Page 1

HydraulicSystemCoolingKit

GrandStand

ModelNo.121-7480

®

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3373-396RevB

Mower

InstallationInstructions

ProcedureDescription

1

2

3

4

5

6

Nopartsrequired

Nopartsrequired

Hydraulicsystemcoolingassembly1

Bolt(5/16x3/4inch)

Nut(5/16inch)

61cm(24inch)hose

HoseassemblywiththeT-connector1

Cabletie

Hoseclamps

Wireharness1

Cabletie

Nopartsrequired

Qty.

10

Use

–

–

2

2

1

2

5

–

Preparingtheunit.

Removingthelowpressurehoses.

Installingthehydraulicsystemcooling

assembly.

Installingthelowpressurehoses.

Routingthewireharness.

Bleedingthehydraulicsystem.

©2012—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

*3373-396*B

Page 2

1

1

2

3

g018697

1

2 3

1

g018698

PreparingtheUnit

NoPartsRequired

Procedure

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

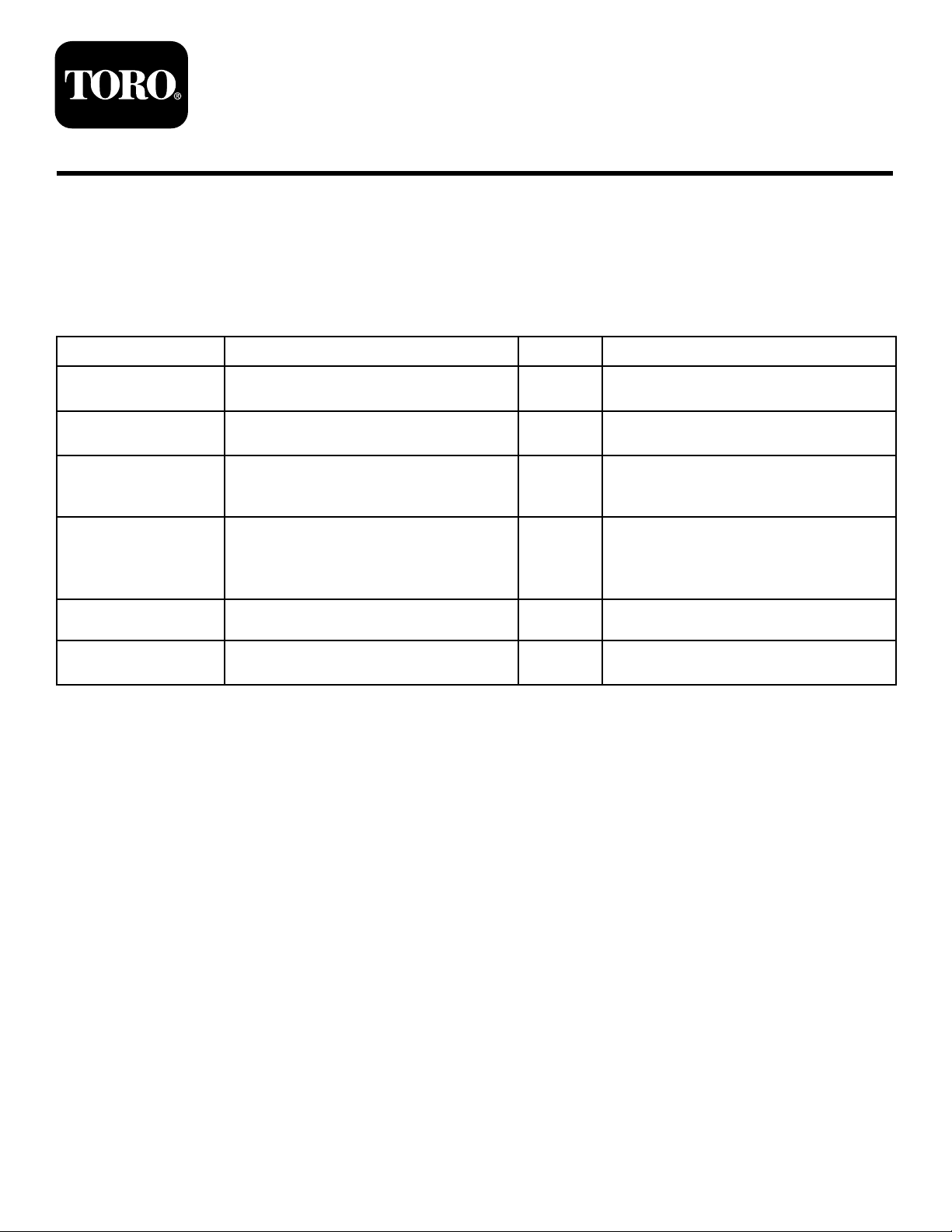

Figure1

•Makesureallhydraulicuidhosesandlinesare

ingoodconditionandallhydraulicconnections

andttingsaretightbeforeapplyingpressureto

thehydraulicsystem.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

•Seekimmediatemedicalattentionifuidis

injectedintoskin.

1.Positionmachineonalevelsurface.

2.Disengagethepowertakeoff(PTO)andsetthe

parkingbrake.

3.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

4.Removethekey.

1.Platformup

2.Platformdown

9.Removethehairpincottersecuringtherearcushion

bracket(Figure2).

10.Slidethebushingnexttothemachine(Figure2).

11.Lowertherearcushionbracketontotheplatform

(Figure1andFigure2).

3.Pulltheknobouttorelease

theplatform

Figure1).

Figure33).

Figure2

1.Hairpincotter3.Rearcushionbracket

2.Bushing

5.Removethebatterycover(

6.Removethenegativebatterycablefromthebattery.

7.Lowerthemowerdecktothelowestheight-of-cut

setting.

8.Lowertheplatform(

2

Page 3

2

1

g01842 5

2

3

g018420

1

2

g018419

1

2

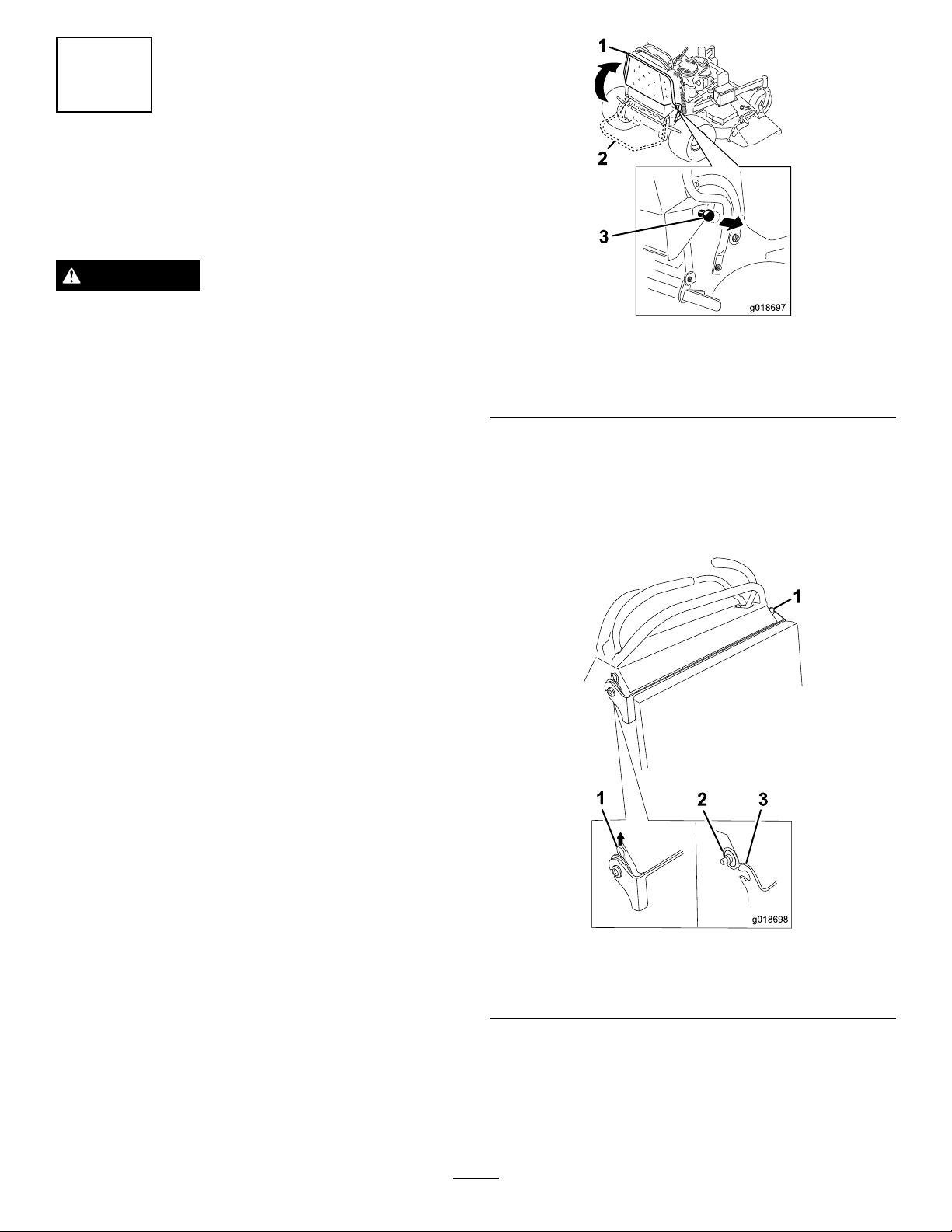

RemovingtheLowPressure

Hoses

NoPartsRequired

Procedure

1.Removethebolt,nut,andR-clampsecuringthehose

connectingtheright-handpumptothehydraulic

reservoirbracket(Figure3).

Note:DiscardtheR-clamp.

Figure4

Yourmodelmayvaryfromthisdiagram.

Figure3

1.Boltsecuringthehose3.Frontconnectoron

hydraulicreservoirtank

2.Hydraulicreservoirbracket

2.Removethelowpressurehosefromthefronttting

underthehydraulicreservoirtank(Figure3).

Note:Draintheoilintoanoilpan.

1.Cabletie

1.Cabletie

2.Hoses

Figure5

Yourmodelmayvaryfromthisdiagram.

2.Lowpressurehoses

3.Removeanddiscardthecabletiessecuringthelow

pressurehoses(

Figure4andFigure5).

3

Page 4

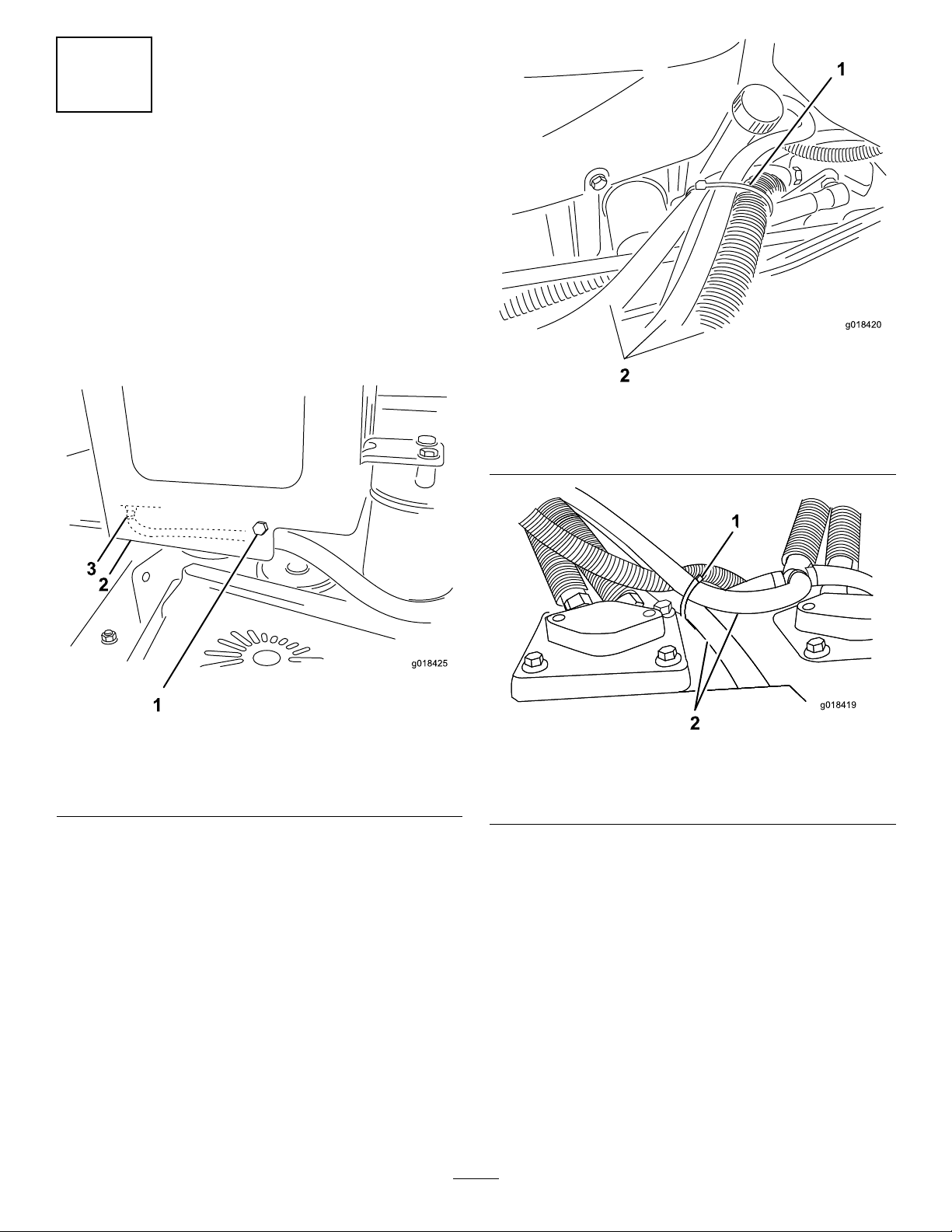

4.Removethelowpressurehosefromtheright-hand

1

g018421

1

g018422

1

g018424

pump(Figure6).

Figure6

1.Disconnecthere

5.Removethelowpressurehosefromtheleft-hand

pump(Figure7).

Figure8

1.Removehose

3

InstallingtheHydraulic SystemCoolingAssembly

Partsneededforthisprocedure:

1Hydraulicsystemcoolingassembly

2

Bolt(5/16x3/4inch)

2

Nut(5/16inch)

Procedure

1.Usinga5/16inchdrillbit,reamtheholeinthe

reservoirbracket(Figure9).

Figure7

1.Disconnecthere

6.Removethehosefromtheunit(Figure8).

4

Page 5

1

g018426

g018327

1

g018427

1

2

2

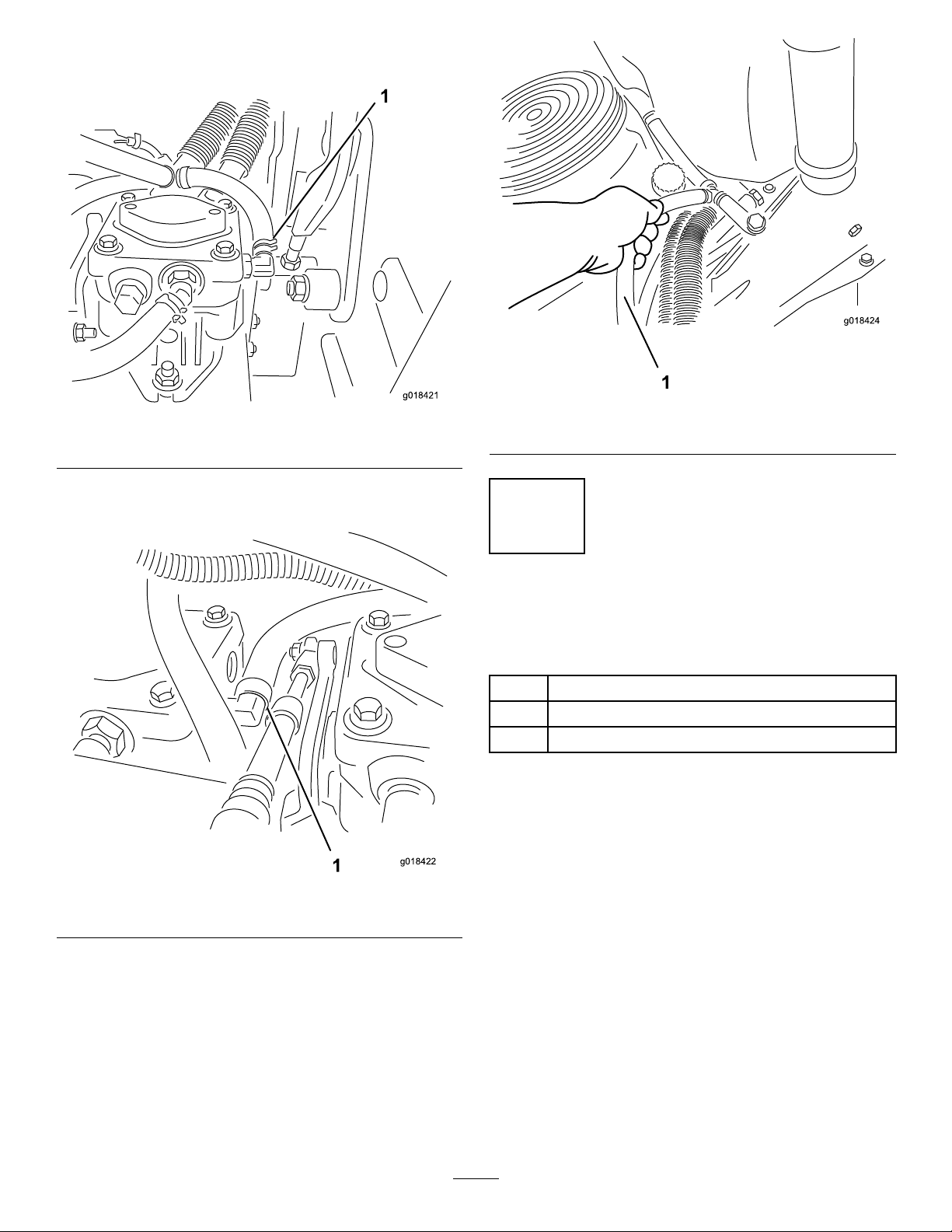

Figure11

1.Hole

2.Locatetheserialnumberdecal.

Figure10

1.Locationofthemodelandserialnumbers

Figure9

1.Uppersetoftheholesfor

2011models.

2.Lowersetofholesfor

2009and2010models.

3.Determineyourmodelyearfromtheserialnumber.

•2009—serialnumberrange290000001andup

•2010—serialnumberrange310000001andup

•2011—serialnumberrange311000001andup

4.Locatethemountingholesinthecoolingassemblythat

willberequiredforyourunit.

Note:Usetheuppersetoftheholesfor2011models.

Usethelowersetofholesfor2009and2010models.

5

Page 6

5.Alignthecoolingassemblytothereservoirbracket

g018429

1

g018428

1

1

g018451

(Figure12).

Figure12

1.Coolingassembly

6.Usingthecorrectsetofholesforyourunit,secure

therightsideofthecoolingassemblytothehydraulic

reservoirbracketusingabolt(5/16x1inch)andnut

(5/16inch)(Figure12andFigure13).

Figure14

1.Boltandnut

8.Securethecoolerassemblyusingtheboltandnut

(Figure14).

4

Figure13

1.Boltandnut

7.Usingthecoolerbracketasatemplate,drillthesecond

5/16inchholeintothereservoirbracket(Figure12,

Figure13,andFigure14).

InstallingtheLowPressure Hoses

Partsneededforthisprocedure:

1

61cm(24inch)hose

1HoseassemblywiththeT-connector

2

Cabletie

5

Hoseclamps

Procedure

Note:Thehosefromtheleft-handpumpconnectstothe

radiatorinletport(Figure15).

6

Page 7

1

2

3

g018473

1.Coolingassemblyinlet

g018472

1

2

3

4

5

6

7

g018452

1

2

1

g018690

2

3

4

5

port

2.Hosefromleft-handpump

connectingtocooling

assemblyinletport

Figure15

3.Left-handpump

Note:Securethehosewithahoseclampsothatthe

tabsoftheclamparepointingdownwardasshown.

Figure17

1.Left-handpump

2.Returnport

2.Routethehoseandinstalltheotherendtothecooling

assemblyinlet.

Note:Thehosefromtheright-handpumpconnectstoa

T-connector.TheshorthosecomingofftheT-connector

goestotheradiatorexitport.Theotherhoseconnectsto

thehydraulicreservoirtank

1.Hydraulicreservoirtank5.Right-handpump

2.Coolingassembly

3.Shorthose

4.Hosefromtheright-hand

pumpconnectingtothe

T-connector

Figure16

6.T-connector

7.Hoseconnectingtothe

hydraulicreservoir

Note:Rotatetabsonhoseclampasshownin

Figure18.

Figure18

1.CoolingAssemblyoutlet

2.CoolingAssemblyInlet

3.Hosecomingfromthe

left-handpump

4.Hosegoingtothe

T-connector

5.Tabsonclamp

1.Installthe61cm(24inch)hosetoleft-handpump

(Figure17.

3.InstallthehoseconnectingtheT-connectortothe

coolingassemblyoutlet(Figure16andFigure19).

7

Page 8

Note:Rotatetabsonhoseclampasshownin

1

g018454

2

g018455

1

2

g018456

1

g018457

1

Figure18.

Figure19

1.Hosegoingtothe

hydraulicreservoirtank

2.T-connector

4.InstallthehoseconnectingtheT-connectortothe

right-handpump(Figure16andFigure20).

Note:Rotatethetabsofthehoseclampsotheyare

pointingdownward.

Figure21

1.Cabletie

Figure22

Figure20

1.Right-handpump2.Hoseclamp

1.Cabletie

6.Movethedeckfromthehighestheightofcuttothe

lowestheightofcut.

5.Securethehosesusing2cableties(Figure21and

•Repeatthisstepwhileobservingthehoses.

Figure22).

•Verifythatthehosesdonotcontacthotsurfaces,

sharpedges,ormovingcontrolslinkage.

•Adjustthecabletiesandhoseroutingifneededto

avoidcontactforallheightofcutpositions.

8

Page 9

5

g018478

1

2

3

4

g018458

1

1

g018459

RoutingtheWireHarness

Partsneededforthisprocedure:

1Wireharness

10

Cabletie

Procedure

1.Beforestartingthisprocedure,observehowyouwill

routethewireharness.

Figure24

1.Coolingassemblyconnector

3.Routethecoolingassemblywireharnessunderneath

allthehosesandthroughthepumpcompartment

(

Figure25).

Figure23

1.Routingthewireharness

tothebattery

2.Relay4.Wireharnesstothe

2.Connectthecoolingassemblyconnectortothewire

harness(Figure24).

3.Relaysocket

coolingassembly

Figure25

1.Coolingassemblywireharness

4.Continueroutingthecoolingassemblywireharness

betweenthebrakerodandframe(Figure26).

9

Page 10

1

g018460

Figure26

1

2

g018475

1

g018461

1

g018691

2

1.Coolingassemblywireharness

5.Removetherelayfromthewireharnessrelaysocket

(ifinstalled).

7.Installtherelayintotherelaysocket.

8.Removeanddiscardtheprotectivecapfromtheend

oftheAUXconnectoronthewireharnessnearthe

fusebox.

9.Connectthecoolingassemblywireharnesstothe

wireharnessAUXconnectorlocatedatthefuseblock

(Figure28).

6.Installtherelaysockettotheframecrossbrace.

•For2011modelssecuretherelaysockettothe

crossbraceusinganutandbolt(Figure27).

•For2009and2010modelssecuretherelaysocket

tothecrossbraceand/orwireharness,usinga

cabletie.

Note:Thereisnoholeinthecrossbraceon2009

and2010modelsforsecuringtherelaysocketto

thecrossbrace.

Figure28

1.Wireharnesses

10.Securethewireharnesstothehosegoingtothe

coolingassemblyinletwithacabletie(

Figure29).

Figure27

2011modelshown

1.Relaysocket2.Nut

Figure29

1.Cabletie

2.Wireharness

11.Securetheclipattachedtothewireharnesstothe

frame(Figure30).

10

Page 11

1

g018689

Figure30

1

g018463

g018464

1

g018477

3

1.Attachthecliponthewireharnesstotheframe

Figure32

1.Cabletie

12.Securethecoolingassemblywireharnesstothe

R-clamplocatedinthelowerleftfrontcornerofthe

controltower,usingacabletie(Figure31).

Figure31

1.Cabletie

13.Removetheslackfromthewireharnesswhereitpasses

throughthepumpcompartment.

14.Securethecoolingassemblywireharnesstothemain

wireharnessusingacabletie(Figure32).

15.Routetheotherendofthewireharnesstothebattery

(Figure23)and(Figure33).

Figure33

1.Wingnut4.Positivebattery

connection

2.Batterycover5.Battery

3.Wireharnesstothe

positivebatteryterminal

16.Opentheredcapcoveringthepositivebatteryterminal.

17.Installtheconnectoronthecoolingassemblywire

harnesstothepositivebatteryterminal(Figure33).

18.Installtheredcap.

19.Installthenegativebatterycabletothebattery.

11

Page 12

20.Securethepathofthecoolingassemblywireharness

1

g018465

G012005

4 1 3

2

usingthecableties.

21.Installthebatterycover.

22.Installthe15ampfuseintothefuseblock(Figure34).

Figure34

1.Fuse

23.TurnthekeytotheRunpositionandverifytheelectric

fanisrunning,thenturnthekeytothestopposition.

24.Installtherearcushionbracket(Figure2).

Figure35

1.Cap3.Colduidlevel-full

2.Bafe4.Hotuidlevel-full

2.Removecapfromllerneck.(Figure35).

3.Adduidtothereservoiruntilitreachesthecoldlevel

ofthebafe(Figure35).

4.Raisetherearofthemachineupontojackstandshigh

enoughtoraisethedrivewheelsofftheground.

5.Disengagetheparkingbrake.

6.Starttheengineandmovethethrottlecontroltoidle

position.

Note:Ifthedrivewheeldoesnotrotate,itispossible

toassistthepurgingofthesystembycarefullyrotating

thetireintheforwarddirection.

6

BleedingtheHydraulicSystem

NoPartsRequired

Procedure

Note:HydraulicOilType:Toro®HYPR-OIL™500

hydraulicoilorMobil®115W -50syntheticmotoroil.

1.Cleanareaaroundcapandllerneckofhydraulictank

(Figure35).

7.Checkthehydraulicuidlevelasitdropsadduidas

requiredtomaintaintheproperlevel.

8.Repeatthisprocedurefortheoppositewheel.

9.Installthecaponthellerneck.

10.Thoroughlycleantheareaaroundeachofthecharge

pumphousings.

11.Checkthecoolingsystemconnectionsforanyleaks.

12

Loading...

Loading...