Toro Greensmaster 3100, Greensmaster 3150, 112-0266 Installation Instructions Manual

Hydraulic Motor Kit

Greensmaster) 3100 and 3150

Part No. 112-0266

Form No. 3356-114 Rev A

Installation Instructions

Remove Motor and Hub

Assembly

1. Park the machine on a level surface, engage the parking

brake, lower the cutting units, and stop the engine.

Caution

If you leave the key in the ignition switch, someone

could accidently start the engine and seriously

injure you or other bystanders.

Remove the key from the ignition switch before

you do any maintenance.

2. Chock both the front wheels to prevent the machine

from moving. Lift the rear wheel off the ground using a

jack, and place blocks beneath the frame. Secure the

rear wheel off the ground.

3. Label the hydraulic motor hoses for reassembly.

Remove both hose assemblies and O–rings from the

hydraulic fittings at the hydraulic motor and hub

assembly. Plug the hoses to minimize hydraulic fluid

loss.

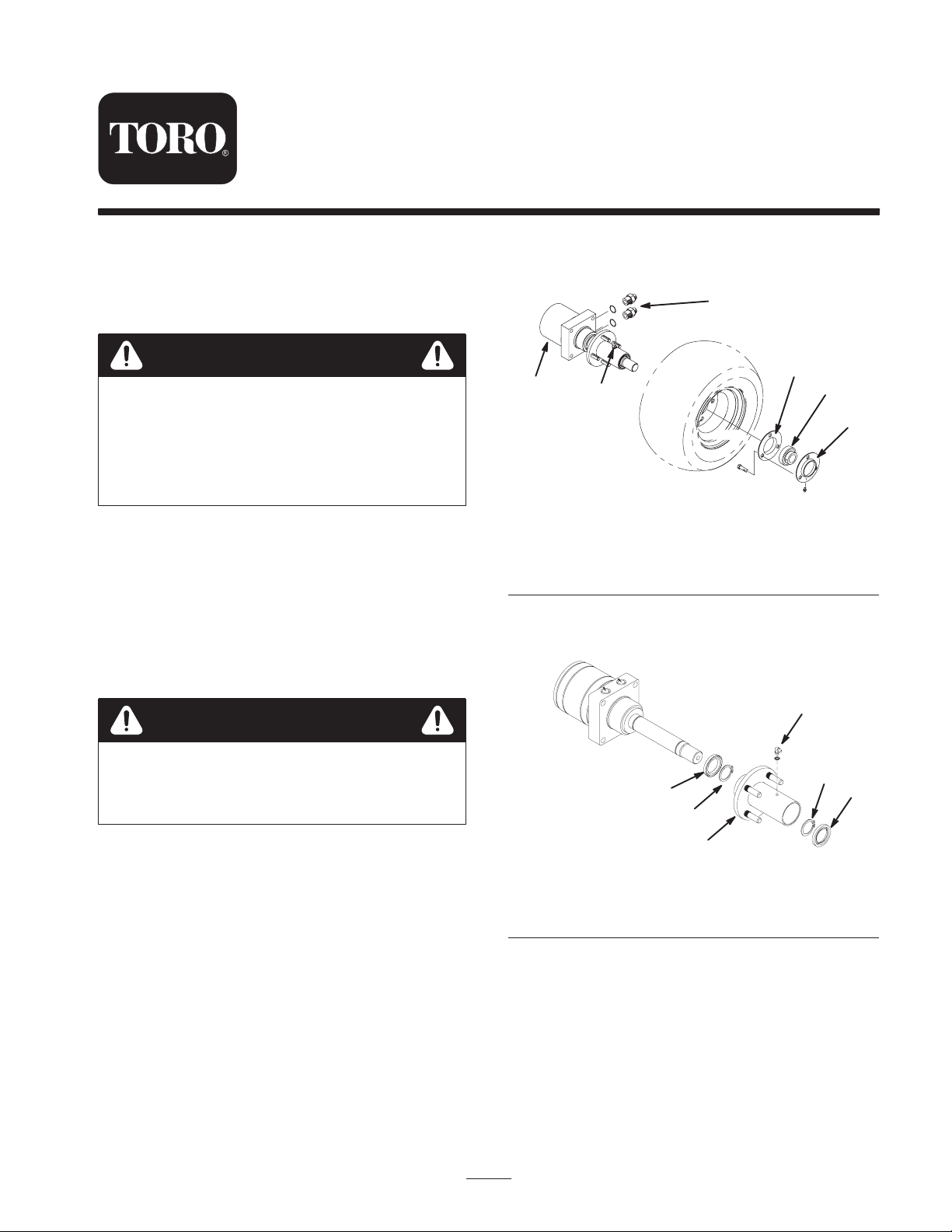

6. Remove the grease fitting from the hydraulic motor and

hub assembly (Fig. 1). Remove four lug nuts and wheel

assembly from the hub drive studs.

6

3

1

1. Motor and hub assembly

2. Grease fitting

3. Standard flangette

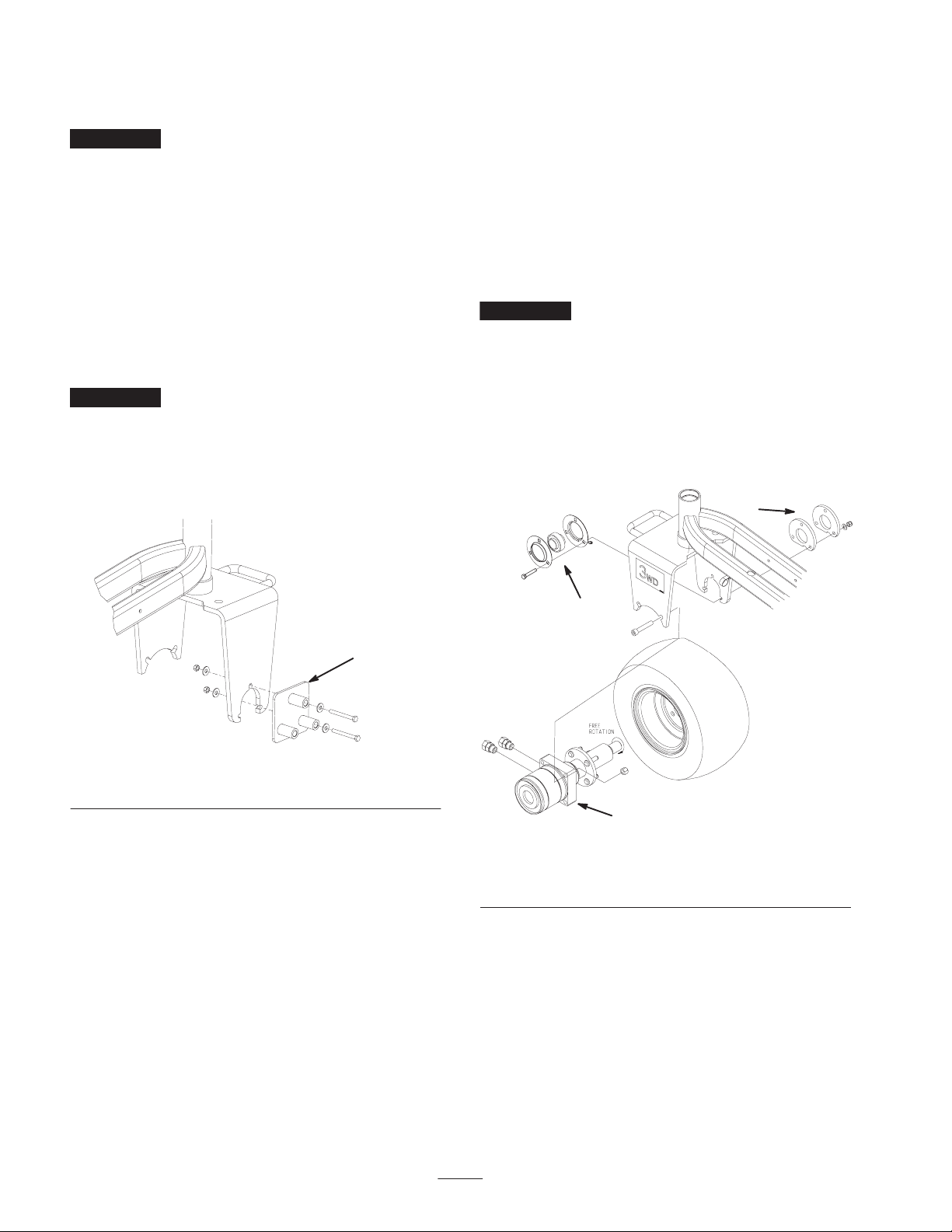

7. Remove the grease seal and snap ring from the long end

of the hub (Fig. 2).

2

Figure 1

4. Bearing

5. Relube flangette

6. Straight fitting (2)

4

5

Caution

Support the wheel and motor and hub assembly

during removal to prevent dropping and causing

personal injury.

4. Remove the wheel and the hydraulic motor and hub

assembly from the castor fork as follows:

A. Remove the capscrews and lock nuts securing the

flangettes and bearing tab to the castor fork (Fig. 1).

B. Remove both socket head screws, flat washers and

lock nuts securing the hydraulic motor and hub

assembly to the castor fork (Fig. 1).

C. Lower the wheel and hydraulic motor and hub

assembly from the castor fork.

5. Loosen both setscrews on bearing. Slide flangettes and

bearing off the motor shaft (Fig. 1).

4

3

2

3

1

Figure 2

1. Hub

2. Grease seal

8. Remove the snap ring and grease seal from the other

end of the shaft and remove the hub from the shaft

(Fig. 2).

9. Grease inner edge of the new grease seals with No. 2

multipurpose lithium base grease. Slide one seal onto

motor shaft past groove closest to the motor. Install

snap ring into groove(Fig. 2).

10. Slide the hub onto the shaft with the short side first.

3. Snap ring

4. Grease fitting

2

W 2006 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

All Rights Reserved

Printed in the USA

1

11. Install remaining snap ring into the shaft groove. Slide

remaining new grease seal onto motor shaft.

Important The hub should spin freely in the forward

direction, but lock on the hydraulic motor shaft when it is

spun in the reverse direction.

12. Press the grease seals into the hub so they are flush with

the ends of the hub.

Modify Castor Fork

1. Mount the drill guide to the left side of the castor fork

with (2) 5/16 x 3 in. bolts, (4) 3/8 x 7/8 washers and

nuts. Position the components as shown in figure 3.

2. Using remaining hole in drill guide, enlarge hole in

castor fork to 9/16 in.

Important It is highly recommended that a new or

recently sharpened 9/16 in. drill bit be used. Proceed slowly

when drilling. Do not use excessive force when drilling as

jamming may occur.

3. Move the fasteners to the other holes in the drill guide

and repeat the process until all (3) holes are enlarged.

5. Position the motor hub, flangettes with bearing and tire

assembly into castor fork. Ensure that ports on motor

face rearward (Fig. 4).

6. Loosely secure motor to the inside of caster fork with

(2) socket-head screws and (2) nuts (Fig. 4).

7. Tighten motor screws to 100 ft–lbs (135 Nm).

8. Loosely assemble flangettes with bearing to inside of

castor fork with (3) new 3/8 x 2 in. screws, (2) spacer

mounts, (3) 13/32 x 13/16 hardened washers and (3)

3/8 in. locknuts.

Important Make sure no radial load is put on the motor

shaft.

Note: The grease fitting must be in the downward position

on the flangette (Fig. 4)

9. Tighten the flangette screws to 40 ft-lbs (55 N⋅m).

Note: Failure to carefully follow the above assembly

sequence may result in premature motor seal and bearing

failure.

3

1

Figure 3

1. Drill guide

Install Motor and Hub

Assembly

1. Mount the tire assembly to the motor and hub assembly

with 4 lug nuts. Torque lug nuts to 70 to 90 ft-lb (95 to

122 N⋅m).

2. Re-install the grease fitting to the hub assembly,

pointing it away from tire.

3. Insert flangettes and bearing onto end of motor shaft as

shown in Figure 4.

4. Mount the (2) straight fittings to the side of the motor

assembly (Fig. 4).

Note: Make sure all O-rings are lubricated and in position

before installing fittings.

2

1

Figure 4

1. Motor and hub assembly

2. Flangettes w/bearing

10. Apply a thread-locking adhesive (such as Loctite®) to

bearing setscrews and torque to 80 to 100 in-lb (9 to 11

N⋅m).

11. Verify overrunning bearing operation: The tire should

roll freely forward, but engage wheel motor when rolled

backward.

12. Lower rear of traction unit to ground.

13. Grease all fittings with No. 2 general purpose

lithium-based grease.

14. Re–connect the hoses to the fittings.

3. Spacer mounts (2)

2

Loading...

Loading...