Page 1

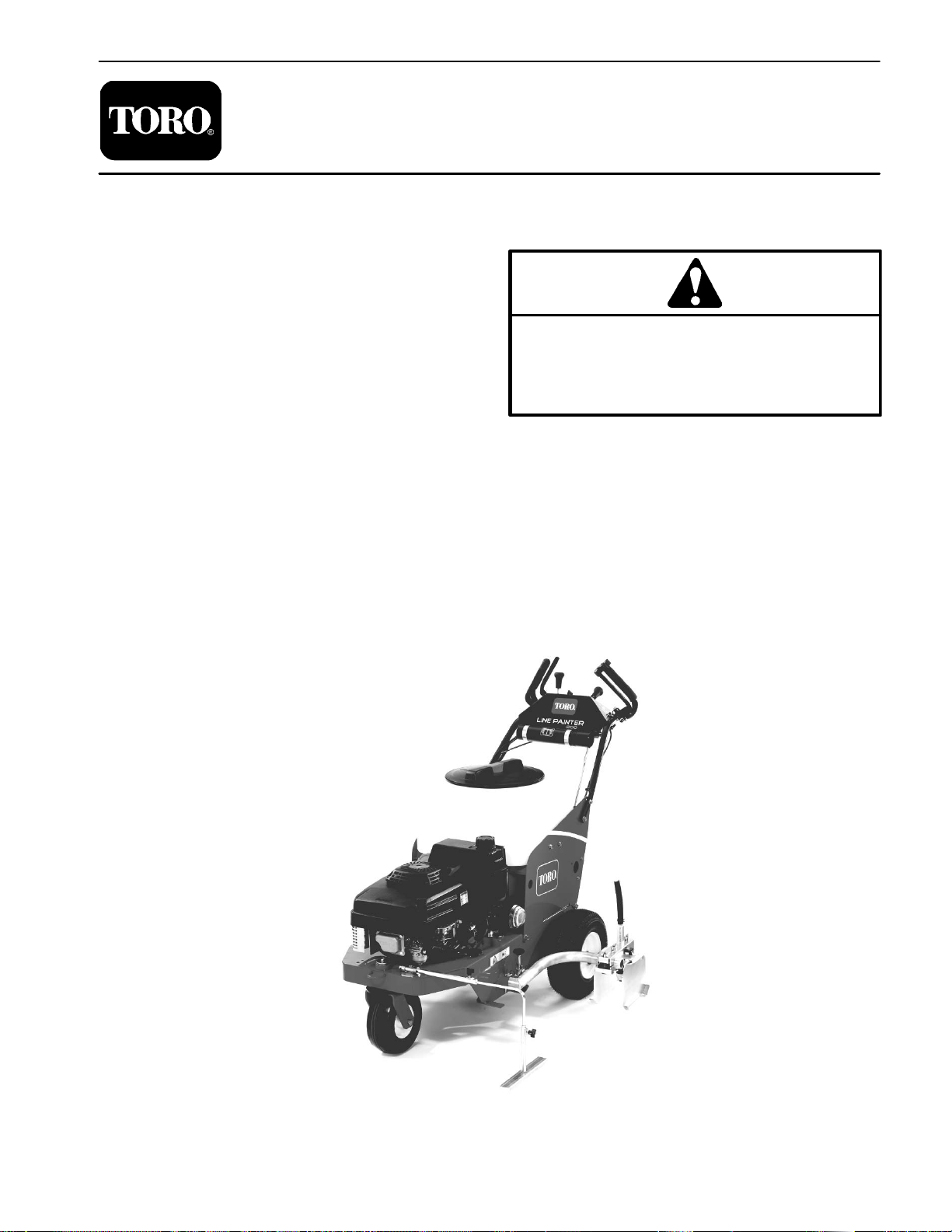

Preface

The purpose of this publication is to provide the service

technician with information for troubleshooting, testing

and repair of major systems and components on the

Line Painter 1200.

REFER TO THE OPERATOR’S MANUALS FOR OPERATING, MAINTENANCE AND ADJUSTMENT

INSTRUCTIONS. Space is provided in Chapter 2 of this

book to insert the Operator’s Manuals and Parts Cata

logs for your machine. Replacement Operator’s Manuals are available on the internet at www.toro.com or by

sending complete Model and Serial Number to:

The Toro Company

Attn. Technical Publications

8111 Lyndale Avenue South

Minneapolis, MN 55420

The Toro Company reserves the right to change product

specifications or this publication without notice.

-

Part No. 05144SL Rev. A

Service Manual

Line Painter 1200

This safety symbol means DANGER, WARNING,

or CAUTION, PERSONAL SAFETY INSTRUCTION. When you see this symbol, carefully read

the instructions that follow. Failure to obey the

instructions may result in personal injury.

NOTE: A NOTE will give general information about the

correct operation, maintenance, service, testing or re

pair of the machine.

IMPORTANT: The IMPORTANT notice will give important instructions which must be followed to prevent damage to systems or components on the

machine.

-

E The Toro Company – 2005, 2007

Page 2

This page is intentionally blank.

Line Painter 1200

Page 3

Table Of Contents

Chapter 1 – Safety

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . 1 – 2

Safety and Instruction Decals . . . . . . . . . . . . . . . . 1 – 4

Chapter 2 – Product Records and Maintenance

Product Records

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 – 1

Equivalents and Conversions . . . . . . . . . . . . . . . . 2 – 2

Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . 2 – 3

Chapter 3 – Gasoline Engine

Introduction

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 – 3

General Information . . . . . . . . . . . . . . . . . . . . . . . . 3 – 4

Service and Repairs . . . . . . . . . . . . . . . . . . . . . . . . 3 – 5

KAWASAKI FJ180V SERVICE MANUAL

Chapter 4 – Electrical System

Electrical Schematic

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 – 3

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 – 4

Component Testing . . . . . . . . . . . . . . . . . . . . . . . . . 4 – 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . 2 – 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 – 2

. . . . . . . . . . . . . . . . . . . . . . . . 4 – 2

Chapter 5 – Paint System

Specifications

Paint Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 – 3

Circuit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 – 4

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 – 8

General Information . . . . . . . . . . . . . . . . . . . . . . . . 5 – 9

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 – 10

Service and Repairs . . . . . . . . . . . . . . . . . . . . . . . 5 – 12

Chapter 6 – Chassis and Controls

Specifications

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 – 3

Service and Repairs . . . . . . . . . . . . . . . . . . . . . . . . 6 – 6

Chapter 7 – Traction Drive System

Service and Repairs

DANA MODEL 4360 TEARDOWN AND ASSEMBLY

INSTRUCTIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 – 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 – 2

. . . . . . . . . . . . . . . . . . . . . . . . 7 – 2

SafetyProduct Records

and Maintenance

Engine

Gasoline

SystemSystem

Electrical

Paint

SystemControls

Chassis and

Traction Drive

Line Painter 1200

Page 4

This page is intentionally blank.

Line Painter 1200

Page 5

Table of Contents

SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . 2

Before Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

While Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Maintenance and Service . . . . . . . . . . . . . . . . . . . . 3

SAFETY AND INSTRUCTION DECALS . . . . . . . . . . 4

Chapter 1

Safety

Safety

Line Painter 1200 Page 1 – 1 Safety

Page 6

Safety Instructions

The Line Painter 1200 is designed and tested to offer

safe service when operated and maintained properly.

Although hazard control and accident prevention par

tially are dependent upon the design and configuration

of the machine, these factors are also dependent upon

the awareness, concern and proper training of the per

sonnel involved in the operation, transport, maintenance and storage of the machine. Improper use or

maintenance of the machine can result in injury or

-

-

Before Operating

1. Read and understand the contents of the Operator’s

Manual before starting and operating the machine. Become familiar with the controls and know how to stop the

machine quickly. A replacement Operator’s Manual is

available on the Internet at www.Toro.com or by sending

the complete model and serial number to:

The Toro Company

Attn. Technical Publications

8111 Lyndale Avenue South

Bloomington, Minnesota 55420–1196

2. Keep all shields, safety devices and decals in place.

If a shield, safety device or decal is defective, illegible

or damaged, repair or replace it before operating the

machine. Also tighten any loose nuts, bolts or screws to

ensure machine is in safe operating condition.

death. To reduce the potential for injury or death, comply

with the following safety instructions.

WARNING

To reduce the potential for injury or death,

comply with the following safety instructions.

3. Since gasoline is highly flammable, handle it carefully:

A. Store fuel in containers specifically designed for

this purpose.

B. Do not remove machine fuel tank cap while engine is hot or running.

C. Do not smoke while handling fuel.

D. Fill fuel tank outdoors and only to within an inch of

the top of the tank, not the filler neck. Do not overfill

the fuel tank.

E. If fuel is spilled, do not start engine. Move the machine away from the area of spillage and allow the

gasoline vapors to dissipate. Properly dispose of any

spilled fuel.

While Operating

1. Operator should be in the operator’s position when

operating the Line Painter 1200.

2. Do not run engine in a confined area without adequate ventilation. Exhaust fumes are hazardous and

could possibly be deadly.

3. Do not touch engine, muffler or exhaust pipe while

engine is running or soon after it is stopped. These

areas could be hot enough to cause burns.

4. If abnormal vibration is detected, stop machine immediately and determine source of vibration. Correct

problems before resuming the use of the machine.

5. Use extreme caution when operating the machine in

reverse or when pulling the machine rearward.

6. Always wear safety goggles or safety glasses with

side shields when operating the machine.

Safety

Page 1 – 2

7. While operating, the Line Painter 1200 may exceed

noise levels of 85dB(A) at the operator position. Hearing

protection is recommended for prolonged exposure to

reduce the potential of permanent hearing damage.

8. Before leaving the operator’s position of the Line

Painter 1200:

A. Release paint control lever to stop the paint operation.

B. Ensure that vehicle traction lever is in neutral, apply parking brake, stop engine and remove key from

ignition switch.

9. Use only latex base paint in the Line Painter 1200.

Do not use oil based paint!

Line Painter 1200

Page 7

Maintenance and Service

1. Before servicing or making adjustments, position

machine on a level surface and apply parking brake to

prevent machine from moving.

2. Disconnect the spark plug wire from the spark plug

and position the wire away from the spark plug to ensure

that the engine will not start accidentally.

3. Make sure machine is in safe operating condition by

keeping all nuts, bolts and screws tight.

4. Never store the machine or fuel container inside

where there is an open flame, such as near a water heat

er or furnace.

5. Make sure all paint system line connectors are tight

and all paint system hoses and lines are in good condi

tion before applying pressure to the paint system.

6. Before disconnecting any paint system component

or performing any work on the paint system, all pressure

in system must be relieved.

7. Do not use lacquers, lacquer thinners, acetones or

other solvents when servicing the paint system of the

Line Painter 1200.

-

-

8. Do not overspeed the engine by changing governor

setting. To assure safety and accuracy, check maximum

engine speed with a tachometer.

9. Shut engine off before checking or adding oil to the

engine crankcase.

10.To reduce potential fire hazard, keep engine area

free of excessive grease, grass, leaves and dirt.

11. If major repairs are ever needed or assistance is desired, contact an Authorized Toro Distributor.

12.When changing tires or performing other service,

make sure machine is properly supported. If the ma

chine is not properly supported, the machine may move

or fall, which may result in personal injury.

13.At the time of manufacture, the machine conformed

to all applicable safety standards. To assure optimum

performance and continued safety certification of the

machine, use genuine Toro replacement parts and ac

cessories. Replacement parts and accessories made

by other manufacturers may result in non-conformance

with the safety standards, and the warranty may be

voided.

Safety

-

-

Line Painter 1200 Page 1 – 3 Safety

Page 8

Safety and Instruction Decals

Numerous safety and instruction decals are affixed to

the Line Painter 1200. If any decal becomes illegible or

damaged, install a new decal. Part numbers for replace

ment decals are listed in your Parts Catalog. Order replacement decals from your Authorized Toro Distributor.

-

Safety

Page 1 – 4

Line Painter 1200

Page 9

Product Records and Maintenance

Table of Contents

Chapter 2

PRODUCT RECORDS . . . . . . . . . . . . . . . . . . . . . . . . . 1

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

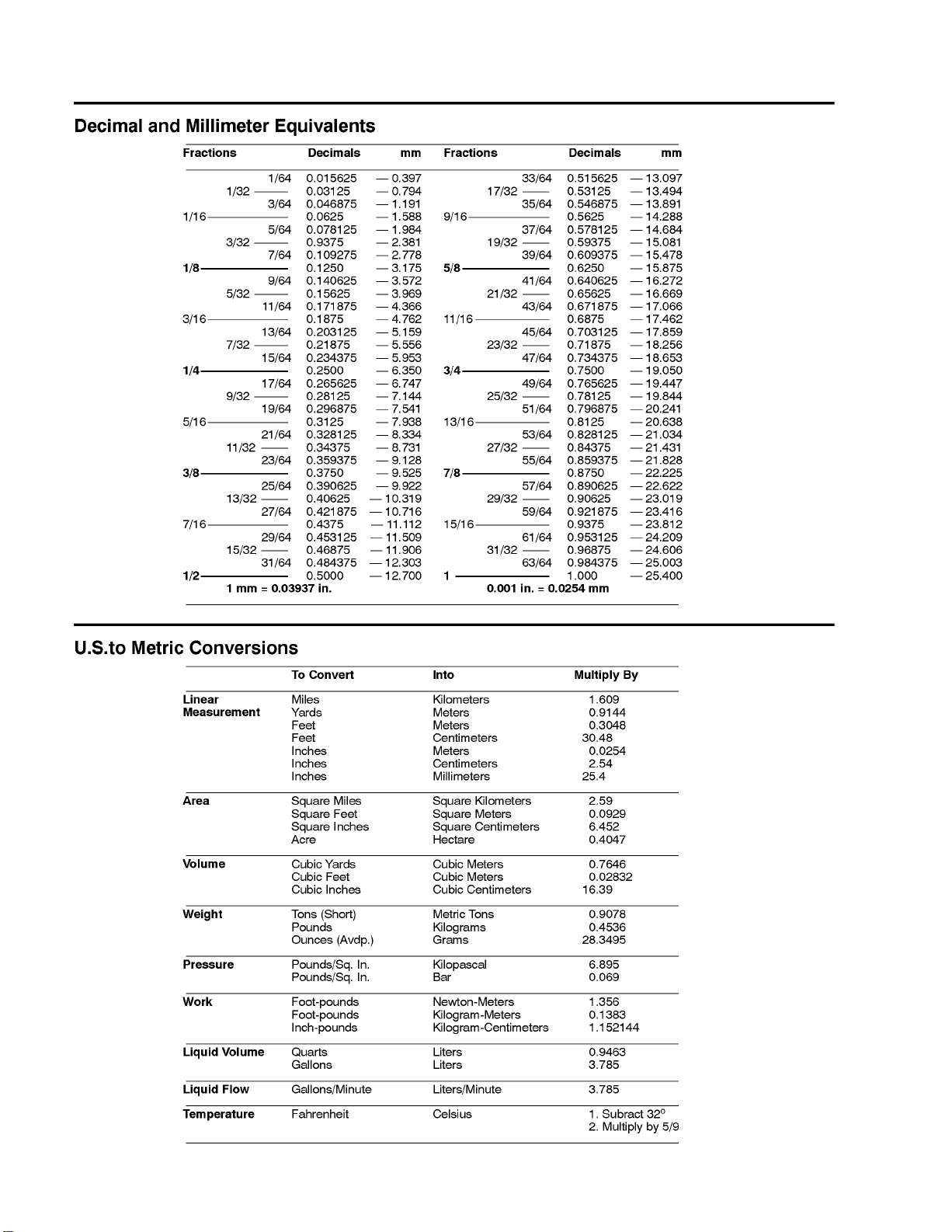

EQUIVALENTS AND CONVERSIONS . . . . . . . . . . . 2

Decimal and Millimeter Equivalents . . . . . . . . . . . . 2

U.S. to Metric Conversions . . . . . . . . . . . . . . . . . . . 2

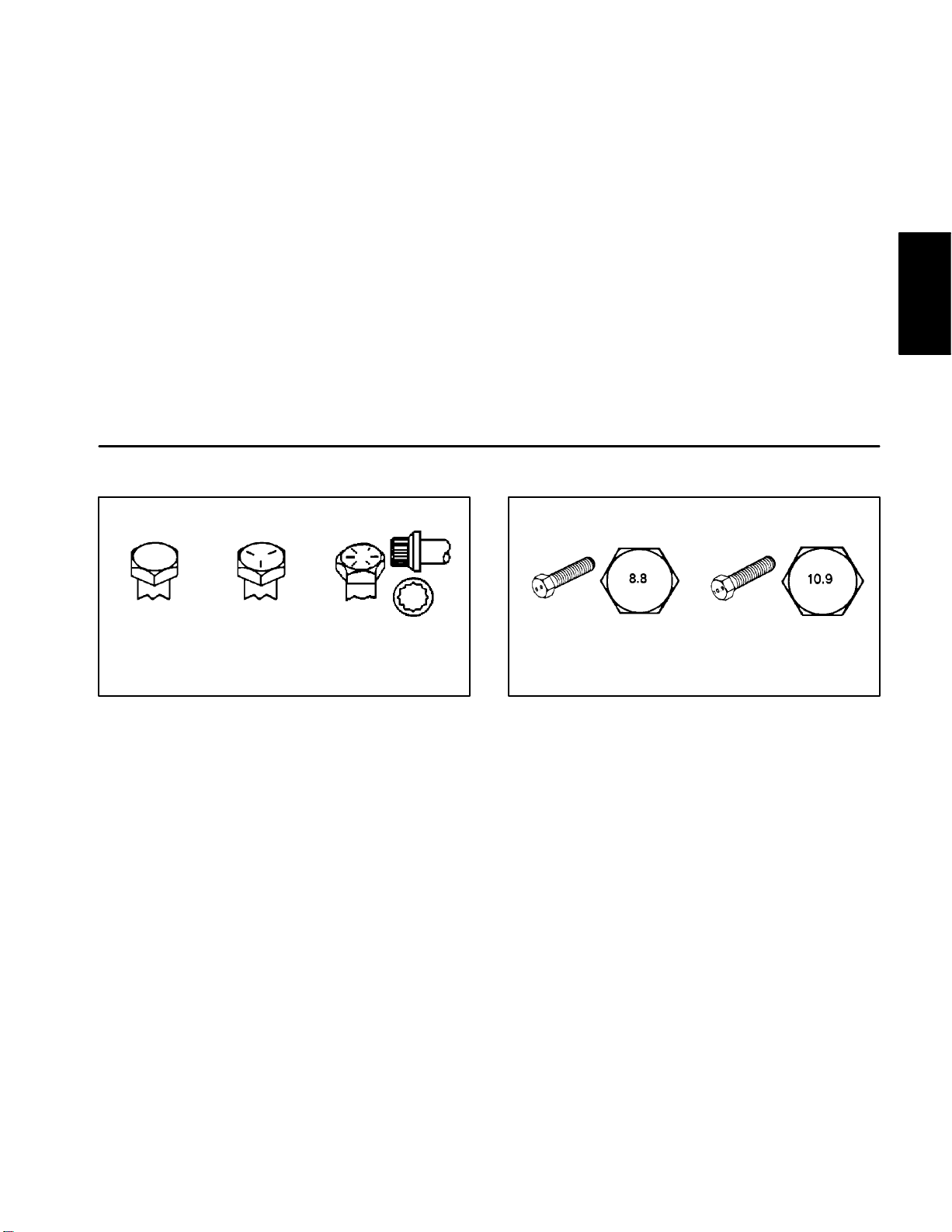

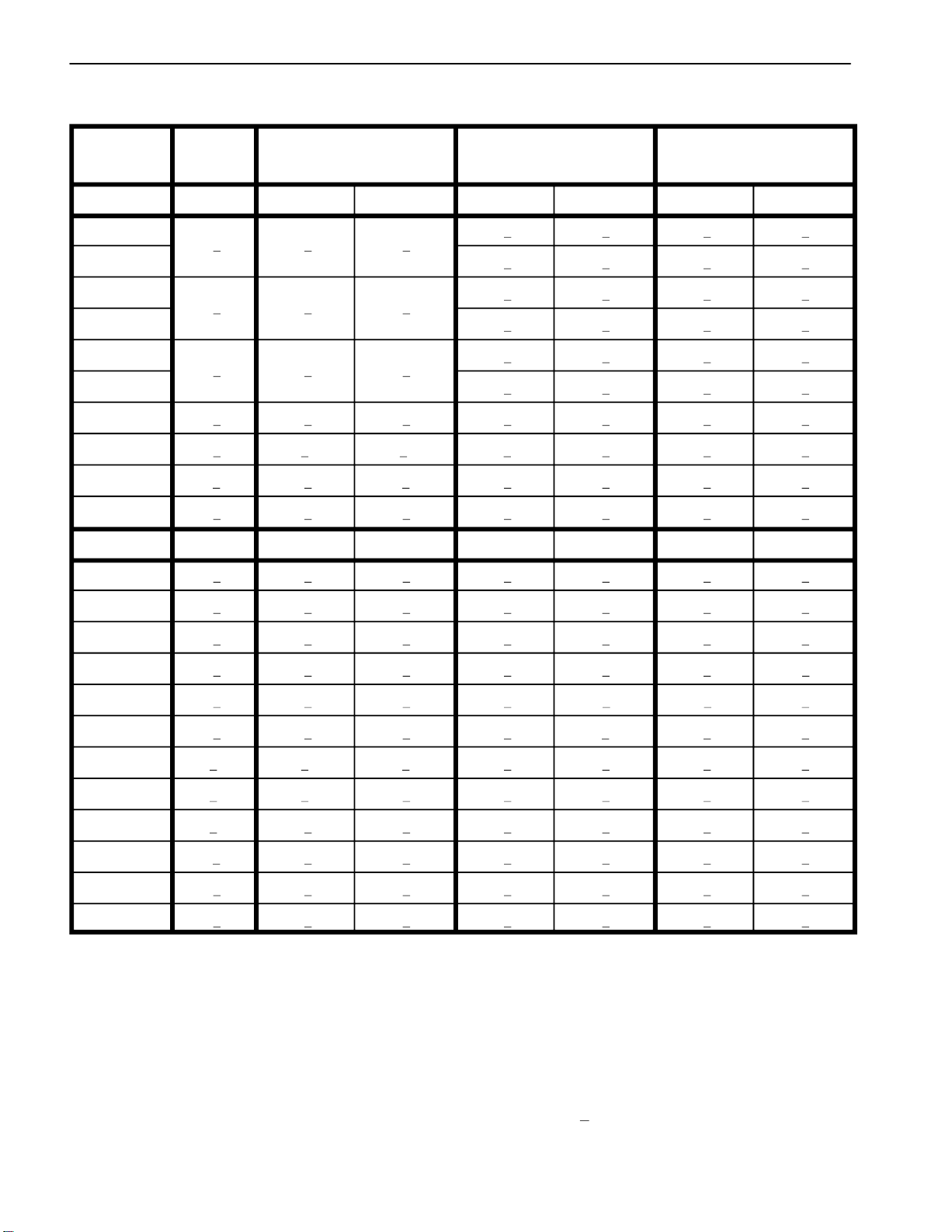

TORQUE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . 3

Fastener Identification . . . . . . . . . . . . . . . . . . . . . . . 3

Product Records

Insert a copy of the Operator’s Manual and Parts Catalog for your Line Painter 1200 at the end of this chapter.

Additionally, if any optional equipment or accessories

have been installed to your machine, insert the Installa

tion Instructions, Operator’s Manuals and Parts Catalogs for those options at the end of this chapter.

-

Maintenance

Maintenance procedures and recommended service intervals for the Line Painter 1200 are covered in the Operator’s Manual. Refer to that publication when

performing regular equipment maintenance.

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Inch Series) . . . . . . . . . . . . . . . 4

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Metric Fasteners) . . . . . . . . . . 5

Other Torque Specifications

Conversion Factors

. . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . 6

Product Records

and Maintenance

Line Painter 1200 Page 2 – 1 Product Records and Maintenance

Page 10

Equivalents and Conversions

Product Records and Maintenance

Page 2 – 2

Line Painter 1200

Page 11

Torque Specifications

Recommended fastener torque values are listed in the

following tables. For critical applications, as determined

by Toro, either the recommended torque or a torque that

is unique to the application is clearly identified and spe

cified in this Service Manual.

These Torque Specifications for the installation and

tightening of fasteners shall apply to all fasteners which

do not have a specific requirement identified in this Ser

vice Manual. The following factors shall be considered

when applying torque: cleanliness of the fastener, use

of a thread sealant (e.g. Loctite), degree of lubrication

on the fastener, presence of a prevailing torque feature

(e.g. Nylock nut), hardness of the surface underneath

the fastener’s head or similar condition which affects the

installation.

-

-

Fastener Identification

As noted in the following tables, torque values should be

reduced by 25% for lubricated fasteners to achieve

the similar stress as a dry fastener. Torque values may

also have to be reduced when the fastener is threaded

into aluminum or brass. The specific torque value

should be determined based on the aluminum or brass

material strength, fastener size, length of thread en

gagement, etc.

The standard method of verifying torque shall be performed by marking a line on the fastener (head or nut)

and mating part, then back off fastener 1/4 of a turn.

Measure the torque required to tighten the fastener until

the lines match up.

-

Product Records

and Maintenance

Grade 1 Grade 5 Grade 8

Inch Series Bolts and Screws

Figure 1 Figure 2

Class 8.8 Class 10.9

Metric Bolts and Screws

Line Painter 1200 Page 2 – 3 Product Records and Maintenance

Page 12

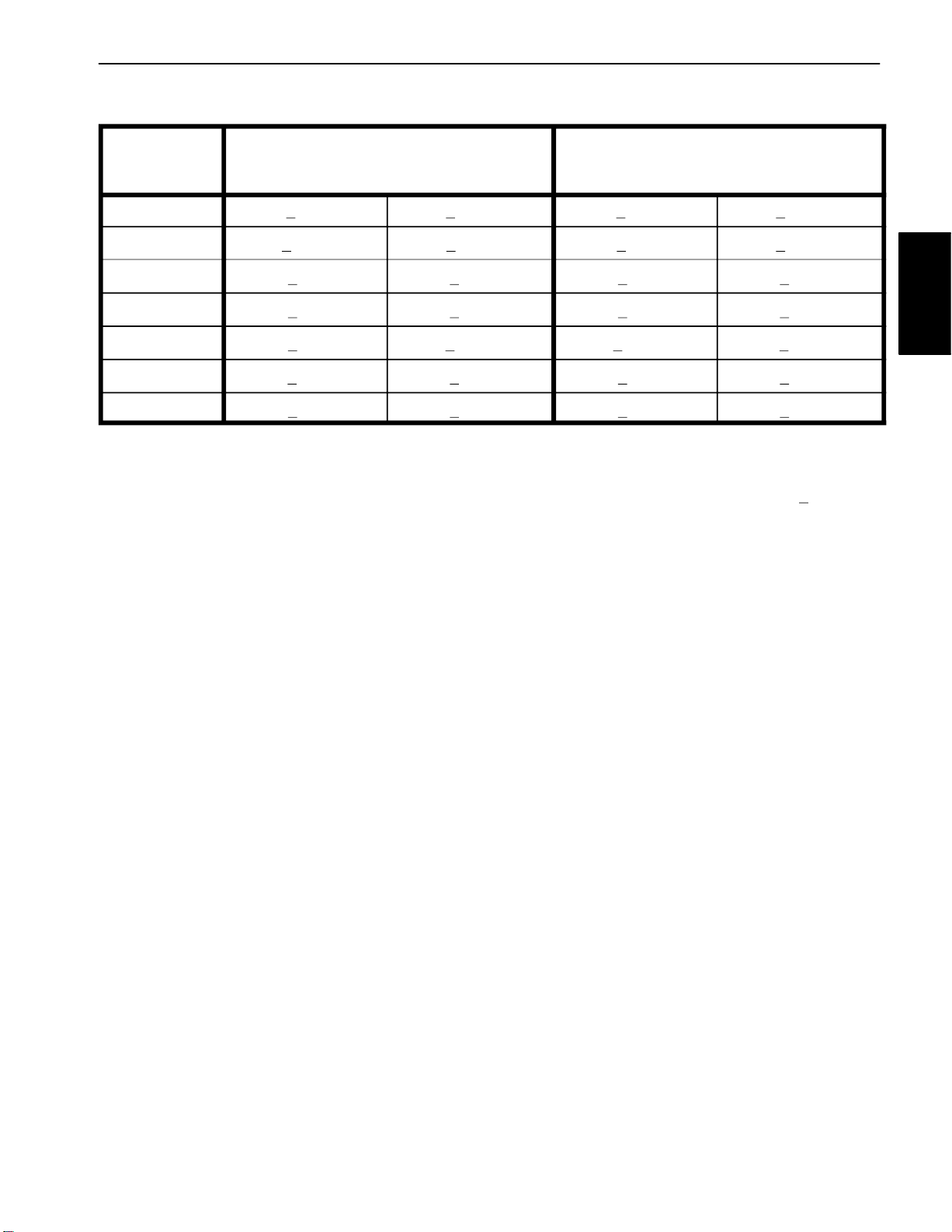

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

Grade 1, 5 & SAE Grade 1 Bolts, Screws, Studs & SAE Grade 5 Bolts, Screws, Studs & SAE Grade 8 Bolts, Screws, Studs &

Thread Size

8 with Thin Sems** with Regular Height Nuts Sems** with Regular Height Nuts Sems** with Regular Height Nuts

Height Nuts (SAE J995 Grade 2 or Stronger Nuts) (SAE J995 Grade 2 or Stronger Nuts) (SAE J995 Grade 5 or Stronger Nuts)

in–lb in–lb N–cm in–lb N–cm in–lb N–cm

# 6 – 32 UNC 15 + 2 169 + 23 23 + 3 262 + 34

# 6 – 40 UNF

# 8 – 32 UNC 29 + 3 328 + 34 41 + 5 463 + 56

# 8 – 36 UNF

# 10 – 24 UNC 42 + 5 475 + 56 60 + 6 678 + 68

# 10 – 32 UNF

1/4 – 20 UNC 48 + 7 53 + 7 599 + 79 100 + 10 1130 + 113 140 + 15 1582 + 169

1/4 – 28 UNF 53 + 7 65 + 10 734 + 113 115 + 12 1299 + 136 160 + 17 1808 + 192

5/16 – 18 UNC 115 + 15 105 + 15 1186 + 169 200 + 25 2260 + 282 300 + 30 3390 + 339

5/16 – 24 UNF 138 + 17 128 + 17 1446 + 192 225 + 25 2542 + 282 325 + 33 3672 + 373

3/8 – 16 UNC 16 + 2 16 + 2 22 + 3 30 + 3 41 + 4 43 + 5 58 + 7

3/8 – 24 UNF 17 + 2 18 + 2 24 + 3 35 + 4 47 + 5 50 + 6 68 + 8

7/16 – 14 UNC 27 + 3 27 + 3 37 + 4 50 + 5 68 + 7 70 + 7 95 + 9

7/16 – 20 UNF 29 + 3 29 + 3 39 + 4 55 + 6 75 + 8 77 + 8 104 + 11

10 + 2

13 + 2

18 + 2

ft–lb ft–lb N–m ft–lb N–m ft–lb N–m

13 + 2

25 + 5

30 + 5

147 + 23

17 + 2 192 + 23 25 + 3 282 + 34

282 + 56

31 + 4 350 + 45 43 + 5 486 + 56

339 + 56

48 + 5 542 + 56 68 + 7 768 + 79

1/2 – 13 UNC 30 + 3 48 + 7 65 + 9 75 + 8 102 + 11 105 + 11 142 + 15

1/2 – 20 UNF 32 + 4 53 + 7 72 + 9 85 + 9 115 + 12 120 + 12 163 + 16

5/8 – 11 UNC 65 + 10 88 + 12 119 + 16 150 + 15 203 + 20 210 + 21 285 + 28

5/8 – 18 UNF 75 + 10 95 + 15 129 + 20 170 + 18 230 + 24 240 + 24 325 + 33

3/4 – 10 UNC 93 + 12 140 + 20 190 + 27 265 + 27 359 + 37 375 + 38 508 + 52

3/4 – 16 UNF 115 + 15 165 + 25 224 + 34 300 + 30 407 + 41 420 + 43 569 + 58

7/8 – 9 UNC 140 + 20 225 + 25 305 + 34 430 + 45 583 + 61 600 + 60 813 + 81

7/8 – 14 UNF 155 + 25 260 + 30 353 + 41 475 + 48 644 + 65 667 + 66 904 + 89

** A Sems screw is a self–tapping screw equipped with

a captive washer.

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

NOTE: Torque values may have to be reduced when

engine oil or thread sealant such as Loctite.

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

NOTE: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the mini

mum proof load specified in SAE J429. The tolerance is

approximately +

10% of the nominal torque value. Thin

height nuts include jam nuts.

-

Product Records and Maintenance

Page 2 – 4

Line Painter 1200

Page 13

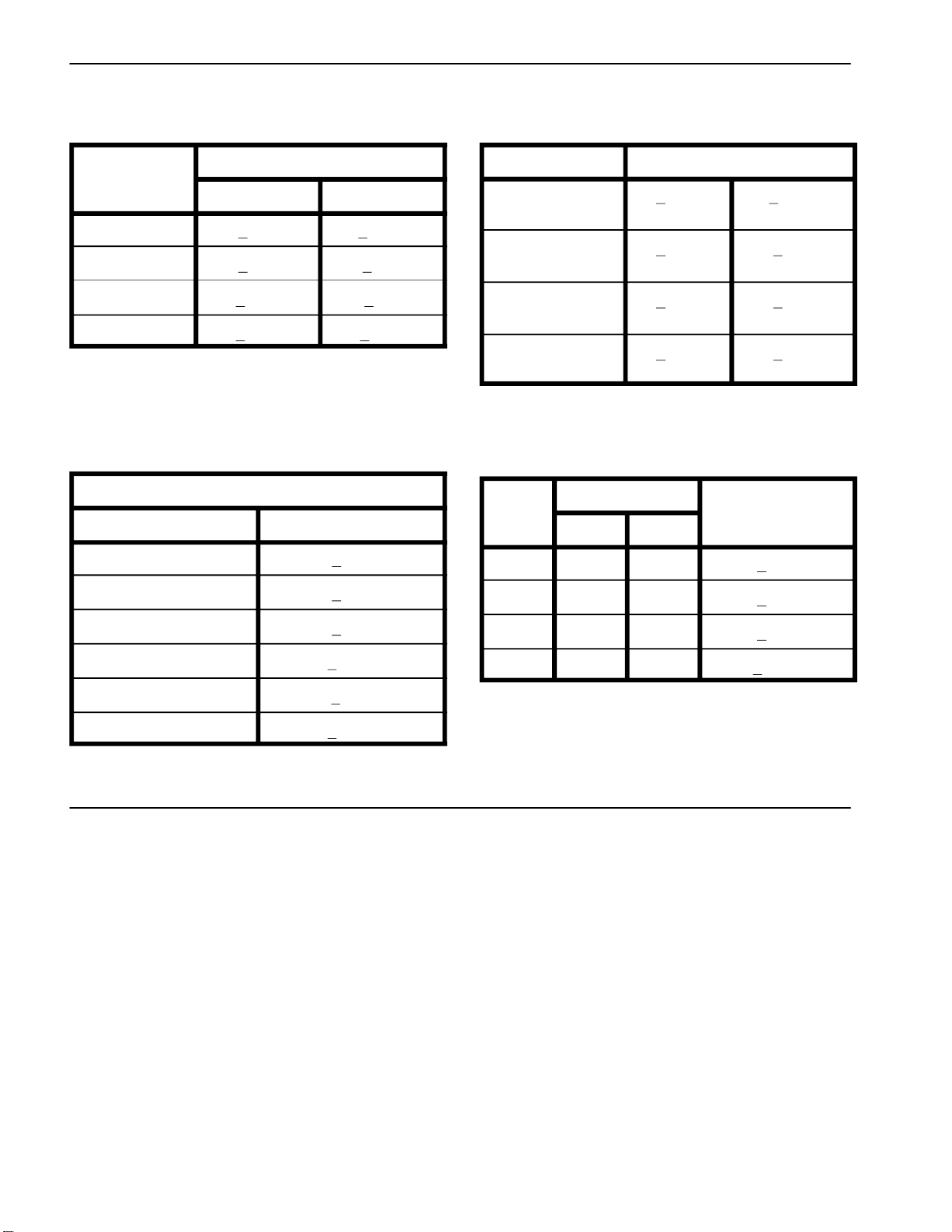

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Fasteners)

Class 8.8 Bolts, Screws and Studs with

Thread Size

M5 X 0.8 57 + 6 in–lb 644 + 68 N–cm 78 + 8 in–lb 881 + 90 N–cm

M6 X 1.0 96 + 10 in–lb 1085 + 113 N–cm 133 + 14 in–lb 1503 + 158 N–cm

M8 X 1.25 19 + 2 ft–lb 26 + 3 N–m 28 + 3 ft–lb 38 + 4 N–m

M10 X 1.5 38 + 4 ft–lb 52 + 5 N–m 54 + 6 ft–lb 73 + 8 N–m

M12 X 1.75 66 + 7 ft–lb 90 + 10 N–m 93 + 10 ft–lb 126 + 14 N–m

M16 X 2.0 166 + 17 ft–lb 225 + 23 N–m 229 + 23 ft–lb 310 + 31 N–m

M20 X 2.5 325 + 33 ft–lb 440 + 45 N–m 450 + 46 ft–lb 610 + 62 N–m

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

Regular Height Nuts

(Class 8 or Stronger Nuts)

NOTE: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAE J1199. The tolerance is approximately +

nominal torque value.

Class 10.9 Bolts, Screws and Studs with

Regular Height Nuts

(Class 10 or Stronger Nuts)

10% of the

Product Records

and Maintenance

Line Painter 1200 Page 2 – 5 Product Records and Maintenance

Page 14

Other Torque Specifications

SAE Grade 8 Steel Set Screws Wheel Bolts and Lug Nuts

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 – 20 UNC 140 + 20 in–lb 73 + 12 in–lb

5/16 – 18 UNC 215 + 35 in–lb 145 + 20 in–lb

3/8 – 16 UNC 35 + 10 ft–lb 18 + 3 ft–lb

1/2 – 13 UNC 75 + 15 ft–lb 50 + 10 ft–lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23 or Type F

Thread Size Baseline Torque*

No. 6 – 32 UNC 20 + 5 in–lb

No. 8 – 32 UNC 30 + 5 in–lb

Thread Size

7/16 – 20 UNF

Grade 5

1/2 – 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non–lubricated fasteners.

Thread Cutting Screws

(Zinc Plated Steel)

Thread

Size

No. 6 18 20 20 + 5 in–lb

No. 8 15 18 30 + 5 in–lb

Threads per Inch

Type A Type B

Recommended Torque**

65 + 10 ft–lb 88 + 14 N–m

80 + 10 ft–lb 108 + 14 N–m

80 + 10 ft–lb 108 + 14 N–m

80 + 10 ft–lb 108 + 14 N–m

orque* Baseline Torque*

No. 10 – 24 UNC 38 + 7 in–lb

1/4 – 20 UNC 85 + 15 in–lb

5/16 – 18 UNC 110 + 20 in–lb

3/8 – 16 UNC 200 + 100 in–lb

Conversion Factors

in–lb X 11.2985 = N–cm N–cm X 0.08851 = in–lb

ft–lb X 1.3558 = N–m N–m X 0.7376 = ft–lb

No. 10 12 16 38 + 7 in–lb

No. 12 11 14 85 + 15 in–lb

* Hole size, material strength, material thickness & finish

must be considered when determining specific torque

values. All torque values are based on non–lubricated

fasteners.

Product Records and Maintenance

Page 2 – 6

Line Painter 1200

Page 15

Table of Contents

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . 4

Fuel Shut–off Valve . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SERVICE AND REPAIRS . . . . . . . . . . . . . . . . . . . . . . 5

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

KAWASAKI FJ180V SERVICE MANUAL

Chapter 3

Gasoline Engine

Engine

Gasoline

Line Painter 1200 Page 3 – 1 Gasoline Engine

Page 16

Introduction

This Chapter gives information about specifications,

maintenance, troubleshooting, testing and repair of the

Kawasaki FJ180V gasoline engine used in the Line

Painter 1200.

Most repairs and adjustments require tools which are

commonly available in many service shops. Special

tools are described in the Kawasaki FJ180V Service

Manual that is included at the end of this Chapter. The

use of some specialized test equipment is explained.

However, the cost of the test equipment and the special

ized nature of some repairs may dictate that the work be

done at an engine repair facility.

-

Service and repair parts for the Kawasaki engine used

to power the Line Painter 1200 are supplied through

your local Toro distributor. Be prepared to provide your

distributor with the Toro model and serial number.

Gasoline Engine Page 3 – 2 Line Painter 1200

Page 17

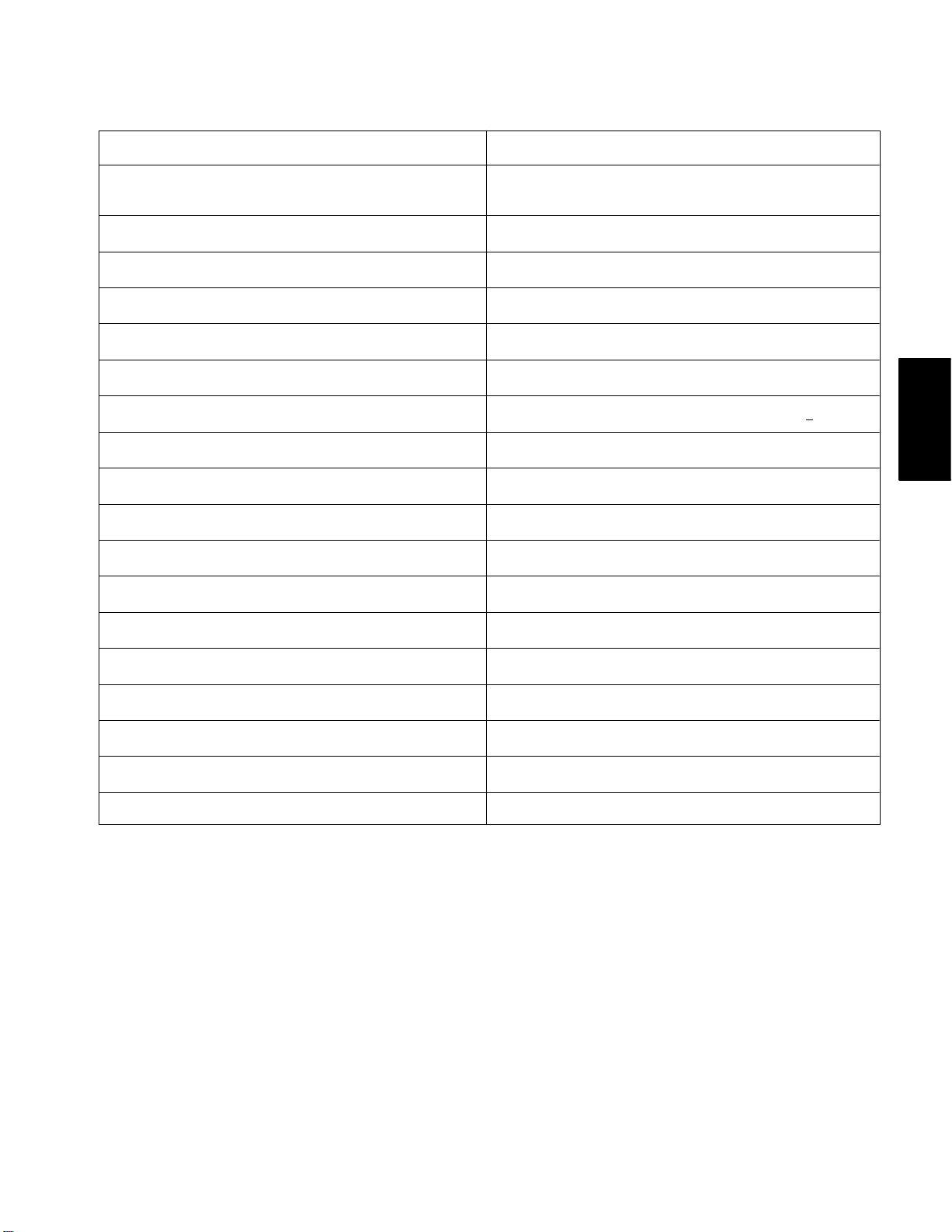

Specifications

Item Description

Make / Designation Kawasaki, FJ180V, 4–stroke,

air–cooled, OHV, single cylinder

Bore x Stroke 2.6” x 2.1” (65 mm x 54 mm)

Total Displacement 10.9 cu. in. (179 cc)

Compression Ratio 8.5:1

Carburetor Float Feed, Fixed Main Jet

Governor Mechanical

High Idle (No Load) 2800 + 100 RPM

Direction of Rotation Counter Clockwise (Facing PTO Shaft)

Fuel Unleaded, Automotive Grade Gasoline

Fuel Tank Capacity 4 Quart (3.8 Liter)

Engine Oil See Operator’s Manual

Lubrication System Pressure Lubrication

Oil Capacity (Including Oil Filter) 0.9 Quart (0.85 Liter)

Engine

Gasoline

Air Cleaner Dual Element

Ignition System Flywheel Magneto CDI

Spark Plug NGK BPR5ES

Spark Plug Gap .028” to .032” (.7 to .8 mm)

Dry Weight 35.3 Pounds (16 Kilograms)

Line Painter 1200 Page 3 – 3 Gasoline Engine

Page 18

General Information

Fuel Shut–off Valve

The fuel shut off valve is positioned in the fuel hose between the fuel tank and the carburetor inlet. It has two

positions: CLOSED and OPEN. Turn valve to the closed

position when storing or transporting the machine. Ro

tate valve to the open position before starting the engine.

-

1

Figure 1

1. Fuel shut–off valve

Gasoline Engine Page 3 – 4 Line Painter 1200

Page 19

Service and Repairs

Cooling System

IMPORTANT: The engine that powers the Line

Painter 1200 is air–cooled. Operating the engine

with dirty or plugged cooling fins or a plugged or

dirty blower housing will result in engine overheat

ing and damage.

1. Park machine on a level surface, stop engine, engage parking brake and remove key from the ignition

switch. Remove high tension lead from the spark plug

and position the lead away from the spark plug.

-

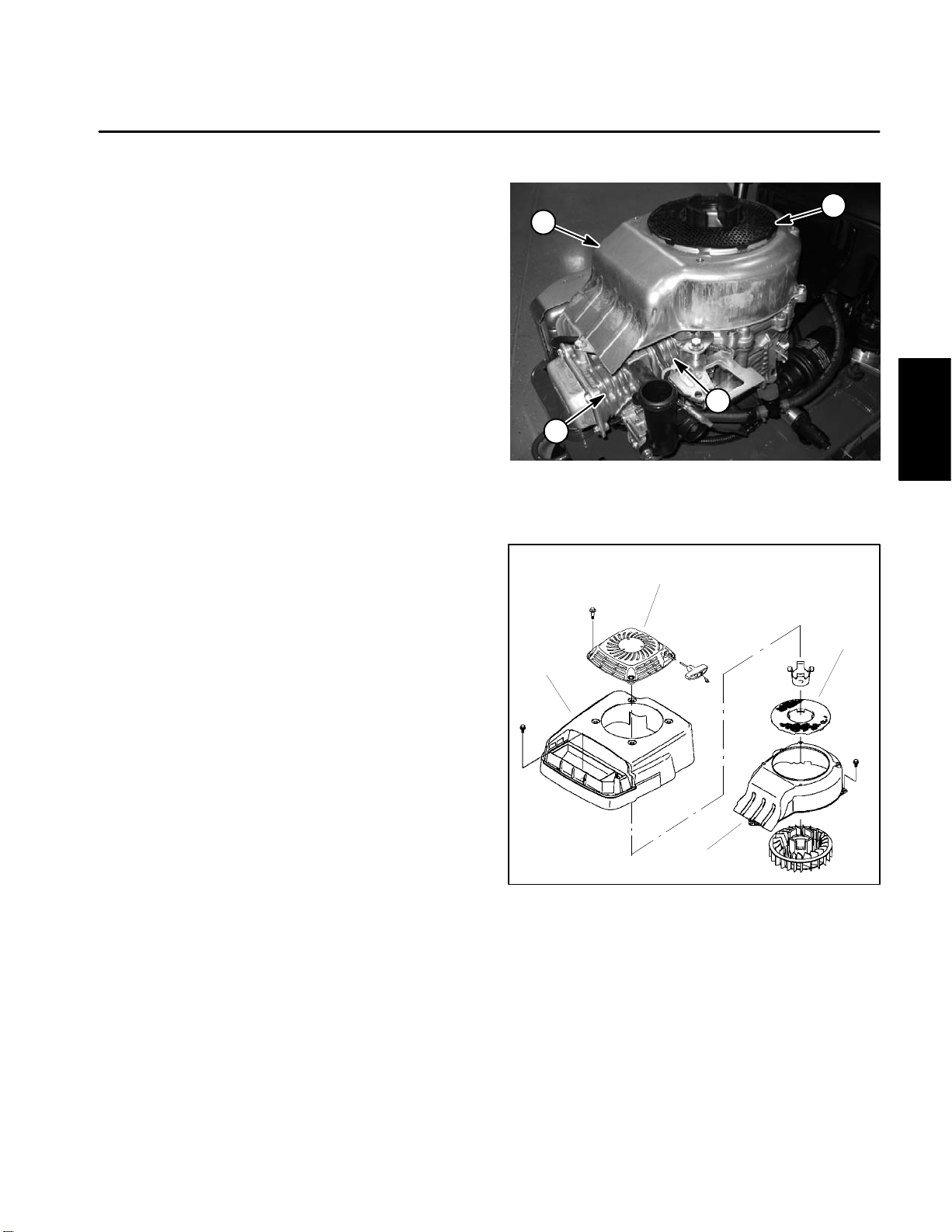

1

2

IMPORTANT: Never clean engine with pressurized

water. Water could enter and contaminate the fuel

system.

2. Remove rewind starter and clean rotating screen

(Fig.2).

3. If necessary, remove engine cover, rotating screen

and blower housing from engine (Fig. 3). Clean blower

housing and engine cooling fins of dirt and debris.

IMPORTANT: Never operate engine without the

blower housing installed. Overheating and engine

damage will result.

4. Make sure blower housing, rotating screen and engine cover are reinstalled to the engine if removed.

5. Attach high tension lead to the spark plug.

3

3

Figure 2

1. Rotating screen 3. Cooling fins

2. Blower housing

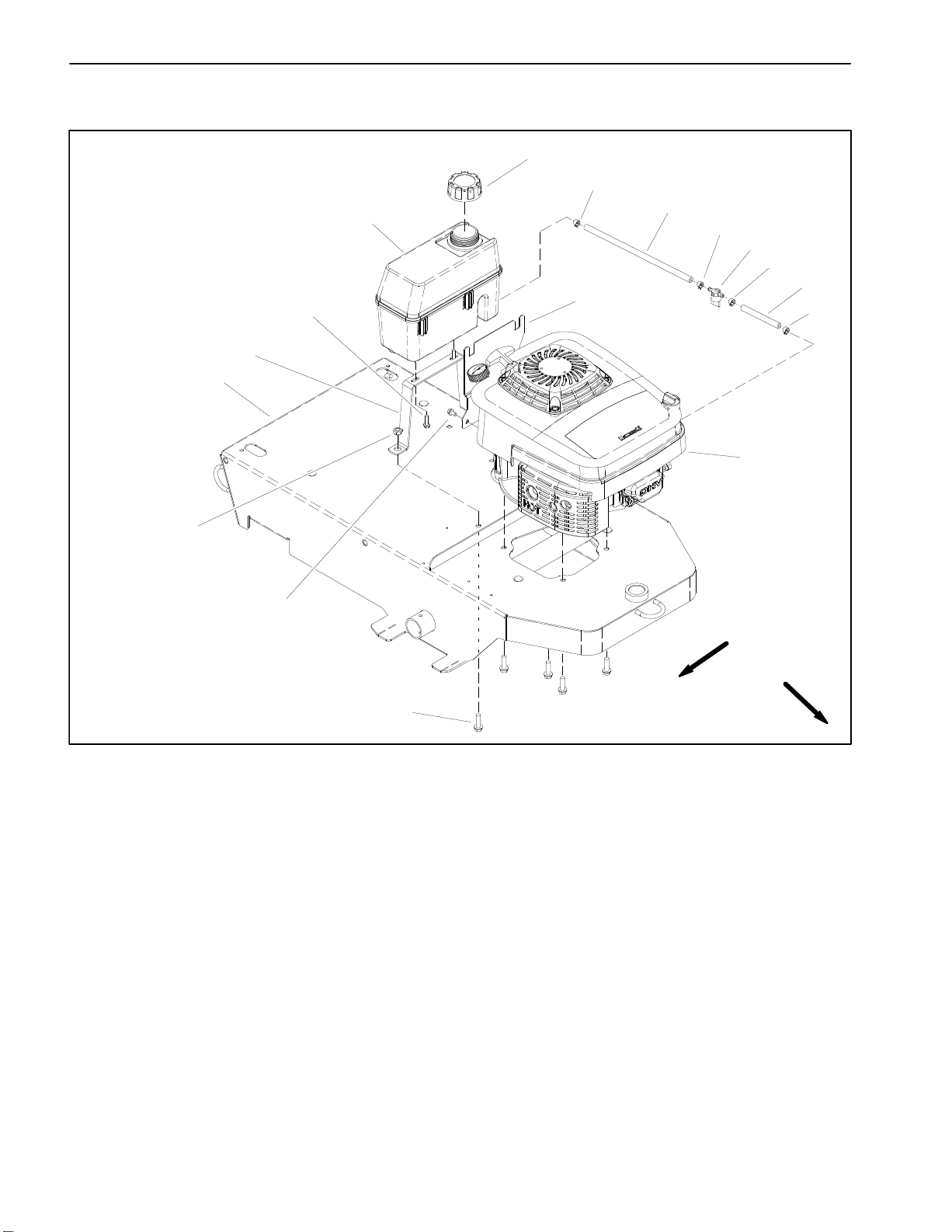

1

2

Engine

Gasoline

3

4

Figure 3

1. Rewind starter 3. Rotating screen

2. Engine cover 4. Blower housing

Line Painter 1200 Page 3 – 5 Gasoline Engine

Page 20

Fuel Tank

10

11

12

13

2

3

1

4

3

5

3

6

14

3

7

1. Fuel tank

2. Fuel tank cap

3. Hose clamp (4 used)

4. Fuel hose

5. Fuel shut off valve

9

RIGHT

FRONT

8

Figure 4

6. Fuel hose

7. Engine

8. Screw (2 used)

9. Washer head screw (2 used)

10. Nut (2 used)

11. Frame

12. Fuel tank support

13. Washer head screw (2 used)

14. Fuel tank bracket

Line Painter 1200Gasoline Engine Page 3 – 6

Page 21

DANGER

Because gasoline is highly flammable, use caution when storing or handling it. Do not smoke

while filling the fuel tank. Do not fill fuel tank

while engine is running, hot, or when machine is

in an enclosed area. Always fill fuel tank outside

and wipe up any spilled fuel before starting the

engine. Store fuel in a clean, safety–approved

container and keep cap in place. Use gasoline for

the engine only; not for any other purpose.

Check Fuel Lines and Connections

Check fuel lines and connections periodically as recommended in the Operator’s Manual. Check lines for deterioration, damage, leaking or loose connections.

Replace hoses, clamps and connections as necessary.

Drain and Clean Fuel Tank

3. Remove high tension lead from the spark plug and

position the lead away from the spark plug.

4. Close fuel shut off valve. Disconnect fuel hose from

carburetor inlet.

5. Place disconnected hose in appropriate container

and open fuel shut off valve to allow fuel tank to drain

completely.

6. Remove fuel tank using Figure 4 as a guide. If fuel

tank bracket (item 14) removal is necessary, remove

ground wire from bracket.

7. If fuel in tank was contaminated, remove and clean

carburetor (see Kawasaki FJ180V Service Manual at

the end of this chapter).

Fuel Tank Installation (Fig. 4)

1. If carburetor was removed from engine for cleaning,

install carburetor (see Kawasaki FJ180V Service Manu

al at the end of this chapter).

-

Engine

Gasoline

IMPORTANT: If fuel tank is to be drained, drain fuel

outdoors.

Drain and clean the fuel tank periodically as recommended in the Operator’s Manual. Also, drain and clean

the fuel tank if the fuel system becomes contaminated

or if the machine is to be stored for an extended period.

NOTE: The fuel tank is equipped with an integral filter

screen at the tank outlet.

To clean fuel tank, flush tank and fuel hoses out with

clean solvent. Make sure tank is free of contaminates

and debris.

Fuel Tank Removal (Fig. 4)

1. Park machine on a level surface, stop engine, engage parking brake and remove key from the ignition

switch. Remove high tension lead from the spark plug

and position the lead away from the spark plug.

2. Allow engine to cool before removing fuel tank.

2. Install fuel tank to frame using Figure 4 as a guide.

If ground wire was removed from fuel tank bracket (item

14) secure ground wire to bracket with screw.

3. Connect fuel hose to carburetor inlet. Make sure that

fuel hoses are secured with hose clamps.

4. Attach high tension lead to the spark plug.

5. Fill fuel tank (see Operator’s Manual).

Line Painter 1200 Page 3 – 7 Gasoline Engine

Page 22

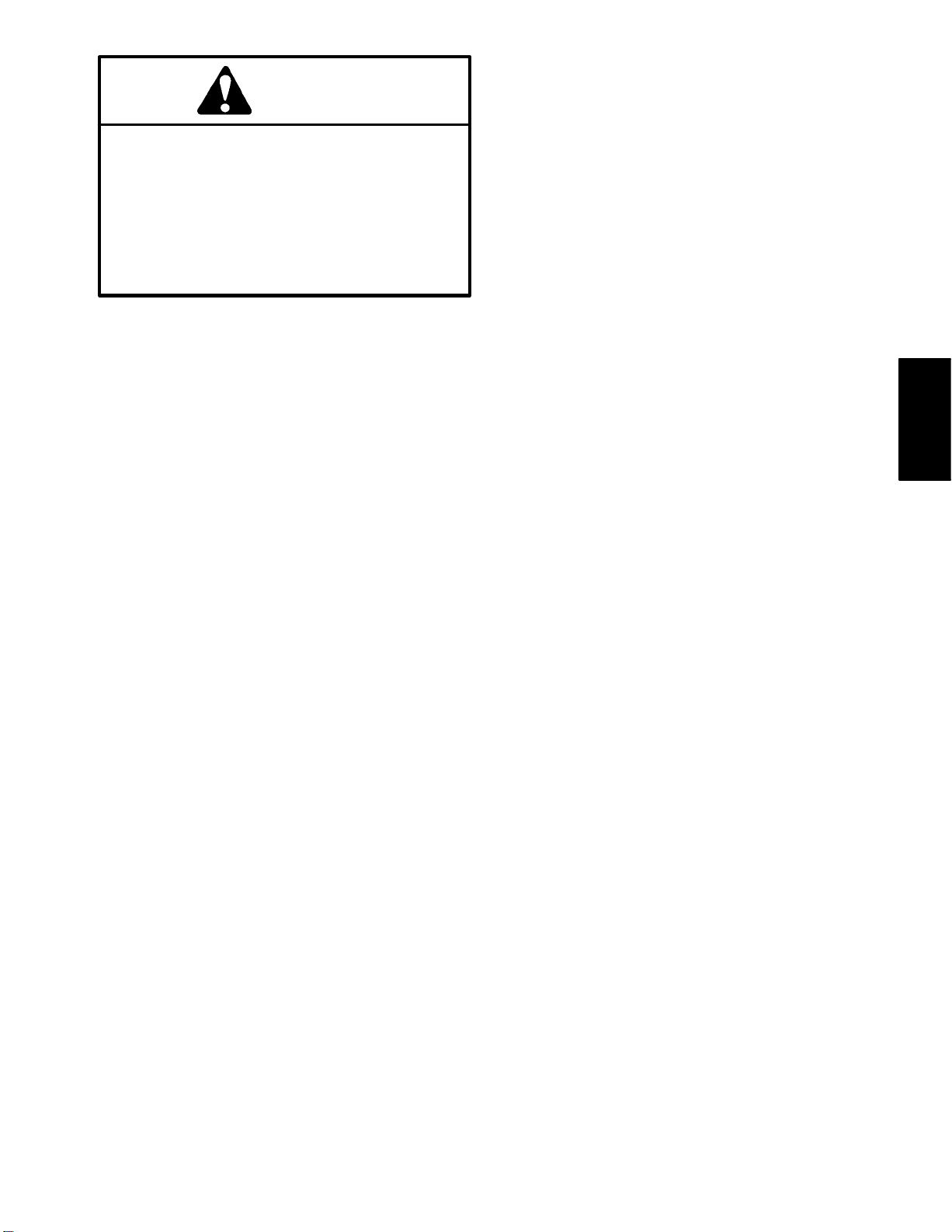

Engine

11

15

14

12

16

14

14

17

13

2

10

9

8

1

14

3

4

3

7

20 to 30 ft–lb

(27 to 41 N–m)

RIGHT

FRONT

6

250 to 450 in–lb

(28 to 51 N–m)

5

1. Engine

2. Oil drain valve

3. O–ring

4. Drain extension

5. Screw (6 used)

6. Washer head screw (2 used)

7. Nut (2 used)

8. Frame

9. Fuel tank support

10. Washer head screw (2 used)

11. Fuel tank cap

12. Fuel tank

13. Fuel tank bracket

Removal (Fig. 5)

1. Park machine on a level surface, stop engine, engage parking brake and remove key from the ignition

switch. Remove high tension lead from the spark plug

and position the lead away from the spark plug.

2. If engine is to be disassembled, it may be easier to

drain oil from engine before removing engine from machine (see Operator’s Manual).

18

50 to 60 ft–lb

(68 to 81 N–m)

Loctite #242

19

5

Figure 5

14. Hose clamp (4 used)

15. Fuel hose

16. Fuel shut off valve

17. Fuel hose

18. Engine pulley

19. Cap screw

4. Remove fuel tank from machine (see Fuel Tank Removal in this section).

5. If machine is equipped with a hour meter, remove

hour meter pickup wire from spark plug lead on engine.

Position pickup wire away from engine.

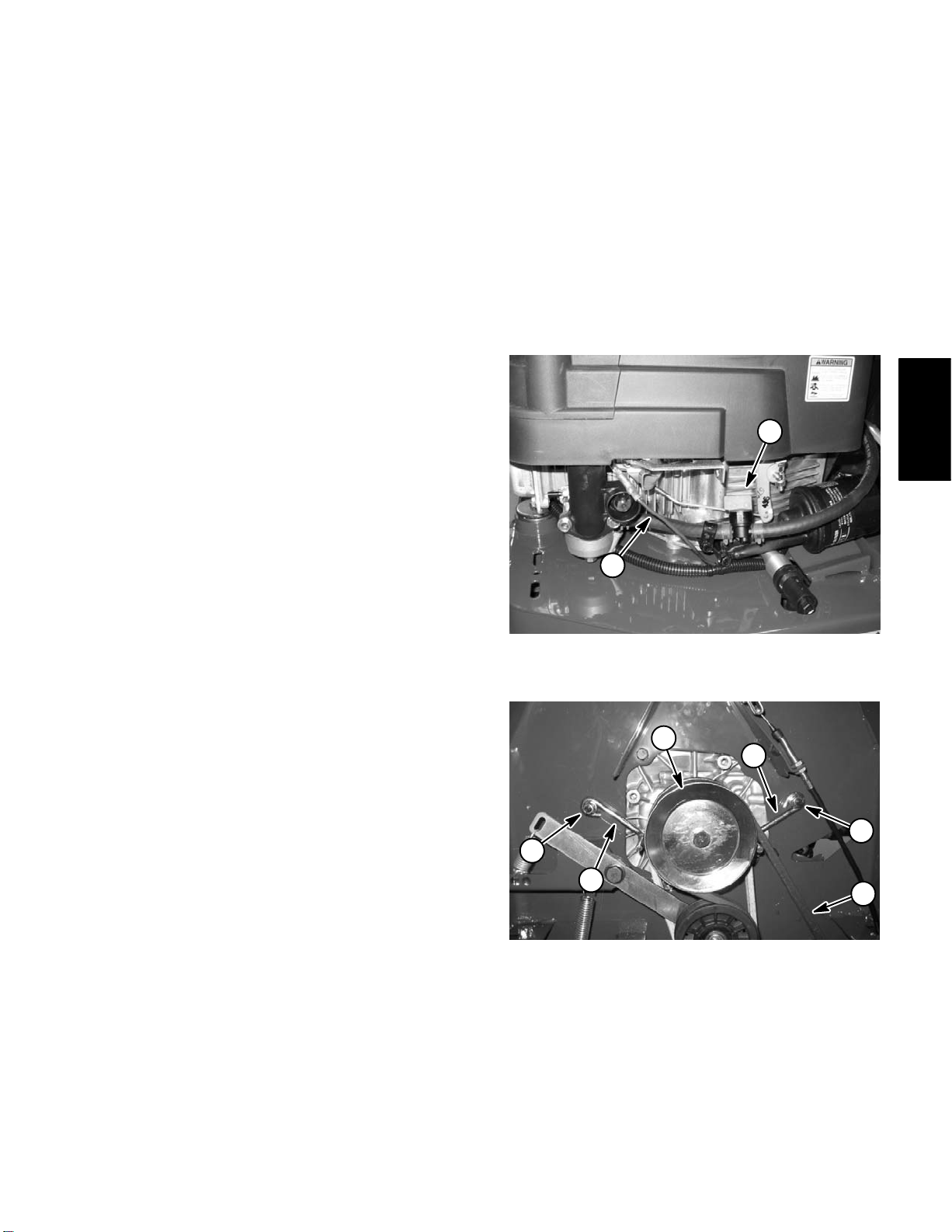

6. Disconnect stop switch wire from engine (Fig. 6).

Make sure that ground wire is removed from fuel tank

bracket (item 14).

3. Close fuel shut off valve. Disconnect fuel hose from

carburetor inlet.

Line Painter 1200Gasoline Engine Page 3 – 8

Page 23

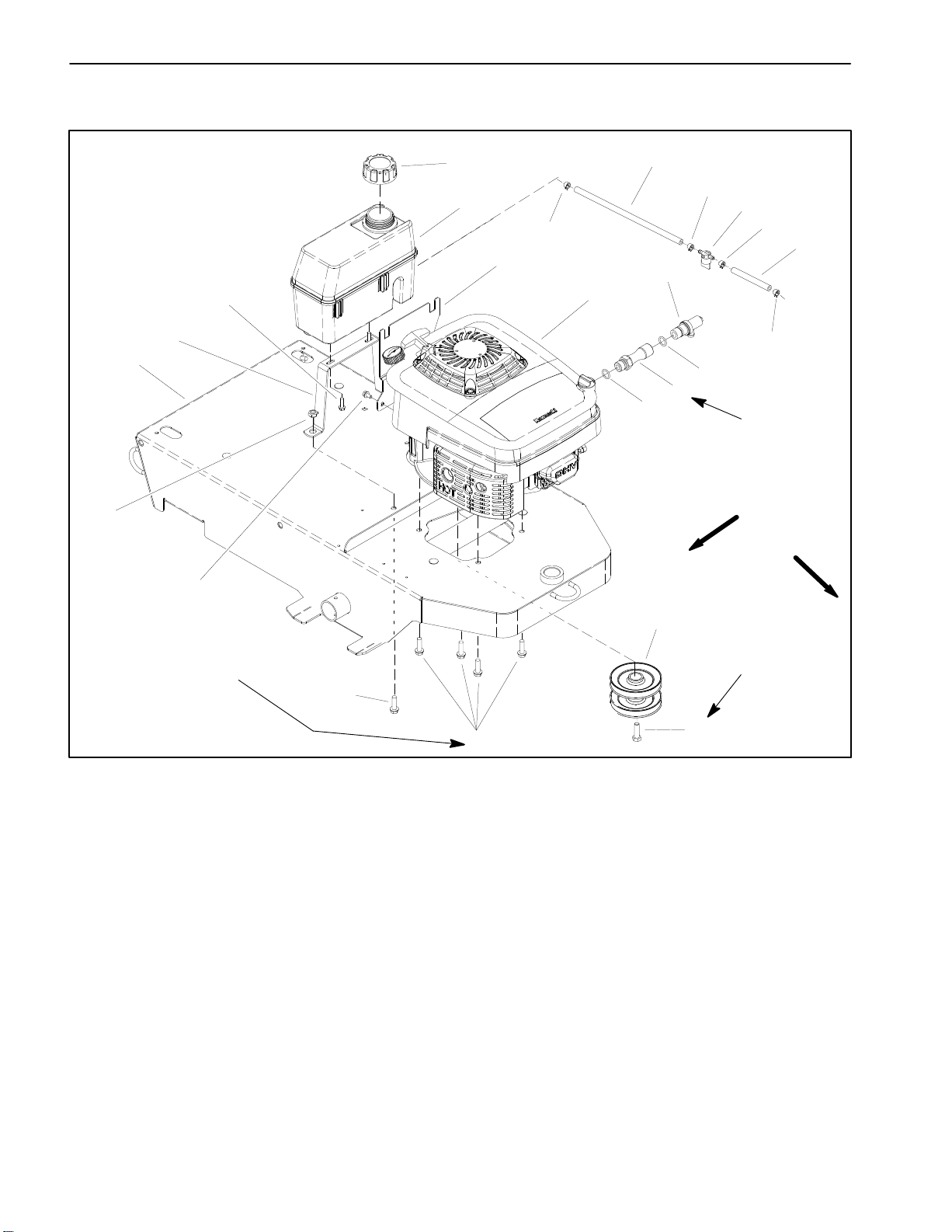

7. On the underside of the machine frame (Fig. 7):

A. Loosen flange nuts that retain two (2) belt guides

to frame. Position belt guides away from engine

pulley.

8. Install fuel tank to machine (see Fuel Tank Installation in this section).

9. If machine is equipped with a hour meter, install hour

meter pickup wire to spark plug lead on engine.

B. Loosen idler tension on pump drive belt (lower)

and transmission drive bolt (upper) and remove belts

from engine pulley.

C. Remove four (4) screws that secure engine to

machine.

8. Lift the engine from the frame.

9. If necessary, remove cap screw that secures pulley

to engine crankshaft. Slide pulley from crankshaft.

Installation (Fig. 5)

1. Position machine on a level surface.

2. Make sure that all parts removed from the engine

during maintenance or rebuilding are properly installed

to the engine.

3. If pulley was removed from engine, apply antisieze

lubricant to engine crankshaft. Slide pulley onto crank

shaft making sure to align pulley key with crankshaft

slot.

4. Apply Loctite #242 (or equivalent) to threads of cap

screw (item 19). Secure pulley to crankshaft with cap

screw. Torque cap screw from 50 to 60 ft–lb (68 to 81

N–m).

10.Connect stop switch wire to engine. Secure ground

wire to fuel tank bracket (item 14) with screw.

11. Check and adjust engine oil level as needed (See

Checking Engine Oil Level).

12.Attach high tension lead to the spark plug.

13.Make sure that fuel hose is secured to carburetor inlet. Open fuel shut–off valve.

1

-

2

Figure 6

1. Fuel shut off valve 2. Stop switch wire

Engine

Gasoline

5. Position engine on the frame.

6. Align holes in frame with engine mounting holes. Secure engine to frame with four (4) screws. Torque

screws from 250 to 450 in–lb (28 to 51 N–m).

7. On the underside of the machine frame (Fig. 7):

A. Install transmission drive belt (upper) and pump

drive belt (lower) onto engine pulley. Make sure that

belts are correctly routed at idler pulleys.

B. Position two (2) belt guides to allow from .060” to

.130” (1.5 to 3.3 mm) clearance when the traction

(upper) belt is tensioned by the idler pulley. When

properly positioned, tighten flange nuts to secure

belt guides to frame.

4

2

1

1

2

3

Figure 7

1. Flange nut 3. Pump drive belt

2. Belt guide 4. Engine pulley

Line Painter 1200 Page 3 – 9 Gasoline Engine

Page 24

This page is intentionally blank.

Gasoline Engine Page 3 – 10 Line Painter 1200

Page 25

Table of Contents

ELECTRICAL SCHEMATIC . . . . . . . . . . . . . . . . . . . . 2

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . 4

COMPONENT TESTING . . . . . . . . . . . . . . . . . . . . . . . 5

On/Off Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Hourmeter (Optional) . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 4

Electrical System

System

Electrical

Line Painter 1200 Page 4 – 1 Electrical System

Page 26

Electrical Schematic

HIGH TENSION LEAD

BLACK

BLACK

IGNITION COIL

ENGINE

MAGNETO

(FLYWHEEL)

HOUR METER

(OPTIONAL)

BROWN

ON\OFF SWITCH

is open in the ON

position.

ON/OFF SWITCH

BLACK

Electrical System

Page 4 – 2

Line Painter 1200

Page 27

Special Tools

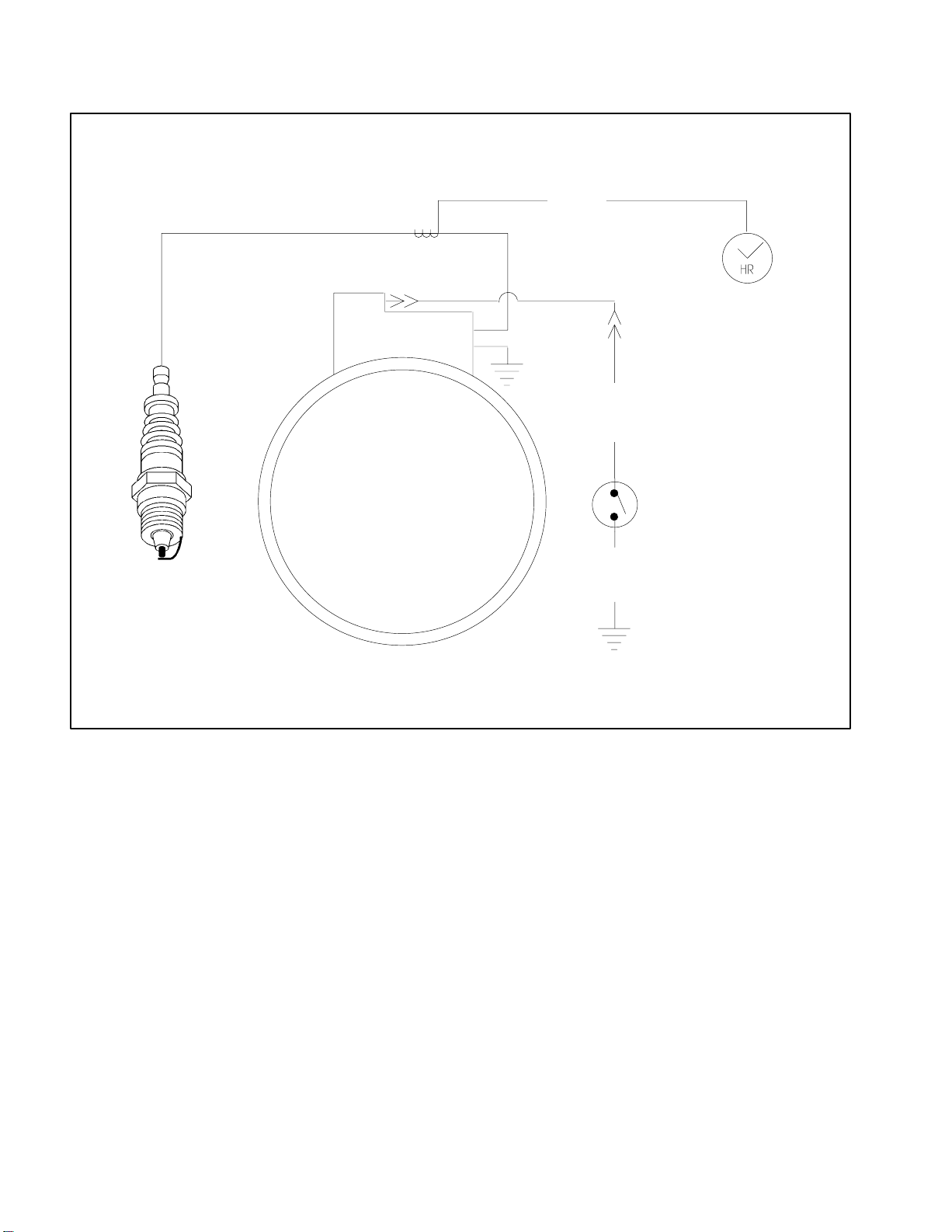

Multimeter

The multimeter can test electrical components and circuits for current (amps), resistance (ohms) or voltage.

NOTE: Toro recommends the use of a DIGITAL Volt–

Ohm–Amp multimeter when testing electrical circuits.

The high impedance (internal resistance) of a digital me

ter in the voltage mode will make sure that excess current is not allowed through the meter. This excess

current can cause damage to circuits not designed to

carry it.

Spark Tester – TOR4036

The spark tester can test magneto ignitions. The spark

tester determines if ignition is present.

-

Figure 1

Figure 2

System

Electrical

Line Painter 1200 Page 4 – 3 Electrical System

Page 28

Troubleshooting

For effective troubleshooting and repairs, there must be

CAUTION

Remove all jewelry, especially rings and

watches, before doing any electrical

troubleshooting or testing.

Starting Problems

Problem Possible Causes Correction

a good understanding of the electrical circuits and com

ponents used on this machine (see Electrical Schematic

in this chapter).

NOTE: See the Kawasaki FJ180V Service Manual at

the end of Chapter 3 – Engine for troubleshooting of en

gine electrical problems.

-

-

Engine will not start. ON/OFF switch is in the OFF

position.

ON/OFF switch is faulty. Replace ON/OFF switch.

Ignition spark plug lead is not

connected to spark plug.

Electrical wires are loose or Check electrical connections.

damaged. Repair wiring.

Engine is malfunctioning. See Kawasaki FJ180V Service

Engine will start, but will not

continue to run.

Electrical wires are loose or

damaged.

ON/OFF switch is faulty. Replace ON/OFF switch.

Engine is malfunctioning. See Kawasaki FJ180V Service

Turn switch to ON.

Connect high tension lead to spark

plug.

Manual at the end of Chapter 3 –

Engine.

Check electrical connections.

Repair wiring.

Manual at the end of Chapter 3 –

Engine.

Electrical System

Page 4 – 4

Line Painter 1200

Page 29

Component Testing

For accurate resistance and/or continuity checks, electrically disconnect the component being tested from the

circuit (e.g. unplug the ignition switch connector before

doing a continuity check).

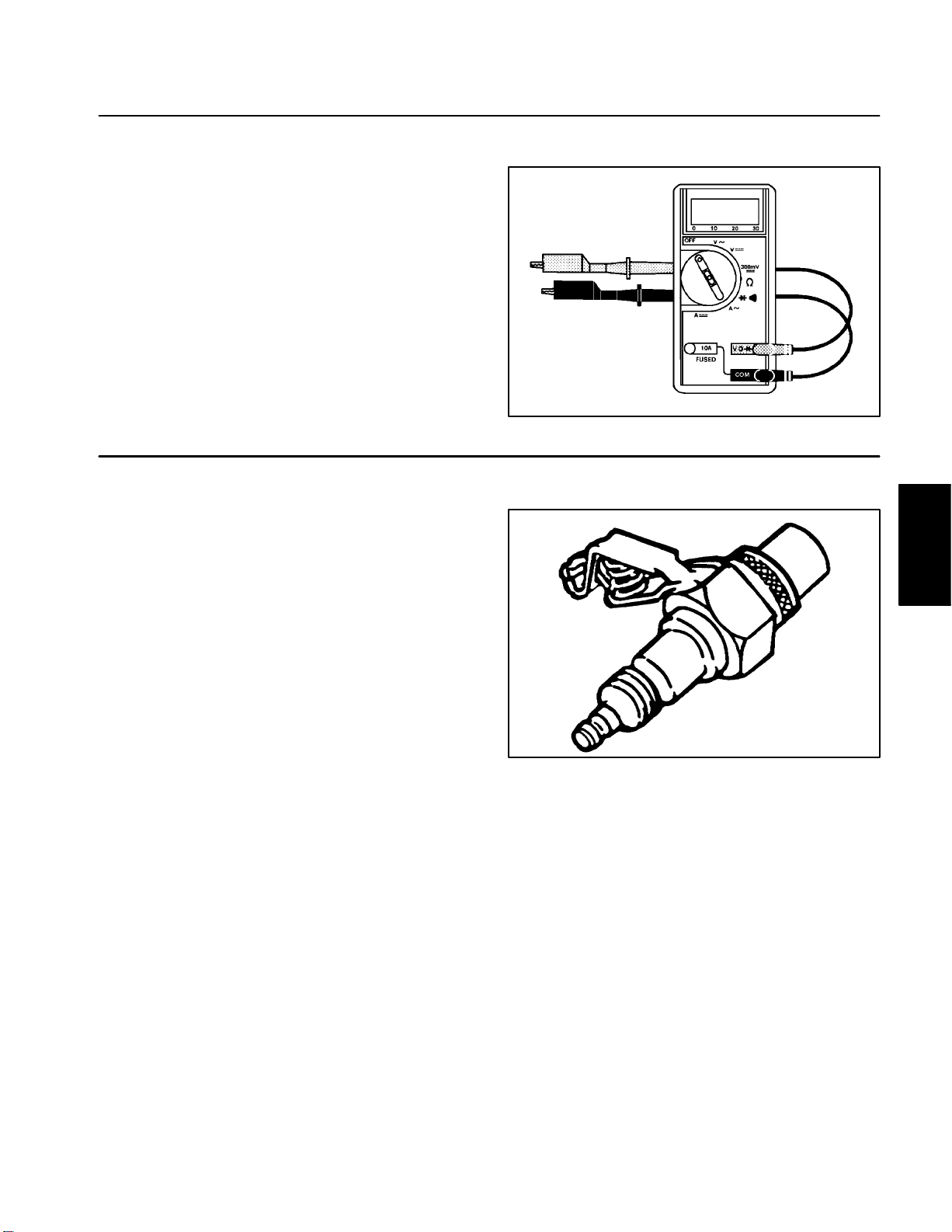

On/Off Switch

The on/off switch is used to shut the engine off. When

the on/off switch is in the off position, the engine arma

ture is grounded to prevent the engine from running.

This switch is located handle panel (Fig. 3).

Testing

In the OFF position, there should be continuity between

the two switch terminals. In the RUN position, there

should not be continuity between the two switch termi

nals.

-

-

1

Figure 3

1. On/Off switch

System

Electrical

Figure 4

Line Painter 1200 Page 4 – 5 Electrical System

Page 30

Hourmeter (Optional)

The optional hourmeter available for the Line Painter

1200 uses an inductive pickup wire connected to the

spark plug wire to sense when the engine is running.

The hourmeter should increase 1/10 of an hour every six

(6) minutes of engine running time.

The hourmeter uses its own internal battery for operation. The hourmeter battery is not replaceable.

NOTE: The hourmeter display is programmed to flash

service reminders initially at 50 hours and then every

100 hours thereafter. The display will flash for three

hours before and three hours after these running times.

Regardless of these service reminders, follow the main

tenance intervals identified in the Line Painter 1200 Operator’s Manual.

-

Figure 5

Electrical System

Page 4 – 6

Line Painter 1200

Page 31

Table of Contents

Chapter 5

Paint System

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

PAINT SCHEMATIC . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

CIRCUIT OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . 4

Paint Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Flush Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . 8

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . 9

Paint/Flush Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Quick Disconnect Fittings . . . . . . . . . . . . . . . . . . . . 9

Thread Sealant for Paint System Fittings . . . . . . . 9

ADJUSTMENTS 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spray Pump Relief Valve Adjustment 10. . . . . . . . .

SERVICE AND REPAIRS . . . . . . . . . . . . . . . . . . . . . 12

Paint Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Tank Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Flush (Water) Tank . . . . . . . . . . . . . . . . . . . . . . . . . 16

Check Valve Service . . . . . . . . . . . . . . . . . . . . . . . . 18

Paint Shutoff Valve . . . . . . . . . . . . . . . . . . . . . . . . . 20

Pressure Regulator . . . . . . . . . . . . . . . . . . . . . . . . . 22

Ball Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Spray Pump Drive Belt . . . . . . . . . . . . . . . . . . . . . . 26

Spray Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Spray Pump Service . . . . . . . . . . . . . . . . . . . . . . . . 30

Spray Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Paint

System

Line Painter 1200 Page 5 – 1 Paint System

Page 32

Specifications

Item Description

Pump Diaphragm Pump with 5 Chambers

Pump Capacity 4 GPM (15.1 LPM)

Relief Pressure 65 PSI (4.5 Bar)

Paint Tank Capacity 12 Gallons (45.4 Liters)

Water (Flush) Tank Capacity 2.5 Gallons (9.5 Liters)

Paint System Page 5 – 2 Line Painter 1200

Page 33

Paint Schematic

(OFF)

(OFF)

(OFF POSITION)

Line Painter 1200

Hydraulic Schematic

Paint

System

Line Painter 1200 Page 5 – 3 Paint System

Page 34

Circuit Operation

(OFF)

(OFF)

Line Painter 1200

Paint Circuit

Working Pressure

Return (Agitation)

Suction

Flow

Paint System Page 5 – 4 Line Painter 1200

Page 35

Paint Circuit

The Line Painter 1200 paint circuit uses a positive displacement diaphragm pump to move paint from the

paint tank to the spray nozzle. The spray pump is a self–

priming diaphragm pump that has a dry crankcase.

The engine drives the spray pump indirectly through pulleys and a V–belt. The spray pump belt is always tensioned by a backside idler pulley so the pump is being

rotated whenever the engine is running.

When the pump is rotated, the downward stroke of the

pump’s diaphragm creates suction to allow fluid (paint)

to be drawn from the paint tank to the pump via hoses,

a ball valve (in the paint position) and a 40 mesh screen

filter. Pump design prevents fluid from being pumped

back into the suction line.

Once to the pump, the fluid (paint) is pushed by the upward stroke of the pump’s diaphragm to the pressure

side of the spray system through hoses, control valves

and the spray nozzle. Pump design prevents fluid from

being drawn back into the pump. Maximum pressure in

the system is limited by an adjustable relief valve located

in the pump.

An adjustable pressure regulator is used by the operator

to set paint circuit pressure on the Line Painter 1200.

Flow in excess of the regulator setting is directed back

to the paint tank via a ball valve (in the paint position).

This return flow is used for paint tank agitation. An op

tional pressure gauge (if equipped) indicates system

pressure.

A mechanically actuated spool valve is used to turn the

spray nozzle on/off. Spool valve shift occurs when the

operator depresses or releases the paint control lever.

-

Paint

System

Line Painter 1200 Page 5 – 5 Paint System

Page 36

(OPEN)

Line Painter 1200

Flush Circuit

Working Pressure

Return

Suction

Flow

Paint System Page 5 – 6 Line Painter 1200

Page 37

Flush Circuit

The Line Painter 1200 paint circuit uses a positive displacement diaphragm pump to move fluid (water) from

the flush (water) tank through the spray system. The

spray pump is a self–priming diaphragm pump that has

a dry crankcase.

When the pump is rotated, the downward stroke of the

pump’s diaphragm creates suction to allow fluid (water)

to be drawn from the flush tank to the pump via hoses,

a one–way check valve, a ball valve (in the flush posi

tion) and a 40 mesh screen filter.

Once to the pump, the fluid (water) is pushed by the upward stroke of the pump’s diaphragm to the pressure

side of the spray system through hoses, control valves

and the spray nozzle. Maximum pressure in the system

is limited by an adjustable relief valve located in the dia

phragm pump.

Flow in excess of the adjustable pressure regulator setting is directed back to the flush (water) suction line via

a ball valve (in the flush position).

Flow through the flush circuit is used to dilute and remove paint from the ball valves, screen filter, spray

pump, regulator, spool valve, spray nozzle and all

hoses.

A one–way check valve is positioned between the flush

(water) tank and the ball valve (see schematic). This

check valve prevents paint from entering the flush (wa

ter) tank when the paint/flush lever is moved from the

paint position to the flush position and while the machine

is operated in the flush mode.

NOTE: If the flush system is not cleaned after use, diluted paint may cause check valve and associated

hoses to become blocked. If the check valve is stuck

open, paint may enter the flush (water) tank when the

paint/flush lever is moved from the paint position to the

flush position. If the check valve is stuck closed, the flush

system may not operate.

-

Paint

System

Line Painter 1200 Page 5 – 7 Paint System

Page 38

Troubleshooting

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Problem

БББББББББББББББББББББББББББББББББББ

Spray system leaks fluid.

БББББББББББ

Á

БББББББББББ

Á

БББББББББББББББББББББББББББББББББББ

Spray pressure is low.

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

No spray output from nozzle.

БББББББББББББББББББББББББББББББББББ

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

БББББББББББББББББББББББББББББББББББ

No spray output from nozzle in the

flush mode.

БББББББББББ

Á

БББББББББББ

Á

Nozzle leaks when paint valve is

БББББББББББББББББББББББББББББББББББ

closed.

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

БББББББББББ

Á

БББББББББББББББББББББББББББББББББББ

Paint is being pumped into the flush

БББББББББББ

Á

tank.

БББББББББББББББББББББББББББББББББББ

Paint System Page 5 – 8 Line Painter 1200

Possible Cause

Fitting(s) or hose(s) are loose or damaged.

ББББББББББББББББББББ

Á

O–ring(s) or seal(s) are missing or damaged.

ББББББББББББББББББББ

Á

Suction line is restricted.

ББББББББББББББББББББ

Á

Filter screen is plugged.

ББББББББББББББББББББ

Á

ББББББББББББББББББББ

Á

Pressure regulator is damaged or incorrectly adjusted.

ББББББББББББББББББББ

Á

Spray nozzle is worn or damaged.

ББББББББББББББББББББ

Á

Check valve in diaphragm nozzle is stuck or plugged.

ББББББББББББББББББББ

Á

ББББББББББББББББББББ

Á

Engine speed is low.

ББББББББББББББББББББ

Á

Pressure relief valve in spray pump is stuck.

ББББББББББББББББББББ

Á

ББББББББББББББББББББ

Á

Pump drive belt is slipping.

ББББББББББББББББББББ

Á

Spray pump is faulty.

ББББББББББББББББББББ

Á

Paint tank is empty.

ББББББББББББББББББББ

Á

Paint/Flush lever is in the off position.

ББББББББББББББББББББ

Á

Hose(s) are pinched or kinked.

ББББББББББББББББББББ

Á

ББББББББББББББББББББ

Á

Dried paint in system.

ББББББББББББББББББББ

Á

Filter screen is plugged.

ББББББББББББББББББББ

Á

ББББББББББББББББББББ

Á

Spray nozzle is clogged or damaged.

ББББББББББББББББББББ

Á

Check valve in diaphragm nozzle is stuck or plugged.

ББББББББББББББББББББ

Á

ББББББББББББББББББББ

Á

Paint shutoff valve is faulty.

ББББББББББББББББББББ

Á

Pump drive belt is slipping, damaged or broken.

ББББББББББББББББББББ

Á

Spray pump is faulty.

ББББББББББББББББББББ

Á

Flush tank is empty.

ББББББББББББББББББББ

Á

Check valve in flush tank outlet tube is stuck closed.

ББББББББББББББББББББ

Á

Check valve diaphragm in diaphragm nozzle body is leaking or

damaged.

ББББББББББББББББББББ

Á

ББББББББББББББББББББ

Á

Paint shutoff valve is not seating.

ББББББББББББББББББББ

Á

Paint control cable is not adjusted correctly (see Paint Control

ББББББББББББББББББББ

Á

Cable in the Service and Repairs section of Chapter 6 – Chassis

ББББББББББББББББББББ

Á

and Controls).

Check valve in flush tank outlet tube is stuck open.

ББББББББББББББББББББ

Á

Page 39

General Information

Paint/Flush Lever

To prevent paint system pressure spikes, the paint/flush

lever should normally be in either the paint mode or the

flush mode. It is recommended to use the OFF position

only when the engine is not running.

2

If the paint filter is to be cleaned and paint is in the paint

tank, turn the paint/flush lever to OFF (engine not run

ning) to prevent paint leakage.

Quick Disconnect Fittings

The Line Painter 1200 uses several quick disconnect fittings that provide excellent sealing and allow easy disassembly. To remove a hose from a quick disconnect

fitting, push the release collar in toward the fitting and

then pull the hose from the fitting. To install a hose into

a quick disconnect fitting, fully push the hose into the col

lar. Pull lightly on the hose to make sure it is secured in

the fitting.

If the end of the tubing is scratched, deformed or not cut

squarely, the fitting seal will not be effective and leakage

will occur.

-

3

Figure 1

1. Paint lever (in OFF) 3. Paint mode

2. Flush mode

2

1

-

3

1

Paint

System

Figure 2

1. Fitting 3. Hose

2. Release collar

Thread Sealant for Paint System Fittings

Many fittings used in the Line Painter 1200 paint system

have a sealant patch applied to the fitting threads. If a

fitting is being replaced and a sealant patch is evident on

the threads of the new fitting, there is no need to apply

additional thread sealant before installation.

If a fitting has been removed, however, the sealant patch

may not allow a leak–free seal if the fitting is re–installed.

If a fitting is to be re–installed, apply Saf–T–Lok brand

Line Painter 1200 Page 5 – 9 (Rev. A) Paint System

TPS (PTFE Sealant) to the fitting threads before

installation. If an alternate sealant is used, make sure

that it is compatible with nylon and polypropylene materials.

Page 40

Adjustments

Spray Pump Relief Valve Adjustment

The spray pump used on the Line Painter 1200 is

equipped with an adjustable relief valve (Fig. 3). Adjust

ment of the relief valve is made with a socket head screw

on the top of the pump. The end of the socket head

screw should be flush with the relief valve housing for

correct relief valve adjustment.

-

2

1

Figure 3

1. Spray pump 2. Socket head screw

Paint System Page 5 – 10 Line Painter 1200

Page 41

This page is intentionally blank.

Paint

System

Line Painter 1200 Page 5 – 11 Paint System

Page 42

Service and Repairs

Paint Tank

144 to 156 in–lb

(16.3 to 17.6 N–m)

192 to 216 in–lb

(21.7 to 24.4 N–m)

6

5

4

2

1

10

8

11

3

19

5

20

7

8

9

10

192 to 216 in–lb

(21.7 to 24.4 N–m)

14

13

12

15

16

17

18

RIGHT

FRONT

1. Paint tank

2. Nut

3. Tank support

4. Flat washer

5. Jam nut

6. Elbow fitting

7. Tank clamp (2 used)

8. Rubber washer

9. Outlet port

10. Ball valve

11. Recirculation port

12. O–ring

13. Drain valve

14. Elbow fitting

Removal (Fig. 4)

1. Park machine on a level surface, stop engine, engage parking brake and remove key from the ignition

switch. Remove high tension lead from the spark plug

and position the lead away from the spark plug.

2. Drain paint tank (see Operator’s Manual). Remove

tank lid and strainer.

Figure 4

15. Valve bracket

16. Flange head screw

17. Flange head screw (4 used)

18. Pump assembly

19. Flush tank

20. Slotted washer

3. Loosen nut that secures drain valve to tank (Fig. 5).

4. Remove two (2) flange head screws (item 16) that

secure drain valve to valve bracket. Remove nut from

drain valve and remove valve from machine. Retrieve

o–ring (item 12) from outside tank.

5. Remove agitation tube from elbow fitting (Fig. 5) (see

Quick Disconnect Fitting in the General Information section). Loosen and remove elbow fitting.

Line Painter 1200Page 5 – 12Paint System

Page 43

6. Remove two (2) jam nuts that secure tank to ball

valve ports (Fig. 5). Locate and retrieve washers (items

4 and 20).

2

7. Remove four (4) flange head screws (item 17) that

secure tank to tank support.

8. Lift tank from machine. Locate and retrieve rubber

washers (item 8) that seal tank to ball valve ports. Discard washers.

9. If necessary, remove tank lid flange using Figure 6 as

a guide.

Installation (Fig. 4)

1. Place new rubber washers (item 8) on ball valve

ports.

2. Position tank on ball valve ports.

3. Loosely install the following components:

A. Valve fitting washers (items 4 and 20) and jam

nuts (item 5).

B. Drain valve, o–ring (item 12) and nut (item 2).

C. Four (4) flange head screws (item 17).

4. Torque jam nuts (item 5) from 192 to 216 in–lb (21.7

to 24.4 N–m).

1. Drain valve

2. Elbow fitting

5

4

3

2

1

1

3

3

4

Figure 5

3. Jam nut

4. Agitation tube

6

10 to 12 in–lb

(1.1 to 1.4 N–m)

5. Tighten drain valve nut (item 2) to secure drain valve

to tank. Then tighten two (2) flange head screws (item

16) that secure drain valve to valve bracket. Finally tighten the four screws (item 17) to secure tank to machine.

6. Install elbow fitting (item 6) and torque from 144 to

156 in–lb (16.3 to 17.6 N–m). Install agitation tube to elbow fitting (Fig. 5) (see Quick Disconnect Fitting in the

General Information section).

7. If removed, install tank lid flange using Figure 6 as a

guide. Torque screws from 10 to 12 in–lb (1.1 to 1.4

N–m).

8. Install high tension lead to spark plug when service

is complete.

1. Paint tank

2. O–ring

3. Lid flange

Figure 6

4. Strainer

5. Lid

6. Screw (8 used)

Paint

System

Line Painter 1200 Page 5 – 13 Paint System

Page 44

Tank Support

6

1

5

2

3

RIGHT

FRONT

1. Handle assembly

2. Flange head screw (4 used)

4

Figure 7

3. Chassis

4. Flush tank

5. Tank support

6. Paint tank

Line Painter 1200Page 5 – 14Paint System

Page 45

To ease service of paint components attached to the

tank support, the tank support and handle can be tipped

back using the following procedure:

1. Drain paint tank (see Operator’s Manual).

NOTE: The nozzle can be removed from the spray

head to allow the flush tank to be emptied faster.

2. Clean paint system hoses by operating line painter

in the flush mode until the flush tank is empty.

3. Park machine on a level surface, stop engine, engage parking brake and remove key from the ignition

switch. Remove high tension lead from the spark plug

and position the lead away from the spark plug.

4. Remove the hairpin and flat washer that secure the

shift rod to the shift bellcrank at the rear of the machine

(Fig. 8).

2

1

5

3

4

Figure 8

1. Shift rod 4. Flat washer

2. Shift bellcrank 5. Fitting

3. Hairpin

5. Disconnect shift rod from shift bellcrank. Take care

to not change location of fitting on shift rod.

6. Loosen the rear two flange head screws that fasten

tank support to chassis (Fig. 9).

7. While supporting handle and tank support in the upright position, remove the front two (2) flange head

screws that fasten tank support to chassis (Fig. 9).

8. Carefully, tilt handle and tank support back to allow

access to tank support components (Fig. 10).

9. After repairs are completed, raise handle and tank

support. Install front two (2) flange head screws to fas

-

ten tank support to chassis. Tighten all four (4) flange

head screws to secure tank support to machine.

10.Slide shift rod fitting onto shift bellcrank and secure

with flat washer and hairpin.

1

2

3

Figure 9

1. Tank support 3. Front flange screw

2. Rear flange screw

Paint

System

Figure 10

Line Painter 1200 Page 5 – 15 Paint System

Page 46

Flush (Water) Tank

RIGHT

1

2

14

3

4

5

6

7

8

9

10

13

12

11

FRONT

1. Paint tank

2. Tank support

3. Cap

4. Cap insert

5. Gasket

6. Stud

7. Flush tank

8. Extension spring

9. Tank support rod

10. Spray pump assembly

Removal (Fig. 11)

1. Drain paint tank (see Operator’s Manual).

NOTE: The nozzle can be removed from the spray

head to allow the flush tank to be emptied faster.

2. Operate line painter in the flush mode until the flush

tank is empty.

3. Park machine on a level surface, stop engine, engage parking brake and remove key from the ignition

switch. Remove high tension lead from the spark plug

and position the lead away from the spark plug.

4. Tip tank support to gain access to flush tank (see

Tank Support in this section).

Figure 11

1. Flush tank

2. Extension spring

11. Elbow fitting

12. Clamp

13. Bushing

14. Flange head screw (4 used)

2

3

1

Figure 12

3. Tank support rod

Line Painter 1200Page 5 – 16Paint System

Page 47

5. Unhook extension spring from hole in tank support

(Fig. 12). Remove spring and tank support rod from machine.

6. Remove flush tank outlet tube from elbow fitting on

bottom of ball valve (Fig. 13 and 14) (see Quick Disconnect Fitting in the General Information section).

7. Remove flush tank with outlet tube attached from

machine.

1

8. If necessary, remove outlet tube and check valve

from flush tank (Fig. 14).

Installation (Fig. 11)

1. If removed, attach outlet tube and check valve to

flush tank (Fig. 14). Make sure that check valve is

installed to allow free flow from flush (water) tank (Fig.

15).

2. Position flush tank to machine. Connect flush valve

outlet tube to elbow fitting on bottom of ball valve (Fig.

13 and 14) (see Quick Disconnect Fitting in the General

Information section).

3. Secure flush tank to machine with tank support rod

and extension spring.

4. Return tank support to upright position and secure

with flange head screws (see Tank Support in this section).

5. Secure high tension lead to spark plug.

2

Figure 13

1. Ball valve 2. Outlet tube location

1

2

3

Figure 14

1. Flush tank

2. Outlet tube

3. Check valve

Paint

System

2

1

Figure 15

1. Outlet tube from tank 2. Tube to ball valve

Line Painter 1200 Page 5 – 17 Paint System

Page 48

Check Valve Service

The one–way check valve that is positioned between

the flush (water) tank and the ball valve (see schematic)

prevents paint from entering the flush (water) tank when

the paint/flush lever is moved from the paint position to

the flush position and while the machine is operated in

the flush mode.

NOTE: If the flush system is not cleaned after use, diluted paint may cause check valve and associated

hoses to become blocked. If the check valve is stuck

open, paint may enter the flush (water) tank when the

paint/flush lever is moved from the paint position to the

flush position. If the check valve is stuck closed, the flush

system may not operate.

1. Remove flush tank (see Flush Tank Removal in this

section).

2. Remove check valve from tubes (see Quick Disconnect Fitting in the General Information section) (Fig. 16).

3. Inspect check valve:

A. The spring loaded plunger in the check valve

should unseat with very light pressure when pressed

on with a suitable probe. Take care when pressing on

the plunger not to damage the check valve or to allow

contaminates into the valve.

4

Figure 16

1. Flush tank

2. Outlet tube (from tank)

2

1

2

3

3. Check valve

4. Outlet tube (to valve)

1

B. If the check valve is stuck due to dried paint, soak

check valve in water to clean. If soaking in water will

not free valve, check valve replacement is necessary.

4. Install check valve to tubes (see Quick Disconnect

Fitting in the General Information section) (Fig. 16).

Make sure that check valve is installed to allow free flow

from flush (water) tank (Fig. 17).

5. Install flush tank (see Flush Tank Installation in this

section).

Figure 17

1. Outlet tube from tank 2. Tube to ball valve

Line Painter 1200Page 5 – 18Paint System

Page 49

This page is intentionally blank.

Paint

System

Line Painter 1200 Page 5 – 19 Paint System

Page 50

Paint Shutoff Valve

PAINT SHUTOFF VALVE

18

20

1

16

192 to 216 in–lb

(21.7 to 24.4 N–m)

17

19

13

RIGHT

11

FRONT

Figure 18

1. Paint tank

2. Tank support

3. Elbow fitting

4. Paint shutoff valve

5. Flange nut

6. Straight fitting

7. Tee fitting

8. Plug

9. Extension spring

10. Lever

11. Hair pin

12. Pin

13. Cotterless pin

14. Cap screw

Paint Shutoff Valve Spool (Fig. 18)

The spool can be removed from the paint shutoff valve

without removing the complete valve from the machine

using the following procedure:

1. Drain paint tank (see Operator’s Manual). Operate

line painter in the flush mode to clean paint tubes.

12

10

14

15

3

4

5

2

9

8

6

7

15. Flat washer

16. Manifold block

17. O–ring

18. O–ring

19. O–ring

20. Spool

144 to 156 in–lb

(16.3 to 17.6 N–m)

3. Remove two (2) cotterless pins (item 13) that retain

lever to shutoff valve (Fig. 20).

4. Slide lever out of manifold block and place to side.

5. Pull spool from manifold block. Remove and discard

o–rings from spool. Thoroughly clean spool and manifold block.

2. Park machine on a level surface, stop engine, engage parking brake and remove key from the ignition

switch. Remove high tension lead from the spark plug

and position the lead away from the spark plug.

6. Install new o–rings on spool. Lightly grease o–rings

and spool. Push spool into manifold block.

7. Install lever and secure with two (2) cotterless pins

(item 13).

Line Painter 1200Page 5 – 20Paint System

Page 51

Paint Shutoff Valve Removal (Fig. 18)

7. Connect extension spring (item 9) to lever.

1. Drain paint tank (see Operator’s Manual). Operate

line painter in the flush mode to clean paint tubes.

2. Park machine on a level surface, stop engine, engage parking brake and remove key from the ignition

switch. Remove high tension lead from the spark plug

and position the lead away from the spark plug.

3. Remove flush tank (see Flush Tank Removal in this

section).

4. Remove inlet and outlet hoses from paint shutoff

valve (Fig. 19) (see Quick Disconnect Fitting in the Gen

eral Information section).

5. Disconnect extension spring (item 9) from lever (item

10).

6. Remove hair pin (item 11) and pin (item 12) that secure cable to lever.

7. Remove two (2) cotterless pins (item 13) that retain

lever to shutoff valve (Fig. 20). Remove lever from valve.

8. Remove flange nut (item 5), cap screw (item 14) and

flat washer (item 15) that secure shutoff valve to tank

support. Remove valve from machine.

9. If needed, remove fittings from shutoff valve.

10.If required, push spool from manifold block. Remove

and discard o–rings. Thoroughly clean spool and man

ifold block.

Paint Shutoff Valve Installation (Fig. 18)

8. Connect inlet and outlet hoses to paint shutoff valve

(Fig. 19) (see Quick Disconnect Fitting in the General In

formation section).

9. Install flush tank (see Flush Tank Installation in this

section).

10.Secure high tension lead to spark plug.

-

4

3

Figure 19

1. Cable 3. Inlet hose

2. Outlet hose 4. Paint shutoff valve

-

1

2

-

1

Paint

System

1. If spool was removed from manifold block, install

new o–rings on spool. Lightly grease o–rings and spool.

Push spool into manifold block.

2

2. If fittings were removed from shutoff valve, apply

Saf–T–Lok PTFE Pipe Sealant (or equivalent) to

threads of fittings (see Thread Sealant for Paint System

Fittings in the General Information section). Install fit

tings to valve. Torque fittings to values identified in Fig.

-

1. Pivot cotterless pin 2. Spool cotterless pin

Figure 20

18.

3. Position valve to tank support and install cap screw

(item 14), flat washer (item 15) and flange nut (item 5).

5

34

Do not fully tighten nut.

4. Position lever to valve and install two (2) cotterless

pins (item 13) to secure lever to shutoff valve.

5. Secure cable to lever with pin (item 12) and hair pin

(item 11).

6. Tighten flange nut (item 5) to secure shutoff valve to

machine.

1. Manifold block 4. O–ring

2. Spool 5. O–ring

3. O–ring

1

2

Figure 21

Line Painter 1200 Page 5 – 21 (Rev. A) Paint System

Page 52

Pressure Regulator

144 to 156 in–lb

(16.3 to 17.6 N–m)

7

6

5

8

RIGHT

FRONT

Figure 22

1. Pressure regulator

2. Flange head screw (2 used)

3. Straight fitting

4. Tee fitting

5. Tank support

6. Elbow fitting

Removal (Fig. 22)

1. Drain paint tank (see Operator’s Manual). Operate

line painter in the flush mode to clean paint tubes.

2. Park machine on a level surface, stop engine, engage parking brake and remove key from the ignition

switch. Remove high tension lead from the spark plug

and position the lead away from the spark plug.

1

2

3

4

7. Bracket

8. Cap screw

120 to 132 in–lb

(13.6 to 14.9 N–m)

5. Label hoses connected to pressure regulator to assist in assembly. Remove hoses from fittings on pressure regulator (Fig. 23) (see Quick Disconnect Fitting in

the General Information section).

6. Remove pressure regulator from machine using Figure 22 as a guide.

7. If necessary, remove fittings from pressure regulator.

3. Remove flush tank (see Flush Tank Removal in this

section).

4. If equipped, remove pressure gauge from machine.

Line Painter 1200Page 5 – 22Paint System

Page 53

Disassembly (Fig. 24)

NOTE: Individual components for the pressure regula-

tor are not available. If pressure regulator is disassembled for cleaning, take care not to damage regulator

components.

1

3

1. Remove knob from pressure regulator.

2. Carefully press spring pin from regulator housing.

3. Remove collar, spring and poppet from regulator

housing.

Assembly (Fig. 24)

1. Assemble regulator in the reverse order of disassembly. Make sure that spring pin is centered in housing

before installing jam nut and knob to housing.

Installation (Fig. 22)

1. If fittings were removed from pressure regulator, ap-

ply Saf–T–Lok PTFE Pipe Sealant (or equivalent) to

threads of fittings (see Thread Sealant for Paint System

Fittings in the General Information section). Install fit

-

tings to regulator. Torque fittings to values identified in

Fig. 22.

2. Install regulator to machine using Figure 22 as a

guide.

3. Install hoses to fittings on pressure regulator (Fig.

19) (see Quick Disconnect Fitting in the General Infor

-

mation section).

4. If equipped, install pressure gauge to machine.

5. Install flush tank (see Flush Tank Installation in this

section).

6. Secure high tension lead to spark plug.

2

4

Figure 23

1. Pressure regulator 3. To paint shutoff valve

2. To RH ball valve 4. To spray pump

7

4

6

5

3

2

1

Figure 24

1. Knob 5. Spring pin

2. Collar 6. Jam nut

3. Spring 7. Housing

4. Poppet

Paint

System

Line Painter 1200 Page 5 – 23 (Rev. A) Paint System

Page 54

Ball Valve

144 to 156 in–lb

(16.3 to 17.6 N–m)

192 to 216 in–lb

(21.7 to 24.4 N–m)

84 to 108 in–lb

(9.5 to 12.2 N–m)

RIGHT

1

20

3

2

4

192 to 216 in–lb

2

(21.7 to 24.4 N–m)

5

144 to 156 in–lb

(16.3 to 17.6 N–m)

84 to 108 in–lb

(9.5 to 12.2 N–m)

14

19

18

21

24

22

23

6

7

8

9

10

13

11

12

15

16

FRONT

Figure 25

1. Paint tank

2. Jam nut

3. Elbow fitting

4. Flat washer

5. Slotted washer

6. Rubber washer

7. Outlet port

8. Ball valve bracket

9. Straight fitting

10. Hose clamp

11. Tee fitting

12. O–ring

13. Ball valve

14. Elbow fitting

15. Drain valve bracket

16. Flange screw (5 used)

Removal (Fig. 25)

1. Drain paint tank and clean the paint system with

clean water (see Operator’s Manual).

2. Park machine on a level surface, stop engine, engage parking brake and remove key from the ignition

switch. Remove high tension lead from the spark plug

and position the lead away from the spark plug.

3. Remove flush tank (see Flush (Water) Tank Removal

in this section).

4. Remove elbow fitting (item 3), jam nuts (item 2) and

washers (items 4 and 5) that secure ball valve ports to

paint tank.

17

17. Tank support

18. Elbow fitting

19. Lever

20. Knob

21. Screw

22. Flat washer

23. Spacer

24. Recirculation port

5. Label hoses connected to ball valves to assist in assembly. Remove hoses from fittings on ball valves (Fig.

26) (see Quick Disconnect Fitting in the General Information section).

6. Remove knob (item 20) from lever (item 19).

7. Remove two (2) flange screws (item 16) that secure

ball valve assembly to tank support.

8. Remove ball valve assembly from machine. Locate

and retrieve rubber washers (item 6) that seal ports on

ball valves to paint tank. Discard rubber washers.

9. As necessary, remove fittings and lever from ball

valves to allow removal of ball valve(s) from ball valve

bracket.

Line Painter 1200Page 5 – 24Paint System

Page 55

NOTE: Individual components for the ball valves are

not available.

10.Install flush tank (see Flush (Water) Tank Installation

in this section).

NOTE: Ball valve nut threads have thread sealant applied during initial assembly. Nut removal may be difficult.

10.If needed, disassemble ball valve using Fig. 27 as a

guide.

Installation (Fig. 25)

1. If ball valves were disassembled, assemble ball

valves using Fig. 27 as a guide. Torque nut 45 to 55 in–lb

(5.1 to 6.2 N–m).

NOTE: When assembling ball valves and lever to ball

valve bracket, make sure that valve ball is orientated to

upper fitting opening of ball valve assembly and lever is

in the paint (lowered) position.

2. Position ball valves and lever to ball valve bracket.

IMPORTANT: Install fittings into ball valves by hand

to prevent cross–threading the ball valve threads.

3. Apply Saf–T–Lok PTFE Pipe Sealant (or equivalent)

to threads of all removed fittings (see Thread Sealant for

Paint System Fittings in the General Information sec

-

tion). Install fittings to ball valves as follows:

A. Tighten recirculation port (item 24) so that clearance between port neck and top of bracket is from

0.000” (flush) to .030” (.0 to .8 mm) (Fig. 28).

B. Tighten outlet port (item 7) so that clearance between bottom of hex and top of bracket is from 0.000”

(flush) to .030” (.0 to .8 mm) (Fig. 28).

C. Torque remaining fittings to value identified in Fig.

25.

4. Place new rubber washers (item 6) on ball valve

ports. Position ball valve assembly to machine.

5. Install two (2) flange screws (item 16) that secure ball

valve assembly to tank support but do not fully tighten.

6. Install washers (items 4 and 5), jam nuts (item 2) and

elbow fitting (item 3) that secure ball valve fittings to

paint tank. Tighten jam nuts. Torque elbow fitting from

144 to 156 in–lb (16.3 to 17.6 N–m).

11. Secure high tension lead to spark plug.

3

Figure 26

1. To spray pump 3. Lever (paint position)

2. To pressure regulator

9

4

7

6

45 to 55 in–lb

(5.1 to 6.2 N–m)

4

2

8

5

3

Figure 27

1. Nut

2. Cover

3. O–ring

4. O–ring

5. Seat

0.000” to .030”

(0.0 to .8 mm)

6. Valve ball

7. Spindle

8. Housing

9. O–ring (2 used)

2

1

1

1

2

Paint

System

7. Tighten two (2) flange screws (item 16).

8. Install hoses to fittings on ball valves (Fig. 26) (see

Quick Disconnect Fitting in the General Information sec

-

tion).

9. Install knob (item 19) to lever.

1. Recirculation port 2. Outlet port

Figure 28

Line Painter 1200 Page 5 – 25 (Rev. A) Paint System

Page 56

Spray Pump Drive Belt

13

14

12

15

16

11

17

1

2

3

4

5

8

6

7

9

10

Figure 29

1. Engine pulley

2. Lock nut

3. Idler pulley

4. Shoulder screw

5. Extension spring

6. Idler bracket

7. Pivot washer

8. Cap screw

9. Lock nut

10. Spray pump

11. Pump drive belt

12. Pump pulley

Removal (Fig. 29)

1. Drain paint tank (see Operator’s Manual).

2. Park machine on a level surface, stop engine, engage parking brake and remove key from the ignition