Page 1

SpindleKit

TITAN

ModelNo.121-5680

ModelNo.121-5681

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

®

Zero-Turn-RadiusRidingMower

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3371-631RevA

InstallationInstructions

ProcedureDescription

1

2

Nopartsrequired

Spindlehousing

Washer(.88inchO.D.)

1

PreparingtheMower

NoPartsRequired

Procedure

1.Thoroughlycleanmowerdeck.Alldebrismust

beremovedtoensurethespindlehousingwillt

properlyagainstmowerdeck.

2.Repairallbentordamagedareasofmowerdeckand

replaceanymissingparts.

Qty.

–

1

Preparethemower.

Installthespindlehousing.

Use

2

InstallingtheSpindleHousing

Partsneededforthisprocedure:

1

Spindlehousing

Washer(.88inchO.D.)

Procedure

WARNING

Whilemaintenanceoradjustmentsarebeingmade,

someonecouldstarttheengine.Accidentalstarting

oftheenginecouldseriouslyinjureyouorother

bystanders.

©2012—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

Removethekeyfromtheignitionswitch,engage

parkingbrake,andpullthewire(s)offthespark

plug(s)beforeyoudoanymaintenance.Alsopush

thewire(s)asidesoitdoesnotaccidentallycontact

thesparkplug.

1.Parkthemachineonalevelsurface,disengagethe

bladecontrolswitch,andmovethemotioncontrol

leversoutwardtotheneutralpositionandengage

parkingbrake.

2.Stoptheengineandremovethekey.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

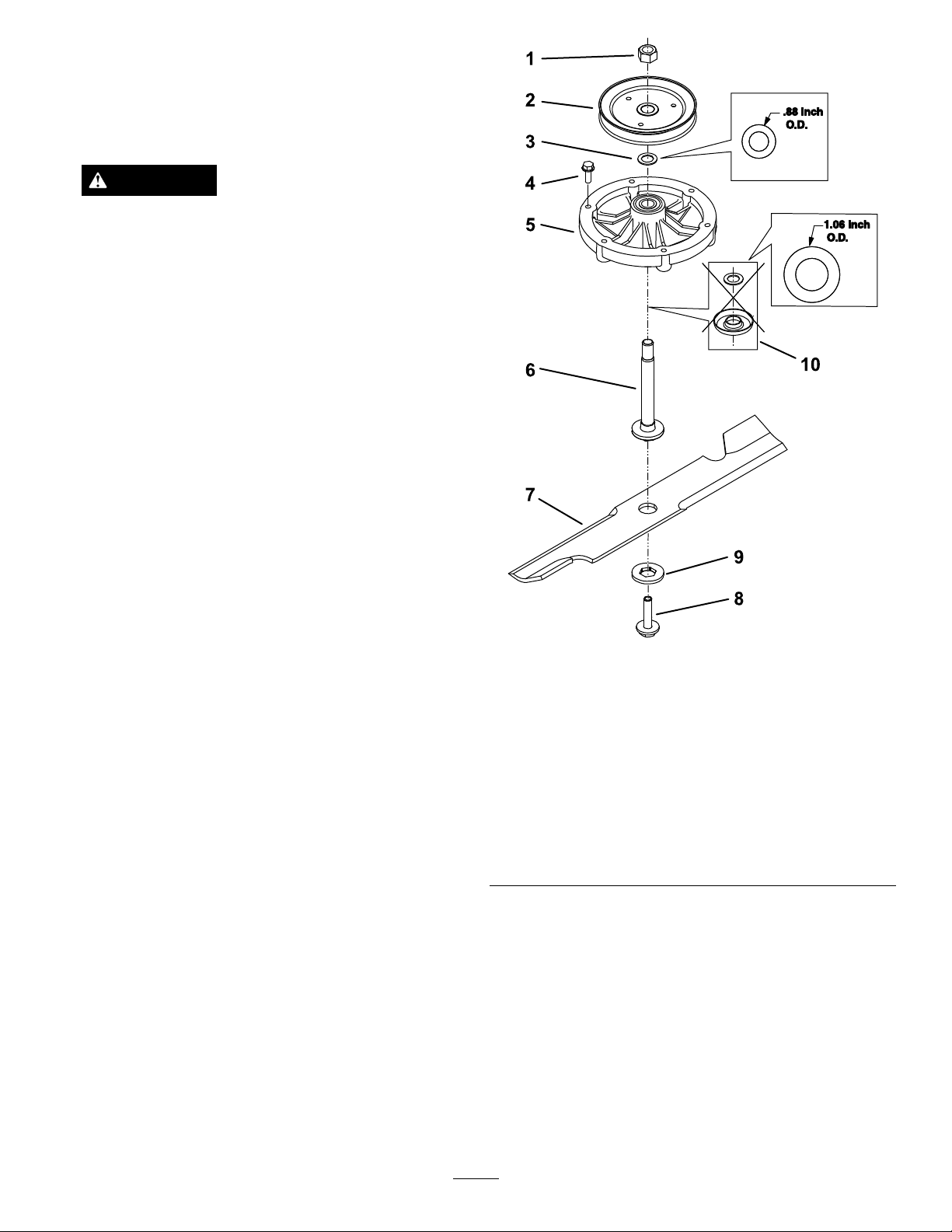

Page 2

3.Allowthemachinetocoolbeforestartingthese

1

2

3

4

5

6

7

9

8

10

instructions.

4.Raisethedecktothetransportposition.Liftthe

frontofthemachineandsupportusingjackstands

orequivalentsupport.

CAUTION

Raisingthemowerdeckforserviceor

maintenancerelyingsolelyonmechanical

orhydraulicjackscouldbedangerous.The

mechanicalorhydraulicjacksmaynotbe

enoughsupportormaymalfunctionallowing

themachinetofall,whichcouldcauseinjury.

DoNotrelysolelyonmechanicalorhydraulic

jacksforsupport.Useadequatejackstandsor

equivalentsupport.

5.Removeandretainthebeltguardsandthehardware.

6.Carefullyremovetheblade.Wrapthebladeorwear

glovesandusecautionwhenservicingthem.Inspect

bladeandsharpenorreplaceasrequired.

7.Removeandretainthepulley .

8.Removetheexistingspindlehousing.Retainall

hardwareandspindleasshownin

theexistingwasherandbearingshieldshownin

Figure1.

9.Installthespindlehousingprovidedinthiskitonto

themowerdeckandtightenthescrewsto200-250

in-lb(23-28N-m)(

Figure1).

10.Applyfoodgradeanti-seeze(i.e.Mobil®HTS

grease)betweenthespindleandbearings.Donot

useacopperornickelbasedanti-seeze.

11.Installthespindle,newwasher,pulleyandspindle

nut.T orquethespindleto75-85ft-lb(102-115N-m).

12.Applylubricanttothethreadsofthebladeboltas

neededtopreventseizing.Copperbasedanti-seize

ispreferable.Greaseisanacceptablesubstitute.

Reinstallthebladeandsheaveasshownin

RefertotheOperator’ sManualformoreinformation

onbladeinstallation.

13.Installthebeltguards.

Figure1.Discard

Figure1.

Figure1

1.Spindlenut—torqueto

75-85ft-lb(102-115N-m)

2.Pulley7.Blade

3.Newatwasher

4.Spindlehousingbolt—

torqueto200-250in-lb

(23-28N-m)

5.Spindlehousing

6.Spindle—lubricatewith

foodgradeanti-seeze(i.e.

Mobil®HTSgrease)

8.Bladebolt—torqueto

32-42ft-lb(43-57N-m)

9.Hexdrivewasher

10.Removeexistingwasher

andbearingshield

14.Removethejackstandsandlowerthemachine.

2

Loading...

Loading...