Page 1

Brake Kit

Dingo TX 420 & 425 Compact Utility Loader

Part No. 106–7580 & 106–7581

Installation Instructions

Loose Parts

Note: Determine the left and right sides of the machine from the normal operating position.

Description Qty. Use

Drive wheel

Brake rim

Wheel hub

Brake plate 1 Removing the brake assembly

Brake block 1 Installing the brake block

1

2

2

1

1

1

Removing the rear wheel

Form No. 3329-412

Hex socket screw, 3/8 x 1-1/4 inch

Lock washer, 3/8 inch

1

Found in 106-7580 only

2

Found in 106-7581 only

This kit requires parts to be welded to the chassis. Welding can expose you to a number of

hazards including toxic fumes, smoke, dust, burns, fires, explosions, electric shock, radiation,

noise, and heat stress which can cause serious injury and death.

• Welding portions of the kit should be performed by a trained welder.

• Weld in a adequately ventilated area with suitable fire extinguishing equipment readily

available.

• Weld in a firesafe workplace. This can be accomplished by welding behind firesafe barriers or

curtains and on concrete or other firesafe flooring. Remove or protect all combustibles from

ignition sources.

• Wear proper protective clothing when welding, such as fire retardant coveralls. Protect your

hands with leather gauntlet gloves. Feet should be protected by high top leather shoes,

preferably safety shoes.

• Protect your eyes when welding. A welding helmet or hand shield with filter plate and cover

plate is mandatory to protect the eyes while welding. Transparent goggles or safety glasses

should be worn at all times.

2

Installing the brake assembly

2

Warning

2003 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

All Rights Reserved

Printed in the USA

1

Page 2

Installation

Preparing the Unit

1. Lower the loader arms, stop the engine, and remove the

key.

2. Open the rear access cover and disconnect the negative

battery cable.

4. Push the tension wheel toward the rear of the unit to

move the fork tube against the frame (Fig. 2). (If it does

not touch the frame, continue turning the tensioning

screw until it does.)

5. Begin removing the track at the top of the tension

wheel, peeling it off of the wheel while rotating the

track forwards.

6. When the track is off of the tension wheel, remove it

from the drive wheel and road wheels (Fig. 2).

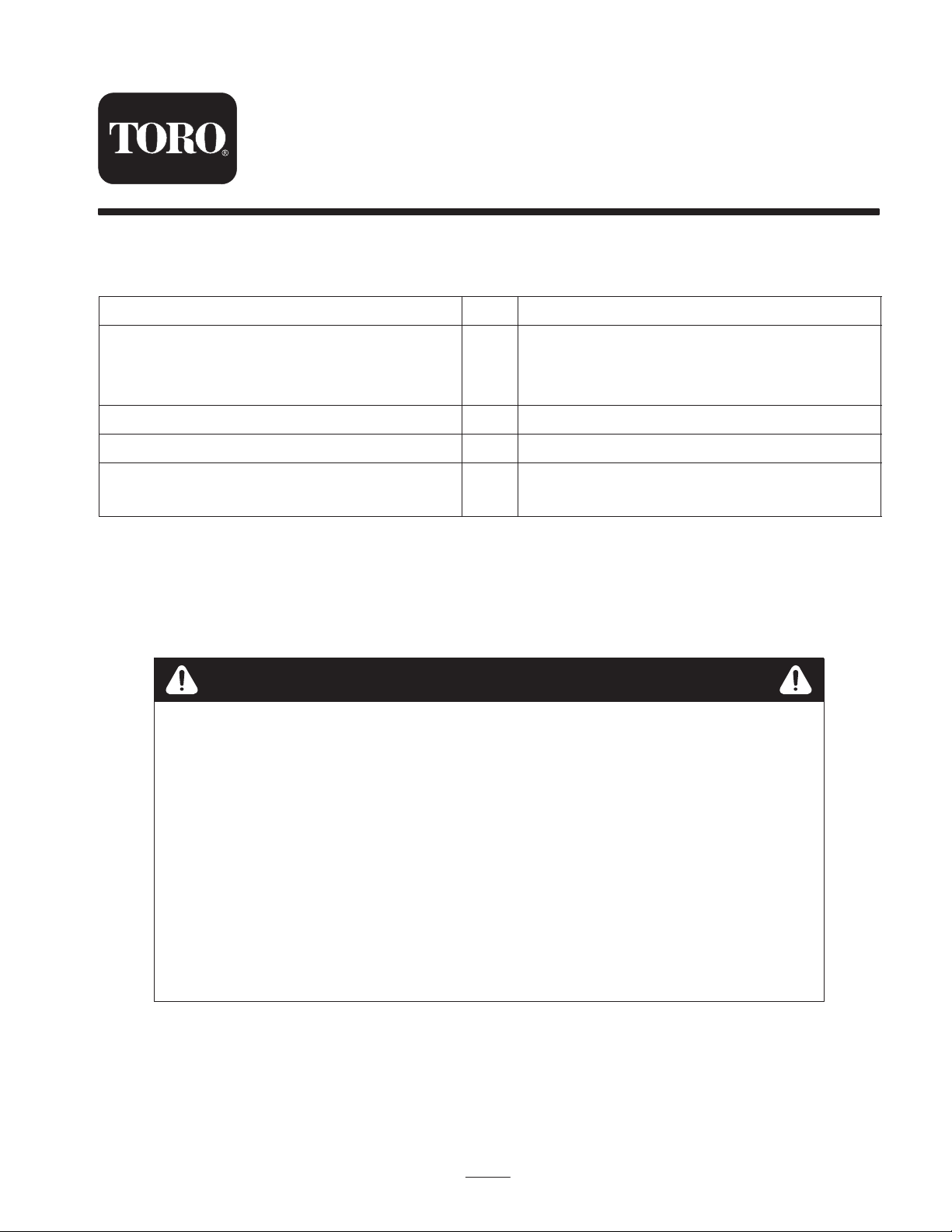

Removing the Track

(Dingo TX 420)

1. Lift/support the side of the unit to be worked on so that

the track is three to four inches (7.6 to 10 cm.) off of the

ground.

2. Remove the tensioning screw locking bolt and nut

(Fig. 1).

4

1. Locking bolt

2. Tensioning screw

3. Using a 1/2 inch drive socket, release the drive tension

by turning the tensioning screw clockwise (Fig. 2).

1

5

m–4774

1. Track

2. 1/2 in. socket

3. Tension wheel

4. Fork tube

23

1

Figure 1

3

4

8

Figure 2

Dingo TX 420

m–4747

3. Tension tube

4. Tension wheel

7

6

2

5. Track lug

6. Drive wheel

7. Wheel spacer

8. Road wheels

7. Repeat steps 1–6 for the opposite track when installing

a second brake kit.

Removing the Track

(Dingo TX 425)

1. Lift/support the side of the unit to be worked on so that

the track is three to four inches (7.6 to 10 cm.) off of the

ground.

2. Remove the tensioning screw locking bolt and nut (Fig.

1).

3. Using a 1/2 inch drive socket, release the drive tension

by turning the tensioning screw clockwise (Fig. 3).

4

1

3

9

6

Figure 3

Dingo TX 425

1. Track

2. 1/2 in. socket

3. Tension wheel nut

4. Outer tension wheel

5. Fork tube

6. Track lug

7. Drive wheel

8. Wheel spacer

9. Road wheels

4. Push the tension wheel toward the rear of the unit to

move the fork tube against the frame (Fig. 3). (If it does

not touch the frame, continue turning the tensioning

screw until it does.)

5. Remove nut securing outer tension wheel and remove

wheel.

5

2

m-6706

8

7

2

Page 3

6. Begin removing the track at the top of the tension

wheel, peeling it off of the wheel while rotating the

track forwards.

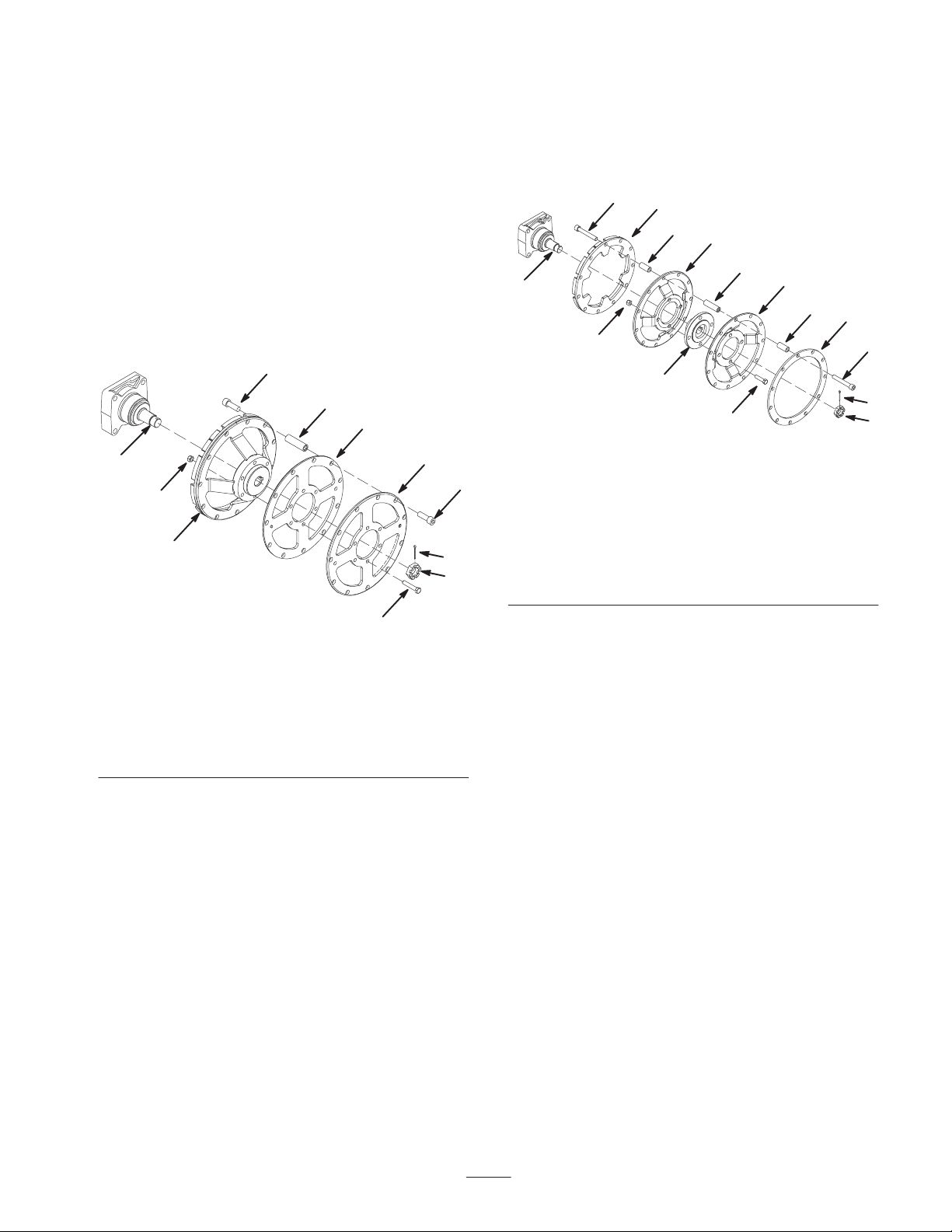

Removing the Rear Drive

Wheel (Dingo TX 425)

7. When the track is off of the tension wheel, remove it

from the drive wheel and road wheels (Fig. 3).

8. Repeat steps 1–6 for the opposite track when installing

a second brake kit.

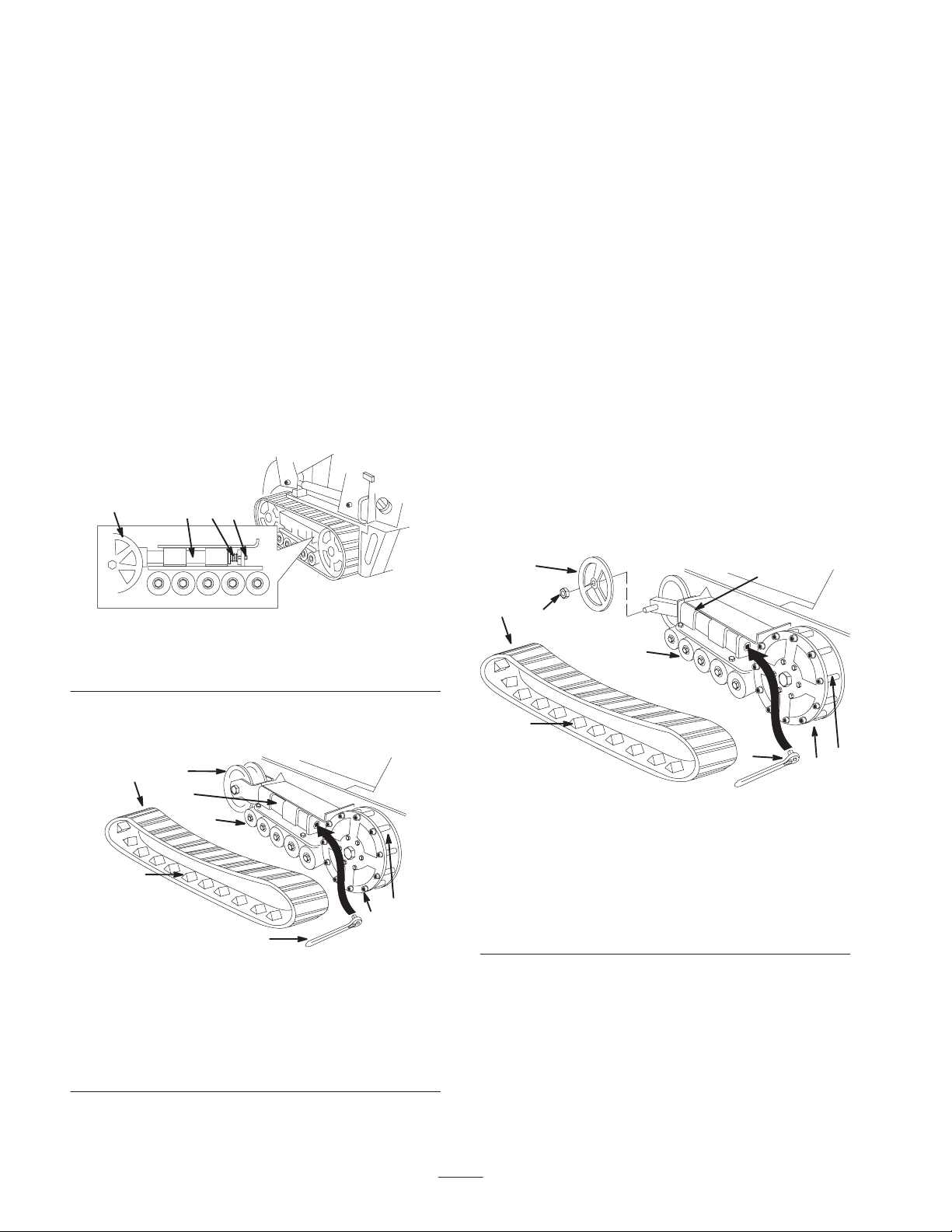

Removing the Rear Wheel

(Dingo TX 420)

1. Remove the cotter pin and wheel nut. Remove the rear

wheel assembly from the motor shaft. (Fig. 4)

5

6

8

9

4

7

8

1

2

1. Remove the cotter pin and motor wheel nut. Remove

the rear wheel assembly from the motor shaft. (Fig. 5)

5

8

6

9

7

12

4

9

6

11

5

10

1

m–6668

3

2

Figure 5

5

1. Cotter pin

2. Wheel nut

3. Bolt, 1/2 x 1-3/4 inch

4. Nut, 1/2 inch

5. Hex socket screw, 1/2 x

1-1/2 inch

6. Spacer, short

7. Spacer, long

8. Brake rim

9. Drive wheel

10. Wheel hub

11. Wheel plate

12. Motor shaft

m–6667

3

Figure 4

1. Cotter pin

2. Wheel nut

3. Bolt, 3/8 x 2 inch

4. Nut, 3/8 inch

5. Hex socket screw, 1/2 x

1-1/2 inch

6. Spacer

7. Drive wheel

8. Wheel plate

9. Motor shaft

2. Disassemble the rear wheel by removing the 22 hex

socket screws and spacers securing the outer ring of the

wheel assembly, and then remove the six bolts and nuts

on the inner ring of the wheel assembly (Fig. 4).

3. Save the fasteners, spacers, and the wheel plates.

4. Discard the drive wheel.

5. Assemble the wheel installing the new drive wheel.

6. Torque the hex socket screws and the inner bolts to 27

to 33 ft-lb (37 to 45 N⋅m).

7. Set the wheel assembly, cotter pin, and wheel nut aside.

8. Repeat steps 1-7 for opposite side when installing a

second brake kit.

2. Disassemble the rear wheel by removing the 22 hex

socket screws, long spacers, and short spacers securing

the outer ring of the wheel assembly, and then remove

the four bolts and nuts on the inner ring of the wheel

assembly (Fig. 5).

3. Save the fasteners, spacers, drive wheels, and wheel

plate.

4. Discard the brake rim assembly and wheel hub.

5. Assemble the wheel, installing the new brake rim

assembly and wheel hub.

6. Torque the hex socket screws and the inner bolts to 67

to 83 ft-lb (91 to 113 N⋅m).

7. Set the wheel assembly, cotter pin, and wheel nut aside.

8. Repeat steps 1-7 for opposite side when installing a

second brake kit.

3

Page 4

Removing Gas Tank and

Battery

Remove the gas tank to access the brake assemblies and

prepare the machine for welding.

Removing the Gas Tank

6. Slide the fuel tank to the rear (Fig. 6).

7. Disconnect the fuel line.

8. Disconnect the two wires leading to the right side of the

tank.

9. Carefully remove the tank and set it upright to keep

from spilling the gasoline.

Danger

In certain conditions, gasoline is extremely

flammable and highly explosive. A fire or

explosion from gasoline can burn you and others

and can damage property.

• Remove the fuel tank outdoors in an open area.

Wipe up any gasoline that spills.

• Do not remove the fuel tank near an open flame

or where gasoline fumes may be ignited by a

spark.

• Do not smoke while handling the fuel tank.

1. Remove the bolts, washers, and lock washers securing

the two side weights, removing the weights (Fig. 6).

1

3

5

4

10.Move the tank a safe distance away from the work area.

11. Wipe up any flammable fluids.

Removing the Battery

Warning

Battery posts, terminals, and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and reproductive harm. Wash hands after

handling.

1. Remove the bolts, nuts, and clamp securing the battery

(Fig. 7).

5

1

6

2

3

4

m–5917

2

1

m–4773

Figure 6

1. Side weights

2. Rear panel

3. Fuel tank bracket

4. Fuel tank

5. Chassis

2. Remove the three carriage bolts and washers from the

battery base and the fuel tank bracket, removing the

bracket (Fig. 6).

3. Remove the six nuts and bolts securing the rear panel,

removing the panel (Fig. 6).

4. Loosen the tank cap to relieve pressure.

5. Place a clamp on the fuel line, two inches from where it

comes out of the fuel tank.

Figure 7

1. Battery

2. Clamp

3. Positive cable

4. Rubber cover

5. Negative cable

6. Bolts and nuts

2. Tilt the top of the battery rearward and slide it out of the

traction unit.

Important Do not allow the battery posts to touch the

frame or hydraulic lines or it may cause sparks.

4

Page 5

Removing the Brake Assembly

1. Remove the bolts and lock washers securing the brake

assembly to the chassis and set aside for later use

(Fig. 8).

3

5. Repeat steps 1-4 the opposite brake assembly when

installing second brake kit.

Installing New Brake Plates

Perform the following procedure for both assemblies when

installing a second brake kit.

1. Remove the hex socket head bolt, jam nut, and locknut

as shown in Figure 9.

2

1

m–6664

Figure 8

Brake assembly and chassis shown from the left side.

1. Bolts

2. Lock washers

3. Brake assembly

2. Remove the cotter and clevis pin from the brake cable

(Fig 9).

6

9

10

7

2

11

13

2. Remove the two bolts and locknuts securing the brake

stop to the plate.

3. Slide the plate out and discard it.

4. Slide the new plate into the assembly.

5. Replace the brake stop and fasteners.

6. Replace the hex socket head screw, jam nut, and

locknut. Be sure to attach the extension spring as you

assemble the fasteners and install them to the brake

plate.

7. Set the assembly aside for later use.

Removing the Brake Channel

Note: Avoid damaging the chassis or wheel motor when

removing the brake channel.

1. With an appropriate tool, cut off old brake block

(Fig. 10).

1

2

1

4

3

12

3

5

8

m–6663

4

Figure 9

1. Brake plate housing

2. Brake cable

3. Clevis pin

4. Cotter pin

5. Cable hook

6. Bolt, 1/4 x 5/8 inch

7. Brake stop

8. Locknut, 1/4 inch

9. Extension spring

10. Hex socket screw, 5/16 x

2 inch

11. Jam nut, 5/16 inch

12. Locknut, 5/16 inch

13. Brake plate

3. Remove the cable from the bracket hook as shown in

Figure 9.

4. Remove the brake assembly.

1

5

m–6662

Figure 10

1. Brake channel

2. Brake block

3. Weldment

4. Socket holes

5. New brake block

2. Grind or file down the remaining channel to create a

clean and level surface.

3. Wipe down surface to remove loose debris.

4. Repeat steps 1-3 for the opposite side if installing a

second brake kit.

5

Page 6

Installing the Brake Block

1. Attach the brake cable to the assembly by installing the

cotter and clevis pins and by hooking the line into the

bracket at the clip ring as shown in Figure 9.

2. Install a brake assembly into position using the

fasteners removed previously (Fig. 9).

3. Engage the parking brake to extend the brake plate.

4. Place the new brake block over the brake plate to line

up the block between, and level with, the two

surrounding socket holes (Fig. 10).

5. Spot weld the block into position on the surface of the

chassis.

3. Torque the hex socket screws to 67 to 83 ft-lb (91 to

113 N⋅m).

2

6. Disengage the parking brake.

7. Remove the bolts and lock washers securing the brake

assembly. Discard the fasteners.

Note: The brake assembly stay in position while the new

brake block is being welded.

8. Weld the new brake block to the frame with a quarter

inch fillet on the left, top and right sides of the block as

shown in Figure 10.

Important Do not weld the brake block out of position

or allow the weldment to cover the surrounding bolt holes.

9. Allow the weldments to cool.

10.Prime and paint the area with a touch-up paint.

11. Repeat steps 1-10 for the opposite side if installing

when second brake kit.

Installing the Brake Assembly

Note: Install the left side brake assembly before installing

the right side brake assembly.

1. Move the brake assembly into position making sure the

brake plate is in place within the new brake block.

1

m–6664

Figure 11

Brake assembly and chassis shown from the left side.

1. Hex socket screws, 3/8 x

1-1/4 inch

4. Manually test the brakes to verify that the brake plate

moves through the brake block freely.

5. Repeat steps 1-4 for the opposite brake assembly when

installing a second brake kit.

2. Lock washers, 3/8 inch

Installing the Gas Tank

1. Slide the fuel tank part way into the chassis (Fig. 6).

2. Connect the fuel line and remove the clamp.

3. On the right side of the tank, connect the orange wire to

the center post and the black wire to the outside post

(Fig. 12).

2. Secure the brake assembly using the hex socket head

screws and lock washers included with the kit (Fig. 11).

2

1

m–4776

Figure 12

1. Black wire 2. Orange wire

6

Page 7

4. Slide the tank all the way into the traction unit.

Important The fuel line and wires must be away from

the engine pulleys and the frame.

5. Replace the rear panel and secure it with the six bolts

and nuts removed previously (Fig. 6).

4. Turn the tensioning screw counter-clockwise until the

distance between the tension nut and the back of the

fork tube (Fig. 13) is 2-3/4 inch (7 cm).

m–4775

6. Place the fuel tank bracket over the tank and secure it

and the battery tray with the bolts and washers removed

previously (Fig. 6).

7. Install the side weights with the bolts, washers, and lock

washers removed previously (Fig. 6).

8. Close the rear access cover.

Installing the Rear Drive Wheel

1. Clean the inside wheel hub and motor shaft with a

degreaser prior to installing the rear drive wheel.

2. Install the rear drive wheel over the motor shaft (Fig. 4

or 5). Be sure to line up the keyway in the hub with the

key in the motor shaft.

3. Install the wheel nut on the motor shaft so that the

cotter pin hole is accessible (Fig. 4 or 5).

4. Torque the nut to 250 to 300 ft-lb (271 to 407 N⋅m).

Note: Do not loosen the nut to allow for the cotter pin to be

installed. If the hole is covered by the nut, tighten the nut to

allow the cotter pin to be installed.

5. Install the cotter pin into the hole in the motor shaft and

bend the ends.

6. Repeat steps 1-5 for opposite side when installing a

second brake kit.

1

Figure 13

1. 2-3/4 inch (7 cm)

5. Align the closest notch in the tension screw to the

locking bolt hole and secure the screw with the locking

bolt and nut.

6. Lower the traction unit to the ground.

7. Repeat steps 1–6 for the opposite track when installing

a second brake kit.

Installing the Track

(Dingo TX 425)

1. Beginning at the drive wheel, coil the new track around

the wheel, ensuring that the lugs on the track fit

between the spacers on the wheel (Fig. 3).

2. Push the track under and between the road wheels

(Fig. 3).

Installing the Track

(Dingo TX 420)

1. Beginning at the drive wheel, coil the new track around

the wheel, ensuring that the lugs on the track fit

between the spacers on the wheel (Fig. 2).

2. Push the track under and between the road wheels

(Fig. 2).

3. Starting at the bottom of the tension wheel, install the

track around the wheel.

3. Starting at the bottom of the tension wheel, install the

track around the inner wheel.

4. Install the outer tension wheel and secure it with the

tension wheel nut.

5. Torque the nut to 250 to 300 ft-lb (271 to 407 N⋅m).

6. Turn the tensioning screw counter-clockwise until the

distance between the tension nut and the back of the

fork tube (Fig. 13) is 2-3/4 inch (7 cm).

7. Align the notch in the tension screw to the locking bolt

hole and secure the screw with the bolt and locking nut.

8. Lower the traction unit to the ground.

9. Repeat steps 1–8 for the opposite track when installing

a second brake kit.

7

Page 8

Loading...

Loading...