Page 1

EFI Fuel Line Conversion Kit

200 Series Z Master with Electronic Fuel Injection

Part No. 105–9385

Installation Instructions

Loose Parts

Note: Use the chart below to identify parts for assembly.

DESCRIPTION QTY. USE

Form No. 3327–793

Connector, 1/4 x 5/16 in.

Fuel hose extension

Hose clamp—Oetiker

Important

pliers. Contact an Authorized Kohler Service Dealer or

tool suppliers for ordering Oetiker pliers.

Installation of hose clamps require special

Removing the Existing Fuel

Filter

Warning

Gasoline is harmful or fatal if swallowed.

Long–term exposure to vapors can cause serious

injury and illness.

• Avoid prolonged breathing of vapors.

• Keep face away from nozzle and gas tank or

conditioner bottle opening.

• Keep gas away from eyes and skin.

1

1

3

Installing the connector

Danger

In certain conditions, gasoline is extremely

flammable and highly explosive. A fire or

explosion from gasoline can burn you and others

and can damage property.

• Wipe up any gasoline that spills. Do this

procedure outdoors in an open area.

• Never smoke when draining gasoline, and stay

away from an open flame or where a spark may

ignite the gasoline fumes.

1. Park the machine on a level surface. Then disengage

the power take off (PTO), set the parking brake, and

turn the ignition key to off. Remove the key.

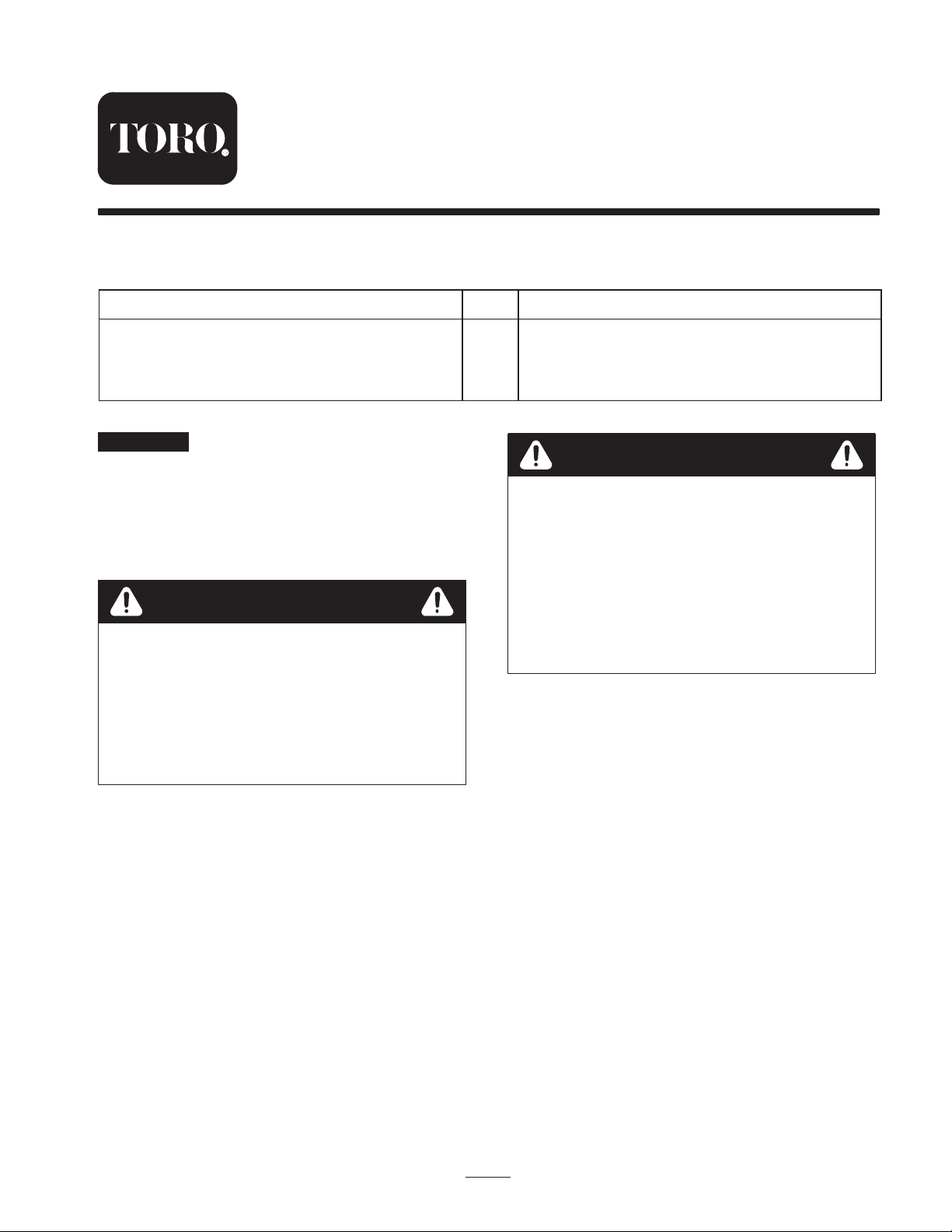

2. Turn the fuel shut–off valve to the off position (Fig. 1).

2002 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

All Rights Reserved

1

Printed in the USA

Page 2

2

1

Figure 1

1. Fuel shut-of f valve 2. Off position

Note: Make sure the fuel shut–off is turned to the off

position (Fig. 1).

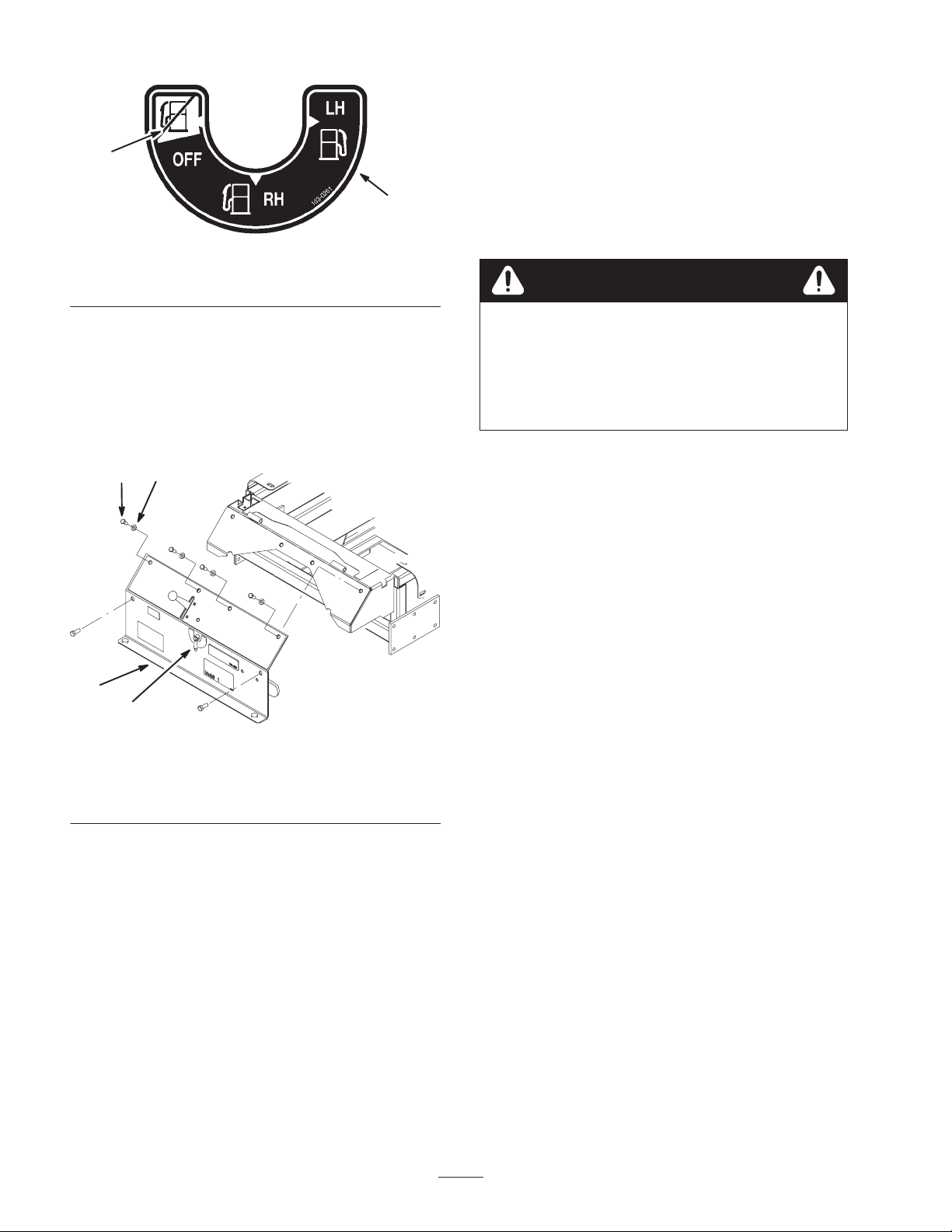

3. Remove the control panel from the machine (Fig. 2).

This will allow access to the fuel shut–off valve and

hoses.

2

3

4. Remove the hose clamps from the fuel filter (Fig. 3).

5. Remove the hoses from the fuel filter (Fig. 3). Discard

the fuel filter.

6. Remove the fuel filter hose from the fuel shut off

valve. Discard this hose and clamps.

Installing the Connector

Warning

Fuel system components are under high pressure.

Use of improper components can result in system

failure, gasoline leakage and possible explosion.

Use only approved fuel lines, hose clamps and fuel

filters for high pressure systems.

1. Route the existing hose under the battery and through

the existing R–clamp (Fig. 3).

2. Slide a clamp onto the fuel pump hose and insert the

connector into the hose (Fig. 3).

1

4

1. Control panel

2. Screw

3. Slide two clamps onto the new fuel hose extension

(Fig. 3).

4. Install the connector into the new fuel hose extension

(Fig. 3).

5. Install the new fuel hose extension onto the fuel

shut–off valve (Fig. 3).

6. Secure all new hose clamps at the fuel shut–off valve

and connector (Fig. 3).

m–6097

Figure 2

3. Washer

4. Shut–off valve

2

Page 3

7

4

2

4

4

3

4

7

6

1

8

45

1. Fuel shut–off valve

2. Fuel filter—remove

3. Connector—install

4. Hose clamp

Checking for Leaks

Important Make sure all hoses and clamps are

secured.

1. Before installing the control panel, turn the shut–off

valve to the right–hand position (right tank) (Fig. 1).

2. Turn the ignition switch on and off 5 times. This will

run the fuel pump.

3. Check for any leaks around the new hose clamps

(Fig. 3).

4. Repeat this installation kit if any leaks are observed.

5. If there are no leaks, start the machine.

6. Check for any leaks around the new hose clamps

(Fig. 3).

7. Turn the shut–off valve to the left–hand position

(left tank) (Fig. 1).

Figure 3

5. Fuel hose extension—install

6. R–clamp

9. Repeat this installation kit if any leaks are observed

(Fig. 1).

10.If no leaks are observed, install the front control panel

(Fig. 2).

m–6042

7. Fuel pump hose

8. Fuel filter hose—remove

8. Check for any leaks around the new hose clamps

(Fig. 3).

3

Page 4

4

Loading...

Loading...