Page 1

Track Guide Refit Kit

Dingo TX 425 Wide Track Compact Utility Loader

Model No. 106-7720, 106-7721, 106-7722

Determine the left and right sides of the traction unit from the operator’s position.

Loose Parts

Description Qty. Use

Form No. 3351-896

Installation Instructions

Track guide

Road wheel

Snap ring, internal

Gasket

Bolt, 5/8 x 1-1/2 inch

Wheel cap

Guide adapter plate, right-hand

Guide adapter plate, left-hand

Carriage bolt, 1/2 x 1-1/4 inch

Locknut, 1/2 inch

Clamp plate

1

1

1

1

1

Hex flush screw, 1/2 x 1-1/2 inch

Bolt, 1/2 x 1-1/4 inch

Lockwasher, 1/2 inch

Track

1

Used in track guide refit on machines within Serial No. range 220000001-220000400 only.

1

10

10

10

10

10

1

1

3

3

1

2

4

4

1

Install the track guide.

W 2004 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Original Instructions (EN)

Contact us at www.Toro.com

All Rights Reserved

Printed in the USA

Page 2

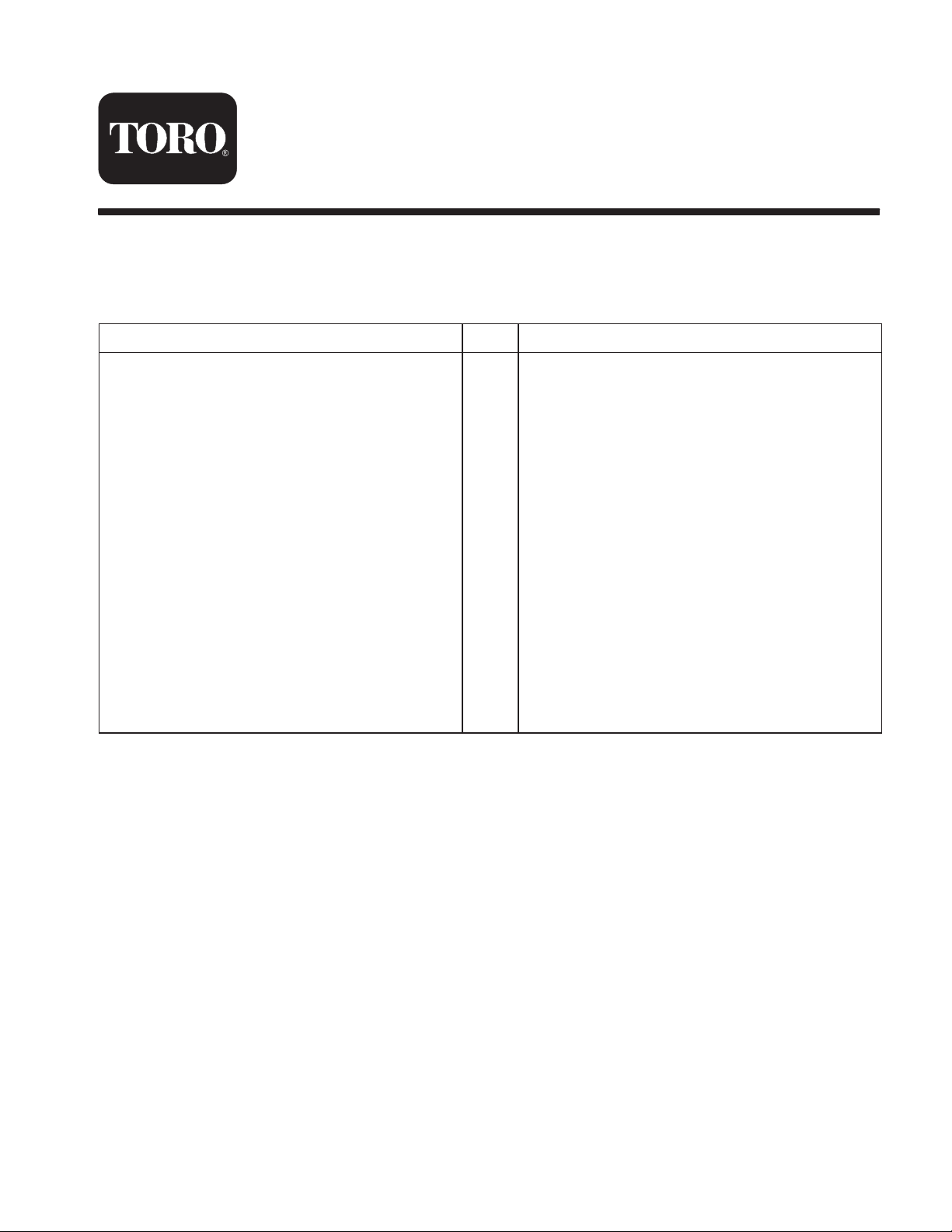

Track Guide Refit:

Serial No. 220000001- 220000400

The Dingo TX 425 Compact Utility Loaders with serial

numbers that range from 220000001 to 220000400 have an

offset track guide and this kit contains both left-hand and

right-hand adapter plates. The following procedure depicts

the track guide refit on the left-hand side; however, it can

be used to refit the track guide on either side.

Preparing the machine

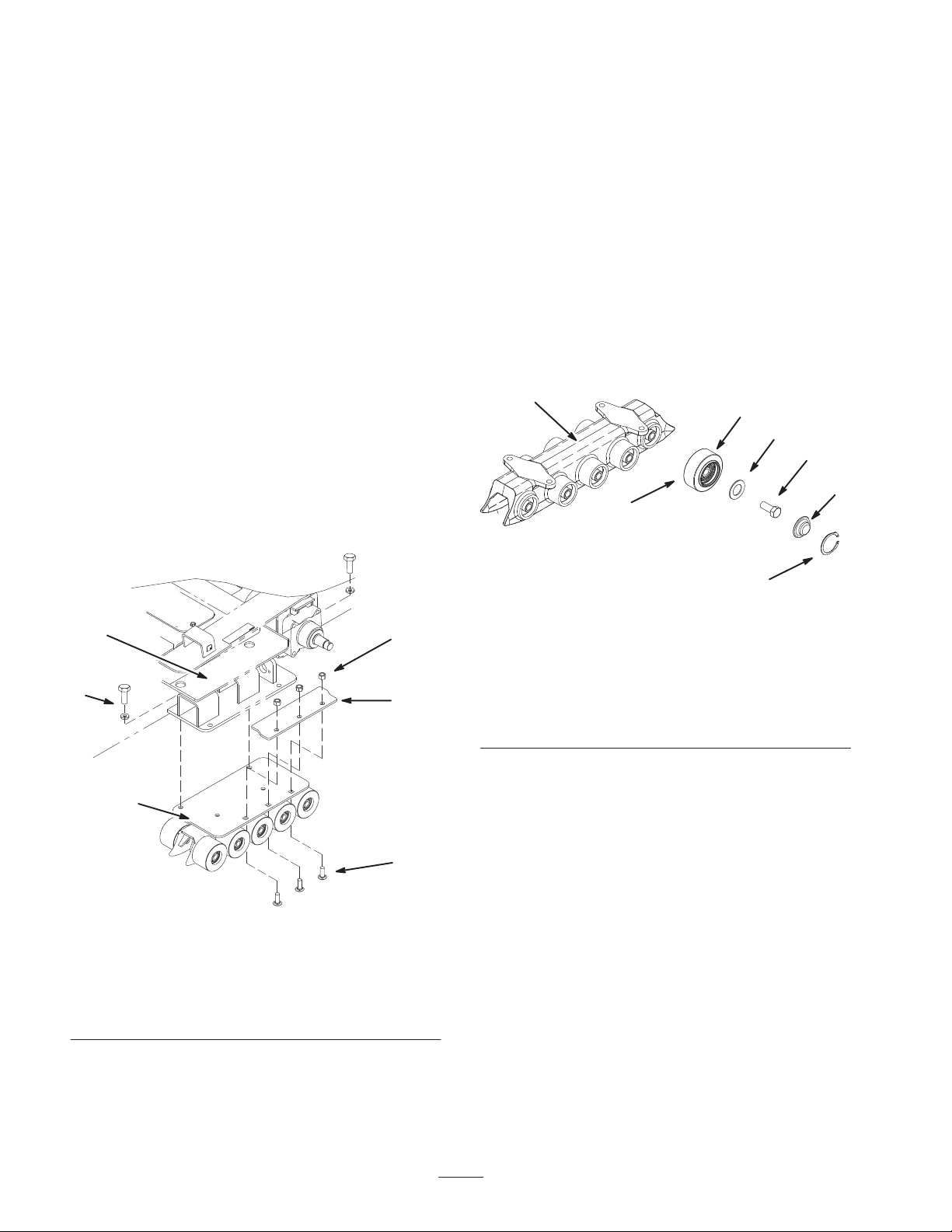

Installing the Track Guide

1. Assemble the new track guide and wheels as shown in

Figure 2.

2. Add grease between the bearing and the seal behind the

wheel (Fig 2).

3. Install the new road wheel onto the track guide using

the gasket in the kit and a new bolt (5/8 x 1-1/2 inch) as

shown in Fig. 2.

4. Torque the road wheel bolt to 135 to 165 ft-lb (183 to

223 N⋅m).

1. Lower the loader arms, stop the engine, and remove the

key.

2. Lift/support the side of the unit to be worked on so that

the track is three to four inches (7.6 to 10 cm) off of the

ground.

3. Remove the track from the machine. Refer to the

Operator’s Manual for more information.

4. Remove the existing track guide from the frame by

removing the three carriage bolts and lock nuts securing

the guide and clamp plate to the frame (Fig. 1). Discard

the clamp plate.

5

6

4

2

5. Fill the road wheel cap with grease and place it over the

bolt head (Fig 2).

6. Secure the road wheel cap with a snap ring (Fig 2).

1

2

3

4

7

m–7731

6

Figure 2

1. Track guide

2. Wheel

3. Gasket

4. Bolt, 5/8 x 1-1/2 inch

5. Wheel cap, add grease

under the cap

6. Snap ring

7. Add grease behind the

wheel between the

bearing and the seal

5

1

3

m–7730

Figure 1

Left-hand side shown

1. Track guide

2. Clamp plate

3. Carriage bolt

4. Locknut

5. Frame

6. Bolt and lock washer

5. Remove the two bolts and two lock washers securing

the track guide to the frame (Fig. 1). Remove the track

guide and fasteners and discard.

7. Repeat Steps 1–6 for all ten wheels.

2

Page 3

8. Install three carriage bolts (1/2 x 1-1/4 inch) to the

adapter plate before installing the plate to the track

guide (Fig. 3).

Important Ensure the notch in the track guide is

pointing toward the rear of the machine.

10. Install the track guide assembly to the machine using

two bolts (1/2 x 1-1/4 inch) and two lock washers

(1/2 inch) down through the frame to the adapter plate

of the track guide assembly (Fig. 4).

m–7733

m–7732

4

1

Left-hand adapter plate shown

1. Adapter plate, left

2. Carriage bolt,

1/2 x 1-1/4 inch

3. Track guide

4. Hex-head flush screw,

1/2 x 1-1/2 inch

Figure 3

5

6

7

3

5. Bolt, 1/2 x 1-1/4 inch

6. Lockwasher, 1/2 inch

7. Notch, toward the rear of

machine

2

3

7

4

5

1

6

Figure 4

2

1. Track guide assembly

2. Frame

3. Bolt, 1/2 x 1-1/4 inch

4. Lock washer, 1/2 inch

Left-hand side shown

5. Clamp plate

6. Carriage bolt,

1/2 x 1-1/4 inch

7. Locknut, 1/2 inch

11. Secure the track guide assembly to the frame installing

the clamp plate and three locknuts (1/2 inch) over the

carriage bolts installed previously as shown in (Fig. 4).

9. Install the adapter plate to the track guide (Fig. 3) using

two hex-head flush screws (1/2 x 1-1/2 inch) and two

bolts (1/2 x 1-1/4 inch) and lock washers (1/2 inch).

Note: Use the adapter plate that corresponds to the side of

the machine being worked on.

12. Install the new track to the machine. Refer to the

Operator’s Manual for more information.

13. Lower the traction unit to the ground.

Track Guide Refit:

Serial No. 220000401- 220000999

Use the following procedures for installing the Track Guide

Refit Kit on Dingo TX 425 Compact Utility Loaders with

serial numbers with range: 220000401-220000999. The

following procedure depicts the track guide refit on the

left-hand side; however, it can be used to refit the track

guide on either side.

Preparing the machine

1. Lower the loader arms, stop the engine, and remove the

key.

2. Lift/support the side of the unit to be worked on so that

the track is three to four inches (7.6 to 10 cm.) off of the

ground.

3

Page 4

3. Remove the track from the machine. Refer to the

Operator’s Manual for more information.

3. Torque the road wheel bolt to 135 to 165 ft-lb (183 to

223 N⋅m).

4. Remove the 4 bolts and 4 lock washers securing the

existing track guide to the frame (Fig. 5). Remove the

track guide and fasteners and discard.

1

3

1

1

1

2

m–7734

Figure 5

Left-hand side shown

1. Bolt and lockwasher

2. Track guide

3. Frame

Installing the Track Guide

1. Assemble the new track guide and wheels as shown in

Figure 6.

2. Add grease between the bearing and the seal behind the

wheel (Fig 6).

1

2

3

4

4. Install the new road wheel onto the track guide using

the gasket in the kit and the bolt (5/8 x 1-1/2 inch) as

shown in (Fig. 6).

5. Fill the road wheel cap with grease and place it over the

bolt head (Fig 6).

6. Secure the road wheel cap with a snap ring (Fig 6).

7. Repeat Steps 1–6 for all ten wheels.

8. Install the track guide assembly to the machine using

four bolts (1/2 x 1-1/4 inch) and four lock washers

(1/2 inch) down through the frame to the track guide

assembly (Fig. 7).

Important Ensure the notch in the track guide is

pointing toward the rear of the machine.

1

2

4

1

1

2

5

2

1

3

m–7735

Figure 7

Left-hand side shown

1. Bolt, 1/2 x 1-1/14 inch

2. Lockwasher, 1/2 inch

3. Track guide assembly

4. Frame

5. Notch, toward the rear of

machine

2

m–7731

1. Track guide

2. Wheel

3. Gasket

4. Bolt, 5/8 x 1-1/2 inch

5. Wheel cap, add grease

under the cap

7

Figure 6

6

6. Snap ring

7. Add grease behind the

wheel between the

bearing and the seal

5

9. Install the new track to the machine. Refer to the

Operator’s Manual for more information.

10. Lower the traction unit to the ground.

4

Loading...

Loading...