Page 1

Form No. 3356-419 Rev A

Standard Suspension Seat Kit

For Compact and Mid-Size Z Master® Mowers

Model No. 107–1892

Installation Instructions

Note: Deter mine the left and right sides of the mac hine from the nor mal operating position.

Loose Parts

Use the chart below to verify that all parts have been shipped.

Step

Z100/400 Switch and actuator

assembly

1

2

3

4

Z200/500 Actuator assembly

Bolt, (1/4 x 3/4 inch)

Flange nut, (5/16 inch)

Z100/400 Switch and actuator

assembly

Z200/500 Actuator assembly

Bolt, (1/4 x 3/4 inch)

Flange nut, (5/16 inch)

No parts required

Seat suspension assembly

Bolt, (5/16 x 1 inch)

Washer, (3/8 inch)

Locknut, (5/16 inch)

Seat stop 2

Flange nut, (5/16 inch)

Description

Step

Qty.

1

1

2

2

1

1

2

2

–

1

4

4

4

4

Install the seat switch assembly.

Install the seat switch for an EFI Z

Master.

Remove the seat.

Install the pulley assembly.

spring . It is necessar y to install the seat switc h

assembly included in this kit to ensure the proper

Use

function of the safety interloc k system.

1

Installing the Seat Switch

Assembly

Parts needed for this step:

1

Z100/400 Switch and actuator assembly

1

Z200/500 Actuator assembly

2

Bolt, (1/4 x 3/4 inch)

2

Flange nut, (5/16 inch)

Procedure

Installation of a seat suspension requires a new ,

long er seat switc h actuator that has a strong er

© 2007—The Toro® Company

8111 Lyndale Avenue South

Bloomington, MN 55420

Register at www.Toro.com. Original Instructions (EN)

If safety inter lock s witches ar e disconnected

or dama ged the machine could operate

unexpectedl y causing per sonal injur y .

• Do not tamper with the inter lock

s witches.

• Check the operation of the inter lock

s witches dail y and r eplace an y dama ged

s witches bef or e operating the machine.

1. Stop the engine , w ait for all mo ving par ts to

stop , and remo v e the ignition k ey .

2. Tip the seat forw ard and disconnect the

neg ati v e batter y cable .

Printed in the USA.

All Rights Reserved

Page 2

3. T he switc h is located on the rear frame of the

seat compar tment.

4. Disconnect the electrical wire har ness from the

existing seat switc h assembly b y pulling fir mly

on the connector . Use Figure 1 for Z100/400

series mo w ers and Figure 2 for Z200/500

series mo w ers .

5. R emo v e the seat switc h assembly b y remo ving

the tw o bolts and n uts that secure the switc h

to the frame . R etain the fasteners for later use

( Figure 1 or Figure 2 ).

6. Install the new seat switc h assembly using the

fasteners remo v ed previously .

Note: On the Z200/500 series only the

actuator is re placed and fasteners pro vided in

the assembly can be used ( Figure 2 ).

7. Install the electrical wire har ness connector to

the seat switc h.

Step

2

Installing the Seat Switch

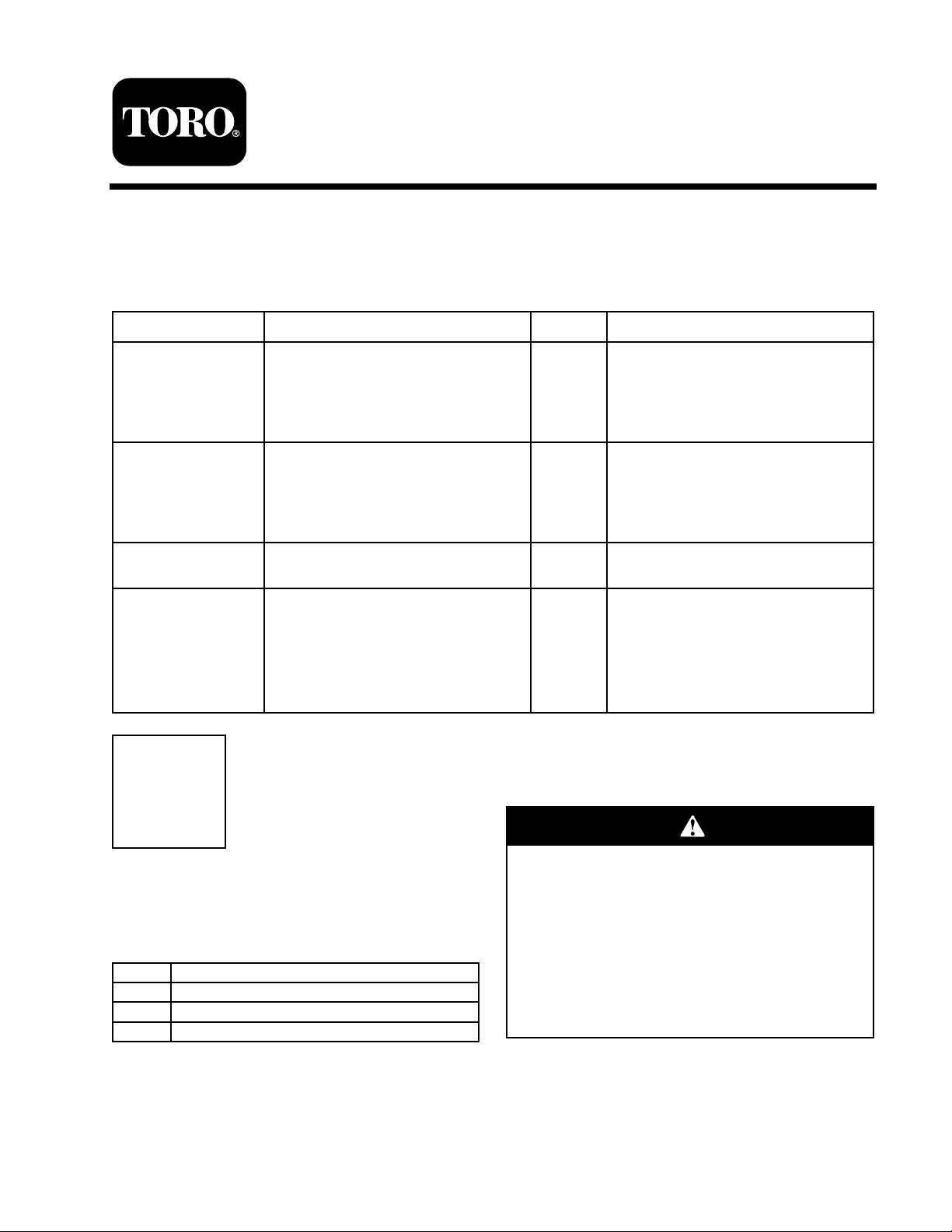

Figure 1

Z100/400 Series Only

1. Frame

2. Switch and catuator

assembly for Z100/400

Series

Note: T he Z100/400 series switc h assembly

v aries from the Z200/500 series actuator

assembly .

for an EFI Z Master

3. Bolt

4. Nut

Parts needed for this step:

1

Z100/400 Switch and actuator assembly

1

Z200/500 Actuator assembly

2

Bolt, (1/4 x 3/4 inch)

2

Flange nut, (5/16 inch)

Procedure

If y ou are re placing a delux e seat with a standard

seat and suspension on a Z Master unit with a

K ohler EFI engine , an actuator assembly and

switc h will not be present. Use the Z100/400

switc h and actuator assembly and the Z200/500

actuator included with this kit to install a new

actuator and switc h.

1. Stop the engine , w ait for all mo ving par ts to

stop , and remo v e the ignition k ey .

2. Tip the seat forw ard and disconnect the

neg ati v e batter y cable .

1. Frame

2. Switch and catuator

assembly for Z200/500

Series

Figure 2

Z200/500 Series Only

3. Disconnect the electrical wire har ness from the

operator presence switc h in the seat b y pulling

fir mly on the connector .

3. Bolt

4. Nut

4. R emo v e the switc h from Z100/400 actuator

and switc h assembly . R emo v e the tw o screws

and tapped plate to se parate the switc h from

the assembly ( Figure 3 ).

2

Page 3

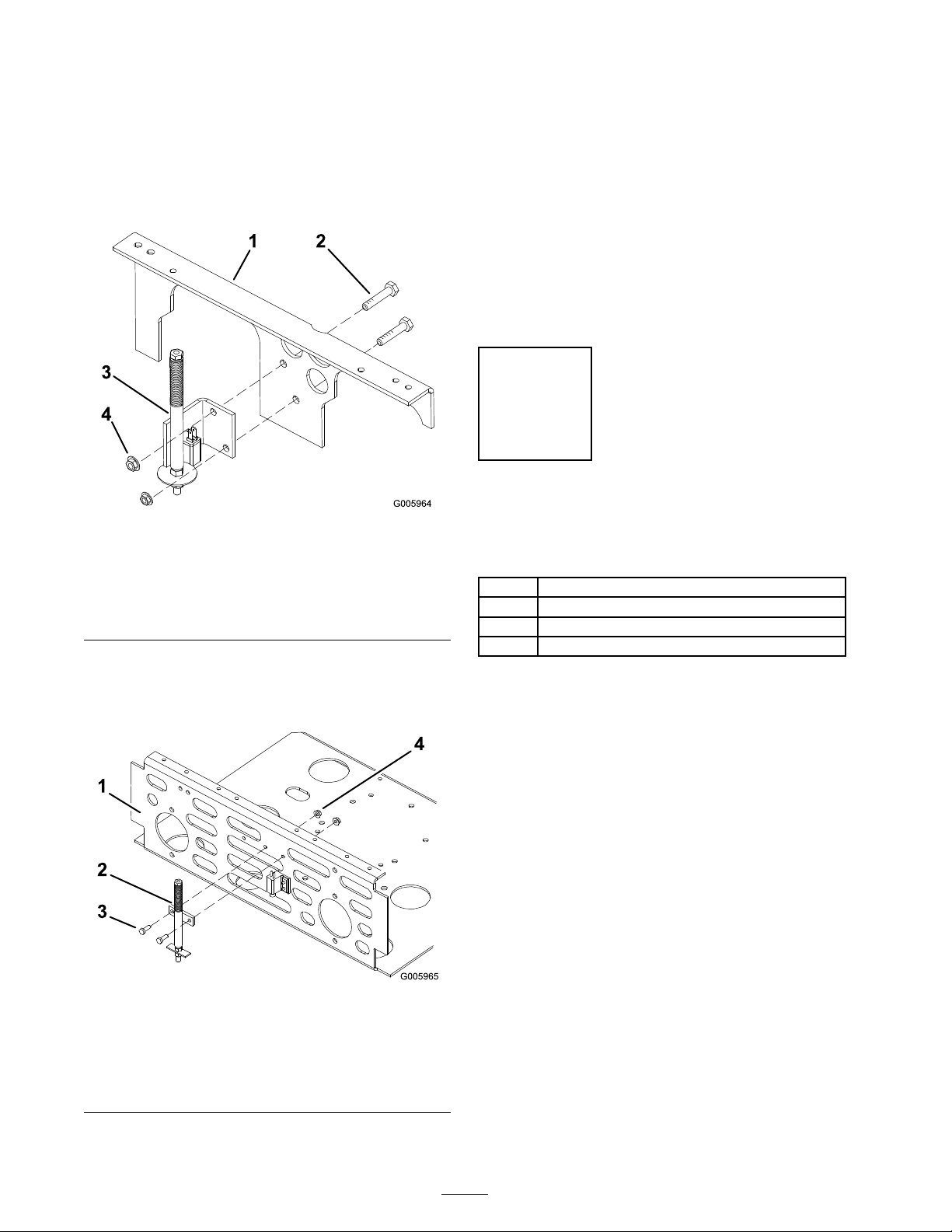

Figure 3

1. Atuator assembly for

Z100/400 Series

2. Screw

3. Switch

4. Tapped plate

5. Using the screws and the tapped plate , attac h

the switc h to the v er tical frame panel at the

rear of the compar tment under the seat as

sho wn in Figure 4 .

Unlatc h and remo v e the right belt co v er . Sa v e

this hardw are .

Step

3

Removing the Seat

No Parts Required

Procedure

Note: Clean the area around the right, rear

anti-scalp wheel.

1. Tip the seat forw ard and remo v e the tw o bolts

and w ashers holding the seat cushion to the

seat pan ( Figure 5 ). R etain the seat cushion

fasteners for later use .

6. Attac h the Z200/500 actuator assembly to

the v er tical frame panel at the rear of the

compar tment under the seat ( Figure 4 ) using

the tw o bolts (1/4 x 3/4 inc h) and tw o flang e

n uts (1/4 inc h) included in the assembly .

Figure 4

1. Frame

2. Z200/500 actuator

assembly

3. Bolt, (1/4 x 3/4 inch)

4. Tapped plate

5. Switch

6. Flange nuts, (1/4 inch)

7. Screws

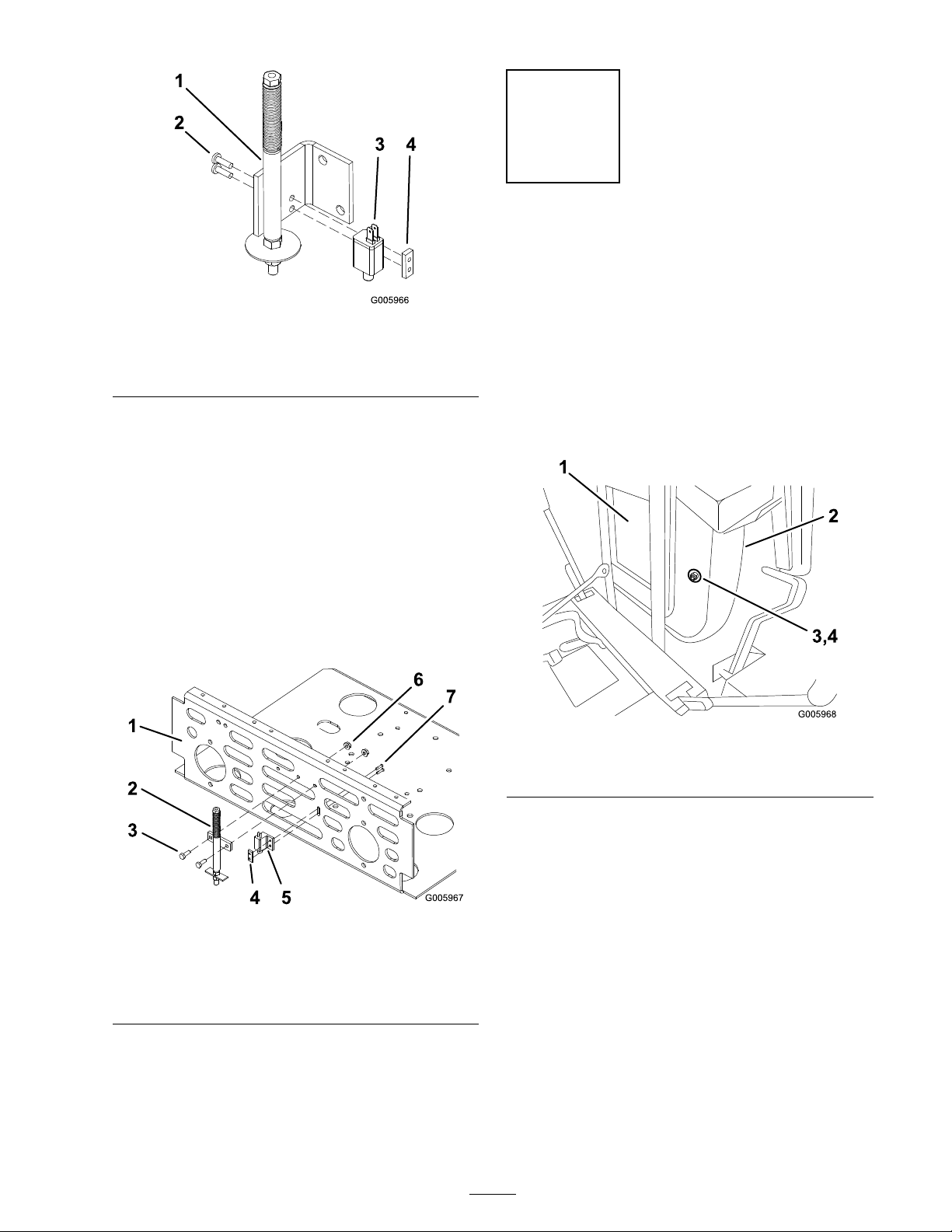

Figure 5

1. Seat cushion 3. Bolt, left and right side

2. Seat pan

4. Washer, left and right side

2. R emo v e the seat cushion and tip the seat bac k

do wn.

3. R emo v e the n uts holding seat pan to the seat

trac ks ( Figure 6 ). R emo v e the seat and set

aside . R etain the seat pan fasteners for later

use . Discard the conical spacers .

7. Install the wire har ness connector to the

switc h.

3

Page 4

Figure 6

1. Seat pan

2. Flange nuts

4. R emo v e the n uts holding the seat trac k to the

seat mounting frame . R etain the seat trac ks

and fasteners for later use ( Figure 7 ).

Step

4

Installing the Suspension

and Seat

Parts needed for this step:

1

Seat suspension assembly

4

Bolt, (5/16 x 1 inch)

4

Washer, (3/8 inch)

4

Locknut, (5/16 inch)

2 Seat stop

4

Flange nut, (5/16 inch)

Procedure

1. Place the seat stops on the seat mounting

frame so that the bent ends are facing up and

the slots are forw ard ( Figure 8 ).

2. Install the seat trac ks onto the seat stops and

mounting frame ( Figure 8 ).

Figure 7

1. Flange nuts 3. Seat mounting frame

2. Seat track

Note: Mak e sure the seat trac k with the

adjustment lev er is on the right side of the seat.

3. Use the four flang e n uts remo v ed previously to

secure the trac ks and stops to the seat frame .

4. Tip the seat frame do wn.

Note: If the pulley does not tur n, loosen

the bolts to raise the bolt heads and allo w the

pulley to loc k into position.

5. P osition the seat suspension assembly with the

front holes onto the studs in the seat trac ks and

the w eight adjustment knob facing the front

( Figure 8 ). Use the four flang e n uts remo v ed

previously to secure the seat suspension to the

trac ks . Note: If the seat suspension has tw o

sets of mounting holes , use the outside set of

mounting holes .

6. Install the seat pan to the seat suspension with

four bolts (5/16 x 1 inc h), four w ashers (3/8

inc h), and four loc k n uts (5/16 inc h) included

in the suspension assembly .

7. Tilt the seat frame and suspension up .

8. Install the seat cushion to the seat pan using the

existing bolts and w ashers remo v ed previously .

9. After the suspension and seat are installed,

c hec k for proper adjustment of the seat switc h

4

Page 5

actuator rod length. See Adjusting the Seat

Actuator .

1. Pull the suspension adjustment knob out

(forw ard) to adjust the seat.

2. T ur n the knob in the direction indicated on the

label to ac hiev e the desired lev el of suspension.

Note: Initially adjust the setting so that the

seat barely mo v es when the operator slo wly

sits do wn.

3. Push the knob bac k in (rearw ard) when

adjustment is completed.

Adjusting the Seat Actuator

If necessar y , adjust the length of the seat actuator

rod so that the safety interloc k system functions

properly . T he mac hine , with the brak e diseng ag ed

or the PTO eng ag ed, should shut off when the

operator rises of the seat, but will contin ue to r un

when the operator shifts their w eight while in the

seat.

1. Tip the seat forw ard to access the seat switc h

and actuator .

Figure 8

1. Seat cushion 7. Seat tracks

2. Seat pan

3. Flange nut, (5/16 inch)

4. Suspension

5. Washer, (3/8 inch)

6. Bolts, (5/16 x 1 inch)

Operation

Adjusting the Suspension

2. Loosen the bottom loc k n ut of the actuator

rod.

3. Loosen the top n ut and mo v e the w asher/plate

to the desired position.

4. Tighten the n uts .

5. T est the seat to ensure the safety system

functions properly .

Note: R e peat the adjustment procedure if

necessar y .

8. Adjustment lever

9. Seat stops

10. Seat frame

11. Slot

Seat

T here are appro ximately 40 rev olutions needed

to c hang e the suspension setting from the softest

to the most stiff setting .

5

Page 6

Page 7

Page 8

Loading...

Loading...