Page 1

Reference Guide Kit

Dingo TX Compact Utility Loaders

Model No. 107-9310

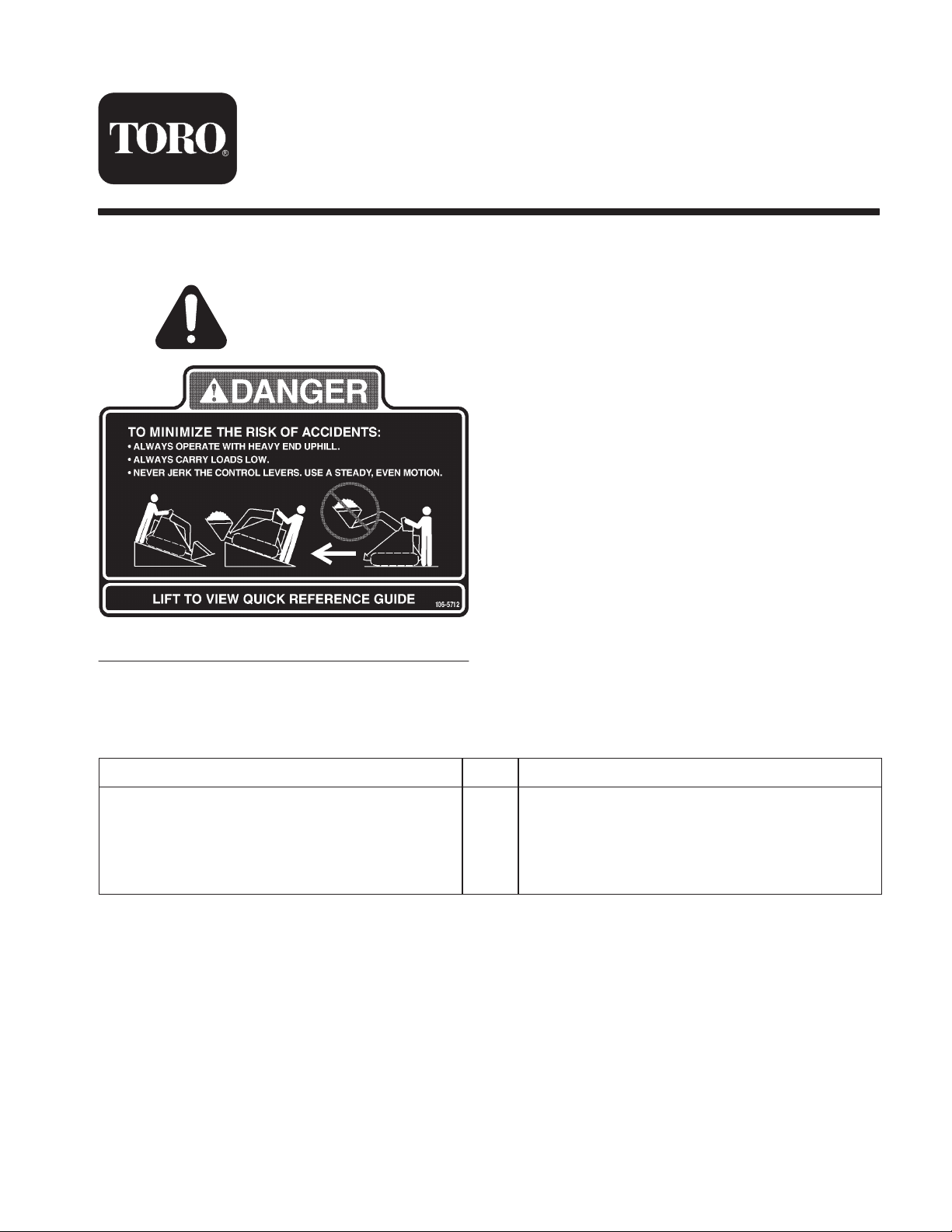

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any area

of potential danger. Replace any decal that is damaged or lost.

Form No. 3351-415

Installation Instructions

106-5712

Loose Parts

Note: Use the chart below to identify parts for assembly.

Description Qty. Use

Locking loop

Reference guide

Reference guide cover plate

Self tapping screw

1

1

Installing the reference guide

1

1

2004 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Original Instructions (EN)

Contact us at www.Toro.com

All Rights Reserved

Printed in the USA

Page 2

Installing the Reference Guide

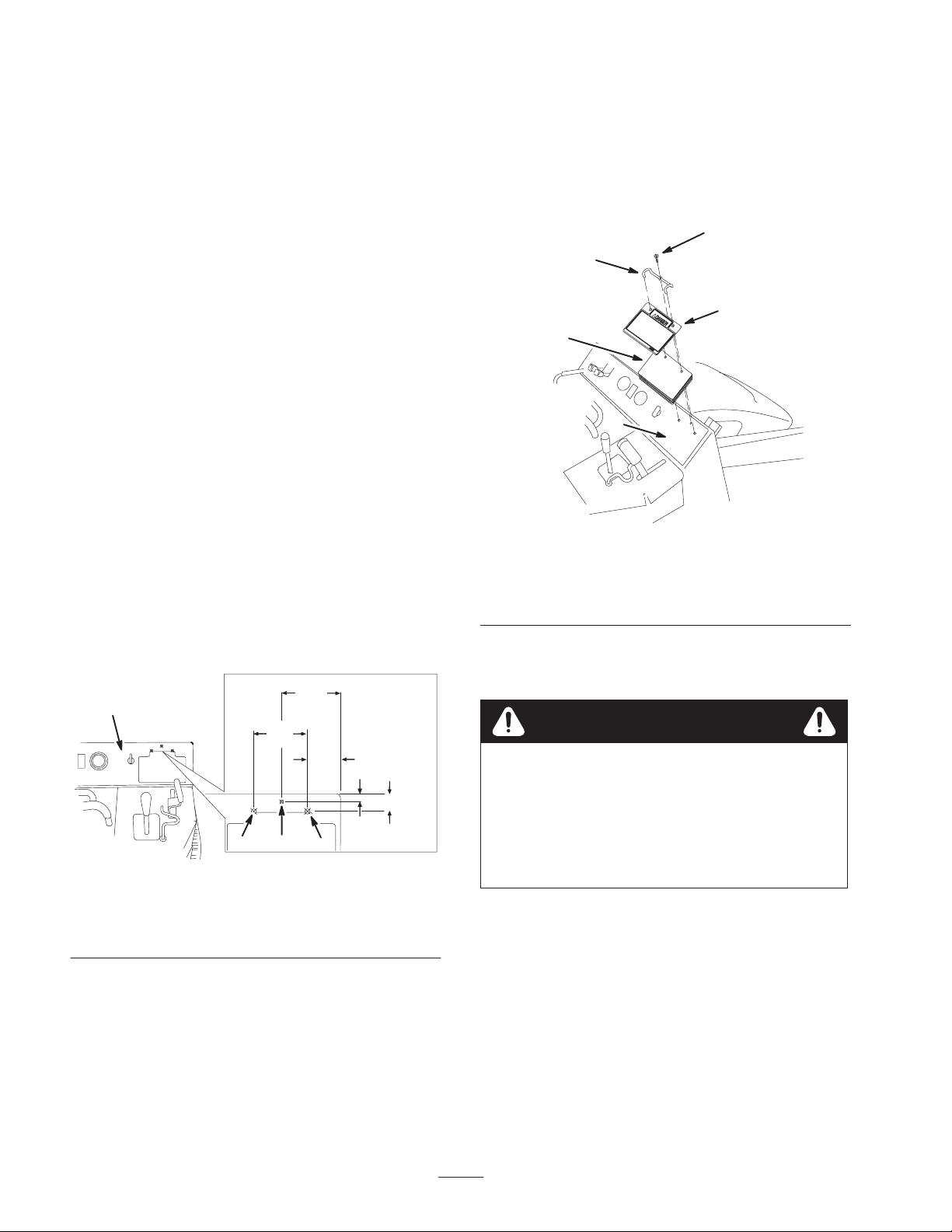

Note: Determine the left and right sides of the machine

from the normal operating position.

The Dingo TX Reference Guide contains essential

operation information found in the Operator’s Manual. The

Reference Guide compliments the information from the

Operator’s Manual, but does not replace it.

1. Lower the loader arms, stop the engine, engage the

parking brake, and remove the key.

4. Assembly the reference guide and install it to the

machine as shown in Figure 2.

Note: Be sure to have the metal cover displaying the safety

decal on top of the reference guide pages.

5. Secure the assembly to the control panel using the self

tapping screw and the center, smaller diameter, hole.

1

2

2. Clean the control panel of dirt and debris.

3. Check the underside of the control panel for existing

mounting holes in your unit in the locations shown in

Figure 1. If the mounting holes already exist, skip to

step 4. If the mounting holes are not present, follow the

procedure below to drill holes:

A. Measure out from the right side of the control panel

and mark a hole, 11/64 inch in diameter, to be

drilled for the self tapping screw as shown in

Figure 1.

B. Measure out from the right side of the control panel

and mark two holes, 9/32 inch in diameter, for the

locking loop posts as shown in Figure 1.

C. Place the center hole of locking loop over the hole

marked for the self tapping screw to verify the hole

marks for the locking loop posts are correct. Adjust

the marks accordingly if necessary.

D. Drill all holes as marked (Fig. 1).

4.03 in

(10.2 cm)

4.25 in

(10.8 cm)

2

3

1.9 in

(4.8 cm)

0.33 in

(0.8 cm)

1.33 in

(3.4 cm)

m–7605

1

3

Figure 1

1. Control panel

2. Self tapping screw hole,

11/64 inch diameter

3. Locking loop post hole,

9/32 inch diameter

3

4

5

m–7606

Figure 2

1. Screw, self tapping

2. Locking loop

3. Cover plate

4. Reference guide

5. Control panel

Using the Guide

Warning

Attempting to the read the Reference Guide while

operating the machine could result in a loss of

control, causing injury to the operator and/or

bystanders.

• Stop the machine and engage the parking brake

before using the guide.

Do not attempt to read the Reference Guide while

operating the machine.

Stop the machine and engage the parking brake before

accessing the reference guide.

2

Loading...

Loading...