Toro 132-3118 Parts Catalogue

©2014 Arctic Cat Inc. ®™Trademarks of Arctic Cat Inc. Thief River Falls, MN 56701

Operator’s Manual

Installation Instructions

Replacement Parts List

TREUIL

3000

p/n 2260-452

n/p 2260-452

©2014 Arctic Cat Inc. ®™Marques déposées d’Arctic Cat Inc. Thief River Falls, MN 56701

3000

WINCH

Manuel de l’opérateur

Instructions d’installation

Liste des pièces de rechange

3000 lb winch eng.fm Page 0 Wednesday, August 27, 2014 2:59 PM

LIMITED WARRANTY

Arctic Cat Inc. (hereinafter referred to as Arctic Cat) extends a limited warranty on each new Arctic Cat / WARN

Cat dealer.

Arctic Cat warrants only the products it manufactures and/or sells and does

not warrant that other products will function properly when used with an

Arctic Cat vehicle or will not damage the vehicle. Arctic Cat does not

assume any liability for incidental or consequential damages.

Arctic Cat will repair or replace, at its option, free of charge (including any

related labor charges), any parts that are found to be warrantable in material

or workmanship. This repair work MUST be done by an authorized Arctic

Cat dealer. No transportation charges will be paid by Arctic Cat. The warranty is validated upon examination of said parts by Arctic Cat or an authorized Arctic Cat dealer. Arctic Cat reserves the right to inspect such parts at

its factory for final determination if warranty should apply.

This warranty does not apply if the winch has been damaged by accident,

abuse, misuse, collision, overloading, exhaust or misapplication, or has been

improperly serviced. The finish and synthetic rope on the winch are

excluded from warranty. In addition commercial or industrial use or application or any hoisting application voids the entire warranty.

In consideration of the foregoing, any implied warranty is limited in duration

to the various warranty periods set forth. This warranty gives you specific

legal rights, and you may also have other rights which vary from state to

state or country to country. Some states do not allow limitations on how long

an implied warranty lasts, so the above limitations may not apply to you.

® Winch sold by an authorized Arctic

The Safety Alert Symbol means ATTEN-

!

! WARNING

CAUTION

NOTE:

WARN® and the WARN logo are trademarks of WARN Industries Inc.

TION! BE ALERT! YOUR SAFETY IS

INVOLVED.

Failure to follow WARNING instructions

could result in severe injury or death to the

vehicle/winch operator, a bystander, or a person inspecting or repairing the vehicle or

winch.

A CAUTION indicates special precautions

that must be taken to avoid damage to the

vehicle.

A NOTE provides key information to make

procedures easier or more clear.

3000 lb winch eng.fm Page 1 Wednesday, August 27, 2014 2:59 PM

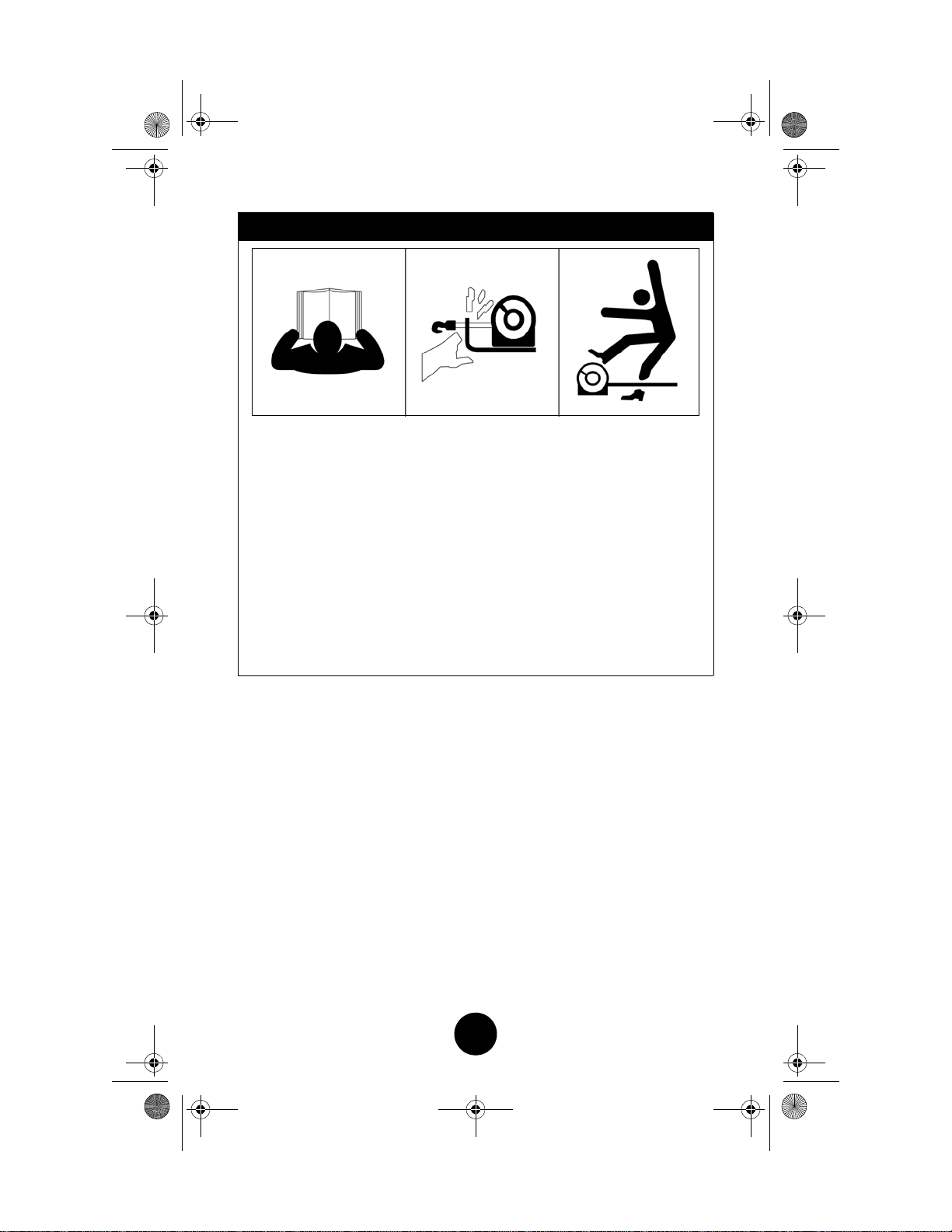

SAFETY PRECAUTIONS

! WARNING

MOVING PART HAZARD

TO PREVENT SERIOUS INJURY AND PROPERTY DAMAGE:

• Do not operate or install winch without reading an d understanding the

Operator’s Manual.

• Keep hands clear of wire cable, hook, and fairlead opening during

operation and when spooling.

• Stand clear of wire cable and load during operation.

• Keep others away.

• Always inspect winch installation and wire cable condition before

operating winch.

• Do not exceed winch rated capacity.

• Never touch wire cable or hook while in tension.

1

3000 lb winch eng.fm Page 2 Wednesday, August 27, 2014 2:59 PM

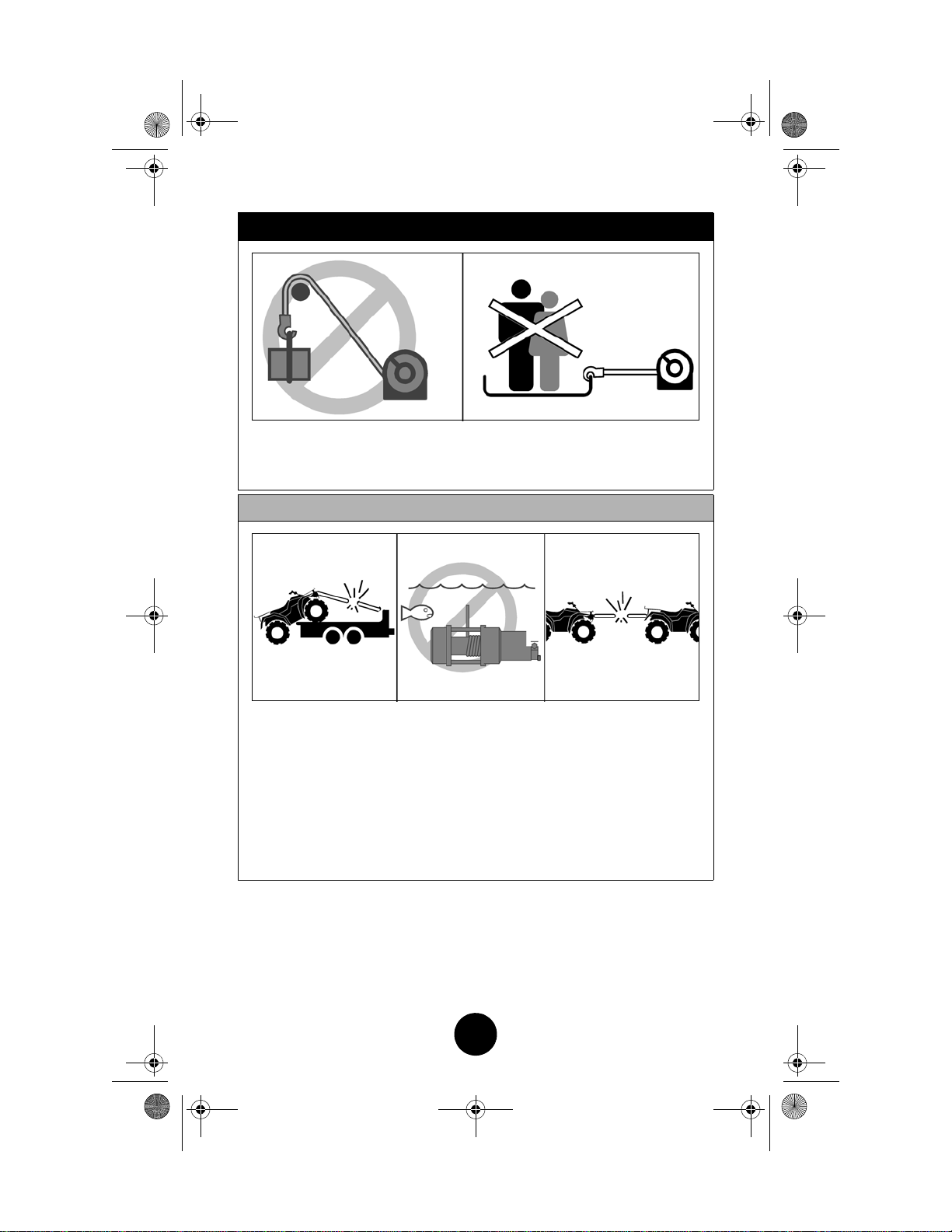

APPLICATION INFORMATION

! WARNING

TO PREVENT SERIOUS INJURY:

• Do not use as a hoist.

• Do not use to move persons.

! CAUTION

TO AVOID INJURY AND PROPERTY DAMAGE:

• Do not use winch to secure a load during transport.

• Do not submerge in water.

• Do not use to tow other vehicles.

• Maximum single line pulling capacity: 3000 lb (1360 kg).

• Intermittent duty rating.

• 12 Volts DC.

• Use only 3/16 in. (4.8 mm) 7 x 19 aircraft wire cable.

2

3000 lb winch eng.fm Page 3 Wednesday, August 27, 2014 2:59 PM

SYSTEM CHECK

Before using the winch, verify the following:

• Wiring to all components is correct. All loose wires are cable tied tight.

• There are no exposed wiring or terminals (cover any existing exposures

with insulator plate), terminal boots, heat shrink tubing, or electricians’

tape.

• The solenoid is properly grounded.

• Turn ATV key switch to ON position. Check winch for proper

operation.

CAUTION

KNOW THE WINCH: Take time to fully understand the winch and the

winching operation.

Testing The Winch And Controls

1. With the ignition switch off and the key removed, turn the winch

selector knob to the “freespool” position. Pull out approximately two to

three feet of cable from the winch reel.

2. Turn the winch selector knob to the “engaged” position; then insert the

ignition key into the ignition switch, and turn to the ON position.

3. Place the winch control in the “IN” position and observe the movement

of the winch cable. If the cable does not wind onto the reel in the proper

direction, reverse the lead connections on the winch motor terminals

and test the winch again.

NOTE: The cable must wind and spool from the top of the reel.

NOTE: The wire cable must always spool onto the drum as indicated

by the drum rotation decal on the winch frame.

3

3000 lb winch eng.fm Page 4 Wednesday, August 27, 2014 2:59 PM

OPERATING INSTRUCTIONS

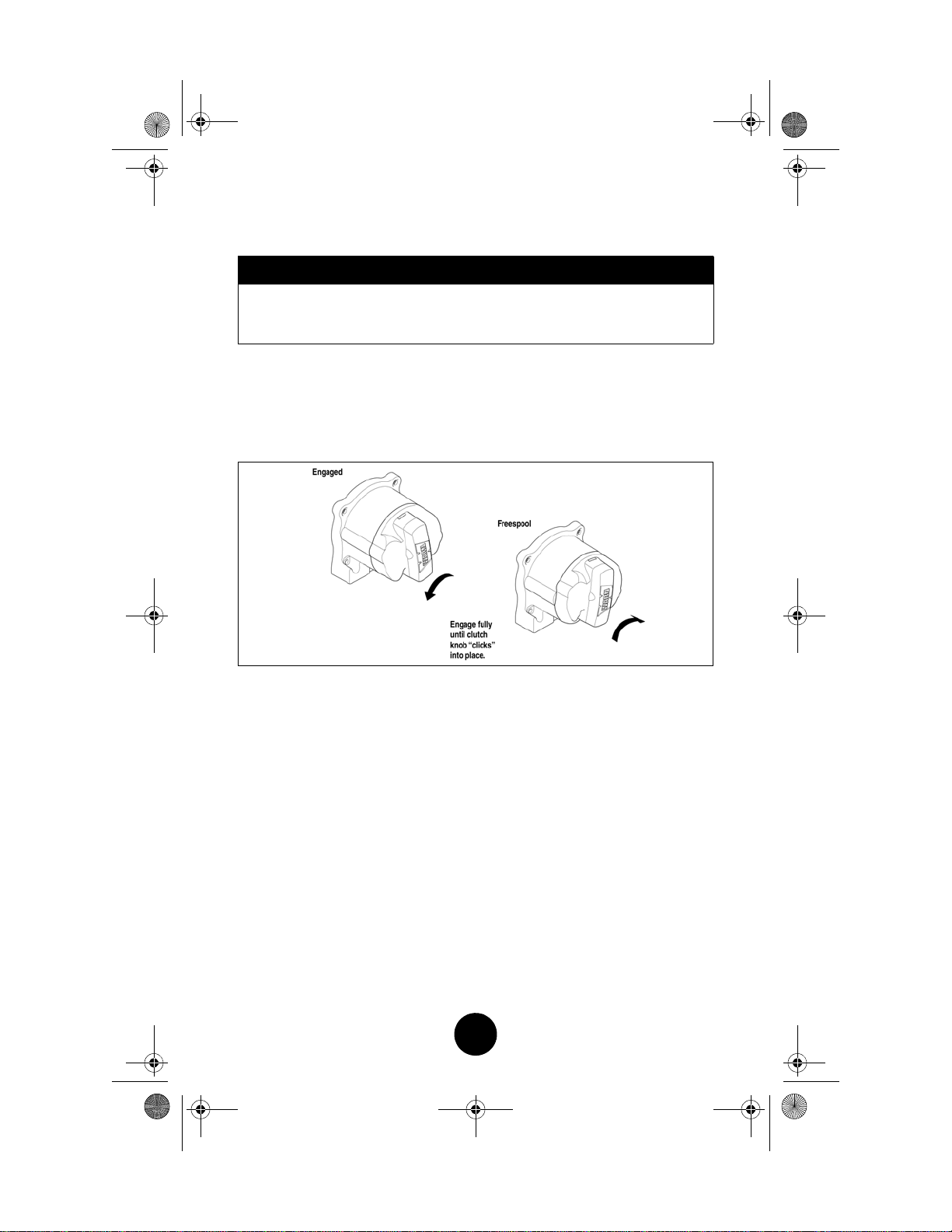

CLUTCH OPERATION

! WARNING

TO PREVENT SERIOUS INJURY OR PROPERTY DAMAGE:

• Do not disengage clutch if winch is under load or wire cable is in

tension.

When the clutch is engaged, the gear train is coupled to the wire cable drum

and power may be transferred from the winch motor. When the clutch is in

freespool, the gear train and wire cable drum are uncoupled allowing the

drum to rotate freely. The clutch knob, located on the winch housing opposite the motor, controls the clutch position. To prevent damage, always fully

engage or fully disengage the clutch knob.

0742-811A

OVERLOADING/OVERHEATING

This winch is rated for intermittent duty. It should not be operated with the

motor slowed down to a low RPM. When the motor approaches stall speed, a

very rapid heat build-up occurs which may cause motor damage. To judge

safe running time, stop winching and lay your hand on the motor. If the temperature is uncomfortable, shut down and cool the motor. This can be used as

an opportunity to recharge the battery. Double line rigging will reduce the

amperage draw from the motor allowing longer continual use (see Rigging

sub-section).

BATTERY RECOMMENDATIONS

A fully charged battery and good connections are essential to the proper

operation of the winch. A minimum 12 DC volt 10 Amp-hour-rated battery

is required.

MAINTENANCE

• No lubrication is required for the life of the winch.

4

3000 lb winch eng.fm Page 5 Wednesday, August 27, 2014 2:59 PM

• Check battery cables at 90 day intervals to be certain that they are clean

and tight at all connections.

• Inspect the wire cable before and after each winching operation.

Replace when damaged.

Operating The Winch

NOTE: Read and understand the winch operating instructions before

operating the winch. Keep the Winch Operator’s Manual with the ATV at

all times.

! WARNING

Read, follow, and understand the operating procedures to ensure

personal safety and long winch life. Extreme caution must be exercised when winching and spooling. Observe all caution and warning labels at all times. Read the Operator's Manual thoroughly

before using the winch.

CAUTION

Prolonged winch operation can lead to deep cycling of the battery.

Failing to allow adequate charging time for the ATV battery could

result in power failure or damage.

Stretching Wire Cable

The life of a wire cable is directly related to the care and use it receives. During its first use, a new wire cable must be spooled onto its drum under a load

of at least 227 kg (500 lb). Spool out the wire cable to the last 5 wraps on the

drum; then power in the wire cable under a load of 227 kg (500 lb) or more.

NOTE: Stretching the new wire cable will help create an even and

tight wire wrap around the drum. Failure to do so will cause binding and

possible damage to the wire cable.

Spooling Out

Freespooling is generally the quickest and easiest way to spool out wire

cable. Before freespooling wire cable from the winch, “power out” enough

cable to remove any cable tension; then turn the winch selector knob to the

“freespool” position. Manually freespool out enough wire cable for the

winching operation.

5

3000 lb winch eng.fm Page 6 Wednesday, August 27, 2014 2:59 PM

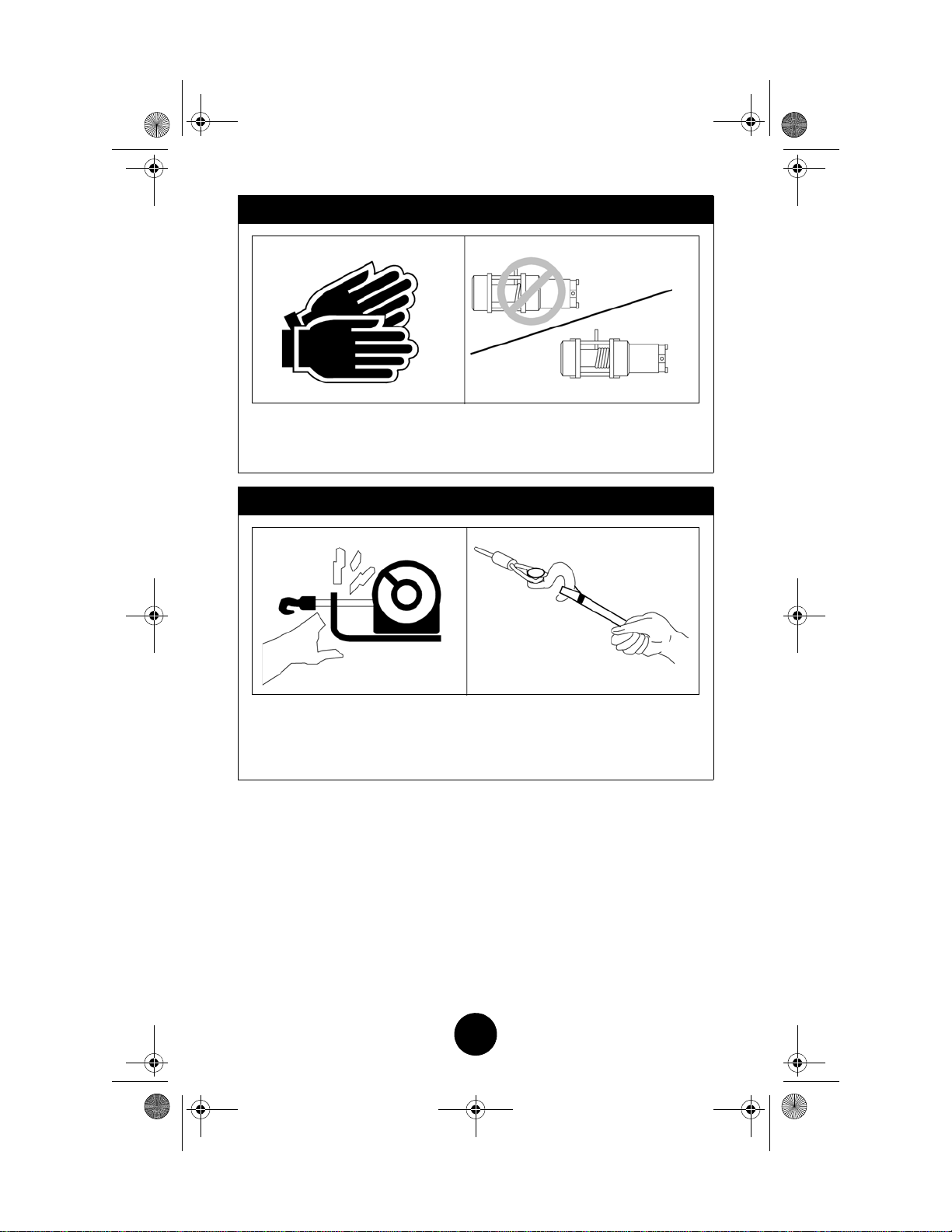

! WARNING

TO AVOID INJURY AND PROPERTY DAMAGE:

• Wear heavy leather gloves when handling wire cable.

• Never winch with less than 5 wraps of wire cable around drum.

! WARNING

TO PREVENT SERIOUS INJURY:

• Keep hands clear of wire cable, hook, and fairlead opening during

operation.

• Always use the hook strap to hold hook when spooling.

SPOOLING IN UNDER LOAD

• The wire cable must always spool onto the drum as indicated by the

drum rotation decal on the winch.

• Power in the wire cable evenly and tightly on the drum. This prevents

the outer wire wraps from drawing into the inner wraps, binding, and

damaging the wire cable.

• Avoid shock loads when spooling by using the control switch

intermittently to take up wire cable slack. Shock loads can momentarily

far exceed the winch and wire cable ratings.

• When powering in wire cable during side pull operations, the wire cable

will stack up at one end of the drum. Eventually, this stack will become

large enough to cause serious damage to the winch. To prevent damage,

6

3000 lb winch eng.fm Page 7 Wednesday, August 27, 2014 2:59 PM

line up pulls as straight ahead as possible and stop winching if the wire

cable comes close to the tie rods or mounting plate. To correct an uneven

stack, spool out that section of the rope and reposition it to the opposite

end of the drum which will free up space for continued winching.

SPOOLING IN UNDER NO LOAD

• Assisted: Have an assistant hold the hook with a cord or rag putting as

much constant tension on the wire cable as possible. While keeping

tension, the assistant should walk toward the winch while you operate

the control switch spooling in the wire cable. Release the switch when

the hook is a minimum of 4 ft (1.2 m) from the fairlead o penin g. Spool

in the remainder for storage.

•

Unassisted: Arrange the wire cable to be spooled so it will not kink or

tangle when spooled. Be sure any wire cable on the drum is tightly and

evenly layered. Spool enough wire cable to complete the next full layer

on the drum. Tighten and straighten the layer. Repeat process until the

hook is a minimum of 4 ft (1.2 m) from the fairlead. Spool in the

remainder for storage.

SPOOLING REMAINDER FOR STORAGE

Keep hands clear of wire cable, hook, and fairlead opening. Always use the

hook strap to hold hook when spooling under no load. Carefully power in the

remaining wire cable jogging the control switch to t ake up the last of the

slack. Secure the hook to a suitable anchor point near the winch. Be careful

not to over-tighten or damage may occur to the wire cable or anchor point.

! WARNING

TO PREVENT SERIOUS INJURY:

• Stand clear of wire cable and load during operation.

• Be certain the anchor will withstand the load.

• Always use a choker chain, wire choker rope, or tree trunk protector on

the anchor.

• Take your time; sloppy rigging caus es accidents.

7

3000 lb winch eng.fm Page 8 Wednesday, August 27, 2014 2:59 PM

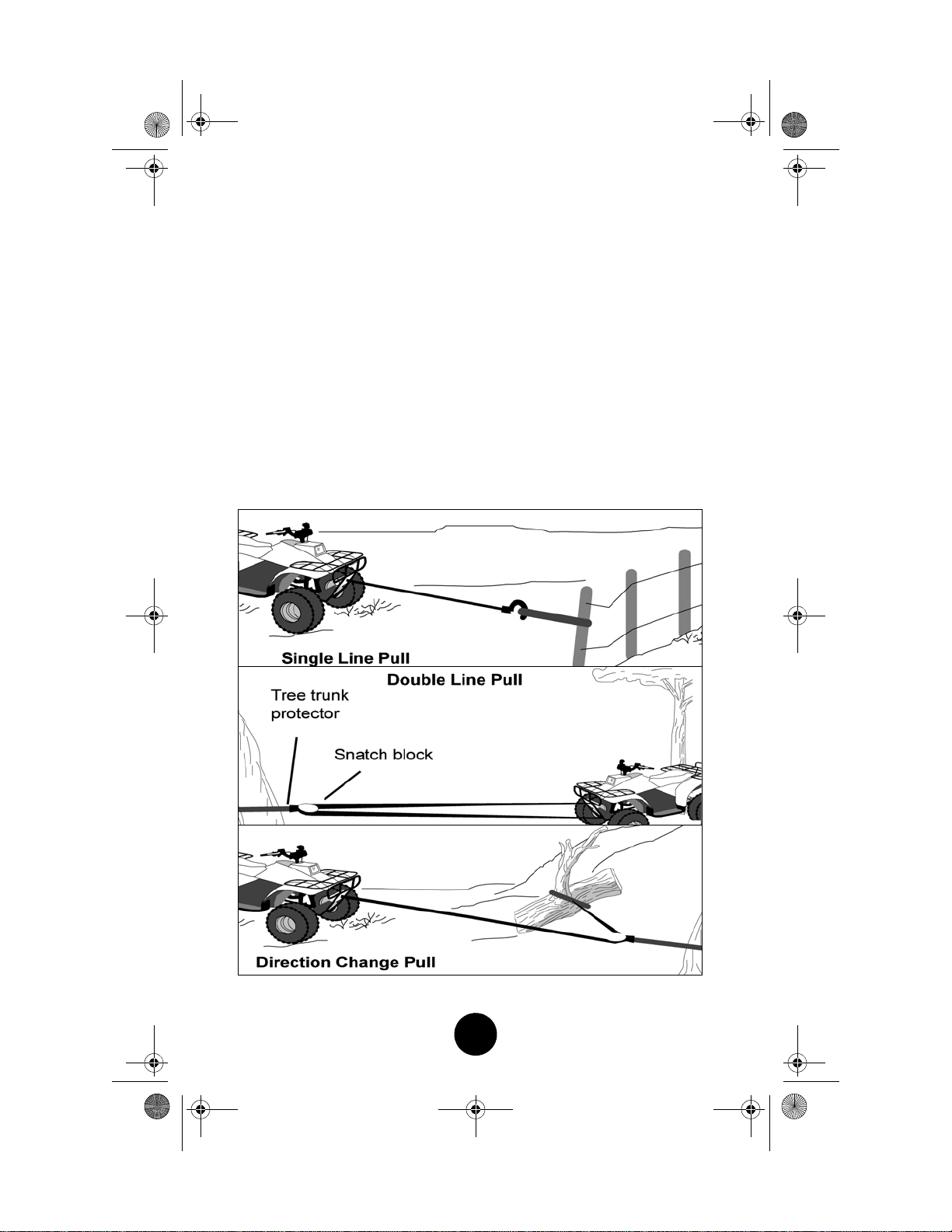

RIGGING

Always spool out as much wire cable as possible when preparing rigging.

Pick an anchor as far away as practical. This provides the winch with its

greatest pulling power.

Rigging a double line with a snatch block will reduce the load on the win ch

to half without significant loss of spooling speed.

Natural anchors such as trees, stumps, and rocks are the handiest when available. Attach the choker chain, wire choker rope, or tree trunk protector on

the anchor as low as possible to avoid pulling the anchor down. If several

possible anchors are available but they are not strong enough individually, it

may be practical to attach a wire or chain choker around several anchors to

form a strong collective anchor point.

Pulling Power Wire Cable Layer

3000 lb (1360 kg) 1st layer closest to drum core

2580 lb (1170 kg) 2nd layer

2220 lb (1007 kg) 3rd layer

1910 lb (866 kg) 4th layer

• Some of the most commonly used riggings are shown below.

8

3000 lb winch eng.fm Page 9 Wednesday, August 27, 2014 2:59 PM

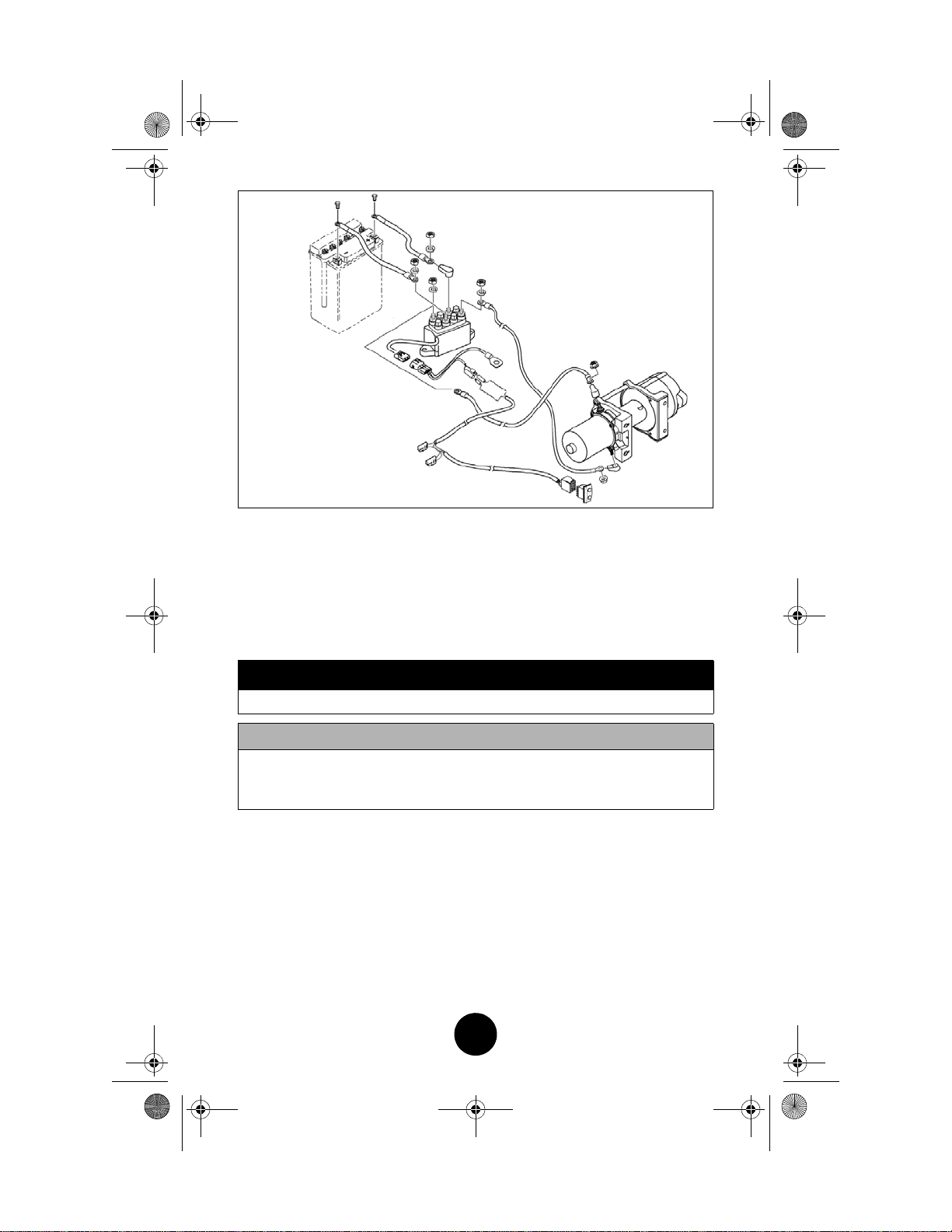

INSTALLATION INSTRUCTIONS

NOTE: Read the installation instructions thoroughly before

beginning the installation process.

Replacement Parts (p/n 2436-102)

p/n Qty Description

2260-452 1 Winch Operator Manual

3441-089 1 3000 lb Winch (with wire cable)

0441-061 1 Wire Cable

0123-903 12 Cable Tie (11.5 in.)

1441-348 1 Winch-to-Solenoid Cable - Blue

1441-347 1 Winch-to-Solenoid Cable - Yellow

0441-416 1 Battery-to-Solenoid Cable - Black

0445-089 1 Battery-to-Solenoid Cable - Red

0441-060 3 Terminal Boot

8400-820 4 Cap Screw - M8 x 20 Gr 8.8

8051-247 4 Spring Lock Washer - 0.314 x 0.593 x 0.097

1541-361 1 Winch Hook w/Strap (Black)

1441-130 1 Clevis Pin

1441-129 1 Cotter Pin

1441-424 1 Winch Hook Strap

0409-066 1 Solenoid

8476-625 2 Machine Screw - M6 x 25

0623-038 2 Hex Nut w/Washer

1441-176 4 Hex Nut - M6 - Solenoid (NIC)

1441-177 4 Spring Washer - M6 - Solenoid (NIC)

0409-176 1 Winch Switch (Backlit)

2441-931 1 Plow Roller Fairlead

8468-820 2 Machine Screw - M8 x 20

1441-449 1 Winch Techniques Guide

8424-602 2 Flange Hex Nut - M6 x 1.0

0486-543 1 Switch Control Harness (for backlit switch)

0486-276 1 Adapter Harness

9

3000 lb winch eng.fm Page 10 Wednesday, August 27, 2014 2:59 PM

INSTALLING WINCH

ROV-659

1. Set the parking brake and remove the key from the ignition.

2. Remove both seats, center console, operator-side seat-base, and battery

cover; then disconnect the battery.

! WARNING

Always disconnect the negative battery cable first.

CAUTION

Remove the bottom tie screw securing the winch together or

damage to the cable/rope may occur. This should be retained for

winch service.

3. From the left-side of the vehicle, position the winch onto the bumper

plate with the cable positione d so it w ill spool from the bottom of the reel.

Loosely secure the winch (A) to the back side of the bumper plate with

the two M8 x 20 Cap Screws (C) and Lock Washers (D) into the two

upper bumper plate mounting holes. Do not tighten at this time.

10

Loading...

Loading...