Form No. 3353–604 Rev B

DFS Bagger Adapter Kit

for Mounting 2005 and After Baggers on 2004 and Before

Z500 Series Z Masters

Part No. 110–0350

Installation Instructions

Note: Use the existing hardware that came with the bagger to install the bagger mounting bracket in Step 3.

Setup

Note: Determine the left and right sides of the machine from the normal operating position.

Loose Parts

Note: Use the chart below to verify all parts have been shipped.

Step

1

2

3

4

5

6

Description Qty. Use

No parts needed Removing the Drive Wheels

No parts needed

Side bracket—right

Side bracket—left

Stiffener bracket

Bolt, 3/8 x 1 inch

Flange Nut, 3/8 inch

Curved washer

Spacer

No parts needed Tightening all mounting bolts

No parts needed Installing the Drive Wheels

1

1

2

6

6

6

4

Removing the Roll Over Protection

System (ROPS)

Installing bagger mounting bracket

Installing the side brackets to the

machine

W 2005 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Original Instructions (Language abbreviation)

Contact us at www.Toro.com

All Rights Reserved

Printed in the USA

Step

1

No parts needed for this step.

Removing the Drive Wheels

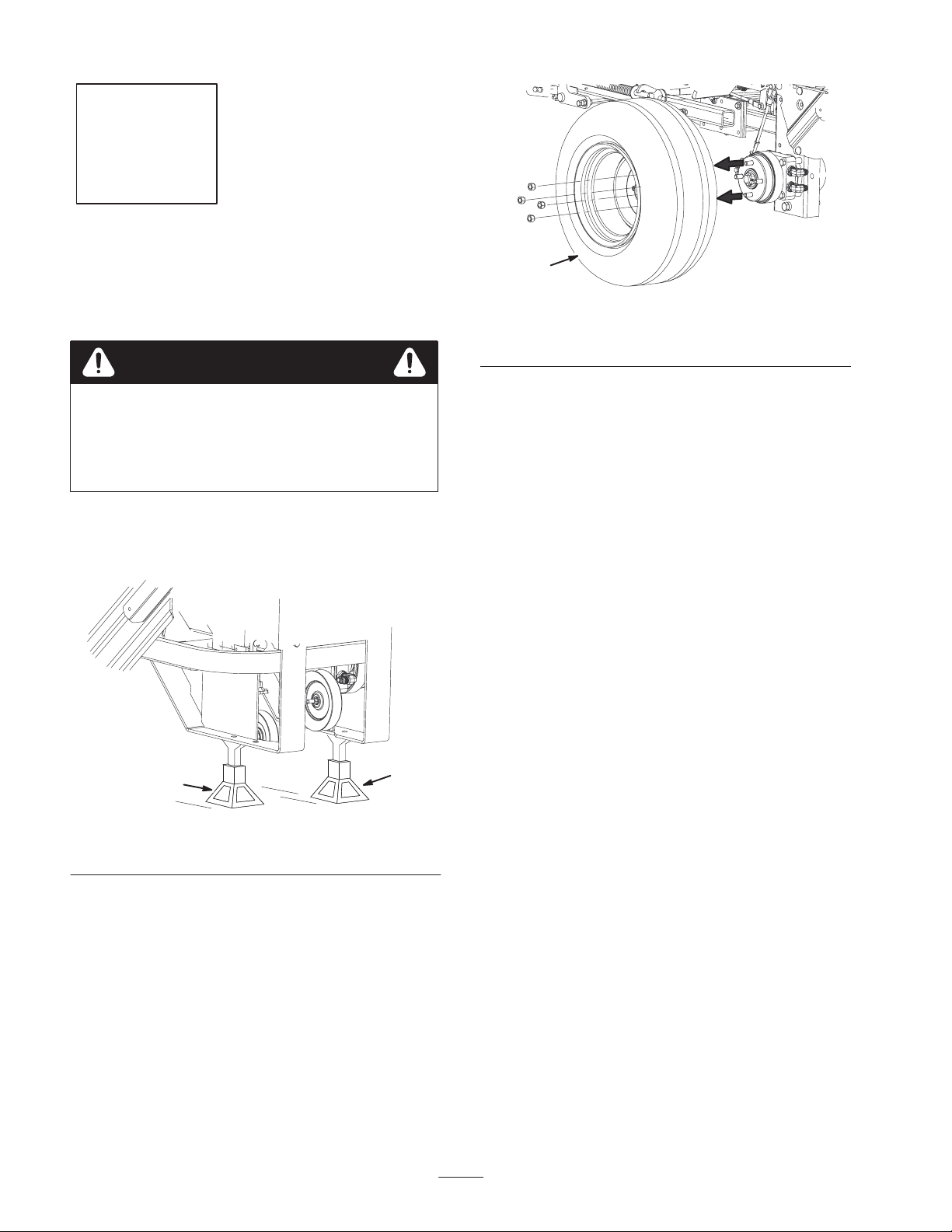

Danger

Mechanical or hydraulic jacks may fail to support

machine and cause a serious injury.

• Use jack stands when supporting machine.

• Do not use hydraulic jacks.

1. Loosen the drive wheel nuts.

2. Raise the rear of the machine and support with jack

stands (Fig. 1).

1

m–6859

Figure 2

1. Drive wheel

1

Figure 1

1. Jack stand

3. Remove the nuts and the drive wheels (Fig. 2).

1

2

Step

2

No parts needed for this step.

Removing the Roll Over

Protection System (ROPS)

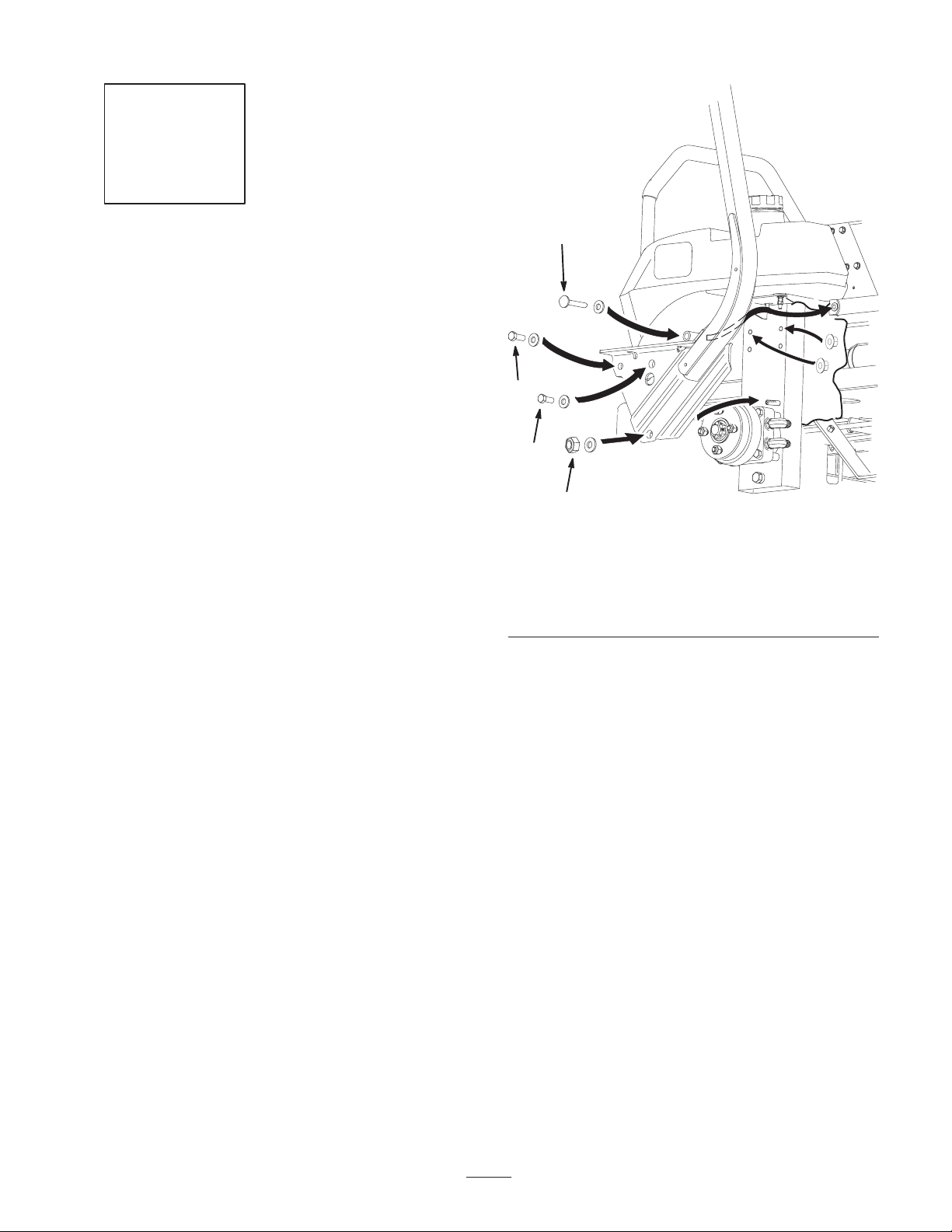

Remove the following fasteners (Fig. 3) securing each

(right and left) roll bar section to the frame:

• Lock nut (3/8 inch) and curved washer. Do not

remove bolt from frame.

• Bolt (3/8 x 1 inch), curved washer and flange nut

(3/8 inch).

• Bolt (3/8 x 1 inch), curved washer and flange nut

(3/8 inch).

• Bolt (3/8 x 4-1/2 inches), curved washer and

flange nut (3/8 inch).

3

2

2

1

1. Lock nut, 3/8 inch &

curved washer

2. Bolt, 3/8 x 1 inch, curved

washer & flange nut,

3/8 inch (2)

m–6854

Figure 3

3. Bolt, 3/8 x 4–1/2 inches,

curved washer & flange

nut, 3/8 inch

3

Step

3

3. In the bottom hole, install a bolt (3/8 x 1–1/4 inch) and

a flange nut (3/8 in.) (Fig. 4).

4. Install a bracket stiffener to the side bracket and bagger

mounting bracket. Use 4 bolts (3/8 x 3/4 inch) and

4 flange nuts (3/8 in.) (Fig. 4).

5. Repeat the previous steps for the opposite side.

6

Parts needed for this step:

• 1 Side bracket—right

• 1 Side bracket—left

• 2 Stiffener brackets

Note: Use the existing hardware that came with the bagger

to install the bagger mounting bracket.

If you have a liquid cooled machine, go to page 5 for

Installing the Bagger Mounting Bracket onto a Liquid

Cooled Machine.

If you have an air cooled machine, use the following

instructions for Installing the Bagger Mounting Bracket

onto a Air Cooled Machine.

Installing the Bagger Mounting

Bracket onto an Air Cooled

Machine

Important Do not tighten any bolts until both side

brackets and bagger mounting bracket are fit loose on the

machine.

1

9

8

1. Bagger mounting bracket

2. Bolt, 3/8 x 1–1/4 inch

3. Flange nut, 3/8 inch

4. Bracket stiffener

5. Left side bracket

5

4

3

2

Figure 4

3

7

4

3

6

6. Bolt, 3/8 x 3/4 inch

7. Long frame spacer

8. Bolt, 3/8 x 1–1/2 inch

9. Short frame spacer

10. Right side bracket

10

m–5978

Refer to Tightening the Mounting Bolts, on page 7, for the

correct procedure to tighten the bolts.

Installing the Bagger Mounting Bracket to

the Side Brackets (Air Cooled)

Important When installing the bagger bracket for an

air cooled machine, use only 2 long frame spacers; 1 per

each side (Fig. 4).

1. Install the side brackets to the bagger mounting bracket

(Fig. 4).

2. In the top two holes, install 2 bolts (3/8 x 1–1/2 inch),

2 flange nuts (3/8 in.) one long frame spacer, and one

short frame spacer (Fig. 4).

Note: Make sure the long frame spacers are installed as

shown in figure 4.

Installing the Bagger Mounting Bracket

onto an Air Cooled Machine

Important When installing the bagger onto an air

cooled machine, use the air cooled spacer (Fig. 5).

1. Pull the bottom of the roll bar away from the frame and

slide the side braket between the machine frame and the

ROPS frame (Fig. 3). Repeat for the opposite side of the

machine.

2. Install the bagger mounting bracket to the rear frame of

the machine (Fig. 5).

3. In the top two holes, install 2 bolts (3/8 x 1–3/4 inch),

2 flange nuts (3/8 in.) and the air cooled frame spacer

(Fig. 5).

4

4. In the bottom two holes, install 2 bolts (3/8 x

6

1–1/4 inch) and 2 flange nuts (3/8 in.) (Fig. 5).

Note: Make sure the long frame spacers are installed as

shown in Figure 6.

4

5

3

3

1

3

6

2

6

2

m–5863

Figure 5

1. Bagger mounting bracket

2. Bolt, 3/8 x 1–1/4 inch

3. Flange nut, 3/8 inch

4. Bumper

5. Air cooled frame spacer

6. Bolt, 3/8 x 1–3/4 inch

Installing the Bagger Mounting

Bracket onto a Liquid Cooled

Machine

Important Do not tighten any bolts until both side

brackets and bagger mounting bracket are fit loose on the

machine.

Refer to Tightening the Mounting Bolts, on page 7, for the

correct procedure to tighten the bolts.

3. In the bottom hole, install a bolt (3/8 x 1–1/4 inch) and

a flange nut (3/8 in.) (Fig. 6).

4. Install a bracket stiffener to the side bracket and bagger

mounting bracket. Use 4 bolts (3/8 x 3/4 inch) and

4 flange nuts (3/8 in.) (Fig. 6).

5. Repeat the previous steps for the opposite side.

5

4

10

3

4

3

7

3

7

1

9

6

8

2

m–5979

Figure 6

1. Bagger mounting bracket

2. Bolt, 3/8 x 1–1/4 inch

3. Flange nut, 3/8 inch

4. Bracket stiffener

5. Left side bracket

6. Bolt, 3/8 x 3/4 inch

7. Long frame spacer

8. Bolt, 3/8 x 1–1/2 inch

9. Short frame spacer

10. Right side bracket

Installing the Bagger Mounting Bracket to

the Side Brackets (Liquid Cooled)

Important When installing the bagger onto a liquid

cooled machine, the rear bumper plate must be removed.

Use 4 long frame spacers for this installation, 2 per each

side (Fig. 6).

1. Install the side brackets to the bagger mounting bracket

(Fig. 6).

2. In the top two holes, install 2 bolts (3/8 x 1–1/2 inch),

2 flange nuts (3/8 in.), 2 long frame spacers, and one

short frame spacer (Fig. 6).

Installing the Bagger Mounting Bracket

onto a Liquid Cooled Machine

1. Pull the bottom of the roll bar away from the frame and

slide the side braket between the machine frame and the

ROPS frame (Fig. 3). Repeat for the opposite side of the

machine.

2. Install the bagger mounting bracket to the rear frame of

the machine (Fig. 7).

3. In the top two holes, install 2 bolts (3/8 x 1–3/4 inch)

and 2 flange nuts (3/8 in.) (Fig. 7).

4. In the bottom two holes, install 2 bolts (3/8 x

1–1/4 inch) and 2 flange nuts (3/8 in.) (Fig. 7).

5

4

3

2

3

• Bolt (3/8 x 1–1/2 inch), curved washer, spacer and

flange nut (3/8 inch) (New).

1

5

2

5

2

1. Bagger mounting bracket

2. Bolt, 3/8 x 1–1/4 inch

3. Flange nut, 3/8 inch

Step

4

Figure 7

3

4. Bumper

5. Bolt, 3/8 x 1–3/4 inch

m–5864

• Bolt (3/8 x 1–1/2 inch), curved washer and

flange nut (3/8 inch) (New).

• Bolt (3/8 x 1–1/2 inch), curved washer and

flange nut (3/8 inch) (New).

Note: Make sure the curved washers and spacers are

installed as shown in figure 8.

Note: Hydraulic lines may need to be adjusted when

installing the side brackets onto the machine. This will

allow for fastener clearance.

4

6

5

6

32

Parts needed for this step:

• 6 Bolts, 3/8 x 1–1/2 inch

• 6 Flange Nuts, 3/8 inch

• 6 Curved washers

• 4 Spacers

Installing the Side Brackets to

the Machine

Important Do not tighten any bolts until both side

brackets and bagger mounting bracket are fit loose on the

machine.

Refer to Tightening the Mounting Bolts, on page 7, for the

correct procedure to tighten the bolts.

1. Install the bagger side plates and the roll bar sections

(Fig. 8) to each side of the mower using the following

fasteners:

• Lock nut (3/8 inch) and curved washer (Previously

removed).

• Bolt (3/8 x 4-1/2 inches), curved washer, spacer and

flange nut (3/8 inch) (Previously removed).

1

1. Side bracket

2. Curved washer, 3/8 inch

3. Bolt, 3/8 x 1–1/2 inch

2

Figure 8

4. Flange nut, 3/8 inch

5. ROPS

6. Spacer

6

Step

Step

5

No parts needed for this step.

Tightening all Mounting Bolts

The following steps are the correct sequence to tighten the

side brackets and the bagger mounting bracket.

All 3/8 inch mounting bolts need to be torqued to 35 ft.–lb.

(48 Nwm).

1. Tighten the bagger mounting bracket to the rear frame

first (Figures 5 or 7).

2. Tighten the bagger mounting bracket to the side

brackets (Figures 4 or 6).

3. Tighten the bracket stiffeners to both the side plates and

the bagger mounting bracket (Figures 4 or 6).

4. Tighten the side brackets to the side of the mower

(Fig. 8).

6

No parts needed for this step.

Installing The Drive Wheels

1. Mount the wheels with the valve stem to the outside and

secure them with the nuts previously removed (Fig. 9).

2. Torque the nuts to 95 ft-lb (128 Nm).

1

2

Figure 9

1. Drive wheel 2. Nuts

m–6859

3. Lower the machine onto the drive wheels.

7

8

Loading...

Loading...