Page 1

Conversion Kit

Z200 to Z500 DFS Bagger

Part No. 107–7650

Loose Parts

Note: Use the chart below to identify parts for assembly.

Step Description Qty. Use

Form No. 3351–335

Installation Instructions

1

2

3

4

5

6

7

No parts needed – Removing the bagger arm

Stop plate 1 Installing the stop plate

Bagger arm 1 Installing the bagger arm

Foam grip 2 Installing the latch lever

Cable

Long clevis, liquid cooled machines only

Short clevis

Clevis pin

Cotter pin

No parts needed – Adjusting the bagger arm

Pulley

Plate

Bearing housing

Key

Bolt, 3/8 x 5/8 inch

Spring washer, 3/8 inch

1

1

1

1

1

2

1

1

2

2

2

Installing the new cable

Installing the drive pulley assembly

Tensioner bracket template

8

9

10

11

2004 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Eyebolt template

Tensioner bracket 1

No parts needed –

No parts needed – Adjusting the bagger belt

1

1

1

Drilling holes for the idler bracket and

the eyebolt

Installing the tensioner bracket and the

eyebolt

Installing the bagger tensioner

assembly and the belt

Contact us at www.Toro.com

All Rights Reserved

Printed in the USA

Page 2

Step UseQty.Description

12

13

14

15

16

Step

No parts needed – Installing and adjusting the mower belt

Middle tube 1

Mounting plate 1

Boot

Middle tube

Flexible tube

Clamp

Weight

U–Bolt, 3/8 X 6 inch

Lock nut, 3/8 inch

Washer, 3/8 inch

Spacer

1

1

1

1

1

2

4

4

4

Installing hardware onto a new middle

tube

Installing the existing boot and brackets

to the new mounting plate

Installing the boot and discharge tubes

Installing the weight

5

2

4

7

8

1

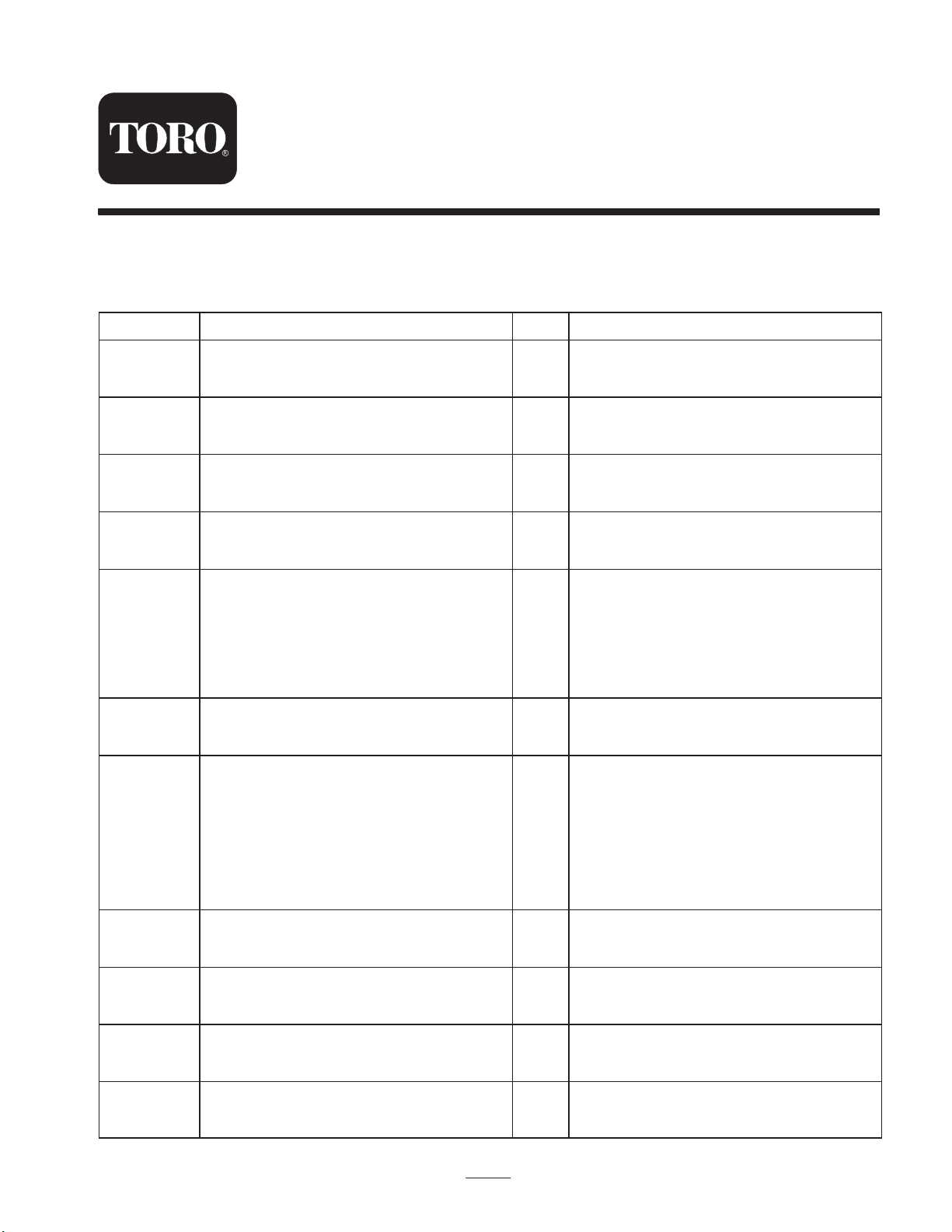

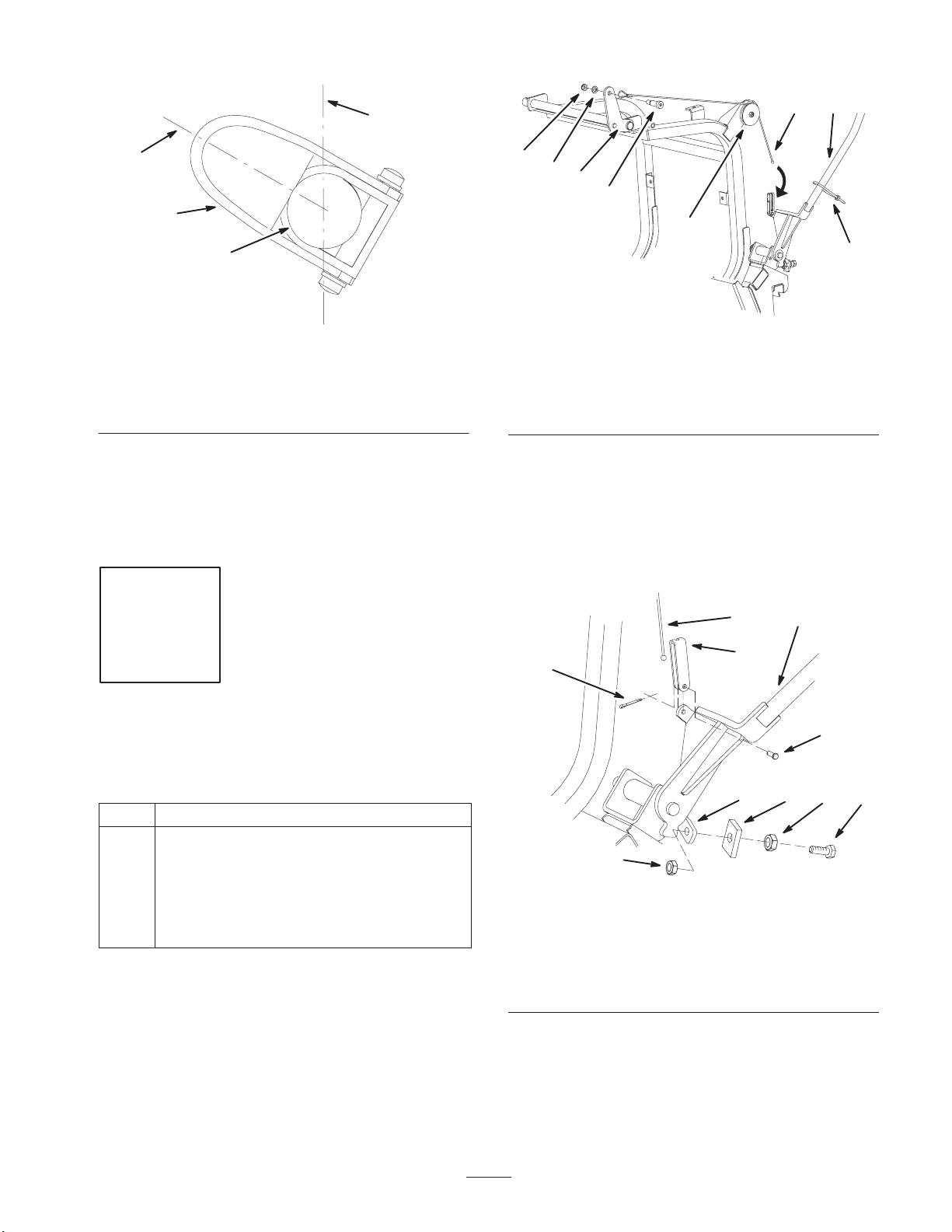

Removing the Existing Bagger

Arm

Parts needed for this step:

None

Procedure

1. Remove the shoulder bolt and cable from the bagger

arm (Fig. 1).

2. Loosen the nut and pulley on the bagger and remove the

cable from the pulley (Fig. 1).

3. Remove the cable from the bagger door hinge (Fig. 1).

Save all the hardware.

1

m–6136

Figure 1

1. Bagger arm

2. Cable

3. Shoulder bolt

4. Pulley and nut

4. Loosen the setscrew holding the latch lever (Fig. 6).

5. Remove the plastic cable ties on the handle and slide

the latch lever down the handle (Fig. 1).

5. Bagger door hinge

6. Cable tie

7. Latch lever

8. Grip

36

6. Remove the grip from the bagger arm (Fig. 3).

2

Page 3

7. Remove the cotter pin and washer from the bagger arm

(Fig. 2). Save the washer and cotter pin.

8. Slide the bagger arm and washer out from the bagger

frame (Fig. 2). Save the washer.

3

Step

2

Installing the Stop Plate

Parts needed for this step:

Qty. Part

1

Stop plate

2

m–6206

1. Bagger arm

2. Bagger

9. Remove the latch lever off of the bagger arm and

discard the the bagger arm (Fig. 3).

4

1

Figure 2

3. Cotter pin

4. Washer

2

1

4

Procedure

1. Remove the existing stop bolt and jam nuts from the

bagger frame (Fig. 4).

2. Install the stop plate to the stop bracket using the bolt

and jam nut previously removed (Fig. 4). Do not

tighten.

2

3

1

3

5

Figure 4

1. Bagger dump lever

2. Bagger cable

3. Bagger cable clevis

4. Bolt, 1/2 x 1–3/4 inch

5. Jam nut, 1/2 inch

6. Stop bracket

7. Stop plate

6

7

5

4

m–7513

1. Bagger Arm

2. Latch lever

m–7173

Figure 3

3. Foam grip

3

Page 4

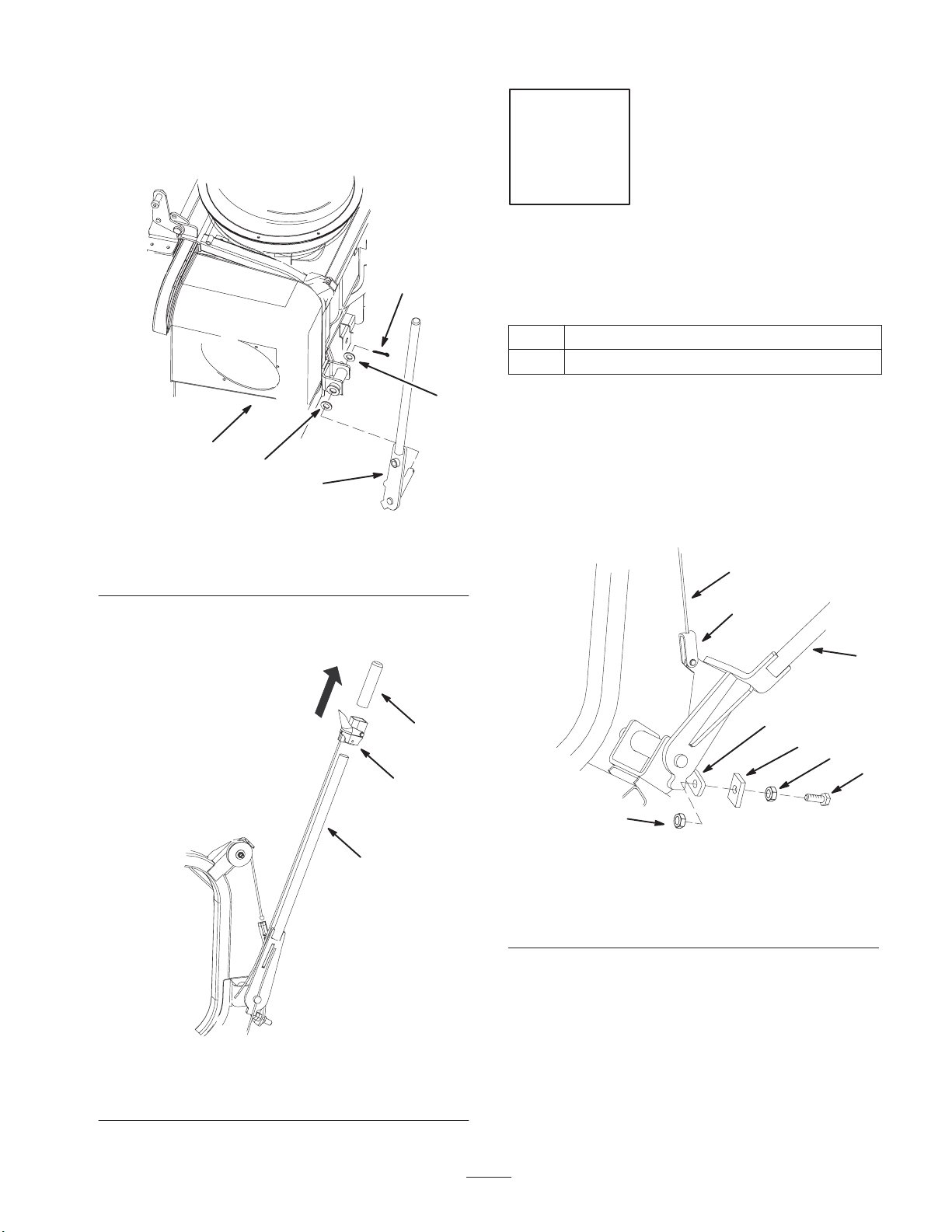

Step

Step

3

Installing the Bagger Arm

Parts needed for this step:

Qty. Part

1

Bagger arm

Procedure

1. Install the latch lever onto the bagger arm.

2. Install 1 washer previously removed onto the bagger

arm pivot and install the bagger dump handle into the

bagger frame (Fig. 5).

3. Secure the bagger handle with the previously removed

washer and cotter pin (Fig. 5).

4

Installing the Latch Lever

Parts needed for this step:

Qty. Part

1

Foam grip

Procedure

1. Position the latch lever 6 inches (15.2 cm) down from

the end of the bagger arm. See Figure 6.

5

214

1. Bagger arm pivot

2. Washer

Figure 5

3. Cotter pin

4. Bagger frame

m–7515

3

2

1. Bagger arm end

2. Latch lever position

3. Latch lever cable

2. Position the latch lever at the 10 o’clock position when

1

2

3

Figure 6

looking at the end of the handle (Fig. 7).

6

4

4. Set screw

5. Foam grip

6. 6 inches (15.2 cm)

m–7175

4

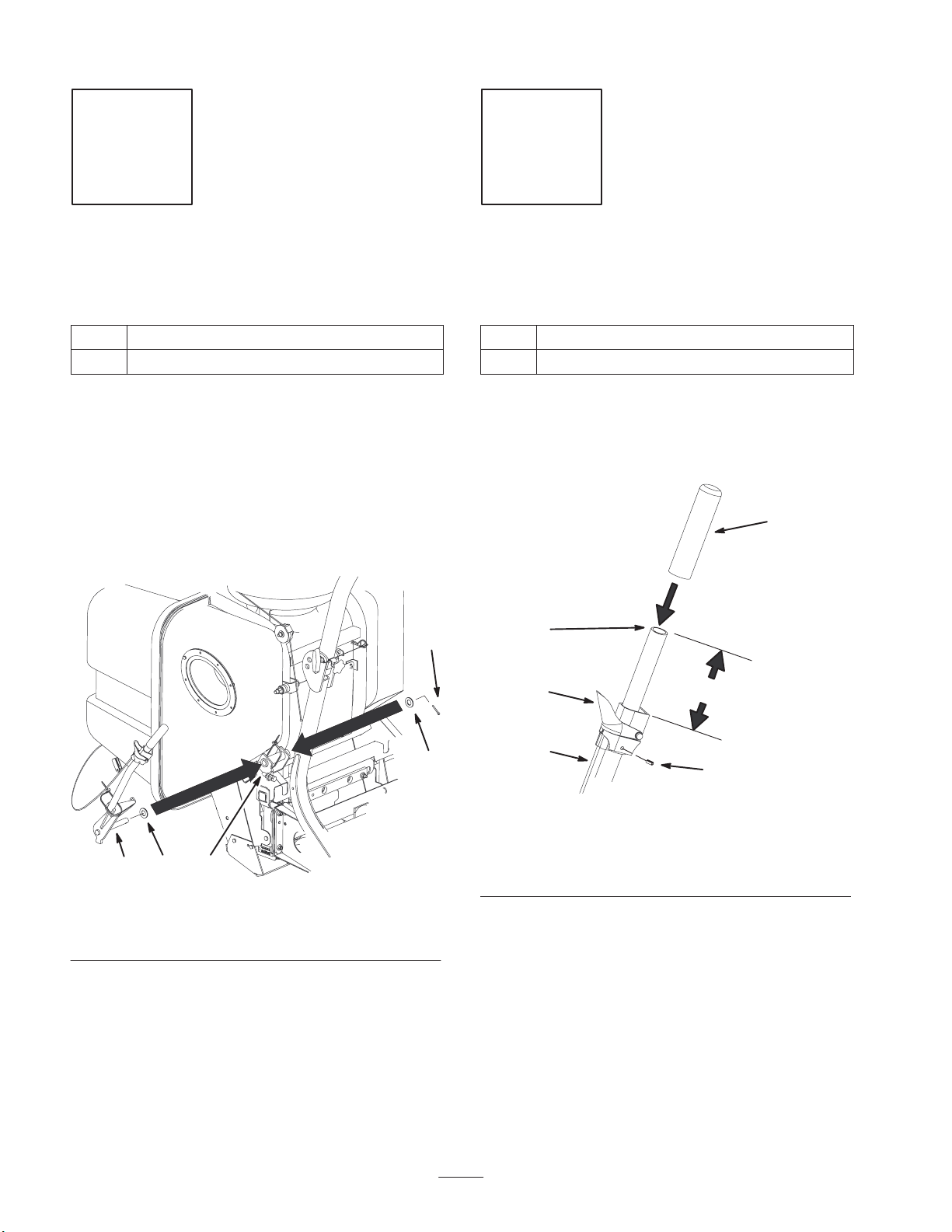

Page 5

2

1

4

3

1

2

m–7176

Figure 7

End view of handle

1. Latch lever

2. End of handle

3. 10 o’clock position

4. 12 o’clock position

3. Tighten the setscrew that holds the latch lever (Fig. 6).

4. Install the cable ties (Fig. 9).

5. Install the foam grip onto the bagger arm (Fig. 6).

Step

7

8

5

3

4

m–7178

Figure 8

1. Bagger arm

2. Cable

3. Shoulder bolt

4. Pulley and nut

5. Bagger door hinge

6. Cable tie

7. Nut

8. Washer

Note: Install the long cable clevis onto the bagger dump

handle if it is for a liquid cooled machine (Fig. 9).

3. Secure the bagger cable clevis to the bagger arm with

the clevis pin and cotter pin (Fig. 9).

4. Install the cable into the cable clevis installed on the

bagger handle (Fig. 9).

6

5

Installing the New Cable

Parts needed for this step:

Qty. Part

1

Cable

1 Long clevis, liquid cooled machines only

1 Short clevis

1 Clevis pin

1 Cotter pin

Procedure

1. Install the new cable to the top of the bagger with the

previously removed shoulder bolt, washer and nut

(Fig. 8).

2. Install the cable into the pulley and tighten the nut

(Fig. 8).

2

1

3

8

7

6

9

5 4

m–7520

5

Figure 9

1. Bagger dump lever

2. Bagger cable

3. Long cable clevis—liquid

cooled machines only

4. Bolt, 1/2 x 1–3/4 inch

5. Jam nut, 1/2 inch

6. Stop bracket

7. Clevis pin

8. Cotter pin

9. Stop plate

5. Adjust the handle stop, refer to Adjusting the Bagger

Arm, page 6.

5

Page 6

Step

Step

6

Adjusting the Bagger Arm

Parts needed for this step:

None

Procedure

The bagger arm needs to be adjusted to remove slack in the

bagger cable with the bagger door closed.

1. Loosen the nuts on both sides of the stop bracket

(Fig. 10).

2. Adjust the stop bolt until there is no slack in the bagger

cable (Fig. 10).

3. Tighten the nuts on both sides of the stop bracket

(Fig. 10).

1

7

Installing the Drive Pulley

Assembly

Parts needed for this step:

Qty. Part

2 Pulley

1 Plate

1 Bearing housing

2 Bolt, 3/8 x 5/8 inch

2 Spring washer, 3/8 inch

2 Key

Procedure

1. Remove the existing drive belts from the machine

(Fig. 21).

m–7514

1. Bagger dump lever

2. Stop bracket

3. Stop bolt

2. Remove the existing drive pulley assembly from the

machine (Fig. 11).

1 5 2645

3

Figure 10

4. Bagger cable

5. Nut

6. Stop plate

6

Page 7

5

1

7

8

9

7

6

9

8

10

2

4

2

1

7

5

6

3

m–6001

Figure 11

1. Rear frame

2. Drive pulley assembly

3. Bolt, 1/2 x 1–1/4 inch

4. Nut, 1/2 inch

5. Washer, 1/2 inch

6. Cut–out

7. Pulley plate

3. Remove the pulleys from the existing assembly.

4. Remove the plate from the existing bearing housing.

5. Install the new bearing housing and existing spacers to

the new plate (Fig. 12).

Note: Install the new small pulley nearest the cutout in the

plate (Fig. 12).

6. Install the new pulleys to the bearing housing with 2

bolts (3/8 x 5/8 inch), 2 spring washer (3/8 inch) and 2

keys (Fig. 12).

3

11

4

m–7495

Figure 12

1. New small pulley

2. New bearing housing

3. New plate

4. Bolt

5. Nut

6. Spacer

7. Bolt, 3/8 x 5/8 inch

8. Spring washer, 3/8 inch

9. Key

10. New large pulley

11. Cut–out

7. Install the mower belt onto the drive pulley assembly

(Figures 13 and 21).

Note: Make sure the cut–out in the pulley plate is on the

left–hand side of the machine (Fig. 11). This cut–out allows

room for the mower spring loaded idler pulley.

8. Install the pulley assembly under the rear frame, and

loosely install 4 bolts (1/2 x 1–1/4 inch), 4 washers

(1/2 in.) and 4 locknuts (1/2 inch) (Fig. 11). Do not

tighten bolts now.

Positioning the Drive Pulley Assembly on

an Air Cooled Machine

1. Push the drive pulley assembly all the way forward and

then rearward a 1/4 inch (6 mm) (Fig. 11).

Note: The bolt head on the drive pulley assembly, should

be approximately centered horizontally, in the frame slot

(Fig. 13). View this from the right–hand side of the

machine.

2. Tighten the 4 bolts (1/2 x 1–1/4 inch), 4 washers

(1/2 in.) and 4 locknuts (1/2 inch) (Fig. 11).

7

Page 8

Important A final adjustment may be needed when

installing the bagger belt.

Positioning the Drive Pulley Assembly on

a Liquid Cooled Machine

1. Pull the drive pulley assembly all the way rearward and

then forward a 1/4 inch (6 mm) (Fig. 11).

Step

8

Note: The bolt head on the drive pulley assembly, should

be approximately a 1/4 inch (6mm) rearward of the center

in the frame slot (Fig. 13). View this from the right–hand

side of the machine.

3

1

4

6

Figure 13

1. Drive pulley assembly

2. Bolt head—air cooled

machine only

3. Mower drive belt

2. Tighten the 4 bolts (1/2 x 1–1/4 inch), 4 washers

(1/2 in.) and 4 locknuts (1/2 inch) (Fig. 11).

Important A final adjustment may be needed when

installing the bagger belt.

4. Bolt head—liquid cooled

machine only

5. Frame slot

6. 1/4 inch—liquid cooled

5

2

m–5861

Drilling Holes for the Tensioner

Bracket and Eyebolt

Parts needed for this step:

Qty. Part

1

Tensioner bracket template

1 Eyebolt template

Procedure

1. Remove the four bolts in the skid plate (Fig. 14).

2. Remove the skid plate (Fig. 14). This will make it easier

to remove and install the hardware and belts.

1

2

m–6984

1. Bolts

2. Skid plate

4

Figure 14

3

3. Bagger tensioner

assembly

4. Existing tensioner bracket

3. Remove the existing bagger tensioner assembly from

the tensioner bracket (Fig. 14). Save the hardware.

4. Remove the existing tensioner bracket and eyebolt from

the bagger frame. Save the hardware.

5. Place the tensioner bracket template flush against the

wall and bottom of the bagger bracket and tight against

the side of the bagger bracket (Fig. 15).

8

Page 9

6. Align the eyebolt template with the existing hole in the

bagger frame (Fig. 15).

Note: Make sure the templates are tight against the bagger

frame (Fig. 15).

3

5

1

4

5

1

2

m–7491

Figure 15

1. Tensioner bracket

template

2. Eyebolt template

3. Bagger frame

4. Correct template position

5. Bagger wall

7. Using the templates, mark and center punch the holes.

8. Drill three 1/8 inch pilot holes into the frame (Fig. 16).

9. Remove the templates and discard them.

4

2

1. 9/32 inch hole to drill

2. 11/32 inch holes to drill

3. Bagger frame

2

3

1

m–7492

Figure 16

4. Tensioner bracket

template

5. Eyebolt template

10.Drill 2 holes, 11/32 inch diameter, into the 1/8 inch pilot

holes from the tensioner bracket template (Fig. 16).

11. Drill 1 hole, 9/32 inch diameter, into the 1/8 inch pilot

holes from the eyebolt template (Fig. 16).

9

Page 10

Step

Step

9

Installing the Tensioner

Bracket and Eyebolt

Parts needed for this step:

Qty. Part

1

Tensioner bracket

Procedure

1. Install the tensioner bracket to the bagger frame with

the previously removed nuts (Fig. 14).

2. Install the previously removed eyebolt with the

previously removed nuts (Fig. 14).

5

10

Installing the Bagger Tensioner

Assembly and Belt

Parts needed for this step:

None

Procedure

1. Install the bagger tensioner assembly to the tensioner

bracket with with the previously removed bolt, washers

and lock nut (Fig. 18).

7

3

4

1

1. Bolt

2. Eyebolt

3. Nut

Figure 17

4. New tensioner bracket

5. Bagger frame

3

3

2

m–7493

1. Bagger tensioner bracket

2. Eyebolt

3. Lock nut

4. Bolt

2. Install the bagger belt onto the drive pulley

(Fig. 20 and 21).

3. Route the bagger belt onto the bagger pulley

(Figures 19 and 20).

10

1

5

6

Figure 18

5. Washer

6. Bagger tensioner

7. Bagger frame

2

5

4

m–7496

assembly

Page 11

3

2

1

1

5

5

1. Tensioner spring

2. Eye bolt

3. Bagger tensioner pulley

4. Bagger pulley

Note: There should be a 1/4 twist in the belt when it is

installed onto the bagger tensioner pulley

4. Install the spring onto the idler arm (Fig. 19).

5. Install the tensioner spring onto the eyebolt attached to

the bagger (Fig. 19 and 22).

6. Adjust the bagger belt for proper tension. Refer to

Adjusting the Bagger Belt on page 11.

7. Adjust the Mower belt tension. Refer to Adjusting the

Mower Belt Tension on page 12.

8. Install the skid plate (Fig. 14).

3

Figure 19

5. Belt

6. Shortest space between

m–5887

belt strands, 1 inch

±1/8 inch

4

6

2

Figure 21

1. Drive pulley assembly

2. Mower belt

3. Bagger belt

4. Mounting bolts

5. Back of machine

Step

11

Adjusting the Bagger Belt

Parts needed for this step:

None

4

m–5892

1. Drive pulley

2. Bagger tensioner pulley

1

Figure 20

3. Bagger pulley

4. 1/4 twist

Procedure

1. Check the belt tension (Fig 22).

2. Measure the gap at the bagger tensioner pulley, between

the tight and slack side of the belt when the bagger

tensioner pulley and spring are installed (Fig. 22).

3

2

4

m–5773

3. There must be a gap of 1 inch ± 1/8 inch (26mm ± 3

mm) between the belt strands (Fig 22).

4. If the gap is not correct, remove the tensioner spring

from the eyebolt to remove the tension on the PTO

spring loaded idler (Fig 22).

5. Loosen the 4 mounting bolts holding the drive pulley

assembly (Fig 21).

6. If the gap measurement is too small, push the pulley

assembly forward slightly [1/8–3/16 inch (3–5 mm)]

from the original set–up position (Fig 21).

11

Page 12

7. If the gap measurement is too large, pull the pulley

assembly rearward slightly [1/8–3/16 inch (3–5 mm)]

from the original set–up position (Fig 21).

8. Tighten the 4 mounting bolts holding the drive pulley

assembly to the machine frame (Fig 21).

9. Install the tensioner spring to the eyebolt to apply

tension on the PTO spring loaded idler.

Step

12

10.Measure the bagger belt spacing. There must be a gap

of 1 inch ± 1/8 inch (26mm ± 3 mm) between the belt

strands (Fig 22).

11. Repeat this procedure if a gap of 1 inch ± 1/8 inch

(26mm ± 3 mm) was not achieved (Fig 22).

2

1

4

6

5

1. Tensioner spring

2. Eye bolt

3. Bagger tensioner pulley

4. Bagger pulley

3

Figure 22

5. Belt

6. Shortest space between

m–5887

belt strands, 1 inch

±1/8 inch

Installing and Adjusting the

Mower Belt

Parts needed for this step:

None

Procedure

1. Disengage the PTO, move the motion control levers to

the neutral locked position and set the parking brake.

2. Stop the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

3. Raise the mower to the transport position.

4. Ensure the mower belt is installed on all mower pulleys

(Fig 23).

Important Check the amount of twist in the belt

between the pulleys. Make sure it is only what is specified

in Figure 23.

1

3

3

5

2

1. Clutch

2. Mower belt

3. 1/4 turn belt twist

Important Check and make sure the belt is installed

into both the front and rear belt guides (Fig 24).

5. Check the belt tension. The spring loaded idler center

bolt needs to be near the top alignment hole in the left

support plate (Fig 24).

12

3

4

6

Figure 23

4. Belt guide

5. Mower spindle pulley

6. Mower idler pulley

4

3

m–6825

Page 13

Step

1

2

3

1

Figure 24

1. Center bolt

2. Alignment hole

6. If adjustment is required, loosen the mower idler plate

to adjust it (Fig. 25).

7. Insert a ratchet or breaker bar into the square hole in the

mower idler plate to adjust the tension (Fig. 25).

8. To increase belt tension, rotate the mower idler plate

until resistance is felt and rotation stops. Do not go past

when it stops (Fig. 25).

9. Tighten the idler plate bolts (Fig. 25).

3. Left support plate

4. Spring loaded idler

3

4

M–4417

13

Installing Hardware onto the

New Middle Tube

Parts needed for this step:

Qty. Part

1

Middle tube

Procedure

1. Remove the rubber latch, mounting bracket and the

hardware from the existing middle tube.

2. Install the rubber latch, mounting bracket to the new

middle tube with the existing hardware (Fig. 26).

1

2

m–6826

1. Mower idler plate

2. Square hole

1

Figure 25

3. Ratchet or breaker bar

4. Idler plate bolt

4

2

1. Middle tube

2. Existing rubber latch

3

4

4

m–7497

Figure 26

3. Existing mounting bracket

4. Hardware

13

Page 14

Step

4. Install the boot to the new mounting plate with exiting

hardware (Fig. 28).

14

Installing the Existing Boot and

Brackets to the New Mounting

Plate

Parts needed for this step:

Qty. Part

1

Mounting plate

Procedure

1. Remove the existing mounting plate from the boot.

Save the hardware.

2. Remove the existing mounting bracket and bracket

clamp from the existing mounting plate. Save the

hardware.

4

1

1. Boot

2. New mounting plate

Step

15

3

2

m–7499

Figure 28

3. Existing bolt

4. Existing nut

3. Install the existing mounting bracket and bracket clamp

to the new mounting plate (Fig. 27).

4

3 4

4

2

m–7500

1. New mounting plate

2. Existing mounting

bracket

1

Figure 27

3. Existing bracket clamp

4. Existing hardware

Installing the Boot and

Discharge Tubes

Parts needed for this step:

Qty. Part

1

Upper flexible tube

1 Middle tube

1 Boot

1 Clamp

Procedure

Note: Remember to replace the L or the straight end of the

spring when in side discharge mode.

1. Disengage the PTO and set the parking brake.

2. Stop the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

14

Page 15

3. To relieve the spring tension on the grass deflector,

place the L or the straight end of the spring in front of

the mounting bracket (Fig. 29).

4. Lift the grass deflector all the way back.

9

5. Position the boot’s front hook into the front slot on the

mounting bracket (Fig. 30).

1

2

m–7056

Figure 29

1. Grass deflector frame 2. Grind this part off

6. Place the rear hook over the rear of the mounting

bracket (Fig. 30).

7. Install the upper flexible tube into the bagger (Fig. 30).

8. Slide the clamp onto the upper flexible tube (Fig. 30).

4

1

8

6

5

1. Boot

2. Middle tube

3. Upper flexible tube

4. Latch

5. Mounting bracket

2

3

7

m–7498

Figure 30

6. Front slot

7. Rear hook

8. Front hook

9. Clamp

9. Slide the middle tube into the upper tube (Fig. 30).

10.Tighten the clamp around the upper and middle tube

connection (Fig. 30).

11. Slide the middle tube onto the boot and latch them

together (Fig. 30).

12.Adjust the flow baffle in the mower to match the

opening of the boot. Refer to your mower Operator’s

Manual.

15

Page 16

Step

2

16

Installing the Weight

Parts needed for this step:

Qty. Part

1

Weight

2 U–Bolt, 3/8 X 6 inch

4 Lock nut, 3/8 inch

4 Washer, 3/8 inch

4 Spacer

Procedure

1. Raise the foot pan and then remove the footrest from

the machine (Fig. 31).

2

1

m–7501

1. U–bolt

2. Single weight plate

3. Lock nut, 3/8 inch

6

Figure 32

1

4

5

3

4. Front caster

5. Spacer

6. Washer, 3/8 inch

4

3

M–6961

Figure 31

1. Footrest

2. Bolt

2. Install the single weight plate onto the machine frame

with 2 U–bolts (3/8 x 6 inch), 2 spacers, 2 washers

(3/8 inch), and 2 nuts (3/8 inch) (Fig. 32).

3. Install the footrest onto the machine and lower the

footpan (Fig. 31).

3. Nut

4. Machine frame

16

Loading...

Loading...