FORM NO. 3326–318 Rev A

Z–Stand Kit

Z–Master 100 Series

Part No. 105–1621

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any

area of potential danger. Replace any decal that is damaged or lost.

Part No. 104–7759

Loose Parts

INSTALLATION

INSTRUCTIONS

Note: Use the chart below to identify parts for assembly.

DESCRIPTION QTY. USE

Z–Stand hub

Bracket latch

Bolt, 3/8 x 1–1/2 in.

Lock nut, 3/8 in.

Z–Stand hub

Bolt, 3/8 x 3–1/2 in.

Lock nut, 3/8 in.

Hair Pin cotter

Clevis pin, 3 in.

Clevis pin, 2–5/8 in.

1

1

Assemble 100 Series Z–Stand hub

1

1

1

2

2

Install 100 Series Z–Stand hub

2

1

1

The Toro Company – 2002

Printed in USA

All Rights Reserved

Installation Instructions

DESCRIPTION USEQTY.

Z–Stand foot

Z–Stand tube

Thrust washers

Lynch pin

Hair pin cotter

Clevis pin

Z–Stand bracket

Bolt, 5/16 x 2–3/4 in.

Lock Nut, 5/16 in.

Bolt, 1/4 x 3/4 in.

Lock Nut, 1/4 in.

Lanyard

The following instructions are for installing the

Z–Stand on a 100 Series Z–Master.

Assemble 100 Series Z–Stand

1

1

2

Install 100 Series Z–Stand

1

2

2

1

1

1

Install 100 Z–Stand bracket

1

1

1

2

4

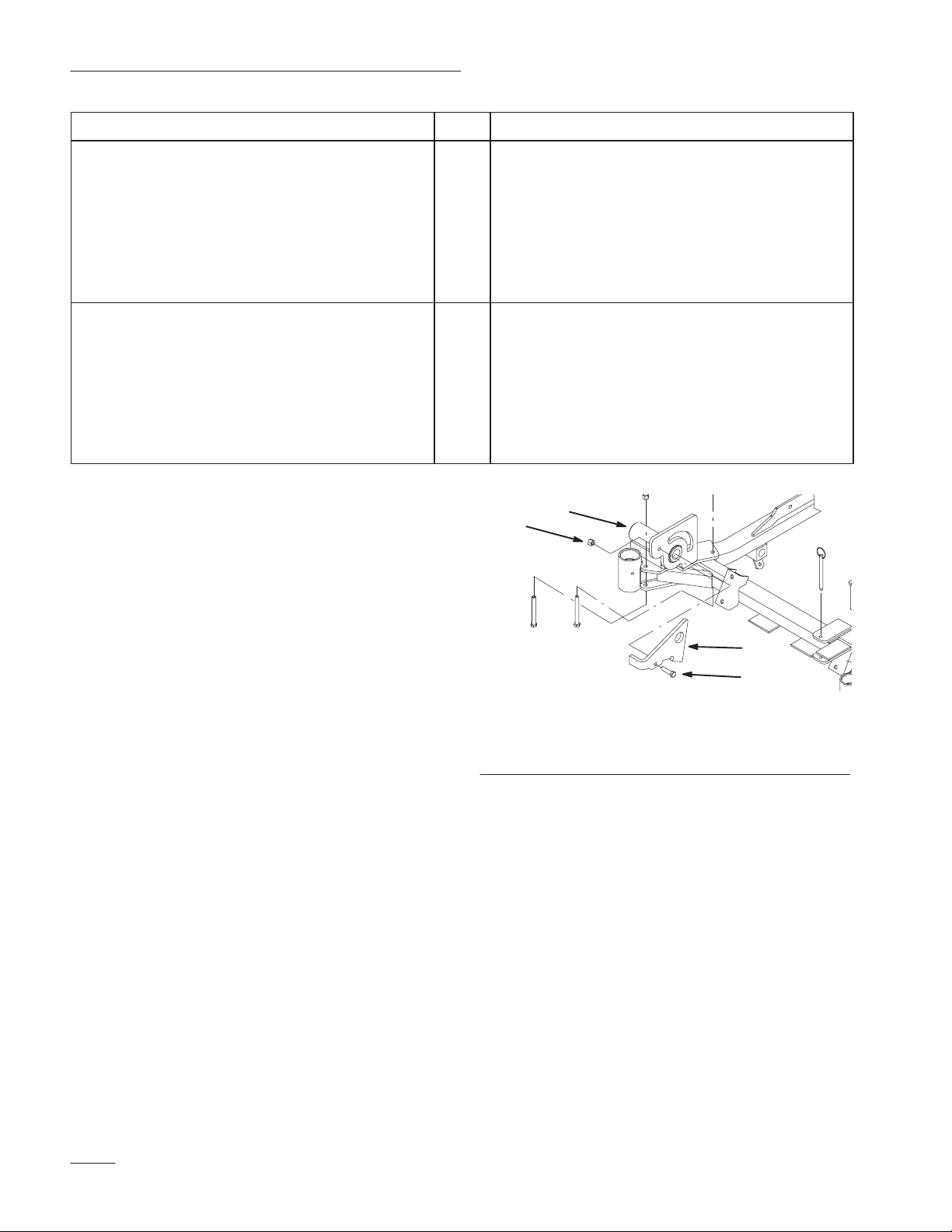

Hub

1. Install the bracket latch to the Z–Stand hub with

a bolt (3/8 x 1–1/2 in.) and lock nut (3/8 in.)

(Fig. 1).

Note: Tighten the nut and bolt. Then,

unscrew it one full turn or until the

latch will freely rotate (Fig. 1).

1

m–5357

1. Bracket latch

2. Z–Stand hub

Figure 1

3. Bolt, 3/8 x 1–1/2 in.

4. Lock Nut, 3/8 in.

3

Install 100 Series Z–Stand Hub

1. Place the Z–Stand hub on the right front frame

as shown in figure 2.

Note: Make sure the Z–Stand hub assembly

is against the front caster housing.

2. Install Z–Stand hub to frame with 2 bolts

3/8 x 3–1/2 in.) and 2 lock nuts (3/8 in.) (Fig. 2).

(

Note: Install bolts as shown in figure 2.

2

Installation Instructions

1

2 4

4

3

m–5357

Figure 2

1. Right front frame

2. Z–Stand hub assembly

3. Bolt, 3/8 x 3–1/2 in.

4. Lock Nut, 3/8 in.

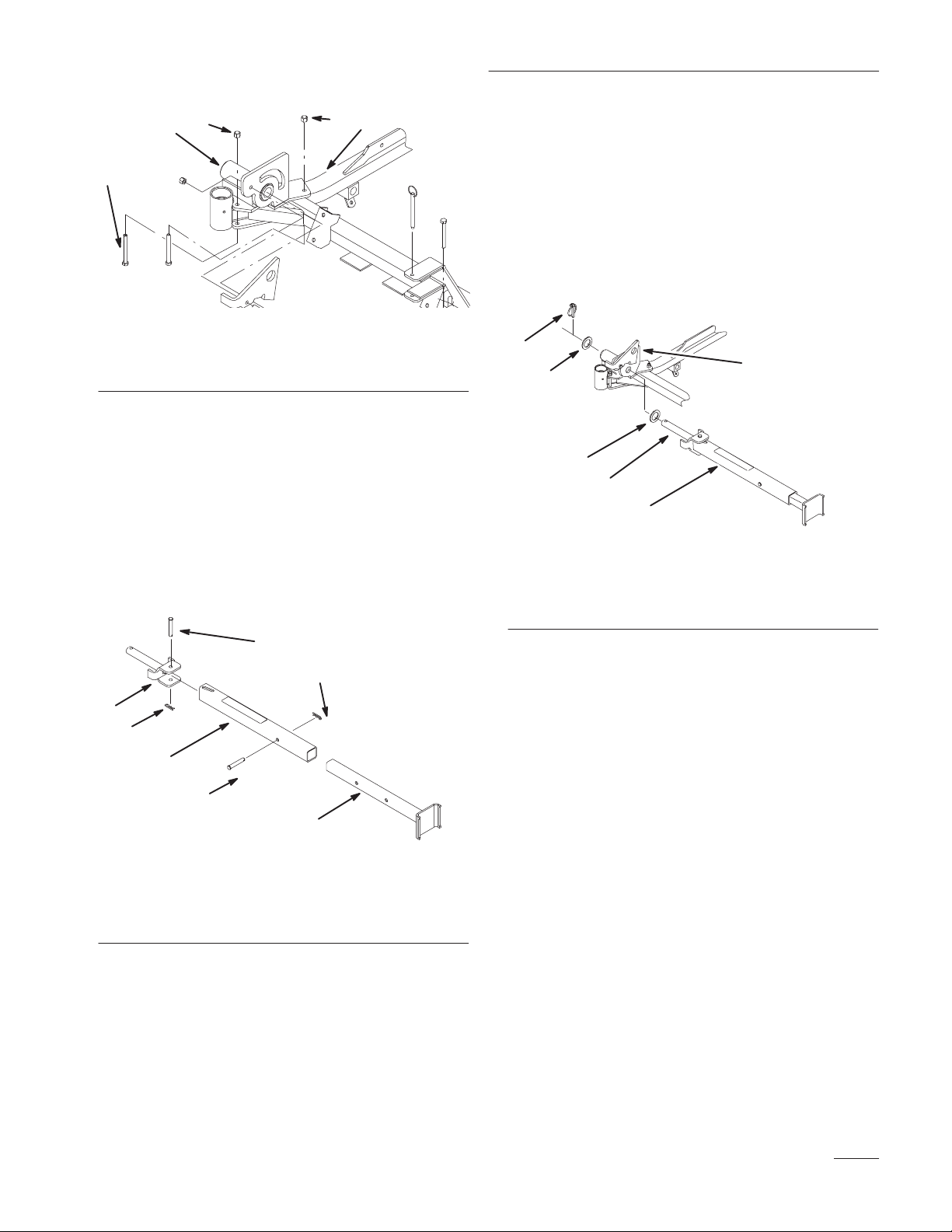

Install 100 Series Z–Stand

1. Place the foot part of stand into the Z–Stand

tube. Align holes and secure with a clevis pin

(2–5/8 in.) and hair pin cotter (Fig. 3).

2. Install Z–Stand assembly to the pivot pin with a

clevis pin (3 in.) and hair pin cotter (Fig. 3).

4. Insert pivot pin into the Z–Stand hub as shown

in figure 4.

Note: When inserting the pivot pin, make

sure the position of slot in tube is as

shown in figure 3.

5. Place a thrust washer onto the pivot pin and

secure with a lynch pin (Fig. 4).

5

3

4

4

2

1. Z–Stand

2. Pivot Pin

3. Z–Stand hub

1

Figure 4

4. Thrust washer

5. Lynch pin

m–5358

3

4

2

4

1

6

m–5359

5

Figure 3

1. Z–Stand tube

2. Pivot Pin

3. Clevis Pin, 3 in.

4. Hair pin cotter

5. Z–Stand foot

6. Clevis Pin, 2–5/8 in.

3. Place a thrust washer onto the pivot pin (Fig. 4).

Install 100 Series Z–Stand

Bracket

1. Place the Z–Stand bracket on the left front frame

as shown in figure 5.

2. Install Z–Stand bracket with a bolt

(5/16 x 3–1/4 in.) and lock nut (5/16 in.)

(Fig. 5).

Note: Install bolt as shown in figure 5.

3. Install lanyard to bracket pin. Use large loop on

lanyard (Fig. 5).

4. Install lanyard with a bolt (1/4 x 3/4 in.) and

lock nut (1/4 in.) (Fig. 5).

3

Installation Instructions

8

7

4

5

2

6

1

3

m–5357

Figure 5

1. Left front caster housing

2. Z–Stand bracket

3. Bolt, 5/16 x 3–1/4 in.

4. Lock Nut, 5/16 in.

Using the Z–Stand

5. Lock Nut, 1/4 in.

6. Bolt, 1/4 x 3/4 in.

7. Lanyard

8. Bracket Pin

The Z–Stand is used for raising the front end of the

machine. This allows for cleaning of the deck and

removal of the blades.

4

2

5

1

3

m–5375

Figure 6

1. Z–Stand

2. Latch

3. Bracket

4. Bracket Pin

5. Bottom of slot

3. Raise latch. Swing stand foot out front and slide stand

toward machine, into the bottom of slot (Fig. 6 and 8).

4. Remove the cotter hair pin and clevis pin (Fig. 7).

5. Pull out the foot part of stand and insert clevis pins and

cotter hair pins (Fig. 7).

2

Warning

Unit could fall onto someone and cause serious

injury or death.

• Use extreme caution when operating unit

on Z–Stand.

• Use only for cleaning deck and removing

blades.

• Do not keep unit on Z–Stand for extended

periods of time.

• Always shut engine off and set parking

brake before performing any maintenance

to deck.

Driving up onto the Z–Stand

1. Raise deck to transport position.

2. Remove bracket pin (Fig. 6).

1

3

m–5380

Figure 7

1. Clevis Pin

2. Hair pin cotter

3. Z–Stand foot

6. Set foot of stand on the ground and rest latch on pivot

tab (Fig. 8).

7. Start engine and put at half throttle.

Note: For best results, place foot of stand

into seams in sidewalks or into turf

(Fig. 8).

4

Installation Instructions

3

1

2

m–5374

Figure 8

1. Z–Stand (Positioned in

slot)

2. Crack in side walk or turf

3. Latch resting on pivot tab

8. Drive onto stand. Stop when latch drops over tab into

locked position (Fig. 9). Once onto stand, engage

parking brake. Shut off engine.

9. Chock or block the drive wheels.

Warning

Parking brake may not hold machine parked on

Z–Stand and could cause personal injury or

property damage.

4

2

1

1. Z–Stand

2. Latch

3

m–5373

Figure 9

3. Locked position

4. Unlocked position

Do not park on Z–Stand unless wheels are

chocked or blocked.

10.Perform maintenance.

11. Remove chocks or blocks.

Driving off the Z–Stand

1. Raise latch to unlocked position (Fig. 9).

2. Start engine and place at half throttle. Disengage

parking brake.

3. Slowly drive backwards off of stand.

4. Remove the cotter hair pins and stand pins (Fig. 7).

5. Push in the inner part of stand and insert stand pins

and cotter hair pins (Fig. 7).

6. Return stand to its rest position (Fig. 6).

7. Insert bracket pin into Z–Stand bracket (Fig. 6).

5

Installation Instructions

6

Installation Instructions

7

Installation Instructions

8

Loading...

Loading...