal choke shaft

with a plastic bushing, an atmospheric vent tube

and an alcohol resistant float. The floats used on

47PZ2 carburetors should be replaced with a 810970

float.

This

float is black

and

is equipped with a

metal hinge. Correct float height is 17.5 mm (1 1 /16

in). The standard main jet is a number 76.3 (part

number 81-1 940). There is a lean, number 72.5,

main jet (part number 81 -2340) available for high

altitude conditions.

The standard main jet on 47PZ2 carburetors is a

number

tude (77.5 jet part number 81 -1

80

(part number 81 -1 040) with a high alti-

050)

option.

Models 47PD3, 47PE4 and 47PF5 are also

equipped with a heat deflector and insulator as

shown in Figure 2-1 8). Model 47PZ2 was built with-

STORAGE

Drain the gasoline

oline is drained, start the engine and let

from

the

fuel

tank.

After the gas-

it

run until

all fuel is expended. Move the recoil starter a number of times to assure

all

fuel is expended.

All

gasoline must be removed to prevent gumlike varnish

deposits from forming in the fuel system. Pull the

off

high tension wire

the spark plug. Clean the area

around the plug to prevent dirt from entering the

cylinder when the plug is removed. Remove the

plug from the cylinder head and pour two teaspoons of two-cycle oil into the spark plug hole.

Pull the recoil starter handle slowly to distribute

the oil inside of the cylinder. Install the spark plug

and tighten to the recommended torque. DO NOT

INSTALL THE HIGH TENSION WIRE

ON

THE

SPARK PLUG. Pull the recoil starter slowly until a

positive resistance is felt. This will ensure the combustion chamber is sealed by

the

piston to prevent

any damage which might be caused by the environment. Clean the dirt and chaff from the outside

of

the cylinder, cylinder head fins and blower hous-

ing. The air cleaner assembly should be serviced

as mentioned earlier in this section. For lawn

mower storage instructions refer to the Operators

Manual.

Page 17

111.

TROUBLESHOOTING AND TEST PROCEDURES

Generally all gasoline-powered products require

some form of service

time. The amount of time and expense involved

in repairing a product can be greatly impacted

by the amount of time required to initially determine the cause of the difficulty. Therefore, it is

recommended to make these preliminary checks

before proceeding to secondary troubleshooting

procedures.

PRELIMINARY TROUBLESHOOTING

Ignition System

1. Check the ignition switch and wiring

2.

Ensure the spark plug is the correct type

3.

Check the spark plug for the correct gap,

damaged and excessively carboned

electrodes

4.

Check the spark intensity.

Fuel System

1.

Check the choke position and controls

2.

Check the throttle (if

nor mechanism

3. Ensure the fuel is fresh, clean and of the

proper gas-oil mixture

4.

Check the fuel filter.

Air Cleaner

1. Check for housing and element damage

2.

Check for dirty element

3.

Check for too much

element

Compression

1.

Check the cylinder compression. (Refer to

page

111-2)

Crankcase

1. Ensure the crankcase is sealed. (Refer to

I11-3)

page

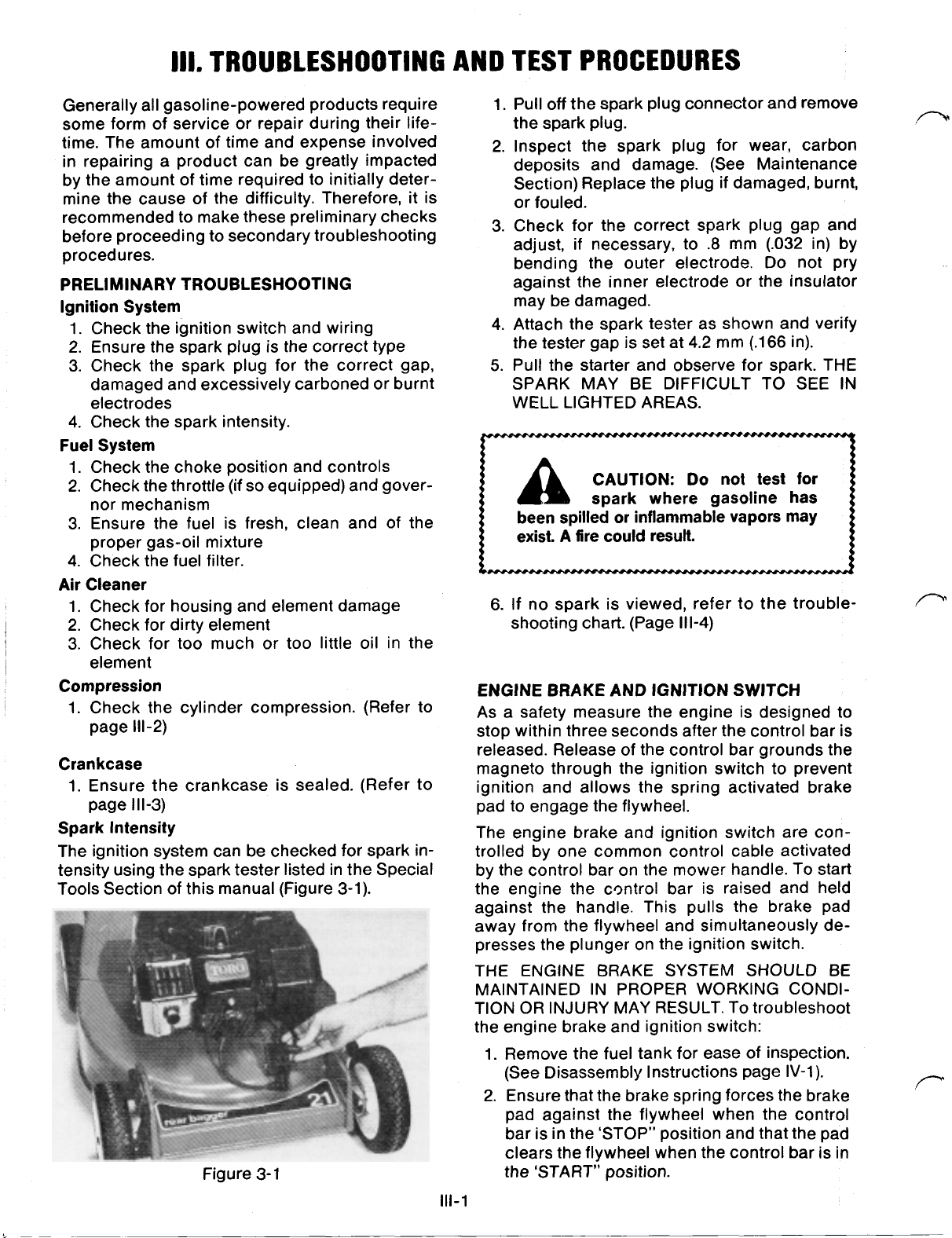

Spark Intensity

The ignition system can be checked

tensity using the spark tester listed in the Special

Tools Section of this manual (Figure

or

repair during their life-

or

so

equipped) and gover-

or

too little oil in the

for

spark in-

3-1).

burnt

1. Pull

2.

3. Check for the correct spark plug gap and

4.

5.

6.

ENGINE

As a safety measure the engine is designed to

stop within three seconds after the control bar is

released. Release of the control bar grounds the

magneto through the ignition switch to prevent

ignition and allows the spring activated brake

pad to engage the flywheel.

The engine brake and ignition switch are controlled by one common control cable activated

by the control bar on the mower handle. To start

the engine the control bar is raised and held

against the handle. This pulls the brake pad

away from the flywheel and simultaneously depresses the plunger on the ignition switch.

THE ENGiNE BRAKE SYSTEM SHOULD

MAINTAINED

TION

the engine brake and ignition switch:

off

the spark plug connector and remove

the spark plug.

Inspect the spark plug for wear, carbon

deposits and damage. (See Maintenance

if

Section) Replace the plug

or

fouled.

adjust,

bending the outer electrode. Do not pry

against the inner electrode

may be damaged.

Attach the spark tester as shown and verify

the tester gap is set at

Pull the starter and observe for spark. THE

SPARK MAY BE DIFFICULT TO SEE

WELL LIGHTED AREAS.

A

been spilled or inflammable vapors may

exist.

If

shooting chart. (Page

OR

if

necessary, to

CAUTION:

spark where gasoline has

A

fire could result.

no spark is viewed, refer to the trouble-

111-4)

BRAKE

INJURY MAY RESULT. To troubleshoot

AND IGNITION SWITCH

IN

PROPER WORKING CONDI-

damaged, burnt,

.8

mm

or

the insulator

4.2

mm (.166 in).

Do

not test for

(.032

in) by

IN

BE

Figure

3-1

1. Remove the fuel tank for ease of inspection.

(See Disassembly Instructions page IV-1).

2.

Ensure that the brake spring forces the brake

pad against the flywheel when the control

bar is in the ‘STOP” position and that the pad

clears the flywheel when the control bar is in

the ‘START” position.

111-1

Page 18

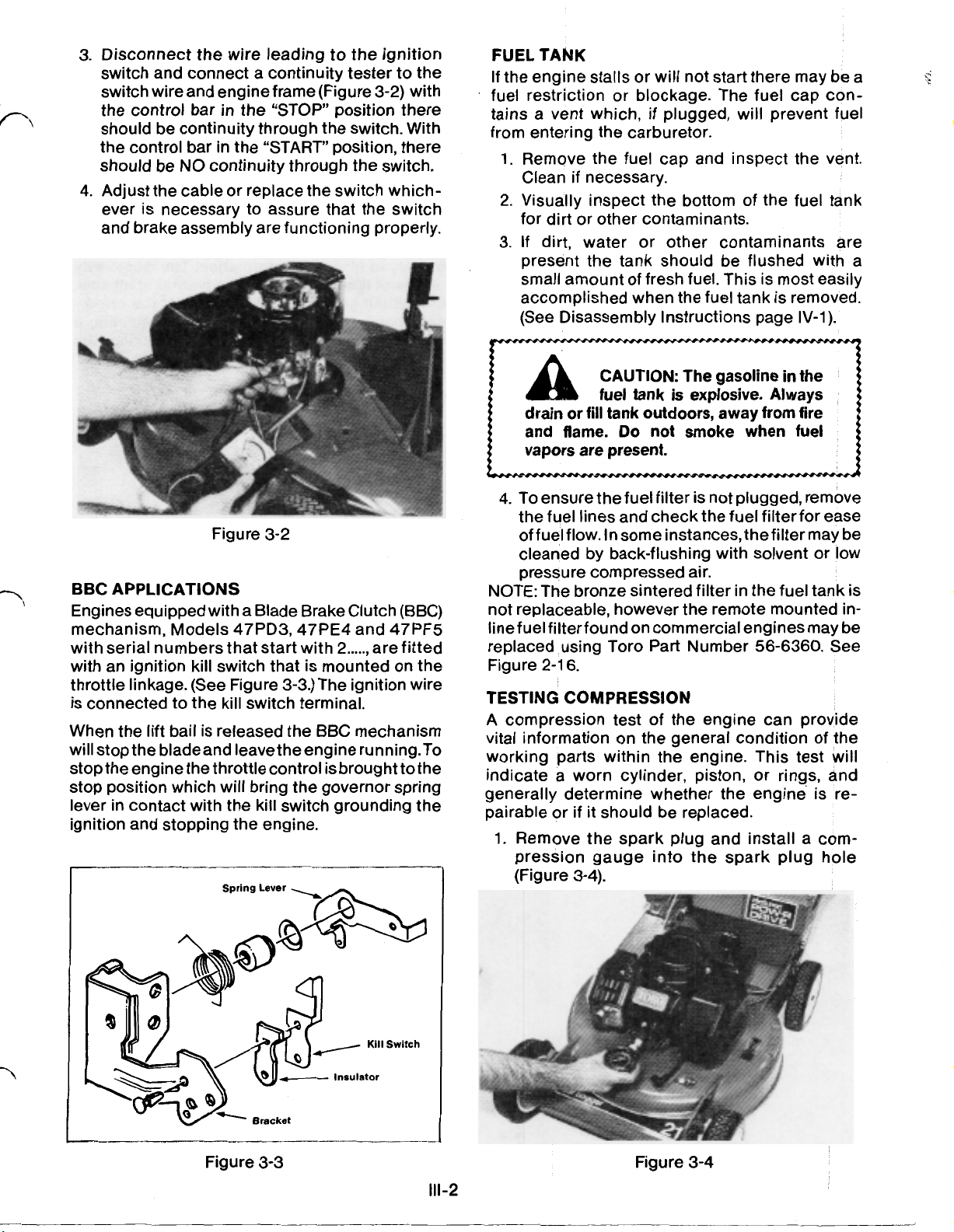

Disconnect

3.

switch and connect a continuity tester to the

switch wire and engine frame (Figure

the control bar in the

should be continuity through the switch. With

the control bar in the “START” position, there

should be

4.

Adjust the cable

ever is necessary to assure that the switch

and brake assembly are functioning properly.

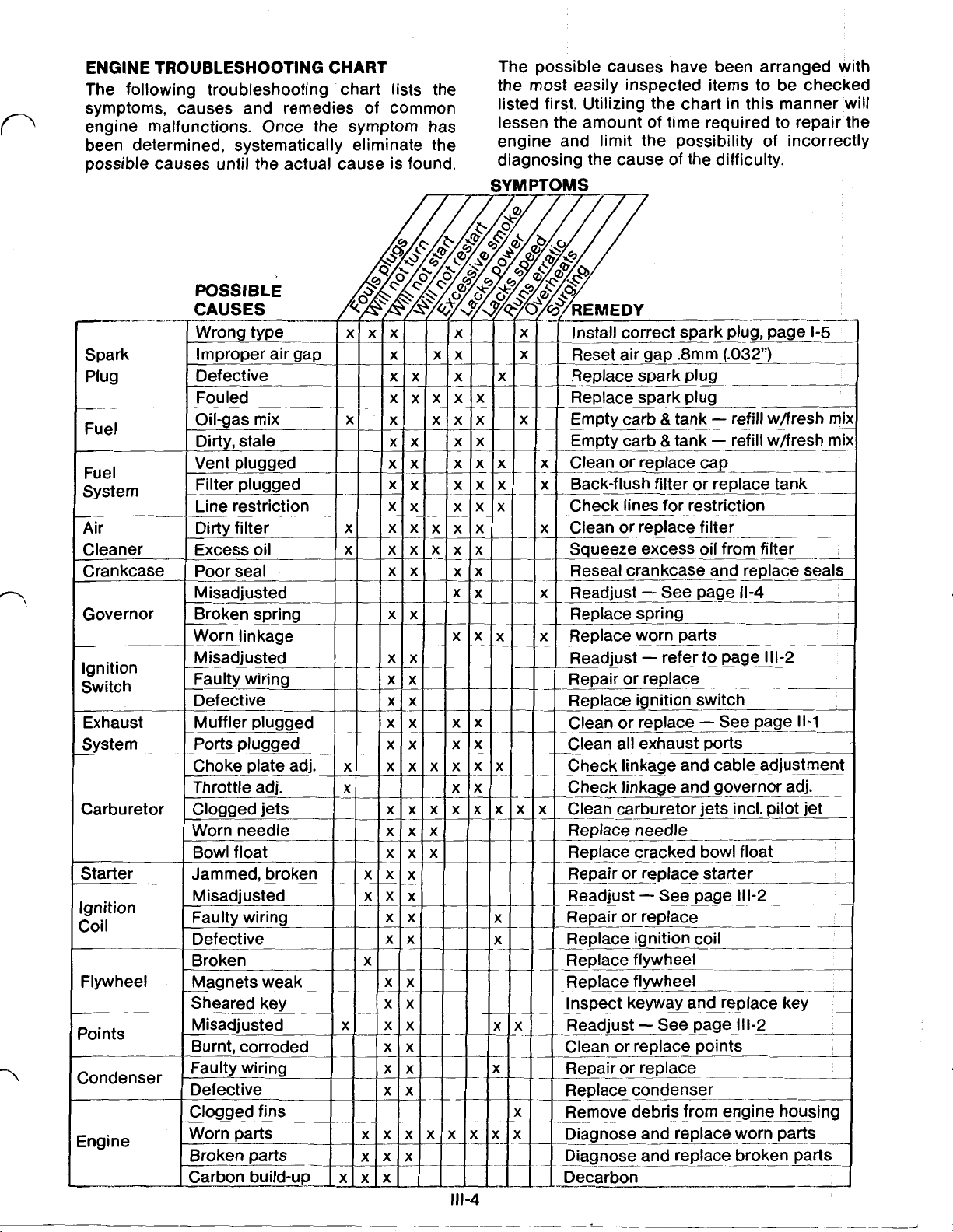

BBC

APPLICATIONS

Engines equipped with a Blade Brake Clutch (BBC)

mechanism, Models 47PD3,47PE4 and 47PF5

with serial numbers that start with

with an ignition kill switch that is mounted on the

throttle linkage. (See Figure

is connected to the kill switch terminal.

When the lift bail is released the BBC mechanism

will stop the blade and leave the engine running. To

stop the engine the throttle control is brought to the

stop position which will bring the governor spring

lever in contact with the kill switch grounding the

ignition and stopping the engine.

I

the

wire leading to the ignition

“STOP”

NO

continuity through the switch.

or

replace the switch which-

Figure

3-2

position there

2.....,

3-3.)

The ignition wire

Spring

Lever

3-2)

with

are fitted

FUEL TANK

If

the engine stalls or will not start there may be a

fuel restriction or blockage. The fuel cap contains a vent which,

from entering the carburetor.

Remove the fuel cap and inspect the vent.

1.

if

Clean

Visually inspect the bottom of the fuel tank

2.

for dirt or other contaminants.

If

3.

present the tank should be flushed with a

small amount of fresh fuel. This is most easily

accomplished when the fuel tank is removed.

(See Disassembly Instructions page

a

drain

and flame.

vapors are present.

4. To ensure the fuel filter is not plugged, remove

the fuel lines and check the fuel filter for ease

necessary.

dirt, water

CAUTION: The gasoline in the

fuel tank

or

fill

if

plugged, will prevent fuel

or

other contaminants are

is

explosive. Always

tank outdoors, away from fire

Do

not smoke when fuel

of fuel flow. In some instances, the filter may be

cleaned by back-flushing with solvent or low

pressure compressed air.

NOTE:

not replaceable, however the remote mounted inline fuel filter found on commercial engines may be

replaced using Toro Part Number 56-6360. See

Figure

TESTING COMPRESSION

A

vital information on the general condition of the

working parts within the engine. This test will

indicate a worn cylinder, piston,

generally determine whether the engine is repairable

I

The bronze sintered filter in the fuel tank is

2-1

6.

compression test of the engine can provide

or

or

if

it should be replaced.

1.

Remove the spark plug and install a compression gauge into the spark plug hole

(Figure 3-4).

IV-1).

rings, and

Figure

Bracket

3-3

Kill

Switch

Figure 3-4

111-2

Page 19

2.

Pull the starter rope rapidly several times

until the compression reading on the gauge

stabilizes.

3.

If

thecompression reading is below

(92

psi),

cylinder,

be suspected.

kps-cm2

(1

20

piston or ring damage should

A

new engine should have

psi)

1

0.5

kps-cm2

(1

6.5

50

psi).

kps-cm2

8.4

An engine with low compression must be disassembled and inspected for damage of the

internal components. (See Disassembly Instructions.) Check all components to the specifications listed in the Service Data Section of this

manual. Replace all parts which fall outside of

these specifications. The engine contains a cast

iron cylinder liner, which is not replaceable.

Special factory processes are required to install

this liner.

CRANKCASE

The engine relies on a tightly sealed crankcase

in order to function properly. The downward

movement of the piston causes the crankcase to

be pressurized. This pressure is required to

expell the exhaust gases from the combustion

chamber and to supply a fresh fuel mixture for

the compression stroke. The upward movement

of the piston on the compression stroke creates

a vacuum to draw fresh fuel into the crankcase.

In both instances a tightly sealed crankcase is

the key to efficient performance. The most likely

places of leakage are at the governor shaft seal,

crankshaft seals and at the seam of the crankcase halves. The simplest means

of

detecting a

crankcase leak is to check for wet, oily deposits

around the seal areas.

111-3

Page 20

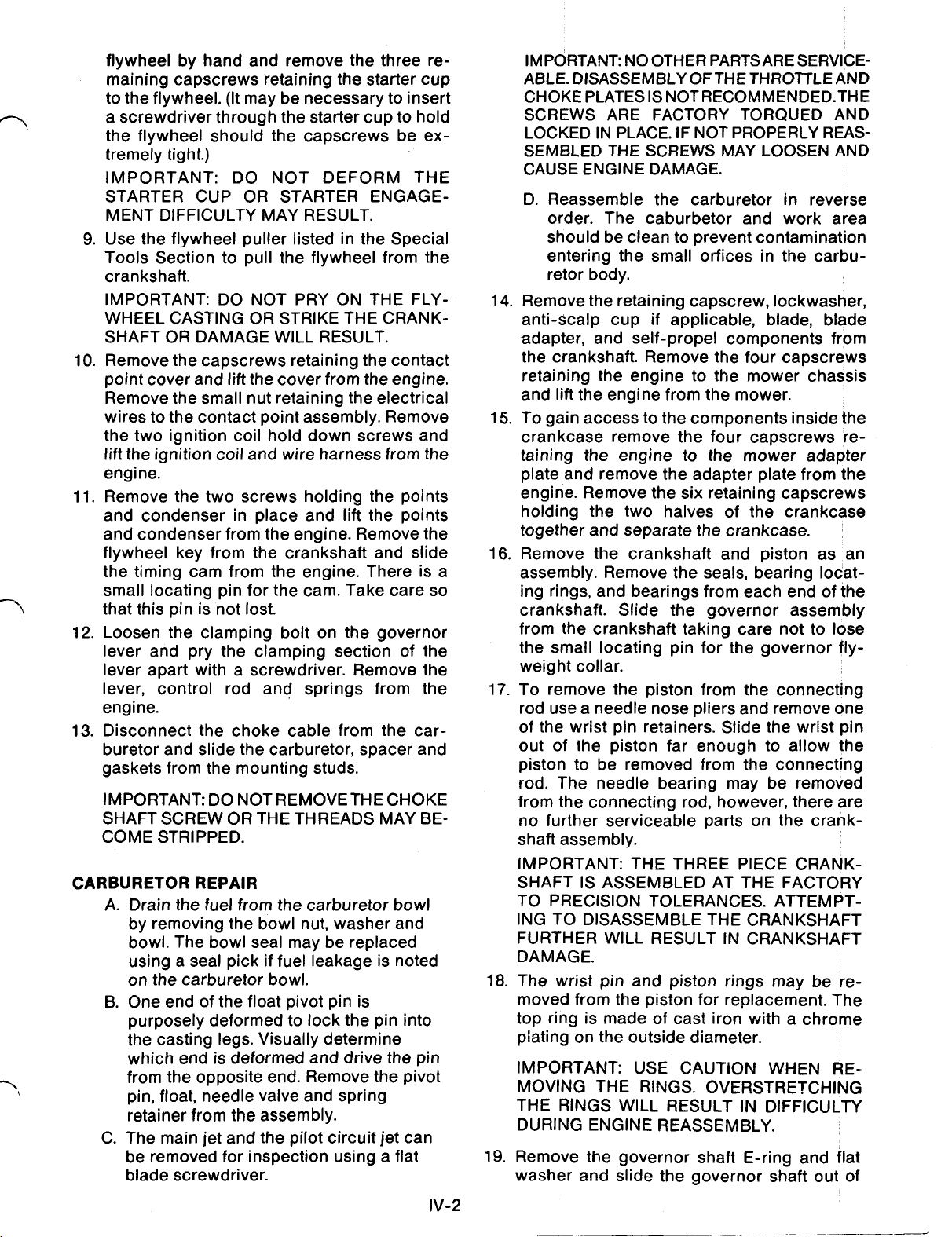

ENGINE TROUBLESHOOTING CHART

The following troubleshooting chart lists the

symptoms, causes and remedies of common

engine malfunctions. Once the symptom

been determined, systematically eliminate the

possible causes until the actual cause is found.

The possible causes have been arranged with

the most easily inspected items to be checked

listed first. Utilizing the chart in this manner

Of

lessen the amount

engine and limit the possibility

diagnosing

the

cause of

time required to repair the

Of

incorrectly

the

difficulty.

SYMPTOMS

Will

Install correct spark plug, page

1-5

Reset air gap .8mm (.032")

Replace spark plug

__-

Replace spark plug

Empty carb

&

tank refill w/fresh

Empty carb &tank refill w/fresh mi)

Clean or replace cap

__-

Check lines for restriction

Clean

Squeeze excess oil

or

replace filter

from

filter

Reseal crankcase and replace seals

Readjust See page

Readjust refer

11-4

to

page 111-2

Replace ignition switch

Clean

replace See page

11-1

or

Clean all exhaust ports

Check linkage and cable adjustment

Check linkage and governor adj.

111-4

Replace needle

____-._-

Replace cracked bowl float

Repair or replace starter

Repair or replace

_-

Replace ignition coil

Replace flywheel

d replace worn parts

Diagnose and replace broken parts

Page 21

IV.

ENGINE

REMOVAL,

DISASSEMBLY

ASSEMBLY AND

REPAIR

ENGINE REMOVAL

To remove the engine from the mower the air

cleaner housing, recoil assembly and fuel tank

must first be removed to disconnect the control

cables. Remove the retaining capscrew, lockwasher, blade, blade adapter and self-propel

components below the mower deck from the

engine crankshaft. Remove the four capscrews

that retain the engine to the mower chassis and

remove the engine from the mower. The engine

can then be placed in a support fixture for repair.

Most common repairs, however, can be accom-

plished with the engine in place on the mower

chassis. Use the following procedures to dis-

assemble the engine on the mower chassis:

ENGINE DISASSEMBLY AND REPAIR

1. Remove the high tension wire from the spark

plug and drain the fuel from the fuel tank.

INSTRUCTIONS

iS

Center Spring Pawl Spring

Center Spring Pawl Spring

/-

Pawl Retainer-

Pawl Retainer-

Figure

4-1

CAUTION: The gasoline in

A

Always drain

away from fire and flame. Do not

smoke when fuel vapors are present.

2. Remove the four retaining capscrews from

the recoil starter and

engine. Disconnect the recoil rope from the

rope handle stop for ease of handling.

RECOIL STARTER REPAIR

A.

Remove the center capscrew from the

recoil assembly and lift

tainer. Remove the center spring, pawl

and pawl spring. Lift the rope pulley

assembly from the recoil housing and

remove the recoil spring and retainer

(Figure 4-1).

B.

Replace all worn or damaged parts before

reassembling. Reassemble the recoil

starter in reverse order. Use Threebond

#1342

the center capscrew during reassembly

and torque to 80-90Kg-Cm

On installation there should be sufficient

spring pretension to hold the recoil rope

taut in the rope pulley.

NOTE: Place a small amount of #2 grease on the

recoil spring to prevent rust and corrosion.

the fuel tank

or

or Loctite #242 on the threads of

is

explosive.

fill

tank outdoors,

lift

the starter from the

off

the pawl re-.

(70-1

10 in-lb).

IV-

3.

Disconnect the fuel line from the carburetor.

Remove the fuel tank by lifting it from the

mounting tabs of the blower housing.

4.

Remove the capscrew, two nuts and lock

washers which retain the muffler and remove

the muffler from the engine. The heat shield

may also be removed from the muffler. Discard the muffler gasket and remove any

gasket material remaining on the engine or

muffler.

5.

Lift the retaining tabs of the air cleaner cover

and remove the cover and filter element.

Remove the capscrew, and two locknuts

retaining the air cleaner housing and lift the

housing from the engine.

6.

Remove the remaining three capscrews from

the blower housing and lift the blower hous-

ing from the engine.

7.

Cage the spring activated engine brake by

compressing and retaining the control bar

against the operating handle. Remove the

capscrew holding the ignition switch and

brake assembly in place. Disconnect the

ignition switch from the electrical lead and

remove the switch from the brake assembly.

Slowly lower the control bar to disengage

the brake. The brake assembly may now be

disconnected from the control cable for

repair.

8.

Use a starter cup wrench as shown in the

Special

while loosening the flywheel nut. Hold the

1

Tools

List to hold the starter cup

r-

Page 22

flywheel by hand and remove the three remaining capscrews retaining the starter cup

to the flywheel. (It may be necessary to insert

a screwdriver through the starter cup to hold

the flywheel should the capscrews be extremely tight.)

IMPORTANT: DO NOT DEFORM THE

STARTER CUP OR STARTER ENGAGEMENT DIFFICULTY MAY RESULT.

9.

Use the flywheel Duller listed in the Special

Tools Section to pull the flywheel from the

crankshaft.

IMPORTANT: DO NOT PRY ON THE FLYWHEEL CASTING OR STRIKE THE CRANKSHAFT OR DAMAGE WILL RESULT.

Remove the capscrews retaining the contact

10

point cover and lift the cover from the engine.

Remove the small nut retaining the electrical

wires to the contact point assembly. Remove

the two ignition coil hold down screws and

lift the ignition coil and wire harness from the

engine.

Remove the two screws holding the points

11

and condenser in place and lift the points

and condenser from the engine. Remove the

flywheel key from the crankshaft and slide

the timing cam from the engine. There is a

small locating pin for the cam. Take care

that this pin is not lost.

12.

Loosen the clamping bolt on the governor

lever and pry the clamping section of the

lever apart with a screwdriver. Remove the

lever, control rod and springs from the

engine.

13.

Disconnect the choke cable from the carburetor and slide the carburetor, spacer and

gaskets from the mounting studs.

IMP0RTANT: DO NOTREMOVETHECHOKE

SHAFT SCREW OR THE THREADS MAY BECOME STRIPPED.

CARBURETOR

REPAIR

A. Drain the fuel from the carburetor bowl

by removing the bowl nut, washer and

bowl. The bowl seal may be replaced

using a seal pick

if

fuel leakage is noted

on the carburetor bowl.

B.

One end of the float pivot pin is

purposely deformed to lock the pin into

the casting legs. Visually determine

which end is deformed and drive the pin

from the opposite end. Remove the pivot

pin, float, needle valve and spring

from

retainer

the assembly.

C. The main jet and the pilot circuit jet can

be removed for inspection using a flat

blade screwdriver.

so

IMPORTANT:

ABLE. DISASSEMBLY

CHOKE PLATES

NO

OTHER

OF

IS

NOT

PARTS ARE

THE THROTTLE AND

RECOMMENDED.

SCREWS ARE FACTORY TORQUED AND

LOCKED IN PLACE.

IF

NOT PROPERLY REASSEMBLED THE SCREWS MAY LOOSEN AND

CAUSE ENGINE DAMAGE.

D. Reassemble the carburetor in reverse

order. The carburetor and work area

should be clean to prevent contamination

entering the small orifices in the carburetor body.

14.

Remove the retaining capscrew, lockwasher,

anti-scalp cup

if

applicable, blade, blade

adapter, and self-propel components from

the crankshaft. Remove the four capscrews

retaining the engine to the mower chassis

and lift the engine from the mower.

15.

To gain access to the components inside the

crankcase remove the four capscrews re-

taining the engine to the mower adapter

plate and remove the adapter plate from the

engine. Remove the six retaining capscrews

holding the two halves of the crankcase

together and separate the crankcase.

16.

Remove the crankshaft and piston as an

assembly. Remove the seals, bearing locating rings, and bearings from each end of the

crankshaft. Slide the governor assembly

from the crankshaft taking care not to lose

the small locating pin for the governor flyweight collar.

17.

To remove the piston from the connecting

rod use a needle nose pliers and remove one

of the wrist pin retainers. Slide the wrist pin

out of the piston far enough to allow the

piston to be removed from the connecting

rod. The needle bearing may be removed

from the connecting rod, however, there are

no further serviceable parts on the crank-

shaft assembly.

IMPORTANT: THE THREE PIECE CRANK-

SHAFT

IS

ASSEMBLED AT THE FACTORY

TO PRECISION TOLERANCES. ATTEMPT-

ING TO DISASSEMBLE THE CRANKSHAFT

FURTHER WILL RESULT IN CRANKSHAFT

DAMAGE.

18.

The wrist pin and piston rings may be removed from the piston for replacement. The

top ring is made of cast iron with a chrome

plating on the outside diameter.

IMPORTANT: USE CAUTION WHEN RE-

MOVING THE RINGS. OVER-STRETCHING

THE RINGS WILL RESULT IN DIFFICULTY

DURING ENGINE REASSEMBLY.

19.

Remove the governor shaft E-ring and flat

washer and slide the governor shaft out of

SERVICE-

THE

IV-2

Page 23

the crankcase. Use a seal pick to remove the

governor shaft seal.

NOTE: The cylinder contains a cast iron sleeve,

however, this sleeve is not replaceable. The

purpose of the sleeve retainer ring is to assist the

manufacturing process and hold the cast iron

sleeve in place to limit engine damage should

the sleeve loosen during operation.

Engine Assembly And Repair

NOTE: Before attempting to reassemble the engine

refer to the Service Data Specifications (page IV-4)

and replace all parts which are outside the recommended values.

1.

Ensure there are no burrs on the governor

shaft which could cause seal damage and

position the governor shaft through the hole

in the crankcase casting. Use a liberal

amount of

#2

grease and install the governor

shaft seal with the lip towards the inside of

the crankcase. Position the flat washer on

the governor shaft against the shaft seal and

install the E-ring.

2.

Install the two piston rings onto the piston.

The chrome surfaced ring should be positioned at the top of the piston. There is a

small letter

‘R”

stamped on the top side of

each piston ring. This letter should face the

top of the piston.

upside down it

If

the piston ring is put in

will

not seat properly in the

ring groove. Lubricate the wrist pin needle

bearing with two-cycle oil and insert into the

connecting rod. Position the piston over the

connecting rod and insert the wrist pin

through the piston, needle bearing and piston rod. Insert the spring retainers to lock the

wrist pin in place.

IMPORTANT: THE ARROW CAST INTO THE

TOP

OF

THE PISTON

MUST

FACE THE

EXHAUST PORT WHEN ASSEMBLED.

3. Lubricate the moving parts and friction surfaces

of

the crankshaft and piston with twocycle oil. Rotate the piston rings until the ring

gap aligns with the locating studs before

attempting to push the piston into the

cylinder. Insert the crankshaft and piston

assembly into the cylinder.

IMP0RTANT:ASSURETHEARROWONTOP

OF THE PISTON FACES EXHAUST PORT

WHEN ASSEMBLED.

4.

Lubricate the large end of the crankshaft

with two-cycle oil and install the sliding

governor collar. Insert the small locating pin

into the crankshaft and slide the flywheel

collar into position. Position the fly weights

on the lip of the governor collar and locate

the control shaft between the collar and the

crankshaft assembly (See Figure 2-1

3

and

4-2). Lubricate the crankshaft bearings with

IV-3

two-cycle

oil

and install onto either end

crankshaft. Insert the bearing locating rings

into the slots of the crankcase housing to

locate the bearings and crankshaft in position.

Removeburrsfromeitherendofthecrankshaft

and slide seals into position. To prevent seal

damage on installation use a small amount of

#2 grease on the inside diameter of the seal.

Both seals should be installed with the lipfac-

ing into the crankcase assembly.

r-

Figure 4-2

5.

Assure both halves of the crankcase are clean

and free of grease and old sealant. Apply a thin

uniform amount of Threebond #1104

tite #515 sealant to the mating surfaces and

position of the crankcase halves together.

6.

There are three different size capscrews on

the model 47PZ2 to hold the crankcase halves

together.(Thecapscrewson

and 47PF5 are all the same length). Starting on

the governor control shaft side install the

medium sized capscrews at either end. Install

one short capscrew and governor spring

bracket in thecenter hole. Install the other

remaining short capscrews into the other side

in the center hole and the hole nearest the

large end

of

the crankshaft. Install the long

capscrew in the remaining hole. Torque all

capscrews evenly

80-95

See Figure 4-3. Position the engine mower

Torque

Capscrews

47P22

to

80-95

Figure 4-3

the47PD3,47PE4

Kg-Cm (70-1

Only

KaCm

(70-1

10

10

in-lb).

of

or

Loc-

in-lb).

the

n

P

two

two

Page 24

adapter plate with the dimple facing the spark

plug end. Install the four retaining capscrews

and torque to the proper specification.

Install the ignition cam and locating pin to the

7.

flywheel end of the crankshaft. Install the condenser and points in position. Rotate the

shaft until the cam follower is on the high point

of the cam. Adjust the point gap using a feeler

gauge of the appropriate size to set the air gap

at

.35

mm (.014 in). (47PZ2 engine only.)

Install the ignition coil loosely on the mount-

8.

ing posts. Connect the double lead to the

contact point assembly (47PZ2 engine only),

making sure the wires are routed between

the ignition coil mounting posts. The single

lead should be routed along side of the

crankcase housing through the hole in the

casting. The ignition coil air gap setting will

be adjusted later.

Place the gasket, spacer and the second gas-

9.

ket over the mounting studs of the carburetor.

2-18

See Figure

for correct gasket and spacer

placement. Slide the carburetor onto the

mounting studs. Assemble the governor con-

trol lever, linkage and springs to the governor

shaft and the carburetor throttle plate. Move

the governor shaft to the right and rotate the

governor shaft to the right. Tighten the clamp

bolt to hold the adjustment.

Install the contact point cover (47PZ2 engine

10.

only), flywheel key and flywheel to the crankshaft. Install thestartercupwith thecapscrews

and torque to

80-90

Kg-Cm (70-1 10 in-lb). Use

the starter cup wrench to hold the flywheel

from turning and tighten the’

retaining

the end of crankshaft to 4-5 Kg-m (29-36 f3-lb).

Use the air gap gauge listed in the Special

Tools Section and adjust the air gap between

the flywheel and ignition coil laminations to

mm (.020 in) maximum.

crank-

nut on

.5

crankshaft. The blade retaining capscrew

should be tightened to 6.2-8.3 Kg-m (45-60

ft-llb).

12. Cage the engine brake spring by lifting the

control bar into the handle and retaining it in

place. Install the ignition switch, brake assembly and brake pad on the engine. Release the

control bar and connect the ignition switch

wire. (47PZ2 and zone start models only.)

IMPORTANT: CHECK

ATION

OF

THE IGNITION SWITCH

FOR

PROPER OPER-

AND

BRAKE ASSEMBLY (See Troubleshooting

Section page 111-1

13.

Place the blower housing on the engine and

).

attach with one capscrew in the front and

another in the rear.

NOTE: USE CAUTION IN ROUTING THE

HIGH TENSION WIRE

SO

THAT IT DOES

NOT BECOME PINCHED BETWEEN THE

BLOWER HOUSING AND THE ENGINE.

14. Place the muffler and muffler gasket over the

engine studs. Install the through-bolt, nuts

and lock washers on the muffler and tighten

to the recommended torque.

15. Connect the choke cable to the carburetor

and camp the cable in place on the blower

housing. Install the air cleaner housing to the

carburetor mounting studs using the appropriate nuts. Install the through-bolt and

tighten the bolt and nuts to the recom-

mended torque. Position the filter element in

place and install the air cleaner cover. En-

sure the cover snaps firmly in place.

16. Slide the fuel tank into position and connect

the fuel line to the carburetor. Attach the

recoil assembly using the four capscrews

required and route the starter rope through

the handle stop on the mower handle.

Attach the engine to the mower chassis and 17. Install the spark plug and attach the high

11.

install the blade components to the engine

tension wire.

SERVICE DATA SPECIFICATIONS

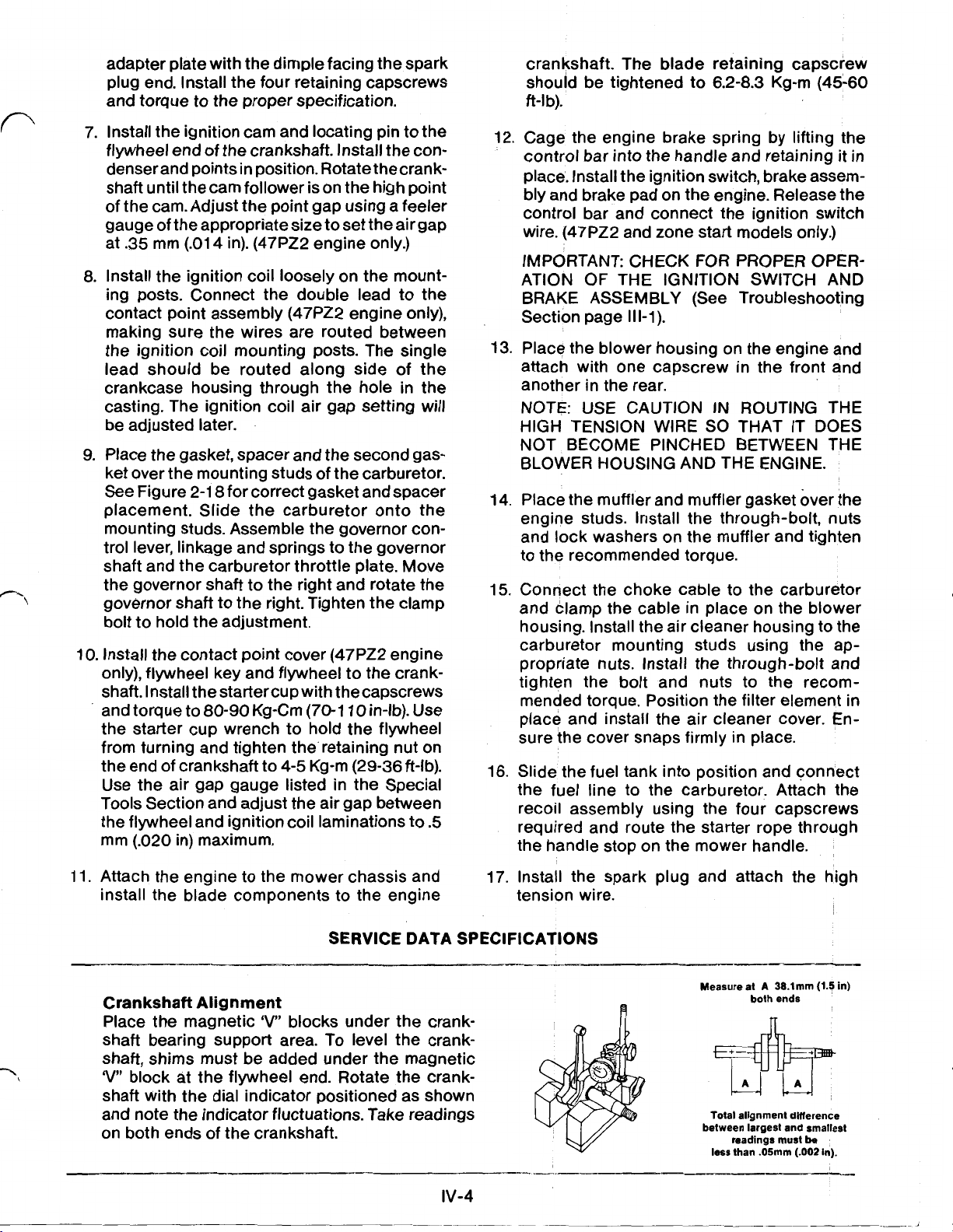

Crankshaft Alignment

Place the magnetic

‘V”

Measure at

blocks under the crank-

A

38.lmm

both ends

shaft bearing support area. To level the crank-

shaft, shims must be added under the magnetic

V”

block at the flywheel end. Rotate the crankshaft with the dial indicator positioned as shown

and note the indicator fluctuations. Take readings

on both ends of the crankshaft.

Total alignment difference

between largest and smallest

readings

less

must

than .05mm (.002

IV-4

be

(1.5

in)

in).

Page 25

Cylinder bore

The cylinder bore is checked by measuring the

cylinder liner at a total of six places using a

cylinder gauge. Two measurements, apart,

must be taken at the approximate

A,

6

and

C

elevations as shown. Readings larger than the

listed specifications indicate an excessively

worn bore and the cylinder block must be replaced. The cylinder liner is not a serviceable

part of the engine.

Piston to Cylinder Clearance

The piston is cam ground into a slightly oval

shape to compensate for heat distortion during

operation. The piston diameter is measured perpendicular to the wrist pin hole at a point above

the piston skirt as indicated. Subtract the piston

measurement from the largest cylinder reading

to determine the clearance. Replace the cylinder

block or the piston if the clearance is excessive.

Exhaust Port

Largest Cylinder Diameter minus