Page 1

SpeedControlLinkageKit

2009GrandStand

ModelNo.119-8770

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3366-810RevC

®

Mower

InstallationInstructions

ProcedureDescription

1

2

3

4

5

Qty.

Nopartsrequired

Nopartsrequired

ObtainpartsfromanAuthorizedService

Dealer

Hairpincotterpin2

Flatwasher4

Speedcontrollinkage

Shoulderhub

Flangenut(1/4inch)

Bolt(1/4x1-3/8inch)

Rodendballjoint2

Rollerbushing8

Bolt(1/4x2-3/4inch)

Controlfork

Upperswitchlever1

Plasticcabletie1

Plasticcabletie1Adjustthespeedcontrol.

–

–

2Replacethepumparm.

2

2

4

2

2

2

Preparethemower.

Removetheexistingcontrols.

Installthenewcontrols.

Use

1

PreparingtheMower

NoPartsRequired

Procedure

1.Allowthemachinetocooldownbeforeinstalling

thiskit.

2.Thoroughlycleanthemachine.Alldebrismustbe

removedtoensurethekitwilltproperly .

3.Repairallbentordamagedareasandreplaceany

missingparts.

©2010—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

2

RemovingtheExisting

Controls

NoPartsRequired

Procedure

1.Releasethecushionforrearaccess.

2.Frombehindtheengine,removethehairpincotter

pinfromtheexistingcontrollinkageandfront

bracket(Figure1).

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

Page 2

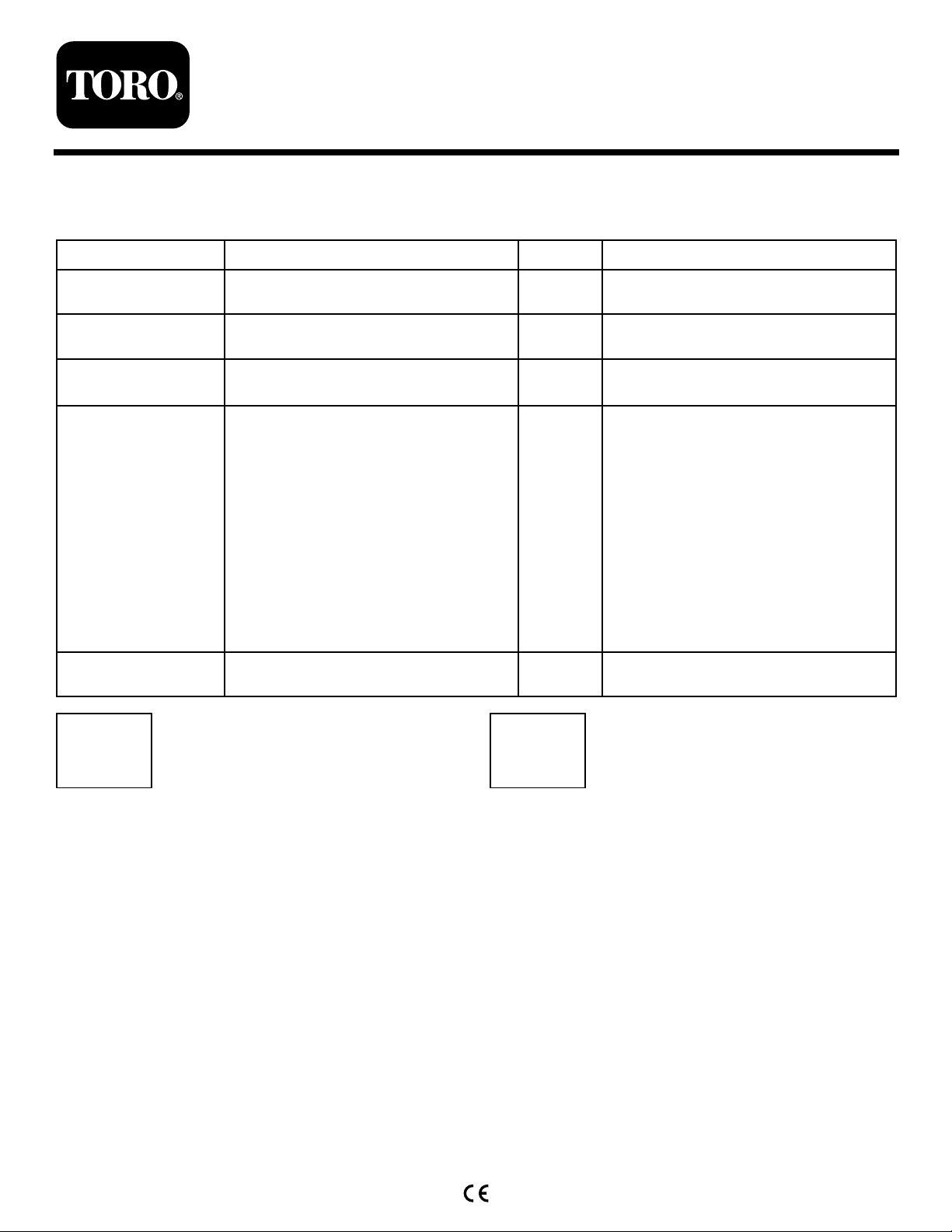

G013702

1

2

3

Figure1

1

2

G013701

3

4

1.Engine3.Hairpincotterpin

2.Existingcontrollinkage

3.Removethehairpincotterpinandwasherfromthe

existingcontrollinkage.Removetheexistingcontrol

linkagefromtheforksandpumparm(

Figure2).

4.Removethecableendfromthefork(Figure2).

5.Removethecableendfromthecable(Figure2).

6.Removethebolt,nut,spacerandwashersfrom

theforkandtheupperandlowerswitchbrackets

Figure2).

(

Figure2

1.Existingcontrollinkage

2.Hairpincotterpin4.Rightcableend

3.Boltandnutinforkand

controlarm

7.Loosenthecableclampsecuringthespeedcontrol

cablejackettotheshifterbracket(Figure3).Itis

easiesttoaccessthisunderthelowerframeandin

frontoftheleftrearwheel.

2

Page 3

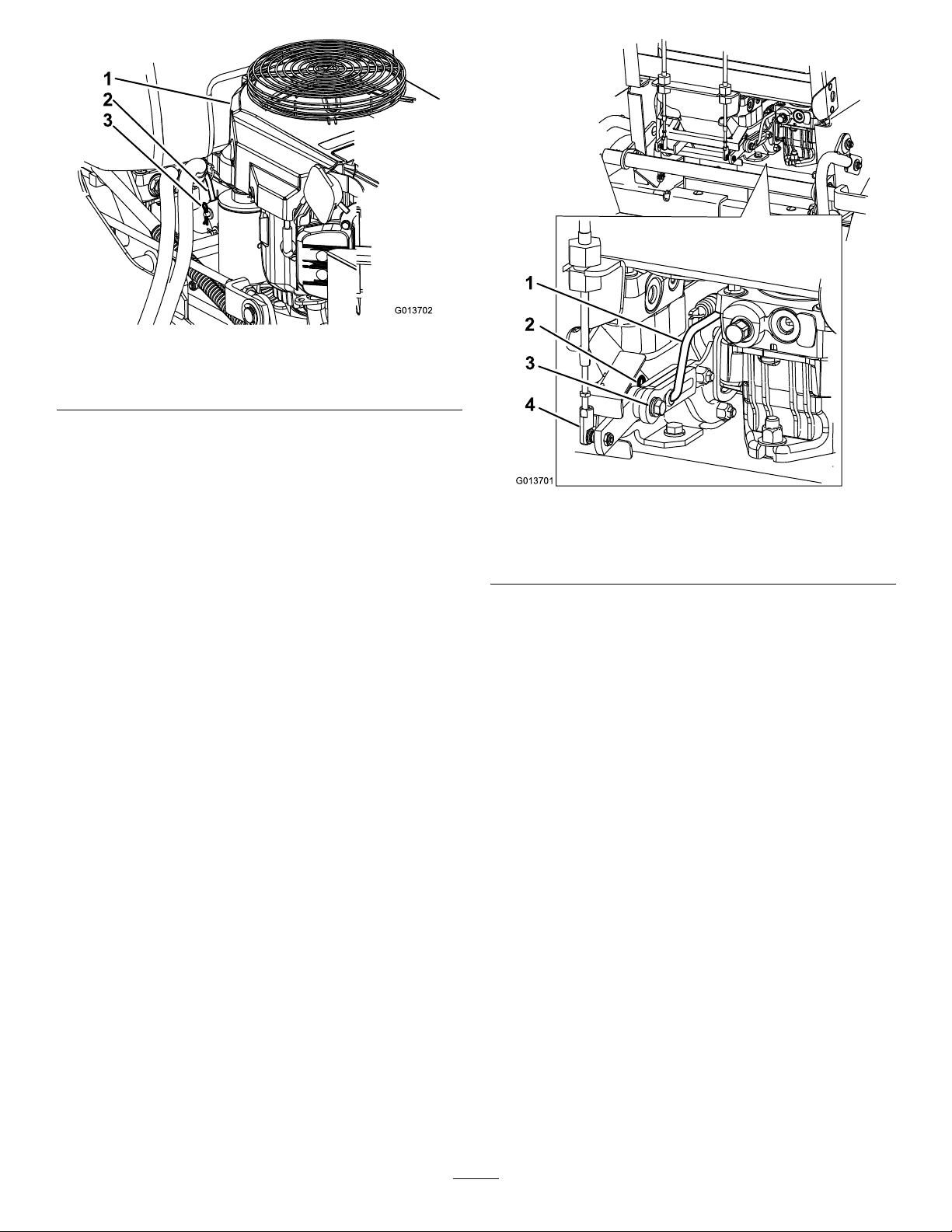

1

2 3

4

G013763

ModelNumber

G013722

1 2

3

74558290000209andbelow

74559290000156andbelow

74568290000205andbelow

74569290000206andbelow

SerialNumber

1.Removethetwonutsandboltsattachedtothepump

arm(Figure4).Savethishardware.

2.Removethepumparmfromthefork(Figure4).

3.Installthenewpumparmwiththeexistinghardware

previouslyremoved.

Figure3

1.Mowerdeck

2.Leftreartire4.Cableclamp

3.Speedcontrolcable

8.Performthissameprocedurefortheopposite

control.

3

ReplacingthePumpArm

Partsneededforthisprocedure:

2

ObtainpartsfromanAuthorizedServiceDealer

Procedure

Note:Thisprocedureisonlyforcertainmodelsof

Grandstandmowerswiththeserialnumberslisted.

1.Lefthandpumpshown

2.Fork

Figure4

3.Pumparm

Pumparmsarenotincludedinthiskit.Contactan

AuthorizedServiceDealerforthepumparms.

Thefollowingtableliststhemachinesthatneedthe

pumparmsreplaced.

3

Page 4

ensurestheforkandcablewilltravelwithoutbinding

Figure5).

(

4

InstallingtheNewControls

Partsneededforthisprocedure:

2Hairpincotterpin

4Flatwasher

2

Speedcontrollinkage

2

Shoulderhub

4

Flangenut(1/4inch)

2

Bolt(1/4x1-3/8inch)

2Rodendballjoint

8Rollerbushing

2

Bolt(1/4x2-3/4inch)

2

Controlfork

1Upperswitchlever

1Plasticcabletie

9.Tightentheexistingjamnutontherodendball

joint.Makesurethecabledoesnothaveatwistinit.

Procedure

1.Positionthenewforkwiththepumparminbetween

thefork.

2.Installthenewupperswitchleverandexisting

lowerswitchleverontothelefthandshoulderhub

Figure5).

(

3.Installtheforktotherearbracketwithanewbolt

(1/4x2-3/4inch),washer,shoulderhubanda

angenut(1/4inch)(Figure5andFigure6).Do

nottightenatthistime.

4.Installthenewspeedcontrollinkagetotheforkwith

3rollerbushings,aatwasherandahairpincotter

Figure5).

pin(

5.Frombehindtheengine,installthespeedcontrol

linkagetothefrontbracketwithaatwasheranda

hairpincotterpin(Figure5andFigure6).

6.Threadtherodendballjointallthewayontothe

endofthecableandthenbackitoff2turns.DO

NOTtightenthejamnutatthistime.

Note:Ensuretheballjointsareinstalledonthe

insideoftheforks(Figure6).

7.Installtherodendballjointtotheforkwithabolt

(1/4x1-3/8inch),rollerbushingandangenut

(1/4inch).

8.Holdtherodendballjointperpendiculartothe

boltwhentighteningtheangenutandbolt.This

4

Page 5

G014214

1 2

2 1

3

4

5

6

7

15

11 10 9

12 13 14

3

2 1 4

18

5 1 6 7 15 10 8 19 9 16 17

8 19

Figure5

1.Flatwasher

2.Hairpincotterpin7.Fork12.Newupperswitchlever17.Useexistinglowerswitch

3.Speedcontrollinkage

4.Rollerbushing

5.Bolt(1/4x2-3/4inch)10.Shoulderhub

6.Flangenut(1/4inch)

8.Rodendballjoint

9.Bolt(1/4x1-3/8inch)14.Correctpositionofrodend

11.Existinglargewasherused

onrightsideonly(shown

hereforillustrativepurposes)

13.Wrongpositionfortherod

endballjoint(topview)

balljoint(topview)

15.Rollerbushing

16.Donotremovetheexisting

switch

lever

18.Existingneutralstoparmon

leftsideonly

19.Existingjamnut(tighten

afterinstallingrodendball

joint)

5

Page 6

G013703

1

3 2

5 4

Figure6

G013818

1 2

G013764

1 2

1.Frontbracket4.Existinglargewasher

usedonrightsideonly

2.Pumpcontrolarm5.Existingneutralstoparm

onleftsideonly

3.Rearbracket

5

AdjustingtheSpeedControl

Partsneededforthisprocedure:

1Plasticcabletie

Procedure

1.SettheHOCleverto2inchesandmovethespeed

controllevertotheFASTposition.

2.Ensurethecableclampsecuringthespeedcontrol

cablejackettotheshifterbracketisloose(Figure10).

3.Loosentheboltthatgoesthroughthecenterofthe

lefthandshoulderhubandcontrolfork(Figure8).

4.Removethehairpincotterpinandwasherfromthe

endofthelefthandspeedcontrollinkageassembly

(Figure8).

10.Usingtheplastictie,fastenthespeedcontrolcable

totherightcontrolcable(Figure7).

1.Plasticcabletie

Figure7

2.Speedcontrolcable

11.Performthissameprocedurefortheopposite

control.

Figure8

1.Hairpincotterpinandat

washer

2.Loosenthisbolt

5.Infrontofthelefthandspeedcontrollinkagerollers,

inserta7/32ndinchallenwrenchintotheslotsof

thecontrolforkandcontrolarm(Figure9).

6.Pushthespeedcontrollinkageforward,andtighten

theclampsecuringthespeedcontrolcablejacketto

theshifterbracket(Figure9andFigure10).

6

Page 7

G013765

1 2

3

1.7/32ndinchallenwrench

1

2 3

4

G013763

5

G013767

1

2

4 3

2.Slots

Figure9

3.Pushthespeedcontrol

linkageforward

(Figure11).Donotforcetheneutralassembly

together.

Figure11

1.Plasticcabletie4.Neutralstoparm

2.Upperswitchlever

3.Lowerswitchlever

5.Switch(Donotremove)

1.Mowerdeck

2.Leftreartire4.Cableclamp

8.Whilepullingthecontrolforkassemblyrearward

(notsohardthatthespeedcontrollinkagemoves)

tightenthescrewthatgoesthroughthecenterofthe

lefthandshoulderhub(Figure12).

Note:Itisimportanttokeepthepumpcontrolarm

andcontrolforkslotsareinlinewitheachother.

Thiscanbeachievedbymakingsurethetopofthe

pumpcontrolarmandcontrolforkareparallelto

eachother.

Figure10

3.Speedcontrolcable

7.Theswitchstoparmmustbealignedwiththe

cableendofthecontrolfork.Usingacabletie,

securetheneutralassemblytoalignthecomponents

7

Page 8

G013768

1 3

2

Figure12

1.Movementofcontrolarm

2.Slotsarealigned

3.Tightenthisbolt

9.Removetheallenwrenchfromslotsofthecontrol

forkandcontrolarmslotsandcutthecabletiefrom

theneutralassembly.

10.Installthewasherandhairpintotheendofthe

speedcontrollinkage.

11.Repeatsteps3through10(donotdostep7)onthe

righthandside.

8

Loading...

Loading...