Page 1

Form No. 3350-456 Rev A

Roll Over Protection System Kit

100 Series Z Masters

Part No. 107–3066

Installation Instructions

Note: This kit is used for replacing an existing ROPS or adding it to a machine without an existing ROPS.

Loose Parts

Note: Use the chart below to identify parts for assembly.

Step Description Qty. Use

1

2

3

4

5

6

7

8

No parts needed – Raising the machine up

No parts needed – Removing the rear tires

Template 1 Drilling holes for the ROPS

No parts needed – Removing the existing seat

Seat frame 1 Installing the new seat frame

Seat latch catch

Bolt, 5/16 x 7/8 inch

Locknut, 5/16 inch

Seat belt

Bolt, 7/16 x 1 inch

Locknut, 7/16 inch

Roll bar, right section

Roll bar, left section

Roll bar, center section

Bolt, 3/8 x 1 inch

Curved washer, 3/8 inch

Flange nut, 3/8 inch

Bolt, 1/2 x 3-1/4 inches

Flange nut, 1/2 inch

Lanyard

1

2

2

1

2

2

1

1

1

8

8

8

2

2

2

Installing the new seat latch catch

Installing the seat belt

Installing the roll over protection system

(ROPS)

Domestic footrest decal

9

10

11

2003—The Toro Company

8111 Lyndale A ve., Blomington, MN 55420, USA

International footrest decal

International ROPS decal

Wheels 2 Installing the drive wheels

No parts needed – Checking the tire pressure

1

1

1

Printed in the USA

All Rights Reserved

Installing the Decals

Original Instructions (EN)

Register your product at www.Toro.com

Page 2

2

Step

1

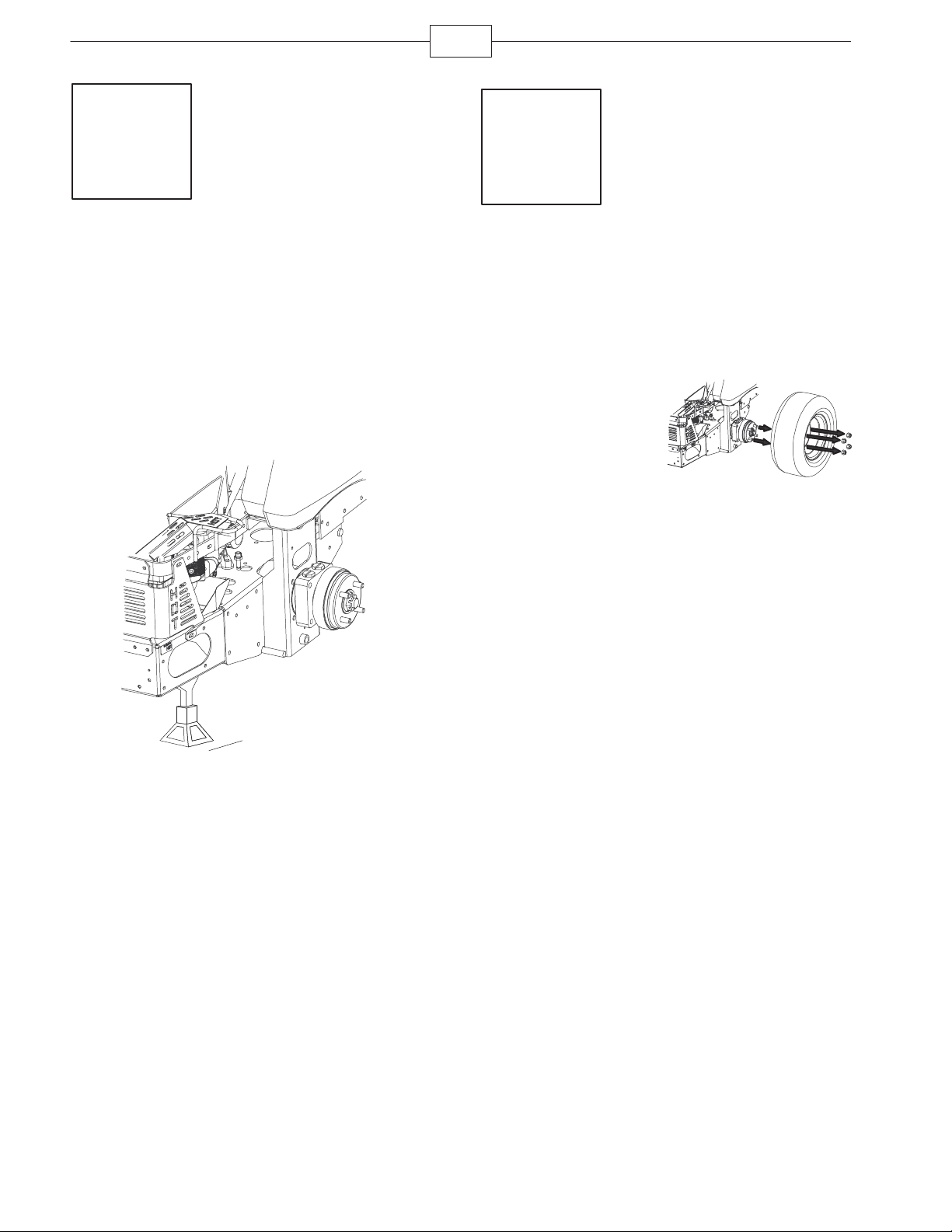

Raising the Machine Up

Parts needed for this step:

None

Procedure

1. Loosen the wheel nuts from both sides of the

vehicle.

2. Raise the back of the machine up and support it

with jack-stands.

Step

2

Removing the Rear Tires

Parts needed for this step:

None

Procedure

1. Remove the wheel

nuts from both sides of

the vehicle.

2. Remove the rear

wheels.

m–7026

m–6919

Page 3

Step

3

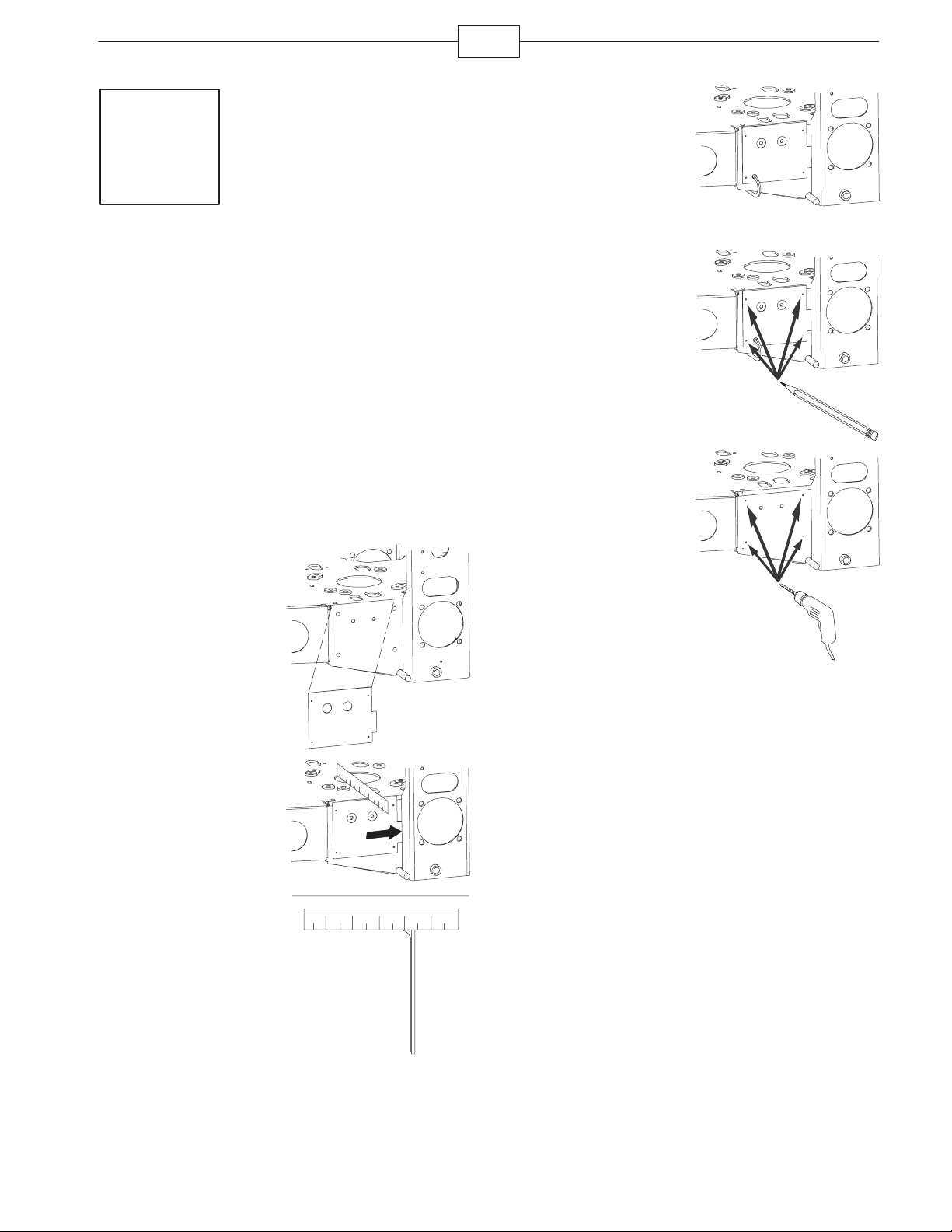

3

3. Clamp the template

into place.

Drilling Holes for the Roll

Over Protection System

(ROPS)

Note: If you are replacing an existing ROPS, this step

does not need to be performed.

Parts needed for this step:

Qty. Part

1 Template

Procedure

1. Place the template

to the side of the frame.

m–7035

4. Mark and center

punch the holes in the

template.

m–7033

5. Remove the

template and drill

1/8 inch pilot holes in

the marked locations.

6. Drill 13/32 inch

holes through the 1/8

inch pilot holes.

m–7034

7. Repeat this for the opposite side of the frame.

2. Align the template

flush to the top of the

frame and against the

wheel motor frame.

m–7032

m–7031

Page 4

4

Step

4

Removing the Existing Seat

Frame

Parts needed for this step:

None

Procedure

1. Remove the 2 bolts

and 2 locknuts at the

front of the seat where it

is hinged. Save the

hardware.

2. Remove the seat

assembly from the

machine.

5. Install the seat

retaining rod with the nut

and bolt previously

removed.

m–7036

3. Remove the nut and

bolt from the seat

retaining rod.

4. Remove the seat

frame from the existing

seat by removing the

four locknuts. Discard

the seat frame.

m–7021

m–7036

m–7023

Page 5

5

Step

5

Installing the New Seat

Frame

Parts needed for this step:

Qty. Part

1 Seat frame

Procedure

1. Install the seat to

the new seat frame with

the four locknuts

previously removed.

Step

6

Installing the Seat Latch

Catch

Parts needed for this step:

Qty. Part

1 Seat latch catch

2 Bolt, 5/16 x 7/8 inches

2 Locknut, 5/16 inch

m–7022

Procedure

1. Locate the existing holes in the right side of the

frame and drill the holes to 11/32 inch diameter.

2. Install the seat latch catch under the frame with 2

bolts (5/16 x 7/8 inch) and 2 locknuts (5/16 inch).

Note: The bent part of the latch catch should point

downward.

2. Install the seat at

the hinges with the 2

bolts and 2 locknuts

previously removed.

m–7029

m–7027

Page 6

6

Step

7

Installing the Seat Belt

Parts needed for this step:

Qty. Part

2 Seat belt

2 Bolt, 7/16 x 1 inch

2 Locknut, 7/16 inch

Procedure

1. Install the receiver

part of the seat belt

between the cushion

and the metal seat

frame with 1 bolt (7/16 x

1 inch) and 1 locknut

(7/16 inch).

Step

8

Installing the Roll Over

Protection System (ROPS)

Parts needed for this step:

Qty. Part

1 Roll bar, right section

1 Roll bar, left section

1 Roll bar, center section

8 Bolt, 3/8 x 1 inch

8 Curved washer

8 Flange nut, 3/8 inch

2 Bolt, 1/2 x 3-1/4 inches

2 Flange nut, 1/2 inch

2 Lanyard

2. Install the long seat

belt strap between the

cushion and the metal

seat frame with 1 bolt

(7/16 x 1 inch) and

1 locknut (7/16 inch).

m–7024

m–7025

Page 7

7

Procedure

1. Loosely install the right and left roll bar sections

to the frame, using 8 bolts (3/8 x 1 inch), 8 curved

washers, and 8 flange nuts (3/8 inch).

m–6916

3. Lightly oil the ends

of the center roll bar

section.

4. Loosely install the

center roll bar section,

using 2 bolts

(1/2 x 3-1/4 inches) and

2 flange nuts (1/2 inch).

Note: Make sure the

bolts are installed from

the outside of the roll

bar.

Note: Make sure the

lanyard tabs are install

as shown and point

forward.

5. Raise the roll bar

into the upright position

and secure it with the

pins and hairpin cotter

pins fastened to the

lanyards.

6. Torque all lower

fasteners, attached to

the machine frame, to

30 ft–lb.

m–6891

m–6893

2. Install the lanyard

clips onto the 2 bolts

(1/2 x 3-1/4 inches).

Note: Make sure the

bent tab points toward

the head of the bolt.

m–6892

7. Tighten the center

roll bar bolts

(1/2 x 3-1/4 inches) so

the roll bar rotates freely

with some resistance.

Note: No more than one

thread should be

exposed outside the nut.

m–6891

Page 8

8

5

8. Tighten the front

handles against the

center roll bar ends.

Step

m–683

Installing the ROPS Decal on

International Machines Only

1. Install the

international ROPS

decal over the existing

domestic decal on the

inside of the ROPS.

m–7028

Step

10

9

Installing the Decals

Parts needed for this step:

Qty. Part

1 Domestic footrest decal

1 International footrest decal

1 International ROPS decal

Installing the Footrest Decal on

Domestic and International

Machines

1. Install the footrest

decal onto the footrest

as shown.

m–7030

Installing the Drive Wheels

Parts needed for this step:

Qty. Part

2 Rear wheels

Procedure

1. Mount the wheels

with the valve stem to

the outside and secure

them with the nuts

previously removed in

Step 1.

2. Torque the nuts to

95 ft-lb (128 N⋅m).

m–6917

Loading...

Loading...