Page 1

BaggerFinishingKit

2011andAfterTITANZX6000SeriesZero-Turn-RadiusRiding

Mower

ModelNo.120-7126

ThiskitrequirestheBaggerKittocompletetheinstallation.Contact

anAuthorizedServiceDealerorCustomerServicetoobtainthe

necessaryparts.Formoreinformation,gotowww.Toro.com.

Safety

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

FormNo.3368-669RevA

InstallationInstructions

110-6691

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard,mower—donotoperatewithoutthe

deector,dischargecover ,orgrasscollectionsystemin

place.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

©2011—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

Page 2

Installation

1

InstallingtheBaggerSupport

andBaggerFrame

Partsneededforthisprocedure:

1Baggersupport

1

Baggerframeassembly

1

Supportspacerplate(fromtheBaggerKit)

Selftappingscrew(5/16x3/4inch)(fromtheBagger

2

Kit)

2

Bolt(5/16x2-1/2inch)(fromtheBaggerKit)

2

Locknut(5/16inch)(fromtheBaggerKit)

1

Clevispin(1/2x2-1/4inch)(fromtheBaggerKit)

5

Hairpincotter(fromtheBaggerKit)

2

Rod(fromtheBaggerKit)

4

Washer(fromtheBaggerKit)

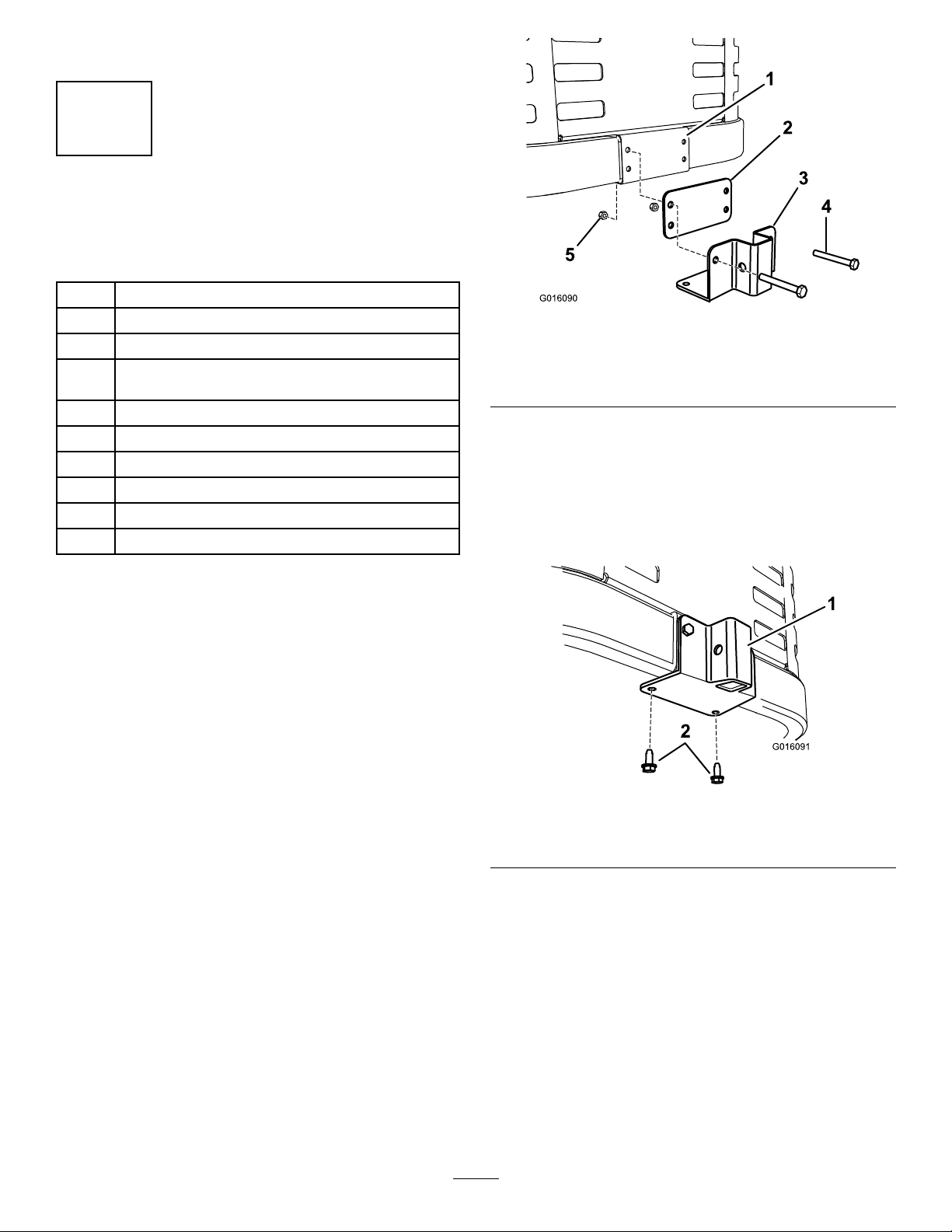

Figure1

1.Machineframe4.Bolt(5/16x2-1/2inch)

2.Supportspacerplate5.Locknut(5/16inch)

3.Supportbracket

3.Securetheplateandbrackettotheframeusing2

bolts(5/16x2-1/2inch)and2locknuts(5/16inch)

(Figure1).

4.Securethesupportbrackettothebottomofthe

machineframefrombelowusing2self-tapping

screws(5/16x3/4inch)asshownin

Figure2.

Procedure

Important:ThisstepsupersedesStep1(Installing

theBaggerFrame)intheSetupsectionofthe

Bagger

Thisbaggernishingkitincludesanewbaggerframe

assemblyandanewsupportbracketformachineswith

a60-inchmowingdeck.Replacethebaggerframe

assemblyandsupportbracketincludedinthebaggerkit

withthesenewparts.

1.Locatethebaggerframesupportspacerplateand

2.Installtheplateandbrackettothemachineframeas

Operator’ s Man ual

bracketinlooseparts.

shownin

Figure1.

.

Figure2

1.Supportbracket2.Selftappingscrews(5/16

x3/4inch)

5.Removetheexistingfastenersthatsecurethe

rectangularspacerplatefromthetopoftheengine

frame,andremovetheplate(Figure3).

2

Page 3

G010581

1

2

3

4

5

6

4

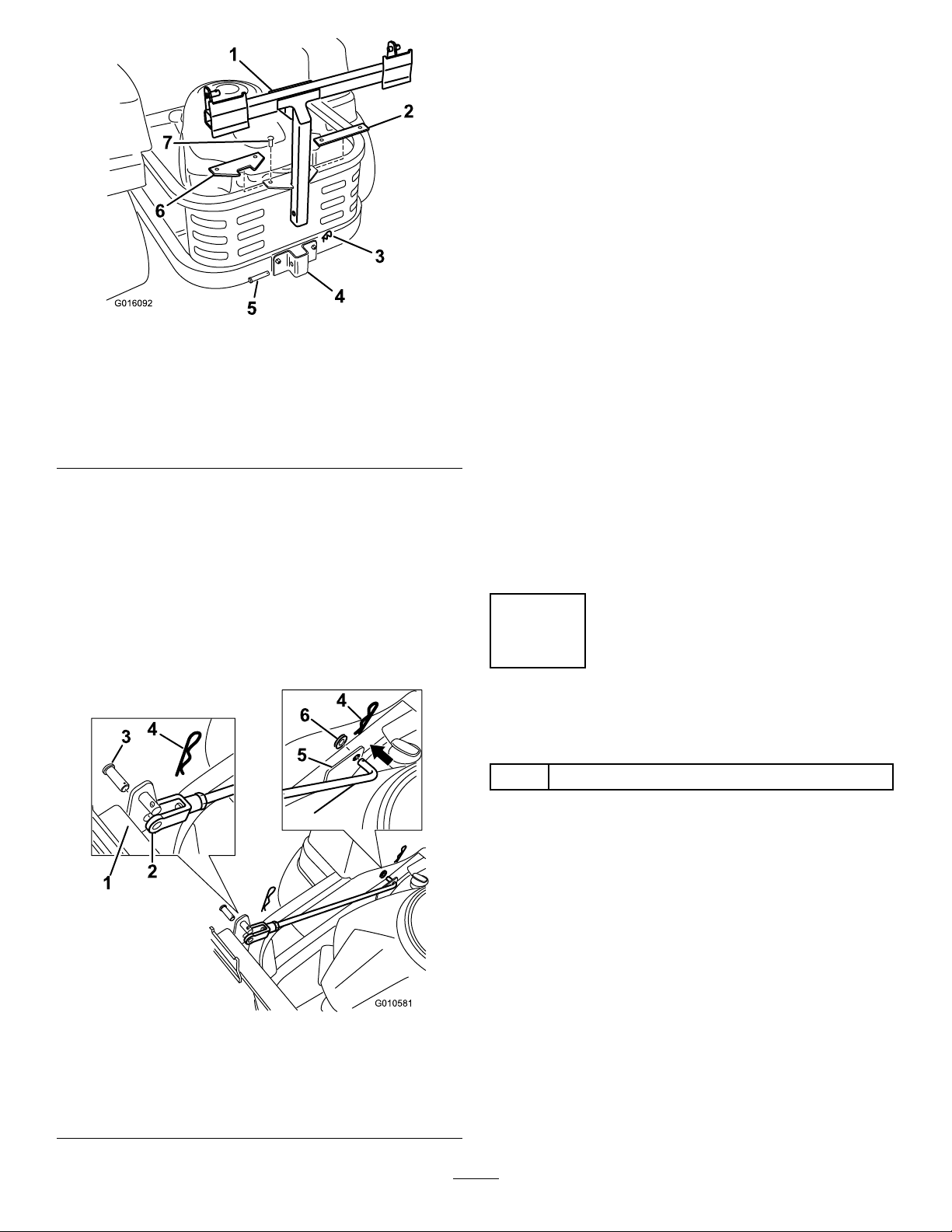

10.Insertthebentendsoftherodintothemachine

frameasshowninFigure4,andsecuretheendof

therodwithawasherandahairpincotter.

11.Adjustthesupportrodssothatthebaggerframeis

heldsecuretothemachineframeandseatsinthe

notchoftheanglespacerplateinstalledpreviously .

12.Repeatthesestepsforeachsupportrod:

A.Loosenthejamnutatthebaseoftheclevisend

oftherod.

B.Rotatetheclevisendoftherodtoadjusttherod

tothedesiredlength.

Figure3

1.Baggerframe5.Clevispin(1/2x2-1/4

2.Spacerplate,rectangular

(existing)

3.Hairpincotter7.Fasteners,existing

4.Supportbracket

inch)

6.Spacerplate,angle(new)

6.Installthenewanglespacerplateasshownin

Figure3usingthefastenersremovedpreviously.

7.Securethebaggerframetothesupportbracketwith

aclevispin(1/2x2-1/4inch)andahairpincotter

(Figure3).

8.Installtwosupportrods,onetoeachsideofthe

baggerframe.

9.Locatetheexistingbracketbetweenthereardrive

wheelandframe(Figure4).

C.Aligntheholesintheclevisendwiththeholein

thebaggerframeattheattachmentpoint.

D.Securetheclevisendoftherodstothebagger

frameusingaclevispinandahairpincotter

Figure4).

(

E.Tightenthejamnut.

13.Withbothrodsinstalledandattached,checkthe

baggerframeforplay.

Note:Thebaggerframeshouldbeheldtightto

themachineframe.Ifnecessary,repeattheprevious

steptosecurethebaggerframe.

2

InstallingtheBlades

Partsneededforthisprocedure:

3

Hi-Liftblade

Procedure

1.Removetheexistingmowerbladesinstalledonyour

deck.RefertotheRemovingtheBladessectionin

theOperator’sManualformoreinformation.

Figure4

Leftsideshown

1.Baggerframe

2.Clevisend5.Bracketonframe

3.Clevispin

4.Hairpincotter

6.Washer

2.InstalltheHi-Liftmowerbladeslocatedinloose

parts.RefertotheInstallingtheBladessectioninthe

Operator’sManualformoreinformation.

3

Page 4

3

2

G010632

1

2

3

4

5

6

G010701

1

2

3

4

InstallingtheWeight

Partsneededforthisprocedure:

1Weight

1Adhesivebumperpad

1Rod

4Flatwasher

2Hairpincotter

8

Spacer

Procedure

Figure6

1.Weight4.Rod

2.Adhesivebumperpad

3.Spacers(8)6.Washer(4)

5.Hairpincotter(2)

3.Installtheweighttothefrontofthemachineframe

(Figure6).

Note:Thisprocedureisonlyformachineswitha

ROPS.MachineswithoutaROPSdonotrequireafront

weights.

1.Removethe2nutsand2boltsthatsecurethefront

ofthemowerhousingpan(Figure5).

Note:Savethenutsandboltstosecurethefrontof

themowerhousingpanlater.

Figure5

1.Nut(2)

2.Bolt(2)

3.Mowerhousingpan

2.Installtheadhesivebumpertotheweight(Figure6).

4.Securetheweightwitharod,8spacers,4washers,

and2hairpincottersasshownin

Figure6.

Note:Whenyouinstalltheweight,allowittorest

onthefrontlipoftheundersideofthemachine

frameasshowninFigure7.Thissuspendsthe

weightwhileyousecureittothemachine.Becareful

nottodislodgetheweightwhenyouinstallthe

supportingrod.

Figure7

1.Cutawayofthefrontofthe

machineframe

2.Bumper4.Resttheweighthere

3.Weight

duringinstallation

Note:Wheneveryouremovethebagger

attachment,removetheweighttorestoretheproper

stabilitytothemachine.

5.Installthefrontofthemowerhousingpanusingthe

nutsandboltsthatyouremovedinstep1.

4

Page 5

4

G013095

1

2

3

4

5

G013096

1

2

3

4

5

6

7

8

9

10

InstallingtheChute

Partsneededforthisprocedure:

1

Angledcutoffbafe

1

Curvedbafe

2

Locknut(5/16inch)

1Handknob

1Washer

1

Chute

Procedure

Figure8

1.Deectorassembly4.Carriagebolt(existing;

reuse)

2.Locknut(existing;retain)5.Carriagebolt(existing;

retain)

3.Locknut(existing,reuse)

WARNING

Anuncovereddischargeopeningcouldallowthe

lawnmowertothrowobjectsintheoperatoror

bystander’sdirectionandresultinseriousinjury.

Also,contactwiththebladecouldoccur.

Neveroperatethelawnmowerunlessyouinstall

acoverplate,amulchplate,oragrasschuteand

catcher.

Neveroperatethemowerwiththedischargeopening

uncovered.Alwaysuseadischargecover,mulchcover,

orbaggingchutewhenoperatingthemowerdeck.

1.Removefastenersthatsecurethedeectorassembly

tothedeck(

Note:Retainallfasteners.

Figure8).

2.Removethedeectorassembly.

Note:Retainallpartstoconvertthedecktoside

discharge.

3.Locateandinstalltheangledcutoffbafetothedeck

attherearholesinthemowerdeck(Figure9).

Note:Usetheexistingfastenersfromthatlocation

tosecuretheangledcutoffbafetothedeck.

1.Holeinfrontwallofthe

deck

2.Locknut

3.Horizontalpost,curved

bafe

4.Verticalpost,curvedbafe9.Locknut(existing;reuse)

5.Curvedbafe10.Center,forwardholein

4.Installthecurvedbafetothedeck(Figure9).

5

Figure9

6.Highliftblade

7.Carriagebolt(existing;

reuse)

8.Angledcutoffbafe

mowerdeck

Page 6

A.Aligntheverticalpostinthecurvedbafe

G013097

1

2

3

4

5

6

G013098

1

2

withcenter,forwardholeinthedeckandthe

horizontalpostwiththeholeinthefrontwall

ofthemowerdeck.

B.Securehorizontalposttothefrontwallofthe

deckusingalocknut.

5.Installthechutetothedeck.

Note:Ensurethattheopeningintopofthechute

alignswiththeexposedpostonthedecktopandthe

forwardverticalplatemateswiththefoldedmetal

bracketofthechute(

Figure10).

Figure11

1.Retainingclasp2.Flexiblelatch

5

ConnectingwiththeDischarge

Tube

NoPartsRequired

Procedure

1.Slidethecurvedendofthedischargetube(supplied

withthebaggerkit)intotheopeninginthebagger

Figure12).

top(

Figure10

1.Dischargechute4.Foldedmetalbracket,

2.Handknob5.Forwardverticalplate,

3.Washer6.Exposedpostinthedeck,

6.Installawasherandhandknoboverthepostcoming

throughthechutetop(

7.Handtightentheknobtosecurethechutetothe

deck.

8.Hooktheexiblelatchonthechutetotheretaining

claspweldedtothesidewallofthedeck(Figure11).

chute

deck

curvedbafe

Figure10).

6

Page 7

G010641

1

2

3

4

5

1.Dischargetube,curved

G013095

1

2

3

4

5

end

2.Openinginbaggertop

3.Dischargetube,aredend

Figure12

Maintenance

RemovingtheFinishingKit

Wheneveryouremovethebaggerkit,removethe

nishingkitusingthefollowingprocedure.Retainall

partsforfutureinstallation.

1.Removethedischargetubefromthemachineand

installthedischargecover.

WARNING

Anuncovereddischargeopeningcouldallowthe

lawnmowertothrowobjectsintheoperatoror

bystander’sdirectionandresultinseriousinjury.

Also,contactwiththebladecouldoccur.

Neveroperatethelawnmowerunlessyouinstall

acoverplate,amulchplate,oragrasschuteand

catcher.

4.Peg

5.Rubberstrap

2.Slidethearedendofthedischargetubeoverthe

endofthechute(Figure12).

3.Movetherubberretainingstraponthechutesnaps

overthepegonthedischargetubetosecureit

Figure12).

(

Figure13

1.Deectorassembly4.Carriagebolt(existing;

2.Locknut(existing;retain)5.Carriagebolt(existing;

3.Locknut(existing;reuse)

reuse)

retain)

2.Replacethemowerblades.

•RemovetheHi-Liftmowerbladesinstalledon

yourdeck;refertotheRemovingtheBlades

sectionintheOperator’sManualformore

information.

•Installthestandardmowerbladesremoved

previously;refertotheInstallingtheBlades

sectionintheOperator’sManualformore

information.

7

Page 8

Loading...

Loading...