Toro 144-1620 Installation Instructions

HDDriveLinkKit

144-1620

HD-Antriebsverbindungskit

144-1620

Kitbielletted'entraînementhauterésistance

144-1620

Heavy-dutyaandrijfkoppeling

144-1620

FormNo.3443-146RevA

www.T oro.com.

*3443-146*

HDDriveLinkKit

ModelNo.144-1620

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3443-134RevA

InstallationInstructions

Description

Nopartsrequired

Tractionplate1

Traction-cablebracket1

Bolt2

Nut2

Tractionrod1

PreparingtheMachine

1.Movethemachinetolevelsurface.

2.Shutofftheengine,removethekey,andwaitfor

allmovingpartstostop.

3.Disconnectthespark-plugwire.

InstallingtheKit

InstallingtheTractionPlateand

Bracket

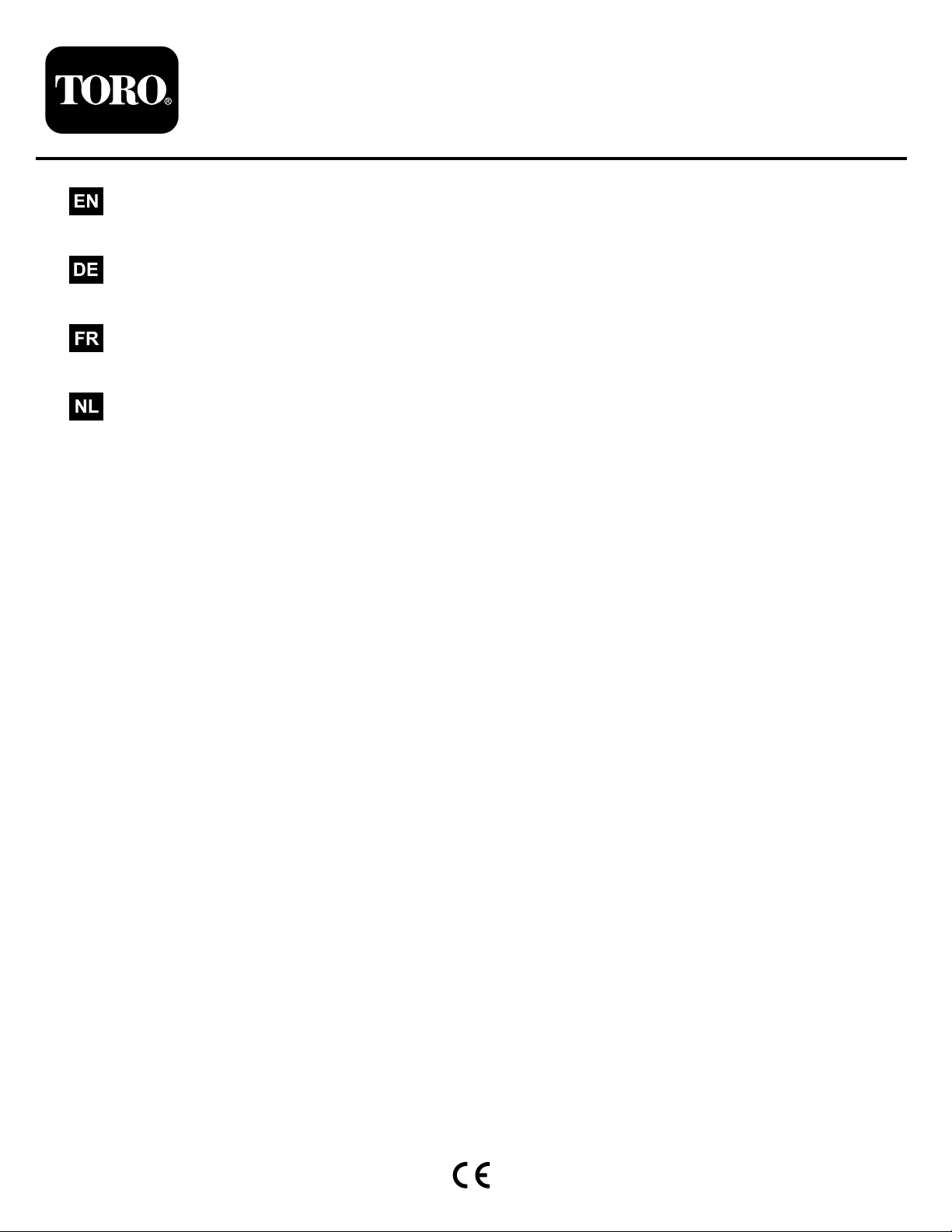

1.Removethe2screwsthatareholdingthebelt

coverinplace(Figure1).

Qty.

Use

–

Preparethemachine.

Installthekit.

g260066

Figure1

2.Removethebeltcover(Figure1).

©2020—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

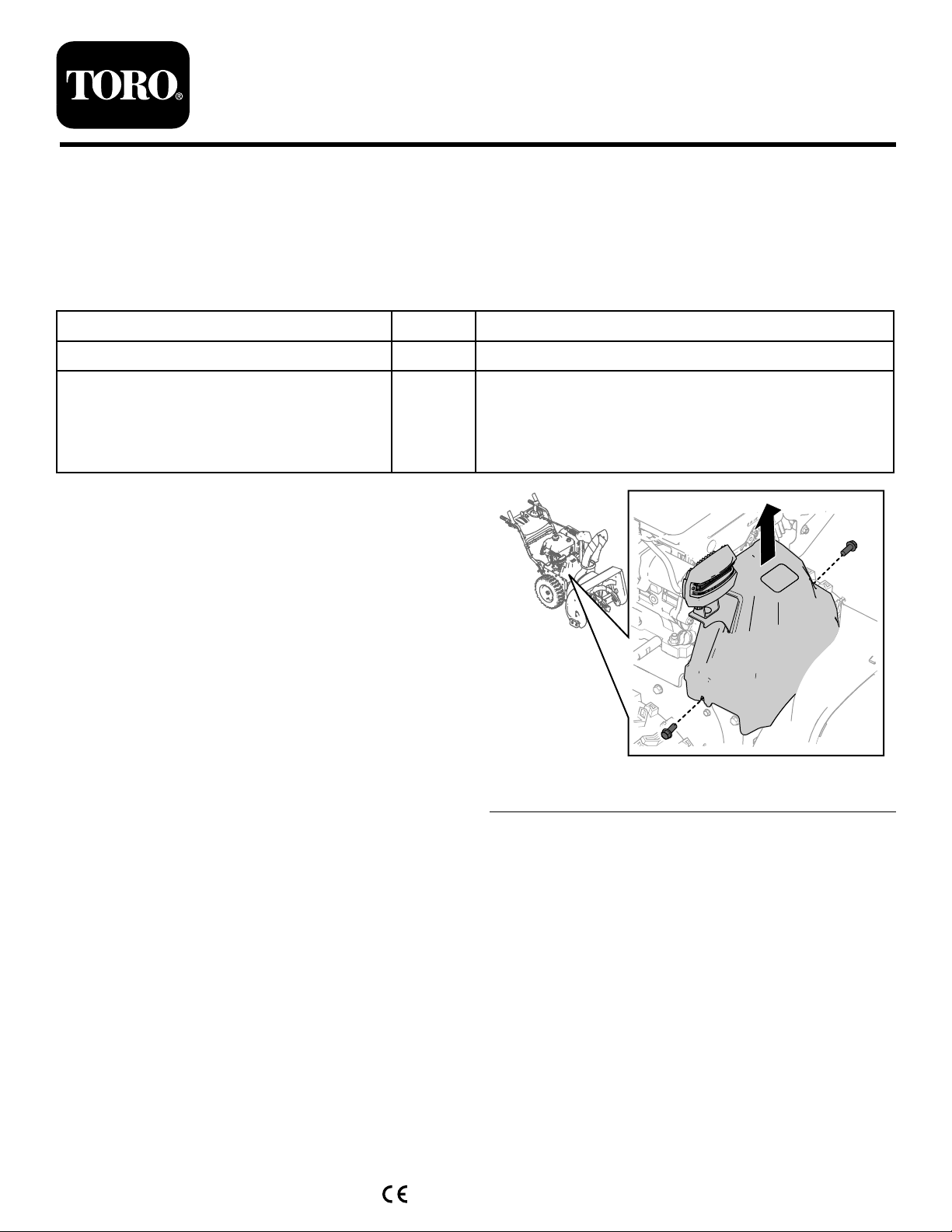

3.Unhookthespringfromtheexistingtraction

plate(Figure2).

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3443-134*

Figure2

g340063

1.Existingtractionplate

2.Spring

4.Removetheexistingtractionplatefromthe

frictionwheelplatebyremovingtheboltholding

itinplace(Figure3).

Figure3

1.Tractionplatebolt2.Existingtractionplate

g340065

Figure4

1.Tractionplatebolt2.Newtractionplate

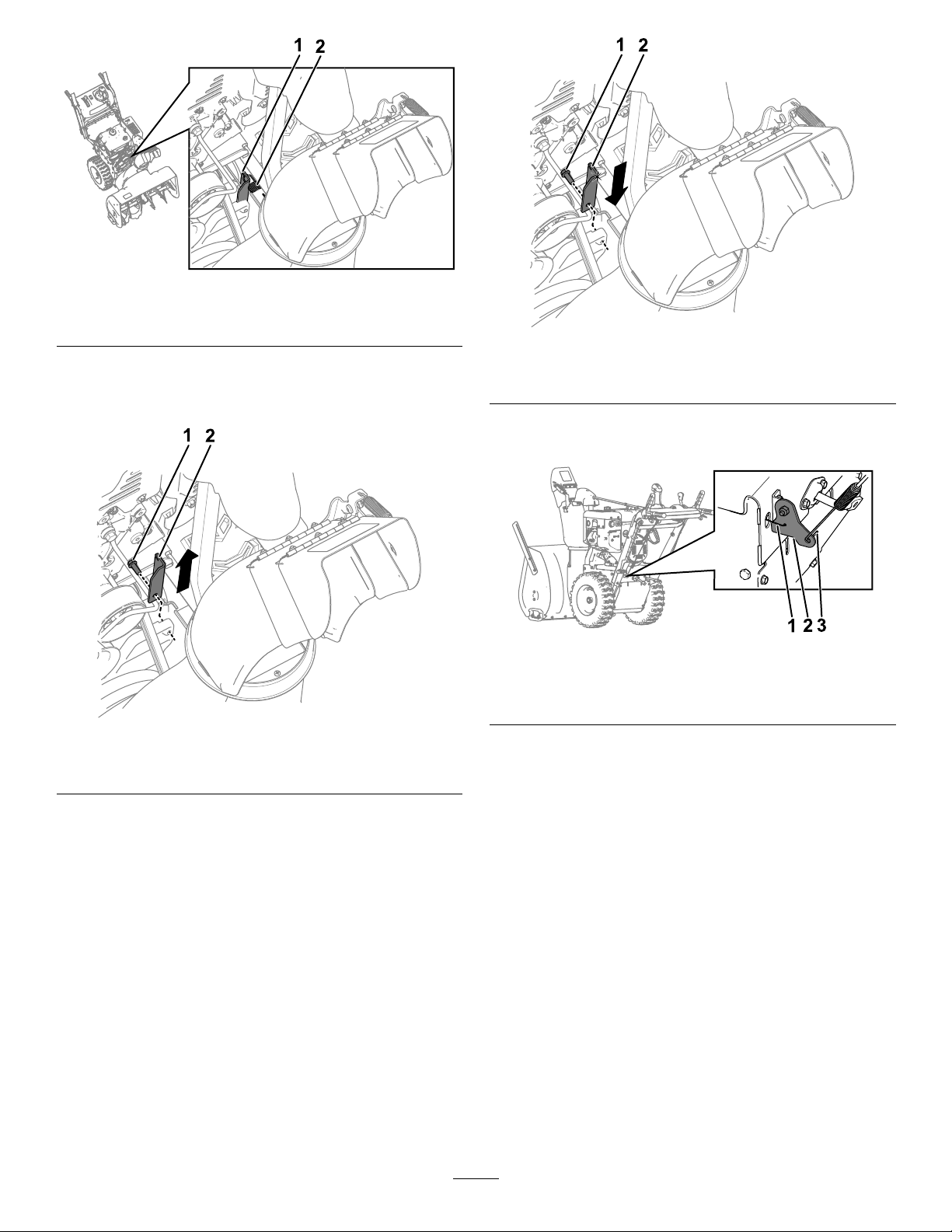

6.Intherearofthemachine,unhookthetraction

cablefromthetraction-cablebracket(Figure5).

g340066

Figure5

1.Tractionrod3.Tractioncable

2.Traction-cablebracket

g340064

7.Unhookthetractionrodfromthetraction-cable

bracketandslidetherodoutthebackofthe

machine.

5.Installthenewtractionplateonthefrictionwheel

plateusingthepreviouslyremovedbolt(Figure

4).

8.Removetheexistingtraction-cablebracketfrom

thecrankbracketbyremovingtheboltandnut

holdingitinplace(Figure6).

2

Figure6

1.Crankbracket

2.Bolt4.Existingtraction-cable

3.Nut

bracket

9.Installthenewtraction-cablebracketonthe

crankbracketusingthepreviouslyremovedbolt

andnut.

10.Hookthetractioncableonthenewtraction-cable

bracketasshowninFigure7.

Note:Ensurethatthetractioncableisoriented

asshowninFigure7.

g340092

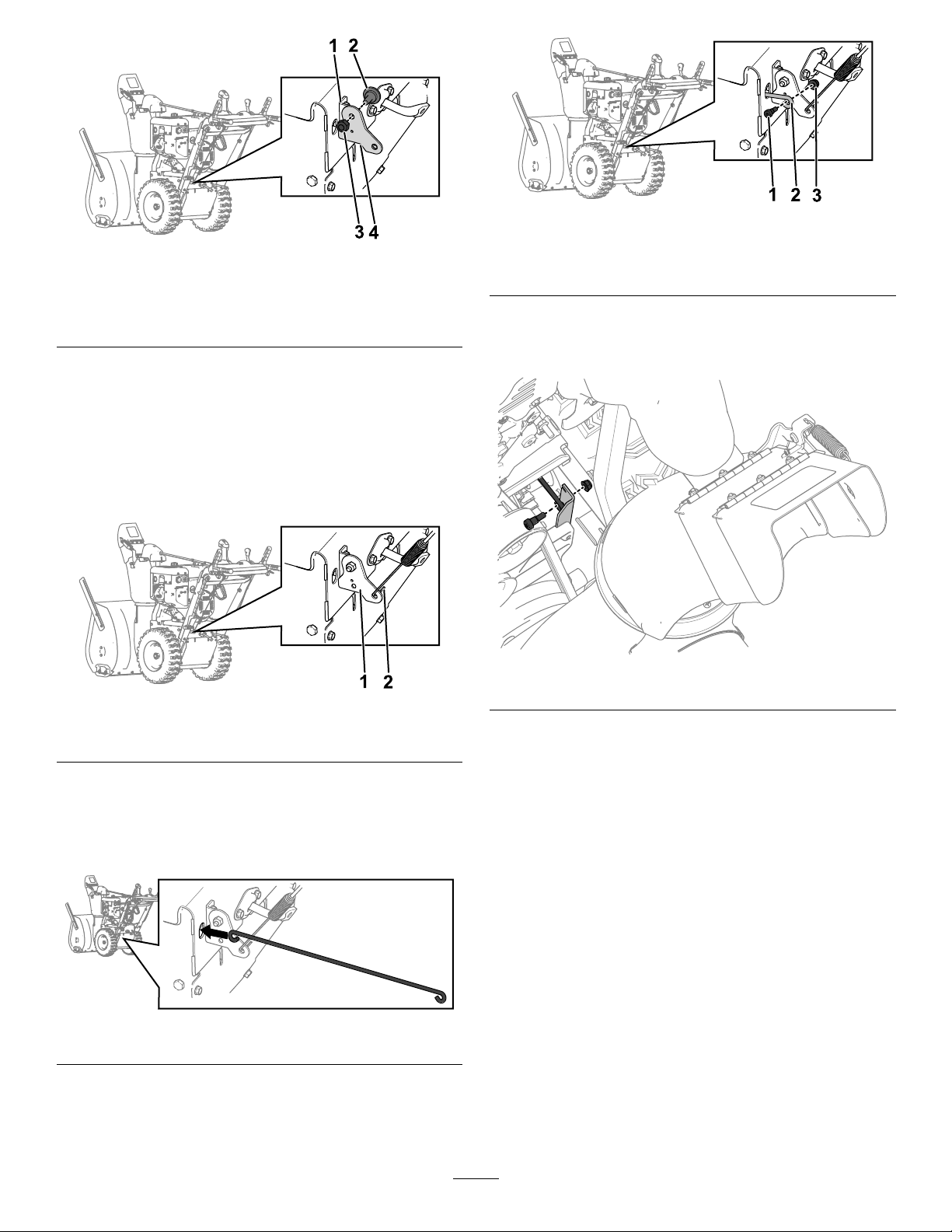

Figure9

g340089

1.Bolt3.Nut

2.Tractionrod

3.Connecttheotherendoftherodtothenew

tractionplateusingaboltandnutincludedwith

thiskit(Figure10).

Figure7

1.Newtraction-cablebracket2.Tractioncable

InstallingtheTractionRod

1.Insertthenewtractionrodthroughtherearof

themachine(Figure8).

Figure8

2.Connecttheoneendoftherodtothenew

traction-cablebracketusingaboltandnut

includedwiththekitasshowninFigure9.

g340093

Figure10

g340090

CompletingtheInstallation

1.HookspringthewasremovedinStep3of

InstallingtheTractionPlateandBracket(page

1)onthenewtractionplate.

2.Installthebeltcoveronthemachineusingthe2

correspondingscrews.

3.Installthesparkplugwire.

4.Checktheoperationofthetractioncableand

adjustitifneeded;refertoCheckingand

AdjustingtheTractionCable(page4).

g340091

3

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst2hours

Yearly

MaintenanceProcedure

•Aftertherst2hours—Inspectthetractioncableandadjustitifnecessary.

•Inspectthetractioncableandadjustorreplaceitifnecessary.

ControlsSystem

Maintenance

CheckingandAdjustingthe

TractionCable

ServiceInterval:Aftertherst2hours—Aftertherst

2hours—Inspectthetractioncable

andadjustitifnecessary.

Yearly—Inspectthetractioncableandadjustor

replaceitifnecessary .

Ifthemachinedoesnotdriveintheforwardorreverse

speedsoritdriveswhenyoureleasethetractionlever,

adjustthetractioncable.

Withthetractionleverdisengaged,ensurethatthe

bottomofthetraction-cablebracketistouchingthe

frameofthemachine(Figure11).

2.Loosenortightentheturnbuckletountilthe

cableistaughtandthebottomofthebracket

touchestheframeofthemachine.

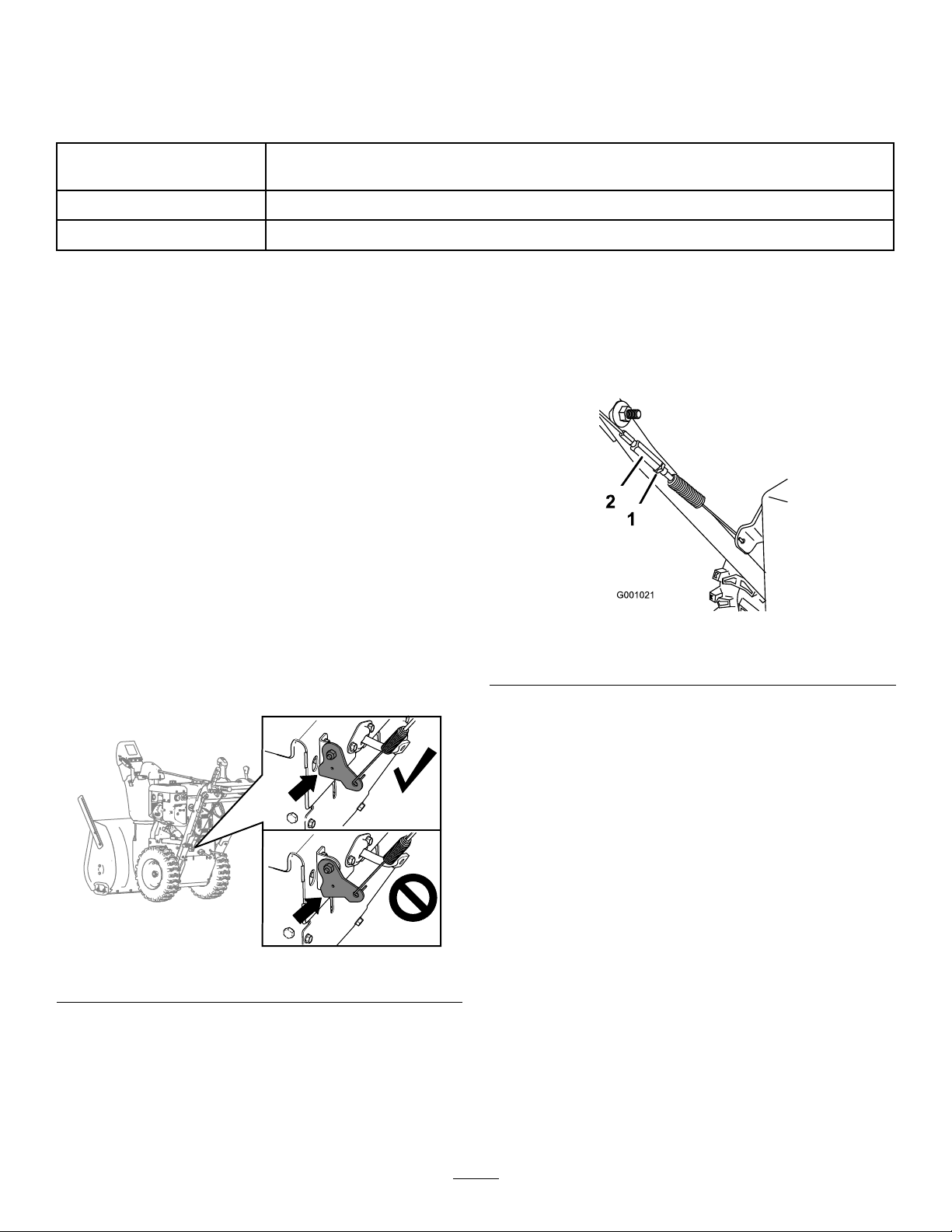

3.Tightenthejamnut(Figure12).

g001021

Figure12

1.Jamnut2.Turnbuckle

Figure11

Ifthebottomofthetraction-cablebracketisnot

touchingtheframeofthemachine,theleft(traction)

cableisnotproperlyadjusted.

Toadjustthetractioncable,dothefollowing:

1.Loosenthejamnut.

g259431

4

Loading...

Loading...