Page 1

Part No. 11 185SL (Rev. A)

Service Manual

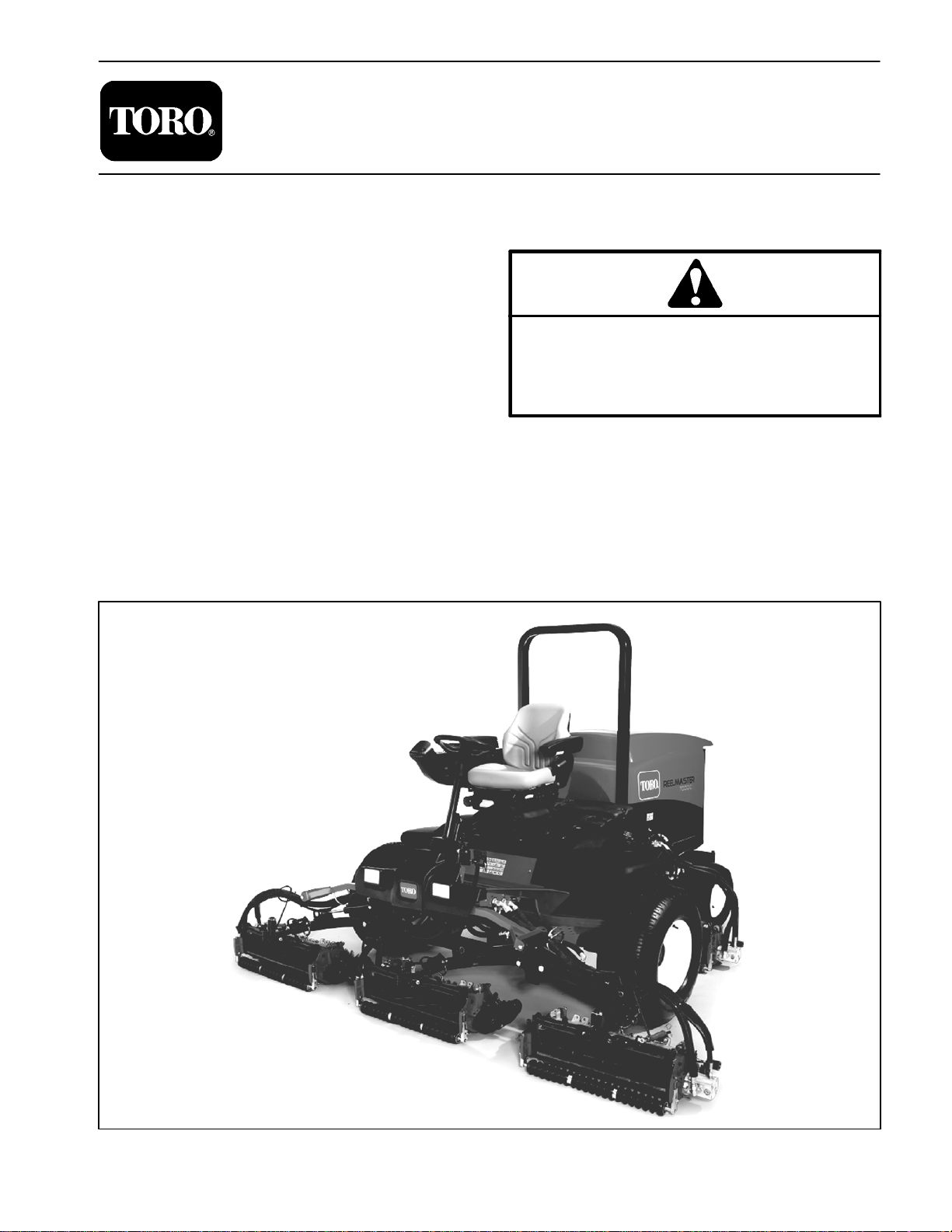

Preface

The purpose of this publication is to provide the service

technician with information for troubleshooting, testing

and repair of major systems and components on the

Reelmaster 7000.

REFER TO THE TRACTION UNIT AND CUTTING

UNIT OPERATOR’S MANUALS FOR OPERATING,

MAINTENANCE AND ADJUSTMENT INSTRUCTIONS. For reference, insert a copy of the Operator’s

ManualsandPartsCatalogfor yourmachineintoChapter 2ofthis service manual. Additional copiesof theOperator’sManuals andPartsCatalog are available onthe

internet at www.Toro.com.

TheToroCompany reserves the rightto changeproduct

specifications or this publication without notice.

Reelmaster

This safety symbol means DANGER, WARNING

or CAUTION, PERSONAL SAFETY INSTRUCTION. When you see this symbol, carefully read

the instructions that follow. Failure to obey the

instructions may result in personal injury.

NOTE: ANOTE will give general information about the

correct operation, maintenance, service, testing or repair of the machine.

IMPORTANT: The IMPORTANT notice will give importantinstructionswhichmustbefollowed to prevent damage to systems or components on the

machine.

7000

R

E The Toro Company -- 2011, 2012

Page 2

This page is intentionally blank.

Reelmaster 7000

Page 3

Table Of Contents

Chapter 1 -- Safety

General Safety Instructions 1 -- 2..................

Jacking Instructions 1 -- 4.........................

Safety and Instruction Decals 1 -- 5................

Chapter 2 -- Product Records and Maintenance

Product Records 2 -- 1...........................

Maintenance 2 -- 1...............................

Equivalents and Conversions 2 -- 2................

Torque Specifications 2 -- 3.......................

Chapter 3 -- Kubota Diesel Engine

Specifications 3 -- 2..............................

General Information 3 -- 3........................

Service and Repairs 3 -- 4........................

KUBOTA WORKSHOP MANUAL, DIESEL ENGINE,

03--M--DI--E3BSERIES

Chapter 4 -- Hydraulic System

Specifications 4 -- 3..............................

General Information 4 -- 4........................

Hydraulic Schematic 4 -- 10.......................

Hydraulic Flow Diagrams 4 -- 12...................

Special Tools 4 -- 26.............................

Troubleshooting 4 -- 30...........................

Testing 4 - - 36...................................

Adjustments 4 -- 68..............................

Service and Repairs 4 -- 69.......................

EATON MODEL 72400 SERVO CONTROLLED PIS-

TON PUMP REPAIR INFORMATION

EATONMODEL 74318 and 74348 PISTONMOTORS:

FIXED DISPLACEMENT, VALVE PLATE DESIGN

REPAIR INFORMATION

SAUER--DANFOSS STEERING UNIT TYPE OSPM

SERVICE MANUAL

Chapter 5 -- Electrical System

General Information 5 -- 2........................

Electrical Drawings 5 -- 3.........................

Special Tools 5 -- 4..............................

Troubleshooting 5 -- 6............................

Electrical System Quick Checks 5 -- 13.............

Adjustments 5 -- 15..............................

Component Testing 5 -- 17........................

Service and Repairs 5 -- 41.......................

Chapter 6 -- Axles, Planetaries and Brakes

Specifications 6 -- 2..............................

General Information 6 -- 3........................

Service and Repairs 6 -- 4........................

Chapter 7 -- Chassis

General Information 7 -- 2........................

Service and Repairs 7 -- 4........................

Chapter 8 -- DPA Cutting Units

Specifications 8 -- 2..............................

General Information 8 -- 3........................

Special Tools 8 -- 4..............................

Factors That Can Affect Cutting Performance 8 -- 8..

Set Up and Adjustments 8 -- 11....................

Service and Repairs 8 -- 14.......................

Chapter 9 -- Foldout Drawings

Hydraulic Schematic 9 -- 3........................

Electrical Schematic 9 -- 4........................

Wire Harness Drawings 9 -- 6.....................

SafetyProduct Records

and Maintenance

Kubota

Diesel Engine

System

Hydraulic

System

Electrical

Axles, Planetaries

and Brakes

Reelmaster 7000

Units

DPACutting Chassis

Foldout

Drawings

Page 4

This page is intentionally blank.

Reelmaster 7000

Page 5

Table of Contents

GENERAL SAFETY INSTRUCTIONS 2............

Before Operating 2............................

While Operating 2.............................

Maintenance and Service 3....................

JACKING INSTRUCTIONS 4.....................

SAFETY AND INSTRUCTION DECALS 5..........

Chapter 1

Safety

Safety

Reelmaster 7000 Page 1 -- 1 Safety

Page 6

General Safety Instructions

TheReelmaster 7000have beentested andcertified by

TORO for compliance with existing safety standards

and specifications. Although hazard control and accidentpreventionpartiallyaredependentupon the design

andconfiguration ofthe machine,these factorsare also

dependent upon the awareness, concern and proper

trainingofthe personnel involvedintheoperation,transport,maintenance and storage ofthe machine. Improperuseormaintenanceofthemachinecanresultininjury

ordeath.To reduce the potential for injury or death,comply with the following safety instructions.

Before Operating

WARNING

To reduce the potential for injury or death,

comply with the following safety instructions.

1. Review and understand the contents of the Operator’s Manuals and Operator’s DVD before starting and

operatingthe vehicle. Becomefamiliar with thecontrols

and know how to stop the vehicle and engine quickly.

AdditionalcopiesoftheOperator’sManualareavailable

on the internet at www.Toro.com.

2. Keep allshields, safety devices and decals in place.

Ifa shield,safetydevice ordecal isdefective, illegibleor

damaged, repair or replace it before operating the machine.Alsotighten any loosenuts,bolts orscrewsto ensure machine is in safe operating condition.

3. Assure interlock switches are adjusted correctly so

engine cannot be started unless traction pedal is in

NEUTRAL and cutting units are DISENGAGED.

While Operating

1. Sit on the seat when starting and operating the machine.

2. Before starting the engine:

A. Engage the parking brake.

4. Since diesel fuel is flammable, handle it carefully:

A. Use an approved fuel container.

B. Donotremovefueltank capwhileengineishotor

running.

C. Do not smoke w hile handling fuel.

D. Fillfuel tankoutdoorsandonly towithinan inch of

the top of the tank, not the filler neck. Do not overfill.

E. Wipe up any spilled fuel.

4. Donottouchengine,exhaustsystemcomponentsor

radiator while engine is running or soon after it is

stopped. These areas could be hot enough to cause

burns.

5. Before getting off the seat:

B. Make sure traction pedal is in neutral and the

PTO switch is OFF (disengaged).

C. Afterengine is started,releaseparkingbrakeand

keepfoot offtractionpedal. Machinemust notmove.

If movement is evident, the traction pedal linkage is

adjusted incorrectly; therefore, shut engine off and

adjust traction pedal linkage until machine does not

move when traction pedal is released.

3. Do not run engine in a c onfined area without adequate ventilation. Exhaust fumes are hazardous and

could possibly be deadly.

A. Ensure that traction pedal is in neutral.

B. Engage parking brake.

C. Disengage PTO and wait for cutting unit reel to

stop rotating.

D. Stop engine and remove key from switch.

E. Toro recommends that anytime the machine is

parked (short or long term), the cutting units should

be lowered to the ground. This relieves pressure

from the lift circuit and eliminates the risk of cutting

units accidentally lowering to the ground.

F. Do notpark on slopesunlesswheelsarechocked

or blocked.

Reelmaster 7000Page 1 -- 2Safety

Page 7

Maintenance and Service

1. TheTractionUnit andCutting Unit Operator’s Manualsprovideinformation regardingtheoperation,general

maintenance and maintenance intervals for your Reelmaster machine. Refer to these publications for additional information when servicing the machine.

2. Before servicing or making adjustments, lower cutting units, stop engine, set parking brake and remove

key from the ignition switch.

3. Make suremachine is in safe operating condition by

keeping all nuts, bolts and screws tight.

4. Never store the machine or fuel container inside

wherethereisanopenflame,suchasnearawaterheater or furnace.

5. Make sure all hydraulic line connectors are tightand

all hydraulic hoses and lines are in good condition before applying pressure to the hydraulic system.

6. Keepbodyandhandsawayfrompinholeleaksinhydrauliclines thatejecthigh pressurehydraulic fluid. Use

cardboard or paper to find hydraulic leaks. Hydraulic

fluid escaping under pressure can penetrate skin and

cause injury. Fluid accidentally injected into the skin

mustbe surgically removedwithin afew hoursby adoctor familiar with this form of injury or gangrene may result.

7. Before disconnecting or performing any work on the

hydraulic system, all pressure in system must be relieved by stopping engine and lowering cutting units to

the ground.

8. If major repairs are everneeded or assistanceis desired, contact an Authorized Toro Distributor.

9. To reduce potential fire hazard, keep engine area

free of excessive grease, grass, leaves and dirt. Clean

protective screen on machine frequently.

10.If enginemustbe runningtoperform maintenanceor

an adjustment, keep hands, feet, clothing and other

partsofthe body awayfromcutting unitsandother moving parts. Keep bystanders away.

11.Do not overspeed the engine by changing governor

setting.To assuresafetyandaccuracy,checkmaximum

engine speed.

12.Shut engine off before checking or adding oil to the

engine crankcase.

13.Disconnect battery before servicing the machine.

Disconnect negative battery cable first and positive

cablelast. If batteryvoltage isrequired fortroubleshooting or test procedures, temporarily connect the battery.

Reconnect positive battery cable first and negative

cable last.

14.Battery acid is poisonous and can cause burns.

Avoidcontact with skin, eyes and clothing. Protectyour

face, eyes and clothing when working with a battery.

15.Battery gases can explode. Keep cigarettes, sparks

and flames away from the battery.

16.When welding on machine, disconnect both battery

cables to prevent damage to machine electronic equipment. Disconnect negative battery cable first and positive cable last. Also, disconnect the wire harness

connectorfrom themachine TECcontroller anddisconnect the terminal connector from the alternator.

17.At the time of manufacture, the machine conformed

tothe safetystandards for riding mowers. Toassureoptimumperformanceand continued safetycertificationof

the machine, use genuine Toro replacement parts and

accessories.Replacementpartsandaccessoriesmade

by other manufacturers may result in non-conformance

with the safety standards and the warranty may be

voided.

18.When changing attachments, tires or performing

other service, use correct blocks, hoists and jacks.

Make sure machine is parked on a solid level surface

suchasaconcretefloor.Priortoraisingthemachine,remove any attachments that may interfere with the safe

and proper raising of the machine. Always chock or

block wheels. Use appropriate jack stands to support

the raised machine. If the machine is not properly supported by jack stands, the machine may move or fall,

whichmayresultinpersonal injury(seeJackingInstructions in this chapter).

Safety

Reelmaster 7000 Page 1 -- 3 Safety

Page 8

Jacking Instructions

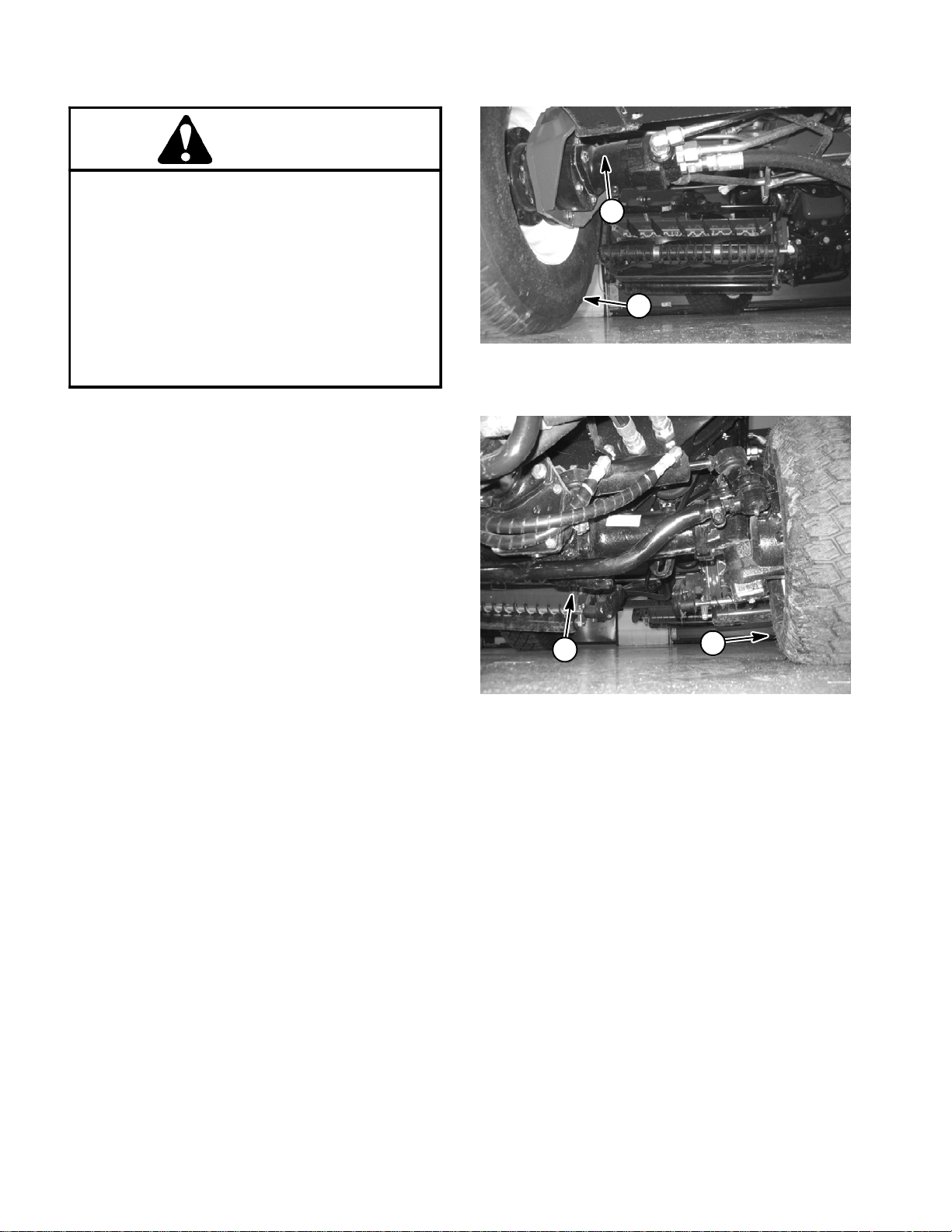

CAUTION

When changing attachments, tires or performing other service, use correct jacks and supports. Make sure machine is parked on a solid,

level surface such as a concrete floor. Prior to

raising machine, remove any attachments that

may interfere with thesafe and properraising of

themachine.Alwayschockorblockwheels.Use

jackstands to support the raisedmachine. Ifthe

machine is not properly supported by jack

stands, the machine may move or fall, which

may result in personal injury.

Jacking the Front End (Fig. 1)

1. Applyparking brakeand chockboth reartires toprevent the machine from moving.

IMPORTANT: Do not place jack, jack stands or

blocks under the wheel motors. Wheel motors can

be damaged if used for jacking or support points.

1

2

Figure 1

1. Frame 2. Front tire (RH shown)

2. Position jack securely underthe frame,just tothe inside of the front tire.

3. Jack front of machine off the ground.

4. Position appropriate jack stands under the frame as

close to the wheels as possible to support themachine.

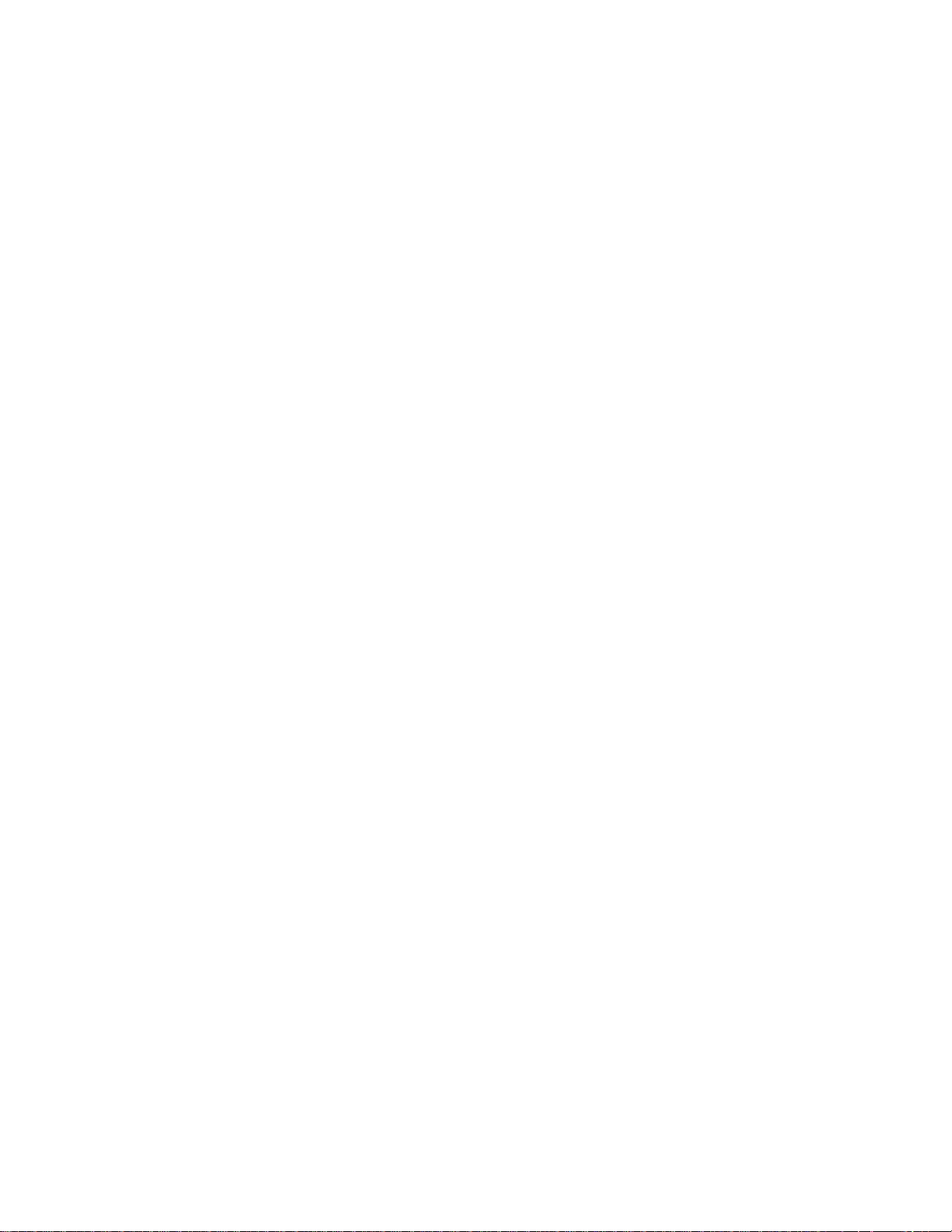

Jacking the Rear End (Fig. 2)

1. Applyparkingbrakeand chock bothfronttirestoprevent the machine from moving.

2. Place jack securely under the center of rear axle.

3. Jack rear of machine off the ground.

4. Position appropriate jack stands under the rear axle

to support the machine.

1

Figure 2

1. Rear axle 2. Rear tire (RH shown)

2

Reelmaster 7000Page 1 -- 4Safety

Page 9

Safety and Instruction Decals

Numerous safety and instruction decals are affixed to

the Reelmaster 7000. If any decal becomes illegible or

damaged, install a new decal. Decal part numbers are

listed in your Parts Catalog.

Safety

Reelmaster 7000 Page 1 -- 5 Safety

Page 10

This page is intentionally blank.

Reelmaster 7000Page 1 -- 6Safety

Page 11

Product Records and Maintenance

Table of Contents

PRODUCT RECORDS 1.........................

MAINTENANCE 1...............................

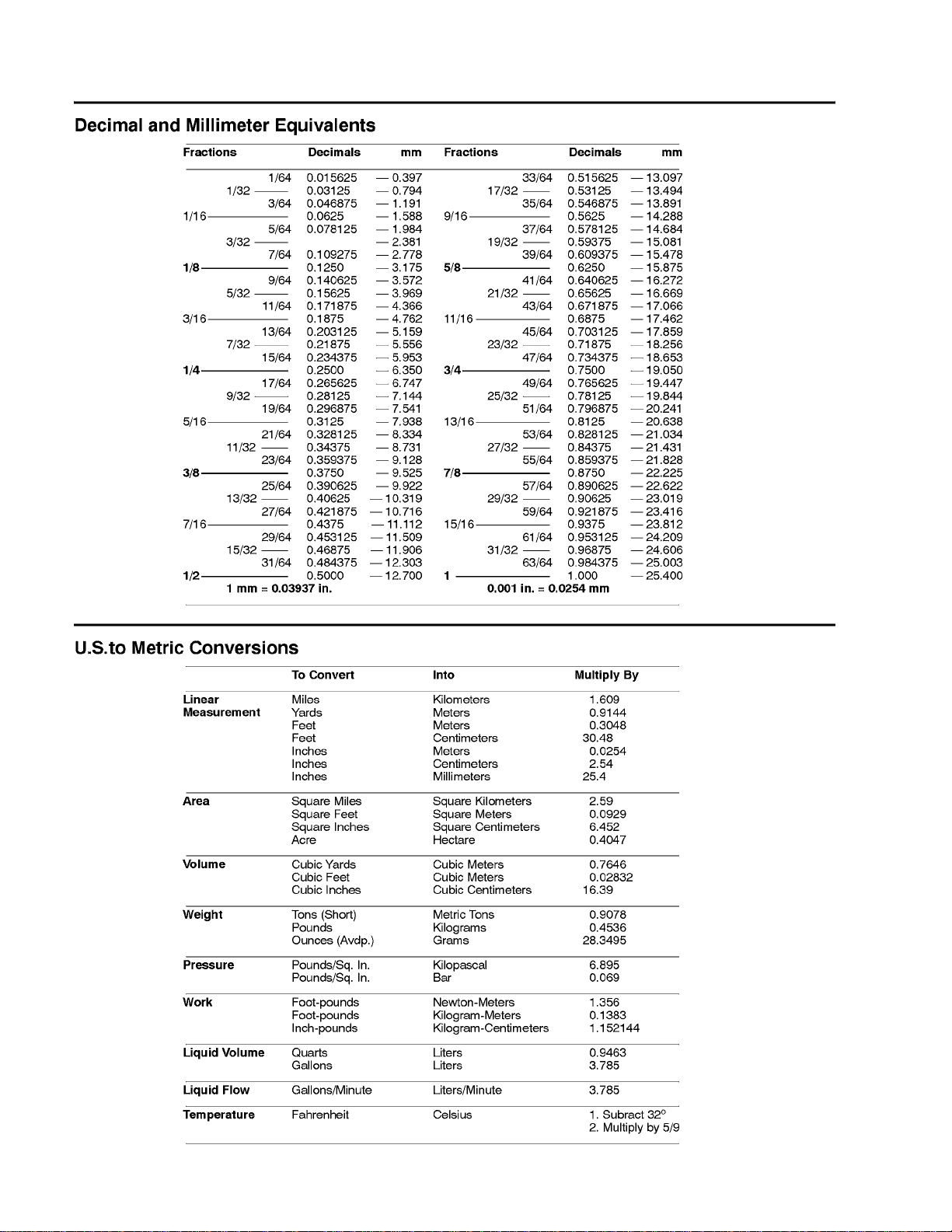

EQUIVALENTS AND CONVERSIONS 2...........

Decimal and Millimeter Equivalents 2............

U.S. to Metric Conversions 2...................

TORQUE SPECIFICATIONS 3....................

Fastener Identification 3.......................

Using a Torque Wrench with an Offset Wrench 3..

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Inch Series) 4...............

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Metric Fasteners) 5...........

Other Torque Specifications 6..................

Conversion Factors 6..........................

Chapter 2

Product Records

and Maintenance

Product Records

Insert Operator’s Manuals and Parts Catalog for your

Reelmasterattheendofthischapter.Additionally,insert

Installation Instructions, Operator’s Manuals and Parts

Catalogs for any accessories that have been installed

on your Reelmaster at the end of this section.

Maintenance

Maintenanceproceduresandrecommended serviceintervals for your Reelmaster are covered in the Traction

Unit and Cutting Unit Operator’s Manuals. Refer to

those publications when performing regular equipment

maintenance. Several maintenance procedures have

break--in intervals identified in the Operator’s Manuals.

RefertotheEngineOperator’sManual foradditionalengine specific maintenance procedures.

Reelmaster 7000

Page 2 -- 1

Product Records and Maintenance

Page 12

Equivalents and Conversions

0.09375

Product Records and Maintenance

Page 2 -- 2

Reelmaster 7000

Page 13

Torque Specifications

Recommended fastener torque values are listed in the

followingtables. Forcritical applications,as determined

byToro,eitherthe recommendedtorqueor atorquethat

is unique to the application is clearly identified and specified in this Service Manual.

These Torque Specifications for the installation and

tightening of fasteners shall apply toall fasteners which

donot have aspecific requirement identified in thisService Manual. The following factors shall be considered

when applying torque: cleanliness of the fastener, use

of a thread sealant (e.g. Loctite), degree of lubrication

on the fastener,presence of a prevailing torque feature

(e.g. Nylock nut), hardness of the surface underneath

thefastener’sheador similar conditionwhichaffectsthe

installation.

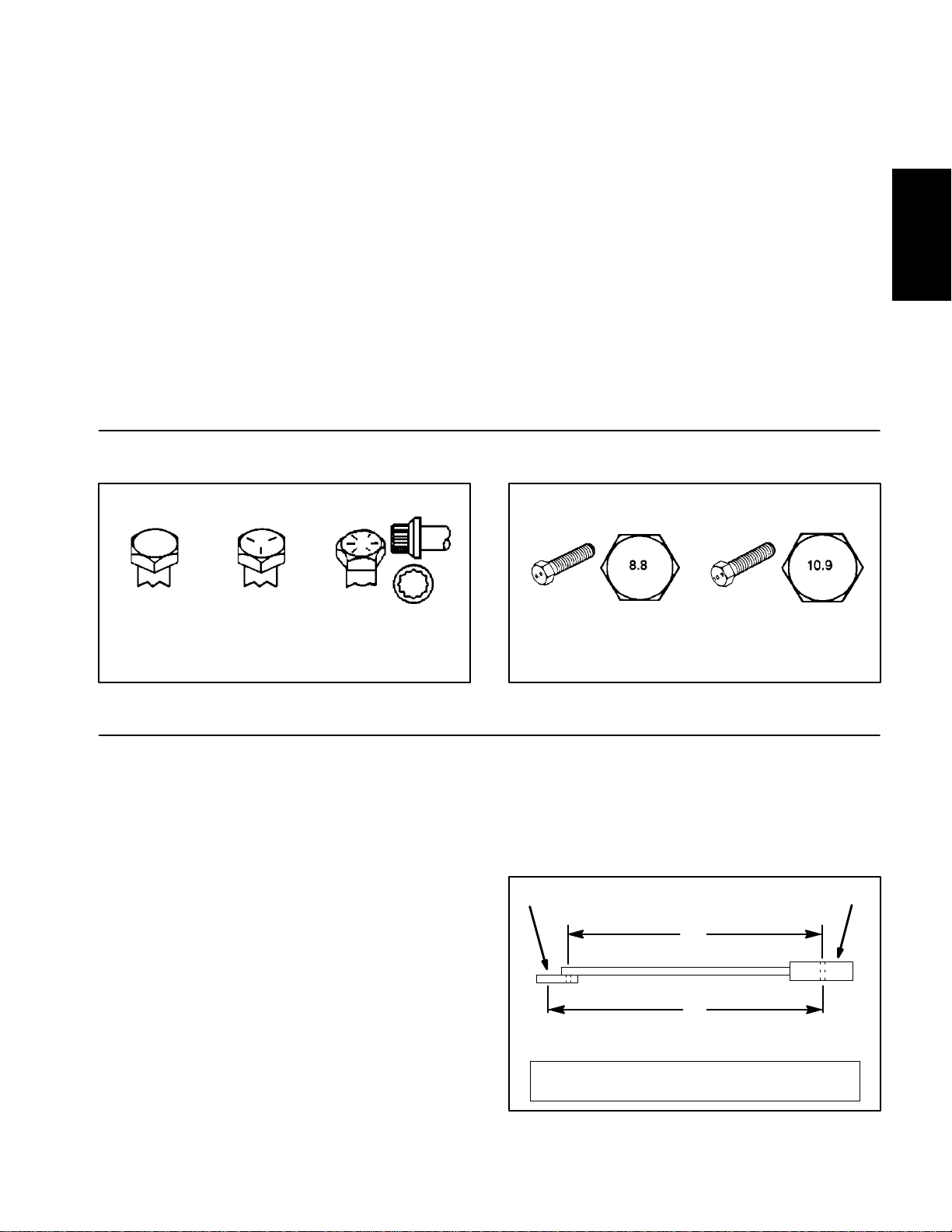

Fastener Identification

Asnotedinthefollowing tables, torquevaluesshouldbe

reduced by 25% for lubricated fasteners to achieve

the similar stress as a dry fastener. Torque values may

also have to be reduced when the fastener is threaded

into aluminum or brass. The specific torque value

should be determined based on the aluminum or brass

material strength, fastener size, length of thread engagement, etc.

The standard method of verifying torque shall be performed by marking a line on the fastener (head or nut)

and mating part, then back off fastener 1/4 of a turn.

Measurethe torque requiredto tightenthe fasteneruntil

the lines match up.

Product Records

and Maintenance

Grade 1 Grade 5 Grade 8

Inch Series Bolts and Screws

Figure 1

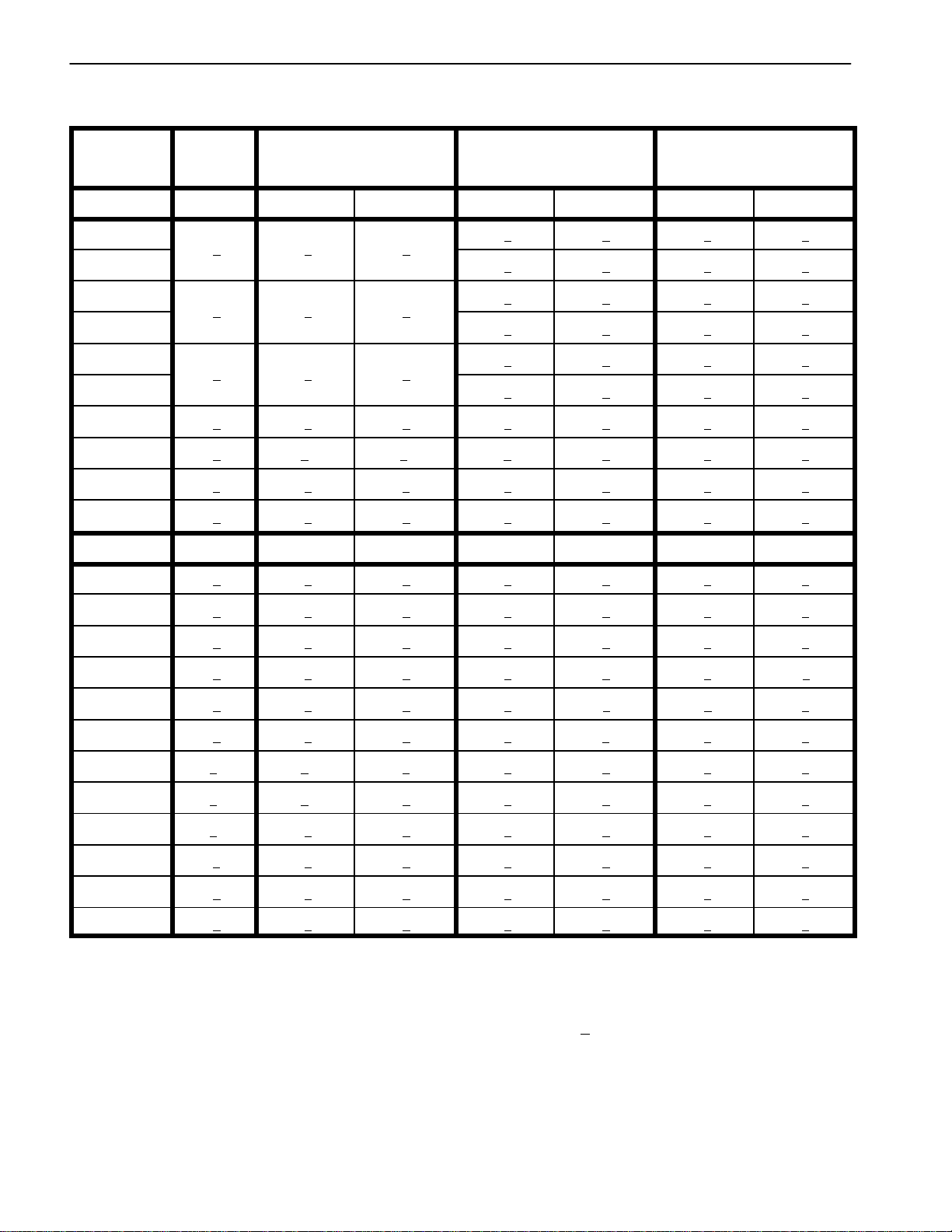

Using a Torque Wrench with an Offset Wrench

Useofanoffsetwrench(e.g.crowfootwrench) will affect

torquewrench calibration dueto theeffective changeof

torquewrench length.Whenusing atorque wrench with

an offset wrench, multiply the listed torque recommendation by the calculated torque conversion factor (Fig.

3) to determine proper tightening torque. Tightening

torque when using a torque wrench with an offset

wrench will be lower than the listed torque recommendation.

Example: The measured effective length of the torque

wrench (distance from the center of the handle to the

center of the square drive) is 18”.

Themeasuredeffectivelengthofthetorquewrenchwith

the offset wrench installed (distance from the center of

the handle to the center of the offset wrench) is 19”.

Class 8.8 Class 10.9

Metric Bolts and Screws

Figure 2

If the listed torque recommendation for a fastener is

from 76 to 94 ft--lb, the proper torque when using this

torque wrench with an offset wrench would be from 72

to 89 ft--lb.

(effective length of

torque wrench)

A

B

(effective length of torque

wrench + offset wrench)

TORQUE CONVERSION FACTOR = A / B

Torque wrenchOffset wrench

The calculated torque conversion factor for this torque

wrenchwith thisoffsetwrench would be18 /19 =0.947.

Reelmaster 7000

Page 2 -- 3

Figure 3

Product Records and Maintenance

Page 14

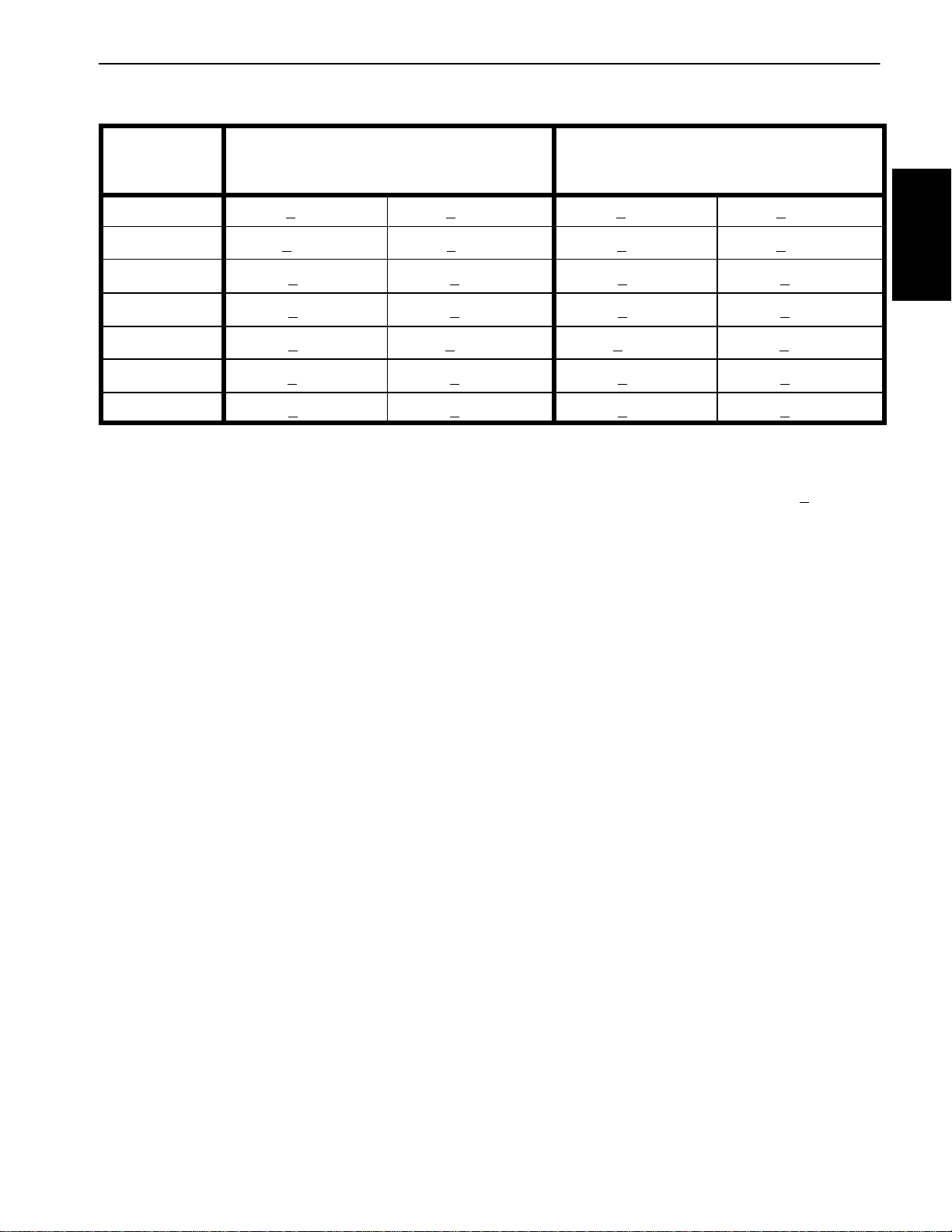

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

Thread Size

# 6 -- 32 UNC

# 6 -- 40 UNF

# 8 -- 32 UNC

# 8 -- 36 UNF

#10--24UNC

#10--32UNF

1/4 -- 20 UNC 48 + 7 53 + 7 599 + 79 100 + 10 1130+ 113 140 + 15 1582+ 169

1/4 -- 28 UNF 53 + 7 65 + 10 734 + 113 115 + 12 1299 + 136 160 + 17 1808+ 192

5/16 -- 18 UNC 115 + 15 105 + 15 1186 + 169 200 + 25 2260 + 282 300 + 30 3390 + 339

5/16 -- 24 UNF 138 + 17 128 + 17 1446 + 192 225 + 25 2542 + 282 325 + 33 3672 + 373

3/8 -- 16 UNC 16 + 2 16 + 2 22+ 3 30 + 3 41 + 4 43 + 5 58 + 7

Grade 1, 5 &

8withThin

Height Nuts

in--lb in--lb N--cm in--lb N--cm in--lb N--cm

10 + 2 13 + 2 147 + 23

13 + 2 25 + 5 282 + 30

18 + 2 30 + 5 339 + 56

ft--lb ft--lb N--m ft--lb N--m ft--lb N--m

SAE Grade 1 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

15 + 2 169 + 23 23 + 3 262 + 34

17 + 2 192 + 23 25 + 3 282 + 34

29 + 3 328 + 34 41 + 5 463 + 56

31 + 4 350 + 45 43 + 5 486 + 56

42 + 5 475 + 56 60 + 6 678 + 68

48 + 5 542 + 56 68 + 7 768 + 79

SAE Grade 8 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 5 or Stronger Nuts)

3/8 -- 24 UNF 17 + 2 18 + 2 24 + 3 35 + 4 47 + 5 50 + 6 68 + 8

7/16 -- 14 UNC 27 + 3 27 + 3 37 + 4 50 + 5 68 + 7 70 + 7 95 + 9

7/16 -- 20 UNF 29 + 3 29 + 3 39 + 4 55 + 6 75 + 8 77 + 8 104 + 11

1/2 -- 13 UNC 30 + 3 48 + 7 65 + 9 75 + 8 102 + 11 105 + 11 142 + 15

1/2 -- 20 UNF 32 + 4 53 + 7 72 + 9 85 + 9 115 + 12 120 + 12 163 + 16

5/8 -- 11 UNC 65 + 10 88 + 12 119 + 16 150 + 15 203 + 20 210 + 21 285+ 28

5/8 -- 18 UNF 75 + 10 95+ 15 129 + 20 170 + 18 230 + 24 240 + 24 325+ 33

3/4 -- 10 UNC 93 + 12 140 + 20 190 + 27 265 + 27 359 + 37 375 + 38 508 + 52

3/4 -- 16 UNF 115 + 15 165 + 25 224 + 34 300 + 30 407 + 41 420 + 43 569 + 58

7/8 -- 9 UNC 140 + 20 225 + 25 305 + 34 430 + 45 583+ 61 600 + 60 813 + 81

7/8 -- 14 UNF 155 + 25 260 + 30 353 + 41 475 + 48 644 + 65 667 + 66 904 + 89

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

NOTE: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the minimumproof load specifiedin SAE J429. The toleranceis

approximately +

10% of the nominal torque value. Thin

height nuts include jam nuts.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Product Records and Maintenance

Page 2 -- 4

Reelmaster 7000

Page 15

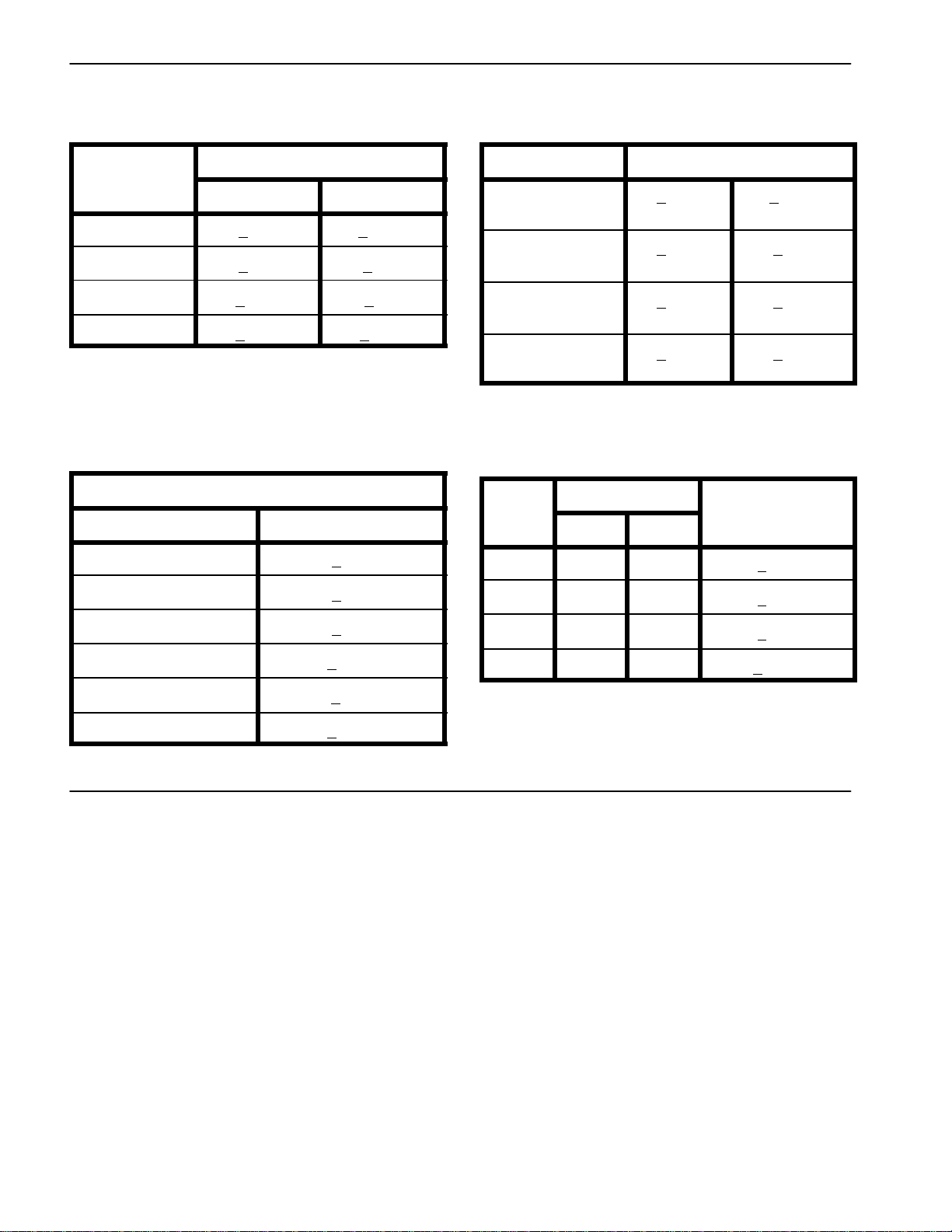

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Series)

Class 8.8 Bolts, Screws and Studs with

Thread Size Regular Height Nuts

(Class 8 or Stronger Nuts)

Class 10.9 Bolts, Screws and Studs with

Regular Height Nuts

(Class 10 or Stronger Nuts)

M5 X 0.8 57 + 6in--lb 644 + 68 N--cm 78 + 8in--lb 881 + 90 N--cm

M6 X 1.0 96 + 10 in--lb 1085 + 113 N- -cm 133 + 14 in--lb 1503 + 158 N--cm

M8 X 1.25 19 + 2ft--lb 26 + 3N--m 28 + 3ft--lb 38 + 4N--m

M10 X 1.5 38 + 4ft--lb 52 + 5N--m 54 + 6ft--lb 73 + 8N--m

M12 X 1.75 66 + 7ft--lb 90 + 10 N--m 93+ 10 ft--lb 126 + 14 N--m

M16 X 2.0 166+ 17 ft--lb 225 + 23 N--m 229 + 23 ft--lb 310 + 31 N--m

M20 X 2.5 325 + 33 ft--lb 440 + 45 N--m 450 + 46 ft--lb 610 + 62 N--m

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

NOTE: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAEJ1199.Thetoleranceisapproximately+

nominal torque value.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

10%ofthe

Product Records

and Maintenance

Reelmaster 7000

Page 2 -- 5

Product Records and Maintenance

Page 16

Other Torque Specifications

*

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 -- 20 UNC 140 + 20 in--lb 73+ 12 in--lb

5/16 -- 18 UNC 215 + 35 in--lb 145 + 20 in--lb

3/8 -- 16 UNC 35 + 10 ft--lb 18 + 3ft--lb

1/2 -- 13 UNC 75 + 15 ft--lb 50 + 10 ft--lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23 or Type F

Thread Size Baseline Torque*

No. 6 -- 32 UNC 20 + 5in--lb

Wheel Bolts and Lug Nuts

Thread Size

7/16 -- 20 UNF

Grade 5

1/2 -- 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non--lubricated fasteners.

Thread Cutting Screws

(Zinc Plated Steel)

Thread

Size

No. 6 18 20 20 + 5in--lb

Threads per Inch

Type A Type B

Recommended Torque**

65 + 10 ft--lb 88 + 14 N--m

80 + 10 ft--lb 108+ 14 N--m

80 + 10 ft--lb 108+ 14 N--m

80 + 10 ft--lb 108+ 14 N--m

Baseline Torque

No. 8 -- 32 UNC 30 + 5in--lb

No. 10 -- 24 UNC 38 + 7in--lb

1/4 -- 20 UNC 85 + 15 in--lb

5/16 -- 18 UNC 110 + 20 in--lb

3/8 -- 16 UNC 200 + 100 in--lb

Conversion Factors

in--lb X 11.2985 = N--cm N--cm X 0.08851 = in--lb

ft--lb X 1.3558 = N--m N--m X 0.7376 = ft--lb

No. 8 15 18 30 + 5in--lb

No. 10 12 16 38 + 7in--lb

No. 12 11 14 85 + 15 in--lb

*Holesize,materialstrength,materialthickness andfinish must be considered when determining specific

torquevalues.Alltorquevalues arebasedonnon--lubricated fasteners.

Product Records and Maintenance

Page 2 -- 6

Reelmaster 7000

Page 17

Table of Contents

SPECIFICATIONS 2.............................

GENERAL INFORMATION 3.....................

Operator’s Manual 3..........................

SERVICE AND REPAIRS 4......................

Air Filter System 4............................

Exhaust System 6............................

Fuel System 8................................

Check Fuel Lines and Connections 9...........

Drain and Clean Fuel Tank 9..................

Fuel Tank Removal 9........................

Fuel Tank Installation 9.......................

Radiator 10..................................

Engine 12....................................

Engine Removal 13..........................

Engine Installation 14........................

Pump Adapter Plate 16........................

KUBOTA WORKSHOP MANUAL, DIESEL ENGINE,

03--M--DI--E3B SERIES

Chapter 3

Kubota Diesel Engine

Kubota

Diesel Engine

Reelmaster 7000 Page 3 -- 1 Kubota Diesel Engine

Page 18

Specifications

Item Description

Make / Designation Kubota Model V2403--M--DI--E3B

Bore 3.425” (87.0 mm)

Stroke 4.031” (102.4 mm)

Total Displacement 148.5 in3(2434 cc)

Firing Order 1 (closest to gear case end) -- 3 -- 4 (closest to flywheel end) -- 2

Combustion Chamber Spherical Type (E--TVCS)

Compression Ratio 23.2:1

Direction of Rotation Counterclockwise (viewed from flywheel)

Fuel Diesel or Biodiesel (up to B20) Fuel with Low or Ultra Low

Fuel Capacity 22 U.S. gallons (83 liters)

Fuel Injection Pump Denso PFR 4M Type Mini Pump

Injection Nozzle Denso OPD Mini Nozzle

4--Cycle, 4 Cylinder, Liquid Cooled, Diesel Engine

Sulfur Content

Governor Centrifugal Mechanical

Low Idle (no load) 1550 + 50 RPM

High Idle (no load) 2850 +50/--120 RPM

Engine Oil API CH--4, CI--4 or higher

Engine Oil Viscosity See Operator’s Manual

Crankcase Oil Capacity 10.0 U.S. Quarts (9.5 Liters) with Filter

Oil Pump Trochoid Type

Coolant Capacity 13 U.S. Quarts (12.3 Liters)

Starter 12 VDC, 2.0 kW

Alternator/Regulator 12 VDC

Alternator Output 60 amp

Engine Dry Weight 406 U.S. pounds (184 kg)

Reelmaster 7000Page 3 -- 2Kubota Diesel Engine

Page 19

General Information

ThisChaptergives informationaboutspecificationsand

repairofthe dieselengineused in theReelmaster7000.

Generalmaintenance procedures aredescribed inyour

TractionUnit Operator’s Manual. Information onengine

troubleshooting, testing, disassembly and assembly is

identified in the Kubota Workshop Manual, Diesel Engine, 03--M--DI--E3B.

Most repairs and adjustments require tools which are

commonly available in many service shops. Special

Operator’s Manual

The Traction Unit and Engine Operator’s Manuals provideinformation regarding the operation,general maintenanceandmaintenanceintervals foryourReelmaster

machine.Refertothesepublicationsfor additionalinformation when servicing the machine.

tools are described in the Kubota Workshop Manual,

Diesel Engine, 03--M--DI--E3B. The use of some specialized test equipment is explained. However,the cost

of the test equipment and the specialized nature of

somerepairsmaydictatethattheworkbedoneatanengine repair facility.

Service and repair parts for Kubota engines are supplied through your Authorized Toro Distributor. If no

partslistisavailable, bepreparedtoprovideyourdistributor with the Toro model and serial number.

Kubota

Diesel Engine

Reelmaster 7000 Page 3 -- 3 Kubota Diesel Engine

Page 20

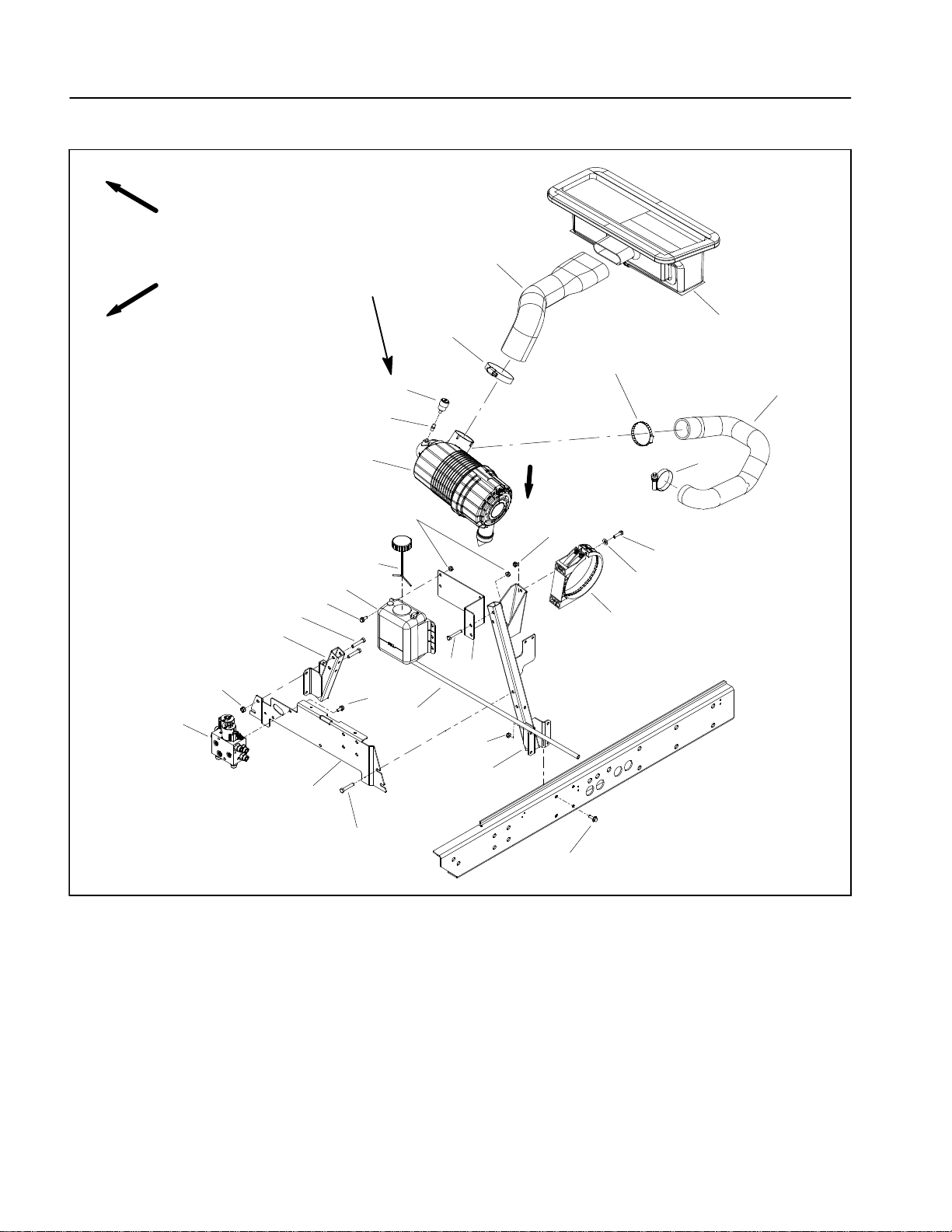

Service and Repairs

Air Filter System

RIGHT

FRONT

8

12 to 15 in--lb

27

(1.4 to 1.6 N--m)

13

26

13

12

24

23

11

14

Vacuator

Direction

18

18

25

16

10

15

20

6

1

19

17

9

7

21

22

4

1. Battery support

2. Bracket

3. Flange head screw (8 used)

4. Flange nut (8 used)

5. Support bracket

6. Cap screw (4 used)

7. Flange nut (4 used)

8. Fan drive manifold

9. Air cleaner strap

5

6

10. Cap screw (2 used)

11. Air cleaner assembly

12. Service indicator

13. Hose clamp

14. Hose clamp

15. Flat washer (2 used)

16. Coolant reservoir

17. Reservoir bracket

18. Flange nut (8 used)

2

3

Figure 1

19. Cap screw (2 used)

20. Flange head screw (4 used)

21. Flange head screw (2 used)

22. Hose

23. Adapter

24. Air cleaner hose

25. Reservoir cap

26. Plenum

27. Air intake hose

Reelmaster 7000Page 3 -- 4Kubota Diesel Engine

Page 21

Removal (Fig. 1)

1. Park machineon a levelsurface, lower cuttingunits,

stop engine, apply parking brake and remove key from

the ignition switch.

2. Raise and support hood.

3. Remove air cleaner components as needed using

Figure 1 as a guide.

Installation (Fig. 1)

IMPORTANT: Any leaks in the air filter system will

causeserious enginedamage. Make sure that allair

cleaner components are in good condition and are

properly secured during assembly.

1. Assemble air filter systemusing Figure 1as aguide.

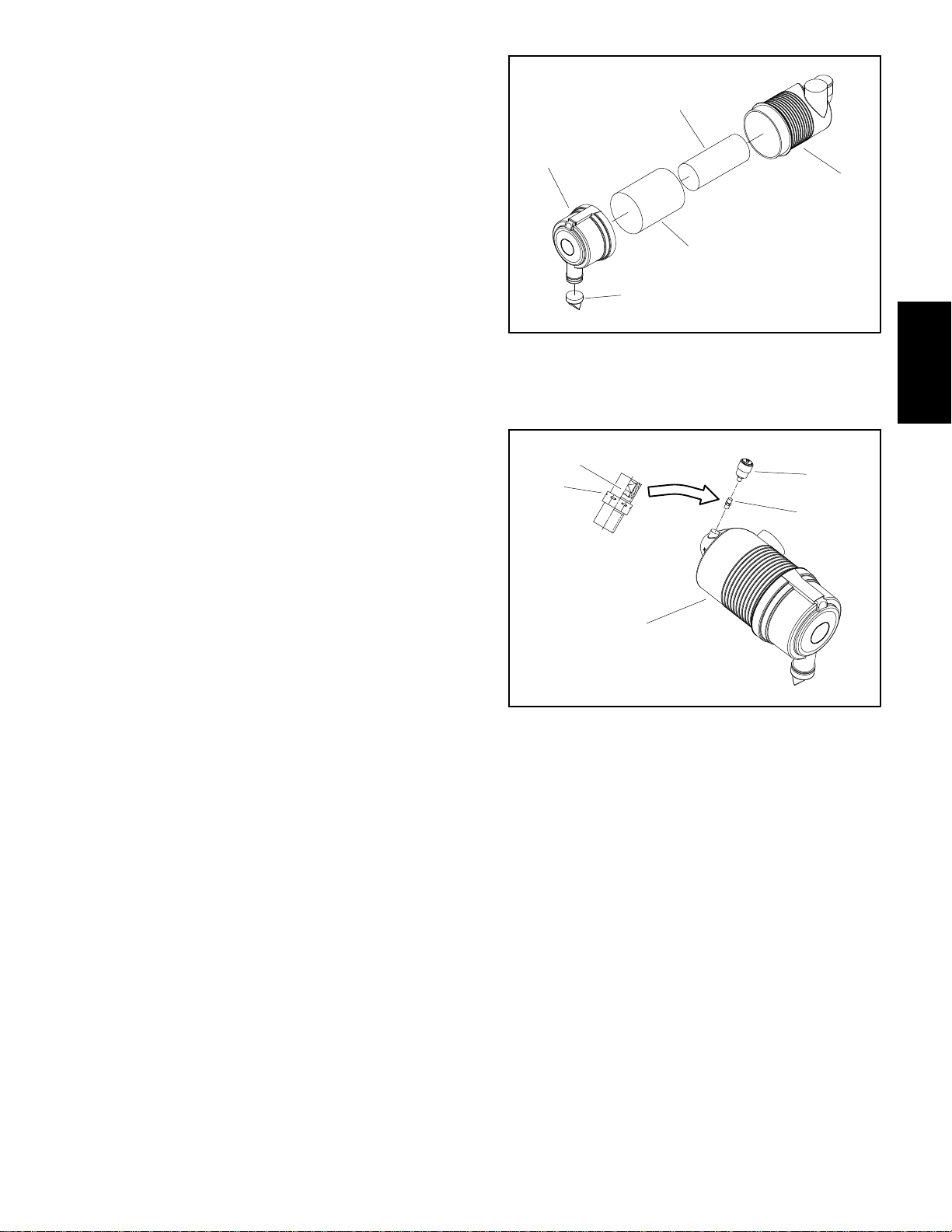

A. If service indicator (item 12) was removed from

air cleaner housing, apply thread sealant to adapter

threads before installing adapter and indicator to

housing. Install adapter so that grooves in adapter

hex and adapter filter element are installed toward

serviceindicator (Fig.3).Torqueindicator from12 to

15 in--lb (1.4 to 1.6 N--m).

4

5

1. Air cleaner housing

2. Safety filter element

3. Air filter element

5

4

2

3

Figure 2

4. Air cleaner cover

5. Vacuator valve

1

Kubota

Diesel Engine

2

3

B. Orientate vacuator valve on air cleaner cover toward ground.

C. Installaircleanersoaircleanerstrap(item9)isas

close as possible to air cleaner cover.

D. Make sure that air cleaner hose (item 24) does

notcontact engine valve coveror other engine components.Tomodify clearance, moveand/or rotateair

cleaner body in air cleaner strap. Verify that tabs in

strap mesh fully with slots in air cleaner body.

2. After air cleaner installation is completed, lower and

secure hood.

1

1. Air cleaner assembly

2. Service indicator

3. Adapter

Figure 3

4. Groove

5. Filter element

Reelmaster 7000 Page 3 -- 5 Kubota Diesel Engine

Page 22

Exhaust System

8

13

12

1

5

3

10

14

7

4

11

6

2

9

RIGHT

FRONT

1. Muffler

2. Flange head screw (2 used)

3. Flange head screw (4 used)

4. Muffler clamp

5. Tailpipe

Figure 4

6. RH engine mount

7. Flat washer

8. Cap screw

9. Muffler bracket

10. Muffler gasket

11. Engine

12. Muffler bracket

13. Flange nut (2 used)

14. Muffler clamp

Reelmaster 7000Page 3 -- 6Kubota Diesel Engine

Page 23

Removal (Fig. 4)

CAUTION

The muffler and exhaust pipe may be hot. To

avoid possible burns, allow the engine and exhaust system to cool before working on themuffler.

Installation (Fig. 4)

IMPORTANT: If exhaust studs were removed from

engine cylinder head, thoroughly clean threads in

head and apply Loctite #277 (or equivalent) to stud

threads before installing studs into head.

NOTE: Makesure mufflerflange and exhaustmanifold

sealing surfaces are free of debris or damage that may

prevent a tight seal.

1. Park machineon a levelsurface, lower cuttingunits,

stop engine, engage parking brake and remove key

from the ignition switch.

2. Raise and support hood.

3. Remove muffler and/or muffler bracket from the en-

gine as necessary using Figure 4 as a guide.

1. Install new exhaust gasket if original gasket is damaged or torn.

IMPORTANT: Failure to follow the suggested mufflerfastenersequence may resultin premature muffler failure.

2. Installexhaustsystemcomponents to theengineusingFigure4 asa guide. Handtighten allexhaustsystem

fasteners before fully tightening any fastener.

3. Tailpipeshouldhaveequalclearancebetweenframe

and engine after installation.

4. Afterexhaustsystem installation iscompleted,lower

and secure hood.

Kubota

Diesel Engine

Reelmaster 7000 Page 3 -- 7 Kubota Diesel Engine

Page 24

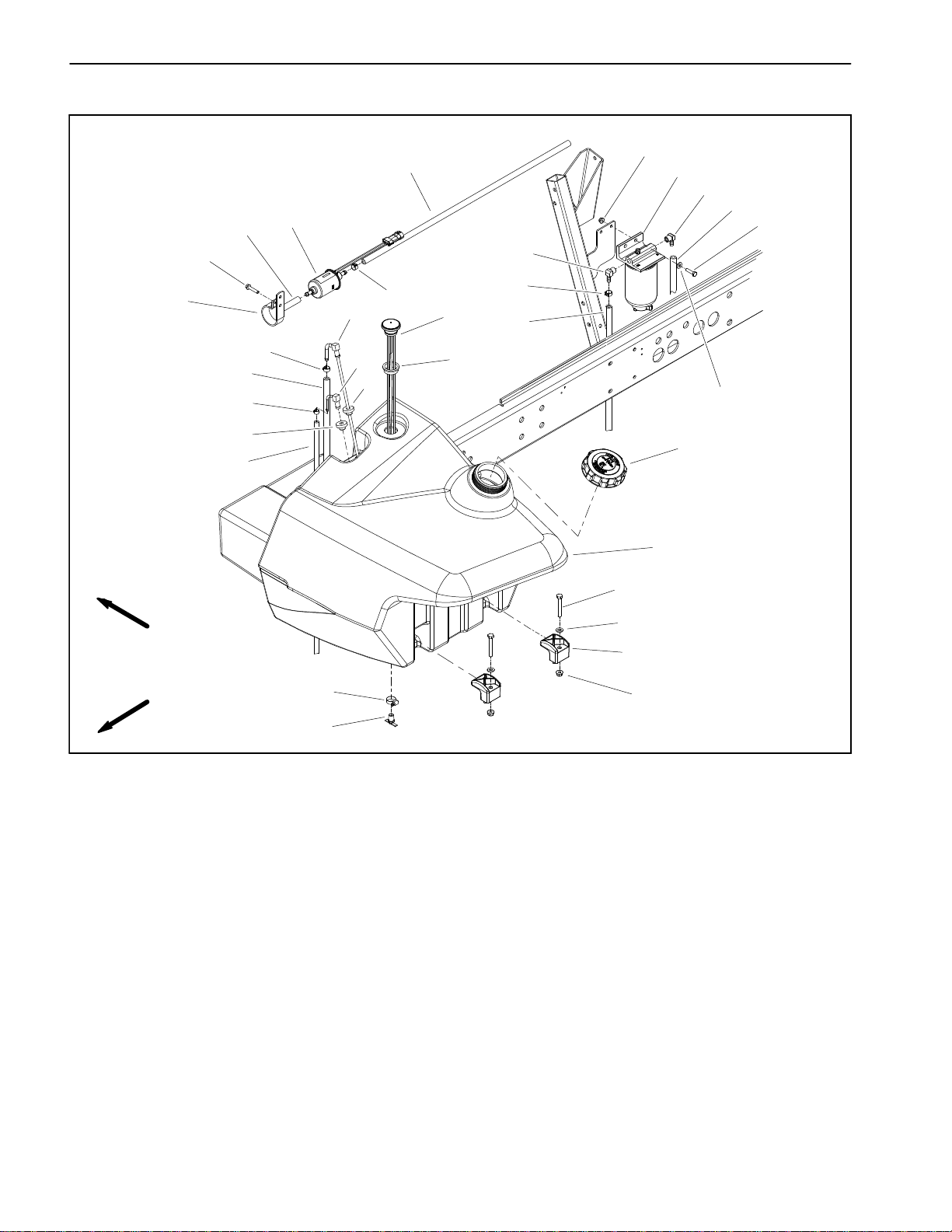

Fuel System

14

19

16

20

21

16

13

3

18

21

15

RIGHT

FRONT

8

8

1

8

3

4

7

2

7

24

17

25

23

6

5

9

10

22

11

26

12

27

1. Fuel suction tube

2. Fuel line clamp (2 used)

3. Fuel hose (supply)

4. Return fitting

5. Fuel hose (return)

6. Fuel tank cap

7. Bushing (2 used)

8. Hose clamp (6 used)

9. Fuel tank

Figure 5

10. Cap screw (2 used)

11. Clamp (2 used)

12. Flange nut (2 used)

13. Fuel pump

14. Washer head screw

15. Fuel pump bracket

16. Fuel hose (supply)

17. Fuel hose (supply)

18. Cap screw (2 used)

19. Flange nut (2 used)

20. Fuel/water separator

21. Elbow fitting (2 used)

22. Flat washer (2 used)

23. Flat washer (2 used)

24. Fuel gauge

25. Grommet

26. Hose clamp

27. Draincock

Reelmaster 7000Page 3 -- 8Kubota Diesel Engine

Page 25

Fuel Tank Removal (Fig. 5)

DANGER

Because diesel fuel is flammable, use caution

when storing or handling it. Do not smoke while

filling the fuel tank. Do not fill fuel tank while engine is running, hot or when machine is in an enclosed area. Always fill fuel tank outside and

wipeupany spilled dieselfuelbefore startingthe

engine. Store fuel in a clean, safety--approved

container and keep cap in place. Use diesel fuel

for the engine only; not for any other purpose.

Check Fuel Lines and Connections

Check fuel lines and connections as recommended in

theTractionUnitOperator’sManual.Check linesfordeterioration, damage, leaking or loose connections. R eplace hoses, clamps and connections as necessary.

Drain and Clean Fuel Tank

Drain and clean the fuel tank periodically as recommended in the Traction Unit Operator’s Manual. Also,

drainand clean thefuel tankif the fuelsystem becomes

contaminatedor if themachine is tobe stored for an extended period. To clean fuel tank, flush tank out with

cleandieselfuel.Make suretankisfree ofcontaminates

and debris.

1. Park machineon a levelsurface, lower cuttingunits,

stop engine, engage parking brake and remove key

from the ignition switch.

2. Disconnectfuelhosesfromthe suctionandreturnfittings in top of tank.

3. Use draincock on bottom of tank to empty fuel tank

into a suitable container.

4. Remove fuel tank from machine using Figure 5 as a

guide.

Fuel Tank Installation (Fig. 5)

1. Install fuel tank to frame using Figure 5 as a guide.

2. Connect fuel hoses to the suction and return fittings

in top of tank.

3. Makesurethatdraincockonbottomoftankisclosed.

4. Fill fuel tank with clean fuel.

Kubota

Diesel Engine

Reelmaster 7000 Page 3 -- 9 Kubota Diesel Engine

Page 26

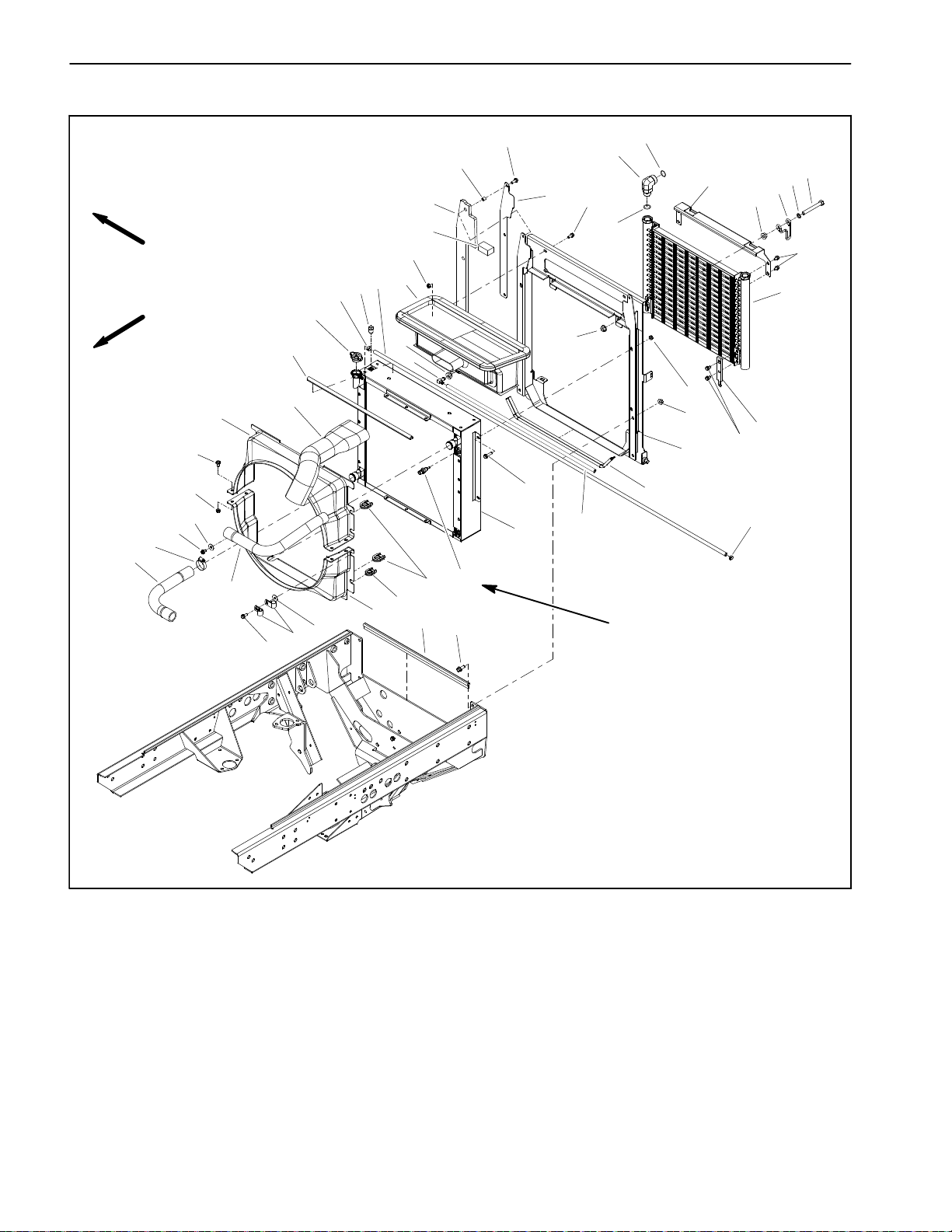

Radiator

RIGHT

FRONT

13

40

18

15

18

17

12

14

28

10

42

39

26

46

25

24

28

23

15

7

29

35

1

31

33

32

30

3

43

2

11

5

37

38

6

3

15

22

27

43

10

36

17

41

20

34

19

21

16

4

44

8

9

45

9to11ft--lb

(12.3 to 14.9 N--m)

1. 90ohydraulic fitting (2 used)

2. Oil cooler

3. Flange nut (4 used)

4. Radiator mount

5. Bulb seal

6. Air cleaner hose

7. Plenum

8. Radiator

9. Hose

10. Hose clamp (3 used)

11. Radiator cap

12. Upper radiator shroud

13. Clamp (4 used)

14. Upper radiator hose

15. Flange nut (12 used)

16. Temperature sender

Figure 6

17. Flat washer (8 used)

18. Flange head screw (11 used)

19. Rubber grommet (2 used)

20. Rubber grommet

21. Flange head screw (4 used)

22. Flange nut (4 used)

23. Foam seal (2 used)

24. Recirculation barrier (2 used)

25. Recirculation barrier bracket (2 used)

26. Screw (2 used)

27. Oil cooler mount plate (2 used)

28. Flange head screw (9 used)

29. O--ring

30. Clamp (2 used)

31. Cap screw (2 used)

32. Washer (2 used)

33. Oil cooler top bracket

34. Bulb seal

35. O--ring

36. R--clamp (2 used)

37. Bushing

38. Elbow fitting

39. Reservoir hose

40. Lower radiator hose

41. Lower radiator shroud

42. Pipe plug

43. Flange head screw (8 used)

44. Flange head screw (4 used)

45. Bulb seal

46. Spacer

Reelmaster 7000Page 3 -- 10Kubota Diesel Engine

Page 27

Removal (Fig. 6)

1. Park machineon a levelsurface, lower cuttingunits,

stop engine, engage parking brake and remove key

from the ignition switch.

2. Removehoodfromthemachine(seeHoodRemoval

inthe Serviceand Repairs section of Chapter7 -- Chassis).

CAUTION

Do not open radiator cap or drain coolant if the

radiator or engine is hot. Pressurized, hot coolant can escape and cause burns.

Ethylene--glycol antifreeze is poisonous. Dispose of coolant properly or store it in a properly

labeled container away from children and pets.

3. Remove radiator cap. Drain radiator into a suitable

container using the radiator draincock.

4. Disconnectupper andlowerhoses fromtheradiator.

5. Remove air cleaner hose (item 6).

2. Carefully position radiator and recirculation barriers

(items24 and 25) to theradiator mount.Secure radiator

and barriers in place with four (4) flange head screws

and flange nuts.

3. Positionlower radiator shroudandfan motor bracket

assembly to the radiator. Make sure that hydraulic

hoses are correctly positioned in grommets in lower radiator shroud.

4. Secure fan motor bracket to radiator withsix (6) cap

screws and flange nuts (Fig. 7).

5. Secure lower radiator shroud to radiator with removed fasteners.

6. Position upper radiator shroud to lower radiator

shroud and radiator.Secure shrouds with removed fasteners.Make sure that clearance between shrouds and

fan is at least 0.180” (4.6 mm) at all points.

7. Connectreservoir hose(item 39)to theradiator vent

tube.

8. Connect upper and lower hoses to the radiator.

9. Install plenum (item 7) to radiator mount and secure

with flange head screws and flange nuts.

Kubota

Diesel Engine

6. Removefour (4)flange headscrewsand flangenuts

that secure plenum (item 7) to radiator mount. Remove

10.Install aircleaner hose(item 6)to theair cleaner and

plenum.

plenum.

11.Fill radiator with coolant.

7. Disconnectreservoirhose(item39)from theradiator

vent tube.

12.Install hoodon the machine(see HoodInstallation in

the Service and Repairs section of Chapter 7 -- C has-

8. Detach upper radiator shroud from the radiator and

sis).

lower radiator shroud. Remove upper shroud from machine.

9. Removefasteners thatsecure lowerradiator shroud

6

to radiator.

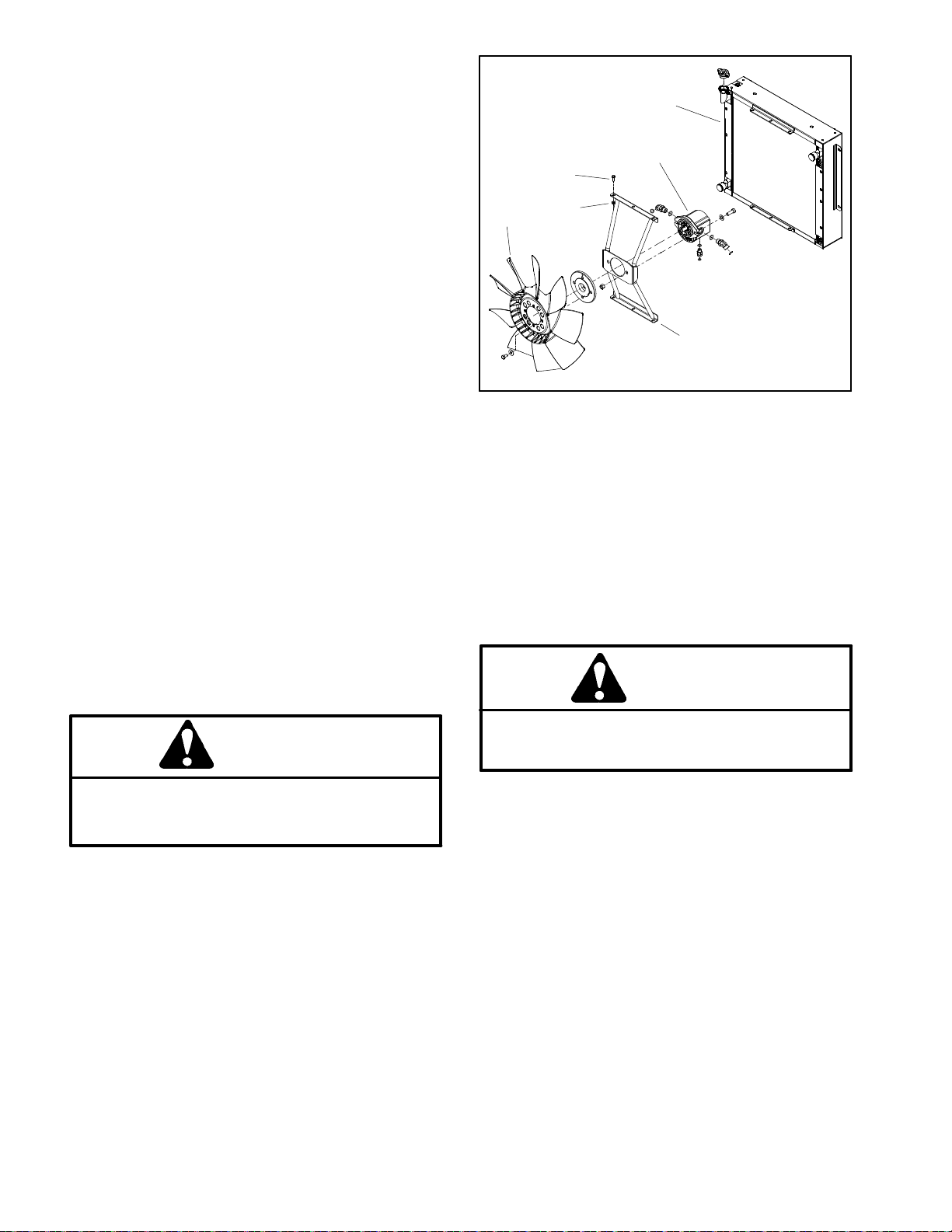

10.Remove six (6) cap screws and flange nuts that se-

cure fan motor bracket to radiator (Fig. 7).

11.Position lowerradiatorshroud and fanmotorbracket

4

1

5

3

assembly away from radiator.

12.Remove four(4) flangeheadscrews andflange nuts

securingtheradiatorandrecirculationbarriers(items24

and25) totheradiator mount.Carefully removebarriers

and radiator from the machine.

2

13.Plug all radiator and hose openings to prevent con-

tamination.

Installation (Fig. 6)

1. Removeplugs placed in radiator andhose openings

1. Fan

2. Fan motor bracket

3. Fan motor

Figure 7

4. Cap screw (6 used)

5. Flange nut (6 used)

6. Radiator

during the removal procedure. Make sure that radiator

draincock is closed.

Reelmaster 7000 Page 3 -- 11 Kubota Diesel Engine

Page 28

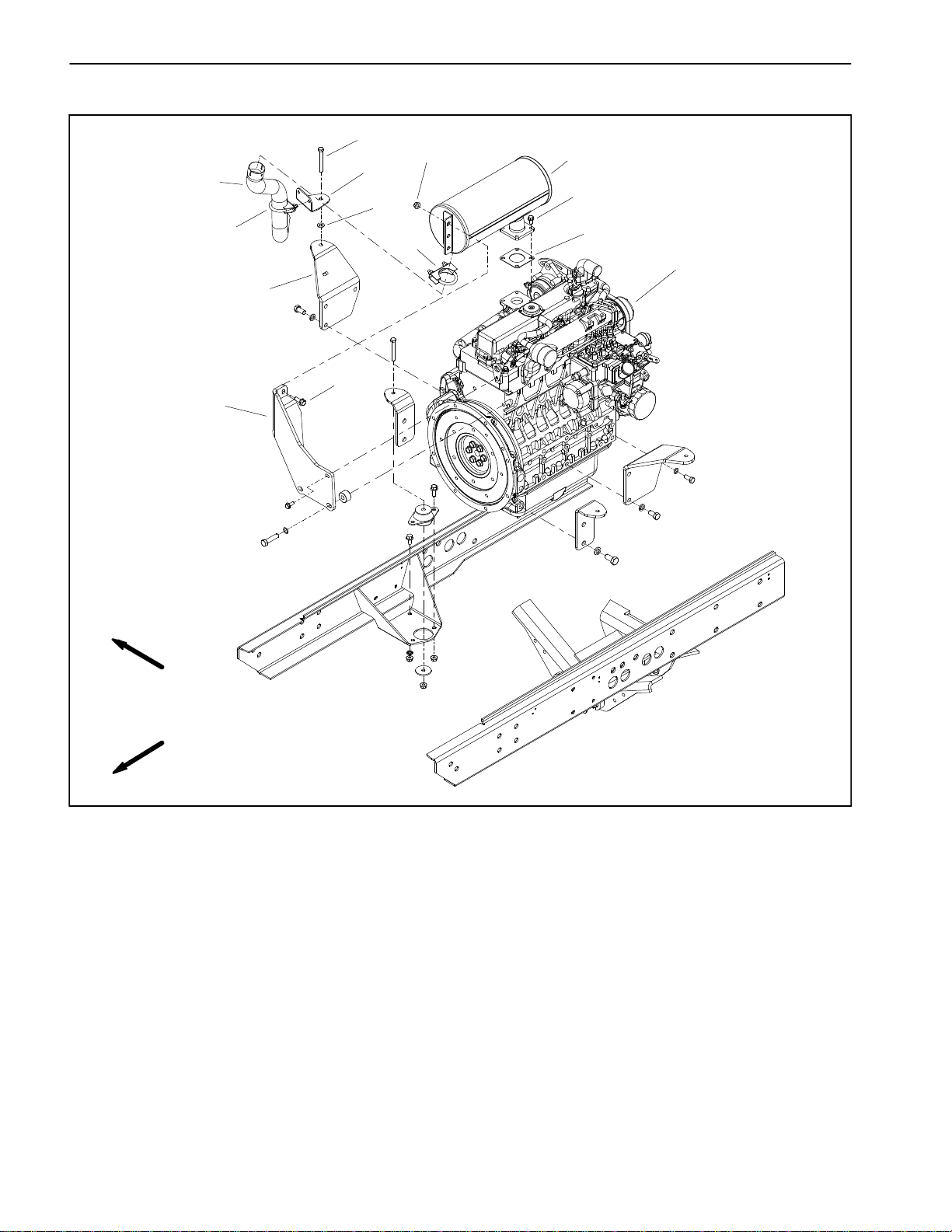

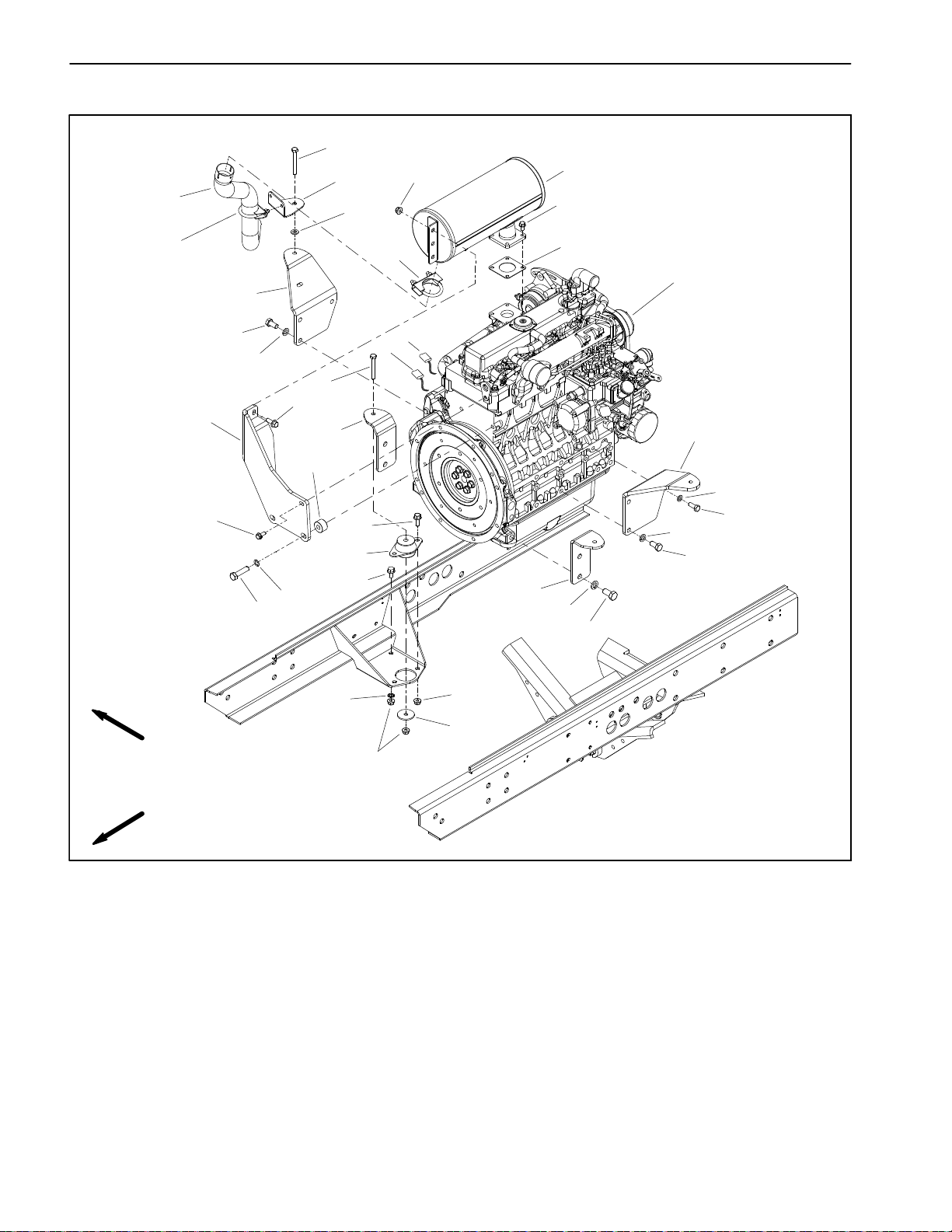

Engine

29

31

5

30

12

1

3

33

20

4

22

9

6

18

21

28

17

7

10

8

19

25

24

2

10

17

11

26

32

34

14

15

23

18

16

27

12

RIGHT

FRONT

1. Muffler

2. Flange head screw

3. Flange head screw (4 used)

4. Muffler clamp

5. Tailpipe

6. RH rear engine mount

7. Cap screw (3 used)

8. RH front engine mount

9. Engine

10. Flange head screw (10 used)

11. Engine mount (4 used)

12. Flange nut (15 used)

13

12

Figure 8

13. Rebound washer (4 used)

14. LH front engine mount

15. Lock washer (4 used)

16. Cap screw (4 used)

17. Lock washer (5 used)

18. Cap screw (5 used)

19. LH rear engine mount

20. Muffler bracket

21. Ground wire harness

22. Muffler gasket

23. Cap screw

24. Lock washer

25. Spacer (2 used)

26. Hardened washer (2 used)

27. Lock washer

28. Alternator wire harness

29. Cap screw

30. Flat washer

31. Muffler bracket

32. Flange head screw

33. Muffler clamp

34. Cap screw (2 used)

Reelmaster 7000Page 3 -- 12Kubota Diesel Engine

Page 29

Engine Removal (Fig. 8)

1. Park machineon a levelsurface, lower cuttingunits,

stop engine, engage parking brake and remove key

from the ignition switch.

2. Removehoodfromthemachine(seeHoodRemoval

inthe Serviceand Repairs section of Chapter7 -- Chassis).

3. Remove battery cover. Disconnect negative battery

cable first and then positive battery cable.

CAUTION

Do not open radiator cap or drain coolant if the

radiator or engine is hot. Pressurized, hot coolant can escape and cause burns.

Ethylene--glycol antifreeze is poisonous. Dispose of coolant properly, or store it in a properly

labeled container away from children and pets.

4. Drain coolant from radiator into a suitable container

(seeRadiatorRemovalinthissection).Disconnectcoolant hoses from the radiator.

5

2

3

1. Engine run solenoid

2. Throttle cable

3. Cable clamp

1

4

Figure 9

4. Cable swivel

5. Fuel supply hose

1

Kubota

Diesel Engine

3

CAUTION

The exhaust system may be hot. To avoid possibleburns, allow the exhaust system to coolbefore working on or near the muffler.

5. Remove exhaust system from engine (see Exhaust

System Removal in this section).

6. Remove air cleaner system from engine (see Air

Cleaner Removal in this section).

7. Note location of cable ties used to secure wire har-

ness. Disconnect wire harness connectors from the following engine components:

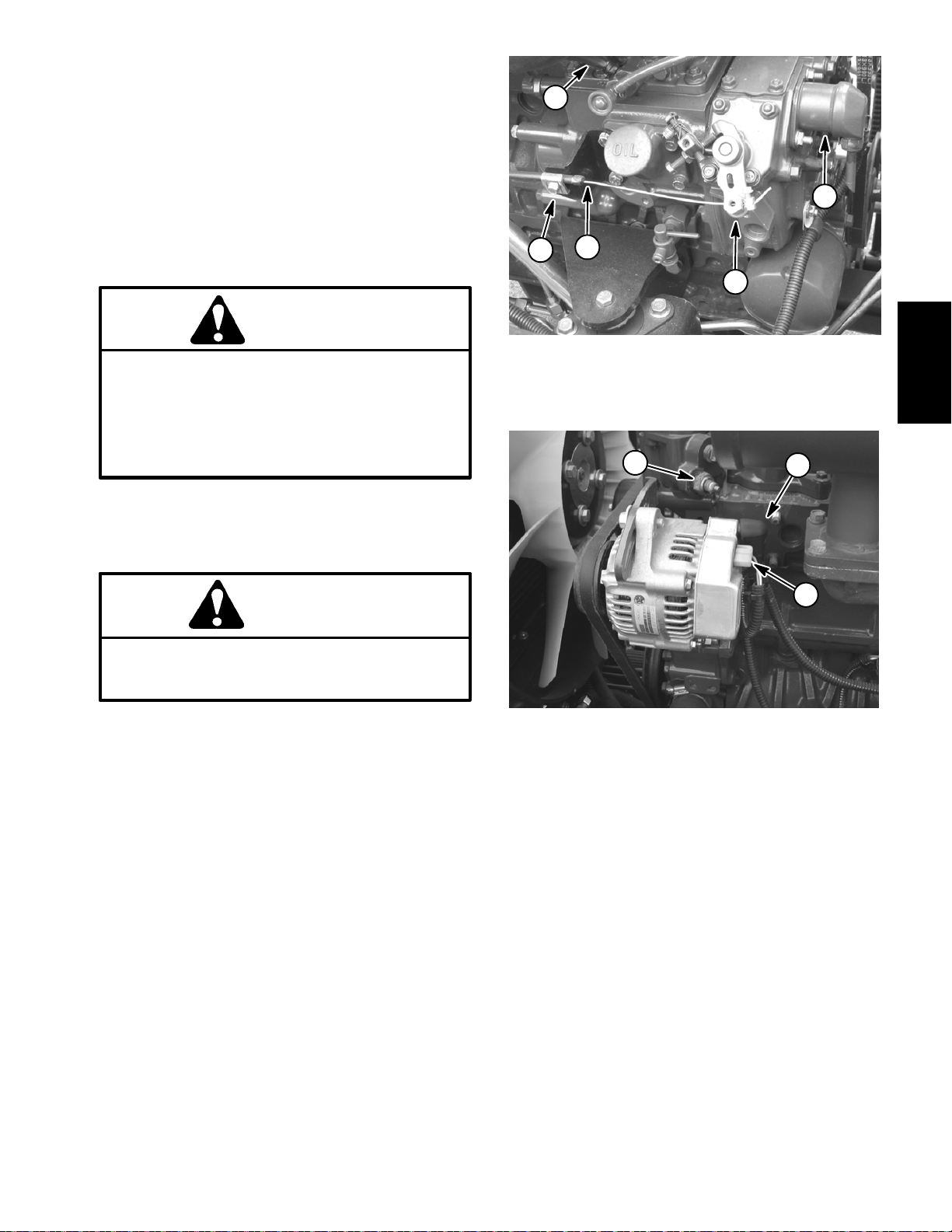

A. The engine run solenoid (Fig. 9).

B. The temperature sender (Fig. 10).

C. The alternator (Fig. 10).

D. The glow plug connection.

E. Wireharness connectorfrom engineground har-

ness.

F. The electric starter motor.

2

Figure 10

1. Temperature sender

2. Harness connector

3. Battery cable

8. Disconnect fuel supply hose from injection pump

(Fig.9).Capfuelhoseandinjectorpumpfuelinlettoprevent contamination.

9. Remove throttle cable from engine (Fig. 9):

A. Removelocknut thatsecuresthrottle cableswiv-

el to speed control lever.

B. Loosen cable clamp and remove throttle cable

from under clamp.

C. Position throttle cable away from the engine.

10.Remove fasteners that secure the upper radiator

shroud to the lower shroud and radiator (see Radiator

Removalinthissection).Removeupperradiator shroud

from machine.

G. Low oilpressureswitchlocatedonalternator side

of engine (above electric starter).

Reelmaster 7000 Page 3 -- 13 Kubota Diesel Engine

Page 30

11.Remove fan motor and fan assembly (Fig. 11).

A. To prevent contamination of hydraulic system,

thoroughly clean exterior of fan motor and fittings.

B. Disconnecthydraulic hosesfrom coolingfan mo-

tor.Putcaps orplugsonfittings andhosestoprevent

contamination. Label hydraulic lines for proper assembly.

C. Remove six (6) cap screws and flange nuts that

secure fan motor bracket to radiator.

D. Carefullyremove fanmotor,fan andmotorbracket assembly from machine.

IMPORTANT: The hydraulic pump assembly canremain in machine during engine removal. Toprevent

pump assembly from shifting or falling, make sure

to support pump assembly before pump mounting

fasteners are removed.

12.Support hydraulic pump assembly.Remove fasten-

ers that secure piston (traction) pump assembly to engine(see Piston (Traction) PumpAssembly Removal in

theService and Repairssection of Chapter4 -- Hydraulic System).

6

3

4

1

5

2

Figure 11

1. Fan

2. Fan motor bracket

3. Fan motor

4. Cap screw (6 used)

5. Flange nut (6 used)

6. Radiator

2. Make sure that all parts removed from the engine

duringmaintenanceor rebuildingareinstalled totheengine.

13.Make sureall cableties securingthe wiringharness,

fuellines or hydraulic hoses to the engineare removed.

14.Connect lift or hoist to the lift tabs on engine.

15.Remove flange nuts, rebound washers and cap

screws that secure the engine mount brackets to the

rubber engine mounts.

CAUTION

One person should operate lift or hoist while a

second person guides the engine out of the machine.

IMPORTANT: Make sure to not damage the engine,

fuel lines, hydraulic lines, electrical harness or other parts while removing the engine.

16.Carefully raise engine from the machine.

17.Ifnecessary,removeenginemountsfrom the engine

using Figure 8 as a guide.

Engine Installation (Fig. 8)

3. Ifremoved,installengine mountstotheengineusing

Figure 8 as a guide.

4. Connect lift or hoist to the lift tabs on engine.

CAUTION

One person should operate lift or hoist while a

second person guides the engine into the machine.

IMPORTANT: Make sure to not damage the engine,

fuel lines, hydraulic lines, electrical harness or other parts while installing the engine.

5. Carefully lower engine into the machine.

6. Align engine to the rubber engine mounts and hydraulic pump input shaft. Secure engine to engine

mounts with cap screws, rebound washers and flange

nuts.

7. Securehydraulicpumpassemblytoengine(seePiston(Traction)Pump AssemblyInstallationintheService

and Repairs section of Chapter 4 -- Hydraulic System).

1. Locatemachine ona levelsurfacewith keyremoved

from the ignition switch. Chock wheels to keep the machine from moving.

Reelmaster 7000Page 3 -- 14Kubota Diesel Engine

Page 31

8. Install fan motor and fan assembly (Fig. 11).

C. The alternator (Fig. 10).

A. Carefullypositionfanmotor,fanandmotorbracket assembly to radiator.

B. Secure fan motor bracket to radiator with six (6)

cap screws and flange nuts.

C. Remove caps and plugs placed in hoses and fittings during removal to prevent contamination.

D. Connect hydraulic hoses to cooling fan motor

(see Hydraulic Hose and Tube Installation in the

GeneralInformationsectionofChapter4 -- Hydraulic

System).

9. Position upperradiator shroud to the radiator.Secureshroud to the radiator and lower radiatorbracket with

removedfasteners(seeRadiator Installationinthissection).Makesure thatclearancebetweenshroud andfan

is at least 0.180” (4.6 mm) at all points.

10.Connect throttle cable to engine (Fig. 9):

A. Secure throttle cable swivel to speed control le-

ver with lock nut.

B. Place throttle cable under cable clamp.

C. Adjust throttle cable position in cable clamp so

that engine governor lever contacts the high speed

stop boltat the same time that the throttle levercontacts the end of the slot in the control console.

D. Tighten cable clamp to secure throttle cable.

11.Remove caps from fuel hose and injector pump fuel

inlet that were placed during engine removal to prevent

contamination. Connect fuel supply hose to injection

pump (Fig. 9). Secure hose with hose clamp.

12.Connect wire harness connectors to the following

engine components:

A. The engine run solenoid (Fig. 9).

B. The temperature sender (Fig. 10).

D. The glow plug connection.

E. Wire harness connector to engine ground har-

ness.

F. Theelectricstarter.TorquenutatstarterB+termi-

nal from 70 to 86 in--lb (7.9 to 9.7 N--m).

G. Low oilpressureswitchlocatedonalternator side

of engine (above electric starter).

13.Using notes taken during engine removal, secure

wires with cable ties in proper locations.

14.Install air cleaner assembly to the engine (see Air

Cleaner Installation in this section).

15.Installexhaustsystemtomachine(seeExhaustSystem Installation in this section).

16.Connect coolanthosesto theradiator.Make sureradiatordraincockisclosed.Fillradiatorandreservoirwith

coolant.

17.Check position of wires, fuel lines, hydraulic hoses

andcables for proper clearance withrotating, high temperature and moving components.

18.Connect positive battery cable first and then negative battery cable. Secure battery cover to machine.

19.Check and adjust engine oil level as needed.

20.Check and adjust hydraulic oil level as needed.

21.Bleed fuel system.

22.Operate hydraulic controls to properly fill hydraulic

system (see Charge Hydraulic System in the Service

andRepairs sectionof Chapter4 -- HydraulicSystems).

23.Install hoodon the machine(see HoodInstallation in

the Service and Repairs section of Chapter 7 -- C hassis).

Kubota

Diesel Engine

Reelmaster 7000 Page 3 -- 15 Kubota Diesel Engine

Page 32

Pump Adapter Plate

RIGHT

1

2

FRONT

29 to 33 ft--lb

(40to44N--m)

3

Boss

Loctite #242

5

6

4

1. Bolt

2. Lock washer

3. Flywheel plate

4

7

Figure 12

4. Hardened washer (14 used)

5. Spring coupler

6. Bolt (6 used)

7. Cap screw (8 used)

Reelmaster 7000Page 3 -- 16Kubota Diesel Engine

Page 33

Coupler Removal (Fig. 12)

NOTE: The hydraulic pump assembly needs to be re-

moved from engine before coupler can be removed.

1. If engine is in machine, remove hydraulic pump as-

sembly(seePiston(Traction)PumpRemovalintheService and Repairs section of Chapter 4 -- Hydraulic

System).

2. Remove flywheel plate and spring coupler from en-

gine using Figure 12 as a guide.

Coupler Installation (Fig. 12)

1. Position spring coupler to engine flywheel and align

mounting holes. Make sure that coupling hub is away

from engine flywheel (Fig. 13).

2. Apply Loctite #242 (orequivalent) to threads of bolts

(item6).Securecouplertoflywheel withsix(6)boltsand

hardened washers. Torque bolts in a crossing pattern

from 29 to 33 ft--lb (40 to 44 N--m).

3. Position flywheel plate to engine. Make sure that

boss on plate is orientated down. Secure flywheel plate

with cap screws (item 7) and hardened washers using

a crossing pattern tightening procedure.

Engine Side Hydraulic

Pump Side

Figure 13

1. Coupler

2. Coupler hub

3. Engine flywheel

1

2

3

Kubota

Diesel Engine

4. If engine is in machine, install hydraulic pump as-

sembly (see Piston (Traction) Pump Installation in the

Service and Repairs section of Chapter 4 -- Hydraulic

System).

Reelmaster 7000 Page 3 -- 17 Kubota Diesel Engine

Page 34

This page is intentionally blank.

Reelmaster 7000Page 3 -- 18Kubota Diesel Engine

Page 35

Table of Contents

Chapter 4

Hydraulic System

SPECIFICATIONS 3............................

GENERAL INFORMATION 4.....................

Operator’s Manual 4..........................

Towing Traction Unit 4.........................

Check Hydraulic Fluid 4.......................

Relieving Hydraulic System Pressure 5..........

Traction Circuit Component Failure 5............

Hydraulic Hoses 6............................

Hydraulic Hose and Tube Installation 7..........

Hydraulic Fitting Installation 8..................

HYDRAULIC SCHEMATIC 10....................

HYDRAULIC FLOW DIAGRAMS 12...............

Traction Circuit: Mow Speed (4WD) 12..........

Traction Circuit: Transport Speed (2WD) 14......

Lower Cutting Units 16........................

Raise Cutting Units 18.........................

Mow Circuit 20...............................

Steering Circuit 22............................

Engine Cooling Fan Circuit 24..................

SPECIAL TOOLS 26............................

TROUBLESHOOTING 30........................

TESTING 36...................................

Traction Circuit Charge Pressure Test 38.........

Traction Circuit Relief Pressure Test 40..........

Traction Circuit Reducing Valve (PR)

Pressure Test 42............................

Rear Traction Circuit Relief (RV) Pressure Test 44

Piston (Traction) Pump Flow Test 46............

Mow Circuit Pressure Test 48...................

Mow Circuit Relief Pressure Test 50.............

Cutting Unit Motor Case Drain Leakage Test 52...

Gear Pump P1 and P2 Flow (Mow Circuits) Test 54

Steering Circuit Relief Pressure Test 56..........

Steering Cylinder Internal Leakage 58...........

Lift/Lower Circuit Relief Pressure Test 60........

Gear Pump P3 Flow (Steering and Lift/Lower

Circuits) Test 62.............................

Cooling Fan Circuit Test 64.....................

Gear Pump P4 Flow (Cooling Fan Circuit) Test 66.

ADJUSTMENTS 68.............................

Adjust Control Manifold Relief Valves 68.........

SERVICE AND REPAIRS 69.....................

General Precautions for Removing and

Installing Hydraulic System Components 69....

Check Hydraulic Lines and Hoses 70............

Flush Hydraulic System 71.....................

Filtering Closed--Loop Traction Circuit 72........

Charge Hydraulic System 73...................

Gear Pump 74................................

Gear Pump Service 76........................

Piston (Traction) Pump 78.....................

Piston (Traction) Pump Service 80..............

4WD/2WD and Filtration/Charge Control

Manifolds 82.....

4WD/2WD Control Manifold Service 84..........

Filtration/Charge Control Manifold Service 86.....

Control Manifold Cartridge Valve Service 87......

Rear Axle Motor 88...........................

Front Wheel Motors 90........................

Rear Axle and Front Wheel Motor Service 92.....

Cutting Reel Motor 93.........................

Cutting Reel Motor Service 94..................

Mow Control Manifold 98......................

Mow Control Manifold Service 100..............

Steering Control Valve 102.....................

Steering Control Valve Service 104..............

Steering Cylinder 106.........................

Steering Cylinder Service 108..................

Engine Cooling Fan Motor 110..................

Engine Cooling Fan Motor Service 112..........

Fan Control Manifold 114......................

Fan Control Manifold Service 116...............

Lift Control Manifold 118.......................

Lift Control Manifold Service 120................

Lift Circuit Junction Manifold 122................

Front Lift Cylinders 124........................

Rear Lift Cylinders 126........................

Lift Cylinder Service 128.......................

Hydraulic Reservoir 130.......................

Hydraulic Oil Cooler 132.......................

EA TON MODEL 72400 SERVO CONTROLLED PIS-

TON PUMP REPAIR INFORMATION

EATON MODEL 74318 and 74348 PISTON MOTORS:

FIXED DISPLACEMENT, VALVE PLATE DESIGN

REPAIR INFORMATION

SAUER--DANFOSS STEERING UNIT TYPE OSPM

SERVICE MANUAL

.......

....................

System

Hydraulic

Reelmaster 7000 Hydraulic SystemPage 4 -- 1

Rev. A

Page 36

This page is intentionally blank.

Reelmaster 7000Hydraulic System Page 4 -- 2

Page 37

Specifications

Item Description

Piston (Traction) Pump Eaton variable displacement piston pump

Maximum Displacement (per revolution) 2.48 in

System Relief Pressure: Forward 5000 PSI (345 bar)

System Relief Pressure: Reverse 5000PSI (345 bar)

Charge Pressure 207 PSI (14.3 bar)

Front Wheel Motors Eaton fixed displacement piston motors

Displacement (per revolution) 2.01 in

Rear Axle Motor Eaton fixed displacement piston motor

Displacement (per revolution) 2.48 in

Gear Pump Casappa 4 section, positive displacement gear type pump

Section P1/P2 Displacement (per revolution) 1.03in

Section P3/P4 Displacement (per revolution) 0.56 in

Steering Control Valve Sauer--Danfoss Steering Unit, Series OSPM

Displacement (per revolution) 6.1 in

Steering Circuit Relief Pressure 1050 PSI (72 bar)

Lift/Lower Circuit Relief Pressure 1700 PSI (117 bar)

Cutting Unit Motors Casappa Gear Motor

Displacement (per revolution) 1.61 in

(Model 72400)

3

(40.6 cc)

(Model 74315)

3

(32.9 cc)

(Model 74318)

3

(40.6 cc)

3

(16.85 cc)

3

(9.16 cc)

3

(100 cc)

3

(26.5 cc)

System

Hydraulic

Cutting Unit Circuit Relief Pressure 3000 PSI (207 bar)

Engine Cooling Fan Motor Casappa Gear Motor

Displacement (per revolution) 0.51 in

Engine Cooling Fan Circuit Relief Pressure 3000 PSI (207 bar)

Hydraulic Filters Spin--on cartridge type

In--line S uction Strainer 100 mesh (in reservoir)

Hydraulic Reservoir Capacity 8.25 U.S. Gallons (31.3 Liters)

Hydraulic Oil See Traction Unit Operator’s Manual

3

(8.4 cc)

NOTE: The pressure specifications listed above are

component settings. When using pressure gauges to

measurecircuit pressures,values may bedifferent than

these specifications. See the Testing section of this

chapterfor hydraulic test proceduresand expected test

results.

Reelmaster 7000 Hydraulic SystemPage 4 -- 3

Page 38

General Information

Operator’s Manual

The Operator’s Manual provides information regarding

the operation, general maintenance and maintenance

intervals for your Reelmaster machine. Refer to that

publicationforadditional information whenservicingthe

machine.

Towing Traction Unit

IMPORTANT: If towing limits are exceeded, severe

damage to the piston pump may occur.

If it becomes necessary to tow (or push) the machine,

tow (or push) in a forward direction only, at a speed

below3 mph(4.8 kph) andfor adistance lessthan 1/4

mile (0.4 km). The piston (traction) pump is equipped

witha bypass valve thatneeds to be turned90

ing(Fig.1).Donotturnbypassvalvewhenengineisrunning.

o

fortow-

1

See Traction Unit Operator’s Manual for additional towing procedures.

IMPORTANT: If the machine must be pushed or

towed in a reverse direction, the check valve in the

4WD/2WD control manifold must be bypassed. To

bypass this check valve, connect a hydraulic hose

between the reverse traction pressure test port and

the 4WD/2WD control manifold test port (G). Toro

part numbers 95--8843 (hydraulic hose), 95--0985

(coupler fitting) (2 required) and 340--77 (hydraulic

fitting) (2 required) are needed for this connection.

Check Hydraulic Fluid

The Reelmaster 7000 hydraulic systems are designed

to operate on anti --wear hydraulic fluid. The reservoir

holdsapproximately8.25U.S.gallons (31.3 liters)ofhydraulic fluid. Check level of hydraulic fluid daily.

Figure 1

1. Bypass valve location

1

2

Figure 2

1. Hydraulic reservoir 2. Reservoir cap

Reelmaster 7000Hydraulic System Page 4 -- 4

Page 39

Relieving Hydraulic System Pressure

Beforedisconnecting orperforming any workon thehydraulic system, all pressure in the hydraulic system

mustbe relieved.Parkmachineonalevelsurface,lower

cutting units fully,stop engine and apply parking brake.

To relieve hydraulic pressure in traction circuit, move

tractionpedal to bothforward andreverse directions.To

relieve hydraulic pressure in steering circuit, rotate

steering wheel in both directions.

Traction Circuit Component Failure

The traction circuit on Reelmaster 7000 machines is a

closed loop system that includes the piston (traction)

pump, two (2) front wheel motors and the rear axle motor.If a component in the traction circuit should fail, debris and contamination from the failed component will

circulatethroughoutthetraction circuit.Thiscontamination can damage other components in the circuit so it

must be removed to prevent additional component failure.

The recommended method of removing traction circuit

contamination would be to temporarily install the Toro

high flow hydraulic filter (see Special Tools in this chapter) into the circuit. This filter should be used when connecting hydraulic test gauges in order to test traction

circuitcomponentsorafterreplacing a failedtractioncircuit component (e.g. traction (piston) pump or wheel

motor). The filter will ensure that contaminates are removedfromtheclosedloop andthus,donotcauseadditional component damage.

Once the Toro high flow hydraulic filter kit has been

placedin the circuit,raise and support the machinewith

Systempressureinmow circuit isrelievedwhen the cuttingunits are disengaged(PTO switchin OFF position).

To relieve hydraulicpressure in lift circuit, fullylower the

cutting units to the ground. Turn ignition switch to OFF.

all drive wheels off the ground. Then, operate the tractioncircuit toallow oil flowthroughout thecircuit. The filter will remove contamination from the traction circuit

duringoperation. Because the Torohigh flowfilter is bi-directional, the traction circuit can be operated in both

the forward and reverse direction. The filter should be

removed from the machine after contamination has

been removed from the traction circuit. See Filtering

Closed--LoopTractionCircuitintheServiceandRepairs

section of this chapter for additional information on using the Toro high flow hydraulic filter.

Thealternativetousingthe Torohighflow hydraulic filter

kit after a traction circuit component failure would be to

disassemble, drain and thoroughly clean all components, tubes and hoses in the traction circuit. If any debris remains in the traction circuit and the machine is

operated,thedebriscancauseadditionalcircuitcomponent failure.

NOTE: If traction circuit contamination exists, the traction pump case drain could allow contaminates to enter

other hydraulic circuits on the machine.

System

Hydraulic

Reelmaster 7000 Hydraulic SystemPage 4 -- 5

Page 40

Hydraulic Hoses

Hydraulichoses are subjectto extremeconditions such

aspressure differentialsduring operation andexposure

to weather, sun, chemicals, very warm storage conditionsormishandlingduringoperationand maintenance.

These conditions can cause hose damage and deterioration. Some hoses are more susceptible to these

conditions than others. Inspect all machine hydraulic

hoses frequently for signs of deterioration or damage:

WARNING

Beforedisconnecting orperforming anywork on

hydraulic system, relieve all pressure in system

(seeRelieving HydraulicSystem Pressure in this

section).

Hard, cracked, cut, abraded, charred, leaking or

otherwise damaged hose.

Kinked, crushed, flattened or twisted hose.

Blistered, soft, degraded or loose hose cover.

Cracked, damaged or badly corroded hose fittings.

When replacing a hydraulic hose, be sure that the hose

is straight (not twisted) before tightening the fittings.

This can be done by observing the imprint (layline) on

thehose. Usetwowrenches; holdthe hosestraight with

one wrench and tighten the hose swivel nut onto the fitting with the other wrench ( See Hydraulic Hose and

Tube Installation in this section). If the hose has an elbowatoneend, tightentheswivelnut on thatendbefore

tightening the nut on the straight end of the hose.

For additional hydraulic hose information, refer to Toro

Service Training Book, Hydraulic Hose Servicing (Part

Number 94813SL).

Keepbodyandhands away from pin hole leaks or

nozzles that eject hydraulic fluid under high

pressure. Use paper or cardboard, not hands, to

search for leaks. Hydraulic fluid escaping under

pressure can have sufficient force to penetrate

the skin and cause serious injury. If fluid is injected into the skin, it must be surgically removed within a few hours by a doctor familiar

withthistypeof injury.Gangrenemayresultfrom

such an injury.

Reelmaster 7000Hydraulic System Page 4 -- 6

Page 41

Hydraulic Hose and Tube Installation (O--Ring Face Seal Fitting)

1. Makesure threadsand sealingsurfacesof thehose/

tube and the fitting are free of burrs, nicks, scratches or

any foreign material.

2. Asa preventativemeasure againstleakage,it isrecommended that the face seal O--ring be replaced any

time the connection is opened. Make sure the O--ring is

installedandproperlyseatedin the fitting groove.Lightly

lubricate the O--ring with clean hydraulic oil.

3. Place the hose/tube against the fitting body so that

theflatfaceofthehose/tubesleevefullycontacts the O-ring in the fitting.

4. Thread the swivel nut onto the fitting by hand.While

holding the hose/tube with a wrench, use a torque

wrench to tighten the swivel nut to the recommended

installation torque shown in Figure 5. This tightening

process will require the use of an offset wrench ( e.g.

crowfoot wrench). Use of an offset wrench will affect

torque wrench calibration due to the effective length

change of the torque wrench. Tightening torque when

usingatorque wrenchwithanoffsetwrenchwillbelower

than the listed installation torque (see Using a Torque

Wrench with an Offset Wrenchin the Torque Specificationssection of Chapter 2 -- Product Recordsand Maintenance).

C. Usea secondwrenchtotighten the nuttothecorrect Flats From Wrench Resistance (F.F.W.R.). The

markingsonthenutand fitting body willverifythatthe

connection has been properly tightened.

Size F.F.W.R.

4 (1/4 in. nominal hose or tubing) 1/2 to 3/4

6 (3/8 in.) 1/2 to 3/4

8 (1/2 in.) 1/2 to 3/4

10 (5/8 in.) 1/2 to 3/4

12 (3/4 in.) 1/3 to 1/2

16 (1 in.) 1/3 to 1/2

Swivel Nut

Tube or Hose

O--ring

Fitting Body

Figure 3

System

Hydraulic

5. If a torque wrench is not available or if space at the

swivelnutprevents useofa torquewrench, an alternate

method of assembly is the Flats From Wrench Resistance (F.F.W.R.) method (Fig. 2).

Mark Nut

and Fitting

Body

Final

Position

A. Usingawrench,tightenthe swivelnutontothefittinguntillightwrenchresistanceis reached (approxi-

Extend Line

mately 30 in--lb).

B. Mark the swivel nut and fitting body. Hold the

hose/tube with a wrench to prevent it from turning.

AT WRENCH RESISTANCE

Figure 4

Fitting Dash Size Hose/Tube Side Thread Size Installation Torque

4 9/16 -- 18 18to22ft--lb(25to29N--m)

6 11/16 - - 16 27to33ft--lb(37to44N--m)

8 13/16 -- 16 37to47ft--lb(51to63N--m)

10 1--14 60 to 74 ft--lb (82 to 100 N--m)

12 13/16--12 85 to 105 ft--lb (116 to 142 N--m)

Initial

Position

AFTER TIGHTENING

16 17/16--12 110 to 136 ft--lb (150 to 184 N--m)

20 1 11/16 -- 12 140 to 172 ft--lb (190 to 233 N--m)

Figure 5

Reelmaster 7000 Hydraulic SystemPage 4 -- 7

Page 42

Hydraulic Fitting Installation (SAE Straight Thread O--Ring Fitting into Component Port)

Non--Adjustable Fitting (Fig. 6)

1. Make sure all threads and sealing surfaces of fitting

and component port are free of burrs, nicks, scratches

or any foreign material.

2. Asa preventativemeasure againstleakage,it isrecommended that the O--ring be replaced any time the

connection is opened.

3. Lightly lubricate the O--ring with clean hydraulic oil.

Fittingthreadsshouldbecleanwithnolubricantapplied.

IMPORTANT: Before installing fitting into port, determine port material. If fitting is to be installed into

an aluminum port, installation torque is reduced.

4. Install the fitting into the port. Then, use a torque

wrench and socket to tighten the fitting to the recommended installation torque shown in Figure 7.

NOTE: Useof an offset wrench (e.g. crowfoot wrench)

will affect torque wrench calibration due to the effective

length change of the torque wrench. Tightening torque

when using a torque wrench with an offset wrench will

be less than the recommended installation torque. See

Using a Torque Wrench with an Offset Wrench in the

Torque Specifications section of Chapter 2 -- Product

RecordsandMaintenancetodetermine necessaryconversion information.

5. If a torque wrench is not available, or if space at the

portpreventsuseofatorque wrench, analternatemethod of assembly is the Flats From Finger Tight (F.F.F.T.)

method.

A. Install the fitting into the port and tighten it down

full length until finger tight.

B. If port material is steel, tighten the fitting to the

listed F.F.F.T.If port material is aluminum, tighten fitting to 60% of listed F.F.F.T.

Size F.F.F.T.

4 (1/4 in. nominal hose or tubing) 1.00 +

6(3/8in.) 1.50+

8(1/2in.) 1.50+

10 (5/8 in.) 1.50 +

12 (3/4 in.) 1.50 +

16 (1 in.) 1.50 +

Fitting

O--ring

0.25

0.25

0.25

0.25

0.25

0.25

Figure 6

Fitting

Dash Size

Fitting Port Side

Thread Size

Installation Torque Into

Steel Port

Installation Torque Into

Aluminum Port

4 7/16 -- 20 15to19ft--lb(21to25N--m) 9to11ft--lb(13to15N--m)

5 1/2 -- 20 18to22ft--lb(25to29N--m) 11to15ft--lb(15to20N--m)

6 9/16 -- 18 34to42ft--lb(47to56N--m) 20to26ft--lb(28to35N--m)

8 3/4 -- 16 58to72ft--lb(79to97N--m) 35to43ft--lb(48to58N--m)

10 7/8 -- 14 99 to 121 ft--lb (135 to 164 N--m) 60 to 74 ft--lb (82 to 100 N--m)

12 11/16--12 134 to 164 ft--lb (182 to 222 N--m) 81 to 99 ft--lb (110to 134 N--m)

14 13/16--12 160 to 196 ft--lb (217 to 265 N--m) 96 to 118 ft--lb (131 to 160 N--m)

16 15/16--12 202 to 248 ft--lb (274 to 336 N--m) 121 to 149 ft--lb (165 to 202 N--m)

20 15/8--12 247 to 303 ft--lb (335 to 410 N--m) 149 to 183 ft--lb (202 to 248 N--m)

Figure 7

Reelmaster 7000Hydraulic System Page 4 -- 8

Page 43

Adjustable Fitting (Fig. 8)

1. Make sure all threads and sealing surfaces of fitting

and component port are free of burrs, nicks, scratches

or any foreign material.

2. Asa preventativemeasure againstleakage,it isrecommended that the O--ring be replaced any time the

connection is opened.

3. Lightly lubricate the O--ring with clean hydraulic oil.

Fittingthreadsshouldbecleanwithnolubricantapplied.

4. Turnback the lock nutas far as possible. Make sure

the back up washer is not looseand is pushed upas far

as possible (Step 1 in Figure 9).

IMPORTANT: Before installing fitting into port, determine port material. If fitting is to be installed into

an aluminum port, installation torque is reduced.

Lock Nut

Back--up Washer

O--ring

Figure 8

5. Install the fitting into the port and tighten finger tight

until the washer contacts the face of the port (Step 2).

6. Toputthe fittingin thedesiredposition, unscrewitby

the required amount, but no more than one full turn

(Step 3).

7. Hold the fitting in the desired position with a wrench

and use a torque wrench to tighten the fitting to the recommended installation torque shown in Figure 7. This

tightening process will require the use of an offset

wrench (e.g. crowfoot wrench). Use of an offsetwrench

will affect torque wrench calibration due to the effective

length change of the torque wrench. Tightening torque

when using a torque wrench with an offset wrench will

be lower than the listed installation torque (see Using a

Torque Wrench with an Offset Wrench in the Torque

Specifications section of Chapter 2 -- Product Records

and Maintenance).

8. If a torque wrench is not available, or if space at the

portpreventsuseofatorque wrench, analternatemethod of assembly is the Flats From Finger Tight (F.F.F.T.)

method. Hold the fitting in the desired position with a

wrench and, if port material is steel, tighten the lock nut

withasecondwrench tothelistedF.F.F.T(Step 4).Ifport

material is aluminum, tighten fitting to 60% of listed

F.F.F.T.

Step 3Step 1

Step 2 Step 4

Figure 9

System

Hydraulic

Size F.F.F.T.

4 (1/4 in. nominal hose or tubing) 1.00 +

6(3/8in.) 1.50+

8(1/2in.) 1.50+

10 (5/8 in.) 1.50 +

12 (3/4 in.) 1.50 +

16 (1 in.) 1.50 +

0.25

0.25

0.25

0.25

0.25