Page 1

Form No. 3354-519 Rev B

32in Recycler® Kit

For Fixed Deck Mid-Size Mowers

Model No. 110-4915

Installation Instructions

Note: Deter mine the left and right sides of the mac hine from the nor mal operating position.

Safety

Side Discharge or Mulch

Grass

W ithout the g rass deflector , discharge

co v er , or complete g rass catcher assembl y

mounted in place, y ou and other s ar e

exposed to blade contact and thr o wn de bris.

Contact with r otating mo w er blade(s) and

thr o wn de bris will cause injur y or death.

• Nev er r emo v e the g rass deflector fr om

the mo w er because the g rass deflector

r outes material do wn to w ard the turf.

If the g rass deflector is ev er dama ged,

r eplace it immediatel y .

• Nev er put y our hands or feet under the

mo w er .

• Nev er tr y to clear the discharge ar ea or

mo w er blades unless y ou disenga ge the

po w er tak e of f (PT O) lev er and tur n the

ignition k ey to of f. Also r emo v e the k ey

and pull the wir e(s) of f the spar k plug(s).

Ensure the mo w er has the hing ed g rass deflector

that disperses clippings to the side and do wn

to w ard the turf , while in side disc harg e mode .

T o m ulc h g rass clippings , the baffles m ust be

installed into the mo w er as sho wn in the follo wing

ste ps .

© 2006—The Toro® Company

8111 Lyndale Avenue South

Bloomington, MN 55420

Register at www.Toro.com. Original Instructions (EN)

Printed in the USA.

All Rights Reserved

Page 2

Installation

Loose Parts

Use the chart below to verify that all parts have been shipped.

Step

1

2

3

4

5

6

7

No parts required

No parts required

No parts required

Bafe

Bolt (5/16 x 5/8 inch)

Flange nut (5/16 inch)

Discharge plate

Bolt (3/8 x 3/4 inch)

Flange nut (3/8 inch)

Blocker plate

Carriage bolt (1/4 x 3/4 inch)

Flange nut (1/4 inch)

Bolt (3/8 x 1-1/4 inches)

Flange nut (3/8 inch)

Kicker

Bolt (5/16 x x 5/8 inch)

Flange nut (5/16 inch)

Description

Qty.

–

–

–

1

3

6

1

4

4

1

2

2

1

1

2

4

4

Prepare the mower.

Remove the existing blades.

Remove the existing discharge

bafe.

Install the bafe.

Install the discharge plate.

Install the blocker plate.

Install the kickers.

Use

8

Recycler blades

Step

1

Preparing the Mower

No Parts Required

Procedure

1. T horoughly clean mo w er dec k. All debris m ust

be remo v ed to ensure baffles will fit properly

ag ainst mo w er dec k.

2. R e pair all bent or damag ed areas of mo w er

dec k and re place any damag ed or missing par ts .

2

Install the new blades.

Step

2

Removing the Existing

Blades

No Parts Required

Procedure

R emo v e the existing blades from the spindles

( Figure 1 ).

Note: Sa v e the blades for use when in side

disc harg mode . Use the blade bolt and w asher for

installing the recycler blades in Ste p 4.

2

Page 3

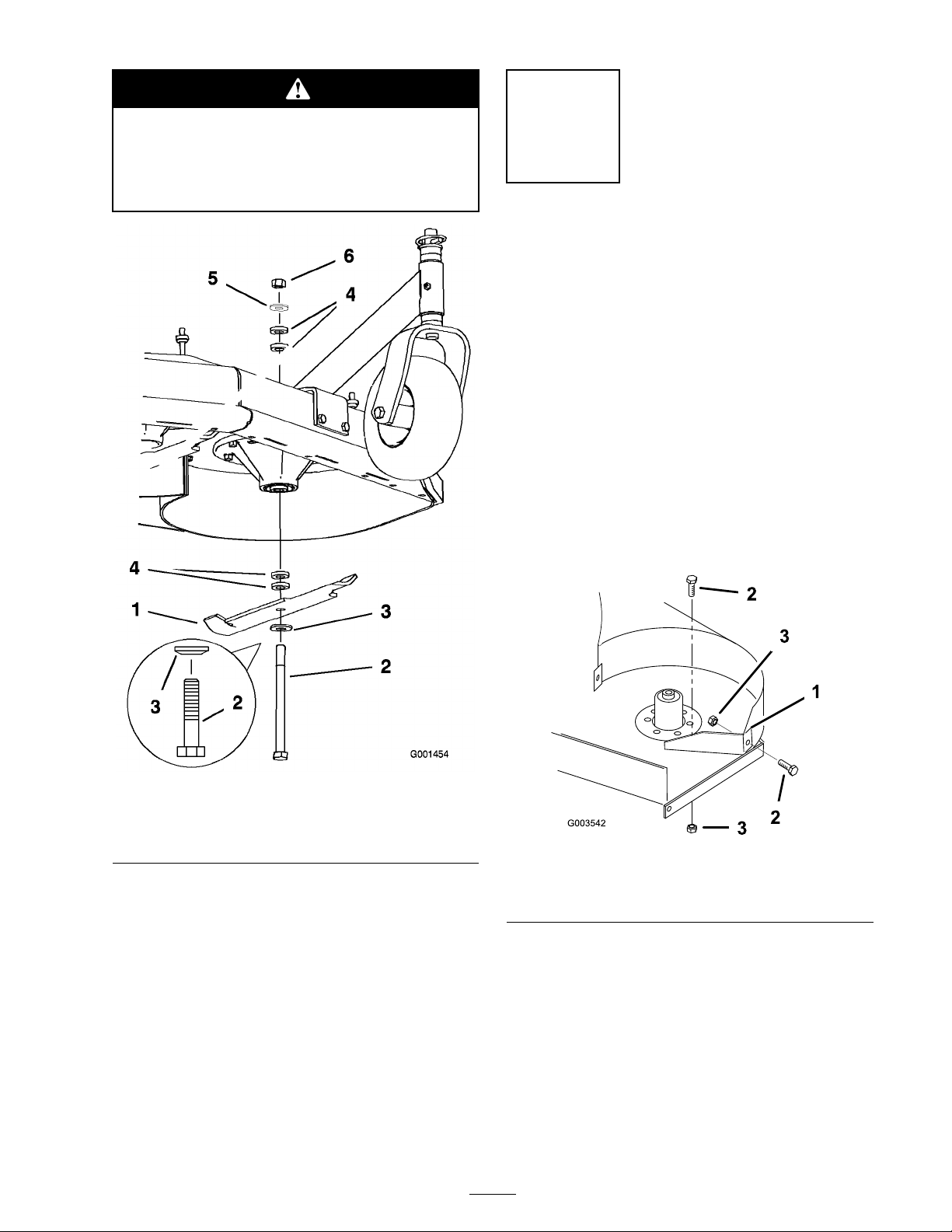

A blade is shar p . Contact with shar p blade

can cause serious per sonal injur y .

W ear g lo v es or wrap shar p edges of the

blade with a ra g .

Step

3

Removing the Existing

Discharge Bafe

No Parts Required

Procedure

Note: In the ste ps belo w , the bolts are threaded

into the mo w er dec k. R emo v e the n uts first before

remo ving bolts .

1. R emo v e the knobs and mo w er belt co v er from

the mo w er dec k ( Figure 2 ).

2. R emo v e the bolts and flang e n uts holding the

disc harg e baffle in place ( Figure 2 ).

Note: Sa v e the baffle and hardw are for use when

c hanging to side disc harging mode .

Figure 1

1. Blade

2. Blade bolt 5. Thin washer

3. Curved washer

4. Spacer

6. Nut

Figure 2

1. Discharge bafe 3. Lock Nut

2. Bolt

3

Page 4

Step

Step

4

Installing the Bafe

Parts needed for this step:

1

Bafe

3

Bolt (5/16 x 5/8 inch)

6

Flange nut (5/16 inch)

Procedure

1. R emo v e the 5 bolts and flang e n uts from the

holes where the baffles will be installed ( Figure

3 ).

Note: Sa v e the previously remo v ed hardw are

for use when using the mo w er in side disc harg e

mode .

2. Place the baffle inside cutting c hamber with

studs through the top of the mo w er dec k.

3. Secure the baffle to top of the mo w er with 2

bolts (5/16 x 5/8 inc h) and 2 flang e n uts (5/16

inc h) and to the bac k of the cutting c hamber

with a bolt (5/16 x 5/8 inc h) and a flang e n ut

(5/16 inc h) ( Figure 3 ).

5

Installing the Discharge

Plate

Parts needed for this step:

1

Discharge plate

4

Bolt (3/8 x 3/4 inch)

4

Flange nut (3/8 inch)

Procedure

Install the disc harg e plate to the outside of the

mounting brac k et with 4 bolts (3/8 x 3/4 inc h)

and 4 n uts (3/8 inc h) ( Figure 4 ).

Figure 3

1. Bafe 4. Studs on bafe

2. Bolt, (5/16 x 5/8 inch)

3. Flange nut, (5/16 inch)

5. Mower deck

6. Back of cutting chamber

1. Discharge plate

Figure 4

2. Bolt (3/8 x 3/4

inch)

3. Nut (3/8 inch)

4

Page 5

Step

6

Installing the Blocker Plate

Parts needed for this step:

1

Blocker plate

2

Carriage bolt (1/4 x 3/4 inch)

2

Flange nut (1/4 inch)

1

Bolt (3/8 x 1-1/4 inches)

1

Flange nut (3/8 inch)

Procedure

1. Place the bloc k er plate inside cutting c hamber

betw een the front of the mo w er dec k and the

baffle .

Note: Mak e sure to remo v e the bolt sho w in

Figure 5 from the front caster .

2. R emo v e the existing bolt (3/8 x 1 inc h), w asher ,

and flang e n ut from the front caster where the

bloc k er plate is to be installed ( Figure 5 ).

3. Secure the bloc k er plate to the front of the

mo w er and front caster with a bolt (3/8 x 1-1/4

inc hes) and a flang e n ut (3/8 inc h) ( Figure 5 ).

4. Secure the bloc k er to the front baffle with 2

bolts (1/4 x 3/4 inc h) and 2 flang e n uts (1/4

inc h) ( Figure 5 ).

1. Blocker plate

2. Bolt, (3/8 x 1-1/4 inches)

use this for blocker plate

3. Flange nut, (3/8 inch)

Step

7

Installing the Kickers

Parts needed for this step:

2

Kicker

4

Bolt (5/16 x x 5/8 inch)

4

Flange nut (5/16 inch)

Procedure

Figure 5

4. Carriage bolt, (1/4 x 3/4

inch)

5. Flange nut, (1/4 inch)

6. Front caster

1. Measure from the spindle center lines , and

locate kic k ers as sho wn ( Figure 6 ). P osition

one kic k er 7/16 inc h (11 mm) off to the right

of the right spindle and one kic k er 1-7/8 inc h

(48 mm) off to the left of the left spindle .

2. Holding kic k ers tight ag ainst baffle , mark,

center punc h and drill 2 holes (11/32 inc h)

holes for eac h kic k er ( Figure 6 ).

5

Page 6

Figure 6

1. 7/16 inch (11 mm) from

center of right spindle

2. 1-7/8 inch (48 mm) from

center of left spindle

3. Mark, center punch and

drill 11/32 inch (9 mm)

holes

3. Place the kic k ers inside the mo w er o v er drilled

holes and install eac h kic k er with 2 bolts (5/16

x 5/8 inc h) through from the bottom of the

mo w er , and 2 flang e n uts (5/16 inc h) ( Figure

7 ).

4. Tighten all mounting hardw are securely .

Step

8

Installing the New Blades

Parts needed for this step:

2

Recycler blades

Procedure

Important: T he sail par t of the blade (i.e.,

the tur ned up section) must f ace the inside of

the mo w er ( Figur e 8 ).

1. Adjust the blades b y using the 4 spacers (1/4

inc h) on the blade spindle bolts; refer to the

Operator’ s Manual .

2. Install the new blades to the spindles with

w ashers and blade bolts that w ere previously

remo v ed ( Figure 8 ).

3. Tighten the blade bolt to 75-80 ft-lb (101-108

N∙m).

1. Kicker

2. Bolt, (5/16 x 5/8 inch)

Figure 7

3. Flange nut, (5/16 inch)

4. R otate the blades and ensure there is clearance

betw een the blades and the baffles .

5. Tighten all bolts and n uts for the baffles

( Figure 5 ).

A blade is shar p . Contact with shar p blade

can cause serious per sonal injur y .

W ear g lo v es or wrap shar p edges of the

blade with a ra g .

6

Page 7

housing free from uncut g rass , allo wing air to be

dra wn into the housing . W hen making an initial

cut through the center of an uncut area, operate

the mac hine slo w er and bac k up if the mo w er

star ts to clog .

Mowing at Proper Intervals

Under most nor mal conditions y ou will need to

mo w ev er y 4–5 da ys . Ho w ev er , g rass g ro ws at

different rates at different times . T hus , in order

to maintain the same height-of-cut, whic h is a

g ood practice , y ou’ll need to cut more frequently

in early spring; as the g rass g ro wth rate slo ws in

mid summer , cut only ev er y 8–10 da ys . If y ou

are unable to mo w for an extended period due to

w eather conditions or other reasons , con v er t to

side disc harg e or bag ging options or mo w first

with the height-of-cut at a high lev el; then mo w

ag ain 2–3 da ys later with a lo w er height setting .

Mowing with Sharp Blades

Figure 8

1. Blade

2. Blade bolt 5. Thin washer

3. Curved washer

4. Spacer

6. Nut

Operation

Selecting the Proper

Height-of-Cut

R emo v e appro ximately one inc h or no more

than 1/3 of the g rass blade when cutting . In

ex ce ptionally lush and dense g rass y ou ma y need

to raise the height-of-cut setting or con v er t to side

disc harg e or bag ging operations .

A shar p blade cuts cleanly and without tearing or

shredding the g rass . A dull blade will tear and

shred the g rass . T earing and shredding causes the

g rass to tur n bro wn at the edg es whic h impairs

g ro wth and increases susce ptibility to disease .

After Operating

T o ensure optim um perfor mance , clean the

underside of the mo w er housing after eac h use .

If residue is allo w ed to build up in the mo w er

housing, cutting perfor mance will decrease .

Mowing in Extreme

Conditions

Air is required to cut and recut g rass clippings in

the mo w er housing, so do not set the height-of-cut

too lo w or totally sur round the housing b y uncut

g rass . Alw a ys tr y to ha v e one side of the mo w er

7

Page 8

Loading...

Loading...