Page 1

FormNo.3369-688RevA

48and54inchBaggerFinishingKit

2011andAfterTITANSeriesZero-Turn-RadiusRidingMower

ModelNo.120-7122

ModelNo.120-7123

InstallationInstructions

ThiskitrequirestheBaggerKit79326tocompleteinstallation.For

allTITANSeriesmowers,beginFinishingKitinstallationbefore

installingthebaggerkit.ContactyourAuthorizedServiceDealer

orToroCustomerServicetoobtainthenecessaryparts.Formore

information,visitusatwww.Toro.com.

Safety

Important:TheROPSrollbarisanintegraland

effectivesafetydevice.Keeptherollbarinthe

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

110-6691

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard,mower—donotoperatewithoutthe

deector,dischargecover,orgrasscollectionsystemin

place.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

fullyraisedandlockedpositionwhenoperatingthe

mower.Lowertherollbartemporarilyonlywhen

absolutelynecessary.

©2011—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

Page 2

Installation

G016271

1

2

3

4

5

G010701

1

2

3

4

1

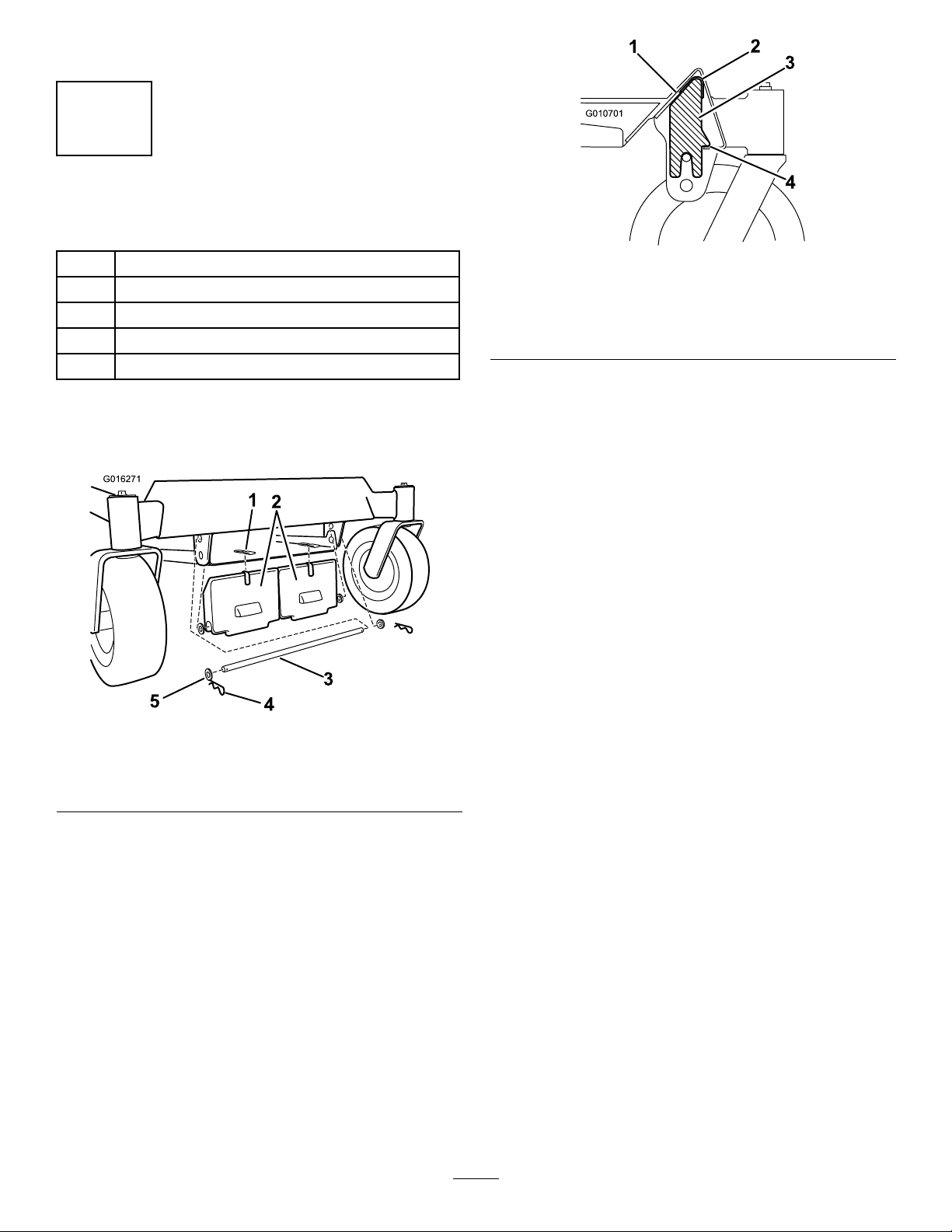

InstallingtheWeight

Partsneededforthisprocedure:

2Weight

2Adhesivebumper

1Rod

4Washer

2Hairpin

Procedure

1.Installanadhesivebumpertotheweight(Figure1).

Figure2

1.Cutawayofthefrontofthe

machineframe

2.Bumper4.Resttheweighthere

Important:Wheneveryouremovethebagger

attachment,remembertoremovethefrontweight

toreturntheproperstabilitytothemachine.

3.Weight

duringinstall

Figure1

1.Adhesivebumper4.Hairpin

2.Frontweight5.Washer

3.Rod

Note:OnTitanMXunits,disconnectthefront

deckpanfromtheframetoallowinstallationofthe

weights.Ensurethepanisinstalledoncetheweights

aresecured.

2.Installtheweighttothefrontofthemachineframe.

Securetheweightwitharod,fourwashers,andtwo

hairpinsasshownin

Note:Wheninstallingthefrontweightallowitto

restonthefrontlipoftheundersideofthemachine

frameasshownFigure2.Thiswillsuspendthe

weightwhileyousecureittothemachine.Use

carenottodislodgetheweightwheninstallingthe

supportingrod.

Figure1.

2

Page 3

2

G016262

G016263

G016264

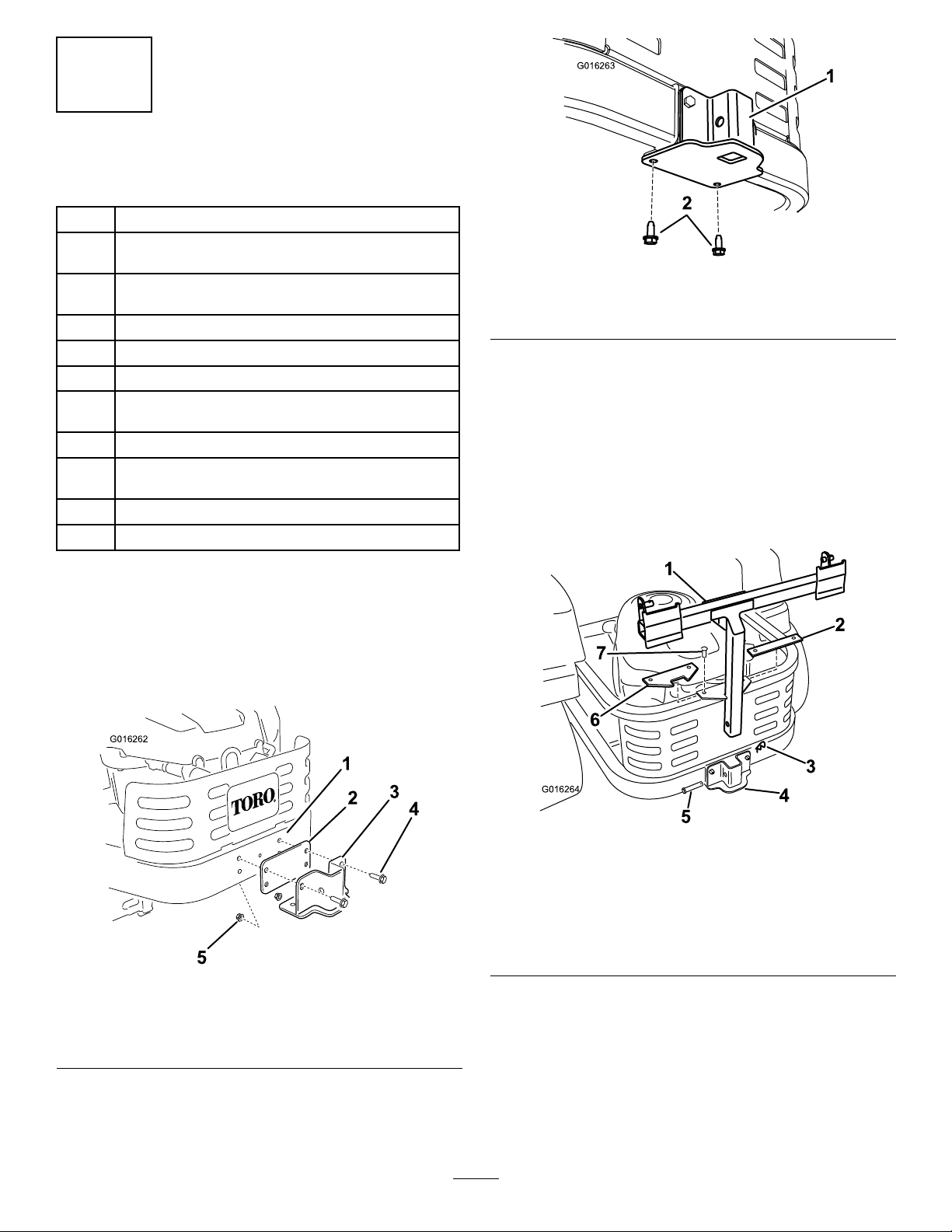

InstallingtheBaggerFrame

Partsneededforthisprocedure:

1

Baggerframe(discardframeinbaggerkit)

Baggerframesupportbracket(discardbracketin

1

baggerkit)

Selftappingscrew(5/16x3/4inch)(includedin

2

baggerkit)

4Hairpincotter—IncludedinBaggerKit79326

2Rod—IncludedinBaggerKit79326

4Washer—IncludedinBaggerKit79326

Bolt(5/16x2-1/2inch)—IncludedinBaggerKit

2

79326

2

Locknut(5/16inch)—IncludedinBaggerKit79326

Clevispin(1/2x2-1/4inch)—IncludedinBagger

1

Kit79326

1

Spacerplate—IncludedinBaggerKit79326

1Angledplate—IncludedinBaggerKit79326

Figure4

1.Supportbracket2.Selftappingscrews(5/16

x3/4inch)

3.Removetheexistingfastenerssecuringthe

rectangularspacerplatefromthetopoftheengine

frameandremovetheplate.

4.Installthenewanglespacerplateasshownin

Figure4usingthefastenersremovedpreviously.

5.Installthebaggerframetothesupportbracket.

Securethebaggerframewithaclevispin(1/2x

2-1/4inch)andhairpincotter(Figure5).

Procedure

1.Locatethebaggerframebracket.Installthebracket

tothemachineframeasshownin

thebrackettotheframeusingtwobolts(5/16x

2-1/2inch)andtwolocknuts(5/16inch).

Figure3

1.Machineframe4.Bolt(5/16x2-1/2inch)

2.Supportspacerplate5.Locknut(5/16inch)

3.Supportbracket

Figure3.Secure

Figure5

1.Baggerframe5.Clevispin(1/2x2-1/4

2.Spacerplate,rectangular

(existing)

3.Hairpin7.Fasteners,existing

4.Supportbracket

inch)

6.Spacerplate,angle(new)

6.Installtwosupportrods,onetoeachsideofthe

baggerframe.Locatetheexistingbracketbetween

thereardrivewheelandframe(Figure6).

2.Securethesupportbrackettothebottomofthe

machineframefrombelowusingtwoselftapping

screws(5/16x3/4inch)asshowninFigure4.

3

Page 4

G010581

1

2

3

4

5

6

4

Figure6

Leftsideshown

1.Baggerframe

2.Clevisend5.Bracketonframe

3.Clevispin

4.Hairpin

6.Washer

3

InstallingtheChute

Partsneededforthisprocedure:

1

Straightbafe(48inchdecksonly)

1

Curvedbafe(54indecksonly)

1

Locknut(5/16inch)

1Handknob

1Washer

1

Chute

Procedure

UsethisprocedurewheninstallingtheFinishingKiton

machineswithboth48and54inchdecks.

7.Insertthebentendoftherodintothebaggerframe

asshowninFigure6.Securetheendoftherodwith

awasherandhairpin.

8.Adjustthesupportrodssothatbaggerframeisheld

securetothemachineframeandseatsinthenotch

oftheanglespacerplateinstalledpreviously.Repeat

thesestepsforeachsupportrod:

A.Loosenthejamnutatthebaseoftheclevisend

oftherod.

B.Rotatetheclevistoadjusttherodtothedesired

length.

C.Aligntheholesintheclevisendwiththeholein

thebaggerframeattheattachmentpoint.

D.Securetheclevisendtothebaggerframeusinga

clevispinandhairpincotter.(

Figure6).

E.Tightenthejamnut.

9.Withbothrodsinstalledandattached,checkthe

baggerframeforplay.Thebaggerframeshouldbe

heldtighttothemachineframe.Ifnecessary,repeat

theprevioussteptosecurethebaggerframe.

10.Forremainingsteps,consultBaggerKit79326

Owner’ s Man ual

,beginningatInstallationstep

2.

WARNING

Anuncovereddischargeopeningcouldallowthe

lawnmowertothrowobjectsintheoperatoror

bystander’sdirectionandresultinseriousinjury.

Also,contactwiththebladecouldoccur.

Neveroperatethelawnmowerunlessyouinstall

acoverplate,amulchplate,oragrasschuteand

catcher.

Neveroperatethemowerwiththedischargeopening

uncovered.Adischargecover,mulchcoverorbagging

chutemustalwaysbeusedwhenthemowerdeckis

operated.

1.Removefastenerssecuringthedeectorassembly

andexistingcutoffbafetothedeck(

Retainallfasteners.Removethefastenersplugging

theforwardhole.

Figure7).

4

Page 5

G010637

1

2

2

3

4

5

6

7

Figure7

1

2

3

4

5

6

7

G015685

G010638

1

2

3

4

5

6

1.Deectorassembly5.Locknut(existing)

2.Fasteners(existing),retain

3.Carriagebolt(existing)

4.Cutoffbafe(existing)

6.Forwardhole

7.Frontretainingclasp

2.Removethedeectorassemblyandreinstallthecut

offbafe.Retainallpartstoconvertthedeckto

sidedischarge.

4.Installthechutetothedeckmakingsuretheopening

intopofthechutealignswiththeexposedposton

thedecktop(Figure9).

Figure9

1.Dischargechute

2.Handknob

3.Washer

4.Postincurvedbafe,

forwardhole

5.Frontexiblelatch

6.Openinginthetopofthe

chute

3.Installabafetodeck(Figure8).For48inch

decks,useastraightbafe.For54inchdecks,

useacurvedbafe.Aligntheverticalpostinthe

bafewithforwardholeinthedeck.Rotatethe

bafeuntilthehorizontalpostalignswiththehole

inthefrontwallofthedeck.Secureittothefront

wallofthedeckusingalocknut.

5.Installawasherandhandknoboverthepostcoming

throughthechutetop.Handtightentosecurethe

chutetothedeck.

6.Hookthefrontexiblelatchonthechutetothe

retainingclaspweldedtothefrontwallofthedeck

Figure10).Hooktheexiblelatchonthebackof

(

thechutetotheretainingclaspweldedtotherear

wallofthedeck.

Figure10

Figure8

1.Retainingclasp5.Horizontalpost

2.Forwardhole6.Locknut

3.Bafe

4.Verticalpost

7.Frontwallhole

1.Flexiblelatchandretainingclasp

5

Page 6

4

G016265

G005672

1

2

3

4

G005757

InstallingtheBaggerTop

Partsneededforthisprocedure:

1

Circularcotterpin

Procedure

1.Installthebaggertoptothebaggerframe.Slide

thebracketsoverthepostsinthebaggerframeand

installthecircularcotterintotheholeintheright

handpost(

totheoperatingposition.Thebaggertopiseasierto

installiftwopeopleworktogether.

Note:Toremovethecircularcotter,continueto

rotateitinthesamedirectionasinstalled.

Figure11).Rotatethebaggertopdown

2.Liftthebaggertopandinstallthebagsbysliding

thebagframehooksontotheretainingbrackets

(Figure12).

1.Baggertop

2.Baggerframe

3.Bracket,baggertop

Figure11

Figure12

1.Bag3.Retainingbracket

2.Baggerframe4.Bagframehook

3.Lowerthebaggertopontothebag(Figure13).

Figure13

4.Circularcotterpin

5.Post

6

Page 7

5

G010641

1

2

3

4

5

6

ConnectingwiththeDischarge

Tube

NoPartsRequired

Procedure

1.Slidethecurvedendofthedischargetubeintothe

openinginthebaggertop(

Figure14).

InstallingtheBlades

Partsneededforthisprocedure:

3

Hi-Liftblade

Procedure

1.Removetheexistingmowerbladesinstalledonyour

deck.RefertotheRemovingtheBladessectionin

theOperator’ sManualformoreinformation.

2.InstalltheHi-Liftmowerbladeslocatedinloose

parts.RefertotheInstallingtheBladessectioninthe

Operator’sManualformoreinformation.

Figure14

1.Dischargetube,curved

end

2.Openinginbaggertop

3.Dischargetube,aredend

2.Slidethearedendofthedischargetubeoverthe

endofthechute.Movetherubberretainingstrapon

thechutesnapsoverthepegonthedischargetube

tosecureit(Figure14).

4.Peg

5.Rubberstrap

7

Page 8

Maintenance

G010637

1

2

2

3

4

5

6

7

RemovingtheFinishingKit

Wheneverthebaggerkitisremoved,thenishingkit

shouldberemovedusingthefollowingprocedure.

Retainallpartsforfutureinstallation.

CAUTION

Removingthebaggerchangestheweight

distributionofthemachine.Operatingthemachine

withthefrontweightsinstalledwithoutthebagger

maycauseanunstableconditionwhichcouldresult

inalossofcontrol.

Ensurethefrontweightsareproperlyremoved

beforeoperatingthemachinewithoutthebagger

attachment.

1.Removethefrontweights.Removethefastener

securingtheweighttothemachine.Takecareto

controltheweightasthesupportrodisremoved.

Figure15

1.Deectorassembly5.Locknut(existing),reuse

2.Fasteners(existing),retain

3.Carriagebolt(existing),

reuse

4.Cutoffbafe(existing)

6.Forwardhole

7.Frontretainingclasp

2.Removethedischargetubefromthemachineinstall

andthedischargecover(

Figure15).

WARNING

Anuncovereddischargeopeningcouldallowthe

lawnmowertothrowobjectsintheoperatoror

bystander’sdirectionandresultinseriousinjury.

Also,contactwiththebladecouldoccur.

Neveroperatethelawnmowerunlessyouinstall

acoverplate,amulchplate,oragrasschuteand

catcher.

3.Replacethemowerblades.

•RemovetheHi-Liftmowerbladesinstalled

onyourdeck.RefertotheRemovingthe

BladessectionintheOperator’sManualformore

information.

•Installthestandardmowerbladesremoved

previously.RefertotheInstallingtheBlades

sectionintheOperator’sManualformore

information.

Important:TheROPSrollbarisanintegraland

effectivesafetydevice.Keeptherollbarinthe

fullyraisedandlockedpositionwhenoperatingthe

mower.Lowertherollbartemporarilyonlywhen

absolutelynecessary.

8

Loading...

Loading...