Page 1

FormNo.3365-252RevA

Operator-ControlledDischargeChuteKitwithBag

GrandStand

ModelNo.117-8565

®

Mowerwith36-inchor40-inchCuttingUnit

InstallationInstructions

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

Safety

117-8569

1.Operatordischargecontrol3.Closed

2.Open4.ReadtheOperator’s

Manual.

©2010—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

Page 2

Installation

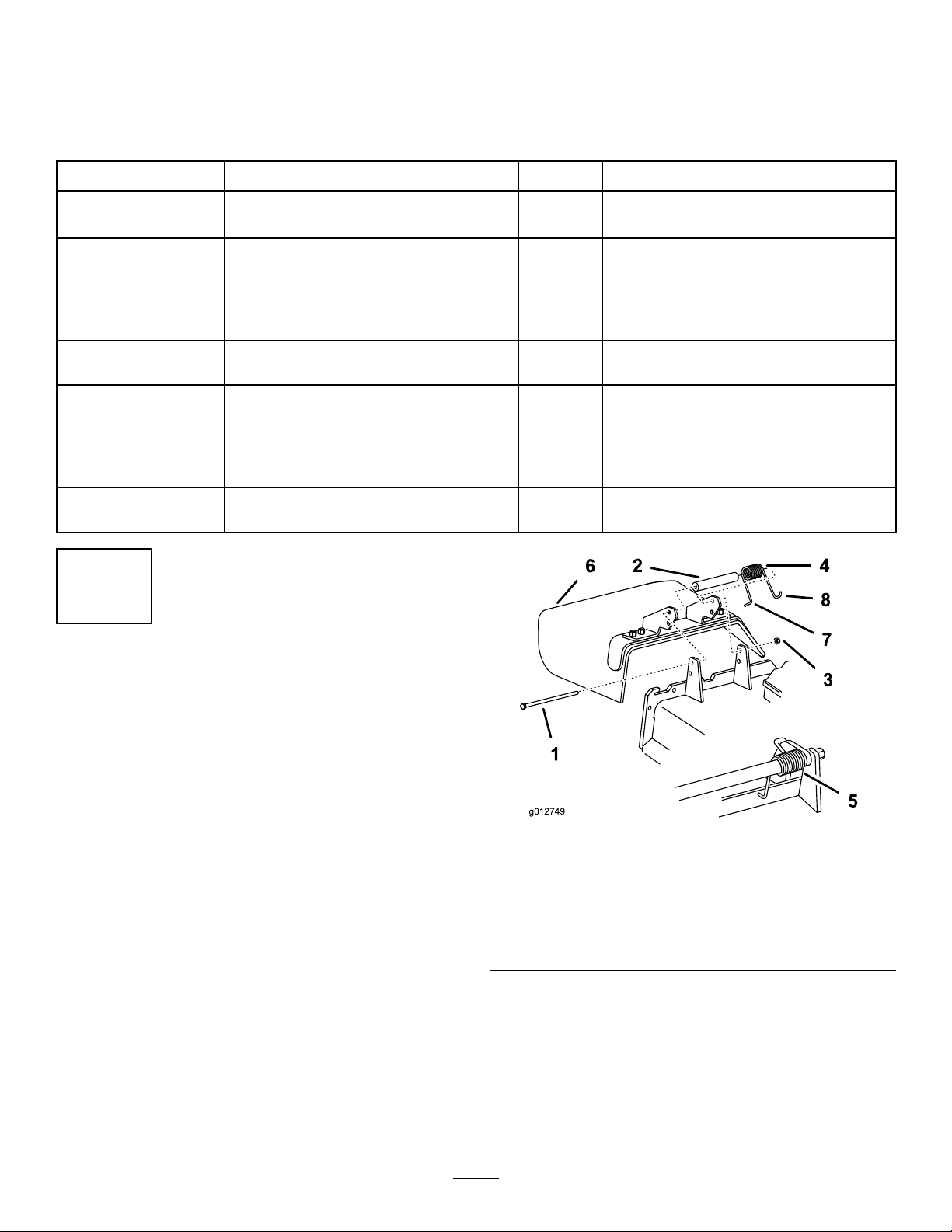

g012749

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

1

Qty.

Nopartsrequired

Sidedischargechute

Bolt,(5/16x7–1/2inches)

Locknut,(5/16inch)

Plasticspacer1

Spring

Nopartsrequired

Handleassembly1

Bolt,(3/8x1inch)(Selftapping)

Plasticcabletie2

Plasticmountwithadhesive2

Locknut1

Trashbag1Installthetrashbag.

–

1

1

1

1

–

2

Removetheexistingsidedischarge

chute.

Installthesidedischargechutewith

gate.

Drilltheholes.

Installthehandleandcables.

Use

RemovingtheExistingSide

DischargeChute

NoPartsRequired

Procedure

1.DisengagethePTO ,settheparkingbrake,andchock

orblockthedrivewheels.

2.Turnofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removethelocknut,bolt,springandspacerholding

thedeectortothepivotbrackets(

Removethegrassdeector.

Figure1).

Figure1

1.Bolt

2.Spacer6.GrassDeector

3.Locknut

4.Spring8.Jhookendofspring

5.Springinstalled

7.Lendofspring,place

behinddeckedgebefore

installingbolt

2

Page 3

2

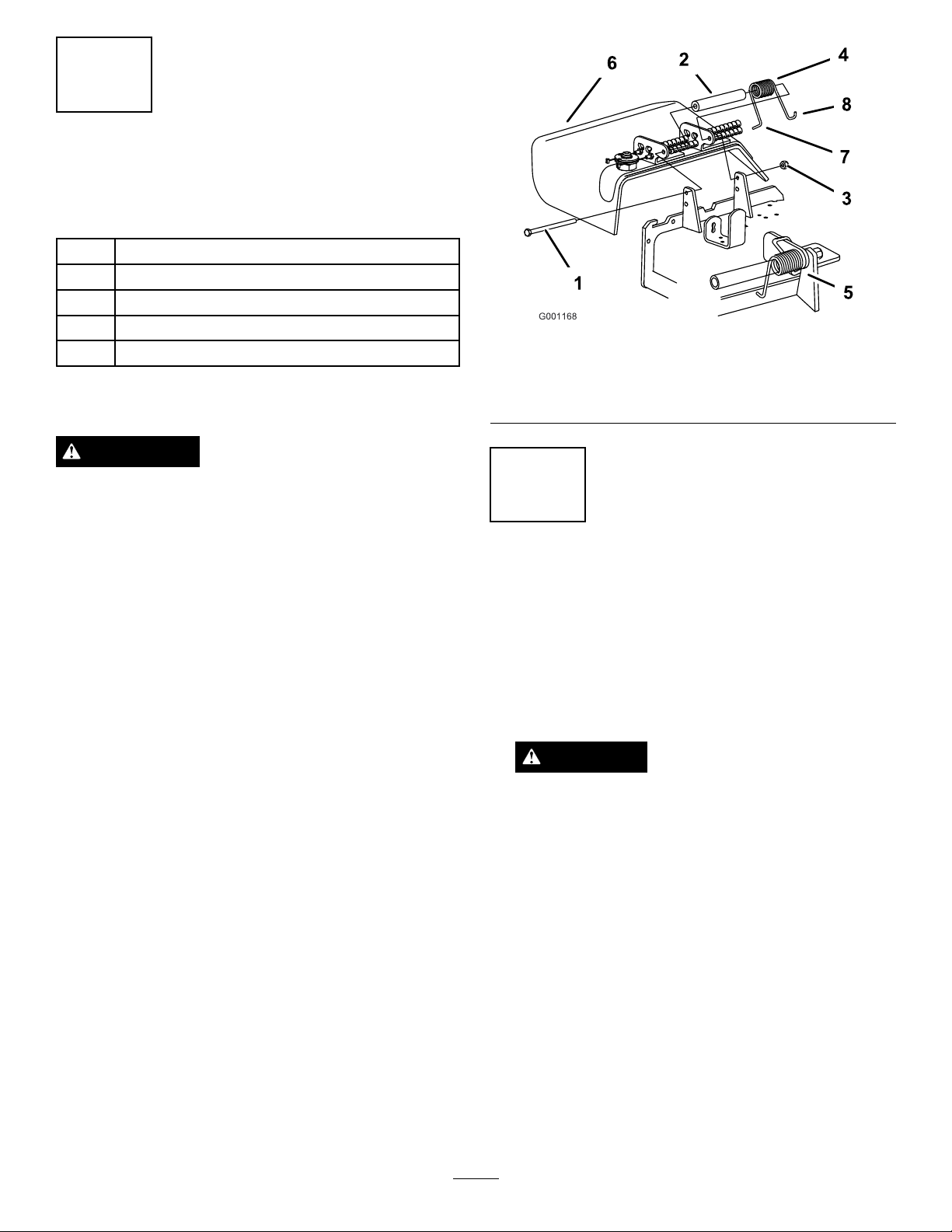

InstallingtheSideDischarge

ChutewithGate

Partsneededforthisprocedure:

1

Sidedischargechute

1

Bolt,(5/16x7–1/2inches)

1

Locknut,(5/16inch)

1Plasticspacer

1

Spring

Procedure

WARNING

Anuncovereddischargeopeningcouldallowthe

lawnmowertothrowobjectsintheoperator’sor

bystander’sdirectionandresultinseriousinjury.

Also,contactwiththebladecouldoccur.

•Neveroperatethelawnmowerunlessyouinstall

acoverplate,amulchplate,oragrasschuteand

catcher.

Figure2

1.Bolt

2.Spacer5.Springinstalled

3.Locknut

3

DrillingtheHoles

NoPartsRequired

4.Spring

6.GrassDeector

•Makesurethegrassdeectorisinthedown

position.

Note:Ensurethegrassdeectorisinstalledinthe

lowerholesinthemowerdeckbrackets.

1.Placethenewspacerandspringontograssdeector.

Placeoneendofspringbehinddeckedge.

Note:Makesuretheendofthespringisinstalled

behindthedeckedgebeforeinstallingtheboltas

shownin

2.Installboltandnutinthelowerhole.Placetheend

ofthespringaroundthegrassdeector(Figure2).

3.Tightenthenutuntiltheendoftheboltisushwith

theendofthenut.Donotovertighten.

Important:Thegrassdeectormustbeableto

lowerdownintoposition.Liftthedeectorup

totestthatitlowersintothefulldownposition.

Figure2.

Procedure

1.Beforedrillingtheholes,checkiftheholesalready

exist(Figure5).Proceedtoprocedure4iftheholes

exist.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouandothers

andcandamageproperty.

•Placeapieceofmetalbetweenthefuel

tankandtheleftsideofthemachinebefore

drillingtheholes.

•Neverdrillintothesideofthefueltank.

•Afueltankleakmayresultinareor

explosionfromgasoline.

2.Placeapieceofmetalbetweenthefueltankandthe

leftsideofthemachine.Thiswillpreventthedrill

bitfromdrillingintothefueltank(Figure3).

3

Page 4

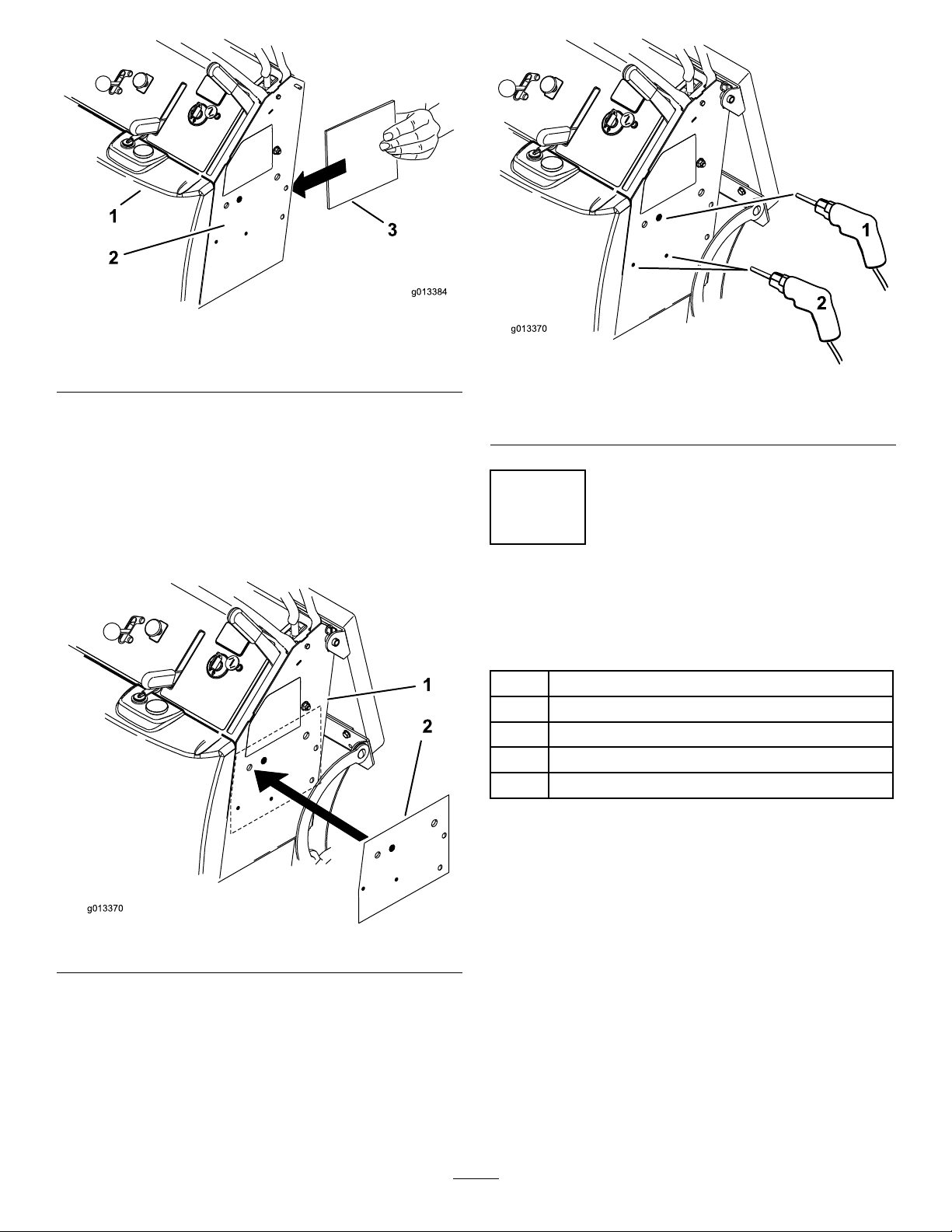

g013384

1

2

3

Figure3

g013370

1

2

g013370

1

2

1.Fueltank

2.Leftsideofmachine

3.Steelplate

3.Locatethepapertemplateatthebackofthis

instructionsheetandcutitout.

4.Locatethetwoexistingholesandplacethetemplate

ontheleftsideofthemachine(

Figure4).

1.Drillone11/32inch

diameterhole

Figure5

2.Drilltwo11/64inch

diameterholes

5.Markthelocationfortheholes.Thesmallholesdo

notneedtobedrilledifthemanualtubeismounted

horizontaltotheground(Figure4).

Figure4

6.Drillone11/32inchdiameterholeintothesideof

themachineforthehandle(

Figure5).

7.Drilltwo11/64inchdiameterholesintothesideof

themachineforthemanualtube(Figure5).

4

InstallingtheHandleand

Cables

Partsneededforthisprocedure:

1Handleassembly

2

Bolt,(3/8x1inch)(Selftapping)

2Plasticcabletie

2Plasticmountwithadhesive

1Locknut

Procedure

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1.Installthehandleassemblytotheleftsideofthe

machinewith2bolts(3/8x1inch)(Figure6).The

boltsarethreadformingbolts.Theholesdonot

requiretapping.

4

Page 5

g013358

3 2 1

Figure6

g013406

1 2 3

g013361

4

5

1

2

3

2

4

6

1.Bolt,(3/8x1inch)(self

tapping)

2.Handleassembly

3.Leftsideofmachine

2.Routethecablesthroughtherectangularopening

ontheleftsideoftheenginebaseandbetween

theenginebaseanddeckontherightsideofthe

machine(Figure7andFigure8).

3.Installanadhesivebackplasticmountontheverticle

partoftheframetubejustinfrontofthehydraulic

oillter.See

theplasticmountandsecurethecableswiththe

Figure8.Threadthecabletiethrough

cabletie.

4.Installanadhesivebackplasticmountonthetopof

themowerdeckontherightsidesothecablesdo

notcontacttheclutchorbeltdrive.See

Figure8.

Threadthecabletiethroughtheplasticmountand

securethecableswiththecabletie.

1.Rectangularopeningon

theleftsideoftheengine

base

2.Hydraulicoillter

Figure7

3.Cables

Figure8

1.Hydraulicoillter4.Cabletieandplastic

2.Cabletieandplastic

mountonsideofframe

3.Hydraulictank

mountontopofmower

deckontherightside

5.Cables

6.Leftsideofthemachine

5.Removethejamnutsfromthethreadendsofthe

cables(Figure10).

6.Locatethecablethatisattachedtotheoutsideof

thehandleassemblyandinstallthiscableintothe

outsideholeinthesidedischargechute(

Figure9).

5

Page 6

g013405

1

1

2

2

Figure9

g013403

1

2

3

4

5

g013404

1 2 3 4 5

1

3

4

5

1.Outsidecableinstalled

intotheoutsideholeinthe

sidedischargechute

2.Insidecableinstalledinto

theinsideholeintheside

dischargechute

7.Installthejamnutsandcablebarrelendthroughthe

largehole(

Figure10).

8.Installthecableintothesmallestdiameterholein

thesidedischargechute(Figure10).

Figure11

1.Outsidecable4.Threadedendofthecable

2.Jamnutthreaded1/2onto

cableend

3.Jamnut

5.Cableendbarrel

11.Whileholdingontothegateassembly,removethe

jamnutanddiscard(Figure12).

Figure10

1.Largehole4.Jamnuts

2.Smallhole5.Cableendbarrel

3.Threadedendofcable

9.Installonejamnutontothethreadedendofthe

cable½waydownthethreads(Figure11).

10.Installthecablethroughthesmallestdiameterhole

inthesidedischargechuteandinstalltheotherjam

nuttosecurethecable(Figure11).

6

Page 7

g013359

1

2

3

4

5

Figure12

g013385

1

2

3

4

5

1.Removejamnutand

discard

2.Washer5.Holdgatewhileremoving

3.Uppercableplate

12.Installthecableendbarrelsintothelowercableplate

4.Cableendbarrel

thejamnut

andsecurethemwiththeuppercableplate,awasher

andlocknut(Figure13)

Note:Makesurethecablesarenotpinchedbefore

tighteningthelocknut.

Figure13

1.Locknut

2.Washer5.Holdgatewhileinstalling

3.Uppercableplate

4.Cableendbarrelsinstalled

inlowercableplate

thelocknut(Makesurethe

cablesarenotpinched)

7

Page 8

g013358

2 1

Operation

5

InstallingtheTrashBag

Partsneededforthisprocedure:

1Trashbag

Procedure

Installthetrashbagintotheslotsinthehandleassembly

(Figure14).

UsingtheChuteGate

CAUTION

Thechutegatedoesnotsealthedischarge

opening.Grassandobjectsmaybethrownina

bystander’sdirectionandresultinseriousinjury.

•Beawareofthemowerdischargedirectionand

donotpointitatanyone.

•Removeobstaclessuchasrocks,treelimbs,

etc.fromthemowingarea.

•Neverputyourhandsorfeetunderthemower

ordischargearea.

•Nevertrytoclearthedischargeareaormower

bladesunlesstheengineisoffandthekeyis

removed.

Usethechutegatetotemporarilystopordeectgrass

clippingsawayfromsidewalks,parkinglots,patios,or

anywhereyoudonotwantgrassclippingstoland.The

chutegatehas3positions:open,45degreeangle,and

closed.

1.Trashbag

Figure14

2.Slotinhandleassembly

•Rotatethechutegatehandletotheopenpositionto

allowgrassclippingstodischarge(Figure

•Rotatethechutegatehandletothe45degreeangle

todeectthegrassclippings(FigureFigure15).

•Rotatethechutegatehandletotheclosedposition

tostopthegrassclippings(FigureFigure15).

Figure15).

8

Page 9

g013409

1

2

Figure15

1.Chutegateopen3.Chutegateclosed

2.Chutegateat45degree

angle

9

Page 10

Notes:

10

Page 11

g013371

Drill this hole

11/32 inch dia.

Scale

Cut along this line

Cut along this line

Cut along this line

Drill this hole

11/64 inch dia.

Drill this hole

11/64 inch dia.

Existing hole

Existing hole

Front edge of tower

Existing carriage bolt

11

Page 12

Loading...

Loading...