SpeedControlKit

2011andAfterGrandStand

ModelNo.119-7390

Safety

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

FormNo.3369-616RevA

®

Mower

InstallationInstructions

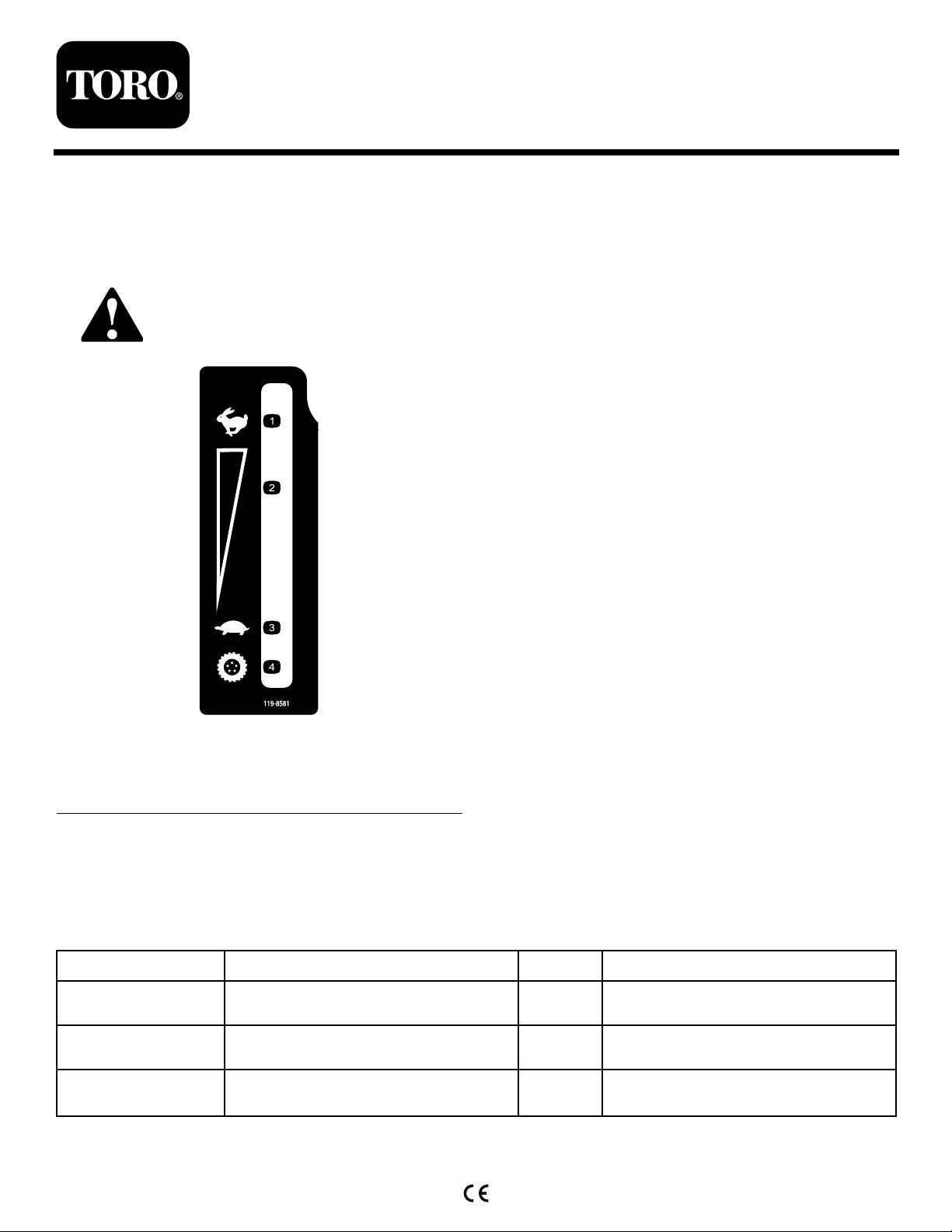

119-8581

1.Fast

2.Continuousvariable

setting

3.Slow

4.Tractioncontrol

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

©2011—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Nopartsrequired

Nopartsrequired

Nopartsrequired

Registeratwww.T oro.com.

Qty.

Use

–

–

–

Preparethemachine.

Removethefueltank.

Removetherearcrossbracketand

cables.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

ProcedureDescription

Qty.

Use

4

5

6

7

8

9

10

11

12

Nopartsrequired

Righthandmotioncontrolbracket1

Flatwasher(5/16inch)(ifneeded)

Lefthandmotioncontrollever

Speedcontrolassembly

Carriagebolt(5/16x1inch)

Flangenut(5/16inch)

Rubbergrip1

Pumparm2

Yoke2

Shoulderbolt

Locknut(1/4inch)

Nopartsrequired

Nopartsrequired

Plasticcabletie1

Nopartsrequired

–

2

1

1

2

2

1

2

–

–

–

Removethemotioncontrolassembly.

Assembletherighthandmotioncontrol

leverandnewbracket.

Installthemotioncontrolleversand

pivotbrackets.

Installthespeedcontrolassembly.

Installtherearcrossbracketandcables.

Adjustingtherightsidemotioncontrol

lever.

Adjusttheneutralpositionforthemotion

controllevers.

Installthefueltank.

Adjustthetracking.

1

PreparingtheMachine

NoPartsRequired

Procedure

1.DisengagethePTO ,movetherightsidemotion

controllevertotheneutralpositionandsetthe

parkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Allowthemachinetocooldownbeforeinstalling

thiskit.

4.Thoroughlycleanthemachine.Alldebrismustbe

removedtoensurethekitwilltproperly .

5.Repairallbentordamagedareasandreplaceany

missingparts.

2

RemovingtheFuelTank

NoPartsRequired

Procedure

Note:Retainallhardwareandpartsforinstallation

afterthekitisinstalled.

1.Releasethecushionfromtherearofthemachine.

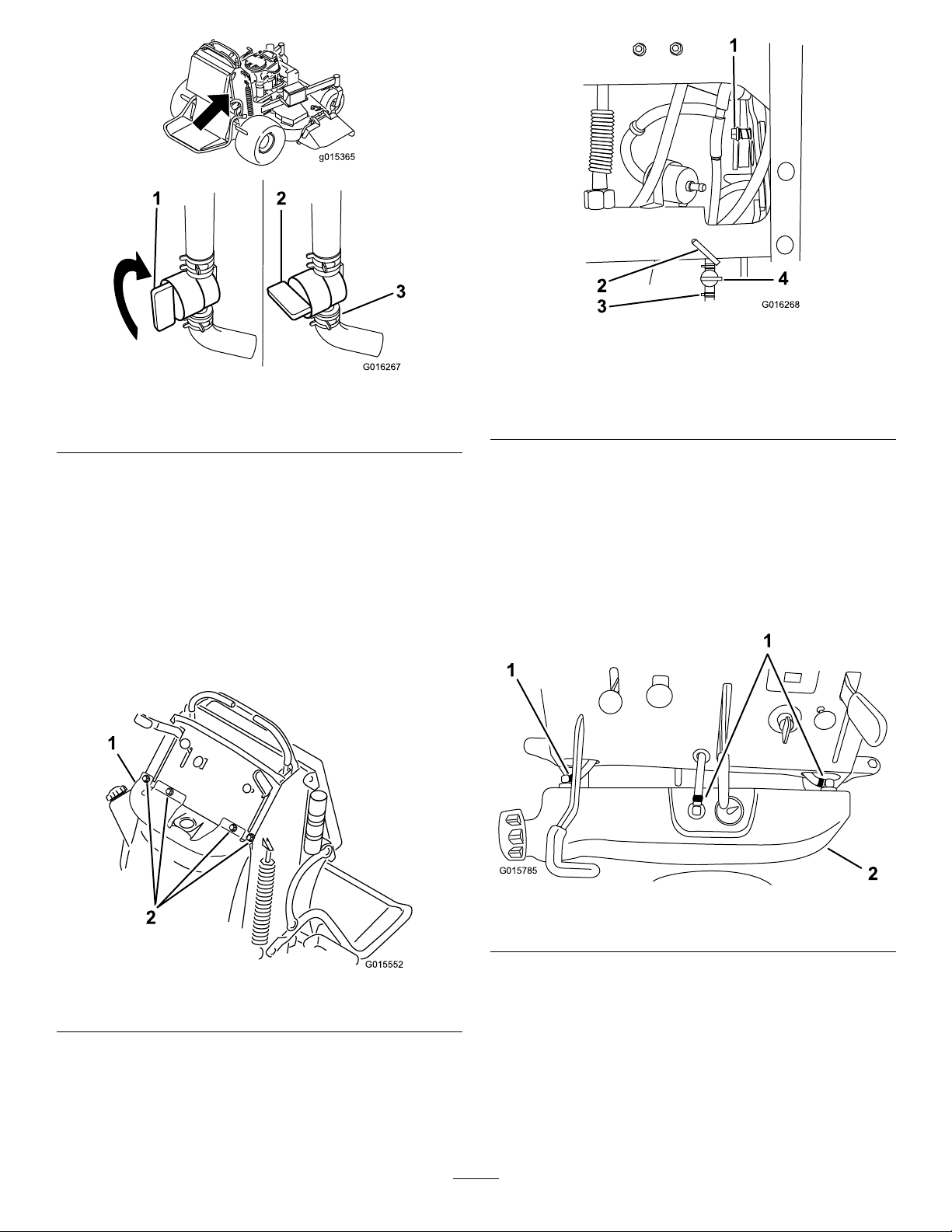

2.Closethefuelshutoffvalve(Figure1).

6.Disconnectthenegative(black)batterycable.

2

g015365

1

3

2

G016267

G015552

2

1

G016268

1

2

3

4

Figure3

G015785

1

1

2

Righthandside

Figure1

1.On

2.Off

3.Removeclampandhose

3.Lowerthemowerdecktothe1inch(2.54cm)

height-of-cut.

4.Removethehoseandclampfromtheshutoff

valveontheenginesideandcuttheplasticcabletie

Figure3).

(

5.Usingthefuelshutoffvalve,drainthefuelintoa

cleanfuelcontainer.

6.Removethe4boltsholdingthebracketontopof

thefueltank(

Figure2).

1.Shoulderboltand

compressionspring

2.Cutplasticcabletie4.Fuelshutoffvalve

3.Removeclampandhose

8.Movethedecklifthandletothetransportposition.

Thiswillallowforroomtoremovethefueltank.

9.Liftthetankupandforwardasfaraspossible

(Figure4).

10.Disconnectthe3venthosesfromthefueltankby

looseningthehoseclamps(

Figure4).

11.Removethetankfromthemachine.

Figure2

1.Bracket2.Bolts

7.Removetheshoulderboltandcompressionspring

atthedecklifthandle(Figure3).

Figure4

1.Venthoseandclamps2.Fueltank

3

G016247

1

2

3

4 5

6

5.Removetherodendbearingfromeachcableend

g015788

1

2

thatwasconnecttothecontrollever.

3

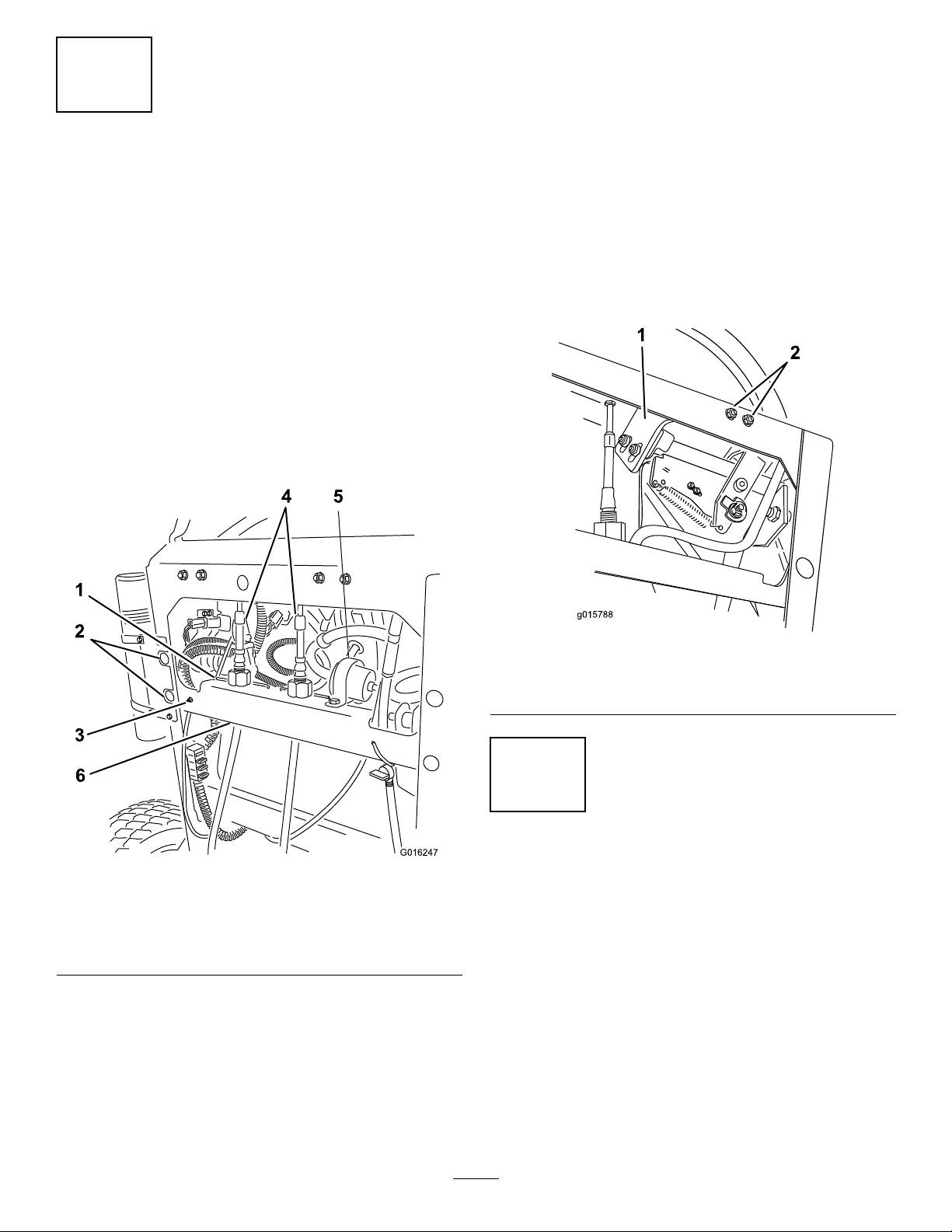

RemovingtheRearCross

BracketandCables

NoPartsRequired

Procedure

Note:Retainallhardwareandpartsforinstallation

afterthekitisinstalled.

1.Removethewirespringholdingtheadjustmentnuts

fortracking(

2.Removethenutandboltholdingeachcableendto

themotioncontrollevers.

3.Slidethecablesoutofthecrossbracket(

andFigure12).

Figure5).

Figure5

6.LoosenthelargeR-clampandremovethelterfrom

theR-clamp(

7.Onthelefthandsideofthecrossbracket,squeeze

theconduitclipandpushitthroughthecross

bracket(Figure5).

8.Removethecrossbracketfromthemachineby

removingthefourbolts.Donotdiscardthis

hardwareandcrossbracket(Figure5).

9.Removetherighthandbracketwiththeproximity

switchattachedtoit(

Figure5).

Figure6).

Figure6

1.Righthandbracketwith

proximityswitch

2.Removethesenutsand

bolts

4

RemovingtheMotionControl

Figure5

1.Wirespring

2.Bolts

3.Conduitclip

4.Removethenutandboltholdingeachcableendto

thepumparms(

Note:Therighthandboltmaynot

comeoutbecauseofinterferencewith

thehydraulichose.Theboltwillberemoved

whenchangingthepumparmsinprocedure

8InstallingtheRearCrossBracketandCables(page7).

Figure13).

4.Cablesandcableends

5.Removelterfrom

R-clamp

6.Rearcrossbracket

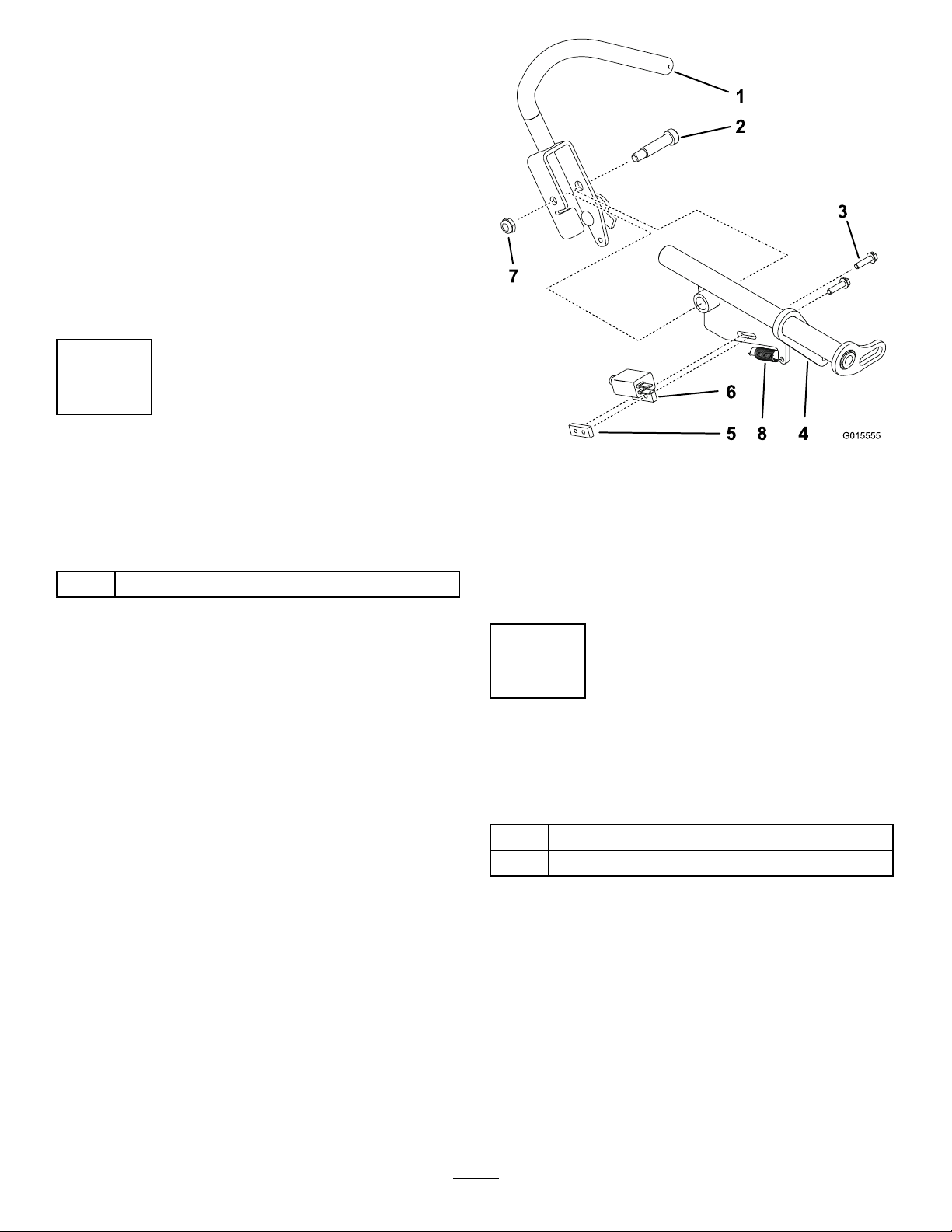

Assembly

NoPartsRequired

Procedure

Note:Retainallhardwareandpartsforinstallation

afterthekitisinstalled.

1.Removethewireharnessfromtheoperatorpresence

control(OPC)switch.

2.Removebothpivotbracketsfromthetopofthe

controlpanelbyremovingthe4nutsandbolts

(

Figure8).

4

3.Slidethelefthandmotioncontrollevertothecenter,

G015555

1

2

3

6

5 8 4

7

offofthepivotandremoveitfromthemachine.

4.Slidetherighthandmotioncontrollevertothe

center,offofthepivotandremoveitfromthe

machine.

5.Disconnectthespringfromtherighthandmotion

controlbracket(

6.Removetheswitchfromtherighthandmotion

controlbracket(

7.Removetheremovetheshoulderboltandrighthand

motioncontrolleverfromtherighthandmotion

controlbracket(Figure7).

Figure7).

Figure7).

5

AssemblingtheRightHand

MotionControlLeverandNew

Bracket

Partsneededforthisprocedure:

1Righthandmotioncontrolbracket

Procedure

1.Installtherighthandmotioncontrolleveronto

thenewmotioncontrolbracketwiththeexisting

shoulderboltandlocknut(

2.InstalltheexistingOPCswitchwithexistingscrews

andswitchnuttothenewmotioncontrolbracket

Figure7).

(

3.Connecttheexistingspringtotherighthandmotion

controlbracketandexistingrighthandmotion

controllever(Figure7).

Figure7).

1.Existingrighthandmotion

controllever

2.Existingshoulderbolt

3.ExistingscrewsforOPC

switch

4.Newmotioncontrol

bracket

6

InstallingtheMotionControl

LeversandPivotBrackets

Partsneededforthisprocedure:

2

Flatwasher(5/16inch)(ifneeded)

1

Lefthandmotioncontrollever

Figure7

5.Existingswitchnut

6.ExistingOPCswitch

7.ExistingLocknut

8.Existingspring

Procedure

Note:Themotioncontrolleversneedtopivotfreely

withoutalotofmovementlaterally(side-to-side).If

needed,usethesuppliedatwasherbetweenthetower

andthehandle(Figure8).

1.Placetherighthandmotioncontrolleverintothe

machineandslideitontothepivotonthesideof

themachine.

2.Securetheotherendwiththepreviouslyremoved

pivotbracketandsecurethepivotbrackettothe

5

Loading...

Loading...