Page 1

DeluxeSuspensionSeatKit

Z100,Z200,Z400andZ500SeriesZMaster

ModelNo.78530or107–1891

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3365-958RevA

®

Mowers

InstallationInstructions

ProcedureDescription

1

2

3

4

5

6

1

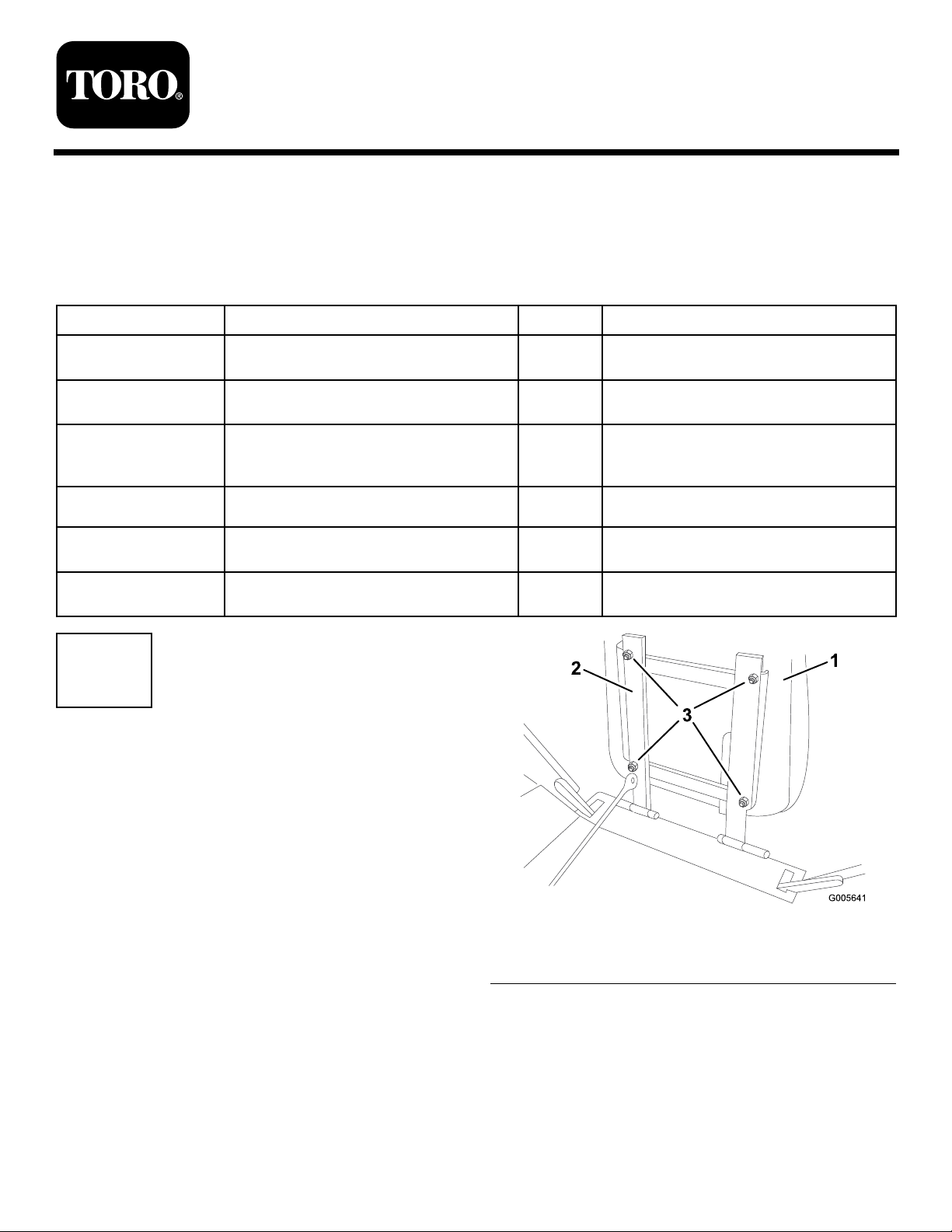

RemovingtheSeat

Qty.

Nopartsrequired

Bolt(7/16x1inch)

Deluxesuspensionseat1

Spacer(2holesforZ200/Z500Series)

Spacer(3holesforZ100/Z400Series)

Wireharness1

Plasticties

Nopartsrequired

Decal1Installthedecal.

–

2Installtheseatbelt.

2

2

5

–

Removetheseat.

Installtheseat.

Installthewireharness.

Testthesafetyinterlocksystem.

Use

NoPartsRequired

Procedure

1.Unlatchtheseatandtiptheseatforward.

2.Removethenutsholdingtheseattothemounting

frame(

3.Removetheseatfromtheframeandsetitaside.

©2010—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1).Retainthenuts.

Registeratwww.Toro.com.

1.Seat

2.Seatframe

Figure1

3.Nut

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

Page 2

2

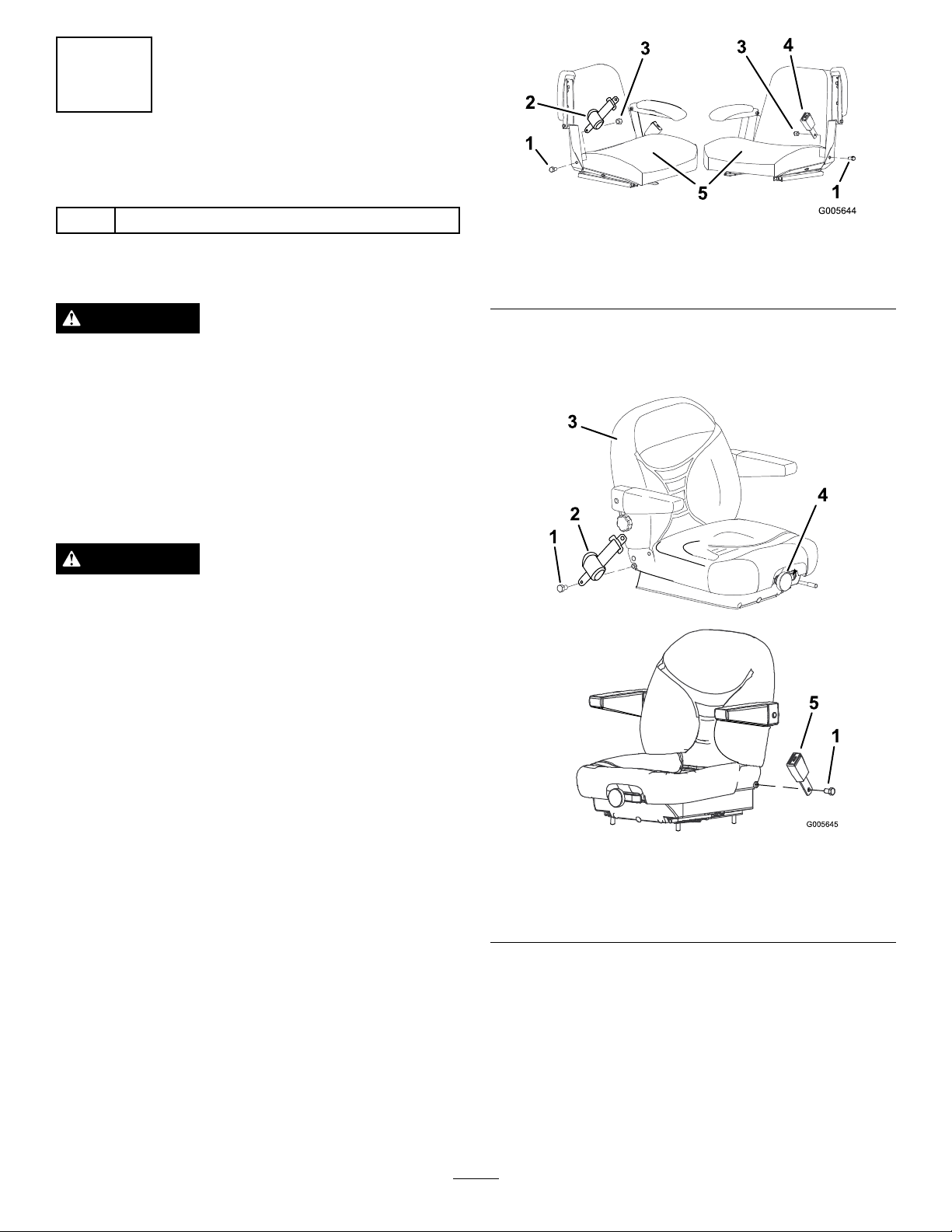

InstallingtheSeatBelt

Partsneededforthisprocedure:

2

Bolt(7/16x1inch)

Procedure

Figure2

1.Bolt

2.Seatbeltretractor5.Seat

3.Nut

4.Seatbeltreceiver

WARNING

Seriousinjuryordeathcanhappenwhentheseat

beltisusedwithoutarollbarinstalled.

Donotinstalltheseatbeltwithoutarollbar

installed.

Ifyoudonothavearollbar,contactanAuthorized

ServicedealertoobtainthecorrectRollOver

ProtectionSystem(ROPS).

WARNING

Toavoidinjuryordeathfromrollover:keepthe

rollbarintheraisedlockedpositionandusethe

seatbelt.

Ensurethattherearpartoftheseatissecuredwith

theseatlatch.

Thedeluxesuspensionseatdoesnotcomeequipped

withseatbeltrestraints.Ifyouareinstallingthe

deluxeseatonamachinewithaRollOverProtection

System(ROPS),theexistingseatbeltrestraintsmustbe

transferredfromtheoldseat.

2.Installtheseatbeltretractorandreceivertothe

deluxeseatusingthe2bolts(7/16x1inch)(Figure5

&Figure3).

Donotinstallandusetheseatbeltwithoutarollbar

installed.ContactanAuthorizedServicedealertoobtain

thecorrectRollOverProtectionSystem(ROPS).

1.Removetheseatbeltretractorandreceiverfromthe

standardseatbyremovingthenutandboltsecuring

thebeltassembliestotheseat(

Figure2).

Figure3

1.Bolt,(7/16x1inch)4.Suspensionadjustment

knob

2.Seatbeltretractor5.Seatbeltreceiver

3.Seat

2

Page 3

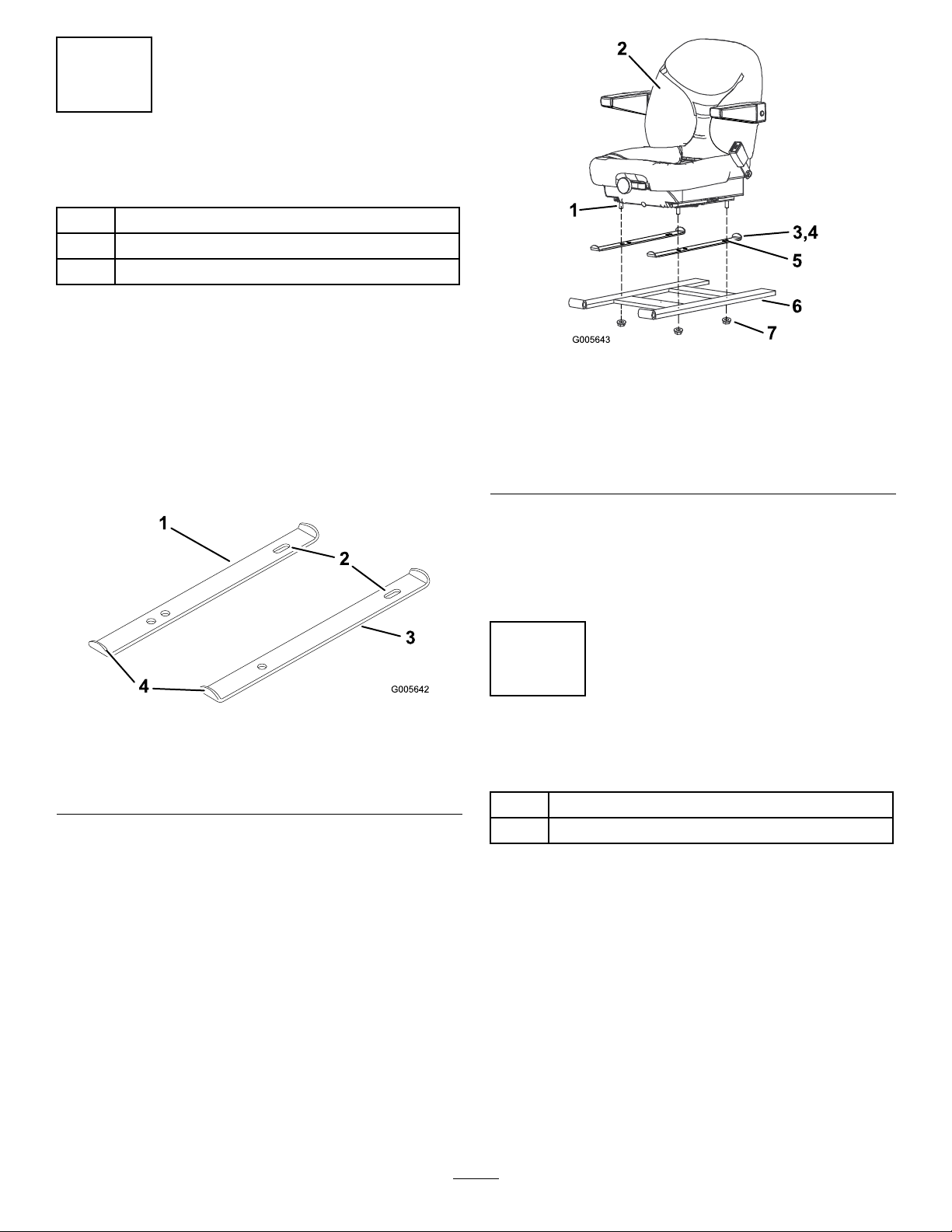

3

InstallingtheSeat

Partsneededforthisprocedure:

1Deluxesuspensionseat

2

Spacer(2holesforZ200/Z500Series)

2

Spacer(3holesforZ100/Z400Series)

Procedure

1.Placethespacersontheseatmountingframewith

thebentendsfacingup.Theslotinthespaceris

installedtothebackoftheseat(Figure4).

Note:ZMaster100or400Seriesmodelsare

installedwithspacersthathave3holes.ZMaster

200or500Seriesmodelsareinstalledwithspacers

thathave2holes(

1.Spacer—3holesforZ100

orZ400seriesmodels

2.Slot—installtobackof

seat

2.Removethepackingcoversguardingtheseattrack

studs.

Figure4).

Figure4

3.Spacer—2holesforZ200

orZ500seriesmodels

4.Bentends

Figure5

1.Seattrackstuds5.Slot

2.Seat6.Seatmountingframe

3.Spacer(2holesforZ200

orZ500seriesshown)

4.Spacer(3holesforZ100

orZ400seriesmodels)

Note:Iftheseatmountingframehastwosetsof

mountingholes,usethefrontsetofmountingholes.

4.Securetheseattotheseattrackswiththenuts

removedpreviously(Figure5).

7.Nut

4

InstallingtheWireHarness

Partsneededforthisprocedure:

1Wireharness

5

Plasticties

3.Positionthenewseatwiththeseattrackstudsinthe

spacersandseatmountingframe(

Figure5).

Procedure

1.Locateanddisconnectthewireharnessconnectors

thatareattachedtooldseatswitch(Figure7).

Note:Ensuretheoldswitchisremovedfromthe

machine.

2.Removetheexistingseatswitch,bolt,spring,switch

bracket,andnuts(

3

Figure7).

Page 4

WARNING

G013786

1 2

3

Ifthesafetyinterlockswitchesareboth

connectedthemachinecouldoperate

unexpectedlycausingpersonalinjury.

•Ensuretheoldswitchisremovedfromthe

machine.

•Ensurethenewharnessisconnectedtothe

newseatswitchintheseat.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitches

beforeoperatingthemachine.

3.Ifyourmachinehasasingleconnectorfromthe

oldswitch,removetheplastictieholdingthewire

harnesstotheframeneartheseatswitch(Figure7).

Reconnecttheotherexistingwirestomachineframe.

4.Plugthesingleconnectorendofthenewwire

harnessintotheconnectorthatwasremovedfrom

theoldseatswitch(

5.Ifyourmachinehastwoleadsfromtheoldswitch,

foldoverthewireleadsandsecurethemwitha

plastictiecable(Figure6).Donotusethesewire

leads.

6.Ifyourmachinehastwoleadsfromtheoldswitch,

locatethesingleconnectorinthemainharnessnear

thecontrolpanel.Plugthenewharnessintothe

singleconnectorfromthemainharness(

Figure7).

Figure6).

Kubotapoweredmachineshown

1.Plastictiecable

2.Twowireleadsfromthe

oldswitch

Figure6

3.Singleconnectorfrom

mainharness(only

onmachineswithtwo

connectorsfromold

switch).

7.Positionthewireharnessalongtheseathold-uprod,

overtotheseatmountingframeanduptothenew

switch,locatedunderseat(

Figure7).

8.Attachthetwoconnectorsofthenewwireharness

intothenewseatswitch(Figure7).

9.Moveseattothefurthestrearposition.Usethethree

plastictiestoattachthewireharnesstoseatholdup

rodandseatmountingframe(

Figure7).

10.Carefullylowertheseatdownandensuretheharness

doesnotgetpinched.Ifitdoes,repositionthe

plasticties.

4

Page 5

G013785

9

11

12

13

14

15

5

TestingtheSafetyInterlock

System

NoPartsRequired

Procedure

WARNING

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Thesafetyinterlocksystemisdesignedtopreventthe

enginefromstartingunless:

Figure7

1.Removeexistingplastic

tieandreplacewhendone

2.Seathold-uprod10.Seatmountingframe

3.Singleconnectorfromold

seatswitch

4.Singleconnectoronnew

harness

5.Plasticties

6.Newwireharness14.Nuts

7.Newseatswitch

8.Twoconnectorsfromnew

harness

9.Oldseatswitchbracket

assembly

11.Bolt

12.Spring

13.Switchbracket

15.Oldseatswitch(remove)

•Theparkingbrakeisengaged.

•Thepowertakeoff(PTO)isdisengaged.

•Themotioncontrolleversareintheneutrallocked

position.

Thesafetyinterlocksystemalsoisdesignedtostopthe

enginewhenthetractioncontrolsaremovedfromthe

lockedpositionwiththeparkingbrakeengagedorifyou

risefromtheseatwhenthePTOisengaged.

Testthesafetyinterlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnotoperate

asdescribedbelow,haveanAuthorizedServiceDealer

repairthesafetysystemimmediately.

1.Sittingontheseat,engagetheparkingbrakeand

movethePTOtoon.Trystartingtheengine;the

engineshouldnotcrank.

2.Sittingontheseat,engagetheparkingbrakeand

movethePTOtooff.Moveeithermotioncontrol

lever(outofneutrallockedposition).Trystarting

theengine;theengineshouldnotcrank.Repeatfor

othercontrollever.

3.Sittingontheseat,engagetheparkingbrake,move

thePTOswitchtooffandmovethemotioncontrol

leverstoneutrallockposition.Nowstarttheengine.

Whiletheengineisrunning,releasetheparking

brake,engagethePTOandriseslightlyfromthe

seat;theengineshouldstop.

4.Sittingontheseat,engagetheparkingbrake,move

thePTOswitchtooffandmovethemotioncontrol

5

Page 6

leverstoneutrallockposition.Nowstarttheengine.

Whiletheengineisrunning,centereithermotion

controlandmove(forwardorreverse);theengine

shouldstop.Repeatforothermotioncontrol.

Operation

AdjustingtheSuspension

5.Sittingontheseat,disengagetheparkingbrake,

movethePTOswitchtooffandmovethemotion

controlleverstoneutrallockposition.Trystarting

theengine;theengineshouldnotcrank.

6

InstallingtheDecal

Partsneededforthisprocedure:

1Decal

Procedure

Removethebackingoffthedecalandplacethedecalon

thebackoftheseatasshowninFigure8.

Seat

Usetheadjustmentknobandweightgaugelocatedin

thefrontoftheseattoadjusttheseatsuspensiontothe

weightoftheoperator

Figure3.

1.Backofseat

Figure8

2.Decal

6

Page 7

Notes:

7

Page 8

Loading...

Loading...