Page 1

BeltGuardKit

DH200SeriesLawnTractor

ModelNo.120-1 190

Donotsupplytheseinstructionstothecustomer.

TheseinstructionsareforadealertoinstalladditionalbeltguardsmandatedbytheFrenchgovernment.

FormNo.3368-455RevA

InstallationInstructions

Safety

SafetyandInstructional

Decals

Safetydecalsandinstructionsareeasily

visibletotheoperatorandarelocated

nearanyareaofpotentialdanger.

Replaceanydecalthatisdamagedor

lost.

120-1119

1.Firehazard—readtheOperator’sManual.

Installation

1

PreparingforInstallation

NoPartsRequired

Procedure

Important:Refertothe

areunfamiliarwiththespecicsofoperatingthis

machinebeforeproceeding.Themanualcontains

importantinformationaboutsafelyoperatingthe

machine.Ifyoudonotknowthisinformation,you

couldseriouslyinjureyourselforothers.

1.Parkthemachineonalevel,smoothsurfacewith

sufcientspacetoaccessbothsidesofthemowing

deck.

2.Lowerthemowingdecktotheshortestcutting

height.

Operator’ s Man ual

ifyou

©2011—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

WARNING

Beforeworkingonthemachine,stoptheengine,

settheparkingbrake,removetheignitionkey,

anddisconnectthesparkplugwire.

CAUTION

Ifyouleavethekeyintheignitionswitch,

someonecouldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionanddisconnect

thewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoes

notaccidentallycontactthesparkplug.

3.Supporttherearaxleonbothsidesandremoveboth

rearwheels.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

Page 2

2

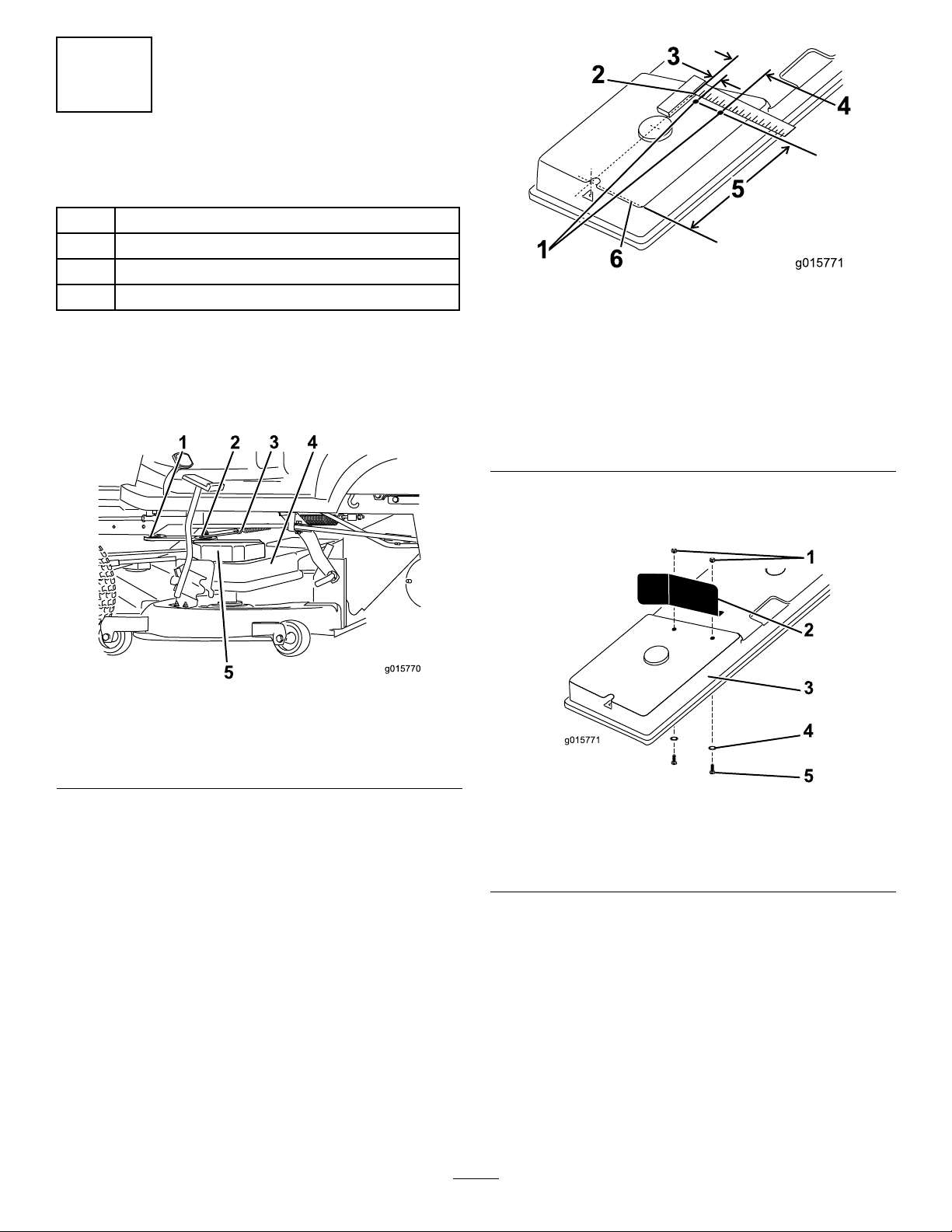

InstallingtheDeckGuard

Partsneededforthisprocedure:

1Deckbeltguard

2

Bolt(M5x12)

2

Washer(M5.3)

2

Locknut(M5)

Procedure

1.RemovethebeltfromthePTOclutchandtheidler

tensionspringfromtheidlerpulley(Figure1).

Figure2

1.Drill5.5mmdiameter(2)

2.Measuredimensions

3and4fromtheline

betweenthecenterofthe

rightboltholeandthe

centerofthespindle.

3.16mm

4.90mm

5.256mm(2)

6.Measuredimension5from

thecenterlineoftheright

bolthole.

6.Mountthedeckguardtothedeckcoverasshown

inFigure3.

Figure1

1.PTOclutch

2.Idlerpulley5.Pulleycoverandpulley

3.Idlertensionspring

4.Deckcover

2.Removetheidlerpulley.

3.Removethepulleycoverandthepulleyunderit

fromtheleftsideofdeckbeltcover(Figure1).

4.Removethedeckbeltcoverfromthedeck.

5.Drill2holesinthetopofthedeckbeltcover

(Figure2).

Figure3

1.Locknut(M5)4.Washer(M5.3)

2.Deckguard

3.Deckcover

5.Bolt(M5x12)

7.Assemblethedeck.

8.Raisethedecktothetallestheight-of-cutand

verifythatthenewlyinstalledguardclearsallwires,

switchesandbeltsandwillnotinterferewiththesafe

operationofthetractionunitorthecuttingdeck.

2

Page 3

3

InstallingtheLeftBeltGuard

Partsneededforthisprocedure:

1

Leftbeltguard

1

Hexbolt(M8-1.25x12)

1

Washer(M8)

1

Locknut(NIM8-1.25)

2

Self-tappingscrew(M4.2x13)

Procedure

1.Ontheleftsideofthemachine,drill2holesas

speciedinFigure4.

Figure5

Fastenersandattachmentpointsfortheleftbeltguard

1.Locknut(NIM8-1.25)4.Locknut,existing(2)

2.Washer(M8)5.Self-tappingscrew(M4.2

3.Hexbolt(M8-1.25x12)

x13)(2)

Note:Theinstalledleftbeltguardshouldappearas

shownin

Figure6.

Figure4

Measurementsfordrillingholesinthepulleybracket

1.Pulleybracket

2.25mm4.35mm

3.3.6mmdiameter(2)

2.Removethe2locknutslocatedatbothsupportson

theundersideofthefootrest.

3.Installtheleftbeltguard.

Note:UsethefastenersshowninFigure5.

Figure6

Theleftbeltguardinstalled

1.Cutoutforsteeringlinkage3.Cutoutforthefuelline

2.Cutoutforparkingbrake4.Guardpassesbetween

thebag-on-demandpedal

andthepulleycover

4.Verifythattheguardisclearofallmovingparts

acrosstheirfullrangeofoperation,thatitwillnot

causedamagetowires,hosesorothercomponents

andthatitwillnotinterferewiththesafeoperation

ofthetractionunitorthecuttingdeck.

3

Page 4

4

InstallingtheRightBeltGuard

Partsneededforthisprocedure:

1Rightbeltguard

1

Hexbolt(M8-1.25x12)

1

Washer(M8)

1

Locknut(NIM8-1.25)

5

Self-tappingscrew(M4.2x13)

Procedure

1.Ontherightsideofthemachine,drillholesinthe

pulleybracket,intherearfootrestsupportandinthe

frontsectionoftheframe(

Figure7).

Figure8

Measurementstodrillholeintherearfootrestsupport

1.3.4mmdiameter3.50mm

2.11mm

C.Drilltheholesinthefrontframeasspeciedin

Figure9.

Figure9

Measurementstodrillholesinthefrontframe

Figure7

1.Pulleybracket

2.Rearfootrestsupport6.Washer(M8)

3.Frontframesection7.Hexbolt(M8-1.25x12)

4.Locknut(NIM8-1.25)8.Self-tappingscrew(M4.2

5.Self-tappingscrew(M4.2

x13)(2)

x13)(3)

A.Measurethelocationfortheholesinthepulley

bracketasspeciedin

Figure4.

B.Fortheholeintherearfootrestsupport,usethe

measurementsinFigure8.

1.3.4mmdiameter(2)

2.10mm4.152.5mm

3.25mm

2.Positiontherightbeltguardbehindthetraction

pedalassemblyandtheswitchmountedbehindit

andattachittotheframeofthemachineasshown

inFigure10.

Figure10

1.Rightbeltguard2.Tractionpedalassembly

3.Verifythattheguardisclearofallmovingparts

acrosstheirfullrangeofoperation,thatitwillnot

causedamagetowires,hosesorothercomponents

andthatitwillnotinterferewiththesafeoperation

ofthetractionunitorthecuttingdeck.

4

Loading...

Loading...